Struers Exotom 100 Instruction Manual

Exotom-100

Instruction Manual

Manual No.: 15047001

Date of Release 30.07.2003

Exotom-100

A

A

Instruction Manual

Table of Contents Page

User’s Guide ..............................................................1

Reference Guide.......................................................19

Quick Reference Card .............................................48

lways state Serial No and Voltage/frequency if you have technical questions or when ordering spare parts. You will

find the Serial No. and Voltage on the type plate of the machine itself. We may also need the Date and Article No of

the manual. This information is found on the front cover.

The following restrictions should be observed, as violation of the restrictions may cause cancellation of Struers legal

obligations:

Instruction Manuals: Struers Instruction Manual may only be used in connection with Struers equipment covered by

the Instruction Manual.

Service Manuals: Struers Service Manual may only be used by a trained technician authorised by Struers. The

Service Manual may only be used in connection with Struers equipment covered by the Service Manual.

Struers assumes no responsibility for errors in the manual text/illustrations. The information in this manual is subject

to changes without notice. The manual may mention accessories or parts not included in the present version of the

equipment.

The contents of this manual is the property of Struers. Reproduction of any part of this manual without the written

permission of Struers is not allowed.

ll rights reserved. © Struers 2003.

Struers A/S

Pederstrupvej 84

DK-2750 Ballerup

Denmark

Telephone +45

Fax +45 44 600 801

44 600 800

Exotom-100

Instruction Manual

Exotom-100

Safety Precaution Sheet

To be read carefully

before use

1. The operator(s) should be fully instructed in the use of the machine and its cut-

off wheels according the Instruction Manual and the instructions on the cut-off

wheels.

2. Use the supplied Allen key to remove the two red transport screws at the rear of

the machine. Do not attempt to open the protection guard before the screws

have been removed.

3. The machine must be placed on a safe and stable support. All safety functions

of the machine must be in working order. The machine must be levelled by

means of the adjustable legs provided.

4. The unit must be installed in compliance with local safety regulations.

5. Prior to lifting the unit by the built-in truck lifting point, ensure that the boom is

properly secured with the locking pins provided. Before transport, secure the

cutting arm with the locking system provided.

6. To achieve maximum safety and lifetime of the machine, use only original

Struers consumables.

7. Use only intact cut-off wheels. The cut-off wheels must be approved for a

spindle speed of min. 1950 rpm / 42 m/s. Do not use sawblades.

8. Observe the current safety regulations for handling, mixing, filling, emptying and

disposal of the additive for cooling fluid.

9. The workpiece must be securely clamped in the quick-clamping device or the

like. Large or sharp workpieces must be handled in a safe way.

10. Struers recommend the use of an exhaust system as the cutting materials may

emit harmful gasses or dust. See the instructions of the cut-off wheel.

11. The machine emits only moderate noise. However, the cutting process itself

may emit noise, depending on the nature of the workpiece. In such cases, use

of hearing protection is recommended.

12. The machine must be disconnected from the mains prior to any service.

13. Ensure that the cut-off wheel is secured before working on or around the cutting

table.

14. Do not put hands through the rubber curtain during operation of the machine.

Exotom-100

Instruction Manual

15. Protruding workpieces should be shielded or marked.

16. Use of working gloves is recommended as workpieces may be both very hot

and produce sharp edges.

17. If any unusual noise is heard when the protection hood is operated, refrain from

further use of the machine, and contact Struers service technician.

The equipment is designed for use with consumables supplied by Struers. If subjected to misuse, improper

installation, alteration, neglect, accident or improper repair, Struers will accept no responsibility for

damage(s) to the user or the equipment.

Dismantling of any part of the equipment, during service or repair, should always be performed by a qualified

technician (electromechanical, electronic, mechanical, pneumatic, etc.).

Exotom-100

Instruction Manual

User’s Guide

Table of Contents Page

1. Getting Started

Checking the Contents of Packing................................................... 3

Recirculation Cooling Unit........................................................ 3

Unpacking and Placing Exotom-100................................................ 3

Mounting the Control Panel............................................................. 4

Getting Acquainted with Exotom-100 ............................................. 5

Side view, left............................................................................. 6

Side view, right.......................................................................... 6

Cooling unit compartment ........................................................7

Power Supply .................................................................................... 8

Mounting the Cut-off wheel .............................................................8

Direction of the Cut-off Wheel .................................................. 8

Connection to an External Exhaust System ...................................8

Setting Up the Recirculation Cooling Unit .....................................9

Direct Water Supply for the Cooling Unit....................................... 9

2.

Operation

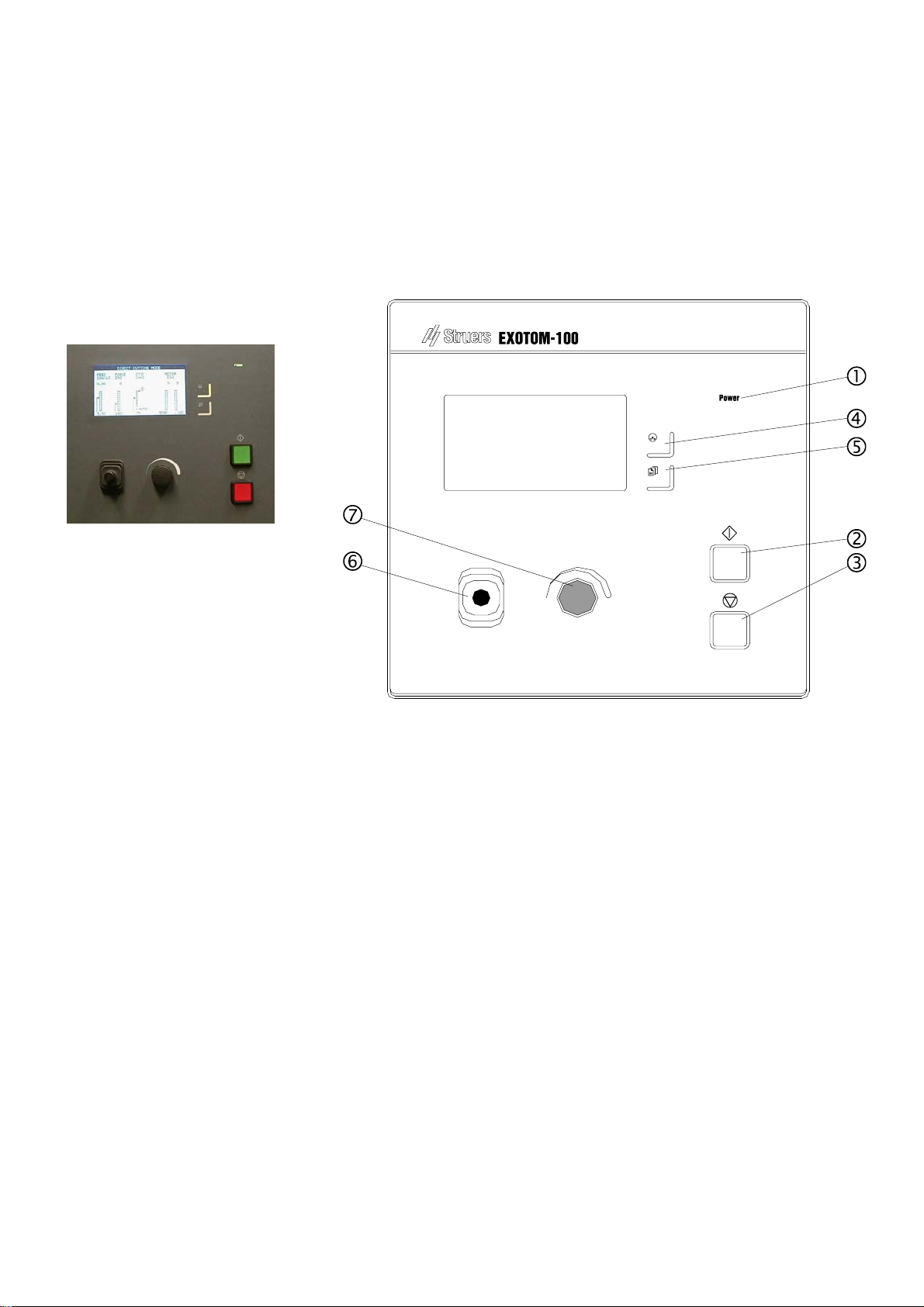

Using the Controls.......................................................................... 10

Control Panel of Exotom-100 ..................................................10

Control Panel Functions................................................................. 11

Display Types.................................................................................. 11

