Structural Concepts GLDSV3R, GLDSV3R.6094, GLDSV3R.6602, GLDSV4R, GLDSV6R Installation And Operating Manual

...

READ AND SAVE THESE INSTRUCTIONS

INSTALLATION AND

G-SERIES P/N 21-01524

G-SERIES MID-VOLUME REFRIGERATED SERVICE DELI MERCHANDISERS

> VERTICAL FRONT GLASS WITH REAR HINGES

> REMOTE & SELF-CONTAINED > FULL AND OPEN END PANELS

> REFRIGERATED-TO-DRY SWITCH AT CASE REAR (OPTIONAL)

> REAR SLIDING DOORS > OPTIONAL SCALE STAND

GMDSV12R.7183

OPERATING MANUAL

GMDSVC3R

CAUTION!

FRAGILE!

HOLD

GLASS

FIRMLY.

SLOWLY

OPEN &

CLOSE.

CAUTION!

FRAGILE!

DO NOT

STRIKE

DECKS

OR PANS

AGAINST

EDGE OF

GLASS.

GMDSV6R.7115C

Note: See Next Page

For Partial List Of

Models To Which

This Operating

Manual Applies.

Structural Concepts Corporation ∙ 888 E. Porter Road ∙ Muskegon, MI 49441 Phone: 231.798.8888 Fax: 231.798.4960 ∙ www.structuralconcepts.com

Operating Manuals\Standard\G-Series_Mid-Volume Ref Svc Deli_Vertical Glass_Rear Hinges_21-01524.pub

GMDSV4R

GLDSV6R.6670C

GLDSV4R

GMDSV8R

Rev B Date: 1.22.2019

TABLE OF CONTENTS / LIST OF MODELS INCLUDED IN MANUAL

TABLE OF CONTENTS / LIST OF MODELS ENCOMPASSED IN MANUAL ……….………………….…..

OVERVIEW / UNIT TYPE / COMPLIANCE / WARNINGS / PRECAUTIONS / WIRING …..……….……...

INSTALLATION: REMOVAL FROM SKID, REMOVING LOWER FRONT PANELS ..……...…….…….….

INSTALLATION, CONT’D: CASE ADJOINMENT INSTRUCTIONS ……………….………...……………….

INSTALLATION, CONT’D: FRAME SUPPORT RAIL SHIMMING ……………………………………….......

INSTALLATION, CONT’D: FRONT GLASS ALIGNMENT & ADJUSTMENT (VIA RAIL SYSTEM) ……...

INSTALLATION, CONT’D: FIELD WIRING BOX / RACEWAY / LED DRIVER / ANTI-CONDENSATE

AXIAL FANS .…………………………………………..….……………………………………………….

INSTALLATION, CONT’D: REFRIGERATION LINES / STUB-UPS / DRAINS ……..…………….….……..

INSTALLATION, CONT’D: SCALE STAND WITH OUTLETS & CAT5 / FLIP-UP LEDGE ………….……..

START-UP AND OPERATION ………………..………………………………………………………………….

MAINTENANCE FUNDAMENTALS: LED LIGHT FIXTURES / REMOVAL & REPLACEMENT…………...

MAINTENANCE FUNDAMENTALS, CONT’D: SHELF ASSEMBLIES ………………………………....……

MAINTENANCE FUNDAMENTALS, CONT’D: DRAIN, TXV VALVE ACCESS ………………………....….

MAINTENANCE FUNDAMENTALS, CONT’D: REAR SLIDING DOORS ……………………………….…..

MAINTENANCE FUNDAMENTALS, CONT’D: REAR HINGED FRONT GLASS …………………………..

MAINTENANCE FUNDAMENTALS, CONT’D: REFRIGERATED TO DRY SWITCH (OPTIONAL) ……...

MAINTENANCE FUNDAMENTALS, CONT’D: CUTTING BOARD / REAR LEDGE REMOVAL ...……….

MAINTENANCE FUNDAMENTALS, CONT’D: CONDENSATE PACKAGE LAYOUT ……………….…….

CLEANING SCHEDULE - INTERIOR: TO BE PERFORMED BY STORE PERSONNEL .………………...

CLEANING SCHEDULE - EXTERIOR: TO BE PERFORMED BY STORE PERSONNEL ………….……..

CLEANING SCHEDULE -STAINLESS STEEL: TO BE PERFORMED BY STORE PERSONNEL ……...

PREVENTIVE MAINTENANCE - TO BE PERFORMED BY TRAINED SERVICE PROVIDERS ONLY ....

TROUBLESHOOTING - TO BE PERFORMED BY STORE PERSONNEL (UNLESS NOTED

OTHERWISE) ……………………………………………………………………………………………...

TROUBLESHOOTING - CONDENSING SYSTEM (TO BE PERFORMED BY TRAINED SERVICE

PROVIDERS ONLY) ……………………………………………………………………………………...

TROUBLESHOOTING - EVAPORATOR SYSTEM (TO BE PERFORMED BY TRAINED SERVICE

PROVIDERS ONLY) ………………………...……………………………………………………….…...

SERIAL LABEL INFORMATION & LOCATION ..……………………………………...…....…………..….…..

CAREL® TEMPERATURE CONTROLLER INFORMATION ………………………………………….….…..

TECHNICAL SERVICE CONTACT INFORMATION & WARRANTY INFORMATION ...……….…............

2

3-4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25-27

28

29

30

31-33

34

THIS OPERATING MANUAL INCLUDES (BUT IS NOT LIMITED TO) THE FOLLOWING MODELS:

GLDSV3R

GLDSV3R.6094

GLDSV3R.6602

GLDSV4R

GLDSV6R

GLDSV6RG.5718

GLDSV8R

GLDSV10R

GLDSV8R.7183

GLDSV10R.6094E

GLDSV10R.6670A

GLDSV12R

GLDSV442R.6670F

GLDSV542R.7042B

GLDSV642R.6670C

GLDSV842R.6670B

GLDSV842R.7042D

GLDSV1242R.6670D

GLDSV1242R.6839F

GLDSV1242R.7042F

GLDSV1242R.7186F

GMDSESV8R

GMDSESV12R

GMDSV3D.7215

GMDSV4D

GMDSV4D.7215

GMDSV3R.6694

GMDSV4R

GMDSV4R.6806A

GMDSV4R.6694

GMDSV4R.6749B

GMDSV4R.7215

GMDSV5R.7215

GMDSV6R

GMDSV6R.6694

GMDSV6R.6806C

GMDSV6R.7115C

GMDSV8R

GMDSV8R.6694

2

GMDSV8R.6749A

GMDSV8R.7063B

GMDSV8R.7115D

GMDSV8R.7183

GMDSV8R.7215

GMDSV8R-RD

GMDSV10R.6806E

GMDSV10R.7215

GMDSV12R

GMDSV12R.7063D

GMDSV12R.7115F

GMDSV12R.7215

GMDSV12R.7280

GMDSVC3R.6694

GMDSVC3R.7215

GMDSVC4R

GMDSVC4R.7215

GMGV8.7183

OVERVIEW / UNIT TYPE / COMPLIANCE / WARNINGS / PRECAUTIONS / WIRING - PAGE 1 of 2

OVERVIEW

• These Structural Concepts merchandisers are

designed to merchandise packaged products at 41 °F

(5 °C) or less product temperatures (unless custom

cases with wire rack shelving).

