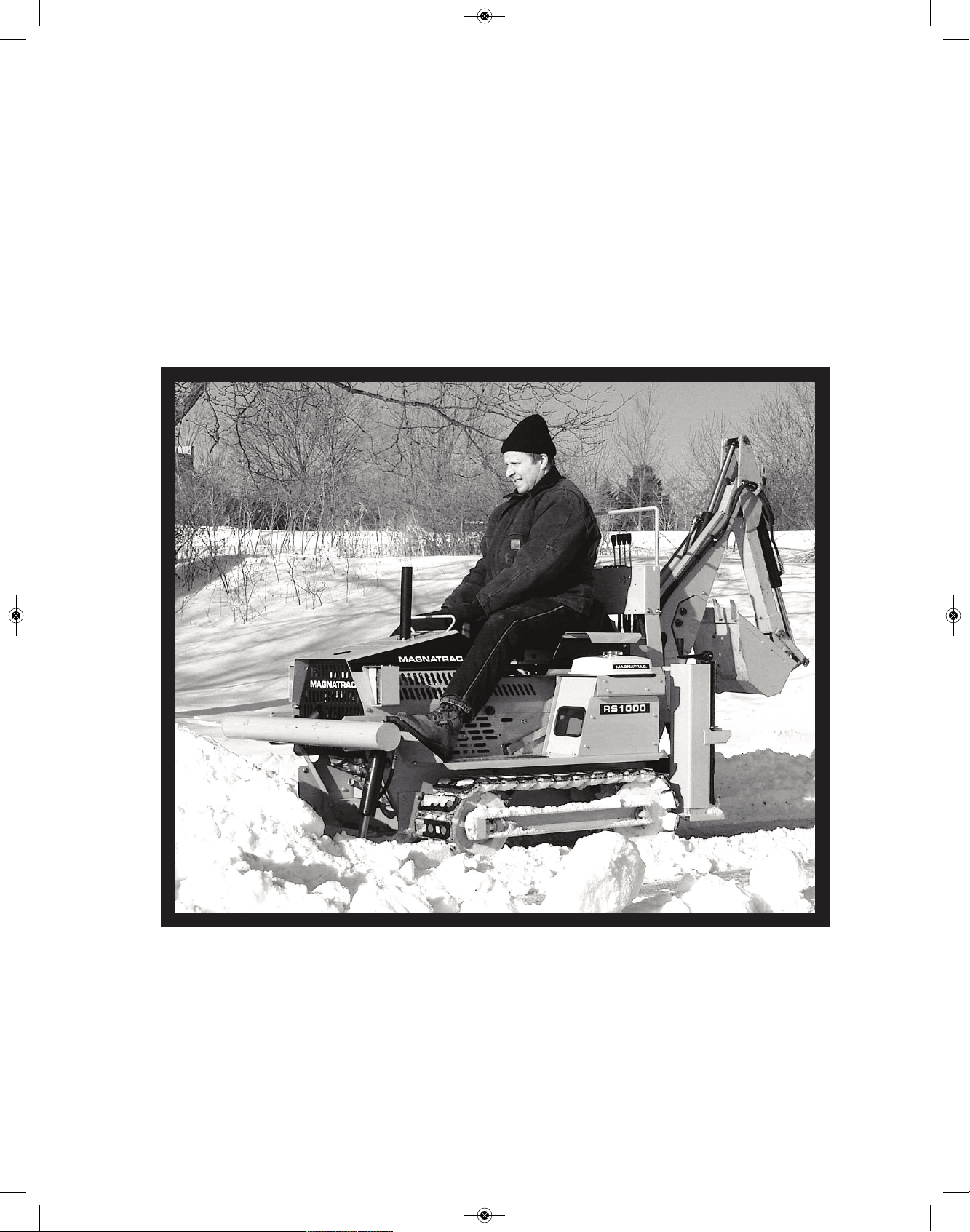

MAGNATRAC

®

RS1000

Operator / Technical Manual

Version 1.01.19

Struck Corp. - Cedarburg, WI 53012

Copyright 2019 C. F. Struck Corp. All rights reserved.

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 1

Very Important Facts

& Tips for

Top Performance

The following are random facts that will be expanded on within this Manual. They are brought

to you “first” to impress upon you their primary importance in preventing damage to your RS1000

and also to protect your safety and prevent costly

and unnecessary maintenance expenses.

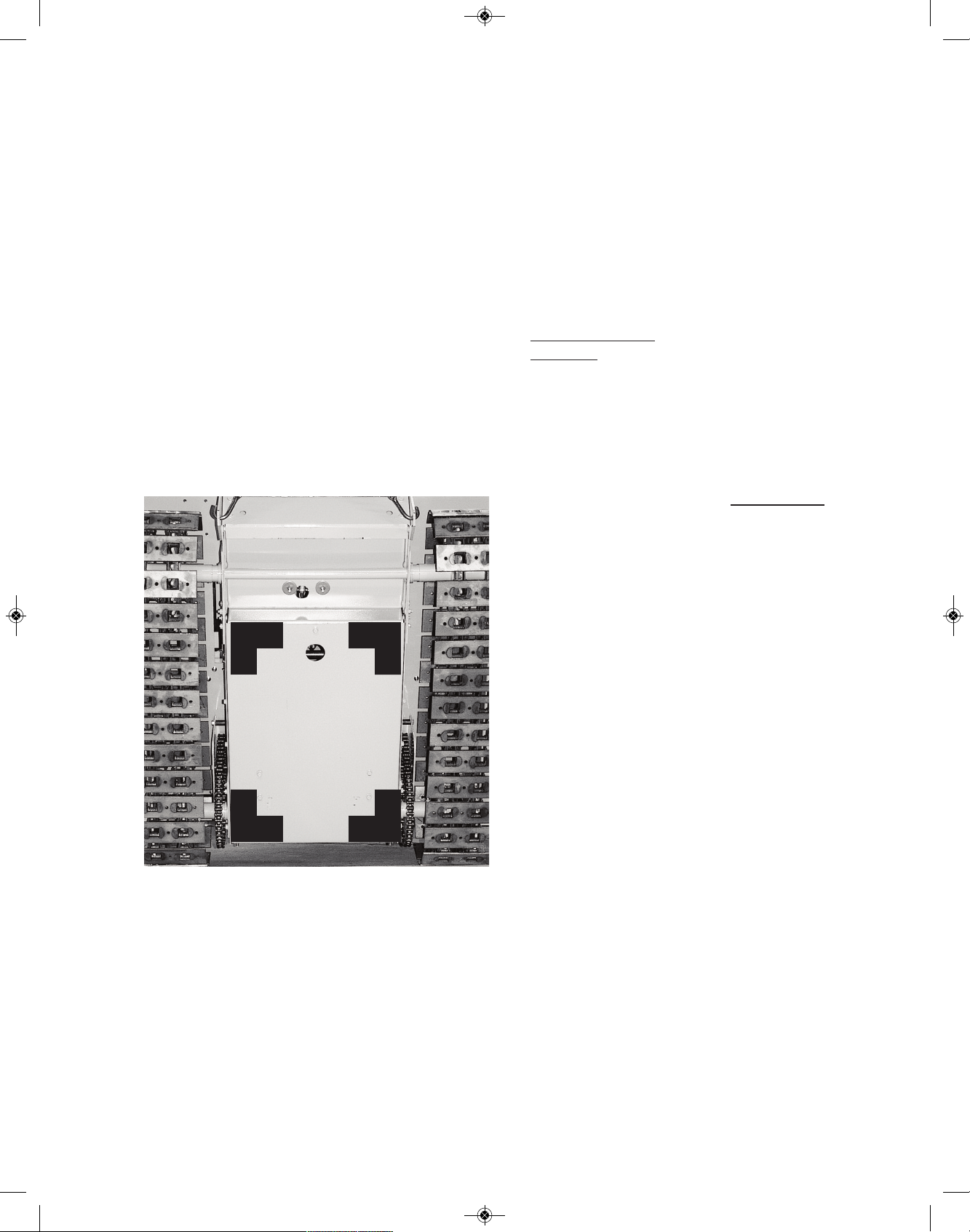

SAFE BLOCKING AREA

When “blocking” your Crawler off the ground for

service, be aware that you should only apply a

hydraulic jack, in the black shaded area

marked below.

ENGINE TORQUE

The greatest amount of power (drawbar torque)

your RS1000 can deliver is near the Engine’s midspeed range. This is marked on your dash area.

To go faster, your Engine’s “drawbar torque” will

be diminished by having to go faster.

Doing all your heavy work at mid-speed does

three things:

1. It keeps the Engine cooler working at a

slower speed.

2

. It gives you maximum drawbar torque.

3. It provides time to make “attachment adjustments” on the go!

You’re encouraged to completely read this Manu

al to get a firm over-view of: how your RS100 operates, significant safety points, and also

maintenance tips on how to increase your MAGNATRAC’S life.

PARKING BRAKE

NEVER FORGET to take off your Parking Brake...

BEFORE you drive away. If you fail to disengage

the Parking Brake, it will wear very rapidly and be

of no value in an emergency!

LUBRICATION OF POWER SHAFT

ENDS

Read and understand the “Special Note” in the

“Belt Installation” section of this manual. By following it ‘s simple lubrication instructions your can

save yourself a lot of work, and potential expense

in the future and make Belt changing much easier.

CLUTCH BELTS

The use of rugged, though uncomplicated Belt

Clutches, gives the RS1000 amazing performance

while at the same time keeps its initial purchase

price and later maintenance costs within the

homeowner’s budget.

The life expectancy of these Clutch Belts is the direct result of the type of work being done and the

operator’s driving technique. It is strongly recommended at this time that you thoroughly read the

Track Clutch Belt Removal & Installation chapter

in the Service Section of this Manual to give you

an over-view of the mechanics of your drive system.

In factory tests of different driving techniques, it

has been found that Belt life will range from 25 to

200 hours. This testing proved that the operator

is the greatest variable in determining Belt life.

From these tests, the following driving rules have

evolved. If followed, they will give you the best

Belt life consistent with the severity of work you

are doing.

2

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 2

1

. Do not “ride” your Clutch Controls ...rather op-

erate them smoothly and engage your belts fully.

If your Crawler can not push a particular load you

have two options: immediately reduce the load

(raise the Bucket or Blade) or backup and take a

n

ew angle at the load...never hold your track

controls in a fixed position (forward or rearward)

against an immovable object, you will unneces-

sarily wear the Belts.

2. Your RS1000 has outstanding pushing ability,

but its up to you, the operator, to use its ability in

the most efficient and economical manner.

3. When you want to go slowly for a sustained period, reduce your engine speed...do not “slip” your

Belt Clutches for long periods of time! Your Belt

Clutches are no different than the disk clutch

found in a large truck...if you constantly slip the

Clutch under heavy loads you will burn the clutch

faces and decrease clutch life. It’s no different

with your Belt Clutches.

4. Reserve horsepower has been designed into

your Crawler. This means you can reach the maximum torque necessary to fully drive your RS1000

with your engine operating at only about halfspeed.

TRACKS

The track system of your Magnatrac is the result of

over 50 years of experience.

It is not uncommon in the inital operating hours for

the steel track system to make popping noises

as the intial “wear in” occurs.

The steel track system is of an “unguided” design,

but is extremely stable due to its double track

chain design. A few rules are listed below that if

followed will give you maximum Track performance.

1. Avoid overloading your track system with the

material you are working in. Always work in loose

materials by clearing a “driving path” with the attachment (Blade, Bucket, etc.) you are using. This

technique will allow a minimum amount of material

to enter the track system.

2. Avoid climbing on a pile of loose material and

counter-rotating your tracks. This action will “corkscrew” the Tracks into the pile and force unnec-

e

ssarily large amounts of material into the Tracks.

The steel or rubber track system is designed to

absorb a great deal of material, but the less you

force it to “digest”, the greater will be the Track’s

stability and overall life.

3. Periodically, following the Steel or Rubber Track

Tensioning instructions in your Operator’s/Technical Manual, check your Track tension by checking

the length of the #1806 Spring.

4. Though this Spring adjustment is not a precise

type of adjustment, it must be realized that to overtension the Spring will cause a higher level of wear

in your track bearings, while under-tensioning will

cause potential derailing of your Track.

As always, the Struck Corporation through the

customer service department, stands ready to

help you with any technical or work related questions you may have either now or in the future!

Call (262) 377-3300 or Fax (262) 377- 9247.

3

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 3

LIMITED WARRANTY

NEW STRUCK CRAWLERS and/or ATTACHMENTS

(Effective with shipments made after August 1st, 2017)

A. GENERAL PROVISIONS

C.F. Struck Corp. will repair or replace, at its option, for the original purchaser of a new Struck Crawler and/or Attachment, any covered part or parts found upon examination at our factory in Cedarburg, Wisconsin, to be defective in material or workmanship or both; this is the exclusive remedy. Warranty service must be performed by the C. F. Struck Corp. at

their factory in Cedarburg, Wisconsin 53012. Warranty service will be performed without charge for parts or labor. The

purchaser will be responsible, however, for transportation charges to and from the factory.

B

. WHAT IS WARRANTED

A

ll parts of any new Struck Crawler and/or Attachment are warranted for two (2) years, with the following exceptions: Belts,

which are warranted for 90 days (excludes normal wear and tear); Engines, which are warranted by their manufacturer;

and Batteries, which are provided on a complimentary basis and carry no warranty whatsoever. C. F. Struck Corp. reserves the right to make product design and specification changes without notice and without obligation on their part to

present product owners. The Warranty term begins on the date the product is shipped to the purchaser.

C. WHAT IS NOT WARRANTED

(1) Used Products; (2) Any product that has been altered or modified in ways not approved by C. F. Struck Corp.; (3) Depreciation or damage caused by normal wear, lack of reasonable and proper maintenance, failure to follow the product’s

Operator’s/Technical Manual instructions, failure to upgrade crawler with parts furnished at no charge, misuse, lack of

proper protection during storage, or accident (4) Normal maintenance parts and service; (5) Use of Struck Crawler and/or

Attachments in certain industrial-type applications may affect Warranty coverage.

D. RETURNS AND REFUNDS

In the event of defective materials or workmanship the purchaser agrees to allow C.F. Struck Corp the opportunity to correct the defect in a timely manner at the expense of C.F. Struck Corp. It is at the discretion of C.F. Struck Corp to either

correct the defect or refund the purchaser.

To return a Struck Crawler and/or attachment for reasons other than defect the purchaser will be financially responsible

for an 8% restocking fee, and for shipping the Struck Crawler and/or Attachment to the C.F Struck Corp. factory in Cedarburg, Wisconsin 53012. No Returns after 90 days.

E. SECURING WARRANTY SERVICE

To secure Warranty service, the purchaser must:

(1) Report the product defect to the factory in Cedarburg, Wisconsin 1-262-377-3300 or 1-877-828-8323.

(2) Make the part available to the factory in a reasonable period of time.

F. LIMITATION OF IMPLIED WARRANTIES AND OTHER REMEDIES

To the extent permitted by law, neither C. F. Struck Corp. nor any company affiliated with it makes any Warranties, representations or promises as to the quality, performance or freedom from defect of the products covered by this Warranty.