Setting the Language .....................................................................12

Reading the Cutting Display.......................................................... 13

Changing Cutting Mode and Cutting Parameters........................ 14

Changing Cutting Mode ..........................................................14

Changing Cutting Parameters................................................ 14

Reading the Motor Information..............................................14

Sleep Mode............................................................................... 14

Changing the Cut-off Wheel........................................................... 15

Clamping the Workpiece ................................................................ 15

Positioning the Cut-off Wheel ........................................................15

QuickPosition.................................................................................. 16

Cutting Parameters........................................................................16

Feed ................................................................................................. 16

Force ................................................................................................16

Stop.................................................................................................. 16

AutoStop................................................................................... 16

1

Exotom-100

Instruction Manual

Setting the Cutting Parameters .................................................... 17

Cutting on Exotom-100................................................................... 17

Starting the Cutting................................................................ 17

Fast advance ............................................................................17

Stopping the Cutting (Manual Stop) ...................................... 17

Re-starting cutting ..................................................................17

Direct Cut........................................................................................ 18

ExciCut............................................................................................ 18

AxioCut (option).............................................................................. 18

Additional cooling ...........................................................................18

2

Checking the Contents of

Packing

Recirculation Cooling Unit

Unpacking and Placing

Exotom-100

Exotom-100

Instruction Manual

1. Getting Started

The packing box contains the following items:

1 Exotom-100

1 Control Panel for Exotom-100

1 Allen key (5 mm) for mounting Control Panel

3 Screws (5 mm)

1 Fork spanner (30 mm) for cut-off wheel

1 Spanner (comb. 12/17 mm) for adjustment of the

Control Panel

1 Drain hose, 2 m

1 Fitting for drain hose

2 Cabinet doors

1 Set of Instruction Manuals

1 Recirculation cooling unit

1 Trolley for cooling unit

Unscrew the nuts from the four transport bolts fixing the machine to

the pallet.

Lift the machine from the pallet by means of a forklift truck from the

front, and place in a suitable location.

Remove the safety-springs from the front crossbar, and remove bar.

Use the supplied Allen key to remove the two red transport

screws at the rear of the machine. Do not attempt to open the

protection hood before the screws have been removed.

Take out the loose parts (trolley, tank, drain hose etc.).

Mount the cabinet doors.

Turn the adjustable feet so that the machine stands firmly and is

level.

NB!

Please remove the transportation

support before use.

3

Exotom-100

Instruction Manual

Mounting the Control Panel

Unpack the Control Panel and mount on right side of unit using the

two 5 mm screws and Allen key supplied (use holes

and as

indicated on drawing).

Mount the earth wire below the mounting plate using the

third 5 mm screw

Press cover towards cabinet wall until it snaps onto the mounting

plate.

Connect Control Panel plug to socket .

The position of the Control Panel is controlled by a friction

mounting. After mounting the control panel it is possible to

adjust the mobility of the Control Panel this way:

Adjust the main joint with the nut using the combined

12/17 mm spanner supplied.

The joint just behind the Control Panel may be adjusted too,

using the same spanner.

.

4

Exotom-100

Instruction Manual

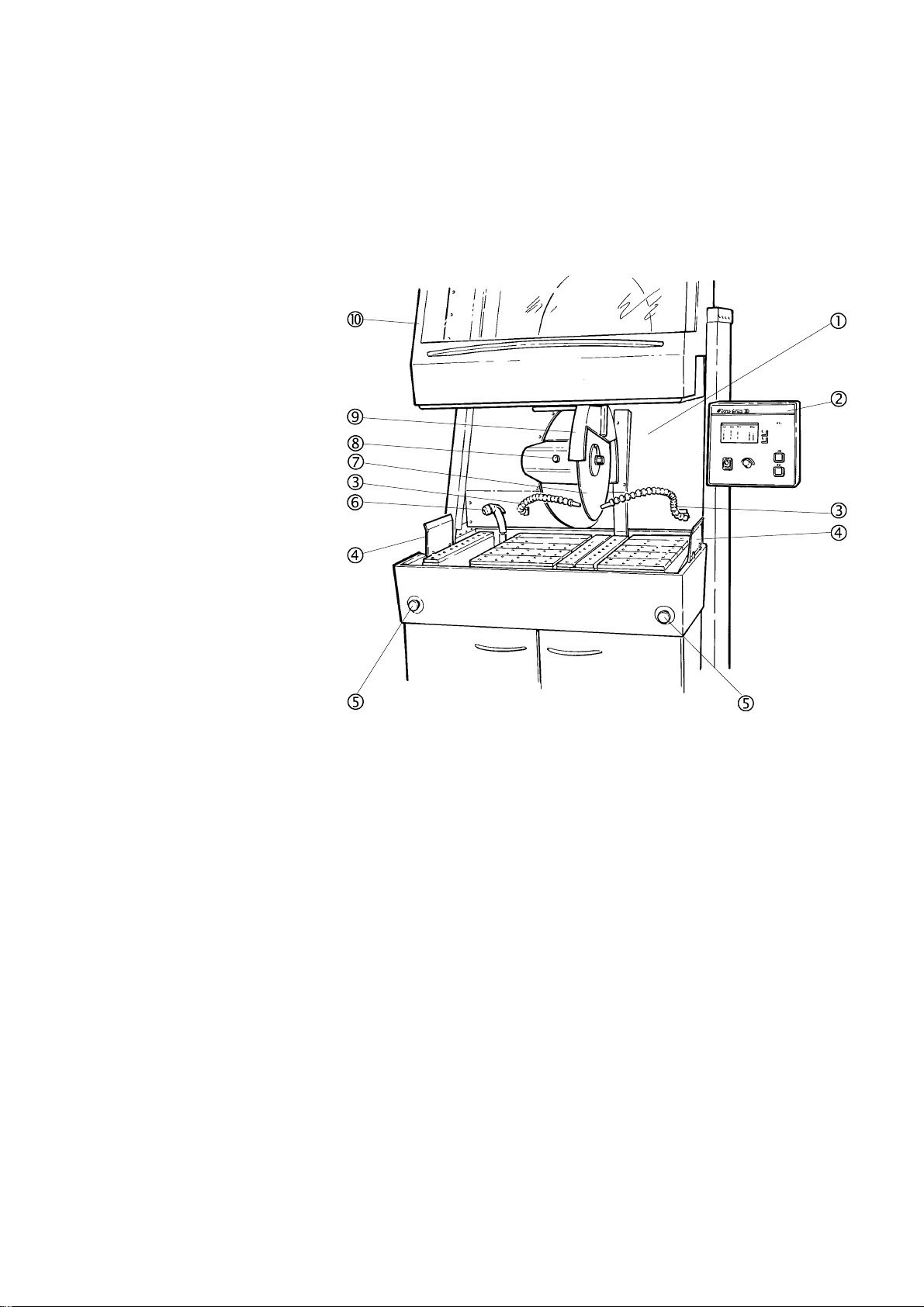

Getting Acquainted with

Exotom-100

Take a moment to familiarise yourself with the location and

names of the Exotom-100 components.

