For the professional user

Operating Instructions

Für den professionellen Anwender

Betriebsanleitung

Class:

Klasse:

Dated:

Stand:

310D-R Ausf. 16

3100D-R Ausf. 3

Spezialmaschinen GmbH

The sign of quality

ou nd the Strobel trademark on every Strobel

Y

machine leaving our works. And with good reason.

This symbol is a guarantee of the high quality of

our products. Quality which creates trust – trust

in our technology, our service and, not least of all,

in our good name.

Im Zeichen der Qualität

ie nden die Strobel-Schutzmarke auf jeder

S

Strobel-Maschine, die unser Werk verlässt.

Und das aus gutem Grund. Denn dieses Zeichen

garantiert Ihnen die hohe Qualität unserer

Produkte. Qualität, die Vertrauen schafft – in unsere

Technik, unseren Service und nicht zuletzt in unseren

guten Namen.

A decision with future

trobel clients know that they can expect a particularly

S

high standard of performance from our company and our

machines. Now you have settled for one of our products.

For us this is a source of encouragement and of obligation

to Justify your trust.

If you wish to prot from the performance and efciency of

your Strobel machine as long as possible, exact handling

and thorough care is necessary. For this reason we kindly

request that you read the operating instructions closely.

It provides all the information you need for trouble free

operation.

And if you do happen to need a spare part the enclosed

spare parts list gives a complete overview. It is clearly

classied according to components so that you can nd the

required part quickly and easily. In order to avoid errors we

request you to quote machine class, machine number and

part number completely on your spare part order.

We wish you lots of success in your work with your new

Strobel machine.

Spezialmaschinen GmbH

1 BA_310D-R_3100D-R_A16-3_180117_en

2 BA_310D-R_3100D-R_A16-3_180117_en

Operating Instructions

STROBEL Classes 310D-R and 3100D-R

Contents

1 General notes on safety ............................................................................................ 5

2 General ..................................................................................................................... 7

2.1 Operating instructions ..................................................................................... 7

2.2 Class description, machine number and reference position left/right ............. 7

2.3 Machine applications ...................................................................................... 7

2.4 Technical data ................................................................................................ 8

3 Set-up and commissioning ........................................................................................ 9

3.1 Unpacking of the machine .............................................................................. 9

3.2 Setting up the machine (Fig. 1 and Fig. 2) ...................................................... 9

3.3 Sense of rotation (Fig. 3) .............................................................................. 13

3.4 Motor drive via toothed belt .......................................................................... 13

3.4.1 Tension of the toothed belt (Fig. 4) .................................................. 13

3.4.2 Positions of the machine .................................................................. 14

3.5 Intermediate venting (Fig. 5) ......................................................................... 15

4 Notes on usage ....................................................................................................... 16

4.1 Needles and threads .................................................................................... 16

4.2 Inserting the needle (Fig. 6) .......................................................................... 16

4.3 Threading and thread run (Fig. 7) ................................................................. 17

4.4 Winding up the thread (Fig. 8) ...................................................................... 19

4.4.1 Installing the bobbin and threading the bobbin thread (Fig. 9) ......... 19

4.5 Thread tensioning (Fig. 6) ............................................................................ 20

4.5.1 Thread tightening spring – needle thread (Fig. 10) .......................... 20

4.5.2 Thread tensioning – reel thread (Fig. 11) ......................................... 21

4.6 Adjusting the stitch length (Fig. 8 and Fig. 12) ............................................. 21

4.6.1 Adjusting the upper feed path (Fig. 6) .............................................. 22

4.7 Stitch depth................................................................................................... 23

4.7.1 Adjusting the stitch depth (Fig. 2 and Fig. 6) .................................... 23

4.7.2 Digital stitch depth display (Fig. 13) ................................................. 24

4.7.3 Changing the battery (Fig. 13) ......................................................... 24

4.8 Plunger stop ................................................................................................. 25

4.8.1 Adjusting the plunger stop (Fig. 14) ................................................. 25

4.9 Interval gear .................................................................................................. 26

4.10 Seam lock ..................................................................................................... 27

4.10.1 General ............................................................................................ 27

4.11 Sewing drive ................................................................................................. 27

3 BA_310D-R_3100D-R_A16-3_180117_en

5 Operating the sewing machine ................................................................................ 28

5.1 Switch-on ...................................................................................................... 28

5.2 Inserting and removing the sewing material ................................................. 29

5.3 Sewing .......................................................................................................... 29

5.3.1 Hemming with blind stitc h ................................................................ 30

5.4 Problems during sewing and troubleshooting ............................................... 31

5.5 Incorrect stitches (Fig. 16) ............................................................................ 34

6 Machine maintenance ............................................................................................. 35

7 Variable sewing tools .............................................................................................. 36

8 Optional Extras ........................................................................................................ 41

8.1 Plunger ......................................................................................................... 41

8.2 Additional parts for hemming half lined jackets ............................................ 41

Subject to change without prior notice

4 BA_310D-R_3100D-R_A16-3_180117_en

1 General notes on safety

Every person in charge of setting up, operating, servicing and repairing the

machine must first read and understand the operating instructions and

particularly the safety instructions before starting up the machine.

Failure to comply with the following safety instructions can lead to bodily

injury or damage to the machine.

1. The machine must only be operated by persons familiar with the relevant

operating instructions and who have been instructed accordingly.