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, TO THE EXTENT APPLICABLE, SHALL BE LIMITED IN DURATION TO THE APPLICABLE PERIOD OF WARRANTY SET FORTH ON THIS PAGE. THE

PURCHASER’S ONLY REMEDIES IN CONNECTION WITH BREACH OR PERFORMANCE OF ANY WARRANTY ON C. F.

STRUCK CORP. PRODUCTS ARE THOSE SET FORTH ON THIS PAGE. IN NO EVENT WILL C. F. STRUCK CORP. OR ANY

COMPANY AFFILIATED WITH IT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

(Note: Some states do not allow limitations on how long an implied Warranty lasts or the exclusion or limitation of incidental

or consequential damages so the above limitations and exclusions may not apply to you.) This Warranty gives you specific

legal rights, and you may also have other rights which vary from state to state.

G. ASSEMBLY RESPONSIBILITY

Though the MAGNATRAC RS1000, MH4900 and MH8500 are offered completely assembled, it’s still the customer’s re-

sponsibility to provide competent service ability! The servicing can be provided either by the mechanically customer, or by a

local mechanic. All Attachments and accessories are shipped in easy-to-assemble “semi-kit” form for lowest cost shipping. We

provide Manuals and Illustrations for complete service and repair so that anyone with reasonable mechanical skill can preform

all required service work. Check the MAGNATRAC Specifications & Ratings (in Spec Book or Buyer’s Guide) for a list of all

standard features.

I hereby accept the terms and conditions of Warranty described above:

RS1000

MH4900

MH8500

Warranty 9.18

signature

print name

date

4

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 4

TABLE OF CONTENTS

VERY IMPORTANT FACTS & TIPS FOR PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1- TO THE OPERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Recognize Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Understand Signal Words . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Follow Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Service Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2- SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Safety Before Starting or Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Service Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Fire Prevention Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Protection From Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Start Engine From Operator Seat Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3- CONTROLS AND INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Left & Right Clutch Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Dashboard Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4- OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Pre-Starting Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Prepare For Engine Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Warm-up Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Traveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Parking & Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5- FUELS AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

6- LUBRICATION AND PERIODIC SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Lubrication and Service Intervals & Periodic Servce Chart . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7- SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Engine & Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Safety Interlock Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Seat & Rear Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Rear Drive Chain Tensioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Parking/Emergency Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Track Clutch Belts (Removal & Install) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Engine Drive Chain (If equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Eninge Drive Micro V-Belt (If equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Steel Track Removal (If equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Steel Track Tensioning (If equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Rubber Track Removal (If equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Rubber Track Tensioning (If equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

8- TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

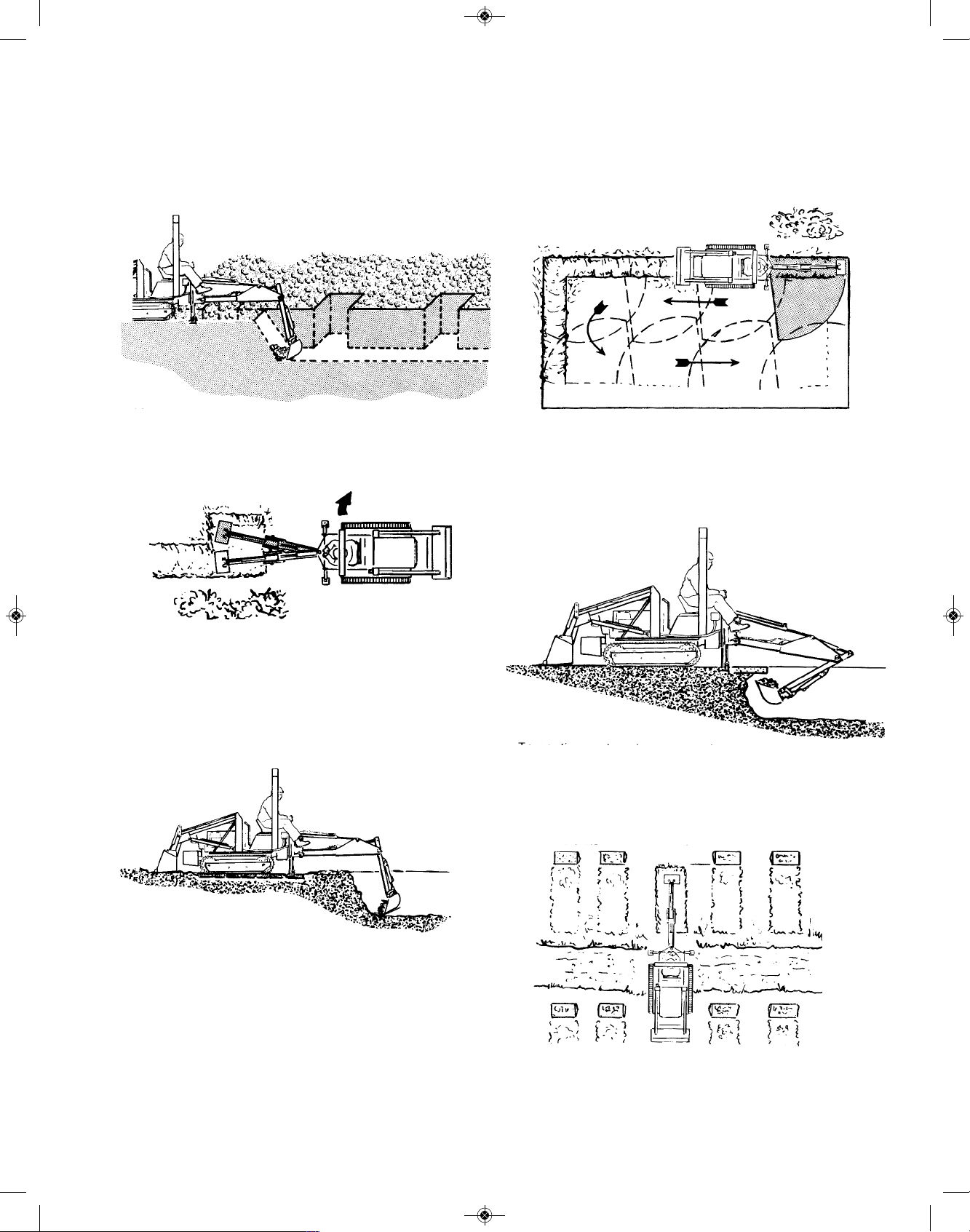

9- SAFETY & WORK PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Loader Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Bulldozing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Backhoe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Misc. (Snowplowing, logging, etc.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

10- PARTS LISTING & DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Index of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

IMPORTANT: Though the MAGNATRAC is offered completely assembled, it’s still the customer’s responsibility

to provide competent service ability! The servicing can be provided either by the mechanically-inclined customer, or by a local mechanic. We provide manuals & drawings for complete service and repair so that anyone

with reasonable mechanical skill can perform all required service work.

5

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 5

Congratulations…

on your purchase of a quality-built, American

made compact Crawler. We are confident that the

d

ependability and economical performance of

your Magnatrac will prove that you made a wise

choice.

The purpose of this Manual is to acquaint you with

the RS1000 Magnatrac Crawler. This Manual explains how to operate and service your Crawler,

and how to maintain its high operating efficiency.

Instructions are given clearly, with the intention of

making these operations as easy as possible.

Keep this Manual in a convenient place for quick

and easy reference. Use it as a guide whenever

questions arise. You have purchased a dependable, sturdy Crawler, but only by operating and

caring for it properly can you expect to receive the

service and long life for which it was designed.

If in the future you need new parts to replace

those that may be worn, insist on genuine Struck

parts. They are exact duplicates of the originals,

made from the same patterns and of the same

high-quality materials.

When ordering parts, always be sure to give the

following information for your Crawler:

MAGNATRAC Records

MAGNATRAC Model: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

MAGNATRAC Serial # _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Engine Model: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Engine Serial # _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Ship Date: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Mail: STRUCK CORPORATION

W51N545 STRUCK LANE

CEDARBURG, WI 53012

Phone*: (262) 377-3300 local

(877) 828-8323 toll-free

Fax: (262) 377-9247

email: techsupport@struckcorp.com

Web: www.struckcorp.com

*

For immediate service always call the factory

and ask for a technician.

1- TO THE OPERATOR

RECOGNIZE

SAFETY

INFORMATION

This is the safety-alert symbol. When

you see this symbol on your Crawler or

in this Manual, be alert to the potential

for personal injury.

UNDERSTAND SIGNAL WORDS

A signal word — DANGER, WARNING, or CAUTION — is used with the safety-alert symbol.

DANGER identifies the most serious hazards.

Safety labels with the signal word DANGER or

WARNING are typically near specific hazards.

General precautions are listed on CAUTION

safety labels. CAUTION also calls attention to

safety messages in this Manual.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this Manual

and on your Crawler and Attachment safety labels.

Follow recommended precautions and safe operating practices.

Keep safety labels in good condition. Replace

missing or damaged safety labels.

To keep your Crawler running efficiently, read the

instructions in this Manual.

Left side, right side, front, and rear are viewed by

facing in the direction of the Crawler’s forward

travel.

Record your Crawler serial numbers in the space

provided. You need this information when you

order parts.

6

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 6

Date Service Work

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Date Service Work

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

SERVICE & MAINTENANCE RECORDS

Proper service and maintenance work is critical to trouble free operation of your equipment. It is

also critical to diagnosing problems should they arise. Use the space provided on the following p

age to record maintenance and service work performed.

7

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 7

2- SAFETY RULES

Reports on accidents show that careless use of machinery causes a high

p

ercentage of accidents. You can avoid

many accidents by following the safety

rules on these pages. Study these rules carefully

and enforce them on the job

.

SAFETY BEFORE STARTING OR

OPERATION

The Crawler should be operated only by persons

approved to do so.

Clothing worn by the operator should be fairly tight

and belted.

Fasten a first aid kit to the Crawler.

Fasten a fire extinguisher to the Crawler. Keep

the extinguisher fully charged. Learn to use it correctly.

If the Crawler has an unsafe condition, do not operate. Put a tag on the Track Drive Controls.

Do not start or operate the Crawler unless you are

in the operator’s seat.

Before you start the Engine, be sure there is

plenty of ventilation.

Keep hands, feet, and clothing away from powerdriven parts.

Fasten a slow-moving vehicle sign to the rear of

the Crawler.

Guards, shields, and other protective devices

must be in place and in good condition.

Before you start or operate the Crawler, clear the

area of all persons and obstacles.

OPERATION SAFETY

When you operate the Crawler, do not allow anyone to ride on the Crawler or its equipment.

Drive at safe speeds at all times, especially on

rough ground and hillsides.

Carry the Bucket or Blade as low as possible at

all times, especially when you work on a hillside

or back up a steep hill.

D

o not drive too close to the edge of a ditch or ex-

cavation.

Watch for overhead wires. Do not touch wires

with any part of the Crawler or its Attachments.

Do not leave your Crawler unattended with the Engine running.

Keep work areas as level as possible.

When loading logs with the Log Forks, make sure

the logs are balanced.

When you drive out of a ditch or excavation, or up

a steep hillside, or when Crawler is hitched to a

heavy load, engage Track Drive Controls slowly. If

the front of the Crawler comes off the ground, release Track Controls immediately.

Do not use the Crawler as a battering ram.

Do not guide cable onto Winch Drum with your

hands.

When you drive the Crawler on a road, use the

correct lights to warn operators of other vehicles.

Before you move any equipment, be sure all persons are away from the Crawler.

When the Crawler is operating, only the operator

should be on it.

If it is necessary to make checks with the Engine

running, always use two people...the operator at

the controls should be able to see the person

doing the checking

KEEP HANDS AWAY FROM MOVING PARTS!

BEFORE YOU GET OFF THE UNIT:

Move Track Drive Controls to neutral.

Engage Parking Brake Lever.

Lower all equipment to the ground.

Move throttle to idle for 1 minute.

Stop Engine and remove the key.

8

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 8

SERVICE SAFETY

Be sure you understand a service procedure before you work on the Crawler.

U

nauthorized modifications to the Crawler may

impair the function and/or safety and affect

Crawler life.

Do not work under Crawler or raised equipment

unless it is correctly supported...contact factory for

recommended procedures.

Before you work on the Engine or electrical system, disconnect the battery’s “ground” ( - ) terminal first! When work is finished, connect battery’s

“ground” terminal ( - ) last.

When driving connecting pins (Spring Pins), wear

goggles or safety glasses.

Do not run Engine while working on the Crawler.

Be careful when handling any type of fuel. Do not

smoke while filling the fuel tank or working on the

fuel system.

Check for faulty wiring or loose connections.

Do not lubricate or work on the Crawler while it is

moving.

When you work near the Track Springs, use extreme care. Do not disassemble parts unless you

know the correct procedure and have correct

tools.

FIRE PREVENTION MAINTENANCE

Be prepared if an accident or fire should occur.

Know where the first aid kit and the fire extinguisher are located...know how to use them.

Check fire extinguisher for correct charge.

Do not smoke while refueling or handling highly

flammable material.

Shut off the Engine when refueling.

Use care in refueling if the Engine is hot.

Do not use open pans of gasoline or diesel fuel for

c

leaning parts. Use good commercial, nonflam-

mable solvents.

Provide adequate ventilation when charging battery.

Do not check battery charge by placing metal objects across the posts.

Do not allow sparks or an open flame near battery.

Do not smoke near battery.

Never check fuel, battery electrolyte, or coolant

levels with an open flame.

Never use an open flame to look for leaks anywhere on the equipment.

Never use an open flame as light anywhere on or

around the equipment.

When preparing Engine for storage, remember

that inhibitor is volatile and therefore dangerous.

Seal and tape openings after adding the inhibitor.

Keep container tightly closed when not in use.

Inspect electrical wiring for worn or frayed insulation. Install new wiring if wires are damaged.

Temperature in Engine compartment may go up

immediately after you stop the Engine. Be on

guard for fires.

Before you clean trash from the Engine compartment, wait until the Engine has cooled. Open

Hood to cool the Engine faster. While the Engine

cools, clean trash from other areas.

Check for leaking fuel lines or fittings with a piece

of cardboard or wood. Do not use your hands.

Tighten loose fittings. If hoses are kinked, install

new parts.

9

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 9

NOISE PROTECTION

Prolonged exposure to loud noise can cause impairment or loss of hearing. Wear a suitable hearing protective device such as earmuffs or earplugs

to protect against objectionable or uncomfortably

l

oud noise.

START ENGINE ONLY FROM THE

OPERATOR’S SEAT!

Avoid possible injury or death from Crawler runaway.

Do not start Engine by shorting across starter solenoid terminals. Crawler may start and move if

normal circuitry is bypassed.

CAUTION: Never start Engine while

standing on ground. Start Engine only

from operator’s seat, with Brake engaged.

Inspect your Crawler carefully each day before

you start it. See “Pre-Start Inspection”.

Clean your Crawler regularly.

