For the professional user

Mechanic‘s Instructions

Für den professionellen Anwender

Mechanikeranleitung

Class:

Klasse:

Dated:

Stand:

441-1 Ausf. 1

441-2 Ausf. 1

Spezialmaschinen GmbH

The sign of quality

ou nd the Strobel trademark on every Strobel

Y

machine leaving our works. And with good reason.

This symbol is a guarantee of the high quality of

our products. Quality which creates trust – trust

in our technology, our service and, not least of all,

in our good name.

Im Zeichen der Qualität

ie nden die Strobel-Schutzmarke auf jeder

S

Strobel-Maschine, die unser Werk verlässt.

Und das aus gutem Grund. Denn dieses Zeichen

garantiert Ihnen die hohe Qualität unserer

Produkte. Qualität, die Vertrauen schafft – in unsere

Technik, unseren Service und nicht zuletzt in unseren

guten Namen.

A decision with future

trobel clients know that they can expect a particularly

S

high standard of performance from our company and our

machines. Now you have settled for one of our products.

For us this is a source of encouragement and of obligation

to Justify your trust.

If you wish to prot from the performance and efciency of

your Strobel machine as long as possible, exact handling

and thorough care is necessary. For this reason we kindly

request that you read the operating instructions closely.

It provides all the information you need for trouble free

operation.

And if you do happen to need a spare part the enclosed

spare parts list gives a complete overview. It is clearly

classied according to components so that you can nd the

required part quickly and easily. In order to avoid errors we

request you to quote machine class, machine number and

part number completely on your spare part order.

We wish you lots of success in your work with your new

Strobel machine.

Spezialmaschinen GmbH

Mechanic’s instructions

STROBEL Class 441-1 and 441-2

Contents

1 General notes on safety ............................................................................................ 4

2 General notes ............................................................................................................ 6

2.1 Operating instructions ..................................................................................... 6

2.2 Class designations, machine number and initial basis for descriptions .......... 6

2.3 Applications of the machine use as intended ................................................. 6

2.4 Technical data ................................................................................................ 7

2.5 Abridged version of adjustment manual ......................................................... 8

3 Disassembly of the machine ................................................................................... 10

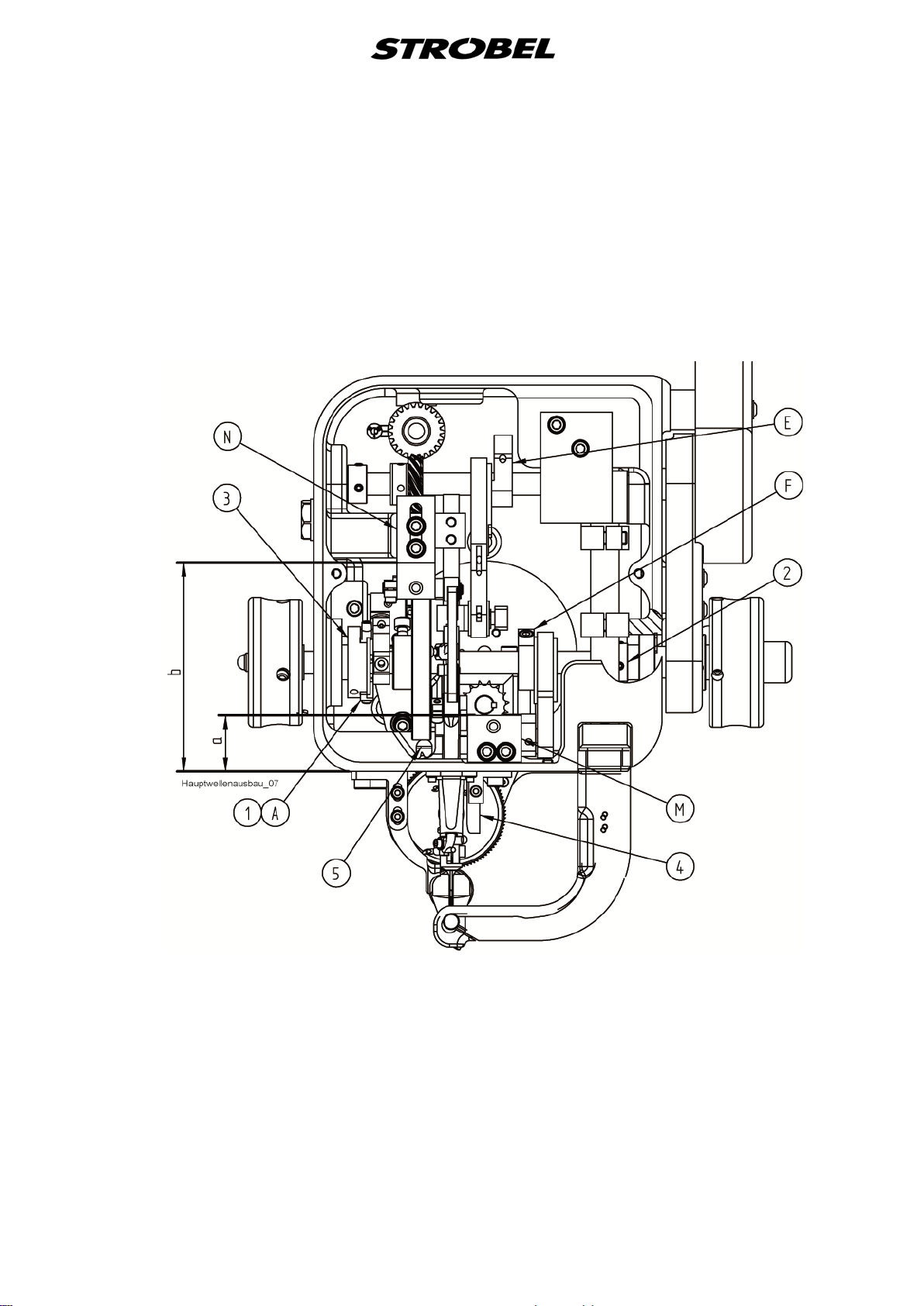

3.1 Disassembly of the front main shaft (Fig. 1 to Fig. 5) ................................... 10

4 Assembly of the machine ........................................................................................ 14

4.1 Assembly of the shaft (Fig. 4, Fig. 6 and Fig. 7) ........................................... 14

4.2 Assembly of the stitch variable eccentric (Fig. 4, Fig. 5, Fig. 6, Fig. 7) ......... 14

4.3 Setting the ecc. pin for stitch adjustment (Fig. 4 and Fig. 8) ........................ 15

4.4 Setting of the needle and transport movement ............................................. 16

4.5 The looper movement ................................................................................... 17

4.5.1 Setting the looper movement ........................................................... 17

4.5.2 Setting the looper eccentric .............................................................. 18

4.5.3 Setting the front crank ...................................................................... 19

4.5.4 Setting the front looper position to the feed cup .............................. 19

4.5.5 Setting the loop stroke ..................................................................... 19

4.5.6 Setting the rear bearing bracket ....................................................... 20

4.6 Height adjustment of the feed cup ................................................................ 20

4.7 Assembly of the front cup ............................................................................. 20

4.8 Tread lifting in the needle bar head .............................................................. 22

4.9 Spring tension at the plate bearing arm ........................................................ 22

4.9.1 Plate arm lifting ................................................................................ 22

4.10 Needle setting ............................................................................................... 23

4.10.1 Height adjustment of the needle (Fig. 13) ........................................ 23

4.11 Replacing the looper ..................................................................................... 24

4.12 Thread trimmer (optional) ............................................................................. 25

4.12.1 Calibration ........................................................................................ 25

1 MA_441-1-2_A1_180830_en

4.13 Positions ....................................................................................................... 26

4.14 Setting the positions ..................................................................................... 28

4.14.1 Setting the reference position .......................................................... 28

4.14.2 Setting the position 1 and 2 ............................................................. 29

4.14.3 Adjustment of the needle position for the use of our thread

trimmer ............................................................................................. 30

4.15 Display of the needle positions ..................................................................... 31

4.16 Sewing drive ................................................................................................. 31

4.17 Working with the control AB425 ................................................................... 32

4.17.1 Setting the stitch length .................................................................... 32

4.17.2 Working with operating control (V850) (Fig. 20) ............................... 33

4.17.3 Parameter und Functions F-714 (Class 441-2) ................................ 40

4.17.4 Parameter and Functions F-715 (Class 441-2) ................................ 42

4.17.5 Parameter and Functions F-760 (Class 441-2) ................................ 42

4.17.6 Copy sewing programs to another machines (Class 441-2) ............ 43

4.17.7 Brief instruction (Class 441-2) .......................................................... 44

4.18 Servicing the machine .................................................................................. 45

4.19 General notes ............................................................................................... 45

5 Notes on repair and adjustments ............................................................................ 46

5.1 Feed cup assembly ...................................................................................... 46

5.2 Replacing the feed cup ................................................................................. 46

5.2.1.1 Chain tension ................................................................... 47

5.3 Setting and installation instruction for the Strobel gathering device ............ 48

2 MA_441-1-2_A1_180830_en

Appendix

Circuit diagrams

Connecting the sewing ma chine:

258.10.27 Electrical wiring diagram AB425S Cl. 441-2 as of version 1

258.10.28 Electrical wiring diagram AB425S Cl. 441-2 as of version 1

258.30.28 Assembly plan AB425S Cl. 441-2 as of version 1

259.00.67 Pneumatic circuit diagram Cl. 441-2 as of version 1

259.10.67 Pneumatic construction circuit diagram Cl. 441-2 as of version 1

Strobel - Switchable functions

(DC1200-AB611A) Kl. 441-1

(DC1500-AB425S) Kl. 441-2

Strobel - Parameter list

(DC1200-AB611A) Kl. 441-1

(DC1500-AB425S) Kl. 441-2

Subject to change without prior notice

3 MA_441-1-2_A1_180830_en

1

General notes on safety

Every person in charge of setting up, operating, servicing and repairing the

machine must first read and understand the operating instructions and

particularly the safety instructions before starting up the machine.

Failure to comply with the following safety instructions can lead to bodily

injury or damage to the machine.

1. The machine must only be operated by persons familiar with the relevant

operating instructions and who have been instructed accordingly.

2. Before commissioning also read the notes on safety and the operating

instructions of the sewing drive manufacturer.

3. Only use the machine in the intended manner and never without the

provided guards. Always observe the pertinent safety regulations.

4. Switch off the main switch or pull the power plug for threading, changing

the reels, exchanging sewing tools such as needle, looper, needle plate,

transport devices, possibly cutter and cutting block, for cleaning and when

leaving the workplace as well as for maintenance.

5. General maintenance tasks may be carried out only by properly trained

persons in accordance with the operating instructions.

6. Repair work, retrofitting and maintenance may be carried out only by

technicians or specially trained personnel.

7. When servicing or repairing pneumatic equipment, the machine must be

disconnected from the pneumatic supply. Exceptions are only allowed for

adjustment work and tests of functionality performed by specially trained

technicians.

8. Only specially qualified technicians may work on the electrical equipment.

9. It is forbidden to work on electrically live components! Exemptions are

covered by the EN50110 (DIN VDE0105) regulations.

10. Any retrofitting or alterations to the machine may only be performed under

strict compliance with all pertinent safety regulations.

11. Only use our approved spare parts when servicing and/or repairing the

machine.

12. It is forbidden to operate the sewing head until it is determined that the

entire sewing unit complies with EU provisions.

13. It is essential that you observe and follow these instructions as well as the

generally valid safety regulations.

4 MA_441-1-2_A1_180830_en

14. Warning instructions given in the operating instructions that pertain to

especially dangerous parts of the machine must be indicated at these

positions using a safety symbol.

Warning instructions given in the operating instructions that pertain to

special injury hazards for operating personnel or technicians must be

indicated at these positions using a safety symbol.

5 MA_441-1-2_A1_180830_en

2

2.1

2.2

2.3

General notes

Operating instructions

Every person in charge of setting up, operating, servicing and repairing the

machine must first read and understand the operating instructions and

particularly the safety instructions before starting up the machine.

Class designati ons , machine number and initial basi s f or descriptions

The operating side of the machine is the initial basis for left/right descriptions.

The class type, machine and model number (after the dash) is attached in the

back of the housing.

Applications of the machine use as intended

Class 441-1

Single-thread overcast machine with gathering device for attaching soles to

shoes made of heavy textile material and leather up to a total thickness of 7

mm.

Class 441-2

Single-thread overcast machine for attaching soles to shoes made of heavy

textile material and leather up to a total thickness of 7 mm, with differential

drive.

6 MA_441-1-2_A1_180830_en

2.4

Technical data

Recommended nominal stitch number 1800 min-1

Belt pulley diameter/machine dw 80

V-belt profile 10 x 6 mm

Stitch length 3 – 8 mm

(depends on sewing material)

Stitch type single-thread overcast stitch

Stitch type 501

Needle system GROZ-BECKERT 134

Needle thickness 140

Thread polyester, continuously twined

Thread thickness 40

Transport type rear plate transport

Pneumatic connection 6 bar

Air consumption, average depends on equipment

Equipment footprint 0.6 x 1.06 m

Operating noise:

Averaged measuring surface sound pressure level

at stitch number n 1800 min

-1

Cl. 441-1 LpAm 71 dB

Cl. 441-2 LpAm 76.1 dB

Noise levels in acc. with DIN 45635-48-1 KL3

7 MA_441-1-2_A1_180830_en

Looper deflection to right from centre needle -

2.5

Abridged version of adjustment m a nua l

Setting value

Class

Needle type

Needle size

Stitch length

Loop stroke

Needle point front measured from plate edge

Needle bar eccentric stroke

Dimensio

n

A

B

C

E

134

120 - 140

3 - 8

5,5

24

32,4

looper point

Looper deflection to left

Looper position front measured from plate edge

Looper position rear

Looper transition

Looper height incl. shaft

Rear end position / Position without needle

Rear end position / Position with needle

F

G

H

J

K

L

M

N

4,9

10,2

11,7

6,2

10,5

37

about 48.5

about 9.4

8 MA_441-1-2_A1_180830_en

The lifting value between the feed cups is 12-14 mm.

9 MA_441-1-2_A1_180830_en

3

3.1

Disassembly of the machine

Disassembly of the front main shaft (Fig. 1 to Fig. 5)

Before beginning with disassembling the main shaft, it is recommended to

record all parts on the shaft using a ruler in a straight line. If necessary, starting

at the front edge of the stand, measure the distances of the front and rear

bearing bracket using a calliper and write them down

(dimension a + b).