• Product must be pre-chilled to 41 °F (5 °C) or less

prior to being placed in merchandiser.

• Cases should be installed and operated according to

this operating manual’s instructions to ensure proper

performance. Improper use will void warranty.

TYPE

This unit is designed for the display of products in ambient

store conditions where temperatures and humidity are

maintained within a specific range.

• For Type 1 Conditions (most cases): ambient

conditions are to be at 55% maximum humidity and

maximum temperatures of 75 °F (24 °C).

• For Type 2 Conditions: ambient conditions are to be

at 55% maximum humidity and maximum

temperatures of 80 °F (27 °C).

This equipment MUST be installed in compliance with all applicable

ATTENTION

CONTRACTORS

NEC, federal, state and local electrical and plumbing codes.

• If unsure if unit is Type 1 or 2, see tag near serial

label.

COMPLIANCE

• Performance issues when in violation of applicable

NEC, federal, state and local electrical and plumbing

codes are not covered by warranty.

• See below compliance guideline.

WARNINGS

• This page contains important warnings to prevent

injury or death. Please read carefully!

PRECAUTIONS and WIRING DIAGRAMS

• See next page for PRECAUTIONS and WIRING

DIAGRAM information.

POWER CORD AND PLUG MAINTENANCE

(FOR CASES THAT ARE NOT FIELD-WIRED)

• Caution! Risk of electric shock.

• If cord or plug becomes damaged, replace only with

cord and plug of same type. See next page.

COMPLIANCE

WARNING

ELECTRICAL

HAZARD

WARNING

KEEP

HANDS

CLEAR

WARNING

Risk of electric shock. Disconnect power before servicing unit.

CAUTION! More than one source of electrical supply is

employed with units that have separate circuits.

Disconnect ALL ELECTRICAL SOURCES before servicing.

WARNING

Hazardous moving parts. Do not operate unit with covers removed.

Fan blades may be exposed when deck panel is removed.

Disconnect power before removing deck panel.

CAUTION! CHECK BOTH CONDENSATE PAN AND OVERFLOW PAN

Water on floor can cause extensive damage! Before powering up unit:

• Condensate pan MUST BE positioned directly under condensate drain.

• Overflow pan MUST HAVE single plug connected to its box. Units with

optional Clean Sweep™ MUST HAVE two plugs connected.

• WARNING for self-contained units only! Overflow condensate pan

heater rod is hot! Electric condensate pan must be disconnected and

allowed to cool before cleaning or removing from case.

3

OVERVIEW / UNIT TYPE / COMPLIANCE / WARNINGS / PRECAUTIONS / WIRING - PAGE 2 of 2

PRECAUTIONS

• Following are important precautions to prevent

damage to unit or merchandise.

• Please read carefully!

• See previous page for specifics on OVERVIEW,

TYPE, COMPLIANCE and WARNINGS.

CAUTION! LAMP REPLACEMENT GUIDELINES

Fluorescent lamps have been treated to resist breakage and

CAUTION

must be replaced with similarly treated lamps.

LED lamps reflect specific size, shape and overall design.

Any replacements must meet factory specifications.

