For the professional user

Für den professionellen Anwender

Betriebsanleitung

Class:

Klasse:

Dated:

Stand:

VEB100-1 Ausf. 3

VEB100-2 Ausf. 3

VEB100-2W Ausf. 3

VEB100-4 Ausf. 1

VEB100-5 Ausf. 1

Operating Instructions

Spezialmaschinen GmbH

Im Zeichen der Qualität

ou nd the Strobel trademark on every Strobel

machine leaving our works. And with good reason.

This symbol is a guarantee of the high quality of

our products. Quality which creates trust – trust

in our technology, our service and, not least of all,

in our good name.

ie nden die Strobel-Schutzmarke auf jeder

Strobel-Maschine, die unser Werk verlässt.

Und das aus gutem Grund. Denn dieses Zeichen

garantiert Ihnen die hohe Qualität unserer

Produkte. Qualität, die Vertrauen schafft – in unsere

Technik, unseren Service und nicht zuletzt in unseren

guten Namen.

S

Y

The sign of quality

trobel clients know that they can expect a particularly

high standard of performance from our company and our

machines. Now you have settled for one of our products.

For us this is a source of encouragement and of obligation

to Justify your trust.

If you wish to prot from the performance and efciency of

your Strobel machine as long as possible, exact handling

and thorough care is necessary. For this reason we kindly

request that you read the operating instructions closely.

It provides all the information you need for trouble free

operation.

And if you do happen to need a spare part the enclosed

spare parts list gives a complete overview. It is clearly

classied according to components so that you can nd the

required part quickly and easily. In order to avoid errors we

request you to quote machine class, machine number and

part number completely on your spare part order.

We wish you lots of success in your work with your new

Strobel machine.