This will save a lot of time during the assembly for calibration. (Fig. 4)

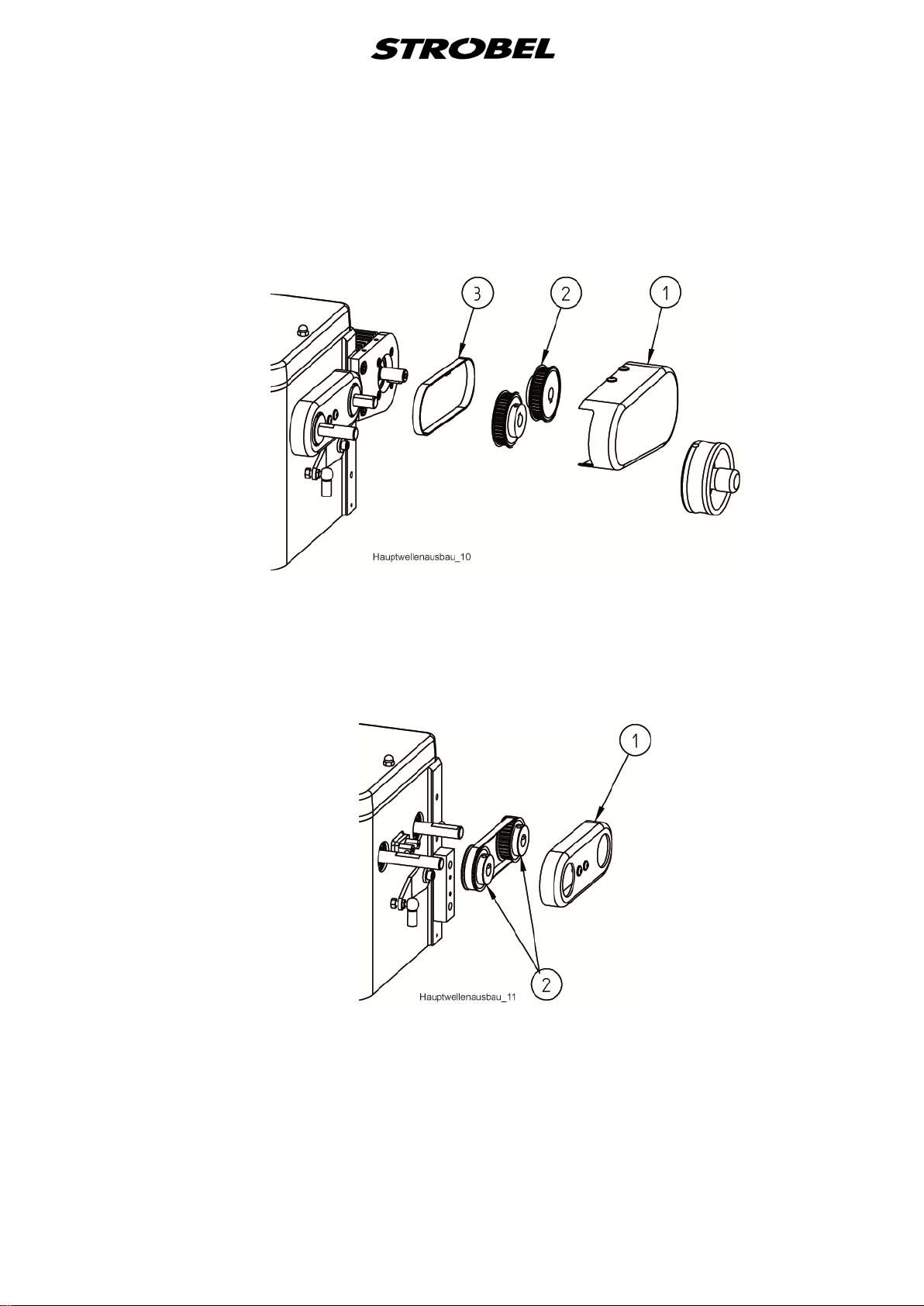

First of all, remove the right handwheel and then disassemble the belt guards in

the following sequence.

Cl. 441-1

The belt guard (1), the V-belt pulley (2) and the belt guard back wall (3). (Fig. 1)

Fig. 1

10 MA_441-1-2_A1_180830_en

Cl. 441-2

The belt guard (1), the toothed belt pulleys (2) and the toothed belt (3).

(Fig. 2)

Fig. 2

Afterwards the belt guard (1). Now make a note of how the two toothed belt

pulleys (2) are mounted on the front and rear shaft. Now the toothed belt

pulleys (2) can be taken off with the toothed belt. (Fig. 3)

Fig. 3

The left handwheel with the stitch variable eccentric bolt does not need to be

removed. Make sure that the threaded pins (2) located on both sides of the

variable eccentric (A) (1) are removed.

(Fig. 4 and Fig. 5)

CAUTION! If not already done, mark the slideway (3) and variable

eccentric (A) (1) for correct installation position. (Fig. 5)

11 MA_441-1-2_A1_180830_en

Only then should the screws of the parts located on the shaft be loosened and

the shaft be pressed out to the left with an extracting tool.

Note here though that the shaft should be pressed to the left by about only

20-30 mm and the glue adhering to the shaft is removed; only then can the

shaft be pushed out all the way. Be careful that the ball bearings do not slip.

Any glue residues still on the shaft can be removed easily using a cleanser

(e.g. chloroethene).

Fig. 4

12 MA_441-1-2_A1_180830_en

Fig. 5

13 MA_441-1-2_A1_180830_en

4

4.1

Assembly of the machine

Assembly of the shaft (Fig. 4, Fig. 6 and Fig. 7)

Once all parts have been in threaded in the correct sequence onto the shaft,

which has been cleaned of grease first, a drop of Loctite can be put each on

the shaft which still protrudes out to the left by about 30 mm, as well as on the

right part of the degreased shaft inside the machine stand, at the ball-bearing

seat. (Loctite, capillary 290)

CAUTION! To make a fault-free connection possible, the surfaces to be

joined must be completely grease-free. The shaft is then

pushed all the way into the stand, turned slightly so that the

Loctite is drawn in evenly all-around by the ball-bearing ring, the

stitch variable eccentric (A) (1) is fixated (see point "4.2

Assembly of the stitch variable eccentric"), the shaft is pushed

all the way to left and the adjusting ring (2) on the right shaft

side is sealed close so that the axial gap of the shaft is

removed. (Fig. 4)

After the adhesive has cured for about one hour (Loctite, capillary 290) the

machine can be assembled further and calibrated. During the repair assembly,

the left handwheel does not need to be taken off the shaft; however the control

knob (1) (Fig. 7) and the pins (3) and springs (2) do have to be removed (Fig.

6).

4.2

Assembly of the stitch variable eccentric (Fig. 4, Fi g. 5, Fig. 6, Fig. 7)

Mount the left handwheel on the installed shaft so that the tip of the first screw

fits, in the direction of rotation, into the depression of the left radial bore of the

shaft and stands upwards during that.

Turn the slideway (3) so that the variable eccentric (1) can be pushed down in

the position described above. (Fig. 5)

Turn the first screw (2) so far into variable eccentric so that the adjustment bolt

(4) can be turned through in the shaft. First, loosen the counter nut. Turn the

handwheel with shaft by 180°. Turn the second screw (2) all the way into

variable eccentric; the adjustment bolt (4) should be able to rotate free of

backlash. Screw slideway (3) onto the shaft. (Fig. 5)

Slide the shaft all the way to the left on the ball bearings, push adjusting ring (2)

on the right shaft side all the way on the ball bearings and tighten. The shaft is

fixated now. (Fig. 4)

Allow stitch variable eccentric (1) to level off and tighten. Slide two greased

springs (2) and two greased pins (3) into the bore of the handwheel (Fig. 6).

14 MA_441-1-2_A1_180830_en

Fig. 6

Fig. 7

4.3

Screw the control knob (1) onto the shaft or the adjustment bolt (2) until the

control knob contacts the handwheel. Hold the control knob tight and screw out

the adjustment bolt until the pointer (3) on the control knob of the handwheel

(marking 5), (large stitch), contacts and can be slightly seen between

handwheel and stand. (Fig. 7)

The control knob needs to be free from the large to the small stitch.

If the setting has been done properly, the variable eccentric (1) is standing at

the large stitch at the top dead centre and the pointer of the control nut is at the

marking 5 on the handwheel. To complete, the counter nut (5) is screwed on.

(Fig. 5)

Setting the ecc. pin for stitch adj us t m e nt (Fig. 4 and Fig. 8 )

In combination with the stitch variable eccentric (A) (1) (

(1) needs to be set to the determined position for the stitch length specified for

each class (see "2.5 Abridged version of adjustment manual"). Please be sure

that the rocker (2) and the connecting rod (3) are not stretched out. The

marking (punch mark) made on the ecc. pin (1) (Fig. 6) has to be mounted

upwards in any case. This has the effect that the punch mark is swivelled to the

right (-) for a smaller stitch and to the left (+) for a larger stitch - arrow direction.

(Fig. 8)

Fig. 4), the ecc. pin (B)

15 MA_441-1-2_A1_180830_en

Fig. 8

4.4

Setting of the needl e a nd t ransport movement

If the largest stitch length is set (see "

manual"), the transport movement is ended when the needle point is located

about 1.5 mm within the plate edge before the piercing.

Transport beginning is when the needle has left the material and is located

about 1 mm behind the plate edge.

The setting is done at the needle bar eccentric (E) (Fig. 4); observe the frontmost needle position thereby (see "2.5 Abridged version of adjustment

manual").

During the setting of the needle bar, make sure that the surface on the needle

bar for needle clamping is precisely at a right angle to the feed cup.

2.5 Abridged version of adjustment

16 MA_441-1-2_A1_180830_en

4.5

4.5.1

The looper movement

The looper movement is determined by the stroke of the looper eccentric (F)

(

Fig. 4) or (1) (Fig. 9), by the crank distance and by the bore distance of the

clamping lever (2) (Fig. 9). The looper movement has to equal temporally the

needle bar movement.

The curve form of the control curve (3) (Fig. 9) produces the lateral looper

deflection, corresponding to the needle movement.

Make sure that the looper carriage (4) (Fig. 9) or the looper shaft is mounted

exactly centrally to the needle bar (5) (Fig. 9).

It is recommended for setting the parts described below to mount them on the

shaft so that they adhere, but can still be turned by hand and then tightening

them after the final setting.

Setting the looper movement

Find the top dead centre of the needle bar eccentric and mark it(corresponds to

position "1"). (E) (

The top dead centre of the needle bar eccentric equals the bottom dead centre

offset by 180° of the looper eccentric (1) (Fig. 9) (see point "4.5.2 Setting the

looper eccentric").

Fig. 4)

Turn the control curve (3) in this position until the leftwards movement of the

looper reaches the reversal point after taking up the loop.

(Fig. 9)

Make sure that the control curve (3) is fixated so that there is a backlash of

about 1 mm between curve and adjusting ring on the looper carriage (4) (Fig.

9). The looper deflection is influenced by a lateral shifting of the control curve

(3).

If the distance is enlarged, this results in a smaller looper deflection to the right.

The total path of the looper changes insignificantly.

17 MA_441-1-2_A1_180830_en

Fig. 9

4.5.2

Setting the looper eccentric

Set the looper eccentric (1) (at position "1") so that its surface is horizontal (

9). During a later partial rotation of about 100° at the handwheel (position "2"),

the back-most needle position is reached. The looper is positioned then about 2

mm left of and about 3 mm over the needle, differently depending on the loop

stroke (Fig. 10a). During forwards movement of the needle, the needle point

arrives then at the right looper edge, whereby the needle point stands about 1

mm over the looper and then moves over the looper at an unvarying distance

(Fig. 10b). The needle point is located at the rear dead centre of the looper,

lateral and longitudinal movement, depending on the loop stroke, about 1 - 3

mm within the feed cup.

Fig.

Fig. 10

18 MA_441-1-2_A1_180830_en

4.5.3

4.5.4

4.5.5

Setting the front c rank

Set the front crank (9) vertically at position "1".

The looper height movement is influenced by the front crank (9). (Fig. 9)

In the front position, the looper comes higher and should pass very closely (0.1

- 0.15 mm) over the needle for a good loop pick-up. The various needle

thicknesses need to be taken into account for that. In the rear looper position,

the looper stands under the needle, the needle about 1 mm over the looper

bevel (Fig. 10b).

Setting the front looper position to the feed cup

At a rotation of about 45° in the opposite direction of rotation to position "1", the

looper has reached its front-most position; set dimension (H) according to point

"

2.5 Abridged version of adjustment manual".

Make sure that the looper height (L) is correct (see "2.5 Abridged version of

adjustment manual"), including the shaft.

Setting the loop stroke

The loop stroke (B) needed for the respective class (see "

of adjustment manual") is set by turning the control curve and the looper

eccentric. Measured from the front dead centre of the needle to the contact of

the looper point over the needle centre.

2.5 Abridged version

Increase loop stroke - Turn curve and looper eccentric contrary to

the machine's direction of rotation.

Reduce loop stroke - Turn curve and looper eccentric in machine's

direction of rotation.

The looper picks up the thread loop from here and places it in as straight a

lined as possible over the sewing material to the back.

19 MA_441-1-2_A1_180830_en

4.5.6

4.6

4.7

Setting the rear bearing bracket

Shifting the rear bearing bracket (N) (

transfer in the end positions. During pushing back, the looper goes closer to the

needle in the front and vertical looper position (without significant change of

height in rear position - ratio about 10:1); during pushing forward, the looper

distance to the needle becomes greater.

Fig. 4) or (7) (Fig. 9) changes the looper

Height adjustment of t he fee d cup

In case the socket (4) is removed, pull it in far enough so that the dimension of

8.8 ±0.1 (a) of (

Fig. 14) results in mounted condition feed cup (5).

Assembly of the front cup

Cl. 441-1 (

During the assembly of the front cup on the machine, make sure that it is

mounted in horizontal position and by 0.1 mm lower in relation to the feed cup.

If there is a needle guard, the base of the needle channel has to be 0.1 mm

lower in turn than the top edge of the front cup.

Cl. 441-2 (Fig. 11)

After the lid has been removed (1) (2x screws [2]), 2 threaded pins (4), which

have been inserted at 90°, can be loosened via the borehole in the flange (3)

and then the gearwheel (5) can be pulled out including the shaft (6).

Fig. 14)

Afterwards the retaining ring (7) can be taken from the bearing pin of the small

front cup and the front cup can be exchanged.

The assembly is done in reverse order.