2. Before commissioning also read the notes on safety and the operating

instructions of the sewing drive manufacturer.

3. Only use the machine in the intended manner and never without the

provided guards. Always observe the pertinent safety regulations.

4. Switch off the main switch or pull the power plug for threading, changing

the reels, exchanging sewing tools such as needle, gripper, needle plate,

transport devices, possibly cutter and cutting block, for cleaning and when

leaving the workplace as well as for maintenance.

5. General maintenance tasks may be carried out only by properly trained

persons in accordance with the operating instructions.

6. Repair work, retrofitting and maintenance may be carried out only by

technicians or specially trained personnel.

7. When servicing or repairing pneumatic equipment, the machine must be

disconnected from the pneumatic supply. Exceptions are only allowed for

adjustment work and tests of functionality performed by specially trained

technicians.

8. Only specially qualified technicians may work on the electrical equipment.

9. It is forbidden to work on electrically live components! Exemptions are

covered by the EN50110 (DIN VDE0105) regulations.

10. Any retrofitting or alterations to the machine may only be performed under

strict compliance with all pertinent safety regulations.

11. Only use our approved spare parts when servicing and/or repairing the

machine.

12. It is forbidden to operate the sewing head until it is determined that the

entire sewing unit complies with EU provisions.

13. It is essential that you observe and follow these instructions as well as the

generally valid safety regulations.

5 BA_310D-R_3100D-R_A16-3_180117_en

14. Warning instructions given in the operating instructions that pertain to

especially dangerous parts of the machine must be indicated at these

positions using a safety symbol.

Warning instructions given in the operating instructions that pertain to

special injury hazards for operating personnel or technicians must be

indicated at these positions using a safety symbol.

6 BA_310D-R_3100D-R_A16-3_180117_en

2 General

2.1 Operating instructions

Any person involved in the installation, operation, maintenance and repair of

the machine must have read and understood the operating instructions and

mainly the safety instructions before starting the machine.

2.2 Class descript ion, machine number a nd reference position left/right

For side-referenced descriptions, the operating side of the machine is the

starting base.

The class descriptions (type) are at the front, the machine and model number

(towards the hyphen) is located below the cover on the right side on the

housing.

2.3 Machine applications

Cl. 310D-R

Two thread blind stitch lock stitch machine for trimming the inside lining up to 8

mm under the lining fold in the jacket hem.

Cl. 3100D-R

Two thread blind stitch lock stitch machine with extended upper and lower arm

for trimming the fabric hem 6 mm (selectable 4 or 8 mm) underneath the hem

edge of jackets.

The enclosed accessories parts enable selectable the execution of both work

sequences for the machines.

Variable sewing tools you will find under point 7.

7 BA_310D-R_3100D-R_A16-3_180117_en

2.4 Technical data

Speed:

Max. mechanically admissible 1300 min-1

Recommanded rated speed 1300 min-1

Motor power 550 W

Toothed belt pulley/machine Z = 38

Toothed belt profile HTD 5M-9

Stitch length-upper feed 3 - 6 mm

(depend on fabric)

Kind of stitch: two thread blindstitch lockstitch

Stitch type 313

Needle system GROZ-BECKERT 1828 E

Needle size 80

Thread polyester continuous filament

Thread size 120/2

Air pressure 6 bar

Average air consumption

Cl.310D-R 25 l/h

Cl.3100D-R 20 l/h

Foot print 0.5 m x 1.1 m

Noise:

Average noise level at a speed of

n = 1300 min-1: LpAm 75 dB(A)

Noise test according to DIN 45635-48-1 KL3

8 BA_310D-R_3100D-R_A16-3_180117_en

3 Set-up and commissioni ng

3.1 Unpacking of the machi ne

Strobel machines are supplied either complete as upper part only.

The cotton stand and another machine accessories are located in the

packaging.

Prior to disposing of the packing material it must be carefully checked whether

all accessories parts have been unpacked.