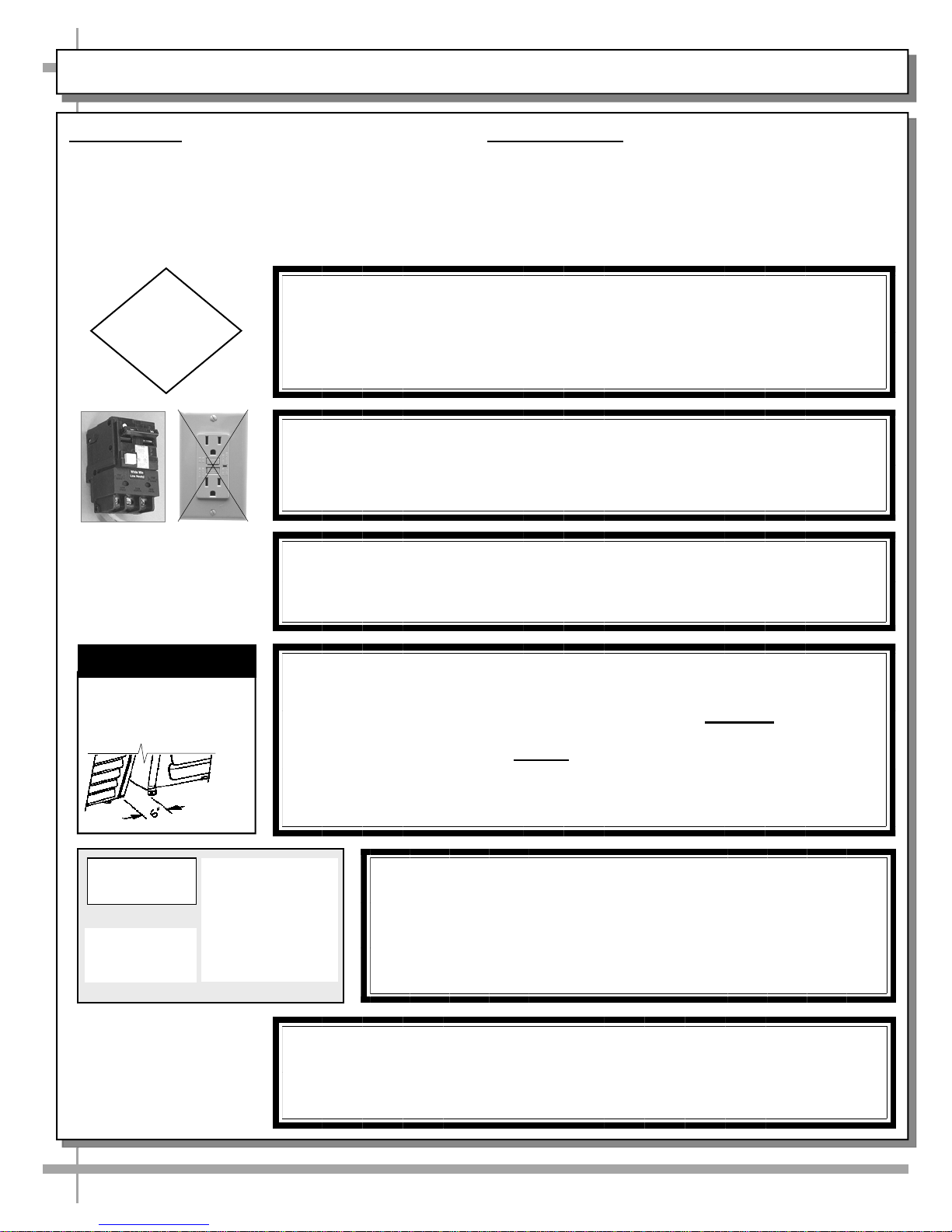

CAUTION! GFCI BREAKER USE REQUIREMENT

If N.E.C. (National Electric Code) or your local code requires

GFCI (Ground Fault Circuit Interrupter) protection,

you MUST use a GFCI breaker in lieu of a GFCI receptacle.

CAUTION! CASES WITH POWER CORD AND PLUG

Risk of electric shock. If cord or plug becomes damaged,

replace only with cord and plug of same type.

WIRING DIAGRAM

• Each case has its own wiring diagram folded and in

its own packet.

• Wiring diagram placement may vary; it may be

placed near ballast box, field wiring box, raceway

cover, or other related location.

CAUTION

CAUTION! ADVERSE CONDITIONS / SPACING ISSUES

• Performance issues caused by adverse conditions are NOT warranted.

• End panels must be tightly joined or kept at least 6-inches away from

any structure to prevent condensation.

• Unit must be kept at least 15-feet from exterior doors, overhead HVAC

vents or any air curtain disruption to maintain proper temperatures.

• Unit must not be exposed to direct sunlight or any heat source.

• Self-Cont. Units: Keep 4” min. air intake / 4” min. air disch. clearance.

CAUTION!

DO NOT RELY ON THERMOMETERS OR THERMOSTATS

FOR ACTUAL PRODUCT (FOOD) TEMPERATURES.

• Thermometers & thermostats reflect air temperatures ONLY.

• For ACTUAL product (food) temperatures, use a calibrated

food thermometer.

WARNING: This product can expose you to chemicals, including

Urethane (Ethyl Carbamate), which are known to the state of

California to cause cancer and birth defects or other reproductive

harm. For more information go to P65Warnings.ca.gov.

4

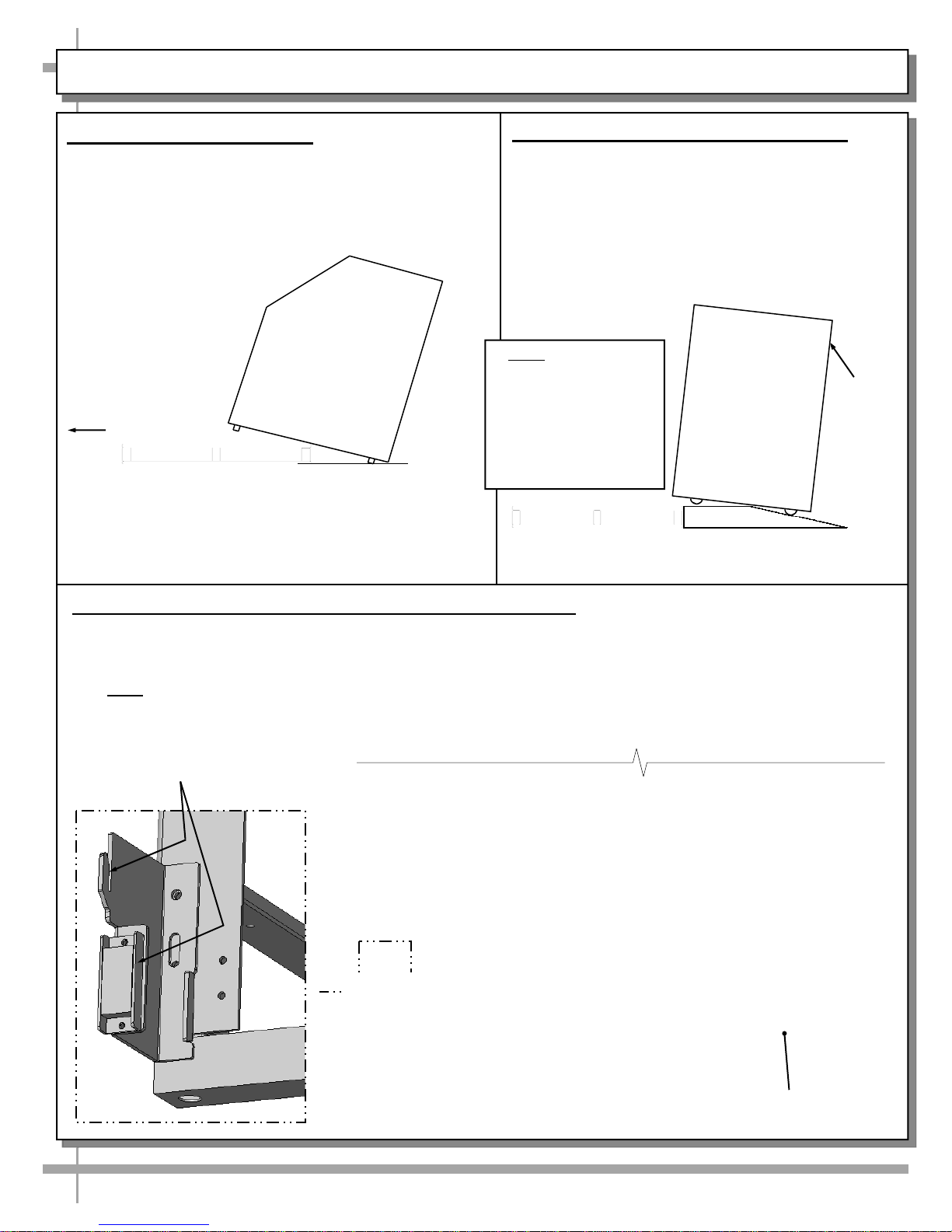

INSTALLATION: REMOVAL FROM SKID, REMOVING LOWER FRONT PANELS

1. Remove Case From Skid

• Remove shipping brace that may be

securing case to skid.