To prevent damage to the feed cup teeth during a possible idling of the

machine, feed cup and front cup should be moved together only so far that

there still is a gap of 0.2 - 0.3 (b) mm between them. (Fig. 11)

The gap can be adjusted with threaded pin (4) and secured with threaded pin

(5). (Fig. 12)

Make sure that the front cup is mounted 0.1 mm lower in relation to the feed

cup. This can be adjusted by loosening the 2 threaded pins (8) from the needle

guard (9). (Fig. 11)

20 MA_441-1-2_A1_180830_en

Fig. 11

21 MA_441-1-2_A1_180830_en

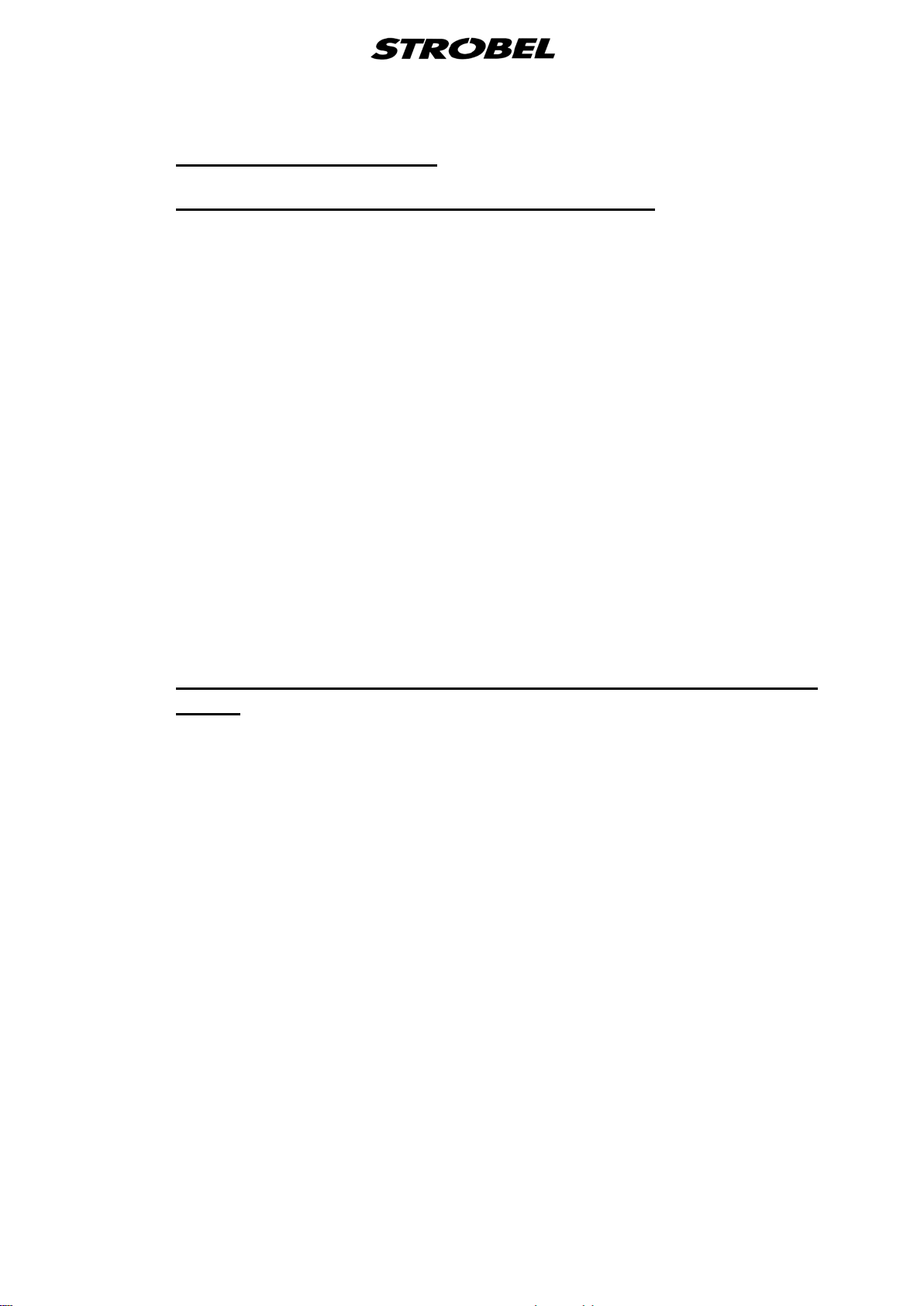

4.8

4.9

Tread lifting in the needle bar hea d

The lifter bar (4) for the tread lifting in the needle bar head has to be set so that

the thread can be lifted when the looper stands vertically over the needle as the

needle retracts and the loop pick-up is done up to the moment when the looper

has reached the needle centre with the left looper point as the needle

advances. (

The thread breaking at the needle bar is 0.35 - 0.4 N.

Fig. 4)

Spring tension at t he plate bearing arm

The tension of the spring (1) needs to be adjusted to the material to be

processed; for shoes it can be up to 200 N for example. The spring tension can

be set using the setting screw (2). (

Fig. 12)

Fig. 12

4.9.1

Plate arm lifting

The plate arm lifting is about 12 - 14 mm and can be adjusted using the lever

(3). (

Fig. 12)

22 MA_441-1-2_A1_180830_en

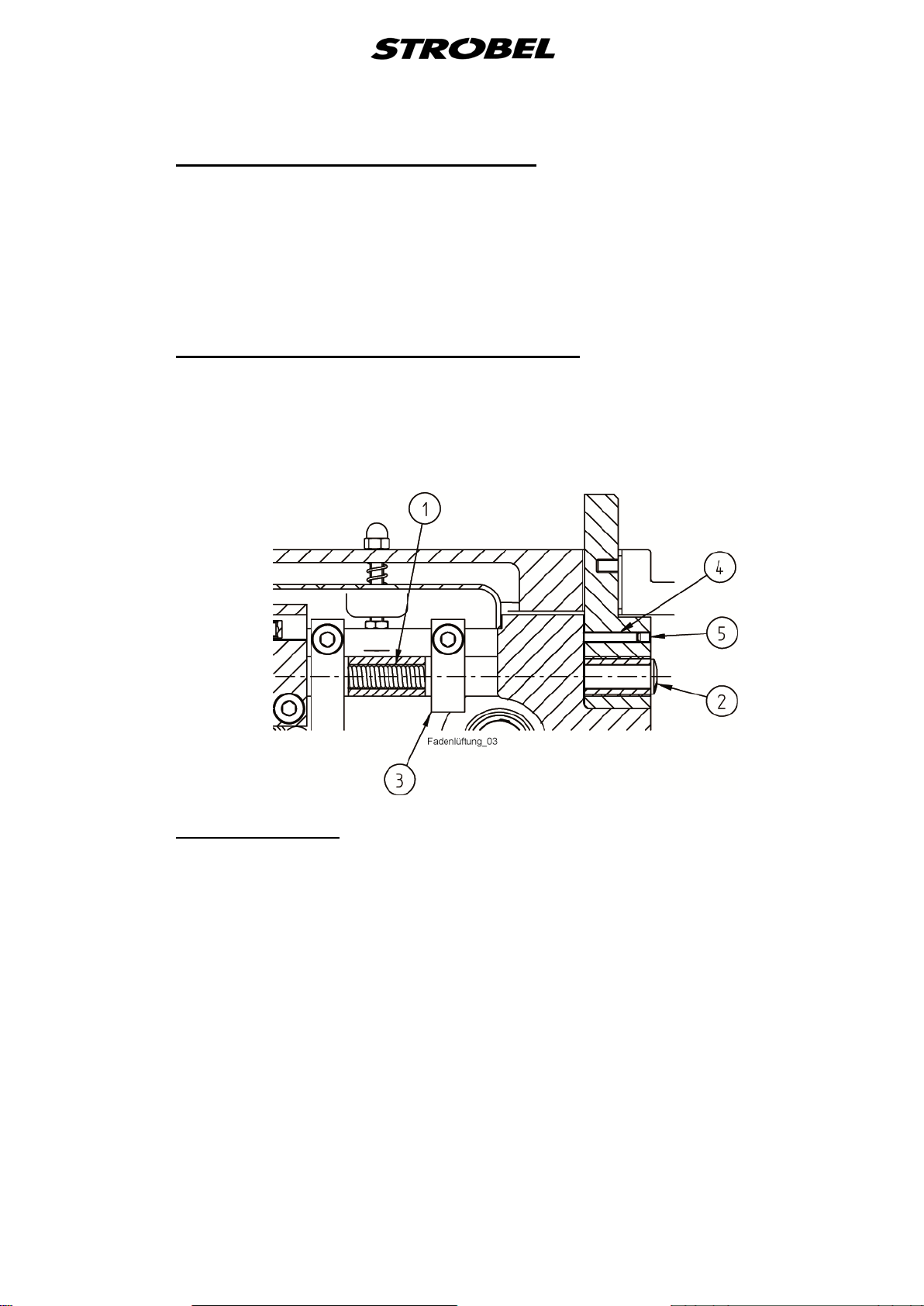

4.10

4.10.1

Needle setting

The setting dimension for the needle bar can be found in the table in point "

Abridged version of adjustment manual".

2.5

Height adjustment of t he ne e dle (Fig. 13)

Using this special construction, the height of the needle can be adjusted. This

device proves to be quite useful when using different needle thicknesses. The

height of the needle can be adjusted by turning the eccentric (6), which features

a groove, that is located on the front side of the needle bar head. Make sure

that the needle of any thickness passes over the feed cup with a gap of about

0.1 mm in the area between the point and the eye of the needle. After

loosening the screw (5) of the needle setting plate (4) and then adjusting the

height of the needle, the screw (5) has to be tightened again.

Fig. 13

23 MA_441-1-2_A1_180830_en

4.11

Replacing the looper

After loosening the clamping screw (1) (

(2), the looper can be removed.

When inserting a new looper, make sure that it contacts the needle or feed cup

neither when it is in the front nor when it is in the rear position(see also

installation dimension (L), point "2.5 Abridged version of adjustment manual").

The wide looper back should be set up as parallel as possible to the needle.

Fig. 14) at the head of the looper shaft

Fig. 14

24 MA_441-1-2_A1_180830_en

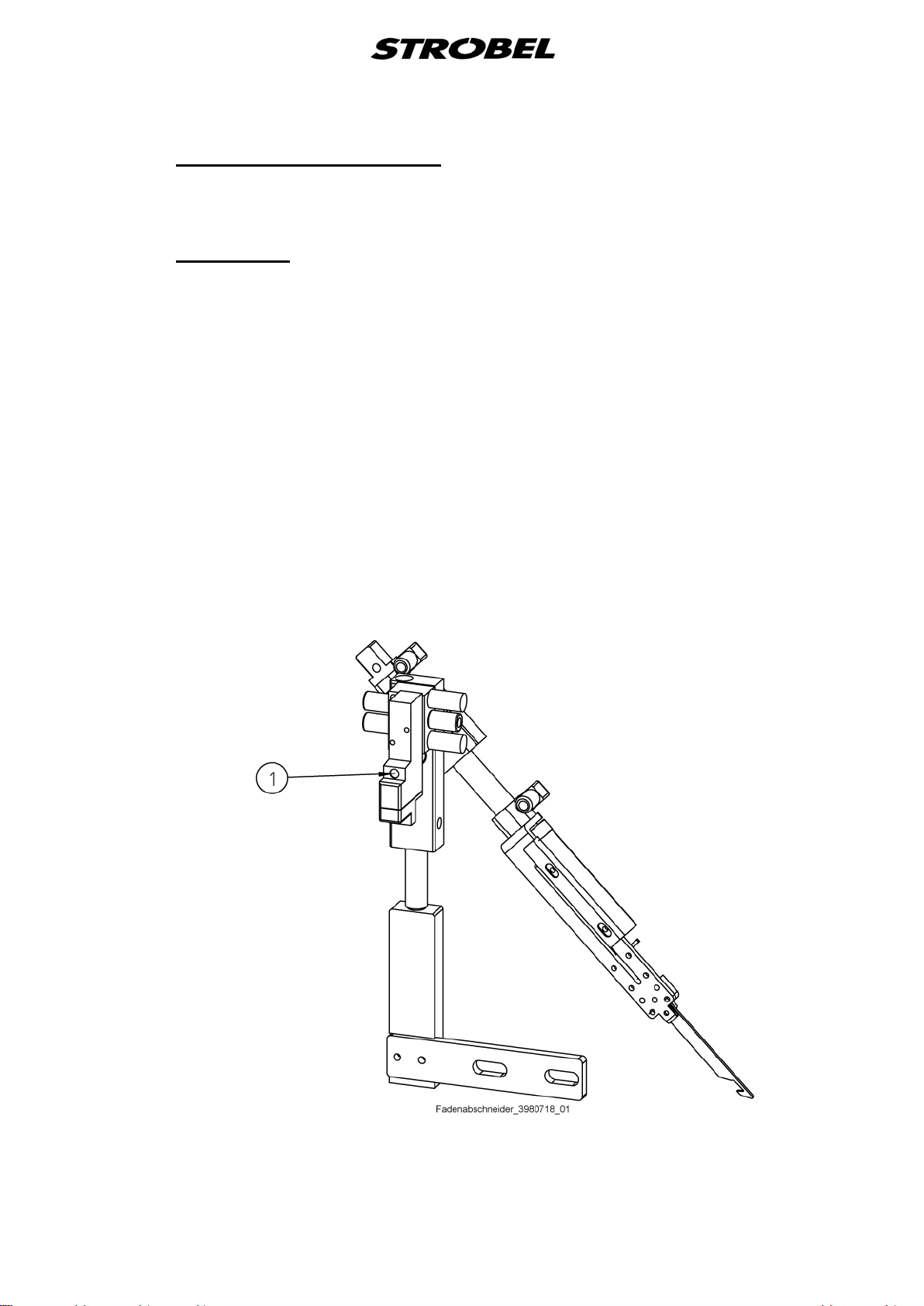

4.12

4.12.1

Thread trimmer (optional)

The optional thread trimmer is controlled by an electro-pneumatic control when

the right pedal is pressed back.

Calibration

Before mounting the thread trimmer, the 2 threaded pins (10) (

stand need to be removed. Then the thread trimmer is mounted on the stand

with the 2 supplied screws. It is aligned so that the thread puller, when it is

extended, DOES NOT collide with the feed cup, looper and needle and picks

up the thread between needle and looper.

CAUTION: The needle position needs to be adjusted for the thread trimmer

before the thread trimmer is put into operation.

More Details see point „4.14.3 Adjustment of the needle position

for the use of our thread trimmer“.

The thread trimmer can be checked by triggering the button (1) on the backside

of the valve, which is mounted on the thread trimmer, using a pointed object

(e.g. ballpoint pen).

(Fig. 15)

Fig. 24) in the

Fig. 15

25 MA_441-1-2_A1_180830_en

4.13

Positions

With the control AB611 or AB425

Function

Setting the reference position

This function sets the reference position.

Function

Setting positions 1 and 2

This function sets the two positions.

The control has two positions. The positions are set exclusively by

programming the control.