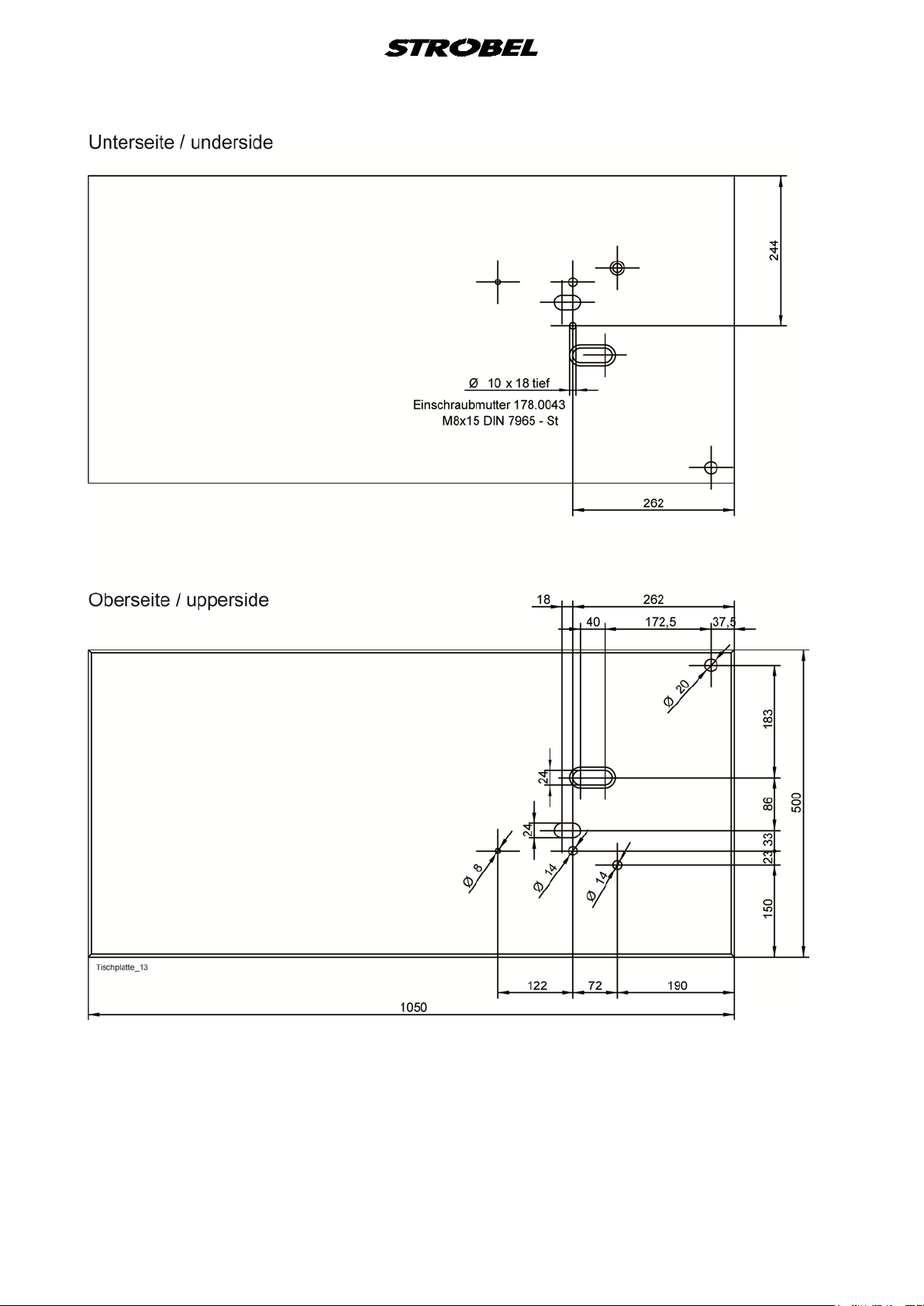

3.2 Setting up the machi ne ( Fig. 1 and Fig. 2)

CAUTION! Danger of injury!

Due to pulling in of parts of clothing or hair as well as

danger of crushing of fingers!

The machine must not be operated without a guard for the

belt for the upper part and for the motor.

The upper part of the table plate must be provided with bores according to the

drawing.

Frame and pedals as well as electrical connections must be mounted according

to the printed circuit.

Screw on the motor. The electric connection must be carried out according to

the printed circuit in the enclosed operating instructions for the motor.

Screw the upper part to the table plate. (Fig. 2)

The bolts (1) and the pressure spring (2) are enclosed with the machine

accessories and must be fitted as shown in Fig. 2.

The pedal rod system must be suspended according to Fig. 1.

Push on the knee lever and secure with knurled screw.

(Not necessary with pneumatic venting)

9 BA_310D-R_3100D-R_A16-3_180117_en

Fig. 1

Class 310D-R

10 BA_310D-R_3100D-R_A16-3_180117_en

Class 3100D-R

11 BA_310D-R_3100D-R_A16-3_180117_en

The cotton stand is mounted at the back on the right on the table plate after

assembly of the individual parts. (Fig. 1)

Check all screws at the frame for tight fit and retighten if necessary.

Mount the position transmitter and adjust corresponding to point “3.4.2

Positions of the machine“.

ATTENTION!

Prior to commissioning the machine it must be checked

whether the electric connection data on the type plate of the

motor, especially the network voltage and the frequency,

are according to the data of your current network.

All rust prevention agents, such as Vaseline or similar, must be carefully

removed from the sewing tools prior to commissioning the machine.

Fig. 2

12 BA_310D-R_3100D-R_A16-3_180117_en

3.3 Sense of rotation (Fig. 3)

The correct sense of rotation of the hand wheel is clockwise when looking at it

from the front.

Fig. 3

3.4 Motor drive via t oot he d be lt

3.4.1 Tension of the toothed bel t ( Fig. 4)

CAUTION! Danger of injury!

To check the tension of the toothed belt, switch off the

machine electrically, pull the mains plug and ensure the

machine has actually stopped by pressing the motor pedal.

The machine must not be operated without a belt guard for

the motor.

The tension of the toothed belt should not be too great. Slight thumb pressure

should be able to push the belt through by approx. 5 mm.

A too little or too great toothed belt tension can deteriorate the positioning of the

machine and therefore impair the function sequence.

Tensioning the toothed belt (Fig. 4):

a) Release upper and lower retaining screw (1), (2) at the machine upper

part.

b) Pull out the motor slightly and tighten the lower retaining screw (2) slightly.

c) Tension the toothed belt by swivelling the motor.

d) Retighten the upper and lower retaining screw (1), (2).