Cutting chamber

Control Panel

Flexible water jets

Protection guards

Emergency stops

Flushing hose with flush nozzle

Cut-off wheel

Spindle lock button

Guard for cut-off wheel

Protection hood

5

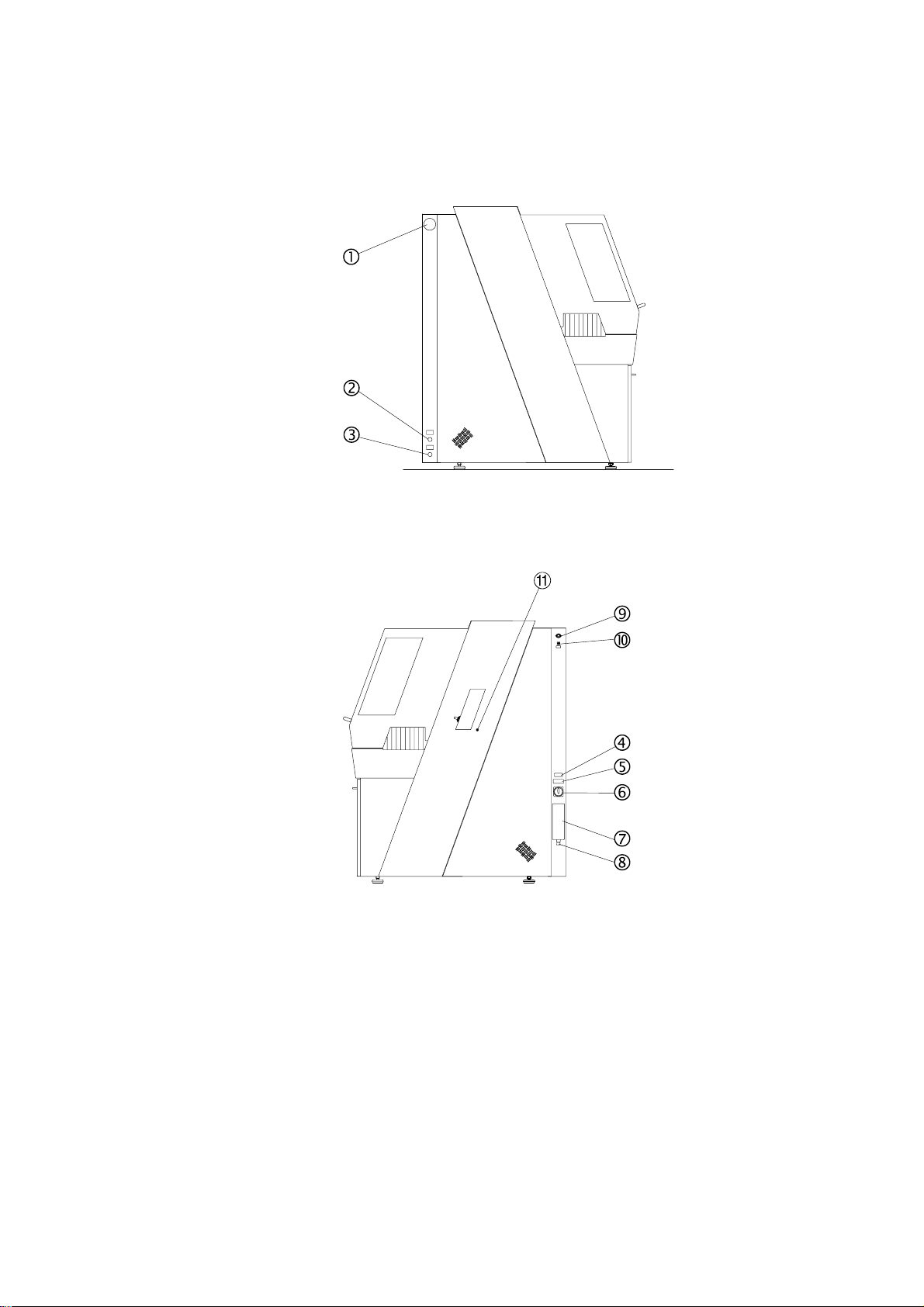

Side view, left

Exotom-100

Instruction Manual

Exhaust flange

Water inlet

Water outlet

Side view, right

Name Plate

Type plate

Main Switch

Electrical connection box

Connection for electrical cable for power supply

Connection for external warning light

Fuse socket for external warning light

1 Connection for Control Panel

6

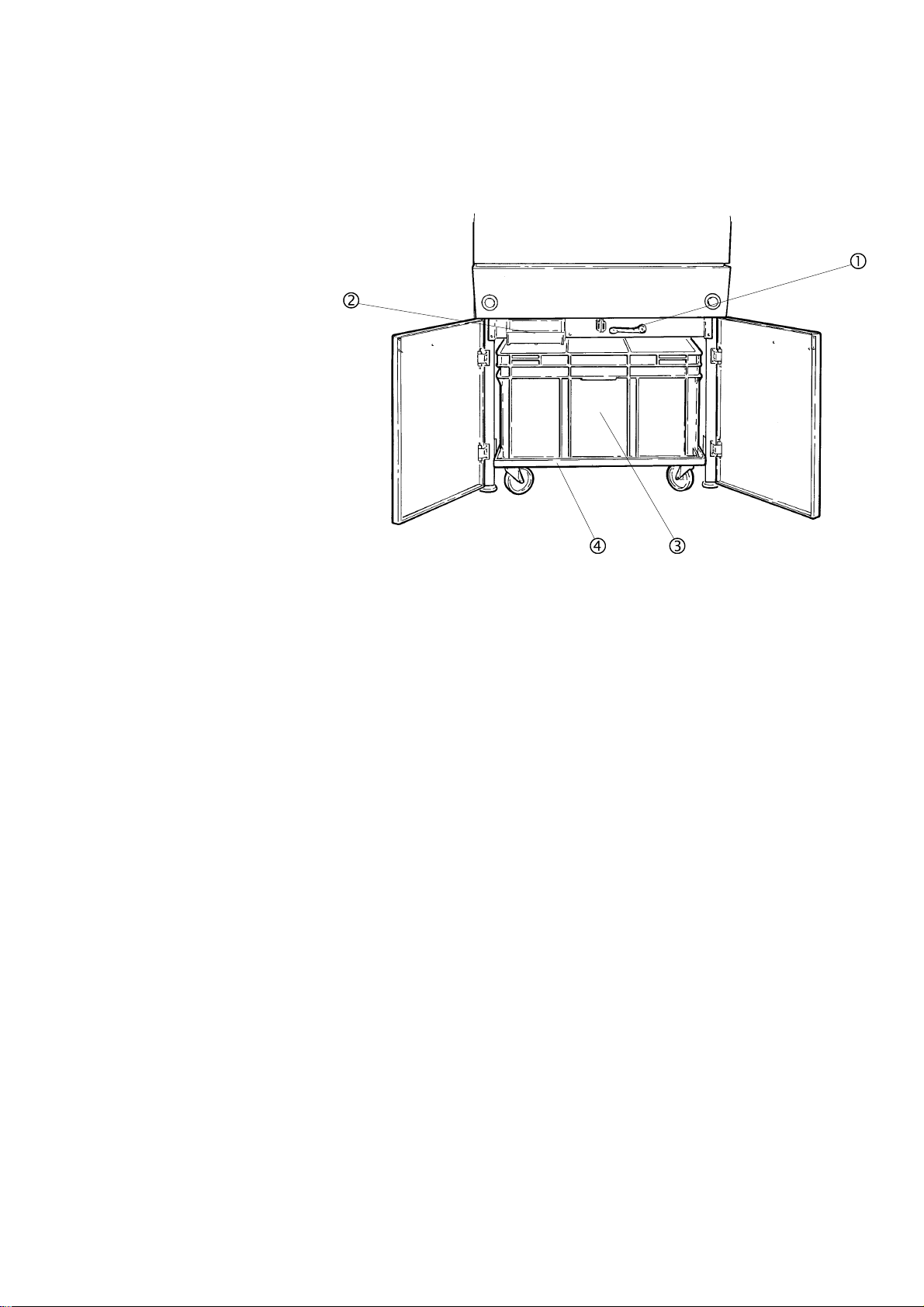

Cooling unit compartment

Exotom-100

Instruction Manual

Cooling unit drain pump on/off

Filter drawer

Recirculation cooling unit

Trolley for cooling unit

7

Exotom-100

Instruction Manual

Power Supply

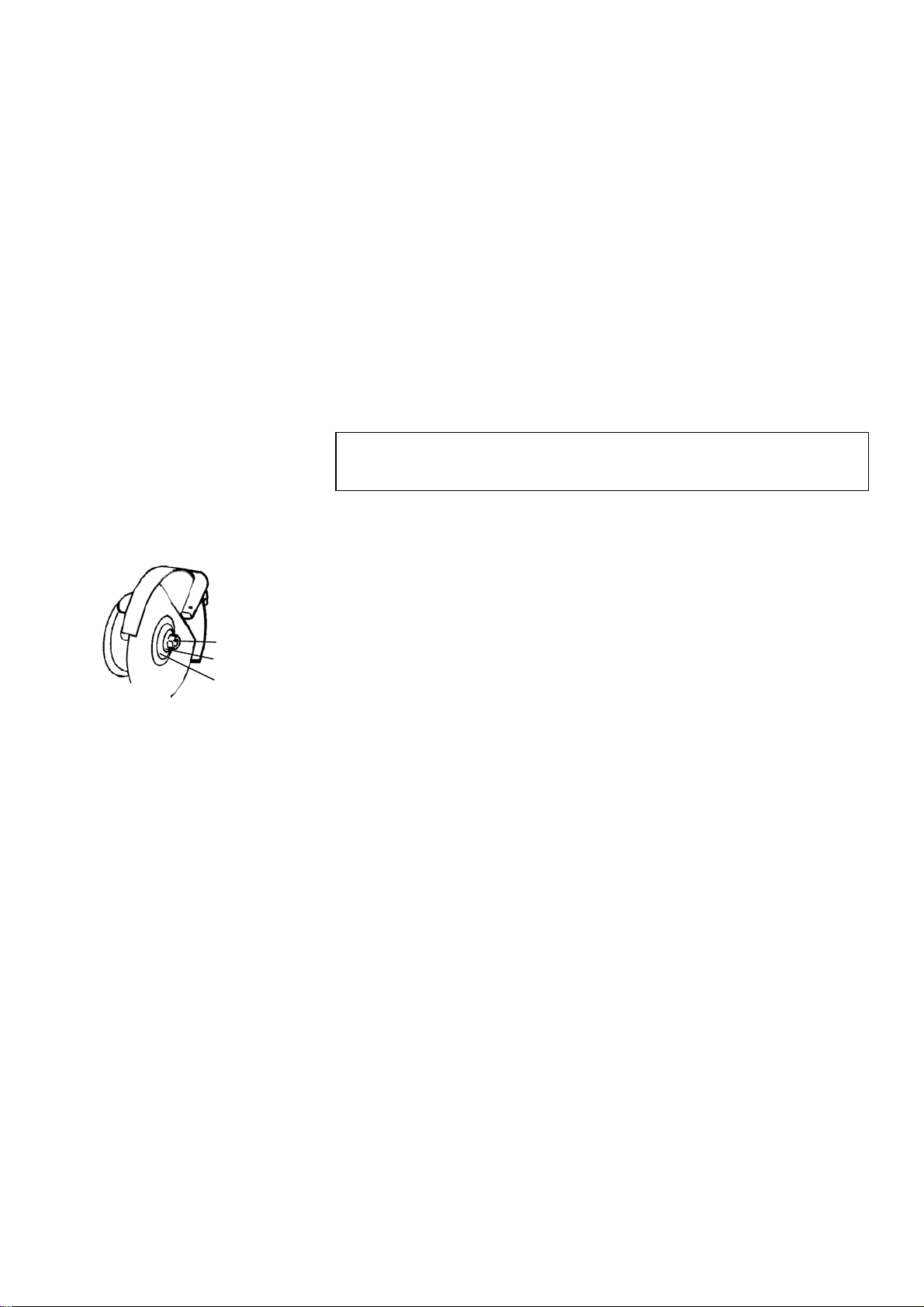

Mounting the Cut-off wheel

ee

Nut

Flange

Washer

Direction of the Cut-off Wheel

Connection to an External

Exhaust System

Before connecting the machine, check that the mains voltage is

correct by referring to the type plate.

Open the electric connection box and connect a 4-lead cable in the

following way:

PE: earth

L1: phase

L2: phase

L3: phase

IMPORTANT

Check that the mains voltage corresponds to the voltage stated on the type

plate on the side of the machine.

Press the knob for the spindle lock on the left-hand side of the cut-off

wheel, while turning the cut-off wheel until the spindle lock clicks.

Remove the nut with a fork spanner (30mm).

Remove the flange and the cut-off wheel.

Mount the new cut-off wheel with a cardboard flange on each side.

Mount the flanges and nut. Tighten carefully.

To check that the cut-off wheel rotates in the direction indicated

on the wheel-guard, do the following:

Close the protection hood.

Turn Main Switch to On.

Press START s.

Check the rotational direction of the wheel.

Press STOP o.