S

A decision with future

Spezialmaschinen GmbH

1 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

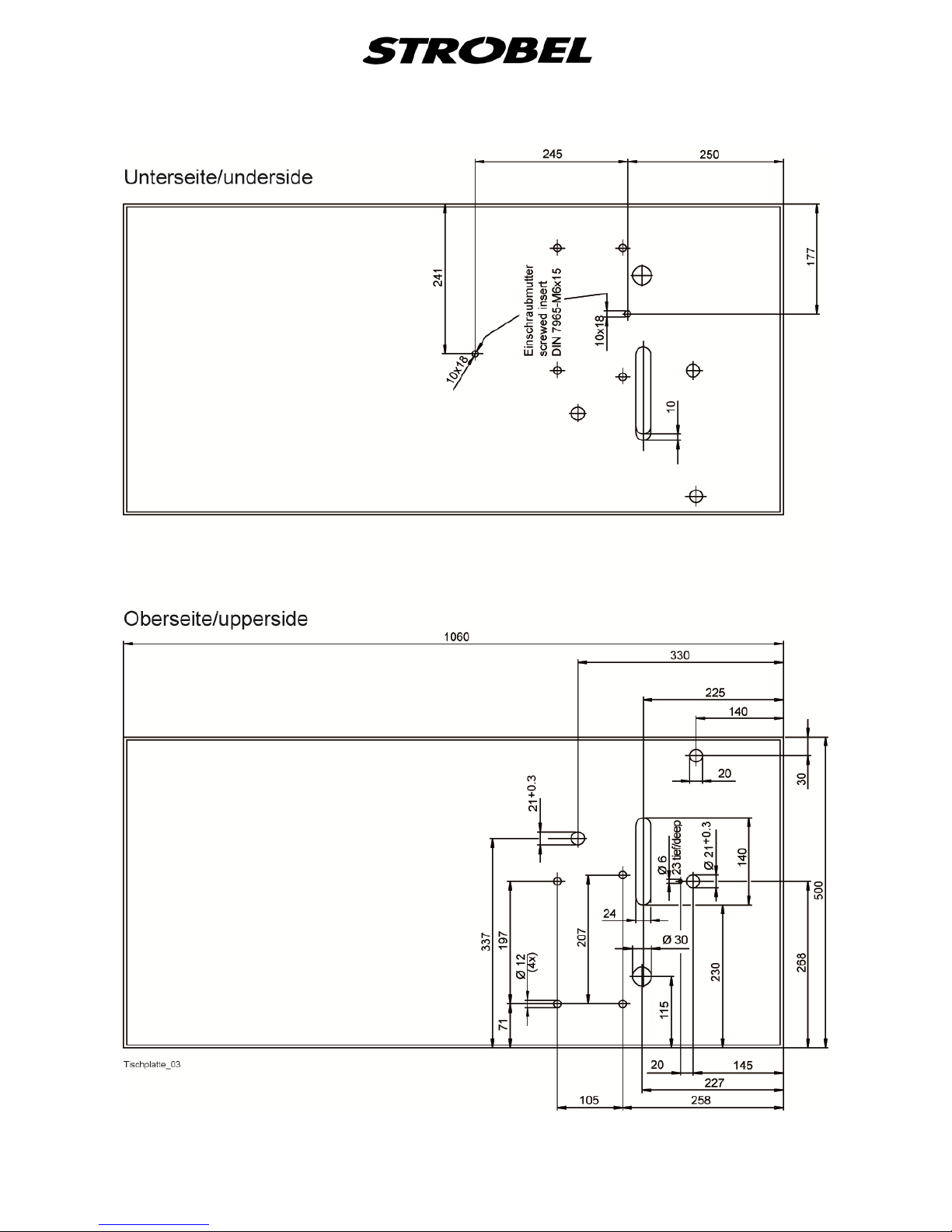

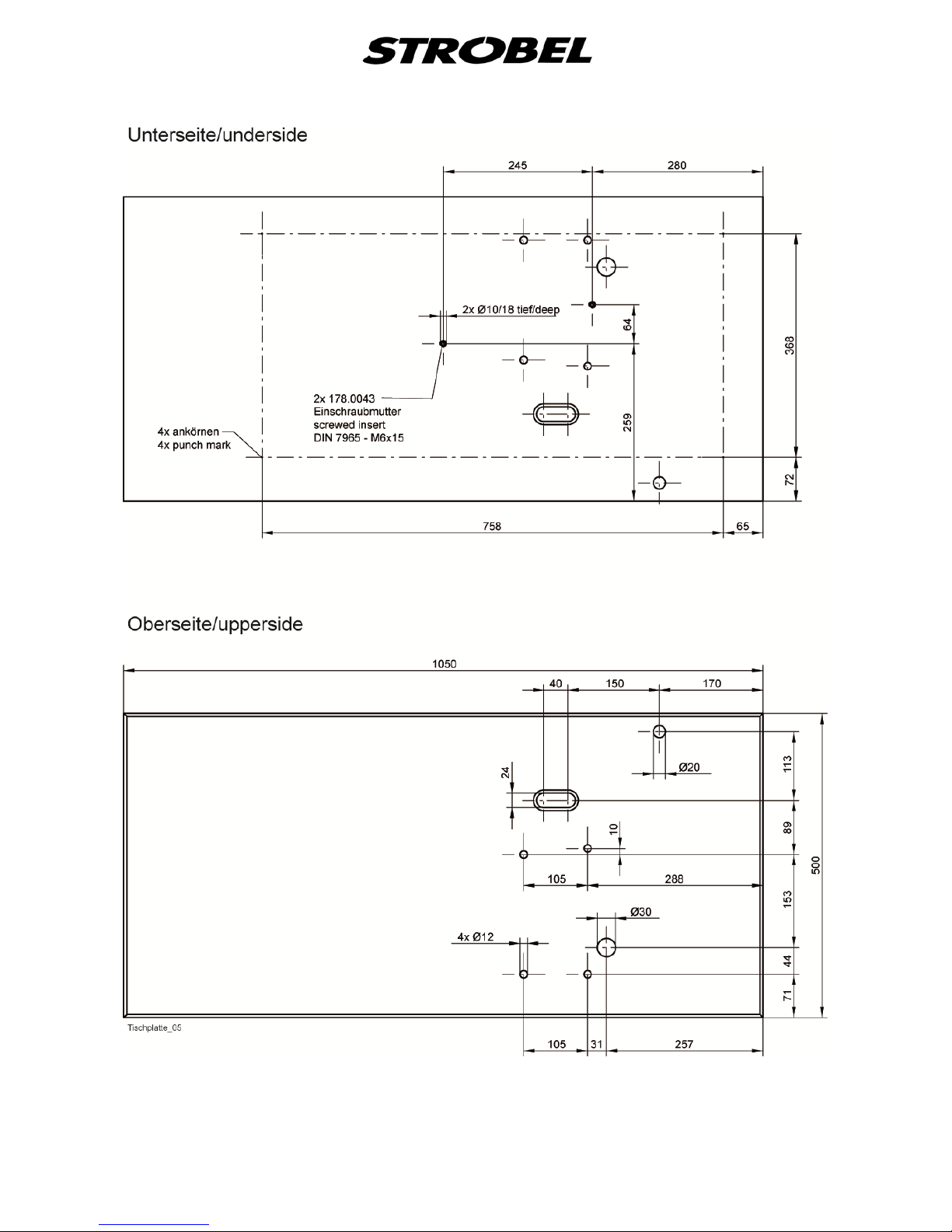

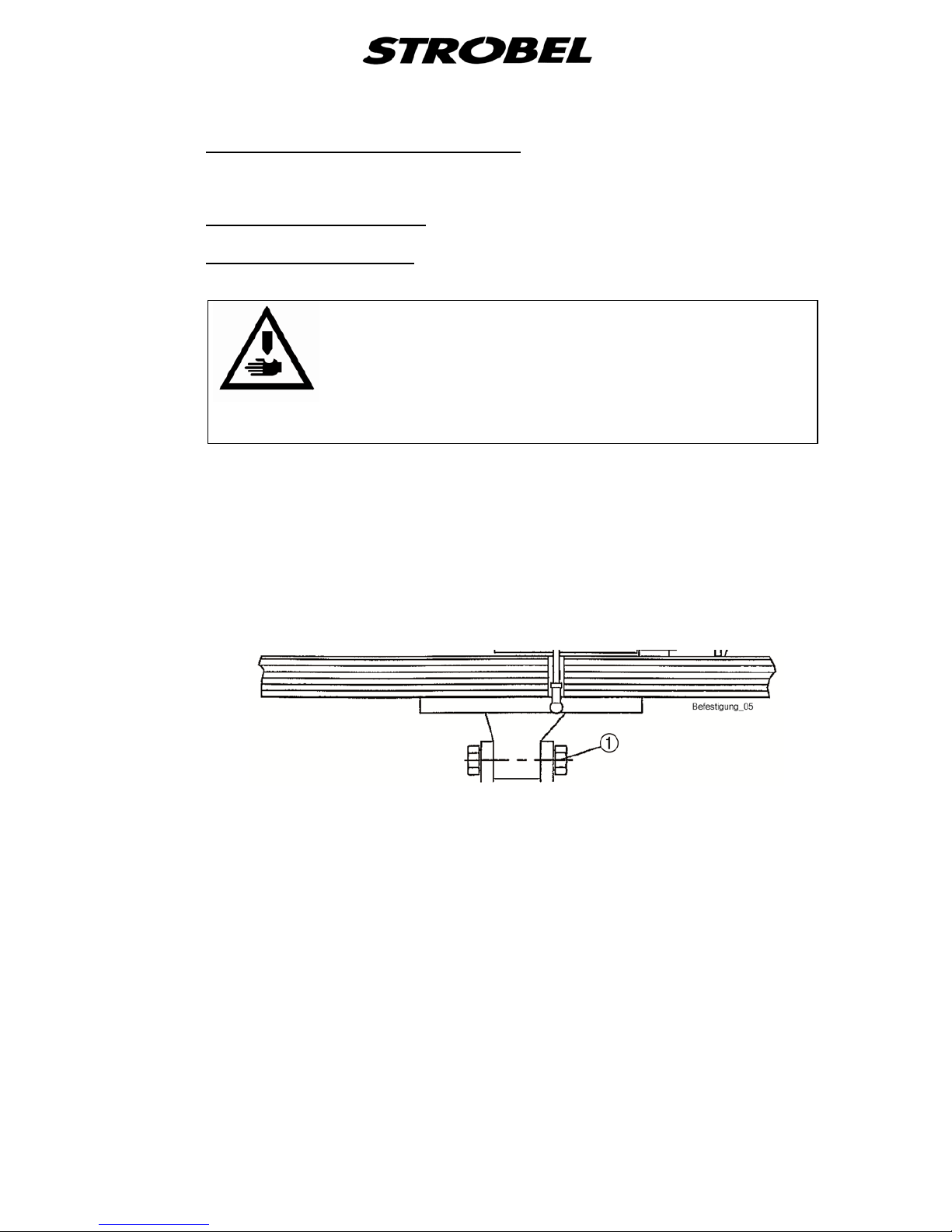

For under table assembly

2 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

3 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Operating instructions

VEB100-1, -2, -2W, -4, -5

Table of contents

1 General notes on safety .............................................................................................. 5

2 General notes .............................................................................................................. 7

2.1 Operating instructions ......................................................................................... 7

2.2 Class designations, machine number and initial basis f or descri pti o n s ............... 7

2.3 Applications of the machine ................................................................................ 7

2.4 Technical data of machine .................................................................................. 8

3 Setup and installation .................................................................................................. 9

3.1 Unpacking the machine ...................................................................................... 9

3.2 Setting up the machine ....................................................................................... 9

3.3 Direction of rotation on machine ....................................................................... 11

3.4 Motor drive via V-belts ...................................................................................... 11

3.4.1 Tensioning the V-belt ............................................................................. 11

3.4.2 Positions of the machine ........................................................................ 12

3.5 Motor drive using tooth belts ............................................................................. 15

3.5.1 Tension of toothed belt (Fig. 5) ............................................................... 15

3.5.2 Machine positions ................................................................................... 16

4 Notes on usage ......................................................................................................... 17

4.1 Needles and threads ......................................................................................... 17

4.2 Inserting the needles ......................................................................................... 17

4.3 Threading and thread insertion ......................................................................... 19

4.4 Thread tension .................................................................................................. 20

4.5 Thread take-up lever ......................................................................................... 20

4.6 Stitch depth control ........................................................................................... 20

4.6.1 Adjusting the stitch depth ...................................................................... 20

4.7 Cloth retainer (Fig. 9) ........................................................................................ 21

4.7.1 Setting the plunger limit stop for sewing over cross seams .................... 23

4.7.2 Setting the automatic plunger ................................................................. 23

4.7.3 Setting the cloth retainer Cl. VEB100-4 .................................................. 24

4.8 Sewing material transport ................................................................................. 25

4.8.1 Adjusting the stitch length....................................................................... 25

4.8.2 Adjusting the upper feed dog .................................................................. 25

4.9 Interval (Cl. VEB100-1, -2, -2W, -4) .................................................................. 26

4.9.1 Activate and adjusting the interval .......................................................... 26

4 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

4.10 Motor ................................................................................................................. 26

4.11 Seam lock (version RF)..................................................................................... 27

4.11.1 General................................................................................................... 27

4.11.2 Switching on the seam lock .................................................................... 27

4.11.3 Seam lock ............................................................................................... 27

4.11.4 Thread tension at seam lock .................................................................. 28

4.11.5 Feed dog at seam lock ........................................................................... 28

4.11.6 Plunger lowering at seam lock ................................................................ 28

4.11.7 Switching off the seam lock .................................................................... 28

5 Operating the machine .............................................................................................. 29

5.1 Switching on ...................................................................................................... 29

5.2 Placing and removing the fabric - sewing process ............................................ 29

5.3 Sewing .............................................................................................................. 30

5.3.1 Seams with blind stitches ....................................................................... 31

5.3.2 Sewing with folder .................................................................................. 32

5.3.2.1 Setting the folder ........................................................................ 33

5.3.2.2 Replacing the folder ................................................................... 35

5.3.2.3 Hemming with folder (Cl.VEB100-5) .......................................... 35

5.3.2.4 Seaming with roll seamer (Cl. VEB100-4) ................................. 36

5.3.3 Attaching the trouser waistband lining (Fig. 17) ...................................... 37

5.3.4 Attaching facings .................................................................................... 37

5.4 Sewing problems and troubleshooting .............................................................. 38

6 Servicing the machine ............................................................................................... 41

7 Variable sewing tools ................................................................................................ 41

8 Optional extras .......................................................................................................... 47

8.1 Thread trimmer ................................................................................................. 47

8.2 Hemmer ............................................................................................................ 47

8.3 Digital display 392.0637 .................................................................................... 47

8.4 Pneumatic lifting ................................................................................................ 47

8.5 Seam lock ......................................................................................................... 47

8.6 Compact drive ................................................................................................... 47

8.7 Stand set ........................................................................................................... 47

Subject to change without prior notice

5 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

1

Every person in charge of setting up, operating, servicing and repairing the

machine must first read and understand the operating instructions and

particularly the safety instructions before starting up the machine.

General notes on safety

Failure to comply with the following safety instructions can lead to bodily

injury or damage to the machine.

1. The machine must only be operated by persons familiar with the relevant

operating instructions and who have been instructed accordingly.

2. Before commissioning also read the notes on safety and the operating

instructions of the sewing drive manufacturer.

3. Only use the machine in the intended manner and never without the

provided guards. Always observe the pertinent safety regulations.

4. Switch off the main switch or pull the power plug for threading, changing

the reels, exchanging sewing tools such as needle, gripper, needle plate,

transport devices, possibly cutter and cutting block, for cleaning and when

leaving the workplace as well as for maintenance.

5. General maintenance tasks may be carried out only by properly trained

persons in accordance with the operating instructions.

6. Repair work, retrofitting and maintenance may be carried out only by

technicians or specially trained personnel.

7. When servicing or repairing pneumatic equipment, the machine must be

disconnected from the pneumatic supply. Exceptions are only allowed for

adjustment work and tests of functionality performed by specially trained

technicians.

8. Only specially qualified technicians may work on the electrical equipment.

9. It is forbidden to work on electrically live components! Exemptions are

covered by the EN50110 (DIN VDE0105) regulations.

10. Any retrofitting or alterations to the machine may only be performed under

strict compliance with all pertinent safety regulations.

11. Only use our approved spare parts when servicing and/or repairing the

machine.

12. It is forbidden to operate the sewing head until it is determined that the

entire sewing unit complies with EU provisions.

13. It is essential that you observe and follow these instructions as well as the

generally valid safety regulations.

6 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

14. Warning instructions given in the operating instructions that pertain to

especially dangerous parts of the machine must be indicated at these

positions using a safety symbol.

Warning instructions given in the operating instructions that pertain to

special injury hazards for operating personnel or technicians must be

indicated at these positions using a safety symbol.

7 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

2

2.1

General notes

Every person in charge of setting up, operating, servicing and repairing the

machine must first read and understand the operating instructions and

particularly the safety instructions before starting up the machine.

Operating instructions

2.2

The operating side of the machine is the initial basis for left/right descriptions.

Class designations, machi ne num ber a nd initial basis for

descriptions

The class designation (type) and machine/model numbers are fastened to the

rear of the machine case.

2.3

Class VEB100-1 are mainly suitable for blind stitching thin woven and knitted

fabrics.