10

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 10

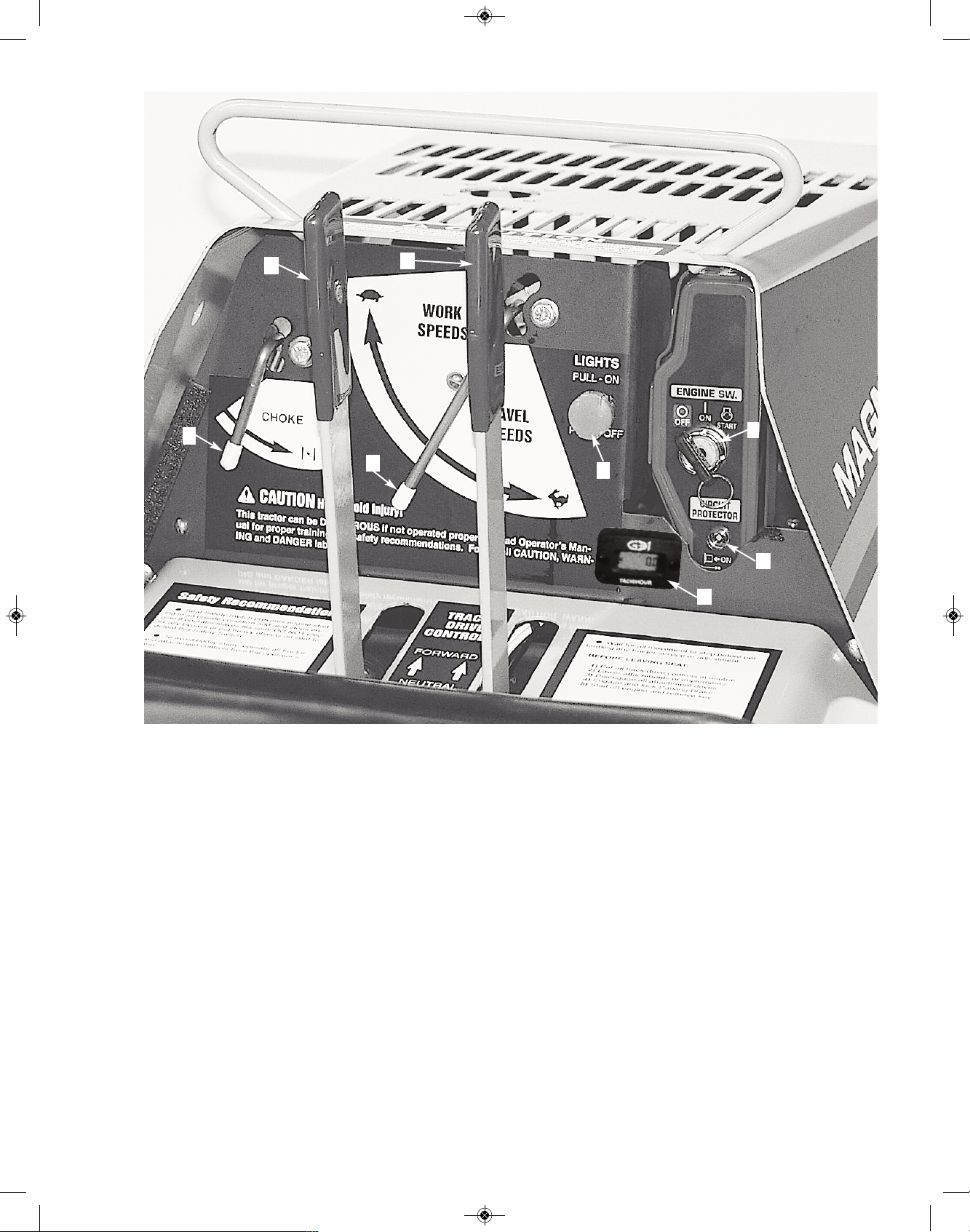

3- CONTROLS

& INSTRUMENTS

Learn the location and purpose of all Controls,

Instruments and Warning labels. Thoroughly

study the Operator’s Manual furnished by the engine manufacture and included with your Crawler

instructions.

A - LEFT TRACK

CLUTCH CONTROL

B - RIGHT TRACK

CLUTCH CONTROL

C - THROTTLE CONTROL

D - CHOKE CONTROL

E - HEADLIGHT SWITCH

F - KEY IGNITION SWITCH

G - CIRCUIT PROTECTOR

H - FUEL VALVE

I - PARKING BRAKE (not shown)

J - HOUR METER/TACH (if equipped)

11

A

B

C

D

E

F

G

J

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 11

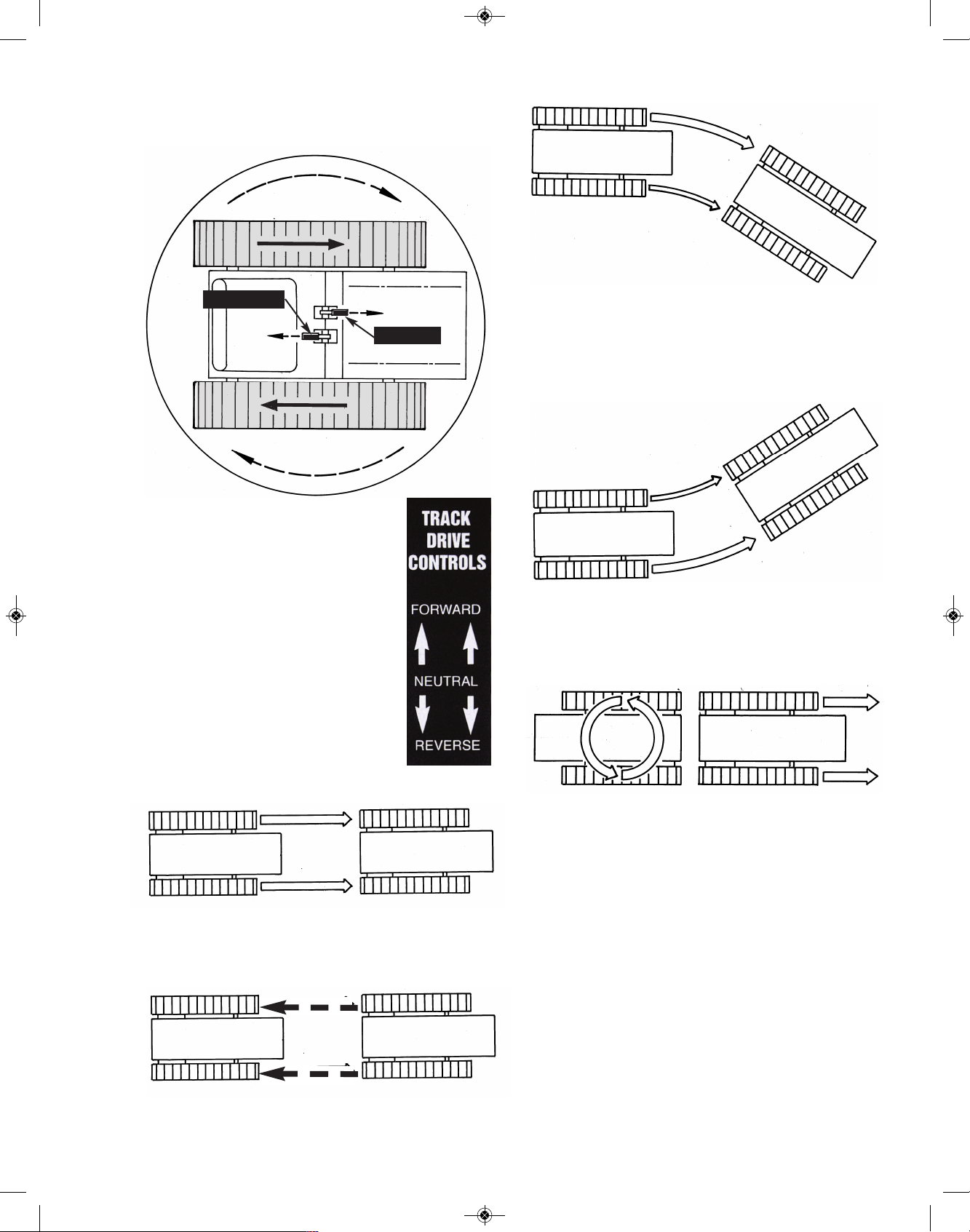

A & B - LEFT & RIGHT

TRACK CLUTCH CONTROLS

INTRODUCTION: The turn

demonstrated (above) is the key to

your Crawler’s superior maneuverability. It is accomplished with only

two controls, the A & B Left & Right

Track Controls. The illustrations

(below) show how to maneuver

your crawler in other turns.

MOVING FORWARD:

To move straight ahead, simultaneously push forward on both Left

and Right Track Controls.

MOVING REARWARD:

To move straight rearward, simultaneously pull

rearward on both Left and Right Track Controls.

T

URNING RIGHT:

To turn sharply right, push forward on Left Track

Control while holding Right Track Control in neutral.

TURNING LEFT:

To turn sharply left, push forward on Right Track

Control while holding Left Track Control in neutral.

COUNTER-ROTATING TRACKS

To counter-rotate Tracks (tightest turn possible),

push one Track Control forward while simultaneously pulling rearward on the other Track Control.

NOTE: When either Track Control is “slowly” re-

leased, it will automatically return to neutral.

NEVER allow Track Controls to “snap-back” to

neutral. See OPERATION section of this manual

for further instructions.

12

A - Left

B - Right

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 12

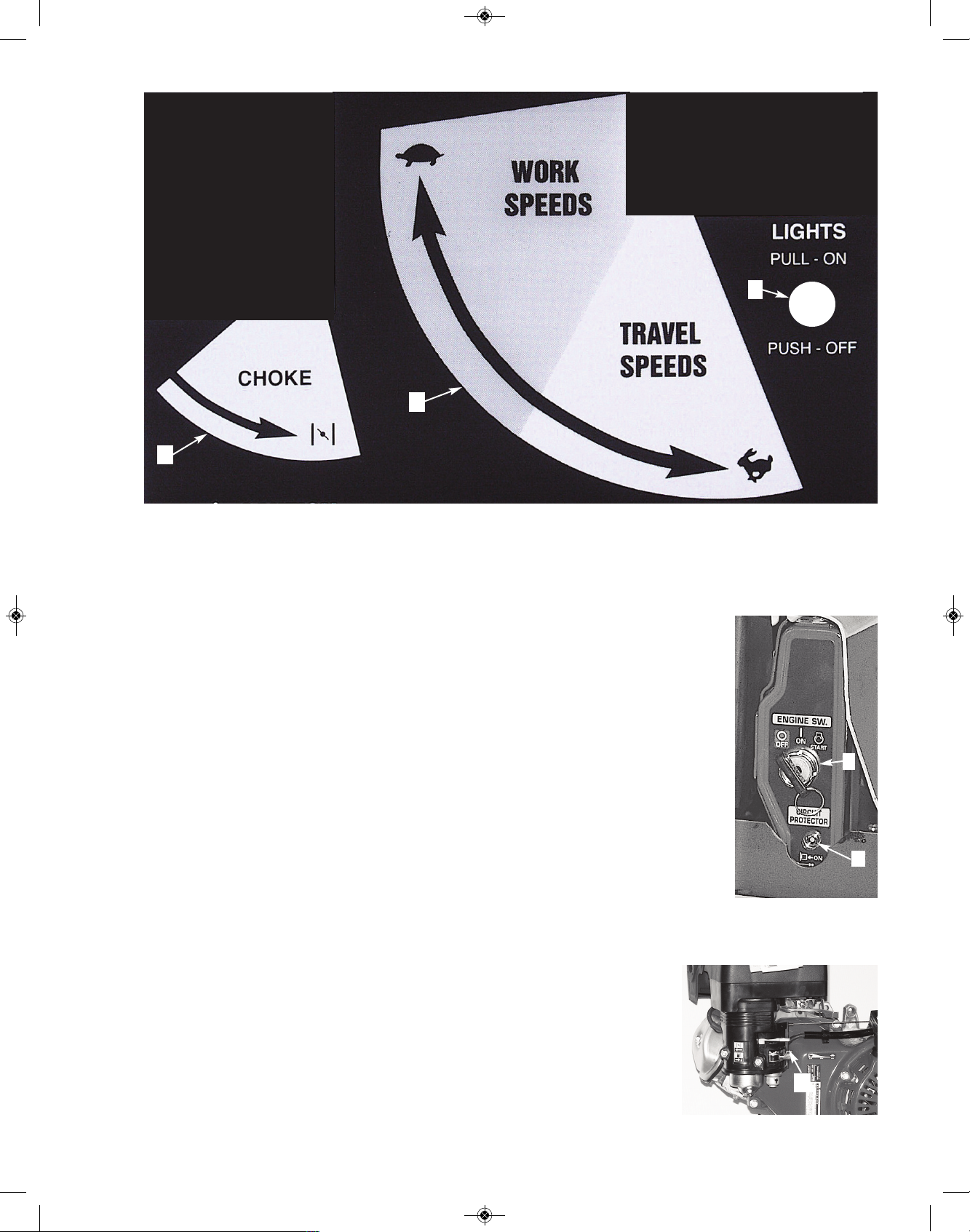

DASHBOARD CONTROLS

C - THROTTLE CONTROL

The Throttle is lever operated, rotating in a wide

arc. This arc is divided into two speed ranges; the

slower Work Speeds and the faster Travel

Speeds. Your Crawler has maximum “pushing

force” (maximum torque, according to the engine

manufacturer) at the mid-range speed but with a

declining level of torque as you increase your

travel speed. We advise using only as much throttle as needed for a particular application. If the

engine bogs down, please feel free to use more

throttle when you feel it is needed.

Though all crawlers by their design are somewhat

“rough riding”, you can minimize the “roughness”

by traveling at the lowest speeds when going over

hard surfaces.

D - CHOKE

The Choke Control is lever operated. Rotate the

lever counter-clockwise to increase engine choking; rotate clockwise to decrease engine choking.

(Consult engine manual for more information).

E - HEADLIGHT SWITCH

The Headlight Switch is a basic “Pull ON”, “Push

OFF” switch. Behind the Switch is a replaceable

Safety Fuse. When replacing, use a new fuse of

the same amps as the one being replaced.