A position is determined by a position input and output value. The values

correspond to the number of increments (steps), counted from an entered

reference position. A rotation is divided into 360 steps (increments) thereby, i.e.

1 step = 1 degree.

Parameter

F-170

Parameter

F-171

CAUTION!

In order to ensure a safe or proper sequence there should be at least 50

steps (increments) between two positions.

Furthermore there should be 25 steps between position input value and

output value of the same position (very important for internal functions of

the control).

For the precise programming of the individual positions refer to point "4.14

Setting the positions".

The setting of the positions can be easily checked using the F-172 function.

Refer to point "4.15 Display of the needle positions"

26 MA_441-1-2_A1_180830_en

Machine with or without gathering device:

The machine requires two needle positions and, depending on sewing drive,

possibly also a reference position.

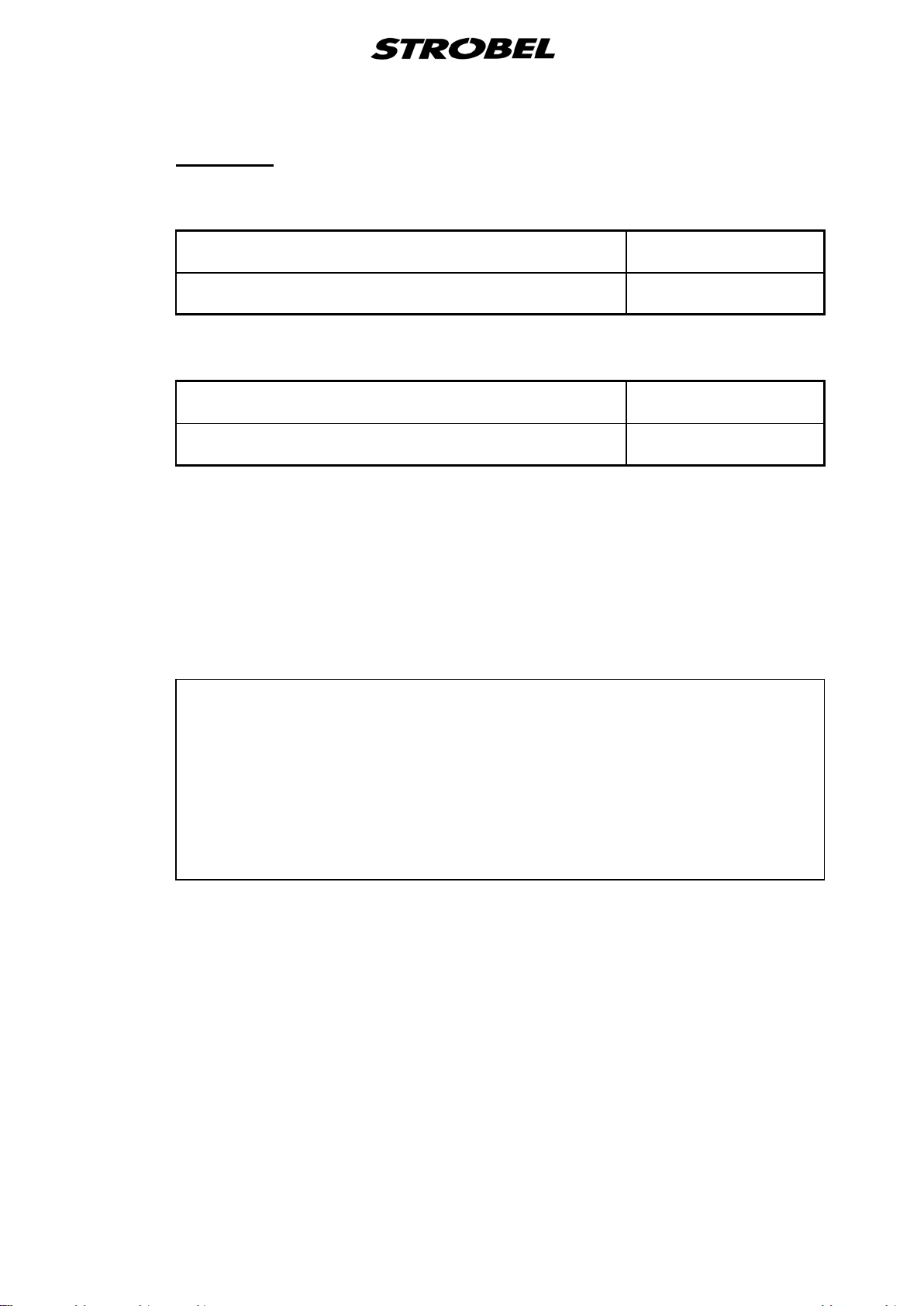

Reference position (Fig. 16):

The reference position needs to be set so that the point of the needle

concludes with the outer plate edge in the direction of the piercing.

Fig. 16

Refer to the enclosed sewing drive instructions for the programming of the

positions on the motor.

Needle position (when stop inside the stitch with pedal position “0” (Fig. 17)):

The needle position needs to be set so that the distance between the

outer plate edge in the direction of the piercing and the point of the needle

is about 10 mm.

The needle position is position 1 at the sewing drive.

Fig. 17

27 MA_441-1-2_A1_180830_en

Needle position (when stop outside the stitch with pedal position “-2” (Fig. 18)):

The needle position needs to be set so that the distance between the

point of the needle in the direction of the piercing and outer plate edge is

about 4 mm.

The needle position is position 2 at the sewing drive.

Fig. 18

Afterwards, check its function by manually actuating the thread trimmer.

4.14

4.14.1

Setting the positions

Refer also to point "

4.13 Positions"

Setting the reference position

After entering the code number "1907" and the button "E" for the technician

level:

- Select parameter F-170. Display shows:.1.7.0.

- Press the "E" button. Sr 1_

- Press the ">>" button. P0 I_I

Turn the handwheel in the machine's direction of rotation

until the rotating icon in the display disappears and then set

the handwheel or needle to the reference position of the

sewing machine (Fig. 16).

- Press the "E" button. .1.7.1.

- Exit the programming level by pressing the button "P"

or

continue with point: "4.14.2 Setting the position 1 and 2" with step 2.

28 MA_441-1-2_A1_180830_en

Needle positions

Parameter

Value

F-451

P1E

036

F-452

P1A

061

F-453

P2E

342

F-454

P2A

009

Starting point for the stepper motor

Parameter

Value

F-749

220

4.14.2

Setting the position 1 and 2

After entering the code number "5913" and the button "E" for the technician

level:

- Select parameter F-171. Display shows:.1.7.1.

- Press the "E" button. Sr2_

- Press the ">>" button. P1E

Keep turning the handwheel in the machine's direction of

rotation until the display of "P1E" changes into the display of

the position value and then set the handwheel or needle to

the position 1 of the sewing machine (Fig. 17). Remember or

record the position value.

- Press the "E" button. P2E

Keep turning the handwheel in the machine's direction of

rotation until the display of "P2E" changes into the display of

the position value and then set the handwheel or needle to

the position 2 of the sewing machine (Fig. 18). Remember or

record the position value.

- Press the "E" button. P1A

Keep turning the handwheel in the machine's direction of

rotation until the display of "P1A" changes into the display of

the position value and then turn the handwheel until the

position value "P1E + 25" is displayed.

- Press the "E" button. Display shows: P2A

Keep turning the handwheel in the machine's direction of

rotation until the display of "P2A" changes into the display of

the position value and then turn the handwheel until the

position value "P2E + 25" is displayed.

- Press the "P" button. .1.7.1.

- Press the "P" button.

At least one cycle needs to be sewn so that the setting is saved before the

machine is switched off.

29 MA_441-1-2_A1_180830_en

Needle positions

Parameter

Value

F-451

P1E

036

F-452

P1A

061

F-453

P2E

273

F-454

P2A

298

Starting point for the stepper motor F-749

Operation without thread cutter

Value 220 (Factory setting)

Operation with thread trimmer

Value 289

4.14.3

Adjustment of the needle position for the use of our thread trimmer

When the thread trimmer is mounted, the needle position parameters and

parameter F-749 must be changed.

After entering the code number "3112" for the supplier level:

- Select parameter F-451 and confirm with the "E" key

- Set the value according to table (Needle positions) and confirm with the

key "E"

- Go to the next parameter and set the value as described in the chart

(Needle positions) and continue this procedure up to Parameter F-454.

- Save the data by pressing the "P" key twice and exit the supplier level.

Starting point for the stepper motor F-749

- Select parameter F-749 and confirm with the "E" key

- Change the value to the value "289" and confirm with the "E" key

- Press the "P" key

Procedure to save the change

- Select parameter F-401

- change value to "1"

- Save the data by pressing the "P" key twice and exit the supplier level.

- Switch the control box off and on again so that the change is saved.

30 MA_441-1-2_A1_180830_en

4.15

Display of the needle positions

Refer also to point "

Function Parameter

Display of the Positions 1 and 2

(down / up)

The setting of the positions can be easily checked using this function.

After entering the code number "1907" and the button "E" for the technician

level:

- Select parameter F-172. Display shows: .1.7.2.

- Press the "E" button. Sr 3

Turn the handwheel according to the motor's direction of rotation.

- Display at the control:

Segment 5 is switched on. ⇒ Position 1E

4.13 Positions"

F-172

4.16

Segment 5 is switched off. ⇒ Position 1A

Segment 6 is switched on. ⇒ Position 2E

Segment 6 is switched off. ⇒ Position 2A

- Press the "P" button. .1.7.2.

- Press the "P" button.

Sewing drive

Refer also to point "

The motor has its own operating instructions included which has information on

programming and circuit diagrams.

4.13 Positions"

31 MA_441-1-2_A1_180830_en

4.17

Working w ith the control AB425

CAUTION!

Switch off the machine electrically!

4.17.1 Setting the stitch length

Function with V850 operating control Parameter

Stitch length setting F-711

In order for the machine to run synchronously, the stitch length needs to be

determined first. To do so, you take a Texon strip for example and feed the strip

between both plates, with the machine switched off, by turning the handwheel

until the needle has pierced 11 times. Afterwards you measure the distance of

the 11 piercings and enters this via the parameter "F-711".

Fig. 19

32 MA_441-1-2_A1_180830_en

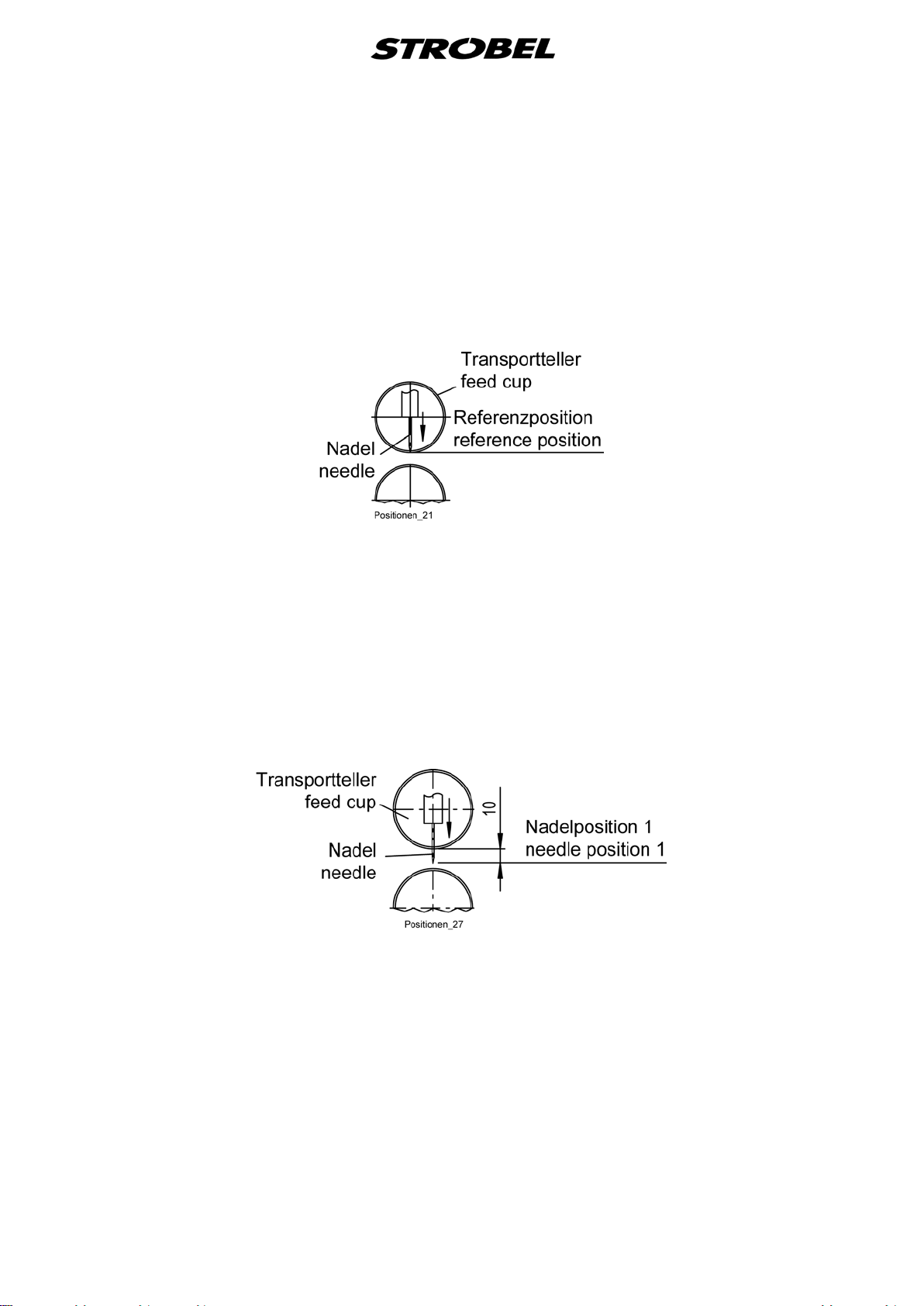

4.17.2

Working w ith operating contr ol (V850) (Fig. 2 0 )

Activation of control panels by code.

For activation you need a two part code, available from your Strobel agent.

Procedure of activation:

- Press and hold button “P” and switch on the machine by “S1”

- Open the supplier level by code “3112” and confirm with “E”

- Select parameter “F-798” and confirm with “E”, for code-A

- Enter the 5-digit code-A and confirm with “E”

- Select parameter “F-799” and confirm with “E”, for code-B

- Enter the 5-digit code-B

- Save data by pressing “P” two times

Fig. 20

Example:

Example:

33 MA_441-1-2_A1_180830_en

1. Display "Standard"

1 Program number

2 Sector

3 Reduction differential transport

- Additional display of the current sector by arrow symbols

- The letter behind the program number (L/R) indicates whether it is a

left or right shoe.