If the direction of rotation is incorrect, turn mains off and switch

two of the phases.

Struers recommends the use of an exhaust system as workpieces

may emit harmful gases when cut. The unit is prepared for

connection to an exhaust system via an 80 mm fitting on the left

hand side of the cabinet.

Recommended capacity for exhaust system: 350m

3

/h at 0mm

water gauge.

8

Exotom-100

Instruction Manual

Setting Up the

Recirculation Cooling Unit

Direct Water Supply for the

Cooling Unit

Check that the nylon sieve in the filter drawer is properly placed and

close the drawer.

Mount the drain hose on the back of the machine.

Place the recirculation cooling unit in the compartment.

IMPORTANT

The cooling unit must be positioned inside the compartment as indicated by

the arrows on the edge of the cooling unit.

Fill the cooling unit with 150 l of water (5-10 cm from the upper

edge).

Use additive enclosed with the machine and add to cooling water as

specified on the bottle label and stir.

Exotom-100 may be directly connected to the water mains.

Connect the water inlet fitting (½” internal, ¾” external thread).

Open the external water supply.

Fill the cooling unit with 150 l of water (5-10 cm from the upper

edge).

Shut off the water.

Add additive in the quantity stated on the bottle label and stir.

IMPORTANT

When the cooling unit is pushed into the compartment, care should be

taken that the flushing hose is not trapped behind it.

To counter this, pull the flushing hose all the way out of its holder, then

replace. The flushing hose, should then rest inside the cooling unit.

9

Using the Controls

Control Panel of Exotom-100

Exotom-100

Instruction Manual

2. Operation

10

Exotom-100

Instruction Manual

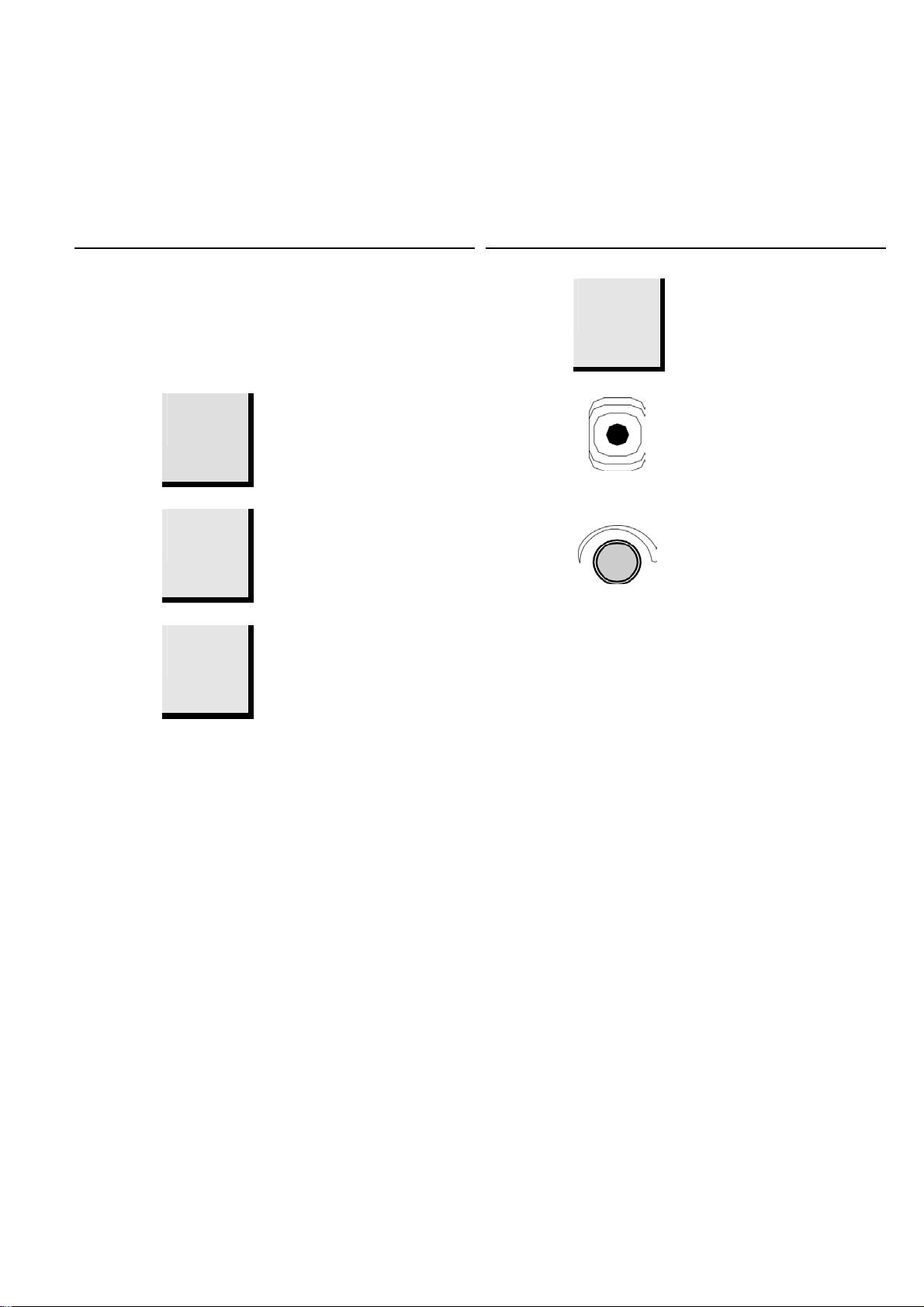

Control Panel Functions

Name Key Function Name Key Function

1

POWER

2

START

3

STOP

4

CUTTING

MODE

Power

s

o

U

Lights when the Main Switch has

been turned to ON.