Applications of the machine

Class VEB100-2 are universal hemming machines for thin and medium weight

material with cross seams.

Class VEB100-2W is suitable for attaching waistbands linings on trousers, also

for waistbands with already closed bel t l oops attached.

Class VEB100-4 serves specifically for uniform, delicate rolling and sewing of

the edges on skirts, dresses, blouses, silk scarves, pochettes, etc. made of

thinnest, thin and medium fabr i cs .

The roll seam width can be varied by exchanging the seamer size.

Class VEB100-5 is suitable for attaching the folded side back and centre back

seams of half-lined sack coats. 6 different folder sizes are available.

Exchanging the variable sewing tools, i.e., can extend the range of applications

of the different machines that other fabric qualities than the above mentioned

ones could be sewn as well.

Variable sewing tools please see point 7.

8 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

2.4

Recommended rated speed:

Technical data of machine

Cl. VEB100-2, -2W 2200 min-1

Cl. VEB100-1, -4, -5 1800 min-1

Machine pulley diameter DW 80 mm

Min. motor power 550 W

V-belt profile 10 x 6 mm

Toothed belt pulley/ma chine Z=38

Toothed belt profile HTD 5M-9

Stitch length Cl. VEB100-1,-2, -2W,-5 5–8 mm

(depend on fabric)

Cl. VEB100-4 2 - 5 mm

(depend on fabric)

Stitch type Single thread-chain stitch-blind stitch

Stitch type 103

Interval: Cl. VEB100-1,-2, -2W,-4 1:2 shiftable

Needle system GROZ-BECKERT 1669 EEO

Needle size Cl. VEB100-1, -2, -5 80

Cl. VEB100-2W 90

Cl. VEB100-4 70

Thread polyester continuous filament

Thread size Cl. VEB100-1, -2, -2W, -5 120/2

Cl. VEB100-4 200/2

Pneumatic connection 6 bar

Average air consumption depending on the equipement

Required space 0.5 m x 1.1 m

Noise:

Average noise level at a speed of

n = 1800 min-1 Cl. VEB100-1, -4, -5: LpAm 70 dB(A)

n = 2200 min-1 Cl. VEB100-2, -2W: LpAm 71 dB(A)

Noise test according to DIN 45635-48-1 KL3

9 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

3

3.1

Setup and installation

Strobel machines are supplied either as complete units with head, stand and

motor, or head with motor only, or the head only.

Unpacking the machine

Reel stand, rods and other accessories are packed into the packing.

Make sure that all accessories have been unpacked before throwing away any

packing material.

3.2

Setting up the machine

CAUTION! Danger of injury!

Entanglement hazard for clothing or hair and

Danger of finger injuries!

Never operate the machine without the belt guards for the

upper part and motor.

If the machine head is supplied without stand and motor first make the borings

into the table top as shown in the drawing. Mount rods and treadles and electric

connections according to the connecting diagram.

Mount the motor. Electric connection as per connecting diagram shown in the

motor's operating instructions.

The upper component must be fastened to the provided rubber plate on the

table top. The belt guard must be installed after inserting the V-belt.

Mount the V-belt and tense it according to “3.4.1 Tensioni ng the V-belt“.

Mount the belt guard.

Mount the lifting and motor operating rods.

Using a compact motor means to assemble the control box and speed controller

under the table. Also the operating rod between speed controller and pedal has

to be connected.

After assembling the single parts of the reel stand mount it to the right hand side

of the tabletop.

Make sure that all screws on the stand are tight and retighten them, if

necessary.

Mount the synchronizer and set it as described under “3.4.2 Positions of the

machine“.

10 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

CAUTION! Danger of injury!

Before starting the machine, check that the electrical

specifications given on the type plate of the motor,

particular grid voltage and frequency, are appropriate for

your electric system.

Any anti-rust substances, such as vaseline or similar, must be carefully

removed from the sewing tools before starting up the machine.

11 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

3.3

When facing the handwheel, turn it in a clockwise direction.

Direction of rotation on machi ne

3.4

3.4.1

Motor drive via V-belts

Tensioning the V-belt

Caution! Danger of injury!

When checking the belt tension, switch off the machine at

the mains. Do not operate the machine without the belt

guard. Otherwise there is a DANGER of crushing

fingers, of injuries to the body and of pulling in parts of

clothing.

The tensioning of the V-belt is carried out by swivelling the motor underneath

the table plate after releasing the retaining nut with SW 24, (1) in Fig. 1.

The V-belt must not be tensioned too much, especially with the stop motor. You

should be able to compress it with light thumb pressure by about 2 cm.

Too little V-belt tensioning can impair the positioning of the machine and

therefore impair the function sequence.

Fig. 1

12 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

3.4.2

Positions of the machine

Caution! Danger of injury!

Danger of crushing fingers and needle through stitching as

well as pulling in of parts of clothing.

Keep fingers and hands away from moving parts when

setting the position generator and checking the positions

with switched-on mach ine.

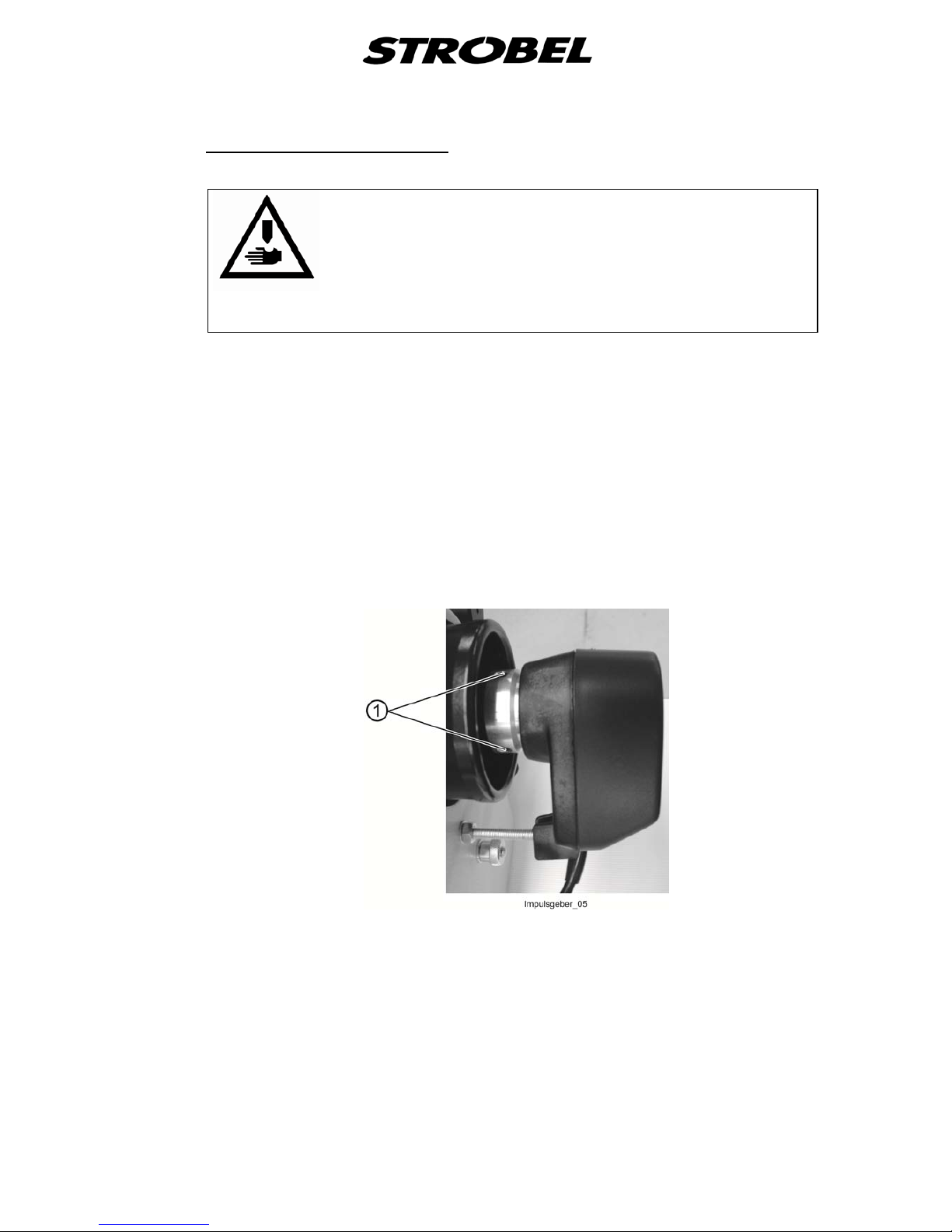

General:

Stop motors require a position generator, which takes the mechanical setting of

the machine from the main screw and transmits this to the control o f the mot or .

With this, for instance, the thread cutter can always be electrically approached

in exactly the same needle looper position. (Fig. 2)

The correct position of the position generator to the flange is marked with a spot

of paint.

To adjust or to remove, release the two clamping screws (1), Fig. 2 tighten

these firmly prior to commissioning.

Fig. 2

With positioning wi th plunger reset, the motor reverses after thread cutting for a

certain value, to facilitate the insertion of the sewing matter. This does not affect

the setting of the position generator.

13 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Machine with or without thread cutter:

The machine requires a needle position and, depending on the sewing drive,

possibly also a reference position.