- If no program is saved at the current program number, then this will be

indicated by "No Prog".

34 MA_441-1-2_A1_180830_en

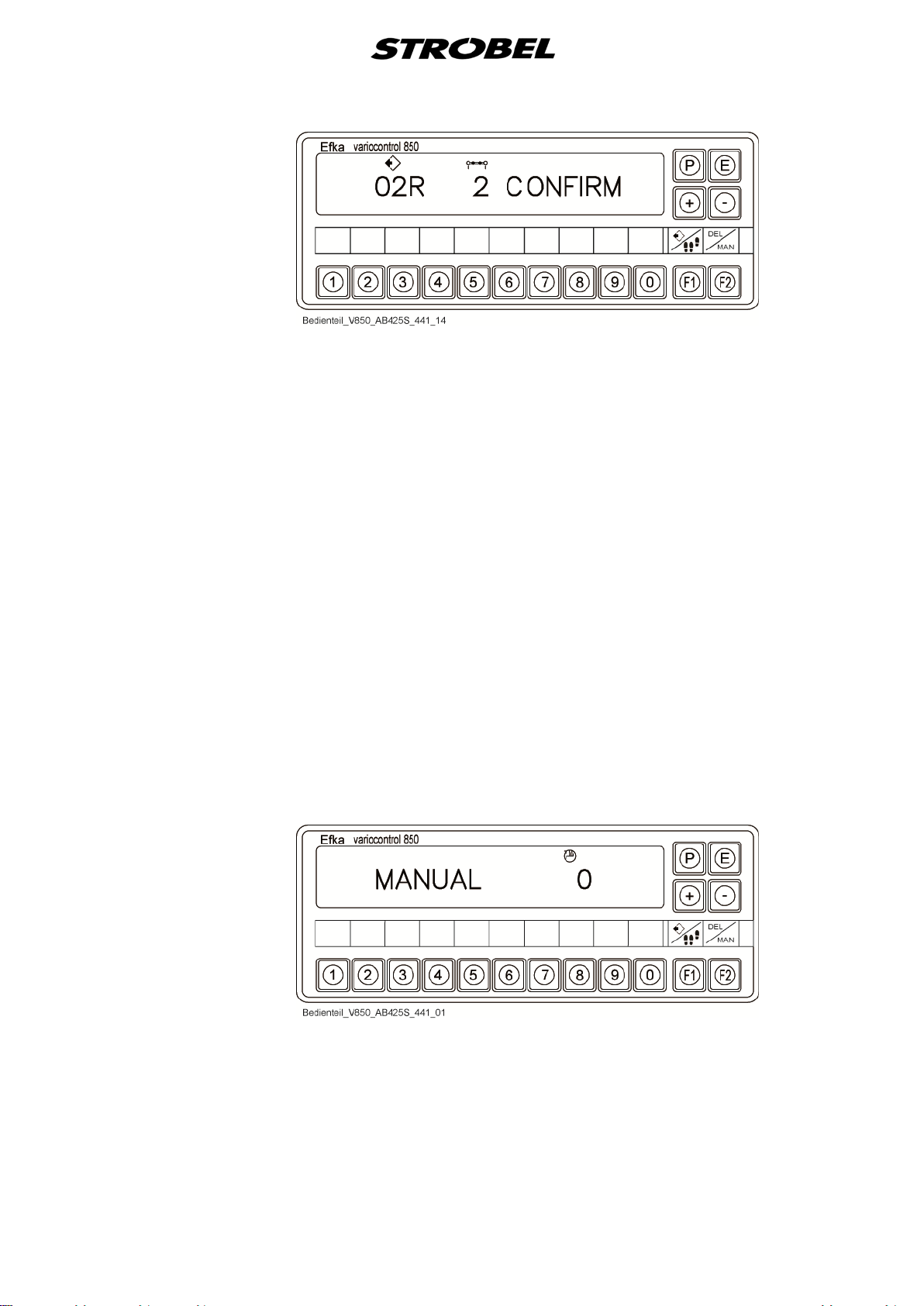

2. Display "Program selection"

- Press the "F1" button in the "Standard" display.

- Enter the program number using the keypad or "+/–" buttons.

- Confirm the entry with the "E" button.

- Corresponding program is loaded.

- Return to the standard display

- If no corresponding program is saved, this is indicated by the "*" icon.

- Use the "P" button to switch into the "Standard" display without

selecting a program.

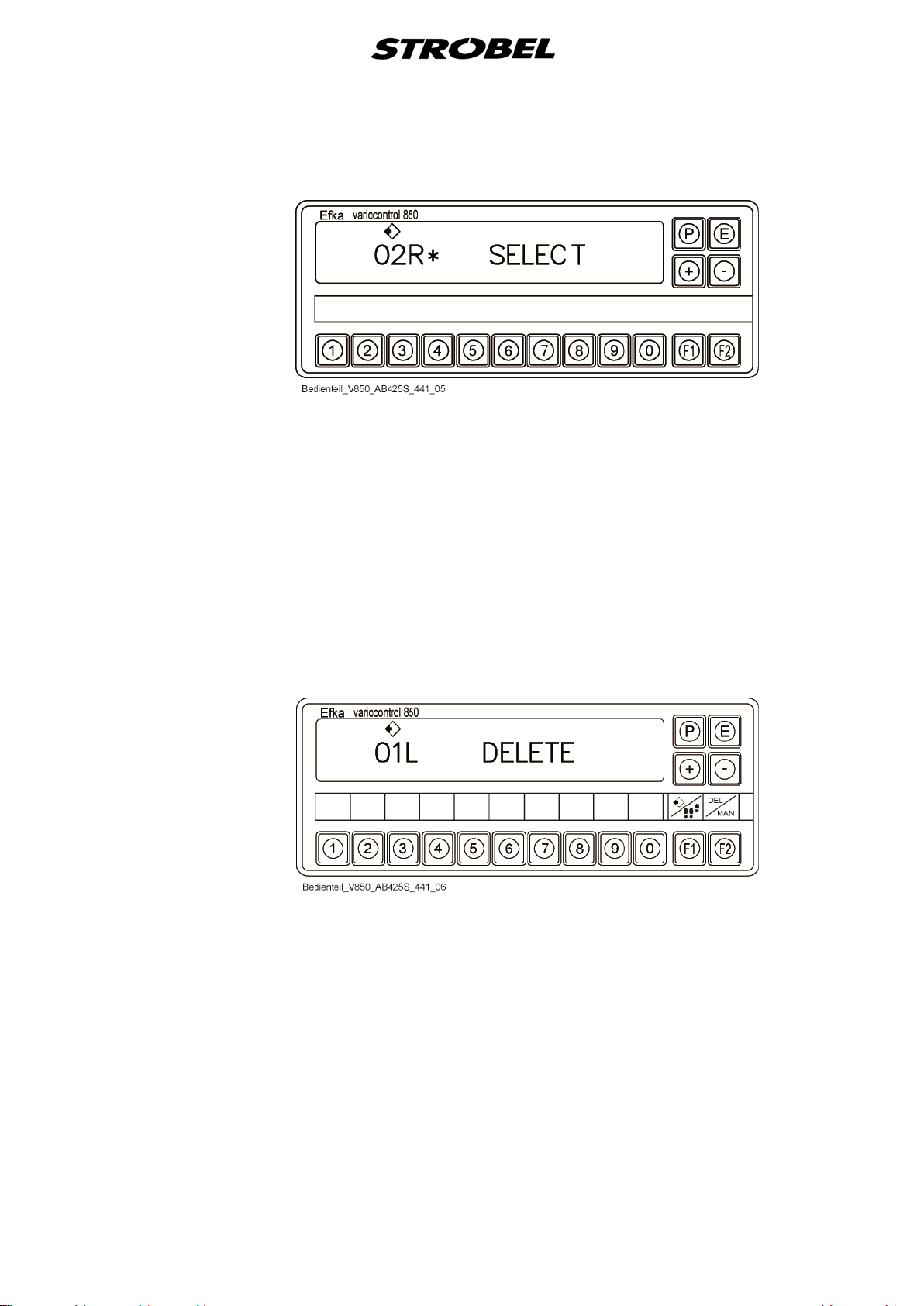

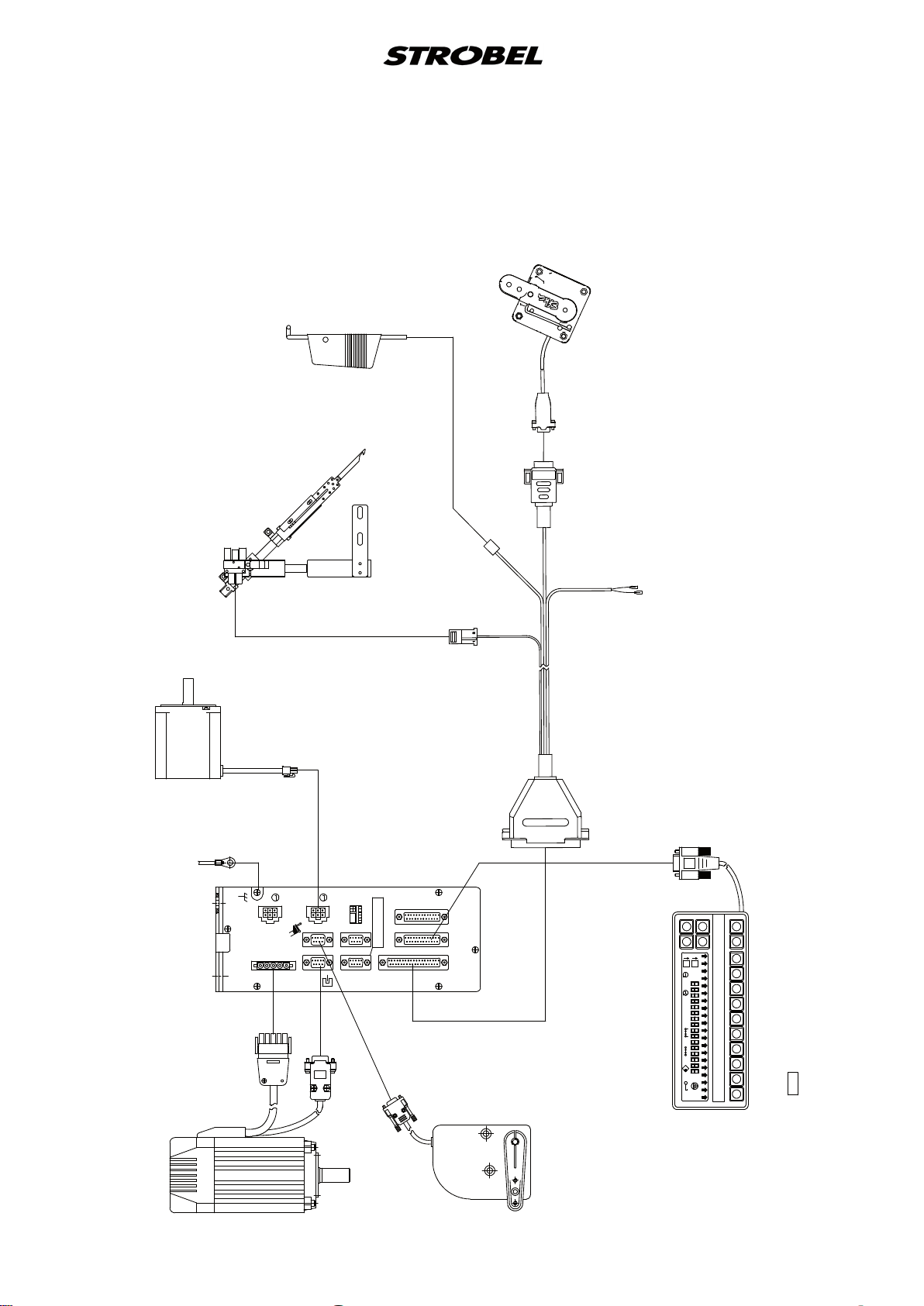

3. Display "Delete program"

- Press the "F2" button in the "Standard" display.

- Enter the program number using the keypad or "+/–" buttons.

- Confirm the entry with the "E" button.

- If no corresponding program is saved, this is indicated by the "*" icon.

- Otherwise a confirmation is expected once more to delete the

program definitely.

35 MA_441-1-2_A1_180830_en

- Confirm the deletion process with the "E" button.

- The two programs that belong together are always deleted (e.g.

00R+01L, 02R+03L…)

- Return to the standard display ("No Prog")

- Use the "P" button to switch into the "Standard" display without

deleting a program.

4. Display "Programming mode"

● Add new program

- Press the "P" button in the "Standard" display invoke the programming

mode.

- Enter the program number using the keypad or "+/–" buttons.

- Confirm with the "E" button or exit with the "P" button.

36 MA_441-1-2_A1_180830_en

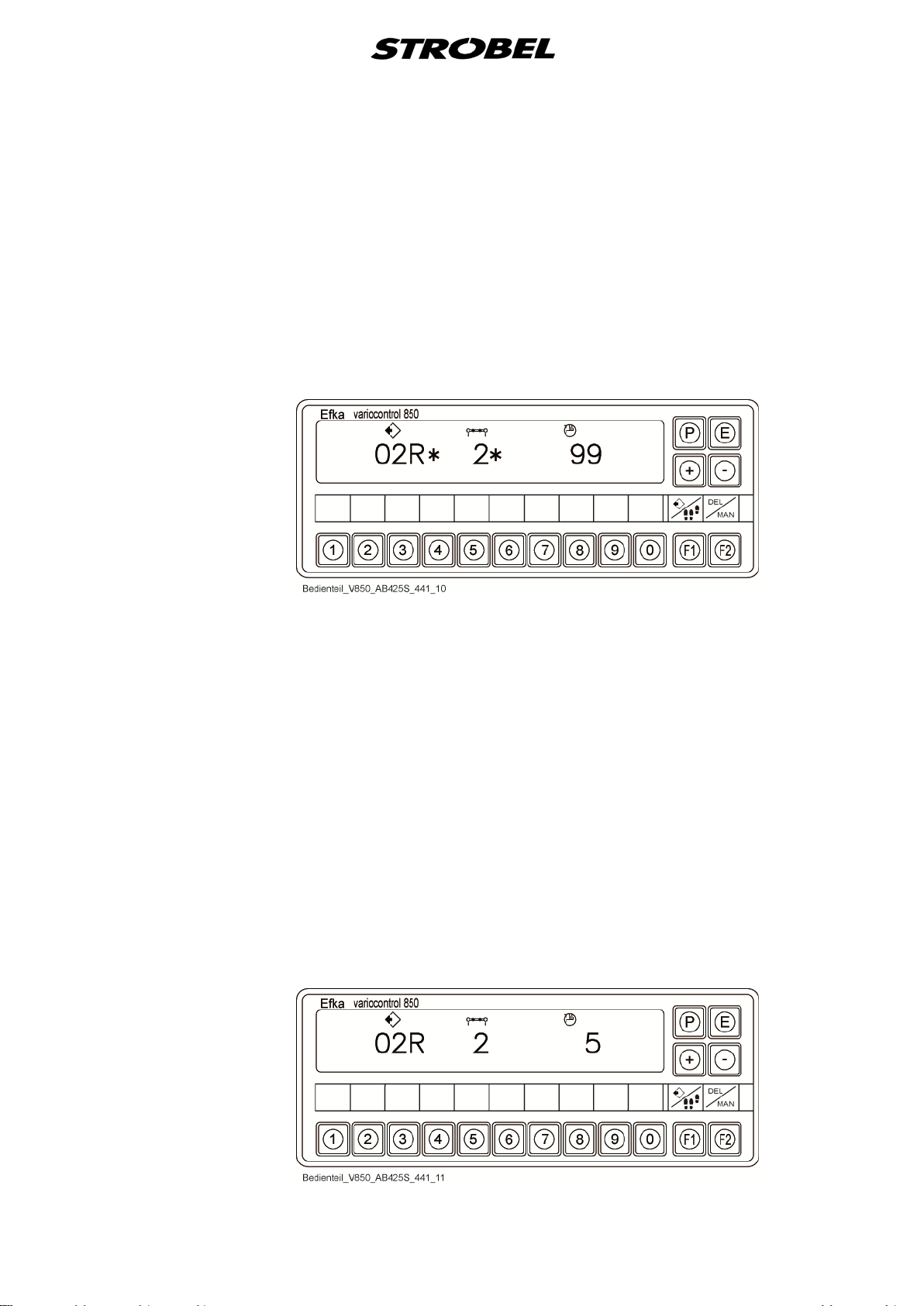

- It starts with the value of the differential transport of sector 1.