Starts the machine and recirculation

unit.

Stops the machine and recirculation

unit.

Push button to select desired cutting

mode: Direct cutting, ExciCut,

AxioCut/Step, AxioCut/Sweep.

5

MENU

m

6

JOYSTICK

7

MULTIFUNCTION

KNOB

Push button to toggle between

Cutting menu (daily use) and

Configuration menu (basic settings).

Move up- or downwards to position

cut-off wheel.

Push knob to select function. Turn

knob to adjust settings.

Display Types

The Cutting Display will be shown on the Control Panel when

turning Exotom-100 on. This display is for everyday use.

By pressing the MENU m button once, the CONFIGURATION

menu will appear on the display. This menu will normally only be

accessed during installation.

11

Exotom-100

Instruction Manual

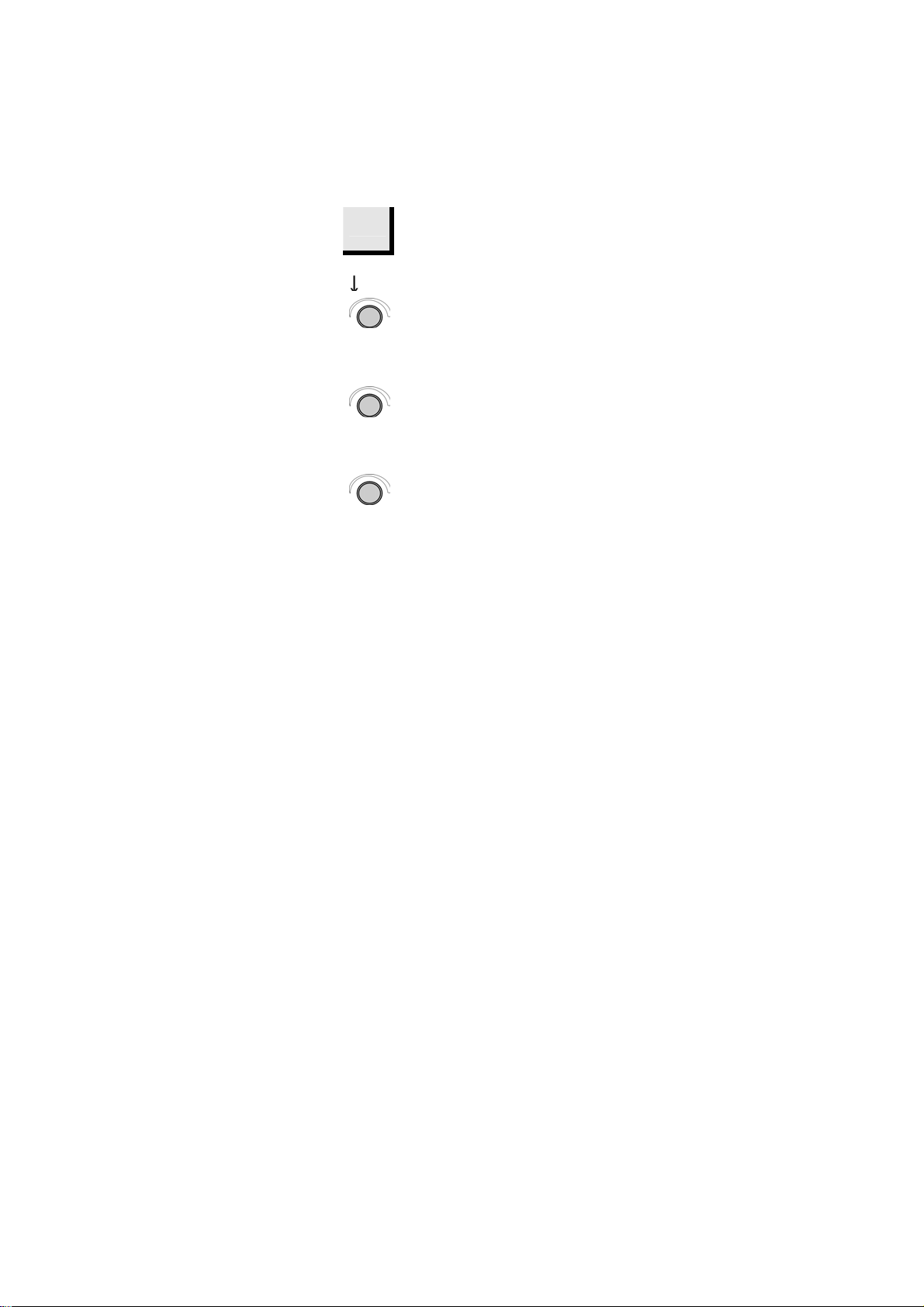

Setting the Language

m

D

D

D

Press MENU m button once to select

CONFIGURATION Menu.

Turn knob to toggle between parameters in the

CONFIGURATION Menu.

Push knob to select LANGUAGE. A pop-up menu

appears.

From the pop-up menu, select your preferred language

by pushing the knob.

Press MENU m button to move from

CONFIGURATION Menu to Cutting Display.

12

Exotom-100

Instruction Manual

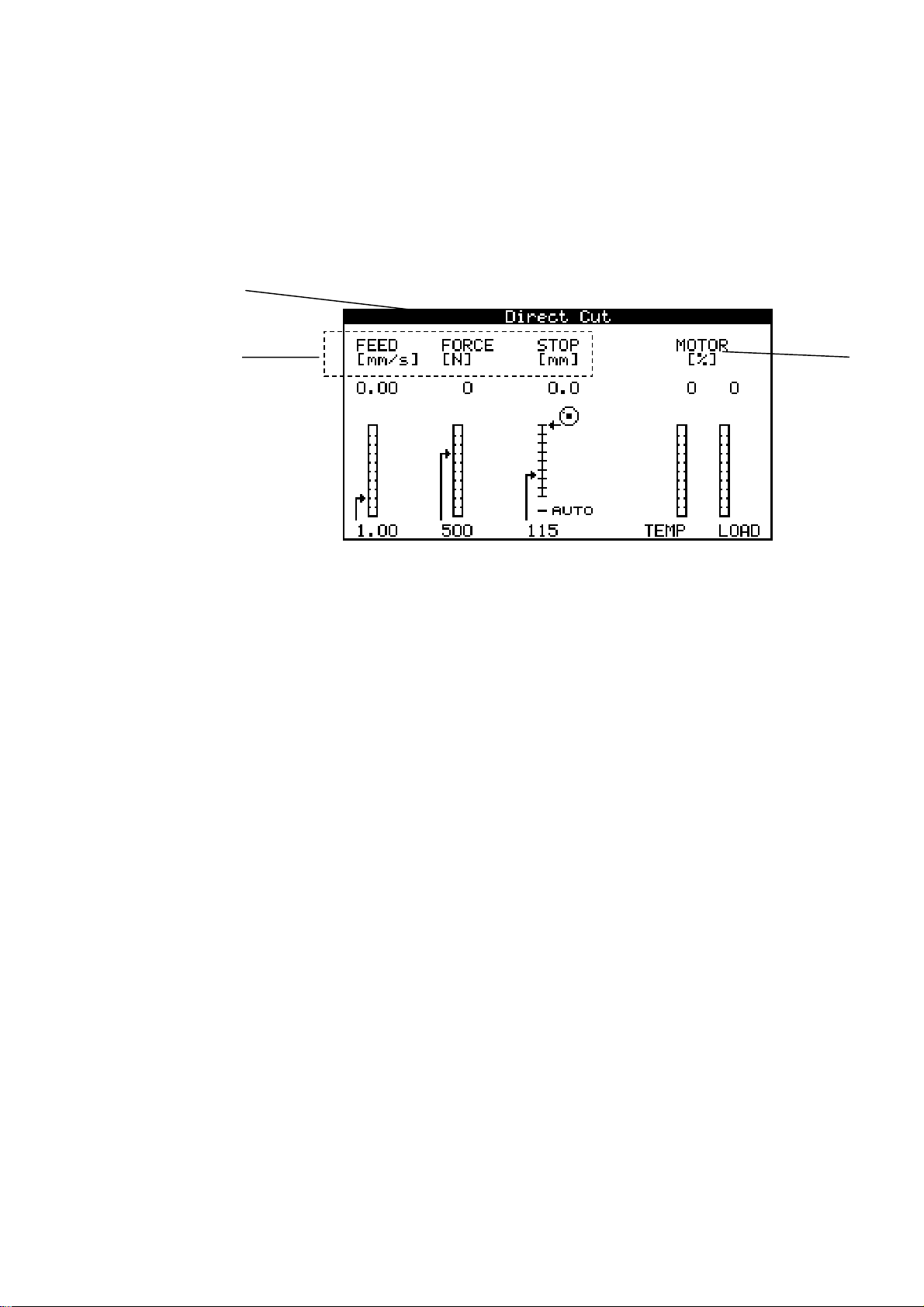

Reading the Cutting Display

A

B

Cutting Mode

Cutting Parameters and Motor

Information

The Cutting Display offers three types of information:

Cutting Mode

Cutting Parameters, and

Motor Information

A Cutting Mode.