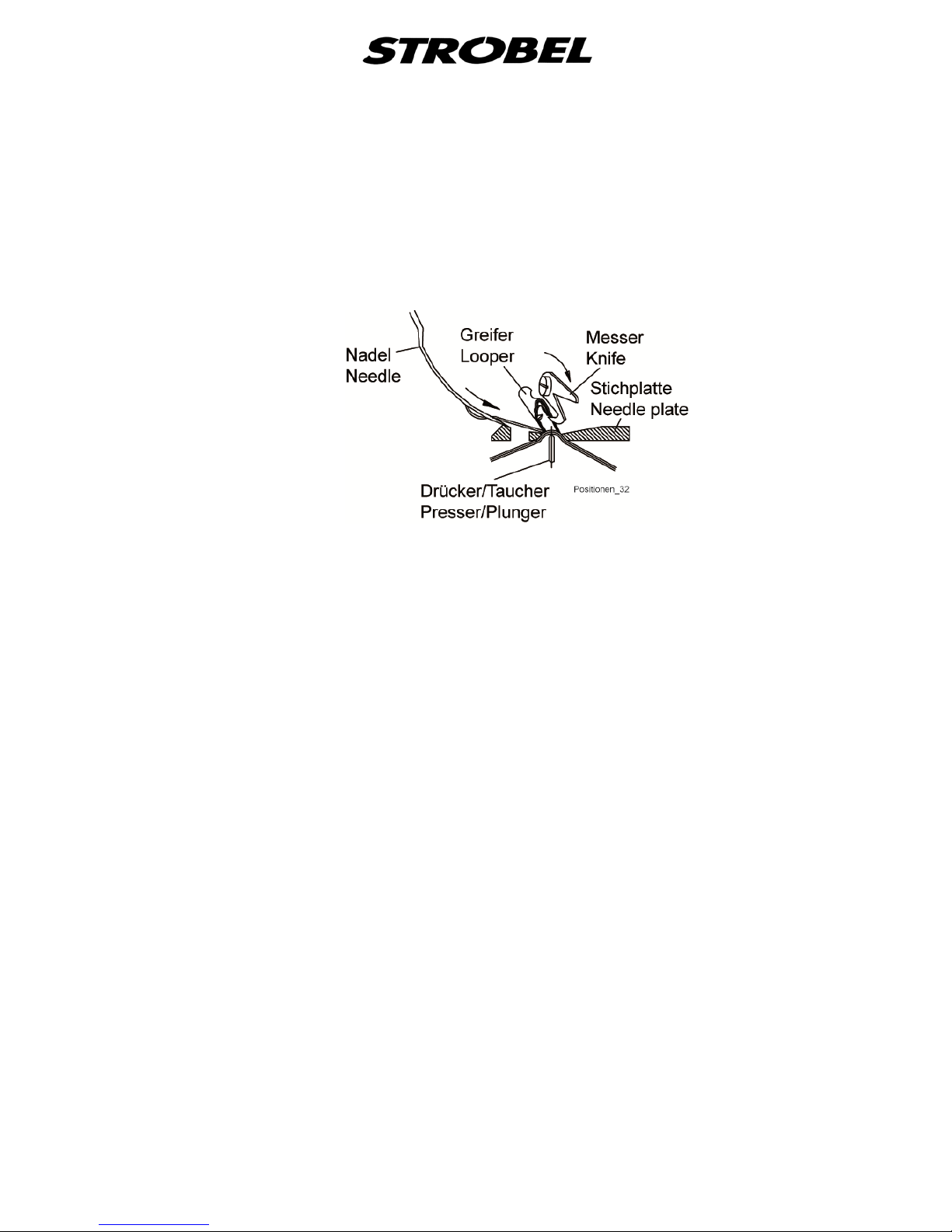

Reference position (Fig. 3):

The reference position must be set in such a way, that the point of the

needle in the direction of the insertion stitch closes with the right (inner)

edge of the needle slide plate.

Fig. 3

14 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Needle position (when stopped within and outside of the stitch (Fig. 4))

(when using a thread trimmer):

Adjust the needle position so that when the machine is switched off, the

hook of the thread blade can reliably catch the thread loop above the

looper without touching it.

In conclusion, check this by manually actuating the thread trimmer.

Fig. 4

Notes for sewing drives with more than needle positions:

The needle position given above is suitable for sewing at position 2.

It is very important to set position 1 in accordance with the operating

instructions pertaining to the chosen mode of sewing.

15 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

3.5

3.5.1

Motor drive using tooth belts

Tension of toothed belt (Fig. 5 )

CAUTION! Danger of injury!

Switch off the machine at the mains when checking the

belt tension. Do not operate the mac hi ne w it hout bel t

guard. Otherwise DANGER of crushing fingers, of injuries

to the body or of pulling in of part of clothing.

The toothed belt should not be tensioned too much. You should be able to push

through it with light thumb pressure by about 5 mm.

Too little or too tight toothed belt tensioning can impair the positioning of the

machine and therefore impair the function sequence.

Tensioning the toothed belt (Fig. 5):

- Release the upper and the bottom retaining screw (1), (2) at the upper part

of the machine.

- Pull out the motor slightly and tighten the bottom retaining screw (2)

slightly.

- Tension the toothed belt by swivelling the motor.

- Tighten the upper and the bottom retaining screw (1), (2) again.

Fig. 5

16 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

3.5.2

Machine positions

CAUTION! Danger of injury!

Entanglement hazard for clothing or hair and danger of

finger injuries and needle punctures! When checking the

positions while the machine is turned on, keep your

fingers and hands away from moving parts.

Machine with or without thread trimmer:

The machine requires a needle position and depending on the sewing drive,

possibly also a reference position.

Reference position:

The reference position must be set in such a way, that the point of the

needle in direction of the insertion stitch closes with the right (inner) edge

of the needle slide plate.

Needle position (with stop in and outside the seam (Fig. 4)):

The needle position must be set in such a way, that when the machine is

stopped, the hook of the thread knife catches the thread loop lying over

the looper securely without touching the looper.

Notes for sewing drives which have two needle positions:

The above mentioned needle position is position 2 at the sewing drive.

It is essential that position 1 is set with consultation of the operating

instructions of the sewing drive

Needle position (when stopped within the stitch):

The needle position must be set so that the tip of the needle closes

against the right edge of the needle slide plate facing towards the outward

stitch.

At the same time, the thread loop lies under tension across the looper.

The needle position is position 1 at the sewing drive.

Fig. 6

17 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

4

4.1

Notes on usage

The sewing quality can be improved by using the most appropriate needles and

threads for the goods to be produced.

Needles and threads

Only use approved GROZ-BECKERT needle system 1669 EEO.

The machine is delivered with needles of size 70 (VEB100-4),

80 (VEB100-1, -2, -5) and 90 (VEB100-2W).

Note: An intact needle is very important for ensuring good quality stitches.

Bent needle tips, that may only be visible under a magnifying glass,

will lead to poorer sewing results. Replace your needles in time!

We recommend using tw ined polyester tread of thickness 120 /2

(VEB100-1, -2, -2W, -5) and 200 (VEB100-4). Due to their high strength and

good sliding behaviour at a small thread size, they are preferable to spun thread.

Guarantee note!

This machine has been configur e d and br ok e n in usi ng

original GROZ-BECKERT needles.

No guarantees can be given when the machine is

readjusted for the use of different needles.

4.2

Inserting the needles

CAUTION! Danger of injury!

Before replacing needles, switch off the machine and

push down the motor switch pedal to ensure that the

machine is truly switched off.

Otherwise there is a danger of finger injur i es and nee dl e

punctures.

The bent shape of the needles determines the position of the needle lever. Only

ensure that the needle shank can be pushed into the groove of the needle lever

until it stops and the needle clamping plate is tightly fastened using the screw

((for pos 4) Fig. 7).

18 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Fig. 7

19 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

4.3

Threading and thread inser t ion

CAUTION! Danger of injury!

Before threading, switch off the machine and push down

the motor switch pedal to ensure that the machine is truly

switched off.

Fig. 8 indicates the correct threading using the thread take-up device

Fig. 8

20 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

4.4

Depending on the quality, configuration and thickness of the thread as well as

the sewing material, the thread tension is set using the knurled nut

Thread tension

((2) Fig. 7)

until the desired seam shape is created (Fig. 11).

4.5

The thread take-up lever

Thread take-up lever

(8) shown in Fig. 7 prevents the thread from twisting

and the loop from collapsing. It also ensures that the loop is properly caught by

the looper and needle.

The seam shape becomes homogeneous and the edge of the hem free of

tension.

The behaviour of the thread take-up lever is affected by the thread mov em ent

(choice of eye) and thread tension.

4.6

The stitch depth controller makes it possible to adjust the distance between

the upper edge of the plunger and the needle radius so that the plunger is lifted

or lowered, depending on the thickness of the material to be sewed. This

determines how deep the needle can penetrate into the layer of material

between the plunger and cloth retainer. This value is referred to as the stitch

depth.

Stitch depth control

4.6.1

The stitch depth is set using the control button

Adjusting the stitch depth

((5) Fig. 7) and is located on the

front side of the machine.

Turn the control button to the left (+) to create a deeper stitch.

T urn the control button to the right (-) to create less stitch depth.