- The value "99" indicates that no differential transport has been set for

the current sector.

- Reduction differential transport begins to flash.

- The "*" icon behind the values of the program and sector numbers

indicate that this program number or this sector has not yet been

occupied (if the "*" icon cannot be seen in this display, then this

program number or the sector is already occupied).

- The corresponding value for differential transport can be set using the

"+/–" buttons.

- The sector is increased with the "E" button or the knee switch and the

next value for the differential transport can be entered.

- Once the desired sectors are programmed, the program is saved by

pressing the "P" button.

- During saving, the second associated program is created

automatically (e.g. 00R+01L, 02R+03L, 04R+05L…)

- Return to the standard display

● Process existing program

Add sector to the end

- Activate programming mode.

- Select and confirm program number.

- Press the "F1" button to display last sector.

37 MA_441-1-2_A1_180830_en

- Add a new sector with the "E" button or knee switch.

- Set the differential transport and save with "P" button.

- During saving, the second associated program is adapted

automatically (e.g. 00R+01L, 02R+03L, 04R+05L…)

- Return to the display "Standard".

Delete last sector

- Activate programming mode.

- Select and confirm program number.

- Press the "F1" button to display last sector.

- Press the "F2" button to delete the last sector ("Delete" is displayed).

- Press the "E" button to confirm the entry.

- The "P" button cancels the deletion process.

- If cancelling, return to display "Programming mode".

38 MA_441-1-2_A1_180830_en

- To make sure, the deletion needs to be confirmed by pressing the "E"

button again.

- Save and return to the display "Standard" by pressing the "P" button.

- The deletion process is also transferred to the second associated

program (e.g. 00R+01L, 02R+03L, 04R+05L…)

Process sector

- Activate programming mode.

- Select and confirm program number.

- If the program number is invalid, "No Prog" is displayed.

- Page through to the corresponding sector with the "E" button or knee

switch.

- Set the value of the differential transport.

- Save with the "P" button

- The processing process is automatically transferred to the second

associated program (e.g. 00R+01L, 02R+03L, 04R+05L…)

- Return to the display "Standard".

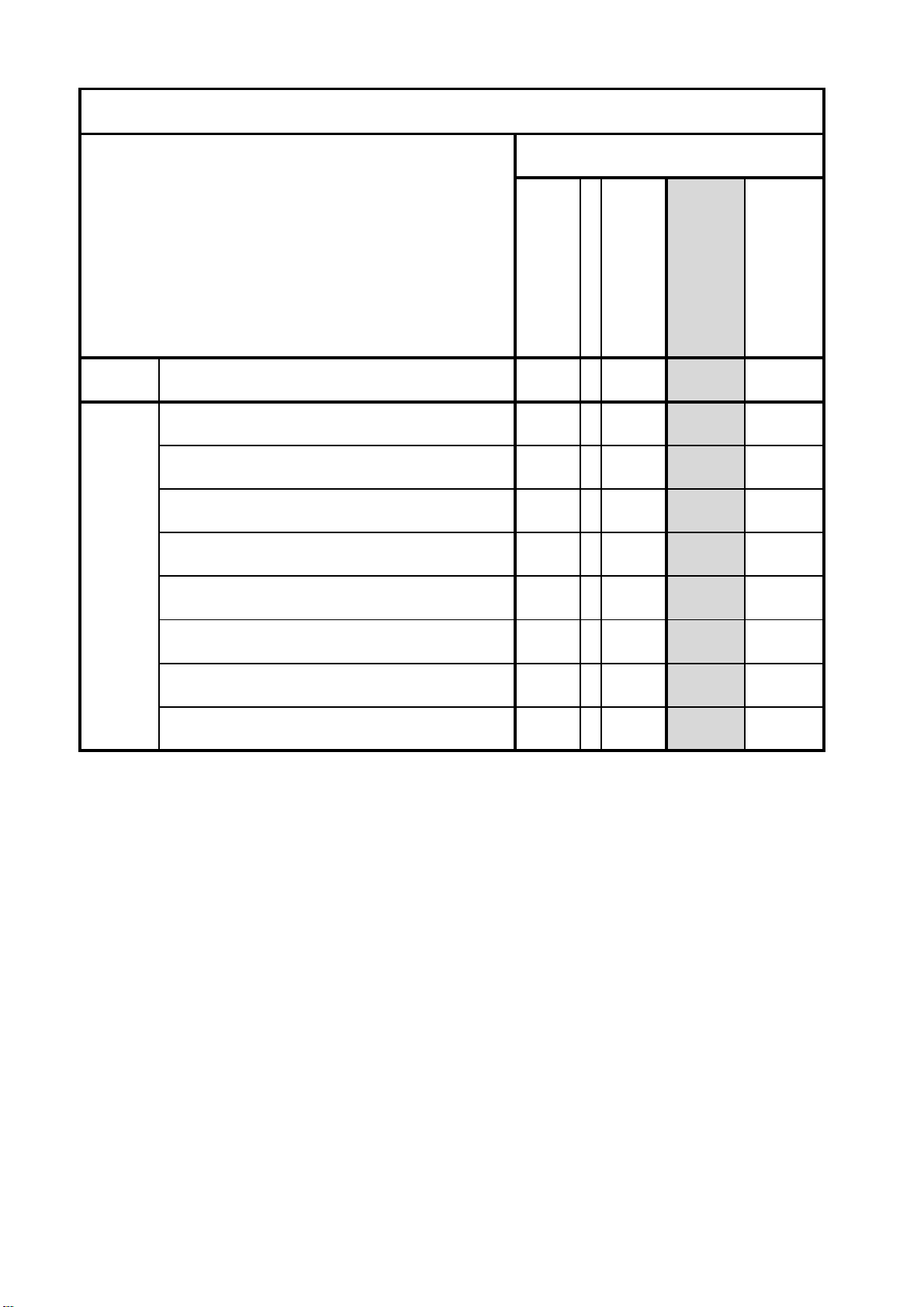

5. Display "Manual mode"

- The switching of the display into manual mode is done by a

parameter.

39 MA_441-1-2_A1_180830_en

4.17.3

Parameter und Functions F-714 (Class 441-2)

Parameter 714 defines the 1st sector for the start of sewing. Two options are

available.

The mirroring is done automatically in the right order for the right or left shoe.

The examples are based on an insole with 8 sectors.

The starting point for sewing is always at sector 1

Fig. 21

Parameter 714 = 0

40 MA_441-1-2_A1_180830_en

Parameter 714 = 1

41 MA_441-1-2_A1_180830_en

F-715 = 0

In this mode, e.g. the sewing program 02 for a right shoe

F-715 = 1

In this mode, e.g. the sewing program 02 for a right shoe

4.17.4 Parameter and Functions F-715 ( Clas s 441-2)

Function Parameter

Selection of processing via parameter F-715 F-715

With the Parameter F-715 you can decide if you want to use a sewing program

for pairwise shoe processing or single shoe processing.

and the sewing program 03 for a left shoe is repeated in

continuous sequence.

is repeated until you manually switch to the next sewing

program 03 for a left shoe.

4.17.5 Parameter and Func t ions F-760 (Class 441-2)

Function Parameter

Setting synchronized differential feed F-760

With this parameter, the synchronisation of the differential transport can be

finely adjusted if the material pairings have different friction values.

The factory setting is set to value "6".

In the factory setting "6" our off-sewing material is transported synchronously

between feed- and front cup.

If the materials have different values of friction, we have the option of fine

adjustment of the differential feed to ensure always synchronized operation.

Value 0 – 5 = More transport by the front cup

Value 6 = factory setting

Value 7 – 10 = Less transport by the front cup

After entering the code number "3112" for the supplier level:

- Select parameter F-760

- Press the "E" key

- Enter the value or correct the value up or down

- Press the "P" key

42 MA_441-1-2_A1_180830_en

Procedure to save the change

- Select parameter F-401

- change value to "1"

- Save the data by pressing the "P" key twice and exit the supplier level.

- Switch the control box off and on again so that the change is saved.

4.17.6

Copy sewing programs to a not he r machines (Class 441-2)

Here is a description, how to copy the sewing programs from a control box to a

USB stick and then transfer them to another control box.

Procedure with control panel V850

1.

Copy the sewing program from the controller

- Insert the USB stick into the control box

- Press the "P" key and switch the control box on at the same time

- Enter code 3112 and confirm with key "E"

- Select parameter F-514 and confirm with "E"

- Press the "F2" key

- Press the "E" key twice

- Then the file with the sewing programs is copied to the USB stick

- Press the "P" key and switch off the controller

- Now you can remove the USB stick from the control box

The file name, which is copied to the USB stick, is titled by the controller

"0300DATA.pay". This file can be renamed up to 8 characters, but the

extension always must be ".pay".

Example:

0300DATA.pay =>> shoe-1.pay

2.

Copy the sewing program to a control box

- Insert the USB stick into the control box

- Press the "P" key and switch the control box on at the same time

- Enter code 3112 and confirm with key "E"

- Select parameter F-515 and confirm with "E"

- Press the "F2" key

- Select the sewing program (for example, shoe -1.pay) using the

+/- buttons on the control panel

- Press the "E" key twice

- File with the sewing program is up-loaded in the control box

- Press the "P" key and switch off the controller

- Now you can remove the USB stick from the control box

43 MA_441-1-2_A1_180830_en

4.17.7 Brief instruction (Class 441-2)

44 MA_441-1-2_A1_180830_en

4.18

4.19

Servicing the mac hine

The individual oiling points of the machine are supplied fully automatically; the

machine needs no maintenance in this regard.

An oil change should be done about twice a year, depending on the amount of

dust and hours of operation. It is recommended to use 0.5 litres of oil for that;

an oil with the viscosity of 46 cSt.

(Recommended oil: Shell Voltol 46)

Also clean the plastic lever and the boreholes.

General notes

Further details such a sewing instructions and the like can be found in the

operating instructions, on the homepage.

45 MA_441-1-2_A1_180830_en

5

5.1

5.2

Notes on repair and adjustments

Feed cup assembly

In addition to the transport and front cups attached to the normal version,

optional transport and front cups are offered according to the various materials

to be processed and requirements with suitable gearing and edge heights; they

can be freely combined with each other.

Replacing the feed cup

If the feed cup in the machine should be exchanged with other geared feed

cups, then proceed first as follows:

1. Remove material guide (1) - 2x screw (2). (Fig. 22)

2. Pull out needle (1), cylinder head screw (2), needle clamping plate (3),

pressure spring (4) and needle setting plate (5). (Fig. 23)

3. Screw out the flat-head screws (6) of the feed cup attachment; take feed

cup off upwards. (Fig. 14)

4. The assembly of the exchanged feed cup is done in reverse order.

Fig. 22

46 MA_441-1-2_A1_180830_en

Fig. 23

5.2.1.1

Chain tension

The chain for the feed cup drive can be tensioned from above by loosening the

threaded pin (3) (

Fig. 22) the chain tensioner (5) (Fig. 4).

47 MA_441-1-2_A1_180830_en

5.3

Setting and installation instr uc t ion for the Strobel gather ing device

(See also operating instructions point "4.1.1.1 Processing with gathering

device")

The gathering device EV (1) (Fig. 24) is attached to the machine housing with

two screws (9). There are two threads made in the housing for that.

When mounting the EV, make sure that after swivelling down the guide (2)

between the feed cups it comes to a stop about 1 mm under the plate edge and

about 5 – 6 mm to the right of the needle.

For a subsequent mounting of the EV, a ∅24 borehole needs to be made in the

tabletop for the rods (3) (see tabletop drawing in the operating instructions).

Fig. 24

48 MA_441-1-2_A1_180830_en

258.10.27

Elekrischer Schaltplan AB425S Kl. 441-2 ab Ausf. 1

Electrical wiring diagram AB425S Cl. 441-2 as of version 1

Schrittmotor (SM)

Step motor (SM)

(B)

ge - ye

(A)

SM

(A)

rt - rd

rt/ws - rd/wh

sw - bk

sw/ws - bk/wh

ge/ws - ye/wh

gn/ws - gn/wh

gn - gn

(B)

B5

1

2

3

4

5

6

Schrittmotor (SM)

Step motor (SM)

Nähantriebsteuerung

Sewing drive control

195.0063

258.10.28

Elekrischer Schaltplan AB425S Kl. 441-2 ab Ausf. 1

Electrical wiring diagram AB425S Cl. 441-2 as of version 1

0V

+5V

Analog1

X10

1

5

7

br - bn

ws - wh

0V

Knietaster

X11

knee switch

2

3

br - bn

ws - wh

+24V

Impuls FA

1

X12

impulse FA

2

EV

br - bn

ws - wh

ws - wh

1V1

br - bn

br - bn

br - bn

ST2

2

+5V

ws - wh

gn - gn gn - gn

3

4

0V

br - bn

11

br - bn

18

+24V

ws - wh

26

27

+24V

Analog1

Knietaster

knee switch

Impuls FA

impulse FA

Nähantriebsteuerung

Sewing drive control

1V1 Magnetventil "Lüftung" (LÜ) solenoid valve "lifting" (LÜ)

EV Einhaltevorrichtung gathering device

ST2 Stecker Steuerkasten (Nähantrieb) plug control box (sewing drive)

X10 9-poliger Stecker "Sollwertgeber" 9-pin plug "setpoint device"

X11 RJ12 Buchse "Knietaster" RJ12 bush "knee switch"

X12 2-poliger Stecker "Fadenabschneider" 2-pin plug "thread trimmer"

ws - wh

29

gathering device (EV)

Einhaltevorrichtung (EV)

195.0064

258.30.28

Montageplan AB425S Kl. 441-2 ab Ausf. 1

Assembly plan AB425S cl. 441-2 as of version 1

298.0069

Knietaster

knee switch

Sollwertgeber

298.0688

setpoint device

298.0718

thread trimmer

Fadenabschneider

gathering device

Einhaltevorrichtung

296.0830

step motor

Schrittmotor

398.0717

(head)

(Oberteil)

296.0817

M

B6

Steuerung Nähantrieb

control box sewing drive

B41

DC15..