B Cutting Parameters.

C Motor Information.

The top bar displays the selected Cutting Mode:

Direct Cutting, ExciCut, AxioCut/Step or AxioCut/Sweep

(AxioCut/Step and -/Sweep are optional).

The large window on the Cutting Display, displays information

about the Cutting Parameters (FEED, FORCE, STOP) as well as

Motor information (TEMP, LOAD).

The Cutting Parameters (FEED, FORCE and STOP) can be set

both prior to and during cutting. The set value is displayed below

the column. Actual value is displayed above the bar graph.

The Motor Information columns TEMP and LOAD, inform about

the condition of the motor during cutting. Read-out in relative

value (%).

C

13

Exotom-100

Instruction Manual

Changing Cutting Mode and

Cutting Parameters

Changing Cutting Mode

Changing Cutting Parameters

Push knob to select Cutting

Parameter.

Turn knob to adjust setting.

Reading the Motor Information

Sleep Mode

Toggle between the four Cutting Modes, by pressing the

CUTTING MODE button. The selected mode, Direct Cutting,

ExciCut, AxioCut/Step or AxioCut/Sweep, appears on the top bar

of the Cutting Display.

Toggle between the three Cutting Parameters by pushing the

knob. The highlighted Cutting Parameter is selected.

A

B

Actual values of the Cutting Parameters FEED, FORCE and

STOP are displayed on top of the columns (A).

The actual position of the cut-off wheel (relative its starting

position) is displayed graphically by the small icon

to the right

of the STOP column.

Turn the knob to change the setting of the selected Cutting

Parameter. The arrow on the left of the column will move to

reflect the new setting (B).

By moving the pointer of the STOP column below the column,

AUTO mode is selected.

The highlighted area of the bar graphs TEMP and LOAD, shows

the status of the cutting motor:

TEMP. Temperature indicator of the cutting motor.

LOAD. Load indicator of the cutting motor.

To increase the lifetime of the display, the backlight is

automatically switched off if Exotom-100 has not been used for 15

min. Push any key on the Control Panel to re-activate the

backlight.

14

Exotom-100

Instruction Manual

Changing the Cut-off Wheel

Clamping the Workpiece

Positioning the Cut-off Wheel

Press the knob for the spindle lock on the left-hand side of the cut-off

wheel, while turning the cut-off wheel until the spindle lock clicks.

Remove the nut with a fork spanner (30 mm).

Remove the flange and the cut-off wheel.

Mount the new cut-off wheel with a cardboard washer on each side.

Mount the flange and nut. Tighten carefully and close the guard.

IMPORTANT

Conventional cut-off wheels based on Al2O3/SiC abrasives should be placed

between two cardboard washers, to protect the cut-off wheel.

For maximum precision with diamond or CBN cut-off wheels, do not use

cardboard washers.

Clamp the workpiece with the clamping device of your choice e.g. a

quick clamping device. Place the workpiece between the clamp and

the back stop.

Push the clamp towards the workpiece, and lock the quick clamping

device with the locking handle.

Ensure that only one of the quick clamping devices is tight, the

other device should only press lightly. Use support tools if the

geometry of the workpiece makes support necessary.

IMPORTANT

When using the AxioCut cutting mode, the cut-off wheel cover may

hit the jaw of the Quick Clamping Device, if same is mounted in the shown

forward position; ie using the cross-directional T-slot closest to the front of

the machine.

To avoid this situation, place the quick-clamping device as far back as

possible, using the front-most T-slot.

Test possible infringement by starting the machine with the cut-off wheel

completely clear of the clamping device.

Should the cut-off wheel hit the clamping device anyway, no danger is

involved. Exotom-100 will stop automatically and display the following

message: "AxioCut motor blocked".

After clamping, test the correct position of the cut on the

workpiece, by lowering the cut-off wheel into position, min. 1 mm

above the workpiece:

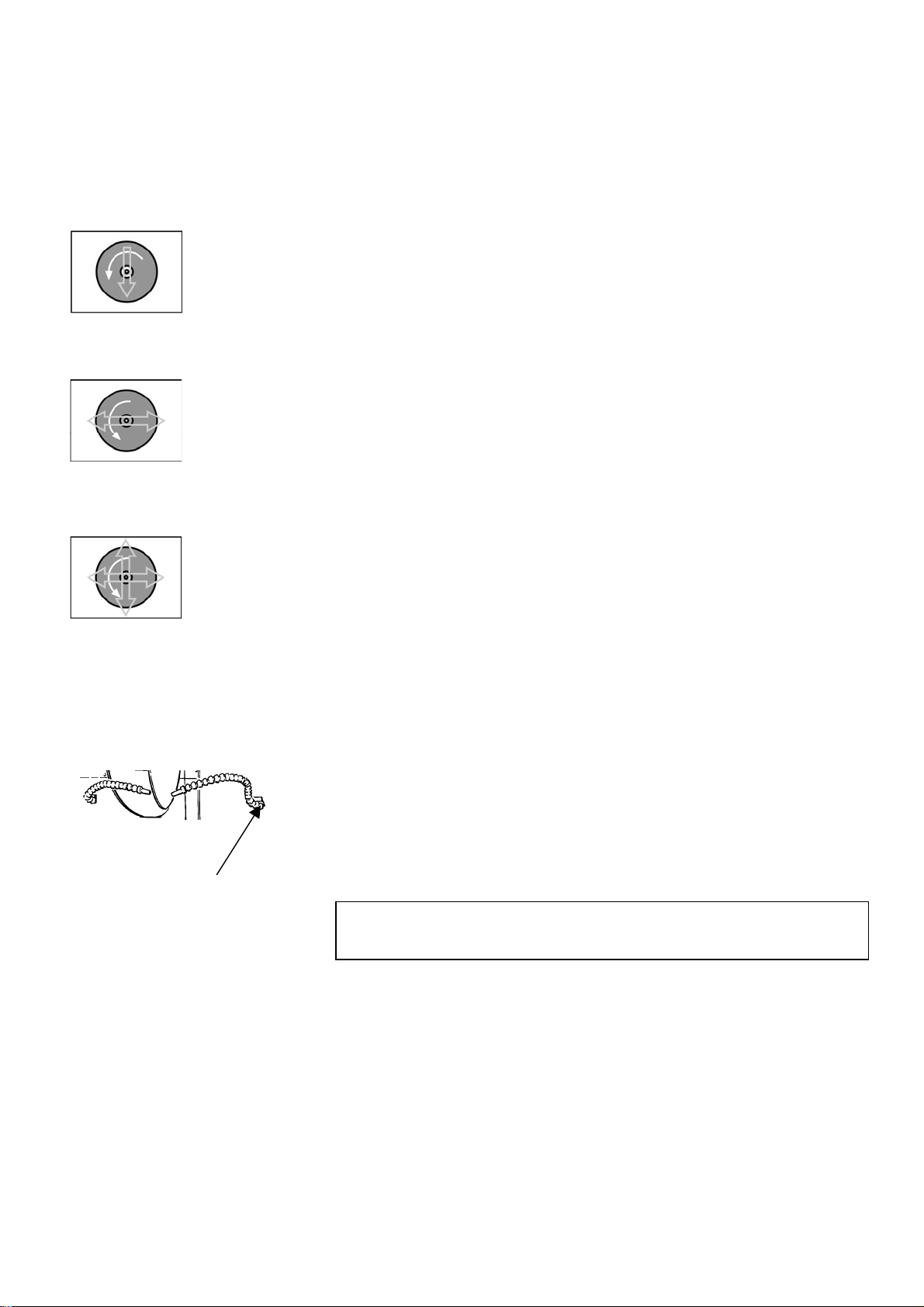

Push the joystick on the Control Panel downwards, to lower the cut-

off wheel. The cut-off wheel stops when the joystick is released.