21 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

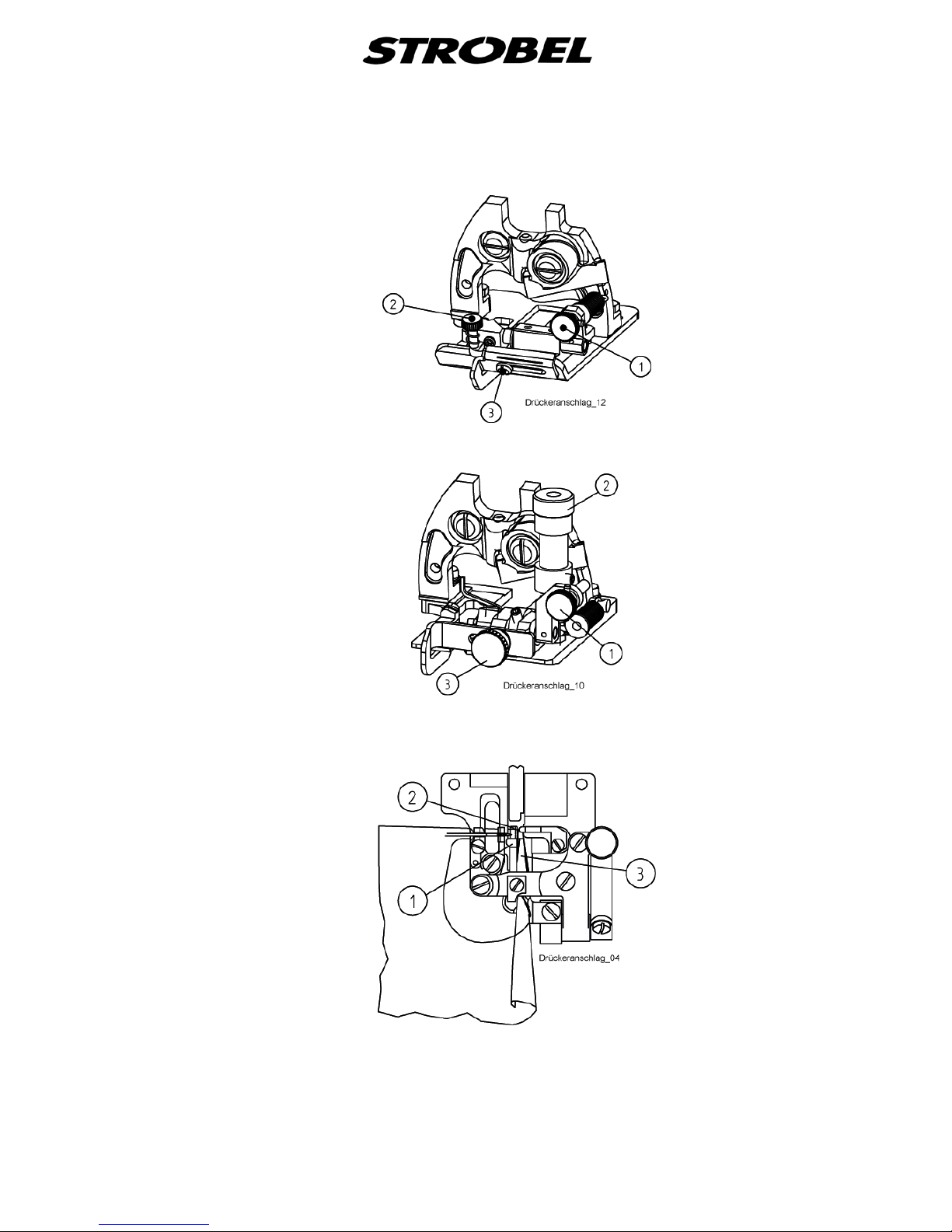

4.7 Cloth retainer (Fig. 9)

CAUTION! Danger of injury!

When making adjustments in the needle plate area, there

is an injury hazard for fingers due to accidental actuation

of the pedal s!

The needle plate is equipped with a cloth retainer. This retainer holds the

sewing material against the plunger to allow needles to insert stitches.

The cloth retainer must be set so that the sewing material cannot move as the

needle inserts stitches.

The correct positioning is important for the quality of the stitch! The pressure

of the cloth retainer against the layers of material or seam edge can be varied

by turning the screw ((1) Fig. 9a and Fig. 9b). This should be kept as small as

possible

to prevent the material from developing tension or becoming marked by the

pressure between the plunger and cloth retainer. This is particularly important

with delicate materials such as velvet.

However, the pressure must still be sufficient to ensure that the sewing material

cannot move during the needle insertion.

The cloth retainer in machines equipped with a spring-loaded plunger is

combined with an adjusting screw which limits the cloth retainer's upwards

stroke. This combination is called plunger limit stop. Plunger limit stop and the

spring-loaded plunger prevent the needle from stitching through the material

over cross seams and other thicker parts and avoid markings.

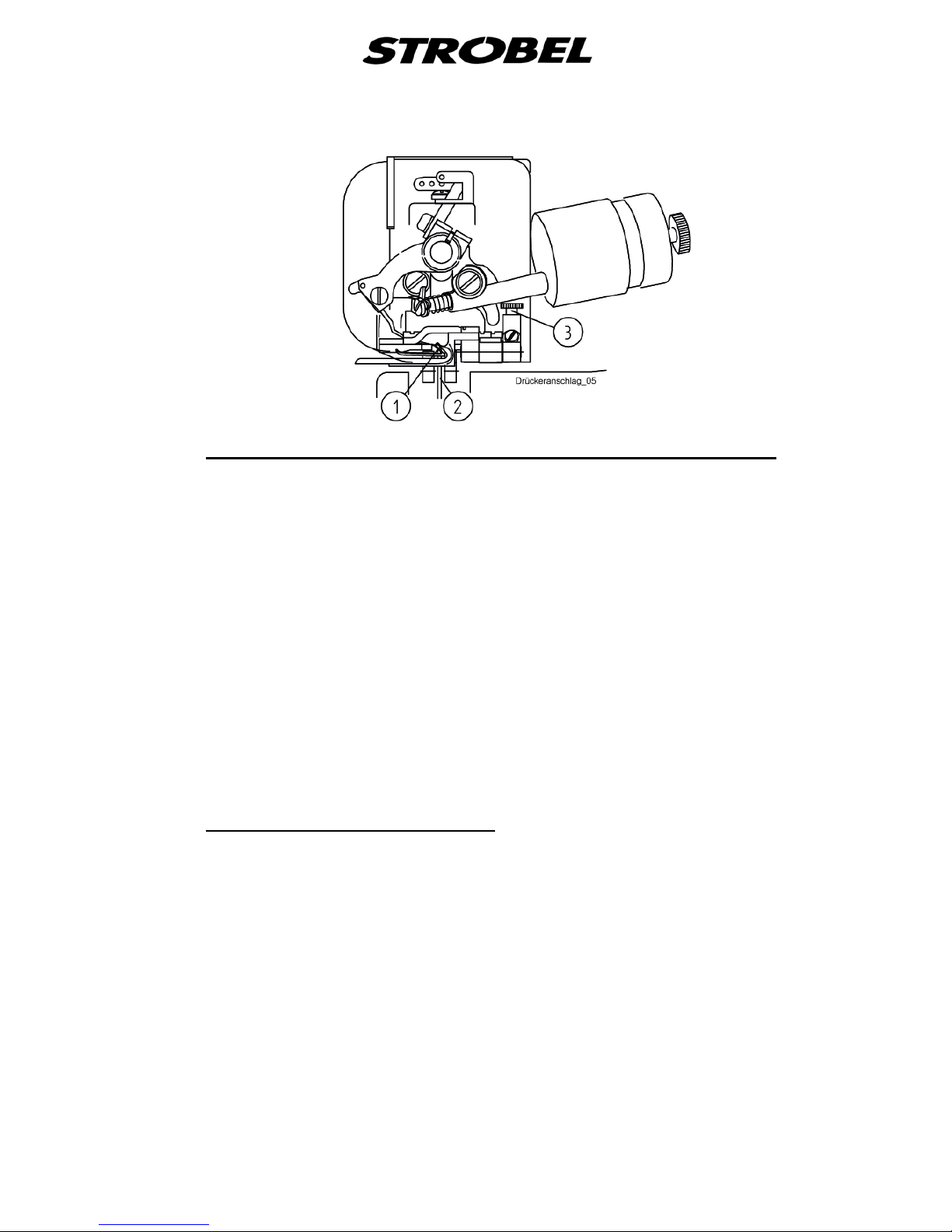

The Cl.VEB100-5 (Fig. 9d) has no real cloth retainer. During the time of ne edle

penetration the material is hold between folder (1) and plunger (2).

The pressure of the folder on the fabric layers should be as low as possible to

avoid any twist or marks.

This is of main importance for delicate fabrics such as e.g. velvet.

Adjustment by turning knur l ed nut (3), depending on the set stitch depth.

The folder should be set in a way that the fabric cannot move during needle

penetration.

This setting is of great importance with regard to the sewing quality!

Correct folder setting please see “5.3.2 Sewing with folder“.

22 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Fig. 9

a Cl. VEB100-1, -2

b Cl. VEB100-2W

c Cl. VEB100-4

23 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

d Cl. VEB100-5

4.7.1

The cloth retainer stroke is set by means of a knurled nut (2)

Setting the plunger limit stop for sewing over cross seam s

Fig. 9a and

Fig. 9b, which serves as upper limit stop. To set the stroke place the material (a

normal fabric layer without cross seam). Close the cloth support arm and turn

the hand wheel manually until the needle penetrates the fabric. In this position

there should be nearly no space between cloth retainer and fabric layer. If the

setting is correct the automatic plunger should be compensating the over cross

seams, so that the needle does not penetrate the outer layer.

The pressure of the cloth retainer on the fabric layers or the hem edge can be

adjusted through turning the knurled nut (1) Fig. 9a and Fig. 9b. The pressure

should be as low as possible to avoid twist or marks resulting from the pressure

between plunger and cloth retainer, mainly when sewing delicate fabrics as e.g.

velvet. However, the pressure should be high enough to keep the material

between plunger and cloth retainer during the time of needle penetration.

The setting of the plunger limit stop has a considerable influence on the stitch

quality.

4.7.2

The spring pressure of the automatic plunger is set at works and usually needs

not to be altered. If the plunger limit stop is set correctly over cross seams the

needle should not penetrate the outer fabric layers.