13 BA_310D-R_3100D-R_A16-3_180117_en

Fig. 4

3.4.2 Positions of the ma c hine

CAUTION! Danger of injury!

Danger of pulling in parts of clothing and of hair and danger

of crushing fingers and stitching fingers with needles!

When checking positions with switched-on machine keep

fingers and hands away from moving parts.

Machine with or without pneumatic:

The machine requires a needle position and depending on the sewing drive,

possibly also a reference position.

Reference position:

The reference position must be set in such a way, that the point of the

needle in direction of the insertion stitch closes with the right (inner) edge

of the needle slide plate.

Needle position (with stop in and outside the seam:

The needle position needs to be set in such a way that when the machine

is at standstill and the lifting is open the tip of the needle points in the

direction of the right stitch and the plunger, feed dog, and presser plate

are at one level (the position is located at about 8 mm after the upper

needle turning point).

Notes for sewing drives which have two needle positions:

The needle position mentioned above is position 2 at the sewing drive.

The position 1 at the sewing drive should be set in such a way that when

the machine is at standstill the tip of the needle stands about

3 mm in the direction of the left stitch after the lower needle turning point.

14 BA_310D-R_3100D-R_A16-3_180117_en

3.5 Intermediat e venting (Fig. 5)

If an intermediate venting with the knee lever should become necessary with

attached pneumatic venting, it can be mounted on the screw (1) in its usual

position.

Fig. 5

15 BA_310D-R_3100D-R_A16-3_180117_en

4 Notes on usage

for using different needle types.

4.1 Needles and threads

By selecting the most suitable needles and threads for the relevant sewing

material one can influence the sewing quality decisively.

Only tested GROZ-BECKERT needle system 1828 E should be used.

The machine is supplied with needles of thickness 80.

Note: An intact needle is of decisive importance for a good initial stitch.

Bent needle points, which can in part only be visible under a

magnifying glass, impair the sewing result.

Therefore, exchange your needles in good time!

We recommend endless twined polyester threads with a thickness of 120/2.

They are to be preferred to a spun thread, due to their high strength and good

sliding ability at low thread volume.

Guaranteed remark!

This machine has been set and sewn off with genuine

GROZ-BECKERT needles.