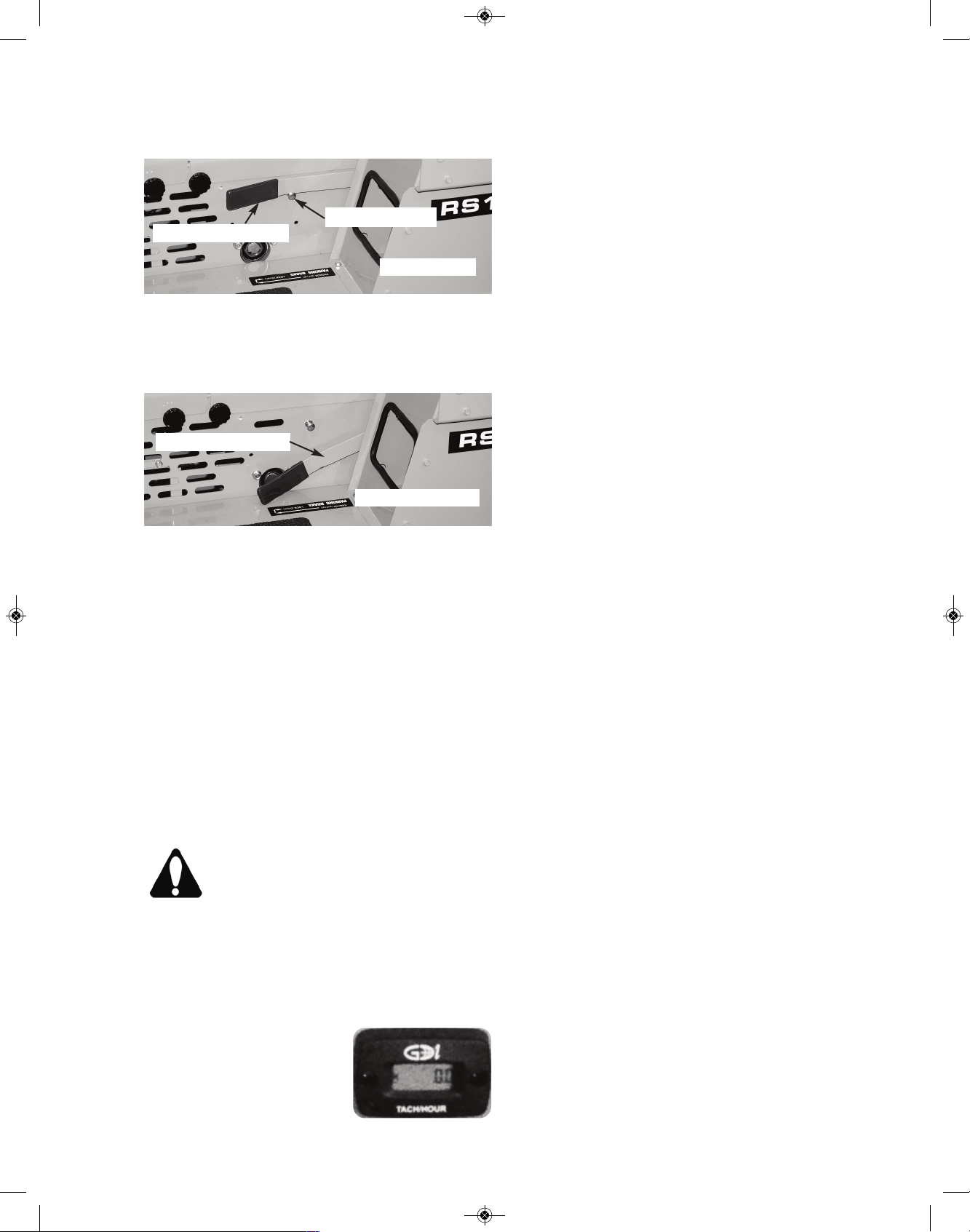

F - KEY IGNITION SWITCH

Switch is activated by rotating key clockwise.

Turning it fully clockwise will engage engine starter

...release key and it will return automatically to the

RUN “ON” position. Turn

fully counter-clockwise to

OFF position to stop engine. Remove key.

G - CIRCUIT

PROTECTOR

The Circuit Protector protects the battery charging

circuit. (Consult engine

manual for more information).

H - FUEL SHUT OFF VALVE

The Fuel Shut Off

Valve Lever controls the fuel to the

carburetor. Turn it

OFF for transport

or when cleaning

carburetor. (Consult Engine Manual

for more information).

13

H

a

r

d

Su

r

fa

c

e

T

r

a

v

e

l

Ma

x

imu

m To

rq

u

e

D

C

E

H

F

G

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 13

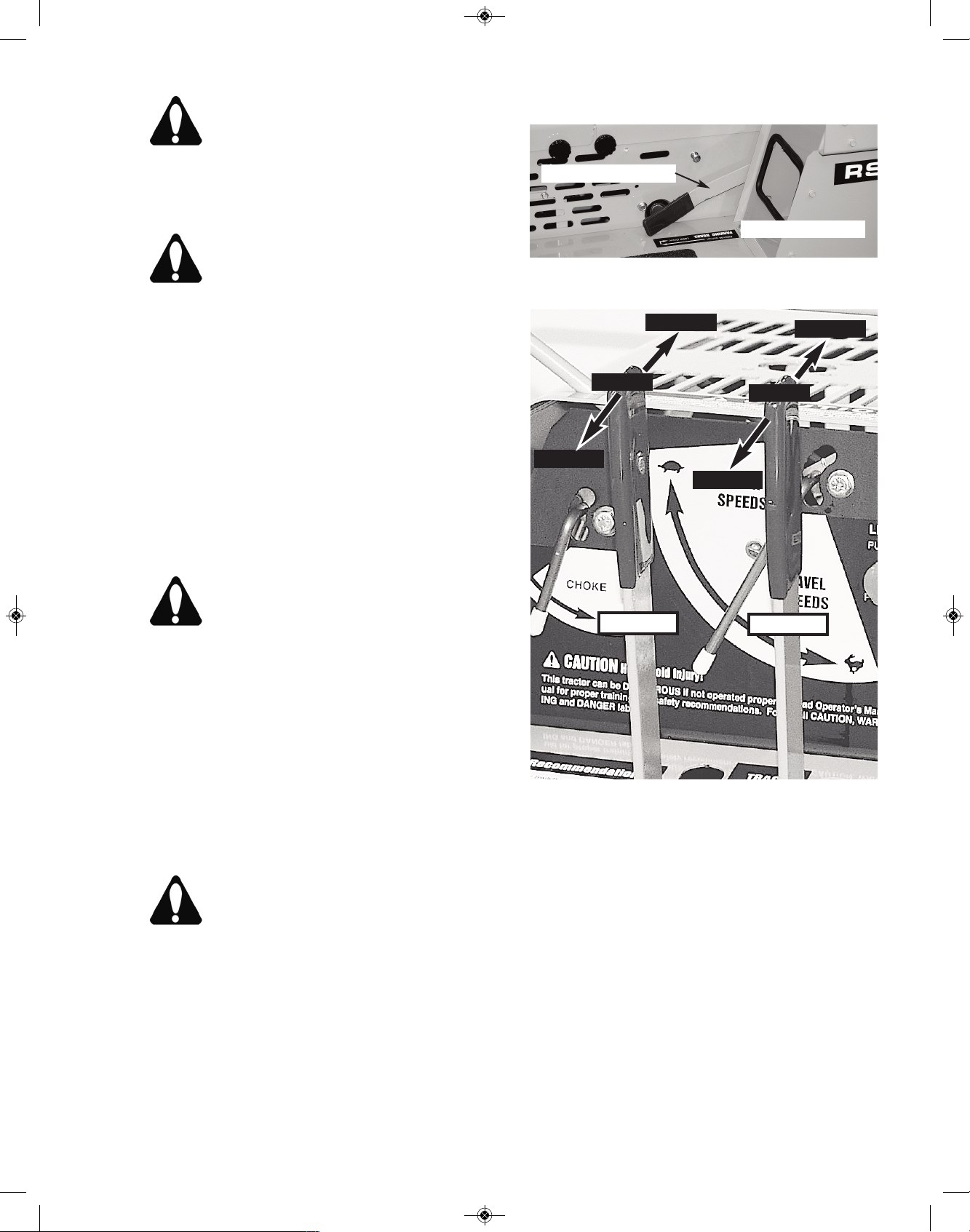

I - PARKING BRAKE

The Parking Brake acts both as a parking brake

and as an emergency brake.

To “engage” Parking Brake, pull Brake Handle up

firmly and loop it “up and over” the Carriage Bolt

provided...make sure handle edge is on top of Bolt

and behind “inside face” of Carriage Bolt.

To “disengage” Parking Brake, reverse the above

procedure and allow Brake Handle to rest on

Fender.

As the Parking Brake is also your emergency

brake, it’s extremely important to maintain its performance with daily inspection. See Service section of this manual for proper procedures.

EXTREMELY IMPORTANT:

As it’s mandatory to engage the Parking Brake be-

fore starting your crawler, always remember to

disengage it before driving away.

If you fail to disengage the Parking

Brake it will wear very rapidly and be

of no value in an emergency!!

J - HOUR METER /TACH (If equipped)

The Hour Meter/Tach displays the hours run and the

RPM of the engine. Keeping

up with your maintenance of

your MAGNATRAC keeps it

running in top condition!

HOUR METER / TACH FLASH ALERT:

Flashes “CHG OIL” at 100 hour service

intervals and “LUBE” at 25 hour service intervals, the service interval is based on actual run

h

ours.

OPERATION:

Alerts begin flashing a warning 4 hours before service is due, and clear automatically 1 hour

afterward. Meter displays RPM while enigne is

running, hours while eningeis off.

FLASH SERVICE RESET:

Service alarms will automatically reset 1

hour after service interval.

14

DISENGAGED

I - Brake Handle

I - Brake Handle

ENGAGED

Carriage Bolt

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 14

4- OPERATION

PRE-STARTING INSPECTION

Before you start your Crawler for the first time

each day, perform the following checks:

ENGINE COMPARTMENT

Check oil level.

Check air intake system.

Remove trash and oil/dirt deposits.

TRACKS, ATTACHMENTS, SHEET METAL

Check for bent, broken, or missing parts.

Check Track Springs.

HARDWARE

Check for loose or missing parts.

ELECTRICAL SYSTEM

Check for worn or frayed wires or loose

connections.

LUBRICATION

Check lubrication points shown in Periodic

Service section of this Manual.

GUARDS AND SHIELDS

Check for tightness and condition.

BATTERY COMPARTMENT

Remove trash.

Check cables for tightness and corrosion.

FUEL TANK

Check fuel level.

OPERATOR’S STATION

Check control levers for free movement.

Clean fenders and instrument panel.

Adjust Seat location to fit operator.

CAUTION - Before you start the engine:

Clear the work area of people and obstacles

C

heck the condition of the Crawler. (Prestart

inspection).

Be sure there is enough ventilation.

Be sure to know the correct starting and stop

ping procedure.

Sit in the Operator’s Seat.

PREPARE FOR ENGINE STARTING

1. Allow Left (A) and Right (B) Track Controls to

assume their natural “spring-loaded” center neutral positions.

2. Engage Parking Brake (I). (Make sure Brake

lever is pulled “up and over” round head of Carriage Bolt provided...make sure handle “edge” is

on top of this Bolt and behind its inside face).

3. Check that all Attachments are in the fully lowered position.

4. Make sure you are properly seated so Seat

Safety Switch will engage

STARTING THE ENGINE

1a. Cold Engine - Place the Throttle Control (C)

midway between the Slow and Fast positions.

Place the Choke Control (D) into the On (fully

choked) position.

1b. Warm Engine (normal operating temperatures) - Place the Throttle Control midway between the Slow and Fast positions. Place the

Choke Control into the Off (no choke) position.

2. Activate the Key Ignition Switch (F) by rotating

the key clockwise until starter engages. Release

the key as soon as the Engine starts ...Switch will

return to the Run “On” position.

NOTE: After starting a “cold” Engine, it may be

necessary to leave the Choke partially On for a

few minutes before moving it to the Off position

15

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 15

C

AUTION: Do not crank the Engine

continuously for more than 10 seconds

at a time. If the Engine does not start,

allow a 60-second cool-down period between starting attempts. Failure to follow these

g

uidelines can burn out the starter motor.

CAUTION: If the Engine develops suffi-

cient speed to disengage the starter but

does not keep running (a “false start”),

the Engine rotation must be allowed to

come to a complete stop before attempting to

restart the Engine.

If the starter is engaged while the flywheel is rotating, the starter pinion and flywheel ring gear

may clash, resulting in damage to the starter.

If the starter does not turn the Engine over, shut off

starter immediately. Do not make further attempts

to start the Engine until the condition is corrected.

If the battery charge is not sufficient to turn over

the Engine, recharge the battery.

CAUTION: Do not attempt to jump start

the Engine with another battery. Start-

ing with batteries larger than those rec-

ommended can burn out starter motor.

WARM-UP PERIOD

Run Engine at half speed for 5 minutes.

Do not run Engine at fast, or slow idle.

Operate Crawler at less-than-normal loads and

speeds for the first 15 minutes.

WARNING: Lethal Exhaust Gases!

Engine exhaust gases contain poison-

ous carbon monoxide. Avoid inhaling

fumes, and never run the Engine in a

closed building or confined area.

NOTE: Assembled Crawlers are “run in”

under no load at the factory to properly

break-in their drive train.

TRAVELING

Disengage Parking Brake (I); Fully raise all Attachments to recommended traveling heights.

To move straight ahead, simultaneously push

both Left Track Control (A) and Right Track Control (B) forward.

To move straight to the rear, simultaneously pull

both Right and Left Track Controls rearward.

To turn sharply to the right, push Left Track

Control fully forward...leave Right Track Control in

neutral.

To turn slowly to the right, push Left Track Control fully forward while simultaneously pushing

“partially” forward on Right Track Control...the farther you push the Right Track Control forward, the

slower you will turn right.

16

DISENGAGED

I - Brake Handle

Reverse

Reverse

Forward

Forward

Neutral

Neutral

Control A

Control B

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 16

To turn sharply to the left, push Right Track

Control fully forward...leave Left Track Control in

neutral.

To turn slowly to the left, push Right Track Control fully forward while simultaneously pushing

“partially” forward on the Left Track Control...the

farther you push the Left Track Control forward,

the slower you will turn to the left.

To counter-rotate Tracks, (shortest turn possible), push one Track Control forward while simultaneously pulling rearward on the other Track

Control. You may counter-rotate “clockwise” or

“counter-clockwise”; move in which ever direction

satisfies the job at hand.

Stopping the Crawler: The Right and Left Track

Controls are of the self-centering (neutral) type.

This allows you to simply release pressure on both

Track Controls to disconnect (declutch) active

power to the Tracks and come to a complete stop.

Never “snap” Track Controls back into neutral!

P

ARKING THE CRAWLER

1. Lower all Attachments to the ground.

2. Allow Right and Left Track Controls

t

o go “slowly” to neutral.

3. Engage Parking Brake.

4. Run Engine at half speed 2 minutes

without load.

5. Move Throttle Control to slow idle.

6. Turn Ignition Switch to Off.

IMPORTANT: If Engine stops under load, remove

load. Start Engine immediately. Run 30 seconds

at half speed before adding load.

CAUTION: When you park your

Crawler on a slope, put blocks against

tracks. Do not park Crawler with

tracks pointed downhill, always park

“cross-ways” to the hill!

STORAGE

Always store your MAGNATRAC in a garage,

shed or barn. If the only option is to park outside,

make sure to securely tarp the unit and park on a

flat surface with the parking brake engaged.

During freezing weather, park on a hard surface

to avoid freezing the Steel Tracks (if equipped) to

the ground. We recomend parking on rubber track

mats or using some inexpensive plywood. This will

keep moisture away from the steel tracks and extend the life of them. If Tracks are frozen to the

ground, be careful to avoid damage to the Tracks

and drive train when you try to move the Crawler.

We advise to turn off the fuel shut off valve and

run until the unit stops if going to store for a long

period of time. This is to ensure easy starting during the next season. Remember to turn ON the

fuel when ready for work the next time!

17

Reverse

Reverse

Forward

Forward

Neutral

Neutral

Control A

Control B

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 17

5- FUELS

&

LUBRICANTS

FUELS

FUEL SPECIFICATIONS

Add fuel to fuel tank per engine manual specs.

Unleaded 86 octane or higher is reccommended per HONDA. Verify fuel shutoff valve is in the open position.

FILLING FUEL TANK

The Fuel Tank is located underneath the hood, on

the eninge.