• Support case to prevent tipping.

• Caution! Rails can be damaged if case hits

floor with heavy force!

• Carefully slide unit to

rear of skid and tip

backward off skid.

• Illustration may not

reflect every feature

or option of your

particular case.

Slide Skid Out

Case can be repositioned with pallet truck when

front lower panel is removed. Blocking may be

necessary to obtain adequate height.

2. Remove Case From Skid (Casters)

Remove shipping brackets that may be securing

casters to skid

• Place ramp up against skid (to allow case to

smoothly slide off from skid).

• Maintain support of case at all times or center

of gravity may cause case to fall.

• Unlock Casters. Roll unit to rear of skid.

Roll down ramp

and off from skid.

Note: Illustrations

shown reflect a

general outline of

sample cases and do

not reflect features or

options of your

particular model.

Ramp

Support

while

rolling

case

down

ramp.

3. Removing Vertical Lower Front Panel (and Rear Panel)

• No screw removal is required to remove lower front/rear panel.

• Simply lift panel slots up and off case hooks.

• Replace in same manner it was removed.

• Note: Illustrations below may not exactly reflect every feature or option of your particular case.

Enlarged View of Hook/Magnet

For Retaining Front Panel

Front Panel Shown

Removed and Reversed

5

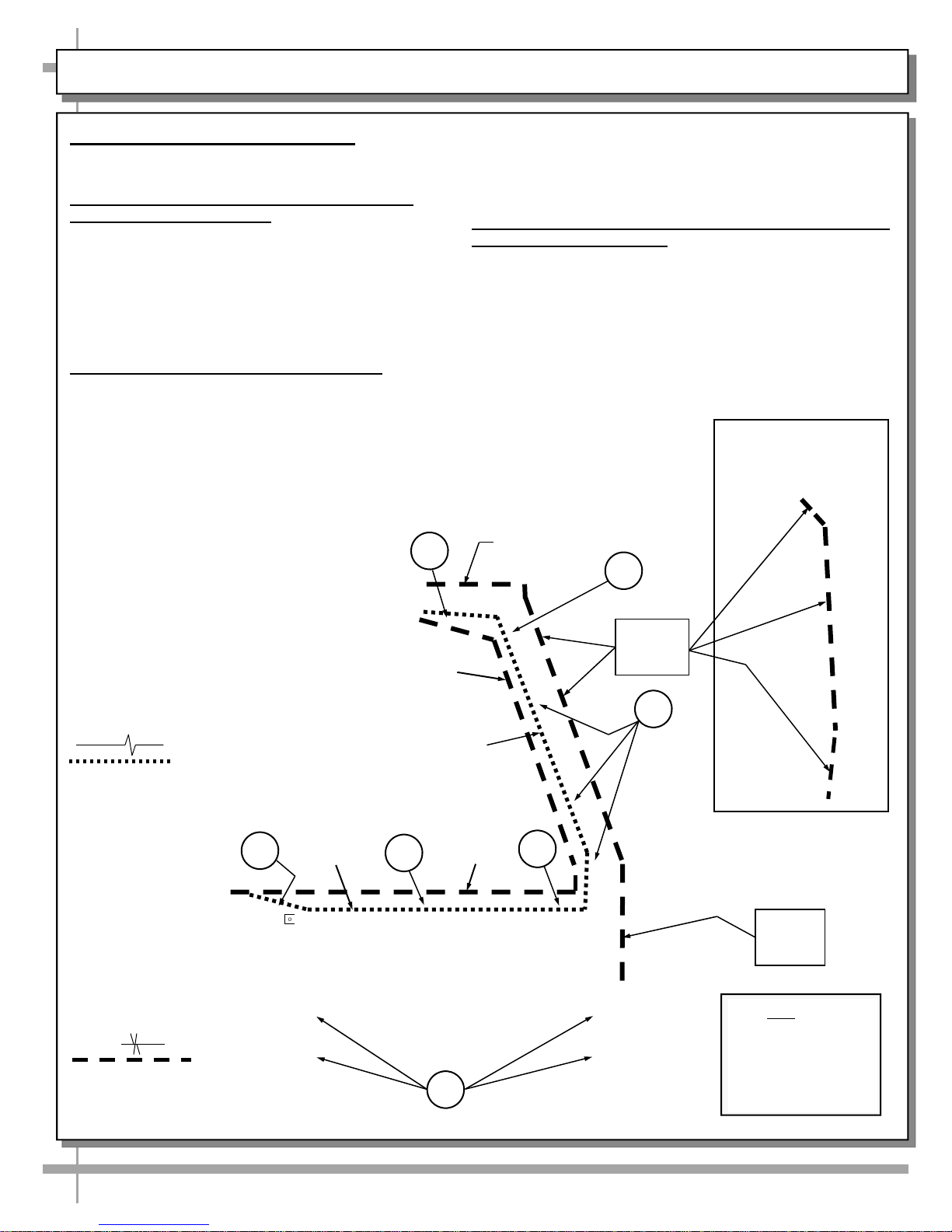

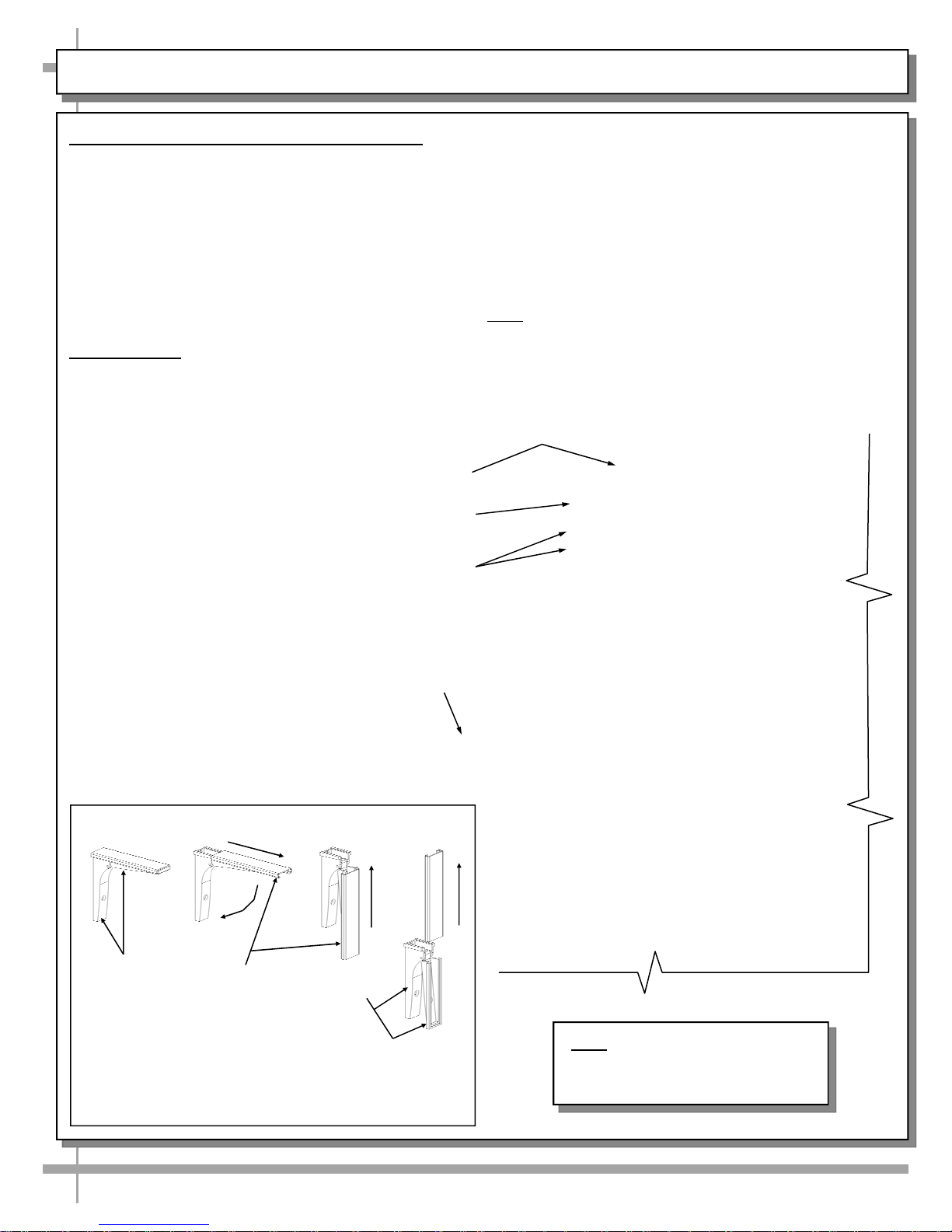

INSTALLATION, CONT’D: CASE ADJOINMENT INSTRUCTIONS

4. Case Adjoinment Instructions

>> Warranty is void if improper caulk/sealant is used.

>> Lay generous beads of caulk/sealant as specified.

A. Prior To Adjoinment - Apply Industrial Butyl

Caulk at Center of Uprights

• Lay a generous bead of industrial grade butyl caulk

at center of uprights (in non-visible areas).

• This butyl caulk prevents refrigerated air from