No guarantee can be granted if the settings are modified

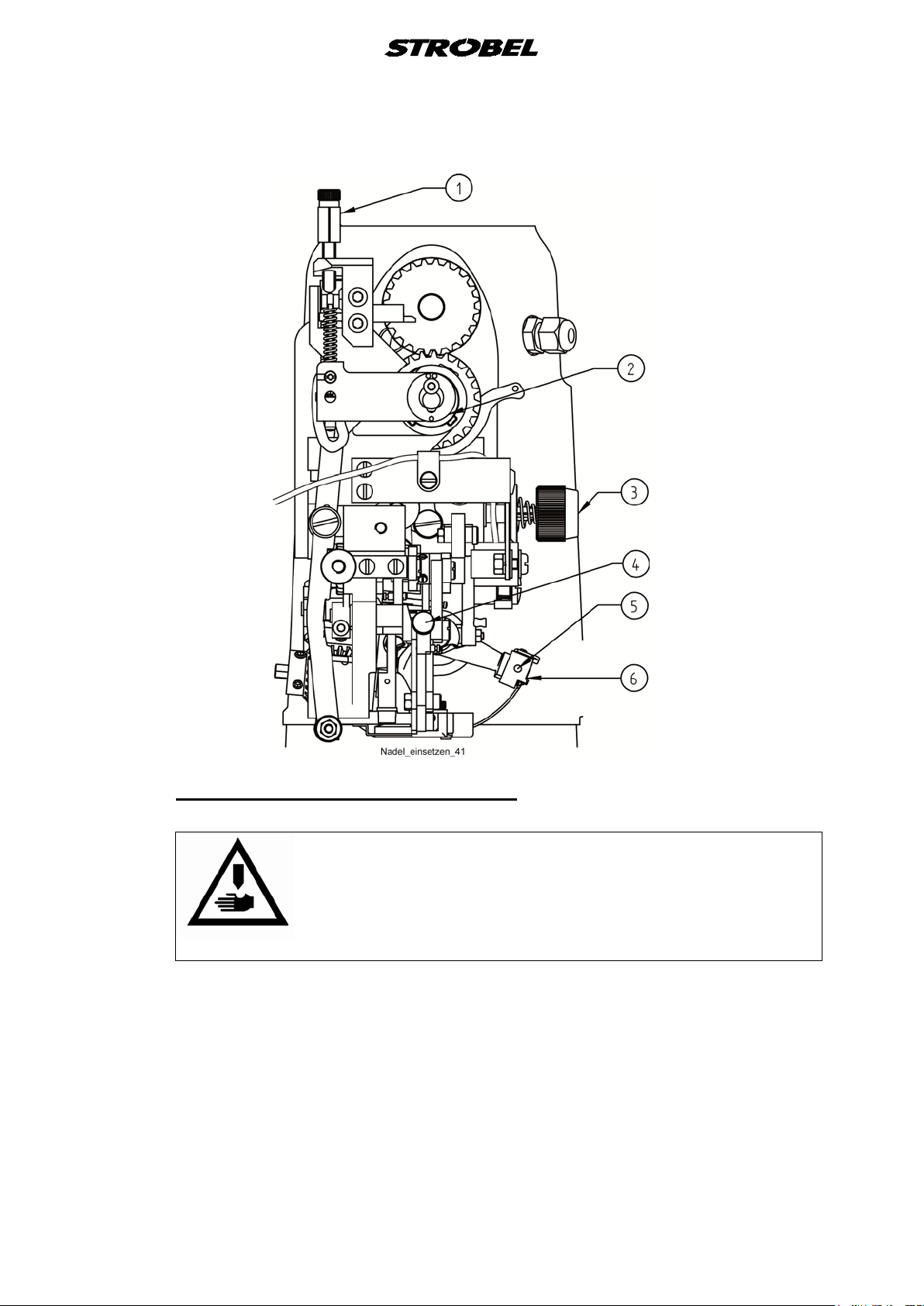

4.2 Inserting the nee dle (Fig. 6)

CAUTION! Danger of Injury!

Switch off the machine before changing the needle and

ensure the machine is off by pressing the pedal for

switching the motor. Otherwise there is a danger of injury

Due to the bent shape of the needle the position in the needle lever is given.

Care must only be taken that the needle piston is pushed in the slot of the

needle lever up to the stop and that the needle clamping plate (6) is tightened

with the screw (5).

through crushing and needle stitches.

16 BA_310D-R_3100D-R_A16-3_180117_en

Fig. 6

4.3 Threading and thread run (Fig. 7)

CAUTION! Danger of injury!

Switch off the machine prior to threading and ensure the

machine is off by pressing the pedal for switching the

motor.

Fig. 7 shows the correct threading by using the thread sensor.

17 BA_310D-R_3100D-R_A16-3_180117_en

Fig. 7

18 BA_310D-R_3100D-R_A16-3_180117_en

4.4 Winding up the thread (Fig. 8)

The course of the thread during winding up is shown in Fig. 8.

Care must be taken that not too much of the thread is wound onto the reel and

that the reel walls are not pushed apart, faulty reels must immediately be

replaced with new ones.

Fig. 8

4.4.1 Installing the bobbin and threading the bobbin thread (Fig. 9)

By turning the needle lever to its highest position with the hand wheel, the

bobbin (1) can be taken out and reinserted. Fold the bobbin holder flap away

from the bobbin capsule with a short jerk, the bobbin then jumps by spring

pressure out of the bobbin capsule so that it can be easily removed.

When inserting the bobbin take care that the bobbin thread unwinds from the

underside of the bobbin. Then guide the start of the bobbin thread through the

slot at the right hand side of the bobbin capsule and hold it lightly at the stitch

plate.

Then turn the hand wheel of the machine a full rotation and at the same time

hold the needle thread lightly tensioned after take up by the hook point. This

pulls the bobbin thread correctly under the leaf spring.

It is best to then lightly twist together the needle thread and the bobbin thread

and pull them together to the back through the stitch plate hole.

19 BA_310D-R_3100D-R_A16-3_180117_en

Fig. 9

4.5 Thread tensioning (Fig. 6)

Dependent on grade, characteristic and thickness of the thread as well as the

sewing material, the thread tensioning is adjusted to the required seam diagram

with the tensioning nut (3).

4.5.1 Thread tightening spring – needle thread (Fig. 10)

The tension of the rotary spring (1) can be modified after releasing the grub

screw (2) and by turning at the headed bolt (3). It starts to tension the thread

when the thread loop is approx. 15° in front of the upper point of the hook, that

is, before it can fall off to the right of the hook.

Fig. 10

20 BA_310D-R_3100D-R_A16-3_180117_en

4.5.2 Thread tensioning – r eel thread (Fig. 11)

The leaf spring (2) regulates the bobbin thread tension. By turning the flat-head

screw with catch (1), the leaf spring must be adjusted in such a way that when

the bobbin is inserted, and the thread is correctly pulled under the leaf spring

and the bobbin case is released, the latter, together with the bobbin drops

slowly down. A slight pull on the thread might be necessary.

Fig. 11

4.6 Adjusting the stitch length ( Fig. 8 and Fig. 12)

CAUTION! Danger of Injury!

Switch off the machine and ensure it is switched off by

pressing the pedal for switching the motor.

Otherwise there is a danger of injury through crushing and

The stitch length can be adjusted after lifting the cover (1) (Fig. 8).

First release grub screw (1) (Fig. 12), then turn cheese-head screw (2) (Fig. 12)

to the left, the stitch length becomes larger, or to the right, the stitch length

becomes smaller.

After adjusting the required stitch lengths, retighten the grub screw (1) (Fig. 12).

needle stitches.

21 BA_310D-R_3100D-R_A16-3_180117_en

Fig. 12

4.6.1 Adjusting the upper feed path (Fig. 6)

By activating the right pedal the upper feed path is enlarged, that is, multi-width

can be worked in.

By turning the knurled screw (1) to the left, multi-width can be worked in

continuously.

Depending on whether you work with short or long stitch length, the position on

eccentric bush (2) = 2-5 mm stitch length or

position = 4 - 7 mm stitch length can be adjusted.

22 BA_310D-R_3100D-R_A16-3_180117_en

4.7 Stitch depth

By stitch depth one understand the distance of the highest plunger position to

the outside radius of the needle, the plunger presses the sewing material from

underneath in the stitch plate opening, so that the needle stitches into the fabric

layers at the required depth.