Setting the automatic plunger

For plunger settings please refer to the mechanic's instructions.

24 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

4.7.3

The Cl. VEB100-4 is equipped with an additional cloth retainer made of a spring

plate (1),

Setting the cloth retaine r Cl. VEB100-4

Fig. 9c, that holds the sewing material firm on the one-sided bevelled

plunger (2) with the roll seam nozzle (3) for the piercing of the needle (Fig. 9c).

The pressure of the cloth retainer on the sewing material is specified by the

shape of the cloth retainer plate.

The cloth retainer is screwed fast to the needle plate and needs to be set so

that the sewing material cannot be shifted while the needle pierces.

The correct setting has a significant influence on the quality of the stitch.

For correct setting of the seamer, refer to point “5.3.2 Sewing with folder".

25 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

4.8

The machine transports the sewing material using a rigid upper transport. The

feed (stitch length) can be set from 5-8 mm (corresponds to 2-5 mm with the Cl.

VEB100-4) in 4 steps. Serially, a pyramid-toothed (saw-toothed for C l . VEB100-

4) feed dog is mounted, which can be exchanged for a saw-t oothe d one

(pyramid-toothed) if necessary. (see point „

Sewing material transport

7 Variable sewing tools“).

4.8.1 Adjusting t he s t itch length

CAUTION!

Switch off the machine and push down the motor switch

pedal to ensure that the machine is truly switched off.

Press the stitch setting knob ((1) Fig. 9) and turn the handwheel until it simply

snaps into place. The config ur ed stit c h le ng t h corr esp onds to the number

engraved in the handwheel as it comes to a standstill in the highest position.

Press down the setting knob and move the handwheel forw ar ds until the

desired stitch length noticeably snaps into place.

4.8.2

The feed dog can be adjusted in its intrusion depth to the needle plate by

loosening the two fastening screws. If the stitch length is adjusted across a

greater range e.g., from 8 to 5 (from 5 to 2 on Cl. VEB100-4), then the feed dog

should be readjusted.

Adjusting the upper feed dog

Adjustments might also be required when changing to sewing materials that are

thicker or otherwise different in quality.

Here, observe the instructions giv en in the me chani c' s manual .

26 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

4.9

The machine is equipped with a shiftable interval 1:2.

Interval (Cl. VEB100-1, -2, -2W, -4)

The interval principle is based on recurrent lowering of the plunger to an exactly

configured value (interval stitch depth).

When switched on, the outer layer of material is only stitched every second time.

This usually makes it possible to create a marking-free, elastic seam in

materials that are difficult to sew.

4.9.1

The interval stroke (= lowering of plunger) defines the stitch depth during the

“interval stitch”.

Activate and a djusting the interval

To switch on the interval for a correctly configured stitch depth, screw in the

control knob ((6) Fig. 7) until the required interval stroke is achieved.

More stroke means a less stitch depth and vice versa.

4.10

General:

Motor

A stop motor (DC 1200) is available for driving the sewing machine.

A needle positioning motor is needed for an exact machine positioning and to

operate the electromec hanic al thr ea d tri m mer and pne umatic lifting.

Please observe the operating instructions of the sewing drive supplied with the

machine where you will find instructions to program the control and the motor

speed.

27 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

4.11

4.11.1

Seam lock (version RF)

The classes VEB100-1, -2 and -2W can be equipped with seam lock and than

they are named: VEB100-2RF.

General

4.11.2

The parameter F-10 m ust be set from 0 to 1.

Switching on the seam lock

CAUTION!

Under no circumstances may the LED 4 light up during sewing operation.

4.11.3

The "simple" backtack sequence is used for technical control in these machine

classes.

Seam lock

Sequence:

The seam lock is made at the seam end by lifting the feed dog.

1. After sewing pedal in position 0, the machine stops in position 1. (Fig. 10)

2. Pedal into position 2 means the second thread tension close, the plunger

drops down and the feed dog lifts up.

3. The machine makes the seam lock stitches with slow speed (normally 3

stitches) and stops in position 1. The second thread tension, the plunger

lift and the feed dog lift switch off now.

4. The machine turns to position 2 and cuts the thread.

28 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

4.11.4

The additional thread tension should pull close the loop of the seam lock when

switched on.

During normal sewing it is lifted by a pneumatic cylinder and is out of operation.

Thread tension at seam lock

4.11.5

The feed dog is lifted up by a pneumatic cylinder at the seam lock. It now glides

gently over the sewing material during the transport movement without

transporting it further.

Feed dog at seam lock

4.11.6

The lowering of the plunger at the seam lock prevents a punctuation of the outer

fabric.

By turning the knurled screw at the pneumatic cylinders under the table top the

height of the lowering can be changed.

Plunger lowering at seam lock

Turn to right - : Lowering is increased

Thick sewing material Stitch depth becomes less

Turn to left + : Lowering is reduced

Thin sewing material Stitch depth becomes greater

4.11.7

The parameter F-10 m ust be set from 1 to 0.

Switching off the seam lock

29 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

5

It is recommended to equip the machine with a pneumatic lifting device to

facilitate machine handling (please see “

Operating the machine

8.4 Pneumatic lifting”).

ATTENTION!

Please observe the sewing area carefully during sewing.

Otherwise danger of finger bruises and needle through

stitches.

5.1

Connect the compressed-air conditioner to the compressed air supplier (max.

10 bar) or to the compressor and set it to 6 bars. Switch on main switch on the

right hand side under the table top, control lamp in the "OFF" switch lights red.

On machines with pneumatic lifting now the material support arm is open, the

machine is ready to sew.

Switching on

5.2

a) treadl e lifting

Placing and removing the fabric - sewing process

By pressing the left hand treadle the cloth support arm is lifted.

Place material under the needle plate and leave the left hand treadle. The

machine starts sewing by operating the right hand treadle.

The machine runs at maximum speed when the right hand treadle is

completely pressed down (please see “4.10 Motor“).

b) pneumatic lifting (optional extra)

Fig. 10 shows the treadle's switching functions when the machine is

equipped with pneumatic lifting. Place the fabric under the needle plate

while the cloth support arm is lifted and close the arm by slightly pressing

the treadle (+1).

The machine is now ready to sew.

If the fabric is not placed correctly, the cloth support arm can be lifted

again by heeling the treadle back into its initial position. At the end of the

sewing process the thread trimmer (optional extra) is operated and the

cloth support arm is lifted by heeling the treadle (-1).

30 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Fig. 10

5.3

The machines of the VEB100 series are mainly designed for blind stitch

hemming. The special applications of the corresponding subclasses are

described under “

Sewing

2.3 Applications of the machine”.

The sewing result should be an elastic seam free of marks. Depending on fabric

quality the sewing requires a certain skill. The following instructions will help the

operator to obtain this skill.

31 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

5.3.1

In situations where no previous experience has been gathered, use sequence

as below:

Seams with blind stitches

1. Set the desired stitch length. Fig. 11 displays the corresponding seam

shape for the required stitch length.

2. Set the stitch depth.

3. Check the cloth retainer pressure and adjust it if necessary.

4. Adjust the plunger stop.

5. Adjust the material guide as desired. To do this, loosen the screw (3)

Fig. 9 and move the material guide to find the limit for the edge of the

seam.

Sewing can be performed along the edge or directly on the hem. For more,

see Fig. 12

6. Cl.VEB100-4, -5 check the folder setting and adjust it, if necessary.

7. Check the stitch length; if necessary readjust the feed dog.

8. Adjust the thread tension. As a rule, the seam should be loosely on the

seam.

9. If desired, switch on the interval and set the interval stroke according to

the required thickness of sewing material.

10. To correct the seam shape, thread in at a different spot if necessary.

To place in the sewing material and ensure that the start of the seam can be

caught by the feed dog a fter the first stitch.

Press the pedal briefly. Sew the part and, if required, changes the previous

settings until the desired sewing results are achieved. When stitching through

the outer material, readjust the stitch depth control.

On extremely thin or hard sewing material, it may not be entirely possible to

prevent “markings” caused by the penetration of needles into the outer material

(filament displacement).

When sewing, ensure that the edge of the seam always runs along the material

guide. Avoid sudden actuation of the pedal since the speed changes can have

a negative effect on stitching during the sewing process.