Fill Fuel Tank at end of each day’s operation.

Fuel Tank capacity is 6.4 U.S. qts. or 1.6 gallons.

Use unleaded gasoline per Engine Owner’s Man-

ual.

CAUTION: Handle fuel carefully. Do

not fill fuel tank when the Engine is running. Do

not smoke while you fill fuel tank or work on fuel

system.

STORING FUELS

Keep fuel in a container in a protected area.

Water and sediment must be removed before fuel

gets to the Engine. Do not depend on fuel filters

to remove water.

If possible, install a water separator at the storage

tank outlet.

Store fuel drums on their sides with plugs up.

IMPORTANT: Keep all dirt, scale, water, or other

foreign matter out of fuel.

LUBRICANTS

ENGINE OIL

Check enclosed Engine Owner’s Manual and

closely follow their recommendations.

HYDRAULIC OIL (If equipped)

Use a premium quality hydraulic oil with maximum anti-wear properties, rust and oxidation

treatment. A high quality antiwear hydraulic fluid

designed for use in high pressure, high speed hydraulic pumps in industrial hydraulic systems. We

use an AW46 Hydraulic Oil. (ISO 46). An ISO of

46 is good in standard temperatures. If operated at exteme hot or cold temperatures,

please consult a local oil shop for an oil viscosity best suited for your conditions.

If the above specifications can not be found

consult with a local tractor/equipment dealership or oil supplier for other brands of hydraulic oil suitable for loaders, backhoe, and

hydraulic drive systems.

Fill Hydraulic Oil Tank through #616 breather,

on the top of the hydraulic tank, behind the operator seat. Check level by “eye check”, it should be

a few inches from the top...remove breather with

a crescent wrench at the black nut and hand

tighten once full!

Approximately 2 gallons of hydraulic fluid

fills the hydraulic reservoir to the proper

level (when empty & no hydraulic cylinders

are attached).

GREASE

Use premium quality SAE Multi-Purpose Grease

in a grease gun with a flexible “nose” to lubricate

grease zerks throughout the MAGNATRACS pivot

points.

STORING LUBRICANTS

Store lubricants in clean containers in an area protected from dust, moisture, and other contamina-

tion.

18

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 18

6- LUBRICATION

&

PERIODIC SERVICE

LUBRICATION AND SERVICE

INTERVALS

Recommended service intervals are for normal

conditions. Service more often if Crawler is operated under more difficult conditions such as high

temperature, dust, etc. Use only quality lubricants

at intervals specified in this manual.

PERIODIC SERVICE CHART

Air Cleaner(s) - Service per instructions in En-

gine Owner’s Manual.

Engine Oil - Service per instructions in Engine

Owner’s Manual

Battery - Change as needed. Approximately every

3 years.

1ST USAGE

1ST USAGE

Hydraulic Oil - Attach any additional attach-

ments first (Grapple, backhoe, rear hitch,

etc.) Check level on a flat & level surface;

with equipment on the ground (retract all

possible cylinders), level should be approx. 5” away from the top of the tank.

Add additional fluid if needed.

Engine Oil - Check enigne oil level before use to

make sure oil level is at acceptable level

on the dipstick. Add additonal if needed.

NOTE: First oil change for a new Engine

is at 5 hours

Fuel - Add fuel to fuel tank per engine manual

specs. Unleaded 86 octane or higher is

reccommended per HONDA. Verify fuel

shut-off valve is in the open position.

EVERY TEN HOURS

EVERY TEN HOURS

Grease Fittings - Lubricate all grease fittings

per location instructions in manual of

each attachment you have mounted on

your MAGNATRAC. Recommended

grease: Multipurpose NLGI 2 Grade

Lithium Complex, ISO VG 220.[Clean

grase fittings and area around them before servicing].

Clean area around each grease fitting on Front

Idler and Rear Drive Assemblies. Grease each

grease fitting until you feel back pressure building.

A small breakdown of how many grease fittings

are on the RS1000 and various Attachments is as

follows:

RS1000 with Steel Tracks: 6

RS1000 with Rubber Tracks: 10

Note: 4 are located on the front idlers &

rear drives and 2 are on the #1791 Rear

Bearings. (shown on the next page)

For all others, please see each individual

attachment for the quantity of grease fittings.

As a standard guide, there will be a grease

fitting for each Axle/Pin that you see on a

particular attachment. (See below).

HFH15 Front Hitch: 2

D1060 Backhoe: 14

D1060UG Backhoe: 18

HRH35 Rear Hitch: 2

Rubber Track Idlers: 4

#1791 Bearing Assemblies: 2

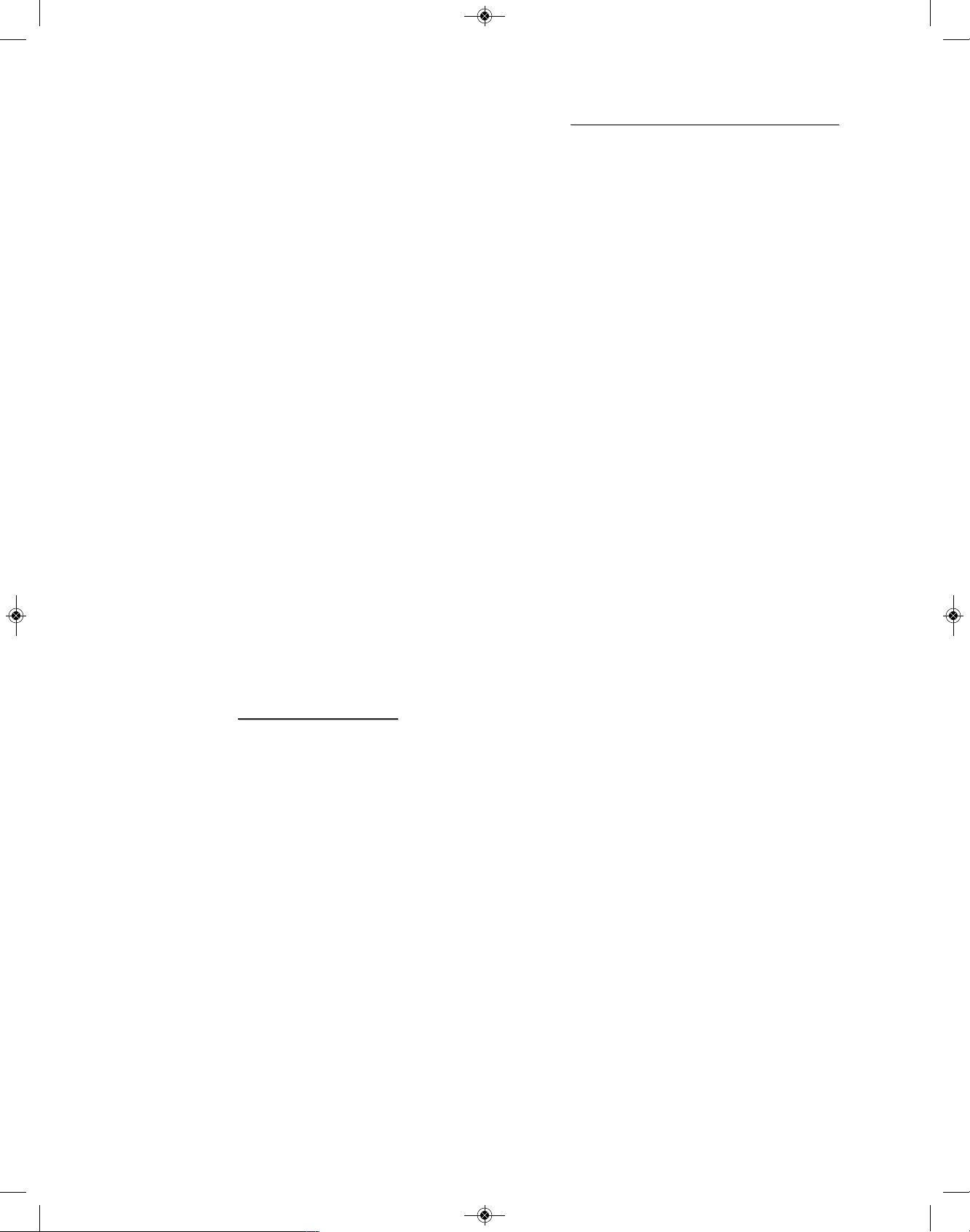

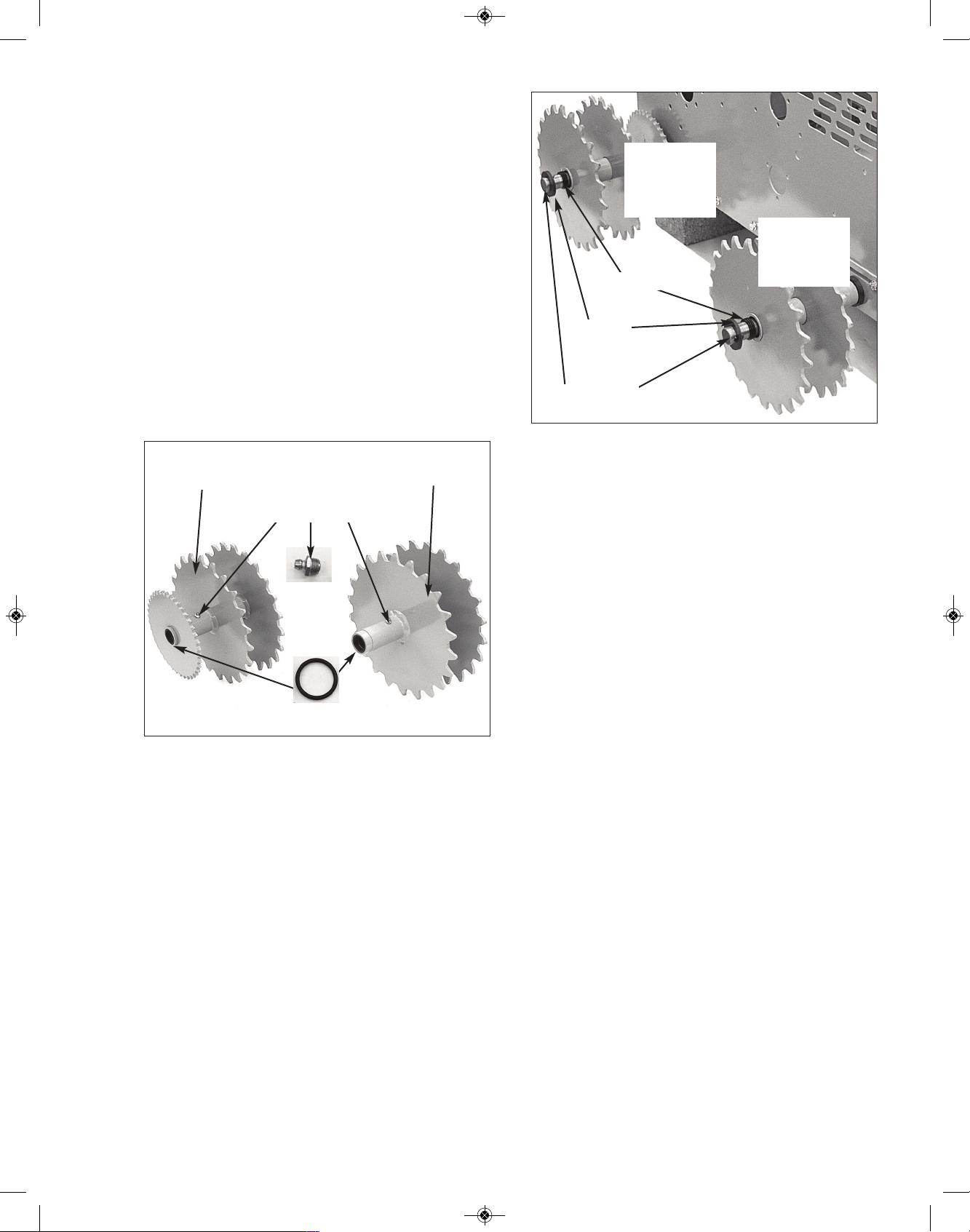

Lubricate the “grease fitting” in each #1791

Bearing Assembly. NOTE: The #1791

Bearings are the hardest working Bearings

in your RS1000, never spare proper lubri

cation and maintenance! See picture on

the next page.

19

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 19

EVERY FIFTY HOURS

EVERY FIFTY HOURS

Engine Oil

Drain and refill per recommendations in

Engine Owner‘s Manual.

NOTE: Change Engine oil every 25 hours

if you’re working under constant heavy

loads or extremely dirty conditions.

Filters

Replace Engine Air Filter with filter recommended in Engine Owner’s Manual.

Tracks and Track Sprockets

Pressure wash track system, including:

Front Idler and Rear Drive Sprockets.

Track Tension

Maintain 1-3/8” overall length of #1806

Spring on each Track.

Check Service section of this Manual for

complete explanation and Track Tensioning procedures.

Rear Drive Chain Tension

Maintain proper chain tension in Crawler’s

Rear Drive. Check Service section of this

Manual for complete Rear Drive Chain

Tensioning procedures.

Rear Drive Chain Lubrication

Use SAE 30 motor oil in pressure oil can.

Thoroughly lubricate each Drive Chain.

[TIP: Drive Crawler forward approximately

six feet stopping to oil the Chain every

foot]. Don’t forget to do both Drive Chains!

T

ip: wipe the chain down after oiling to keep oil

spatter to a minimum.

Engine Drive Chain Tension (If equipped)

M

aintain proper chain tension in Crawler’s

Engine Drive Chain. Check Service section of this Manual for complete Engine

Drive Chain tensioning procedures.

General Once-Over

Check for loose nuts and bolts and any

signs of premature wear. Correct any

problems immediately. Contact factory

with any questions or requests for help.

EVERY 200 HOURS

EVERY 200 HOURS

Fuel Tank

Remove and drain tank of any water or

sediment. Clean or replace the in-tank

fuel filter.

Fuel Filter - Replace with new Fuel Filter at this

time: Filters can be purchased through the

Struck Corporation or through local engine

dealers.

Hydraulic Oil (If equipped) - Run the RS1000 for

approx. 5 minutes at idle, shut off. Drain

system by angling the 90 degree fitting on

the bottom right of the hydraulic oil tank.

NOTE: Drain when fluid is warm. Block up

the right front corner of Crawler a few

inches to get oil to flow completely to drain

opening. Refill with approx. 2 gallons of hydraulic fluid. Fill the hydraulic reservoir to

the proper level. (See PP35 Power Pack

section of the attachment manual)

Enigne Spark Plugs - Replace Engine Spark

Plugs with spark plugs recommended in

Engine Owner’s Manual.

20

Zerk

#1791 Bearing Assembly

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 20

7- SERVICE

In the following Service section of this Manual, you

w

ill be required to do various assembly and dis-

a

ssembly procedures. Each section will try to remind you of safe procedures, but the best safety

device is still the mechanic himself.

CAUTION: Try to do your work in a

level, open area away from people and

obstacles.

1. Pay attention to what you are doing..the parts

you will be handling can be heavy, sharp or could

pinch. Always wear heavy gloves when handling

the Tracks and similar sharp, pinching parts.