Low stitch depth: the needle penetrates less deep into the fabric layers

of the sewing material.

Large stitch depth: the needle penetrates deeper into the fabric layers of

the sewing material.

With too low or too large a stitch depth, omissions or through-stitches can

occur.

4.7.1 Adjusting the stitch depth (Fig. 2 and Fig. 6)

With the aid of the stitch depth regulating button (3) (Fig. 2) on the lower arm on

the right, the plunger can be lifted or lowered dependant on the thickness of the

fabric. Above this regulation button is a plate which shows how the button must

be turned so that the plunger is lowered or lifted.

Turning the button to the right – plunger goes upward,

needle penetrates deeper.

Turning the button to the left – plunger goes downward,

needle penetrates less deep

See also “4.7.2 Digital stitch depth display (Fig. 13)”.

The stitch depth for the side plunger is adjusted with the knurled screw (4)

(Fig. 6) on the left above the stitch plate.

Turning to the front (clockwise) – needle penetrates deeper

Turning to the back (anti-clockwise) – needle penetrates less deep.

23 BA_310D-R_3100D-R_A16-3_180117_en

4.7.2 Digital stit c h de pt h display (Fig. 13)

The plunger height can be read off digitally from the stitch depth display. This

makes finding earlier adjustments substantially easier by frequently changing

sewing material thickness.

The current supply is via a 9 V battery in the housing. To prevent premature

discharging of the battery, the display should be switched off with the toggle

switch at the housing during longer work breaks and when finishing work.

Always valid: Small number - thin sewing material

Large number - thick sewing material

The adjustment of the stitch depth by one digit (= 1 point of the display unit) is

equal to a plunger height modification of 0.01 mm.

When turning the regulating button to the right to the stop a value between 003

and 006 appears on the display.

Fig. 13

4.7.3 Changing the battery (Fig. 13)

a) Bring the switch to 0 position.

b) Open cover on the backside of the housing

c) Change the battery - ATTENTION! Observe the polarity!

d) Close cover.

24 BA_310D-R_3100D-R_A16-3_180117_en

4.8 Plunger stop

danger of injury, especially a danger of crushing fingers due

Frequently it is necessary when trimming fabric to sew over different fabric

thicknesses at the same work piece, whereby the penetration depth of the

needle, viewed from the upper side of the sewing material, must always remain

the same.

The plunger built- into our machines carries out this work automatically in

cooperation with an adjustable plunger stop mounted on the stitch plate.

(This is not true for all machines or stitch plates.)

4.8.1 Adjusting the plunger stop (Fig. 14)

CAUTION! Danger of Injury!

When adjusting in the area of the stitch plate there is

to accidental activation of the pedals!

First set the plunger with the stitch depth regulation button so high that the

required thickness of the sewing material, in most cases the outside fabric, is

stitched blind satisfactory.

Then the plunger stop supported on the stitch plate is adjusted with the knurled

screw (partly also hexagon nut) in such a way, that the sewing material is

pressed from above onto the plunger.

Now the plunger, under pressure from a spring, can rise above several layers of

fabric, cross seams, thickenings etc lying above each other only to such a

height, that the upper fabric layers and not the outside fabric is stitched.

The above adjustment requires some technical knowledge and experience.

Care must be taken that the pressure spring (1) is only adjusted as much as is

necessary for the correct effect of the plunger stop. This keeps the pressure of

the plunger onto the plunger stop as low as possible and less stress is put on

stitch plate and machine.

With adjustment of the plunger pressure at the works, the screw for the plunger

regulation (2) is flush with the plunger guide (4).

By turning the plunger adjusting screw (3), including the screw for the plunger

regulation (2), to the right it increases, to the left it decreases.

25 BA_310D-R_3100D-R_A16-3_180117_en

Fig. 14

4.9 Interval gear

The interval 1:2 or 1:3 guarantees an elastic seam almost free of marking with

extremely difficult to work fabric qualities.

The principle of the interval is based on the repeat of a different plunger height,

which always remains the same with the individual penetrations of the needle.

We use it with two different machine types:

a) Needle lever with radial movement.

The needle stitches the outside or upper fabric with each second (1:2) or

third (1:3) rotation of the machine. With the other rotations the penetration

is carried out only in the upper fabric layers.

b) Needle lever with radial and pendulum movement.

The interval 1:2 enables the needle in each case to make a right (in the

upper fabric) and a left (in the inside lining) penetration

The difference of the plunger height between the individual stitches is partly

fixed set or stepless adjustable from 0 to + (=maximum approx. 0.2 mm).

26 BA_310D-R_3100D-R_A16-3_180117_en

4.10 Seam lock

Attention!

Switch off machine electrically!

Attention!

Danger of finger bruises in the area of pneumatically

operated parts.

4.10.1 General

The sewing cycle begins with the point tack by pressing the pedal forwards.

The sewing speed is independent of the pedal. After completing the point tack,

the machine sews at the speed set by the pedal. When the pedal is released at

the end of the stitch, the seam lock becomes active and the machine lifts off

automatically after finishing the point tack. An intermediate lift thus only

functions using the knee lever.

The point tack function is always switched on by default. The function can be

generally switched off by the software or temporarily by the switch (S2) to the

right of the head.