M

B5

stepper motor 2

EB...

B80

M

B776

stepper motor 1

V8 ..

ST21

Adapter 1113229

LSM+ HSM ; LSM +IPG

ST20

M

B2

DC15..

ST2

B18

IPG...

HSM...

LSM...

Efka

(998.0560)

Bedienteil

+ -

P E

F2

F1

M

298.0663

operating control

variocontrol 850

Efka

298.0560

Sollwertgeber

Motor Nähantrieb

motor sewing drive

setpoint device

Efka

296.0562

1 2 3 4 5 6 7 8 9 0

195.0065

259.00.67

Pneumatischer Schaltplan Kl. 441-2 ab Ausf. 1

Pneumatic circuit diagram cl. 441-2 as of version 1

1 A 1

1 V 1

B

B

P R

A

A

10bar max

0 Z 1 Wartungseinheit service unit

1 V 1 4/2-Magnetventil "Einhaltevorrichtung" (P-EV) 4/2-solenoid-way valve "gathering device" (P-EV)

1 A 1 Zylinder "Einhaltevorrichtung" (P-EV) cylinder "gathering device" (P-EV)

FA Fadenabschneider thread trimmer

0 Z 1

6bar

FA

195.0553

259.10.67

Pneumatischer Bauschaltplan Kl. 441-2 ab Ausf. 1

Pneumatic construction circuit diagram cl. 441-2 as of version

Einhaltevorrichtung / Gathering device (EV)

178.0009 2 Spanplattenschraube Ø5x30 chipboard screw Ø5x30

193.0896 1 Tragschiene mounting rail

293.0469 1 Schalldämpfer R 1/8 silencer R 1/8

293.0772 2 Verschlußschraube R 1/8 lock screw R 1/8

293.0837 2 L-Einschraubanschluss R 1/8-4 L-threaded connection R 1/8-4

293.0850 1 L-Einschraubanschluss R 1/8-6 L-threaded connection R 1/8-6

293.0853 2 L-Einschraubanschluss M5-4 L-threaded connection M5-4

293.0975 1 Wartungseinheit service unit

297.0170 1 Schnellverschlusskupplung Ø8 coupling Ø8

298.0362 1 Miniatur-Zylinder miniature cylinder

298.0510 1 4/2-Wege Magnetventil 4/2-solenoid-way valve

298.0511 1 Eingangsmodul G1/8 links input module G1/8 left

298.0512 1 Eingangsmodul G1/8 rechts input modul G1/8 right

gathering device

Einhaltevorrichtung

293.0853

298.0362

196.0716 Ø4

196.0716 Ø4

293.0837

298.0512

Magnetventil

solenoid valve

298.0510

293.0469

298.0511

193.0772

293.0850

193.0473 Ø6

Fadenabschneider / Thread trimmer (FA)

293.0849 1 T-Einschraubanschluß R1/8x6 T-threaded connection

293.0975 1 Wartungseinheit service unit

297.0170 1 Schnellverschlusskupplung Ø8 coupling Ø8

298.0718 1 Fadenabschneider thread trimmer

298.0718

thread trimmer

Fadenabschneider

193.0478 Ø8

195.0554

293.0849

(293.0850)

service unit

Wartungseinheit

293.0975

(293.0841)

193.0478Ø8 3000 lg

297.0170

service unit

Wartungseinheit

293.0975

(293.0841)

193.0478Ø8 3000 lg

297.0170

56

Softstart ON/OFF

1

Not assigned

1

Thread trimmer ON/O FF

1

Output M3 ON/OFF

1

Button ">>" Seg6

0

Button "-" Seg7

Automatic lifting in the seam

0

1

Button "-" Seg8

Automatic lifting at the seam end

0

1

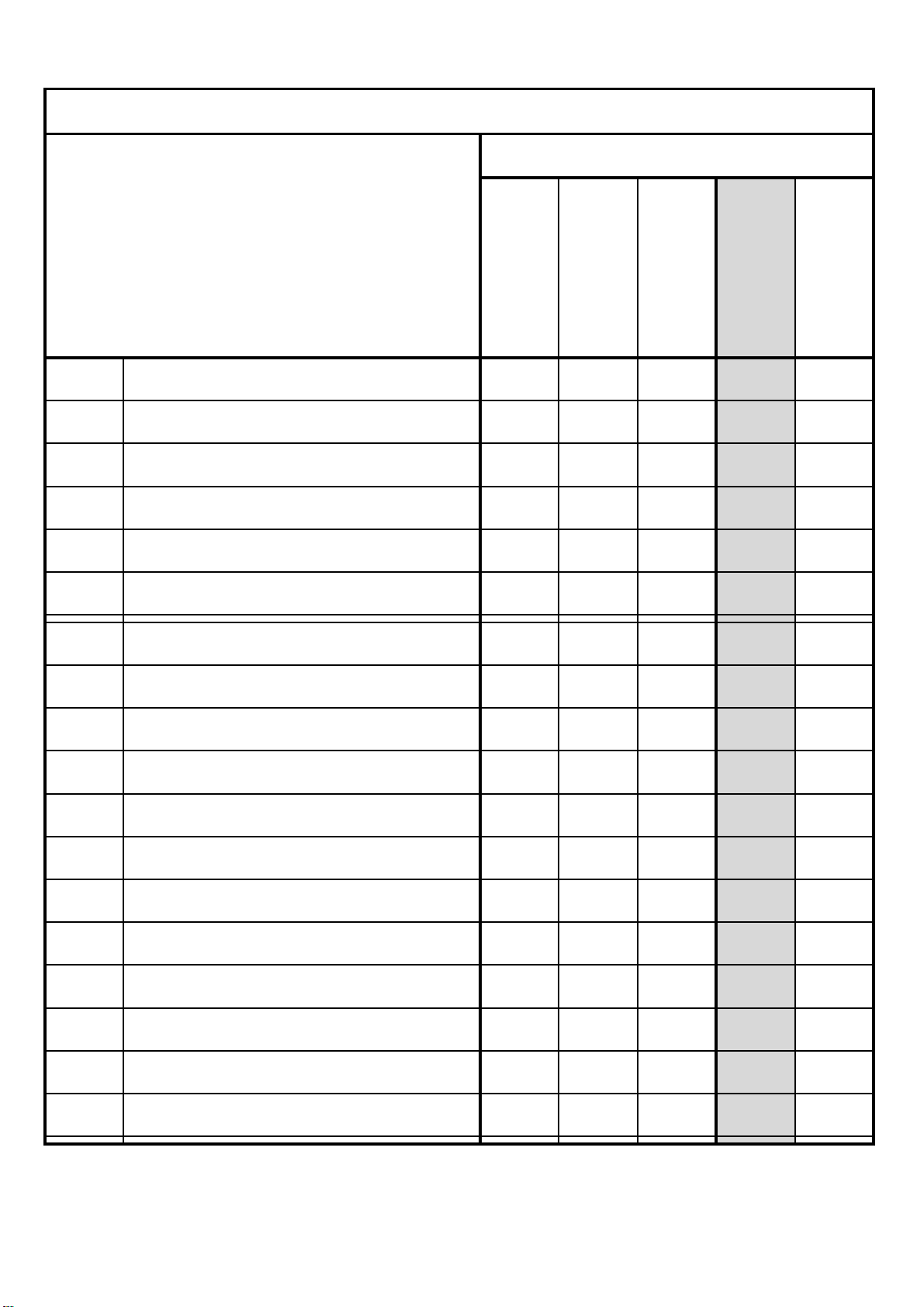

Strobel-Switchable Functions - DC1200-AB611A

Explanation:

0 = Off

1 = On

Machine class

F-290 Mode

Button "E" Seg1

Button "E" Seg2

Button "+" Seg3

Button "+" Seg4

Button ">>" Seg5

"Control"

Stand: 23.07.2018 - PT_AB611A _441-1_180723

Basic position "needle position 1"

Basic position "needle position 2"

00

0

0

0

0

0

1

1

Setting range

Preset at mode 56

56 56 56

0 0 0

0 0 0

0 0 0

0 0 0

0 1 1

1 0 0

0 0 0

1 1 1

441-1

441-1F

1

10

56

0

2

Thread trimmer

OFF/ON

0

1

OFF/ON

1

Lifting with

pedal position "-1"

0

4

EB401

4

000

254

390

Maximum speed n2-

(setting range)

n2_

9900

0070

1500

setting range

n2-

Softstart

OFF/ON

0

1

machine standstill

50

0

1

000

359

990

0

1

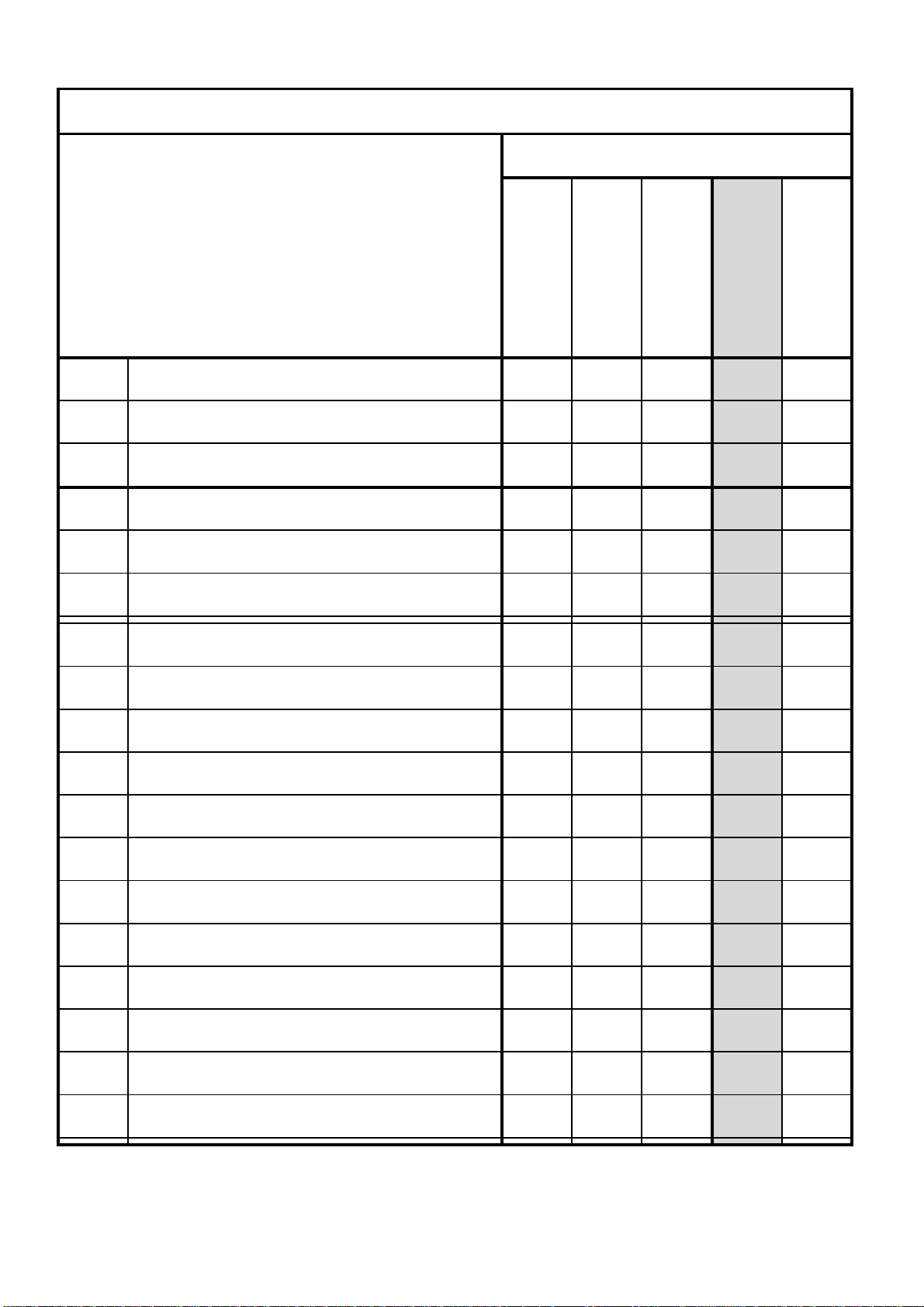

Strobel-Parameter list - DC1200-AB611A

Machine class

F-467 Motor selection

F-290 Mode

F-365 Machine classes selction

F-013

F-014

F-019

F-026

F-100 Stitch number softstart

F-110 Positioning speed n1

F-111

Characteristic of the pedal

Output 3

00

0

0

070

Setting range

Unit

min-1 200 200 200

min-1 2200 1800 1800

Preset at mode 56

3 3 3

56 5 5

0 0 0

0 0 1

0 1 1

3 3 3

4 4 4

002 002 002

441-1

441-1F

F-115 Softstart speed n6

F-121

F-134

F-153

F-161 Direction of rotation of the motor

F-180 Number of turn-back s t eps

F-181 Switch delay for turn back

F-182 Turn backOFF/ON

Lower limit of the n-max

Holding force during

0200

00

000

min-1 0500 0500 0500

min-1 0200 0200 0200

0 0 0

05 05 05

0 0 0

Grad 040 175 175

ms 200 010 010

0 0 0

Strobel-Parameter list - DC1200-AB611A

Braking effec t when changing

transmission ratio 1:1)

Braking effec t when changing

transmission ratio 1:1)

00

55

Accelerating power of the drive

transmission ratio 1:1)

0

1

47

0

6

0150

9999

Thread trimmer (M1)