15

Exotom-100

Instruction Manual

QuickPosition

Cutting Parameters

Feed

Force

Stop

AutoStop

Positioning of the cut-off wheel may be done, by simply pushing

the joystick downwards until the cut-off wheel has contact with

the workpiece. The force is automatically reduced on contact,

preventing damage to the cut-off wheel and the workpiece.

After contact with the workpiece, the cut-off wheel is

automatically retracted 2 mm, to be ready for cutting.

The feed speed can be set to values between 0.05-5.00 mm/sec

(0.002-0.2 "/s).

The maximum permitted force between cut-off wheel and

workpiece can be set to values between 20-700 N (4-150 lbs). A

built-in measuring cell constantly computes the force. If the force

limit is reached, the feed speed will automatically be reduced to a

value that allows the force to stay just below the set limit. As soon

as the force drops below the set limit, the speed will be increased

to the original setting.

NOTE

When cutting with a force below 50 N, beware of hysteresis

(actual force applied may differ from selected cutting force).

There are two ways to set the stop position: AutoStop and Fixed

Stop, explained under Advanced Operations.

When the AutoStop function is selected, the machine

automatically stops when the workpiece has been cut through.

For normal cutting, the AutoStop function is recommended.

16

Exotom-100

Instruction Manual

Setting the Cutting Parameters

Cutting on Exotom-100

Starting the Cutting

Fast advance

Stopping the Cutting

(Manual Stop)

Re-starting cutting

The Cutting Parameters, FEED, FORCE and STOP, are set in the

Cutting Menu.

m

If in CONFIGURATION Menu, press MENU m once to

select Cutting Menu.

Push knob to toggle between parameters in the Cutting

Menu.

D

Turn knob to edit the value of the selected parameter.

D

Push knob to move to next parameter.

Position the cut-off wheel.

Close the protection hood.

Press START s. The cut-off wheel starts rotating, the cooling water

starts running and the cut-off wheel will slowly move down into the

workpiece at the pre-set Feed Rate.

After START

s has been pressed, the cut-off wheel may also be

advanced towards the workpiece manually. To advance the cut-off

wheel, push the joystick downwards. The cut-off wheel will

advance towards the workpiece at maximum speed (5mm/s).

Exotom-100 automatically stops cutting when the workpiece is cut

through.

Press STOP o to manually interrupt the cutting process.

The machine can be stopped at any time during operation by

pressing STOP

o.

Having interrupted cutting, the cut-off wheel has been

automatically moved out of the workpiece.

Press START s to resume cutting.

17

Exotom-100

Instruction Manual

Direct Cut

ExciCut

AxioCut (option)

Additional cooling

To activate jet, turn valve

Direct Cutting is the normal cutting mode. The cut-off wheel is

moved into the workpiece in a slightly curved, vertical movement.

Direct Cutting is intended for ordinary materials.

ExciCut cutting mode is ideal for cutting of very hard materials

(HV >400). The oscillating movement of the cut-off wheel has

three main advantages: less wear on the cut-off wheel, less risk of

damage to workpiece and less risk of motor overheating.

To select ExciCut, press the CUTTING MODE button, until

ExciCut appears in the top bar of the display.

The AxioCut option permits cutting of extra large workpieces

(adding 150mm to max. depth). Two different cutting modes are

provided, Step and Sweep. The Sweep-mode offers better cut-off

wheel economy than the Step-mode. The latter method, however,

is faster.

To select AxioCut/Step or AxioCut/Sweep, press the CUTTING

MODE button, until the desired mode appears in the top bar of

the display.

Two flexible water jets are provided for additional cooling. Cooling

water from the integrated water jets will flow away from the

upper part of the cutting area, particularly when cutting hollow

workpieces. To counter this, use the flexible water jets provided.

Position the cooling jets to the left and right of the cutting area.

Turn the valve on the jet to a position parallel to the hose to activate

the cooling jet. The cooling water will flow as soon as the cutting

starts.

Note

When using the flexible water jets, cooling water is diverted from the

integrated water jets positioned over the cut-off wheel.

18

Exotom-100

Instruction Manual

Reference Guide

Table of Contents Page

1. Advanced Operations

Configuration Menu ....................................................................... 21

Display contrast....................................................................... 22

Language.................................................................................. 22

Return position ........................................................................22

Units......................................................................................... 22

Operation mode .......................................................................22

New Pass Code................................................................................ 23

Changing Operation Mode ............................................................. 24

Cutting Offset .................................................................................25

Cutting Display............................................................................... 26

Cutting Modes................................................................................. 27

Direct Cut........................................................................................ 27

ExciCut............................................................................................ 27

AxioCut (option).............................................................................. 27

AxioCut/Step............................................................................ 28

AxioCut/Sweep......................................................................... 28

Stop Settings................................................................................... 29

AutoStop................................................................................... 29

Fixed Stop ................................................................................ 29

QuickPosition........................................................................... 30

OptiFeed.......................................................................................... 30

Cutting Long Workpieces...............................................................31

Clamping Irregular Workpieces..................................................... 31

Connection to External Exhaust System....................................... 31

Other Safety Features ....................................................................32

Optimising Cutting Results ...........................................................33

2.

Accessories ..........................................................................34

3.

Consumables

Cut-off Wheels................................................................................. 35

Other Consumables ........................................................................ 35

19

Exotom-100

Instruction Manual

4. Trouble-Shooting

Error Messages ............................................................................... 39

Messages ..................................................................................39

Errors ....................................................................................... 39

Fatal Errors .............................................................................39

5.

Maintenance

Daily Service ................................................................................... 42

Cleaning the Cutting Chamber...................................................... 42

Weekly Service................................................................................ 42

Monthly Service ..............................................................................42

Replacing the Cooling Water ..................................................42

Maintenance of Recirculation Unit................................................ 43

Low Level Warning .................................................................43

Refilling the Cooling Unit ....................................................... 43

Emptying the Cooling Unit.....................................................43

Filter Drawer ...........................................................................44

Additive for Cooling Water .....................................................44

Maintenance of Cutting Table .......................................................45

Maintenance of Cut-off Wheels...................................................... 45

Storage of Bakelite Bonded Al2O3 Cut-off Wheels.................. 45

Maintenance of Diamond and CBN Cut-off Wheels ..............45

Maintenance of Clamping Devices................................................. 45

6.

Technical Data......................................................................46

Cutting Capacity...................................................................... 47