#4 - Holes are accessible at base frame (through front of

case after front toe-kick has been removed).

• Tighten nuts securely (but do not over-tighten).

• See illustration below.

C. After Adjoinment - Apply Food Grade Silicone Sealant

To Inner And Outer Seams

• After all nuts/bolts are securely attached to case, apply a

escaping between cases (causing condensation and

reducing refrigeration efficiency) as well as

preventing ants or other insects from entering case.

• See illustration below.

• When properly applied, this food grade silicone sealant

B. Adjoining Cases - Using Bolts and Nuts

• Use appropriately sized nuts and bolts for each hole.

#1 - Hole is accessible through rear sliding door

• See illustrations below.

>> You must reattach toe-kick and decking after case

(if you are able to avoid gas cylinder, attach bolt);

otherwise start at #2 in bolt/nut attachment process.

#2 - Holes are accessible through rear sliding door.

#3 - Holes are accessible at underside of decking.

Decking must be removed to attach bolts/nuts.

1

generous bead of food grade silicone sealant at both

inner and outer seams.

will prevent water from seeping between cases (into the

case or to the floor) as well as crumbs or other residue

from entering between case seams.

adjoinment process is

complete.

Outer

Sanitation Bead

2

Industrial Grade

Butyl Calk (For

Refrigeration Bead

Applications)

Food Grade Silicone

Sealant (For Sanitation

Bead Applications)

3

Inner Sanitation

Refrigeration

Bead

Bead

Refrigeration

Bead

Sanitation

3

4

Inner

Bead

3

Outer

Sanitation

Beads

2

Outer Sanitation Bead

To Be Applied At Rear

Adjoinment Seams

(Shown Above)

Outer

Sanitation

Bead

Note: Model

GMDSV8R.7306 Is

Shown at Left. Decking

And Front Toe-Kick

Have Been Removed

For Illustrated

Purposes Only.