During seam lock, the lower feed dog and side feed dog are deactivated and an

additional thread tension is active. This thread tension needs to be set

separately. (Fig. 7)

The start and end backtack are active by default. As an alternative, you can use

only the end backtack.

4.11 Sewing drive

The machine is as a rule equipped with the sewing drive selected by you.

Please note the separately enclosed operating instructions for the sewing drive.

There you find notes and the instructions for programming the control including

the motor speed adjustments.

27 BA_310D-R_3100D-R_A16-3_180117_en

5 Operating the sewing machine

CAUTION! Danger of Injury!

Take sufficient care during sewing and observe the sewing

area!

Otherwise there is a danger of injury through crushing and

For machines with 2 pedals: push down the left pedal fully increases the top

feed length (multi-width take-up). With this configuration, motor control is taken

over by the right pedal.

To vent the machine, a pneumatic venting system can be supplied instead of

the knee lever.

When releasing the pedal to switch on the motor, the machine moves to its

position and pneumatic venting takes place.

needle through-stitches.

Pressing the pedal forwards closes the vent and the machine starts to sew.

Fig. 15

5.1 Switch-on

Switch on the main switch on the right underneath the table plate.

With pneumatic lifting, connect the service unit to the compressed air network

(10 bar) or connect the compressor and regulate to 5 – 6 bar.

The lifting is now opened and the sewing machine is ready for operation.

28 BA_310D-R_3100D-R_A16-3_180117_en

5.2 Inserting and re m ovi ng the sewing material

When during standstill of the machine the needle is approx. 15 mm after its

upper dead point in front of the right penetration, the presser plate and the

plunger can be moved downwards by activating the knee lever. At the same

time the needle thread tension is vented.

For pneumatic venting also see point “0 The machine is as a rule equipped with

the sewing drive selected by you.

Please note the separately enclosed operating instructions for the sewing drive.

There you find notes and the instructions for programming the control including

the motor speed adjustments.

Operating the sewing machine”.

Now the sewing material can be inserted into the machine between stitch plate

and presser plate.

The sewing material cannot be removed until the last stitch has been

completely carried out, the needle thread loop has dropped from the hook, the

needle is again in the position mentioned above and the knee lever is activated.

When using a sewing drive with needle height position, the positioning is

carried out automatically.

ATTENTION! Do not let the machine run if there is no fabric between stitch

5.3 Sewing

The lining (with cl. 310D-R) or the fabric hem (with cl. 3100D-R half lined

working) will be inserted in the left stitch plate opening standing up.

In both cases it is advantageous to tack or to peg with hairpins.

Cl. 310D-R short machine arm

When hemming the lining the jacket lies to the left.

Cl. 3100D-R long machine arm

When hemming the fabric the jacket lies to the right.

By exchanging the enclosed accessories the work sequences can be

exchanged.

In connection with this please observe point 7 Variable sewing tools.

plate and feed dog.

29 BA_310D-R_3100D-R_A16-3_180117_en

5.3.1 Hemming w ith blind stitch

If there are no experience values available, the best thing to do is to carry out

the following settings in sequence:

a) Adjust required stitch length

b) Adjust stitch depth

c) Check plunger stop and if necessary adjust

d) Adjust material guide (if available)

e) Check presser plate lift. (Mechanic's instructions)

f) Check stitch length.

g) Adjust thread tension, the seam should lie loose on the hem as a rule.

h) Correct the seam diagram.

Insert the sewing material and take care that the start of the hem can be

taken up by the feed dog after the first stitch.

Check the sewing result achieved and possibly modify the adjustments

carried out above.

With through stitches or omissions at the outside fabric (right hand initial

stitch) or the hem edge or the lining (left hand initial stitch), adjust the

stitch depth settings.

„Markings“ caused by the penetration of the needle in the outside fabric

(shift of fibres) sometimes cannot be avoided with extremely thin und hard

sewing material.

When sewing take care that the hem edge always runs along the material

guide (if available). Jerky activation of the pedal should be avoided, as

changes in speed during the sewing process can under certain

circumstances have a negative effect on the initial stitch.

NOTE: To avoid having a build-up with thick fabrics it is recommend to

cut off the corners at the cross seams prior to hemming.

30 BA_310D-R_3100D-R_A16-3_180117_en

5.4 Problems during s e wing and troubleshooting

CAUTION! Danger of Injury!

Switch off the machine and ensure it is switched off by

pressing the pedal for switching the motor.

Otherwise there is a danger of injury through crushing and

needle stitches.

• Thread breaking

Possible causes:

- sharp edges or grooves in needle guide, take-up lever, shuttle or

needle eye when the machine has been used for a long time.

- The thread between shuttle and bobbin case breaks or is pinched off.

- Too much oil has penetrated the shuttle path

- The bobbin is packed too tight or the bobbin sides are forced apart

because the thread is too tightly wound.

- Bobbin case vent or shuttle bridge are not correctly adjusted.

- The shuttle to needle or needle rise has not been correctly adjusted or

has become displaced, meaning that the thread loop is not always

taken up.

- Thread tension is set too slack or too tight.

Remedy:

- Replace or re-polish the damaged parts

- Dismantle shuttle, remove bobbin case and polish the feed edges of

the bobbin case and shuttle path.

- Using an absorbent thread (cotton thread, core spun thread), sew out

on a remnant.

- Insert new bobbin

- Slowly turn the machine by hand and check whether the loop slides

unimpeded through the shuttle. If not, readjust bobbin case vent or

shuttle bridge.