32 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Fig. 11

Fig. 12

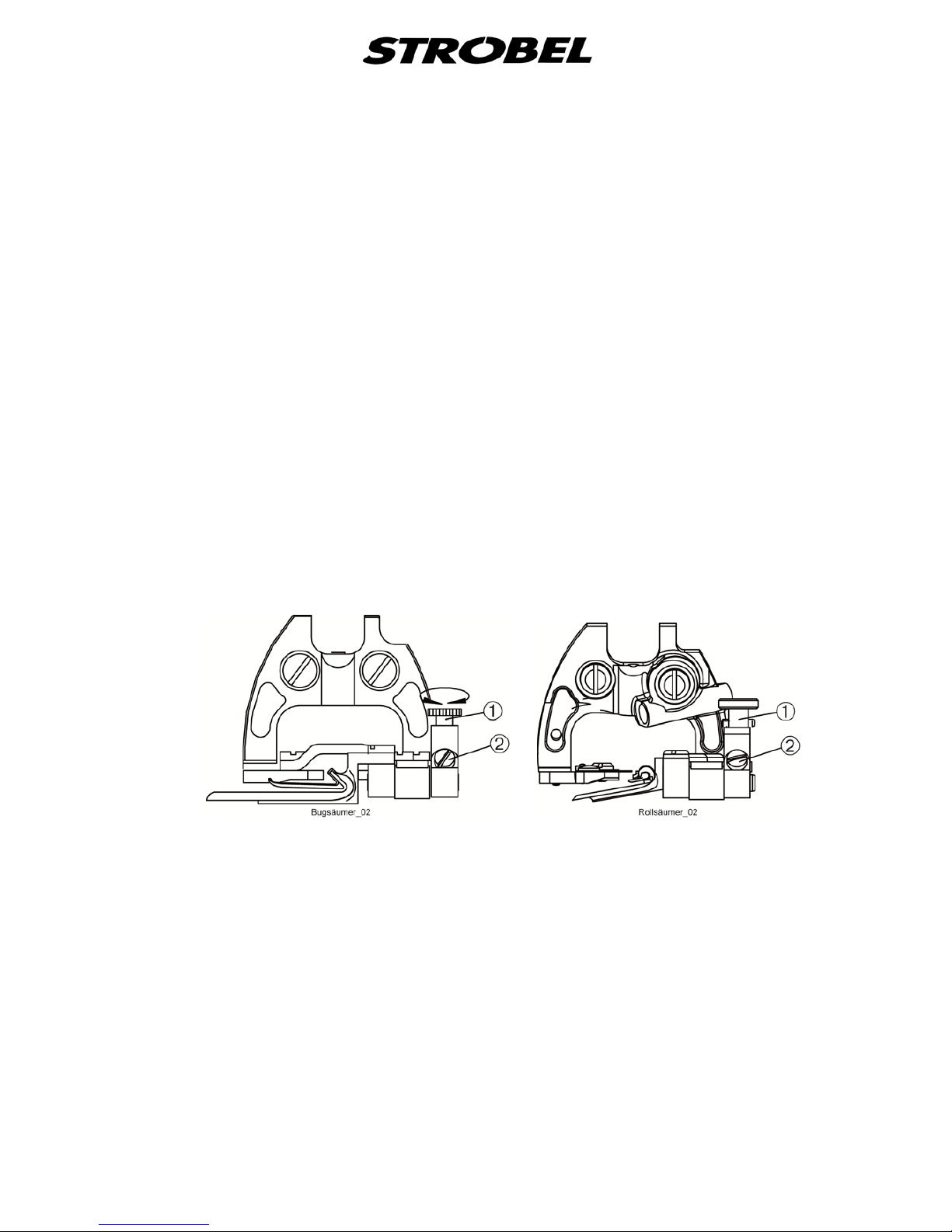

5.3.2

Folder (Cl.VEB100-5)

Sewing with folder

The machine is equipped with a special combination of needle plate and folder

to provide side and back parts of sack coats with a uniform book seam.

Folders with a width of 6, 8 and 10 mm (finished hem width after pressing) are

available.

The standard machine is equipped with folder 286.0364, size 6x1 for thin to

medium material.

Roll seamer (Cl. VEB100-4)

The needle plate is equipped with a special material guide (roll seamer) that

"rolls in" the sewing material at the edge during the running into the needle plate.

The roll seamers No. 0, 1, 2, roll diameter are available for thin medium, thick

material and and the Special roll hemmer for sewing curves.

Serially, the standard roll seamer 286.0428, size 1, has been mounted and set

for medium sewing material.

33 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

5.3.2.1

Folder (Cl.VEB100-5)

Setting the folder

To re-adjust the folder, the angle of inclination can be adapted to the fabric

thickness by means of knurled screw (1) (Fig. 13a and Fig. 14a). The folder

should be placed downwards until one fabric layer is nearly jammed between

the lower side of the folder and the plunger (Fig. 13).

The folder can be set horizontally after loosening screw (4) (Fig. 14a). This

adjustment becomes necessary when a folder is replaced by another one or if

the seam appearance has to be modified.

According to the adjustment the seam can either be placed on the hem edge

(Fig. 15a) or under the hem edge (Fig. 15b).

Being the thread tension set correctly the overseam should be half as wide as

the hem (Fig. 15c).

After re-adjustment of the horizontal folder setting the inclination angle of the

folder has also to be re-adjusted as described above.

If a fine adjustment by means of the knurled screw is not possible any more, a

coarse setting after loosening screw (2) (Fig. 14a) is necessary. Then the shaft

has to be clamped again without any lateral play. If necessary, after releasing

three screws (3) (Fig. 14a) the complete bench with folder can be slightly

displaced on the needle plate.

34 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Roll seamer (Cl. VEB100-4)

Using the knurled screw (1) (Fig. 13b and Fig. 14b), the tilt angle of the roll

seamer towards the plunger can be set.

This influences the seam diagram (zigzag stitch). The needle can pierce the roll

more or less deeply.

This setting is the most important control together with the stitch depth

regulation during roll seaming.

The horizontal setting is done after loosening the screw (4) Fig. 14b. This is

necessary when the seamer is exchanged for a different one, or if the seam

diagram should be changed.

If the horizontal setting of the seamer was changed, the seamer tilt angle needs

to be corrected again afterwards as described above.

If the range for the knurled screw is exhausted, then the rough setting can be

redone after loosening the screw (2) (Fig. 13b and Fig. 14b. Afterwards, the

axle needs to be clamped again without lateral play. If necessary, the entire

bearing block with seamer can be slightly adjusted on the needle plate after

loosening the 3 screws (3) Fig. 14b.

Fig. 13

a b

Cl. VEB100-5 Cl. VEB100-4

35 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Fig. 14

a b

Cl. VEB100-5 Cl. VEB100-4

Fig. 15

a b c

5.3.2.2

Loosen screw (4) (

Replacing the folder

Fig. 14), mount and tighten the new folder.

Realise settings as described in “5.3.2.1 Setti ng the folder “.

5.3.2.3

When the material support arm is lifted place the material from the left side and

push the folded corner under the feed dog ' s front edge. The machine should be

switched on and should have positioned at least one time (stop motor). The

seam starts approx. 1 stitch length behind the fabric edge. When using the

standard 6 mm folder a stitch length of 7 mm is recommended.

Hemming with folder (Cl.VEB100-5)

During the hemming operation the hem edge should always run along the upper

folder edge. As a guide serves opening (5) in (Fig. 14).

36 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

5.3.2.4

The machine should be switch on and have positioned at least once (stop

motor).

Seaming with roll seamer (Cl. VEB100-4)

The sewing material is inserted into the roll seamer from the left side whilst the

material support arm is lifted. Pull the material diagonally forwards to under the

feed dog. A rolling should be done thereby manually in the roll seam nozzle.

Pull back the sewing material so that the feed dog can catch it. Close the

material support arm. The beginning of the stitch is then about 1 stitch length

behind the edge of the material.

During the sewing, the seam edge needs to be guided by hand evenly along the

seamer infeed (3) Fig. 14b.

Of advantage is to turn the material counter-clockwise (Fig. 16) during the

sewing.

Fig. 16

37 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

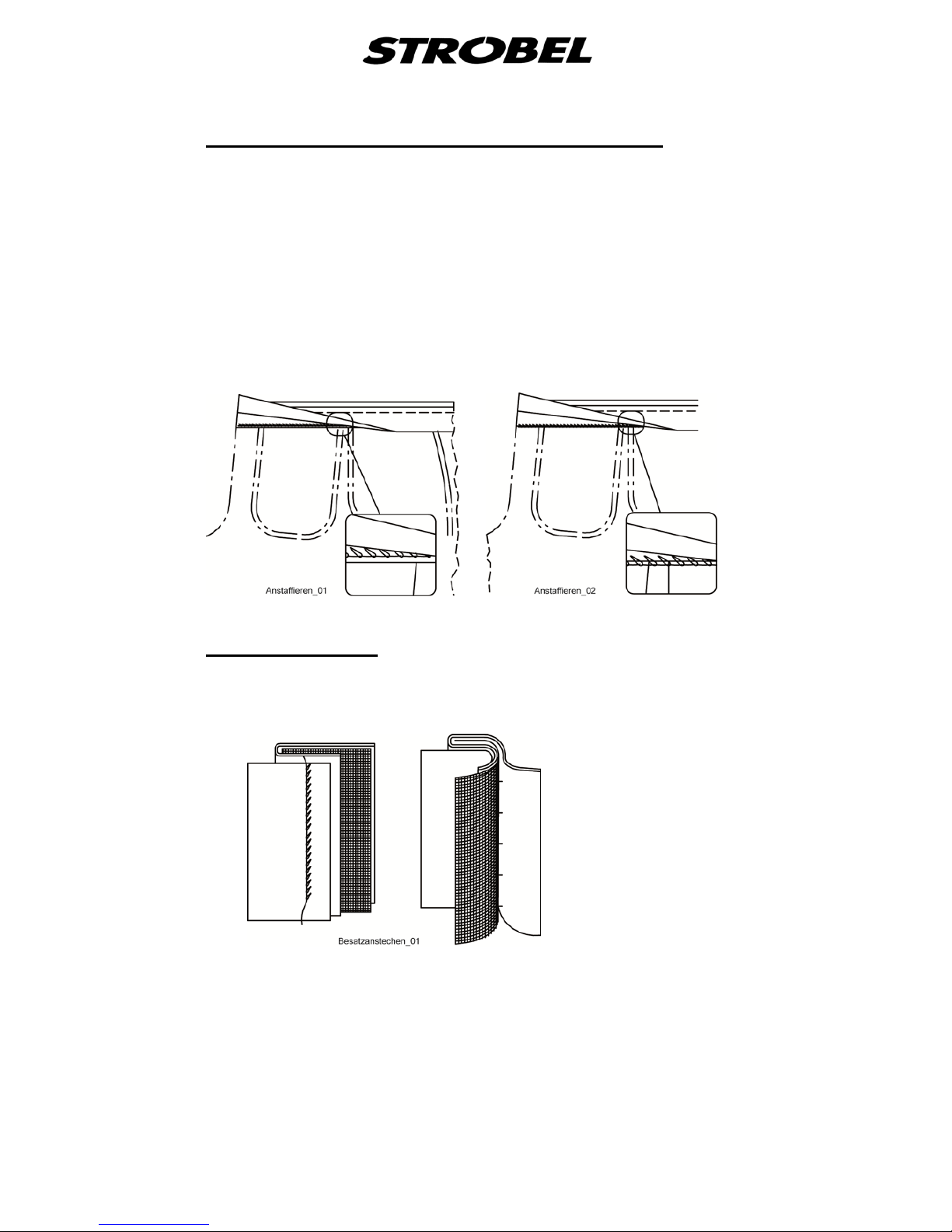

5.3.3

For this operation a needle plate with wide opening is recommended since

usually different fabric layers have to be sewn.