6

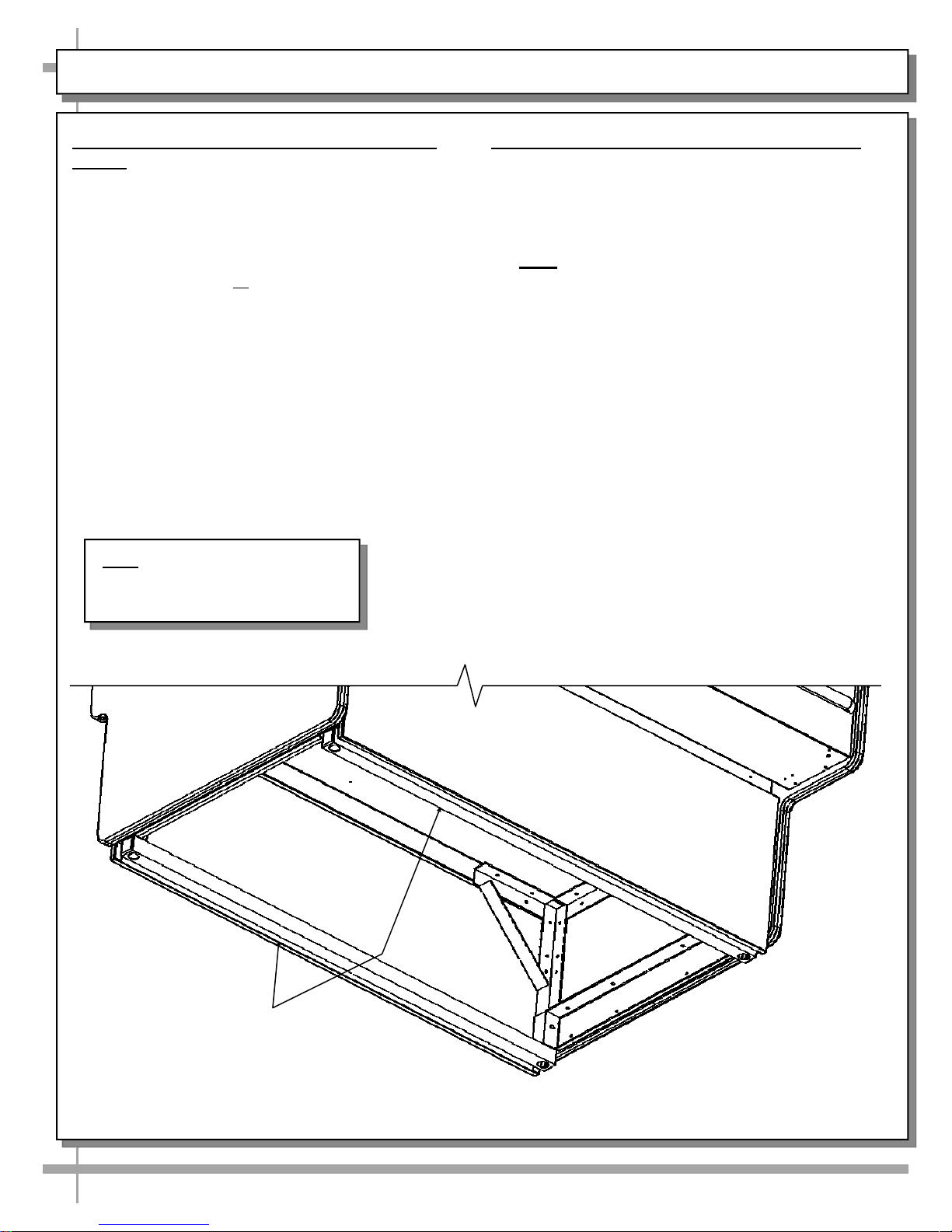

INSTALLATION, CONT’D: FRAME SUPPORT RAIL SHIMMING

5. Position & Align Case Alongside Other

Cases

• Before adjusting levelers (or shimming frame

support rails), make certain that the case is in

proper position and, if required, aligned with

adjoining case.

• This may require the repositioning of the case

you are installing or the already positioned case.

• Though case below shows both end panels,

case adjoinments routinely consist of end panel

removal for case-to-case placement.

Note: Illustration shown may not

exactly reflect every feature or

option of your particular unit.

6. Frame Support Rails Must Be Shimmed

• Illustration below shows case with frame

support rails.

• Shims will be provided with all cases that have

frame support rails.

• Use shims to level case.

• Note: After case is in position, it must be

sealed to floor to prevent entry or leakage

of liquid or moisture.