20

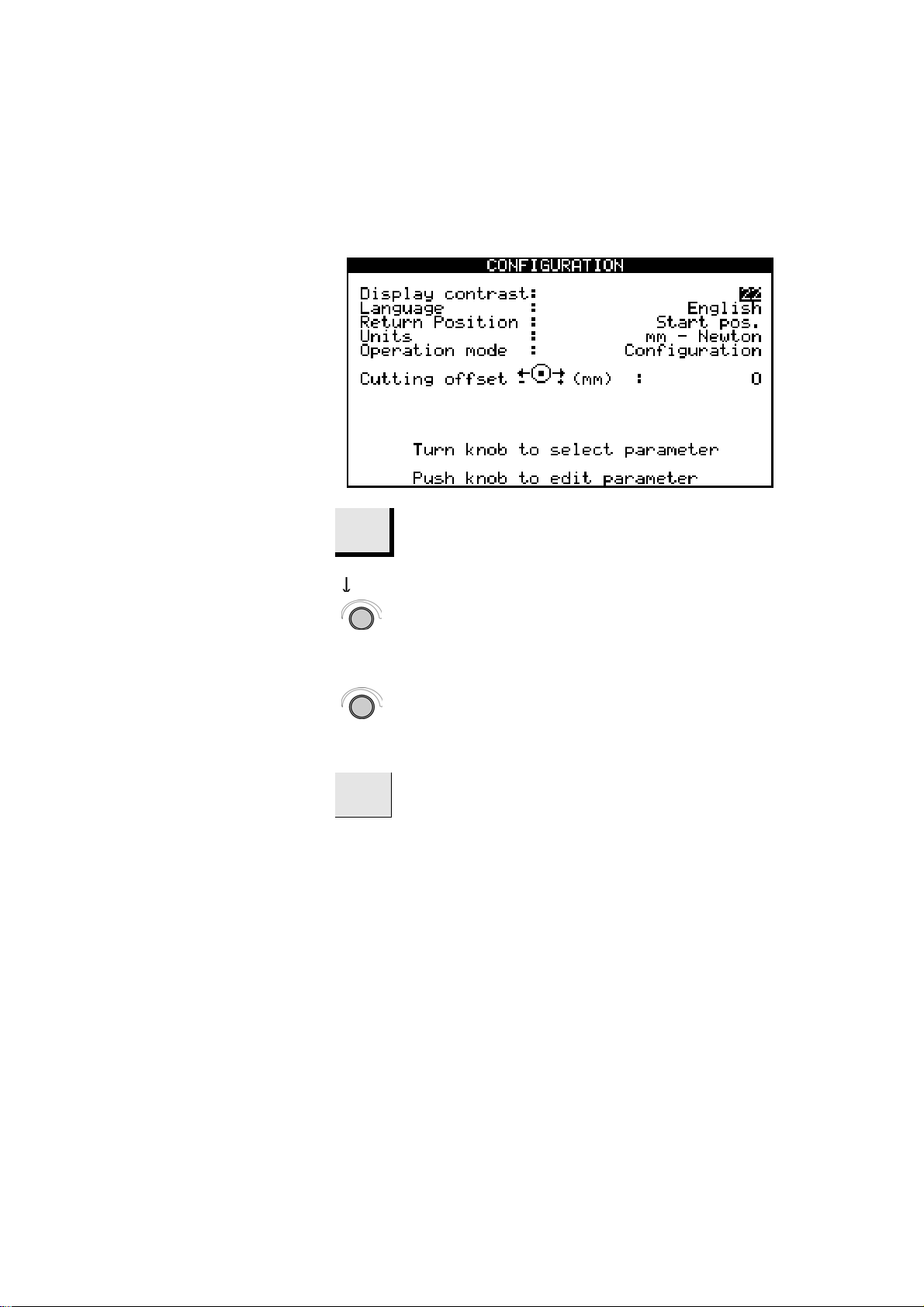

Configuration Menu

Exotom-100

Instruction Manual

1. Advanced Operations

m

Press MENU m button once to select

CONFIGURATION Menu.

D

D

m

Turn knob to highlight different parameters in the

CONFIGURATION Menu.

Push knob to edit the chosen parameter.

Press MENU m button to move from

CONFIGURATION Menu to Cutting Display.

21

Exotom-100

Instruction Manual

Display contrast

Language

Return position

Units

Operation mode

The contrast settings of the display can be adjusted to suit

individual preferences (default value: 22, adjustment interval:

0-50).

The language can be set to English (default), German, French,

Spanish or Japanese.

After cutting or after pressing STOP o, the return movement of

the cut-off wheel can be set to three different functions:

Top: Exotom-100 automatically retracts the cut-off wheel to

the top position.

Start: Exotom-100 automatically retracts the cut-off wheel to

the original position of the cut-off wheel, at the time you

pressed START s (default).

Stay: The cut-off wheel stays down.

Important

Use the Stay function for bakelite bonded diamond or CBN cut-off wheels,

as retraction might destroy the rim of the cut-off wheel.

The Feed, Force and Stop values in the display panel can be set to

displayed in either mm/Newton (default) or inches/pounds force.

It is possible to select three different operation modes:

Configuration: Full functionality

Development: No access to parameters in CONFIGURATION

menu, except Display contrast

Production: Access to START, STOP, Fixed Stop and

movement of cut-off wheel,

and to Display contrast in the

CONFIGURATION menu

To select your own pass code, go to the CONFIGURATION menu.

Select Operation mode to get access to CHANGE OPERATION

MODE menu.

22

Exotom-100

Instruction Manual

New Pass Code

To select your own pass code, go to the CONFIGURATION menu.

Select Operation mode to get access to CHANGE OPERATION

MODE menu.

Push knob to select Pass code

D

Turn knob until default pass code ‘176’ appears.

D

Push knob to select default pass code, and a new line

(New pass code) appears in the CHANGE OPERATION

MODE menu.

D

Turn knob to move the cursor to New Pass Code.

D

D

m

Push knob to select and turn knob to set your own

three-digit pass code.

Press Menu button to confirm your unique pass code

and exit the CHANGE OPERATION MODE menu.

23

Exotom-100

Instruction Manual

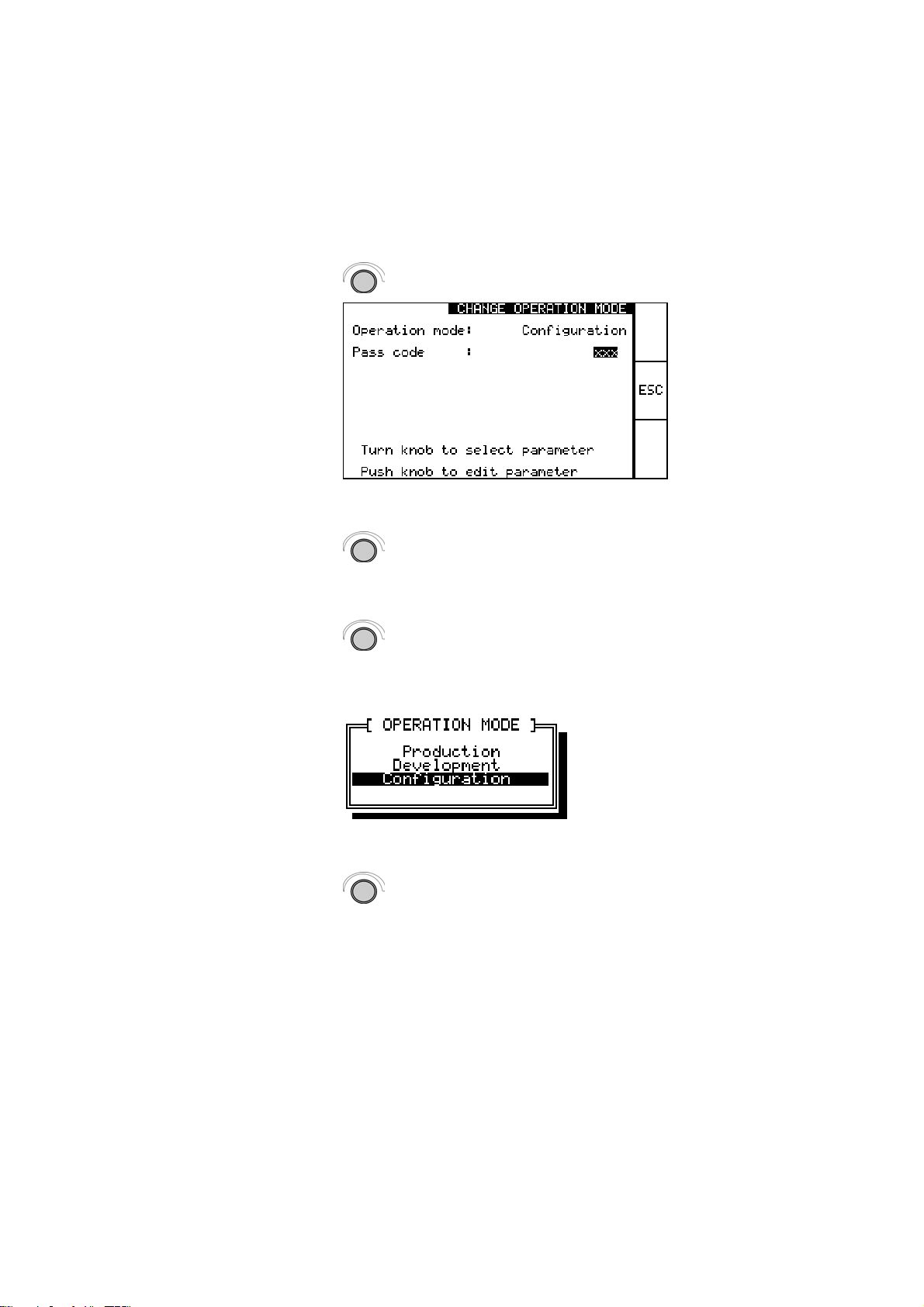

Changing Operation Mode

To change the operation mode, highlight the parameter in the

CONFIGURATION menu.

Push knob to move to Change Operation Mode menu.

D

Enter your unique pass code by turning the knob.

Confirm by pushing knob.

D

Push knob

A pop-up will appear.

D

D

D

Select desired operation mode and push knob to

confirm.

Press Cutting Mode button to move to

CONFIGURATION menu.

24

Loading...

Loading...