5000

On-time

Thread trimmer (M1)

0000

5000

Output M3

5000

On-time

Output M3

0000

5000

0000

5000

Machine class

F-207

F-208

F-219 Positioning force when stopping the dr ive

F-220

F-234 Restarting after activated run inhibition

F-240 Selecting the input function I n. 1

F-270 Selection o9f the position sensors

F-272 Transmission motor shaft to machine shaf t

the set-point <= 4 steps

(indicated valus only with

the set-point >= 5 steps

(indicated valus only with

(indicated valus only with

00

55

00

55

00

55

00

Setting range

Unit

Preset at mode 56

15 15 15

20 20 20

04 04 04

20 20 20

1 0 1

00 00 00

0 6 6

1000 1000 1000

441-1

441-1F

F-280

F-281

F-284

F-285

F-288 Delay time till lifting On

Stand: 23.07.2018 - PT_AB611A _441-1_180723

Delay time

Delay time

0000

0000

ms 0100 0000 0000

ms 0180 0100 0100

ms 0000 0200 0200

ms 0300 0100 0100

ms 0200 0380 0380

56

Softstart ON/OFF

1

Not assigned

1

Thread trimmer ON/O FF

1

Output M3 ON/OFF

1

Button ">>" Seg6

0

Button "-" Seg7

Automatic lifting in the seam

0

1

Button "-" Seg8

Automatic lifting at the seam end

0

1

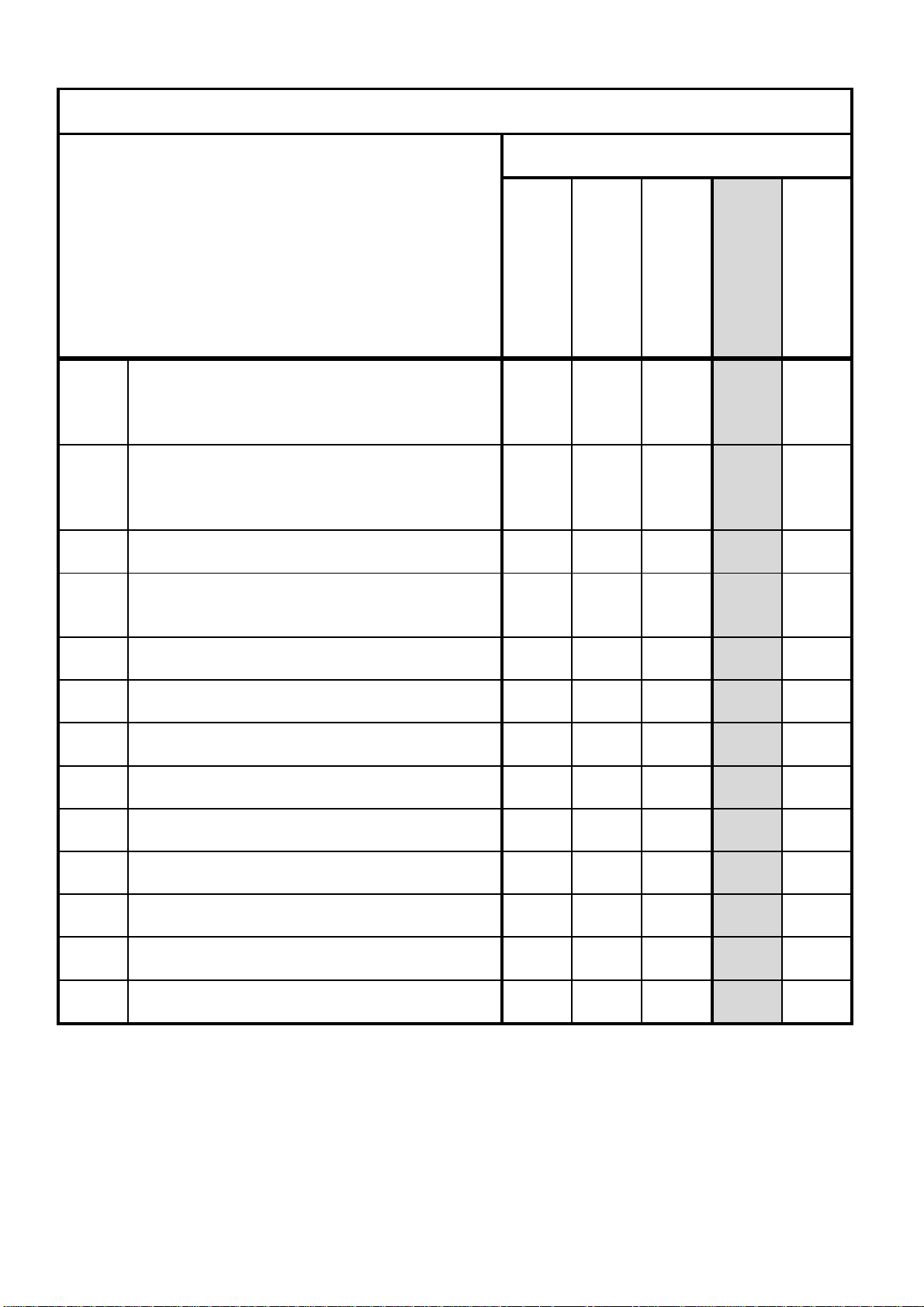

Strobel-Switchable Functions - DC1500-AB425S

Machine class

Explanation:

0 = Off

1 = On

F-290 Mode

Button "E" Seg1

Button "E" Seg2

Button "+" Seg3

Button "+" Seg4

Button ">>" Seg5

"Control"

Stand: 24.07.2018 - PT_AB425S _441-2_180724

Basic position "needle position 1"

Basic position "needle position 2"

00

0

0

0

0

0

1

1

Setting range

Preset at mode 56

56 56 56

0 0 0

0 0 0

0 0 0

0 0 0

0 1 1

1 0 0

0 0 0

1 1 1

441-2

441-2F

1

10

56

2

OFF/ON

1

Output 3

OFF/ON

0

1

Lifting with

pedal position "-1"

0

4

Characteristic of the pedal

EB401

0

4

000

254

070

390

Maximum speed n2-

(setting range)

n2_

9900

1500

Lower limit of the n-max

setting range

0200

n2-

Softstart

OFF/ON

0

1

Holding force during

machine standstill

00

50

0

1

359

000

990

0

1

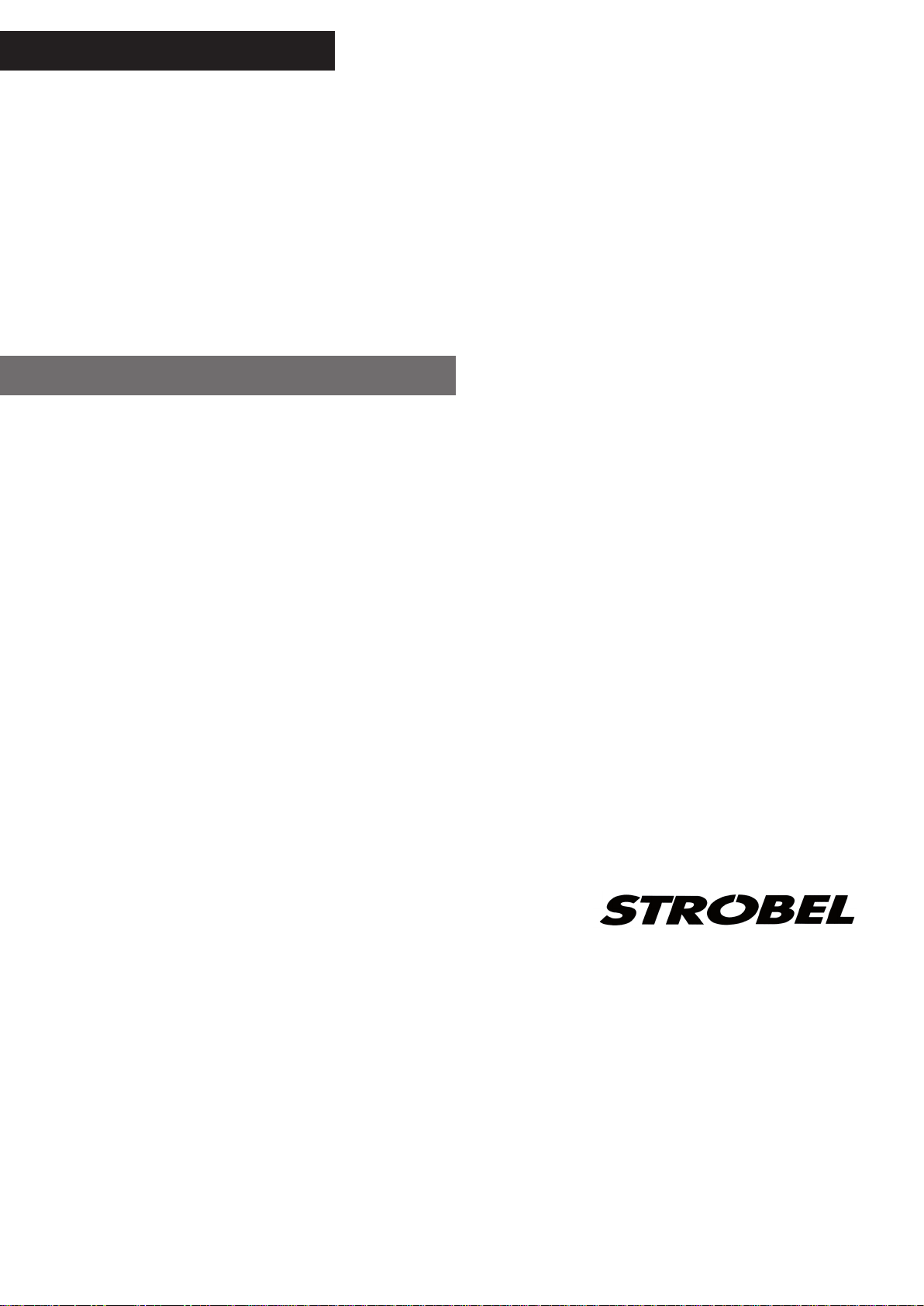

Strobel-Parameter list - DC1500-AB425S

Machine class

F-467 Motor selection

F-290 Mode

F-365 Machine classes selction

F-013

F-014

F-019

F-026

F-100 Stitch number softstar t

F-110 Positioning speed n1

F-111

Thread trimmer

00

0

0

Setting range

Unit

min-1 200 200 200

min-1 2200 1800 1800

Preset at mode 56

3 1 1

56 5 5

0 1 1

0 0 1

0 1 1

3 3 3

4 4 4

002 002 002

441-2

441-2F

F-115 Softstart speed n6

F-121

F-134

F-153

F-161 Direction of rotation of t he m otor

F-180 Number of turn- back steps

F-181 Switch delay for turn back

F-182 Turn backOFF/ON

0070

000

min-1 0500 0500 0500

min-1 0200 0200 0200

0 0 0

05 05 05

0 0 0

Grad 040 040 040

ms 200 200 200

0 0 0

Strobel-Parameter list - DC1500-AB425S

Braking effec t when changing

transmission ratio 1:1)

Braking effec t when changing

transmission ratio 1:1)

00

55

Accelerating power of the drive

transmission ratio 1:1)

0

1

47

0

6

0150

9999

Thread trimmer (M1)

5000

On-time

Thread trimmer (M1)

0000

5000

Output M3

5000

On-time

Output M3

0000

5000

0000

5000

Machine class

F-207

F-208

F-219 Positioning force when stopping the drive

F-220

F-234 Restarting after activated run inhibition

F-240 Selecting the input function In.1

F-270 Selection o9f the position sensors

F-272 Transmission motor shaf t t o machine shaft

the set-point <= 4 steps

(indicated valus only with

the set-point >= 5 steps

(indicated valus only with

(indicated valus only with

00

55

00

55

00

55

00

Setting range

Unit

Preset at mode 56

15 15 15

20 20 20

04 04 04

20 35 35

1 0 1

00 00 00

0 0 0

1000 1000 1000

441-2

441-2F

F-280

F-281

F-284

F-285

F-288 Delay time till lift ing On

Stand: 24.07.2018 - PT_AB425S _441-2_180724

Delay time

Delay time

0000

0000

ms 0100 0000 1000

ms 0180 0180 0180

ms 0000 0200 0200

ms 0300 0300 0300

ms 0200 0200 0200

Und wir können noch mehr für Sie tun!

Unser Lieferprogramm bietet für jede Branche und

jegliche Anforderung genau die richtige Problemlösung.

And we can do a lot more for you!

Our range offers the correct problem solution for

every branch and for all requirements.

Für die Bekleidungsindustrie:

Ein- und ZweifadenHochleistungs-Saummaschinen

DoppelblindstichSaummaschinen

Zweifaden-BlindstichStafermaschinen

Roll- und Flachpikiermaschinen

Pikier-Automat

und

weitere Spezial-Nähmaschinen

For the clothing

industry:

Single and two thread high

performance hemming

machines

Bluff edge hemming machines

Two thread blind stitch felling

machines

Roll and at padding machines

Automatic lapel padding

machine

Für die Schuhverarbeitung:

Einfaden-Überwendlichmaschinen mit und ohne

Differentialtransport

For the shoe industry:

Single-thread overseaming machines with and without differential feed

Für Kürschnereien

und Pelzkonfektion:

Pelzschnellnäher

For the fur industry:

High-speed fur sewing machines

Für Heimtextilien:

Ein- und ZweifadenBlindstichmaschinen

For the home textiles

industry:

Single and two thread

blind stitch machines

Für die Polsterverarbeitung:

Ein- und ZweifadenÜberwendlichmaschinen

Ein- und ZweifadenBlindstichmaschinen

For the upholstery

industry:

Single and two thread

overseaming machines

Single and two thread

blind stitch machines

Für die Konfektion

technischer Textilien:

Ein- und ZweifadenÜberwendlichmaschinen

For the processing

of technical textiles:

Single and two thread

overseaming machines

and other special sewing

machines

Noch Fragen?

Dann rufen Sie uns an, schreiben Sie uns oder

kommen Sie einfach bei uns vorbei.

Sie können jederzeit weitere Informationen über

unsere Produkte anfodern oder die StrobelNähmaschinen in unserem Ausstellungsraum live

erleben. Wir freuen uns auf Sie!

Any further questions?

Then phone, write or simply come and see us. You

can have further information about our products at

any time, or experience the Strobel machines live in

our show room. We’re looking forward to meeting you!

Sp ez i al ma s ch in e n Gm bH

Postfach 1242

82168 Puchheim

Siemensstraße 3

82178 Puchheim

DEUTSCHLAND

www.strobel.biz

Telefon: +49 89 80096-0

Telefax: +49 89 80096-190

Loading...

Loading...