Frame Support

Rails

7

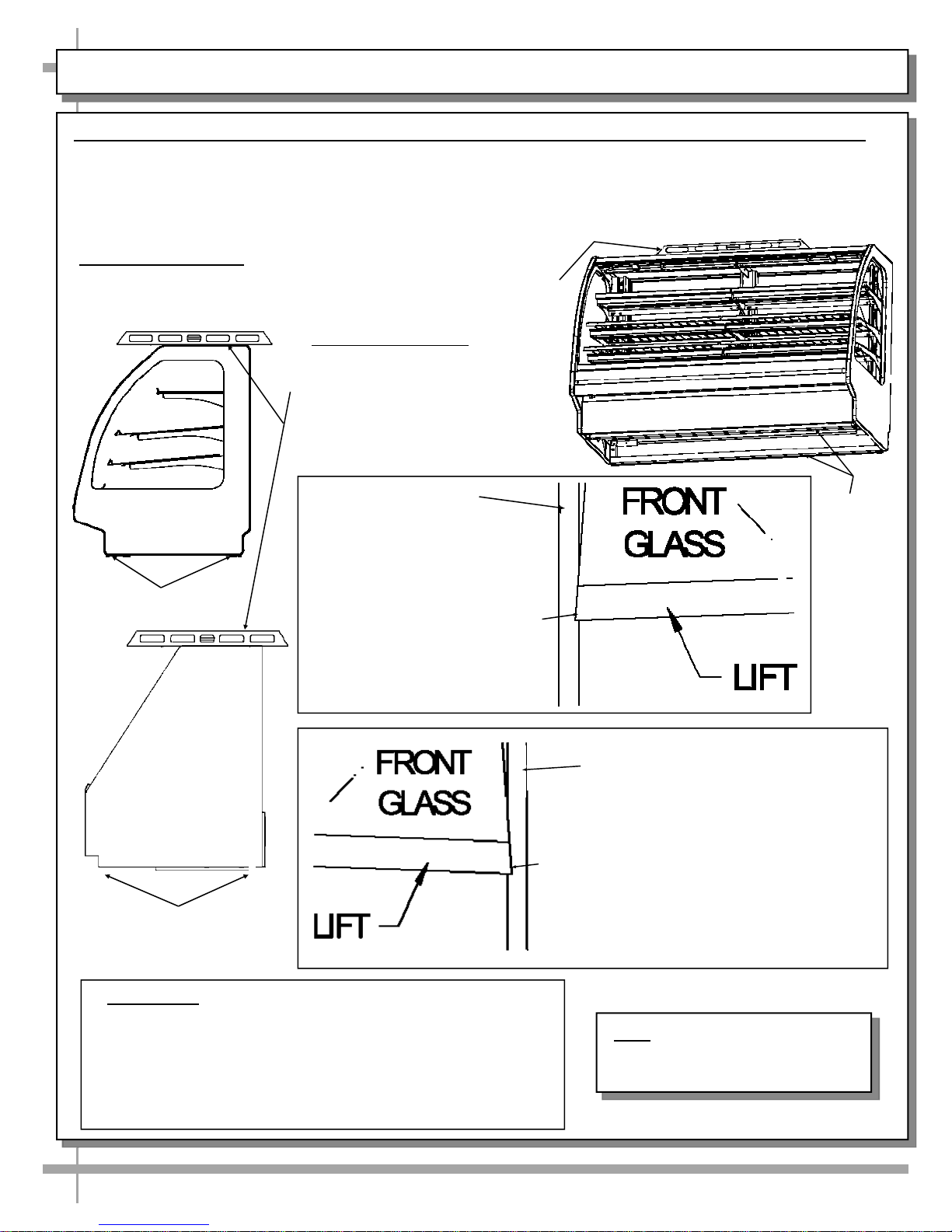

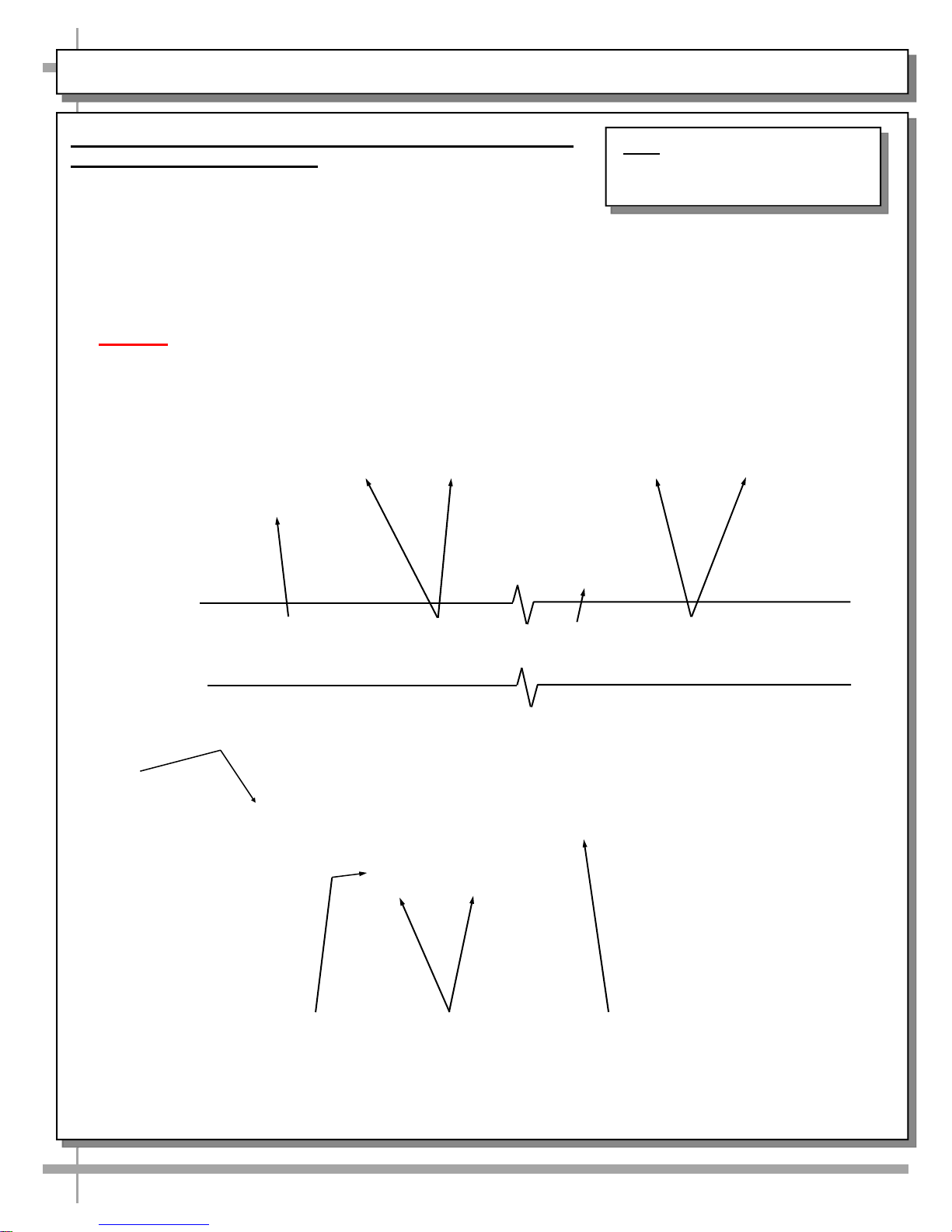

INSTALLATION, CONT’D: FRONT GLASS ALIGNMENT & ADJUSTMENT (VIA RAIL SYSTEM)

7. Front Glass Alignment & Adjustment via Rail System (For Curved and Flat Front Glass)

• Proper alignment of the front glass is important to create and maintain a seal inside the case.

• Improper alignment can cause air leaks compromising the environment inside the case and create condensation.

• Follow the five steps listed below to assure proper front glass alignment.

• Illustrations shown may not exactly reflect every feature or option of your particular case.

1. Side-to-Side Leveling: Place a level on top of display case (parallel

to front glass). Raise or lower either side of case by inserting shims

under the rails to level the case (following steps 3 and 4 below).

2. Front-to-Back Leveling:

• Place a level on top of case,

perpendicular to the front glass.

• Raise or lower either side of case

by shimming under the rails

(following steps 3 & 4 below).

• Double-check the side-to-side level.

Case with Curved

Front Glass

Rails

Case with Flat

Front Glass

Rails

END PANEL

Rails

3. If FRONT-LEFT CORNER is

too close to end panel (or

hitting it), insert shims at the

BACK LEFT CORNER of case.

END PANEL

4. If FRONT-RIGHT CORNER is too close

to end panel (or hitting it), insert shims at

the BACK RIGHT CORNER of case.

5. Verification:

• After inserting shims, open and shut the front glass.

• Verify (again) that the front glass is properly aligned at

both left-hand and right-hand side of the case.

• If not, repeat the shimming procedure until the front

glass is properly aligned along both sides of the case.

Note: Illustration shown may not

exactly reflect every feature or

option of your particular unit.

8

INSTALLATION, CONT’D: FIELD WIRING BOX / RACEWAY / LED DRIVER / ANTI-CONDENSATE FANS

8. Field Wiring Box / LED Driver / Raceway / LED Driver /

Anti-Condensate Axial Fans

• Probe leads are in probe leads box (on certain models).

Note: Illustration shown may not

exactly reflect every feature or

option of your particular unit.

It is located at customer front-left of case (behind front panel).

• Field wiring box is also located at case front)

• LED driver and terminal strip is also located behind front electrical cover (shown removed for illustrative

purposes).

• Screws hold front electrical cover in place. Unscrew and drop electrical cover down and out.

• Anti-condensate axial fans (for front glass) may be accessed (at underside of front panel) by simply

removing four screws, and dropping fans down.

• Caution! Only certified electricians are to access electrical components!

Light

Ballast

Electrical

Raceway (Typ.)

Terminal

Strip

Anti-Condensate

Axial Fans (Typ.)

Field Wiring Box / LED

Driver (Optional,

Dependent Upon Lighting)

Thermostat

Anti-Condensate

Axial Fans (Typ.)