2. When you are required to block your crawler to

raise it off the ground, make sure you use strong

blocking materials and think out how the Crawler

will safely balance on blocking. To protect your-

self and your Crawler from damage, check

“Safe Blocking Diagram” on front page of this

Manual!

Never be too proud to ask a friend or neighbor for

help...especially when blocking up your Crawler

or working with the Tracks.

As always, the factory is your best source for competent service advice and explanations of any

service procedures that are unclear...always feel

comfortable calling for whatever advice you may

need!

ENGINE

Your Crawler comes with a complete Engine

Owner’s ManuaI. It provides complete operation

and maintenance instructions for your engine. If

further help is needed, contact your local engine

dealer...he’s listed in the telephone “Yellow Pages”

under “Engines, gasoline”.

STARTER

IMPORTANT: Don’t operate starter switch longer

than 10 seconds at a time. If engine does not start

within 10 seconds, wait 60 seconds before trying

to start again. After a false start, do not turn starter

button until Engine has stopped turning.

If the starter will not operate or operates slug-

g

ishly, check for the following:

Run down battery.

Dirty, loose, or corroded cables and wires.

Engine oil viscosity too heavy.

BATTERY

Your Crawler has a 12 volt, negative-grounded

system with one battery (battery not included on

basic recoil start models).

BATTERY PRECAUTIONS

CAUTION: Sulfuric acid in batteries is

a poison and could cause severe burns.

Avoid contact with skin, eyes, and

clothes. When you work around batteries, protect eyes and face from battery fluid and

explosion.

Antidotes for Sulfuric Acid:

EXTERNAL

1. Flush skin well with water.

2. Flush eyes for 15 minutes.

3. Get medical attention immediately.

INTERNAL

1. Drink a large amount of water or

milk.

2. Then drink milk of magnesia, beaten

eggs, or vegetable oil.

3. Get medical attention immediately.

CAUTION: Keep flames and sparks

away from battery.

Do not use booster cables or adjust battery terminal connections unless you know the correct procedure.

When you charge a battery or use a battery in a

closed space, be sure there is enough ventilation.

Keep batteries where children cannot reach them

with vent caps tight and level.

21

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 21

COLD WEATHER BATTERY SERVICE

During cold weather, keep electrolyte in battery at

correct level (if applicable). Keep battery fully

c

harged.

BATTERY STORAGE

If Crawler will be stored for more than 30 days, remove battery. Keep it fully charged.

BATTERY MAINTENANCE

1. Remove corrosion from terminals with

a stiff, non-metallic brush.

CAUTION: Use care when cleaning

terminals so that you do not “short them

out” with metallic brushes, scrapers,

screwdrivers etc.

2. Clean battery with a baking soda solution (1/4 pound in a quart of water)...best done

with battery removed from crawler.

3. Flush battery and compartment with

clear water.

4. Check electrolyte level (if applicable).

Fill each cell to bottom of filler neck with distilled

water or clean, soft water (not hard water).

5. Put petroleum jelly on terminals. Maintain protective cover on “positive” (+) terminal of

battery.

SAFETY INTERLOCK SWITCHES

Two Switches, one on underside of the #933A

Seat and the other one on the Brake Lever Rod

inside Crawler.

These switches are used in the Crawler’s electrical system as safety devices. They detect if the

operator is properly seated, and that the Parking

Brake is engaged before the Crawler can start.

To check either the #1162 Seat Switch or the

#1148 Parking Brake Switch, you must remove

the electrical connectors attached to each switch’s

terminals and connect a continuity tester to its terminals (a simple flashlight type continuity tester

would be fine).

SEAT SWITCH TEST

Remove #933A Seat from its #1674 Seat Mounting Bracket. Then remove the electrical connectors attached to each of the #1162 Seat Switch’s

two terminals.

1. By pushing down on the center of the

seat the Seat Switch should “open”. A continuity

tester, attached to the two terminals of the Switch,

should have its light Off at his time!

2. With pressure removed from the seat,

the Switch should “close”...the light should be On!

If both of the above conditions are not met, the

Switch is defective and must be replaced. When

test is completed, remove continuity tester and replace original electrical connectors on both terminals of Seat Switch. Remount seat to its Mounting

Bracket.

Reassemble the Seat Assembly to your Crawler

and reconnect it’s Plug.

At this time following recommended safe starting

procedures, start the Engine and check Seat

Switch response...readjust if necessary.

22

#1162

#1829

#933A

Brake Lever Rod

#440

#1148

#1674

Terminals

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 22

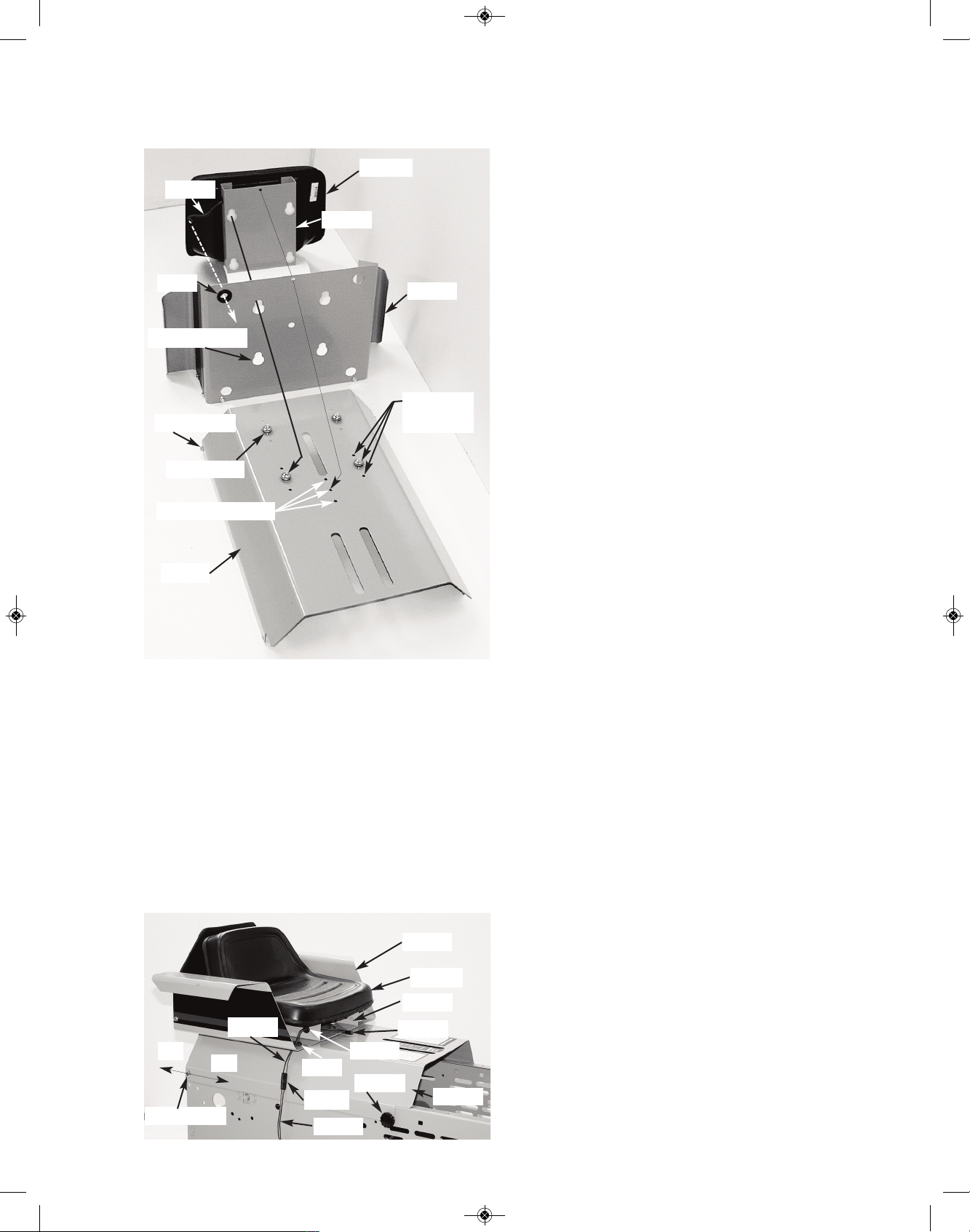

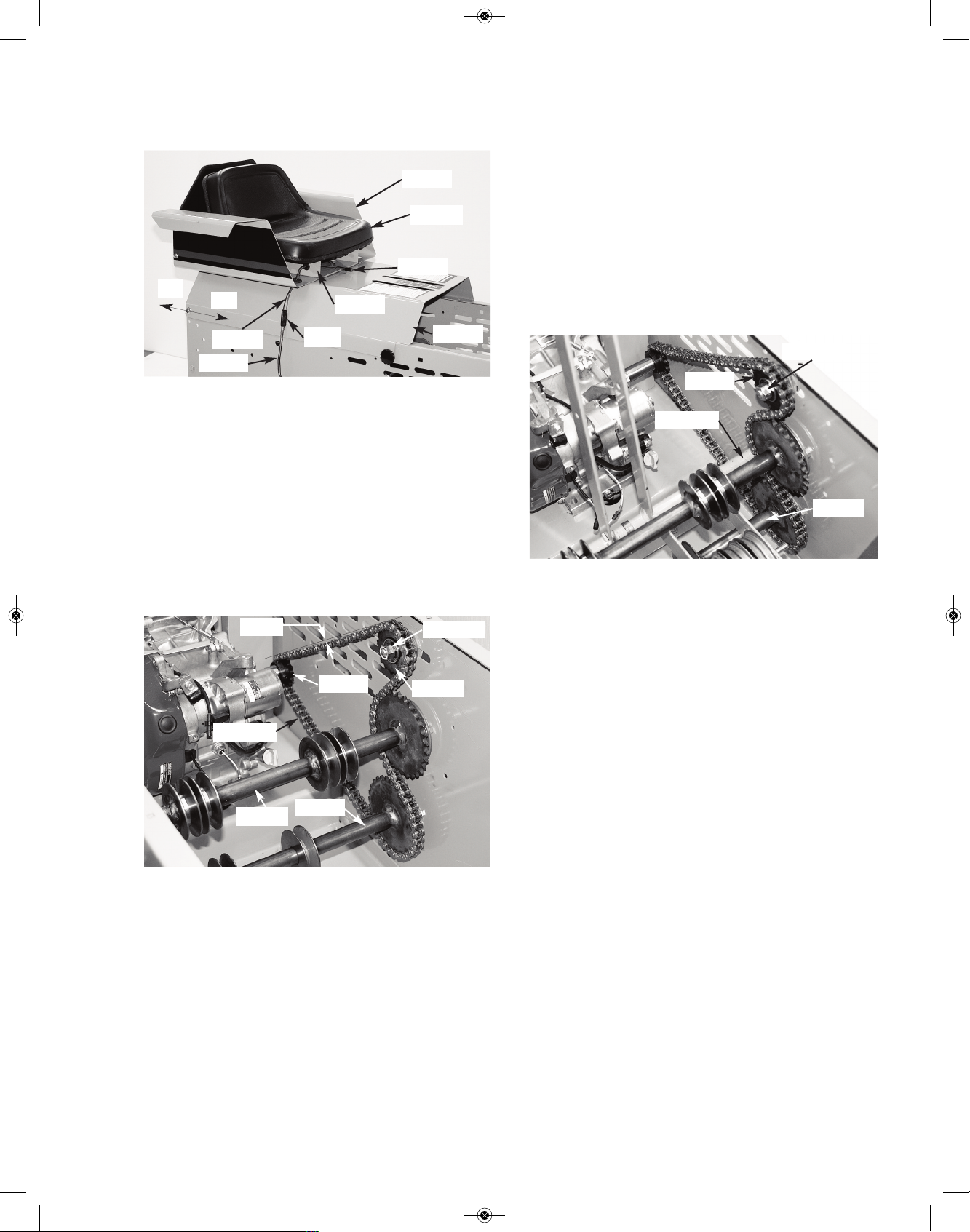

SEAT & REAR COVER

ASSEMBLY

Your Seat & Rear Cover Assembly is made up of

three main components: The #1674 Mounting

Bracket (with attached #933A Seat) and #1625

Arm Rests mounted to #1608 Rear Cover. They

are held together with four “keyhole slots” over

four “posts”. The “posts” can be located in three

different positions to satisfy the operator’s “seating

comfort”.

When all components are nested together they

will share a common “seat pin hole” that will lock

the assembly together with a #1688 Seat Pin.

T

here are two methods to remove the Seat As-

sembly. One is by removing the Assembly as a

complete unit (It weighs about 45 lbs.). The second method takes longer but allows you to disassemble the unit into three components that weigh

a

bout 15 lbs. each. Both methods are explained

below...the choice is yours.

METHOD 1 - Seat Removal

Fully open the Hood by loosening a few turns of

the two #1866 “threaded” Knobs (located at lower

rear of Hood) and then rotating fully forward. Disconnect the #1824 & 1825 Wires at their mating

Plug. Remove the two #1866 “threaded” Knobs at

lower front edge of #1608 Rear Cover. Slide the

complete Seat Assembly rearward and remove.

Seat Assembly:

To replace your Seat Assembly “reverse” the steps

above.

1) Upon completion of reassembly, make sure

that #1824 Wire & Plug pass through #1854 &

#278 Grommets and connects to mating #1825

Wire & Plug.

2) Make sure “front top edge” of #1608 Cover

rests on top of “lip” that protrudes rearward out of

lower section of #1618 Dash.

3) Close Hood and secure it and Cover Assembly

with #1866 Knobs.

METHOD 2 - Seat Removal

Fully open the Hood by loosening a few turns the

two #1866 “threaded” Knobs (located at lower rear

of Hood). Rotate Hood fully forward until Chain

holds it. Disconnect the #1824 & 1825 Wires at

mating Plug. Draw #1824 Wire & Plug out of #278

Grommet. Remove #1688 Seat Pin and slide “forward” the #1674 Mounting Bracket with #933A

Seat and lift up to remove. Take #1625 Arm Rests,

slide forward and lift up to remove. Remove the

two #1866 “threaded” Knobs on front lower edges

of #1608 Cover. Slide the Cover rearward and remove.

Seat Assembly:

To replace your Seat Assembly “reverse” the steps

above.

1) Upon completion of reassembly, make sure

that #1824 Wire & Plug pass through #1854 &

#278 Grommets and connect to mating #1825

Wire & Plug.

2) Make sure “front top edge” of #1608 Cover

rests on top of “lip” that protrudes rearward out of

lower section of #1618 Dash.

3) Close Hood and secure it and Cover Assembly

with #1866 Knobs.