Attaching the trouser waistband lining (Fig. 17)

Recommended needle sizes: 80, 90

There are two different types of operations (Fig. 17a and Fig. 17b):

a) sewing the waistband on the lining

b) sewing the waistband on the edg e

Fig. 17

a b

5.3.4

This operation is shown in

Attaching facings

Fig. 18.

Fig. 18

38 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

5.4

Sewing problems and troubleshoot ing

CAUTION!

Switch off the machine and push down the motor switch

pedal to ensure that the machine is truly switched off.

Otherwise there is hazard of finger injuries and needle

puncture!

Thread breakage

Possible causes:

- Sharp edges or grooves in the needle guide, thread take-up lever,

looper

or needle’s eye after the machine has been used for a long time.

- Looper or loop stroke incorrectly adjusted or has been moved, the

thread loops are not always caught.

- Thread tension is too hi g h

- Thread thickness does not correspond to the needle thickness

(thread too thick)

Solutions:

- Replace or repolish the damaged parts

- Correct the looper setting and/or loop stroke

- Correct the thread tension, check the thread movement.

- Choose a suitable thread thickness

Always observe: Thread movement, thread, needle plate with

corresponding plunger and cloth retainer, tested

needles and thread tension must correspond to the

sewing material being processed!

Imprecise blind stitching

Possible causes:

- Often worn or damaged needle

- Cloth retainer or setting is incorrect

- Needle plate or needle guide is incorrectly set

- Center needle guard damaged or worn

- Needle thickness is not suitable (t o thi n)

- Damaged or incorrectly adjusted plunger

Solutions:

- Replace any damaged needl es , use t he cor r e c t needl e thickness

- Check the settings and correct if necessary

- Replace the center needle guard

39 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Skip a loop

Possible causes:

- Incorrectly adjusted looper

- Loop stroke/needle stroke incorrectly adjusted, therefore loop size

(too small/too large) may not be suitable

- Chaining finger damaged or altered

- Incorrectly set or altered cloth retainer or cloth retainer pressure

Solutions:

- Rotate the machine by hand, check the looper movement; usually the

cause can be seen.

- Check the settings, correct if necessary and/or replace any damaged

parts.

- If necessary, change the threading at take-up

The machine does not start even though the indicator lamp of the

main switch is on.

Possible causes:

- Thread trimmer not in final position, microswitch is locked

- Control box error

- Mechanical damage, machine is blocked

Solutions:

- Turn the machine off and back on again. Check the cutting position

of the blade. Check the programming

- Eliminate any mechanical faults and, if necessary, call the customer

service.

Markings or damage to the sewing material

Possible causes:

- Feed dog gearing is not suitable

- Plunger shape is not suitable for the sewing material

- Cloth retainer, pressure is set too strongly

- Presser foot pressure has been incorrectly adjusted or lift-off is

blocked.

- Damaged sewing parts (lower side of needle plate!)

- Needles or thread thickness not suitable

Solutions:

- Replace the feed dog or plunger

- Check the press er foot , sewing parts and their functionality, replace

any damaged parts and/or repolish them if necessary.

- Choose needles and threads that are suitable for the sewing material

40 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Difficulties in feeding the sewing material

(stitch lengths vary from settings)

Possible causes:

- Feed dog is incorrectly adjusted; need to be set lower or higher

- Feed dog gearing is not suitable

- Different presser foot pressure left/right

- Lift-off of presser foot is blocked

- Blockage of sewing material in needle plate, especially for cross-

seams

- The loop remains stuck at the feed dog, for instance.

- Stitch length accidentally altered

- Spring-load plunger blocks at the cross-seam area

- Correct tension on the lower transport belts

Solutions:

- Check the height of feed dog and the stitch length and, if necessary,

replace the feed dog.

- Correctly adjust the pressure of the presser foot

- Check the lower side of the needle plate and feeding/sewing parts for

signs of damage and, if necessary, replace or polish them

41 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

6

The machine is mostly equipped with maintenance free bearings and bushings.

The areas and oil holes marked in red should be re-oiled after 20 operating

hours or at the very latest once per week. One drop of sewing machine oil is

sufficient.

Servicing the machine

To oil looper drive and the feed dog crank, remove the the cover from the head.

Any fabric fibres that collects in the moving parts must be removed on a regular

basis.

7

Variable sewing tools

Attention!

Switch off machine electrically and confirm that the machine

is really in standstill position by operating the treadle for the

motor control.

Otherwise danger of finger bruises and needle through

stitches.

The following chart shows all sewing tools available.

42 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Cl. VEB100-1

Needle plate

Standard

480.0286

6,0 mm Opening

Optional

480.0287

4,5 mm Opening

Cloth retainer

Standard Optional

188.0243 188.0246

Standard Optional

188.0244 188.0245

Stitch formation

Feed dog

Standard

182.0332

Optional

182.0331

43 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Cl. VEB100-2

Needle plate

Standard

380.0286

6,0 mm Opening

Optional

380.0287

4,5 mm Opening

Cloth retainer

Standard

188.0243 188.0246

Standard

188.0244 188.0245

Stitch formation

Feed dog

Standard

182.0332

Optional

182.0331

44 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Cl. VEB100-2W

Needle plate

Standard

480.0257

7,0 mm opening

Cloth retainer

Standard

288.0217

Optional

288.0218

Stitch formation

Feed dog

Standard

182.0331

45 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Cl. VEB100-4

Needle plate

Standard

380.0275

4,5 mm Opening

Feed dog

Standard

182.0327

Roll hemmer 1

Standard

386.0428

46 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

Cl. VEB100-5

Needle plate

Standard

480.0250

7,0 mm Opening

Folder 6 mm

Standard

286.0364

1,0 mm

Feed dog

Standard

182.0336

47 BA_VEB100-1-2-2W-4-5_A3-1_180615_en

8

The following devices are available as optional extras and can be ordered

together with the machine or as separate kits.

Optional extras

8.1

(not applicable for cl. VEB10 0-4)

Thread trimmer

798.0496 electromechanical thread trimmer

Prerequisite here is use of the

EFKA Kompakt DC 1200 with connection cable

8.2

More hemmer sizes on request.

Hemmer

8.3

(not applicable for cl. VEB100-4)

Digital display 392.0637

8.4

The use of a pneumatic lifting is only recommended if the machine is equipped

with a needle positioning motor.

Pneumatic lifting

8.5

8.6

Seam lock

8.7

Compact drive

Stand set

Und wir können noch mehr für Sie tun!

And we can do a lot more for you!

Unser Lieferprogramm bietet für jede Branche und

jegliche Anforderung genau die richtige Problemlösung.

Our range offers the correct problem solution for

every branch and for all requirements.

Für die Bekleidungsindustrie:

Für die Schuhverarbeitung:

Für die Polsterverarbeitung:

Ein- und ZweifadenHochleistungs-Saummaschinen

DoppelblindstichSaummaschinen

Zweifaden-BlindstichStafermaschinen

Roll- und Flachpikiermaschinen

Pikier-Automat

und

weitere Spezial-Nähmaschinen

Einfaden-Überwendlichmaschinen mit und ohne

Differentialtransport

Ein- und ZweifadenÜberwendlichmaschinen

Ein- und ZweifadenBlindstichmaschinen

For the clothing

industry:

Single and two thread high

performance hemming

machines

Bluff edge hemming machines

Two thread blind stitch felling

machines

Roll and at padding machines

Automatic lapel padding

machine

and other special sewing

machines

For the shoe industry:

Single-thread overseaming machines with and without differential feed

Für Kürschnereien

und Pelzkonfektion:

Pelzschnellnäher

For the fur industry:

High-speed fur sewing machines

Für Heimtextilien:

Ein- und ZweifadenBlindstichmaschinen

For the home textiles

industry:

Single and two thread

blind stitch machines

For the upholstery

industry:

Single and two thread

overseaming machines

Single and two thread

blind stitch machines

Für die Konfektion

technischer Textilien:

Ein- und ZweifadenÜberwendlichmaschinen

For the processing

of technical textiles:

Single and two thread

overseaming machines

Noch Fragen?

Any further questions?

Dann rufen Sie uns an, schreiben Sie uns oder

kommen Sie einfach bei uns vorbei.

Sie können jederzeit weitere Informationen über

unsere Produkte anfodern oder die StrobelNähmaschinen in unserem Ausstellungsraum live

erleben. Wir freuen uns auf Sie!

Then phone, write or simply come and see us. You

can have further information about our products at

any time, or experience the Strobel machines live in

our show room. We’re looking forward to meeting you!

Sp ez i a l ma sc hi n en G mb H

Postfach 1242

82168 Puchheim

Siemensstraße 3

82178 Puchheim

DEUTSCHLAND

www.strobel.biz

Telefon: +49 89 80096-0

Telefax: +49 89 80096-190

Loading...

Loading...