Thermostat

--- View of Model GMDSV6R.7115C With Front Panel Remove / Electrical Box Cover Transparent ---

9

INSTALLATION, CONT’D: REFRIGERATION LINES / STUB-UPS / DRAINS

9. Refrigration Line Stub-Up Connections

• Refrigerant stub-up access is at underside of

case.

• Stub-up connections are accessed by removing

rear panel (no screws required).

• Run case-to-case connections through cutouts in

base.

• Sweat the high and low pressure connections.

• Fill access hole with suitable filler to insure

watertight integrity of tub.

• Note: Illustration below may not reflect every

feature or option of your particular case.

Note: Model GMDSV6R.7115C (model

shown) may not reflect every feature or

option of your particular unit.

10. Drains

• Cases have drains at left and right hand sides.

• Longer cases may have drain at case center.

• Drain field connection location as shown.

• See next page for illustration of TXV Valve,

Drains, Refrigeration Line Stub-Ups Access, etc.

• Depending upon drain access needs, either front

or rear panel may be removed to gain access to

drain stub-up.

• 1.5” male PVC stub-up connection is under case.

• Drain stub-up may be at case center in extended

length cases.

• Connect tub drain to floor drain. Maintain

1/4” fall per foot to provide proper drainage.

Field Connection

P-Trap

for Drain

Refrigeration Line

Stub-Ups Access

10

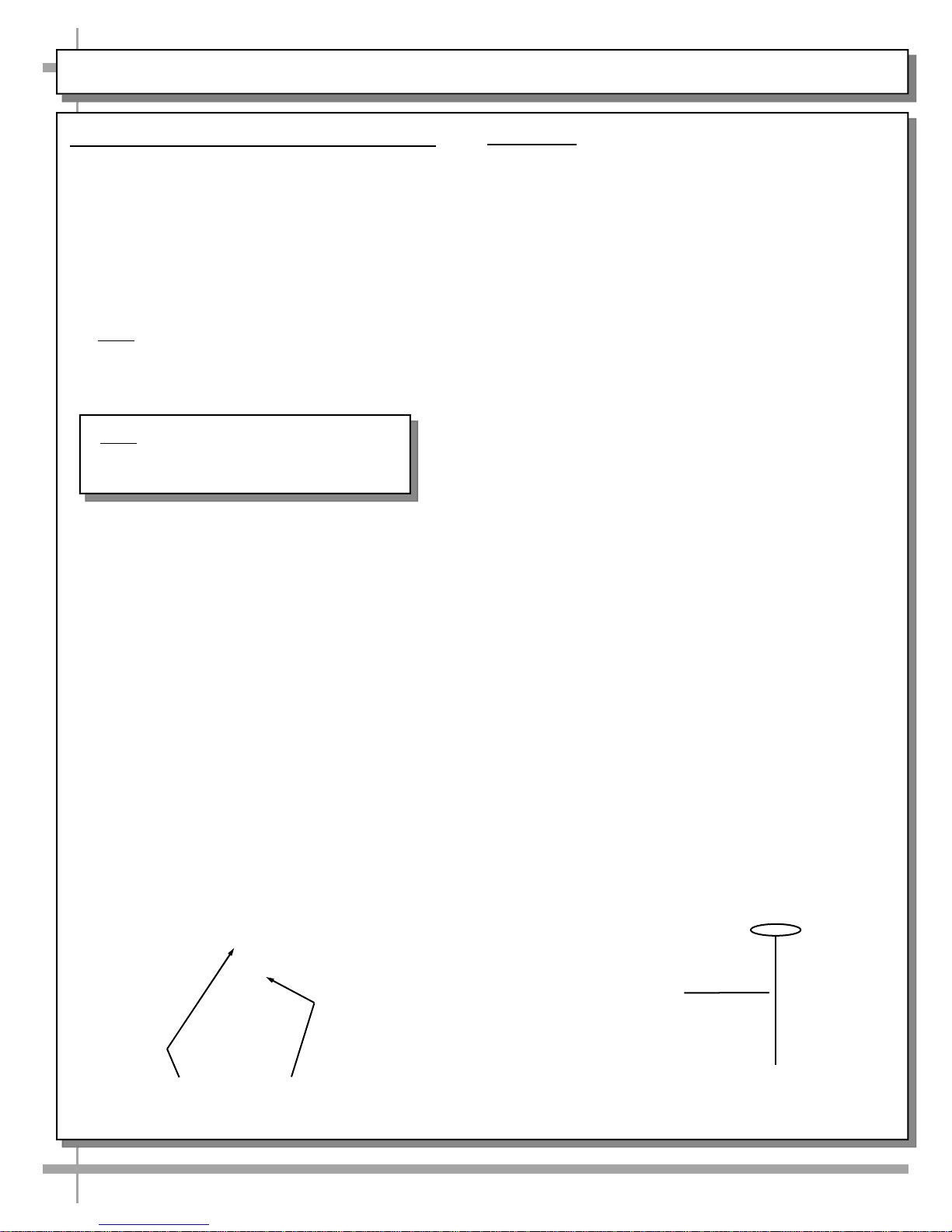

INSTALLATION, CONT’D: SCALE STAND WITH OUTLETS & CAT5 / FLIP-UP LEDGE

1. Scale Stand / Ethernet CAT5 / Receptacle

• Optional scale stand location and illustration is

shown below.

• Route the scale stand cord through into

receptacle (shown below).

• Plug scale stand cord into receptacle as shown

in illustration below.

• Depending upon options chosen, CAT5

(Category 5) network cable outlet may also be

available at scale stand base (as shown below).

2. Rear Ledge

Rear Ledge is connected to Shelf Track. See below

for Rear Ledge removal steps.

Scale Stand

Ethernet CAT5

110V Electrical Outlets

Rear ledge step-by-step removal method is as follows:

1. Hinged Support Bracket is shown in its standard

upright position.

2 & 3. While upright, Rear Ledge must be

slid away from case and then rotated downward to

vertical position.

3 & 4. From the shelf’s lowered position, lift from

bottom edge upward to disengage shelf track (and

attached Rear Ledge) from bracket.

Note: Illustrations shown may not exactly reflect every

feature or option of your particular case.

-1- -2- -3-

Hinged

Support

Bracket

—— Optional Rear Ledge Removal Steps ——

Note: For clarity, only Shelf Track is shown being

removed. Rear Ledge is attached to Shelf Track.

Shelf

Track

Hinged

Support

Bracket

Sanalite Flip-Down

Ledge

-4-

Note: Illustration shown may not

exactly reflect every feature or

option of your particular unit.

11

Loading...

Loading...