23

#933A

#1824

#1674

#1625

#1608

3 Seat

Positions

Seat Post

Keyhole Slot

#278

Seat Pin Holes

Body Post

#1625

#933A

#1608

#1688

#1674

On

Off

#1829

#1825

Plugs

#1854

#278

Body Post

#1866

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 23

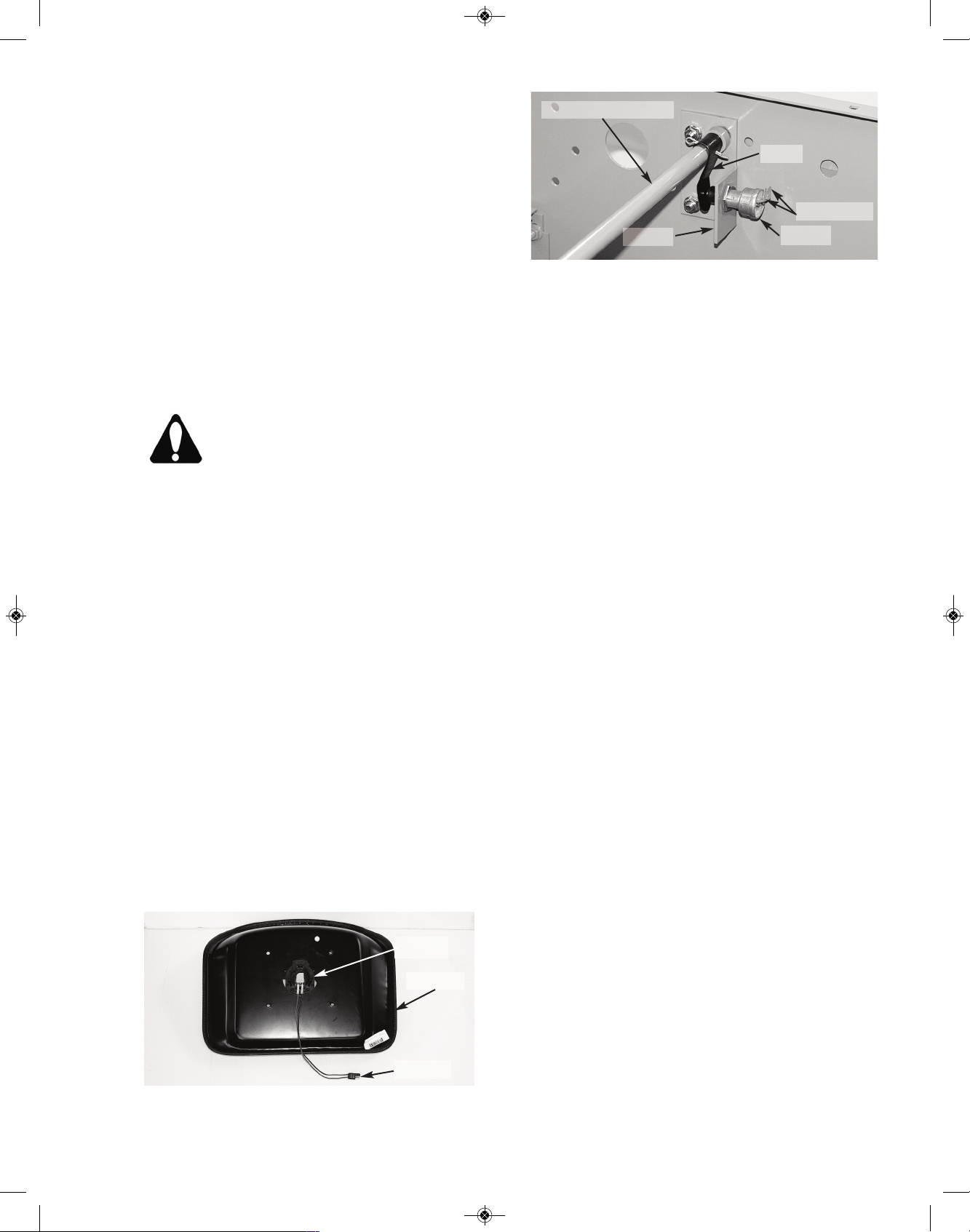

PARKING BRAKE SWITCH TEST

Begin your procedure by parking your Crawler on

an open, firm, level surface. Shut off engine and

engage Parking Brake. Open Hood and swing

fully forward. Remove #1688 Seat Pin. Remove

#933A Seat & #1674 Mounting Bracket, #1625

Arm Rests, and #1608 Rear Cover. NOTE: Be

sure to disconnect the “mating” #1829 and #1825

Seat Wires at their common Plug.

Disengage Parking Brake. Remove the two electrical wire plugs from their #1148 Parking Brake

Switch and connect a continuity tester to its two

terminals.

(1) With “plunger” of #1148 Parking Brake Switch

not depressed, the light of the continuity tester

should be On. With “plunger” of Parking Brake

Switch fully depressed, the light of the continuity

tester should be Off.

(2) When the Parking Brake Lever is pulled “upward” and looped “up and over” the Carriage Bolt

p

rovided into an “engaged” position, Parking

Brake Switch should be “open” (the result of contact with the rotated #440 Leaf Spring). The light of

the continuity tester should be Off!

(3) When the Parking Brake Lever is released

and put into it’s “disengaged” mode (Lever should

be free to touch Left Fender) the Parking Switch

should be “closed” (the Leaf Spring would have

rotated back and away). Continuity light should

now be On!

If both conditions of procedure (1) (above) are not

met, replace Parking Brake Switch. If both conditions of procedure (1) are met, but the conditions

of procedure (2) & (3) are not met, you must adjust

the “horizontal location” of the #1148 Switch in its

#1620 Bracket.

The #1148 Parking Brake Switch is secured “front

to rear” in it’s #1620 Bracket with hex nuts.

Adjust Switch’s location “front to rear” to meet requirements (1), (2) and (3) (above) by relocating

its two hex nuts.

When adjustment is completed, tighten Switch’s

hex nuts...terminals on Switch should point

straight up. Remove continuity tester and replace

electrical plug on terminals of Switch. Replace

Seat & Mounting Bracket, Arm Rest and Rear

Cover Assembly...check that it is positively latched

with #1688 Seat Pin! Close Hood and secure it

and Rear Cover with #1866 threaded Knobs.

NOTE: Be sure to reconnect “mating” #1829 &

1825 Seat Wires at their common Plug.

At this time, following recommended safe starting

procedures, start the Engine and check Parking

Brake’s Switch setting...readjust if necessary.

24

Brake Lever Rod

#440

#1148

#1620

Terminals

ENGAGED

Carriage Bolt

DISENGAGED

#1625

#933A

#1608

#1688

#1674

On

Off

#1829

#1825

Plug

Brake Lever

Brake Lever

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 24

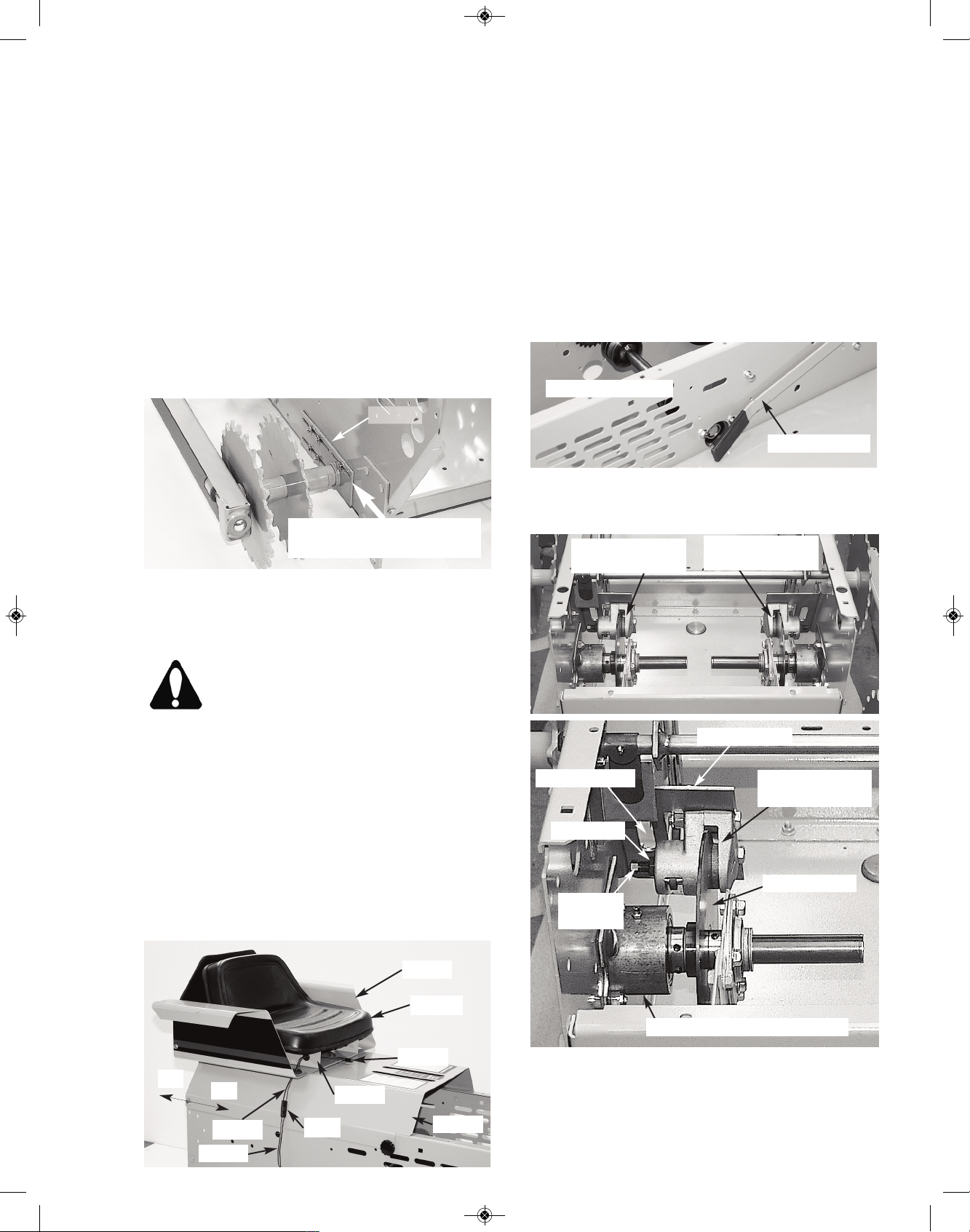

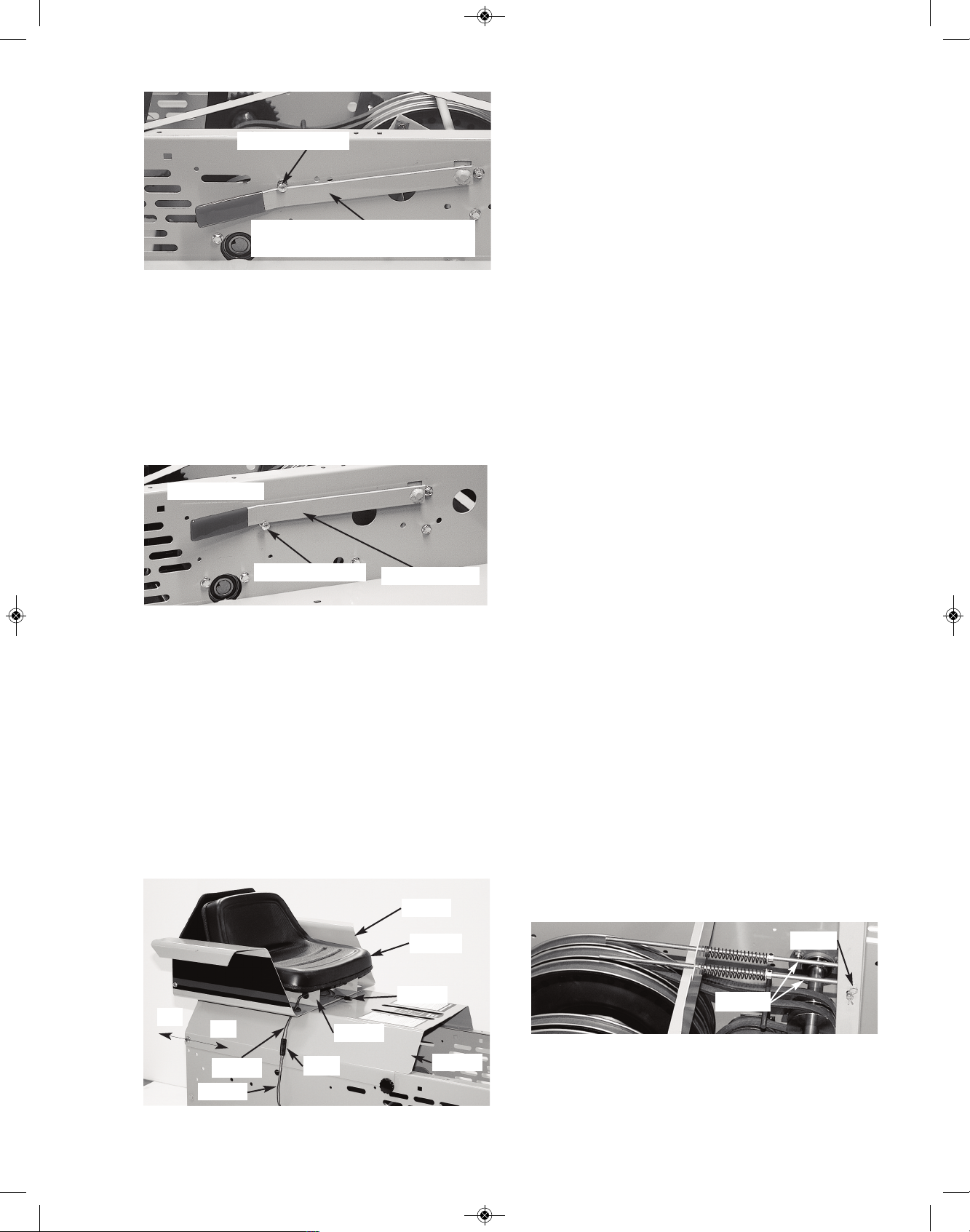

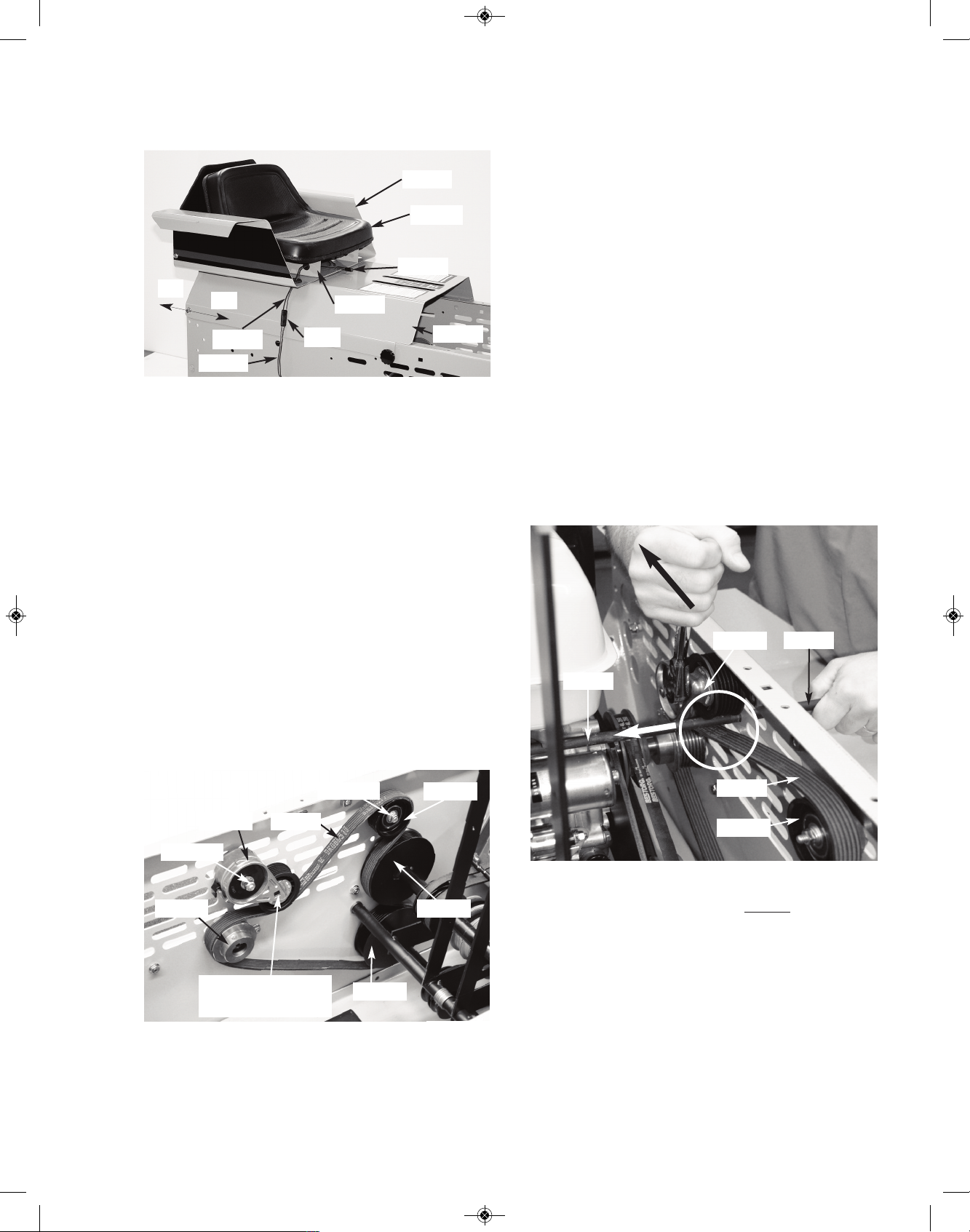

REAR DRIVE CHAIN TENSIONING

The #1805 Rear Drive Chains (#50 Roller Chain)

are tightened by increasing the center distance

between the movable #2065 Rear Axle and the

f

ixed #2048 Sprocket & Shafts.

NOTE: If you have the Rubber Track System

design, the sprockets will look differrent from

the ones shown in the next few pages, but the

rear drive tensioning procedure will still be the

same.

Begin your Drive Chain Tensioning procedure by

driving Crawler onto a firm, level surface. Shut off

Engine and dismount...do not “engage” Parking

Brake Lever.

[Though not absolutely necessary, it’s extremely

helpful in the following procedure to block your

Crawler up and remove its Tracks...see Track Removal section of this Manual for instructions].

Open Hood and swing fully forward; remove

#1688 Seat Pin. Remove Seat & Bracket, Arm

Rests and Rear Cover. Remove the #1636 Right

& Left Chain Guards from left and right sides of

Crawler.

Do a thorough washing and cleaning of the #1805

Chains and mating Sprockets with a powerwasher

or a stiff brush. The Sprockets and their mating

Drive Chains must be clean to give proper chain

adjustment. [Remove the Drive Chains and soak

in penetrating oil overnight if stiff].

From “outside” the Crawler’s body, loosen (but do

not remove) the five nuts on each (Left & Right)

#1611 Front Axle Plate. Similarly loosen, but do

not remove the four nuts on each (Left & Right)

#1656 Rear Axle Plate. NOTE: loosen the Carriage Bolt “nuts” from inside of body, all others

from outside.

On each side, from inside body, rotate each #2043

Pulley Assembly. Check that each #1850 Drive

Chain is moving smoothly and that it is free of debris.

[TIP: It will ease rotating the Pulley Assemblies

(above) if you follow the procedure for “Removal Steering Clutch Belts” in Service section of this

Manual. Replace Belts per “Installation - Steering

Clutch Belts” in Service section of this Manual

after you have completed your chain tensioning].

To tighten the Drive Chains, start rotating clock-

wise the Locknut located on left and right lower

rear of Body. To draw Rear Axle back evenly, turn

one Locknut 1/4 turn, then go to the other side and

tighten the other Locknut 1/4 turn...use this back

and forth procedure until both #1805 Drive Chains

are reasonably tight...not “bow-string” tight, but

about a 1/4” of “sag” in the slack strand when the

balance of the chain is taught.

NOTE: While doing the above procedure, make

sure you rotate each #1650 Rear Track Sprocket

25

#2048

#2065

#1656

#1611

Carriage Bolts

Locknuts

#1637

#1636

#1650

#1805

“Sag”

Locknuts

#1805

#1650

#1805

#2043

#1805

#1650A

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 25

A

ssembly (left side & right of body) a full revolution

after each 1/4 turn of its respective Locknut. This

will determine if there is a slight “high spot” in one

of the (#1805 Chain) mating sprockets...if so, use

the “high spot” location for your point of tighteni

ng. When satisfied that both Drive Chains are

tightened evenly, retighten the four Bolts holding

the #1656 Rear Plates on left & right side of Body.

Thoroughly lubricate your Drive Chains at this

time.

Replace the #1636 Right & Left Chain Guards

using original Cap Screws, #1637 Spacers, and

Nuts . Replace Seat Assembly, Arm Rests and

Rear Cover and close Hood...secure all with

#1866 “threaded” Knobs.

Using a “flat-nosed” punch and hammer, push the

#1611 Front Axle Plate (located on both sides of

Body) rearward till it hits a solid stop. NOTE: in the

work done in steps above, this Plate may have al-

ready worked its way rearward. To

check, push Plate forward from the rear,

then push it back the required 3/16” distance.

NOTE: Though this is a simple adjustment, it’s

proper execution now will result in extremely

stable Track performance in the future!

If you have removed your Tracks, reassemble

them on your crawler at this time using the “Track

Replacement” instructions in Service section of

this manual...make sure to properly tension them.

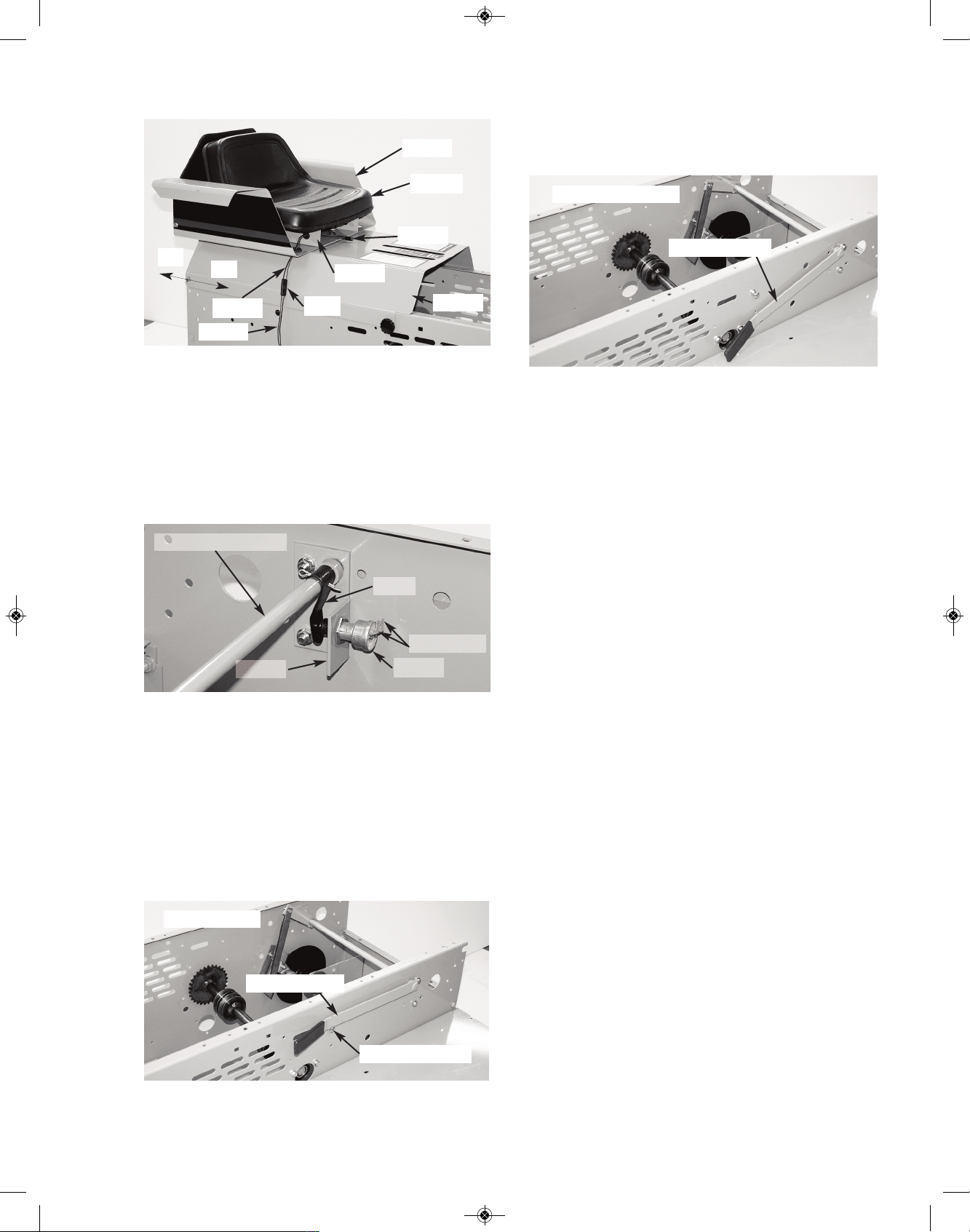

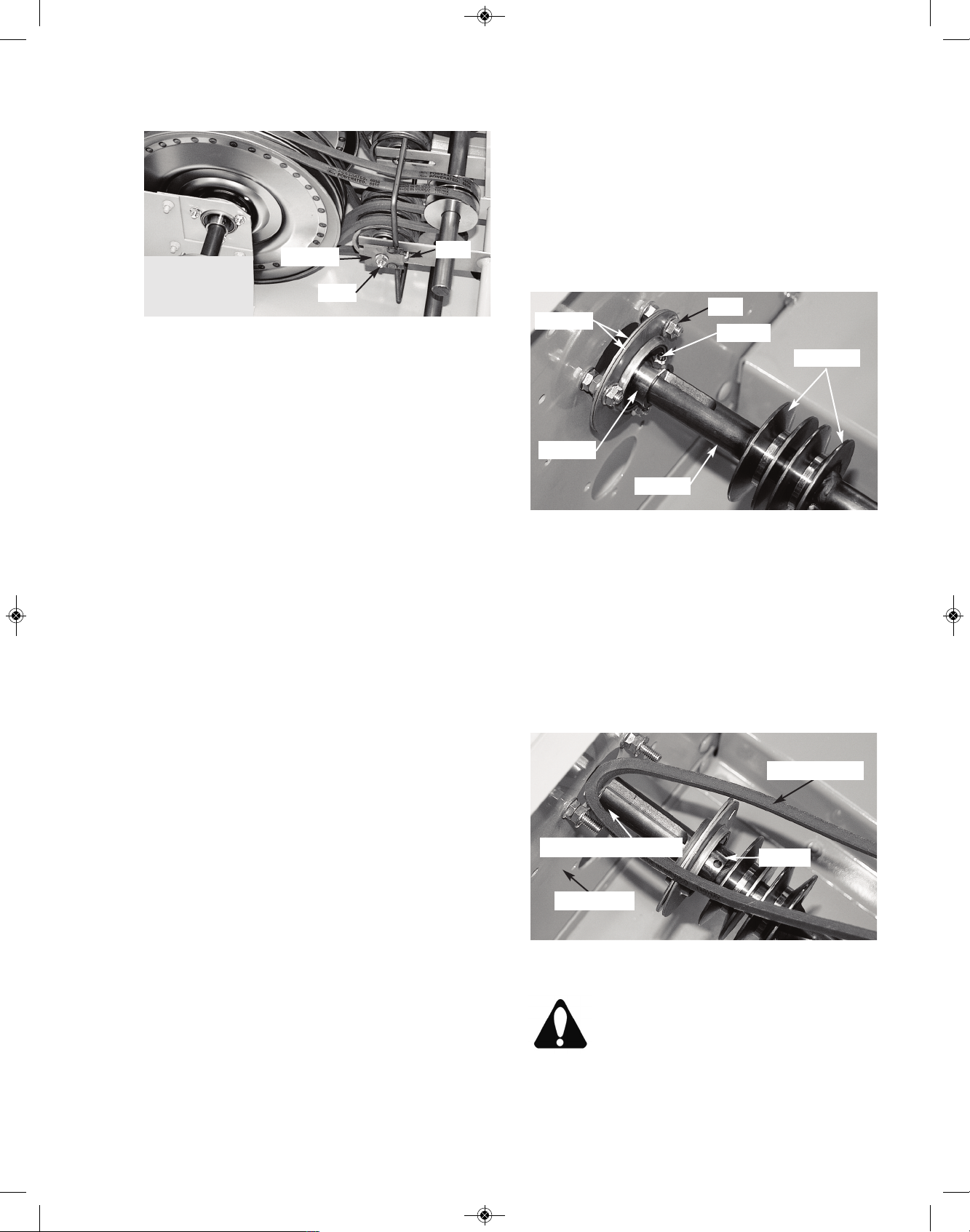

PARKING BRAKE ADJUSTMENT

B

egin your procedure by parking your Crawler on

an open, firm, level surface. Shut off Engine, engage your Parking Brake Lever and dismount.

Raise Hood and rotate it fully forward, then remove the #1688 Seat Pin. Remove the #933A

S

eat & #1674 Mounting Bracket, #1625 Arm

Rests, and #1608 Rear Cover. NOTE: Disconnect

the “mating” #1829 and #1825 Seat Wires at their

common Plug.

Put the Parking Brake Lever in the disengaged position...end of Lever should be free to touch top of

Left Fender.

Loosen Jam Nut on the #225L Left & #225R

Right Disc Brake Calipers a few turns to free their

Adjuster Pins for rotation (see two Photos below).

With Brake Lever firmly touching underside of

Carriage Bolt, set each Brake’s tension by rotating

it’s Adjuster Pin clockwise until the the Pulleys on

each side are not able to be easily rotated by

hand.

26

#1802 Disk

Jam Nut

Wrench Slot

DISENGAGED

Push #1611 fully to rear,

approximately 3/16”!

#1611

#1625

#933A

#1608

#1688

#1674

On

Off

#1829

#1825

Plug

Brake Lever

Adjuster

Pin

#225L Disc

Brake Caliper

#225R Disc

Brake Caliper

#225L Disc

Brake Caliper

#1792 Yoke

#1791 Bearing Assembly

RS1000 Operator Manual 1.01.19.qxp_Layout 1 4/24/19 12:41 PM Page 26

Tighten each of these Brake Assemblies by holding their Adjuster Pin “motionless” with one wrench

while tightening their respective Jam Nut securely... a Wrench Slot is provided in each #1792

Yoke (see Photo previous page, lower right).

Engage Parking Brake by pulling up on Brake