- Correct shuttle position or loop lift.

- Correct thread tension - check thread line.

ATTENTION! thread course, thread, needle plate with plunger and cloth

retainer, needle and thread tension should always be set

and chosen according to the material to be sewn.

31 BA_310D-R_3100D-R_A16-3_180117_en

• Uneven stitching

Possible causes:

- frequently worn or damaged needles

- height of needle plate or needle slide plate incorrectly adjusted

- unsuitable needle thickness (too thin)

Remedy:

- Replace damaged needle. Check adjustments and correct if

necessary. Use correct needle thickness.

• Missing loops

Possible causes:

- incorrectly adjusted or badly adjusted shuttle

- loop lift too small

Remedy:

- Turn machine by hand and check shuttle motion. The cause can

usually be seen.

- If necessary, also correct thread tension or thread tension spring.

- correct loop lift.

• Loops become stuck

Possible causes:

- thread tension too slack

- needle not tacking

Remedy:

- Check thread tension or thread tension spring

- Check stitch depth (even for skip stitch or plunger lowering)

• Machine does not start

Possible causes:

- Control fault

- Mechanical damage

Remedy:

- Switch machine off and on again

- Rectify mechanical faults

- Check programming. If necessary, call customer service.

32 BA_310D-R_3100D-R_A16-3_180117_en

• The sewing resul t doe s not come up to your expectations

Possible causes:

- Damaged sewing tools or wear caused by improper use or natural

wear following long use of machine.

- The machine has become mechanically misadjusted

- Unsuitable needle thickness (see “4.1 Needles and threads”)

- Unsuitable sewing thread (see “4.1 Needles and threads”).

Remedy:

- Replace damaged parts - customer service

- Work carried out by engineers: see also mechanic’s instructions and if

necessary, call customer service

- Replace needle; also check needle tip for damage.

• Marks on or damage to the sewn item

Possible causes:

- unsuitable feed gearing

- Sewing tools incorrectly set

- Damaged sewing tools

- Unsuitable needle or thread thickness.

Remedy:

- check settings

- check feed (gearing), if necessary, replace feed

- choose needle and thread to suit sewing material.

• Difficulties during feeding the sewn material (stitch length)

Possible causes:

- Feed incorrectly adjusted

- Unsuitable feed gearing

- Incorrect presser plate take-up

- Bunching of the sewn item on the needle plate, particularly when

cross-seaming.

Remedy:

- check settings, if necessary change feed.

- Check lower side of needle plate, feed and sewing tools for damage, if

necessary replace or re-polish.

- The suitable stitch plate must be selected for thick sewn material –

see “7 Variable sewing tools” and “8 Optional Extras”.

33 BA_310D-R_3100D-R_A16-3_180117_en

5.5 Incorrect stitches (Fig. 16)

The correct two-thread blind stitch is shown in Fig. 16.

Incorrect stitches can occur if the needle does not take up the sewing material

or does not carry out initial stitch or the hook does not take up the thread loop.

Fig. 16

34 BA_310D-R_3100D-R_A16-3_180117_en

6 Machine maintenance

CAUTION! Danger of Injury!

Disconnect the machine from the mains and ensure that it

is off by pressing the pedal for switching the motor.

Otherwise there is a danger of injury through crushing and

The machine must be oiled daily at the points marked red (oil bottle is included

with the machine accessories). For this remove the housing cover on the right

top, the under arm cover bottom left and the head hood.

Fabric fibres and dirt which collect at the movable parts of the machine must be

removed, as they could cause errors and impair the operating safety.

The hook path should also be oiled from time to time with a drop of oil, there is

a bore for this in the hook cover.

needle stitches.

35 BA_310D-R_3100D-R_A16-3_180117_en

7 Variable sewing tools

CAUTION! Danger of Injury!

Disconnect the machine from the mains and ensure that it

is off by pressing the pedal for switching the motor.

Otherwise there is a danger of injury through crushing and

needle stitches.

The following table shows the available sewing tools.

36 BA_310D-R_3100D-R_A16-3_180117_en

Cl. 310D-R

Standard

8,0 mm Opening

Optional

7,0 mm Opening

Standard

Optional

250g to 700g

Fabric and lining hems

under 300g

Fabric and lining hems

Standard

Optional

Standard

Optional

Needle plate

Plunger

Pressure spring

280.0265

281.0131

Standard

161.0157

280.0266

281.0125

Fabric qualitiy

Stitch formation

Feed dog

182.0140

182.0318

8 mm

(or 6 mm or 4 mm)

under the hem edge

182.0131

282.0320

37 BA_310D-R_3100D-R_A16-3_180117_en

Cl. 310D-R

Optional

Optional

at 500g

only lining hems

Optional

182.0131

Needle plate

280.0267

10,0 mm Opening

281.0126

Plunger

Pressure spring

Fabric qualitiy

Stitch formation

Optional

161.0047

8 mm

(or 6 mm or 4 mm)

under the hem edge

38 BA_310D-R_3100D-R_A16-3_180117_en

Feed dog

282.0320

Cl. 3100D-R

Standard

8,0 mm Opening

Optional

7,0 mm Opening

Standard

Optional

250g to 700g

Fabric and lining hems

under 300g

Fabric and lining hems

Standard

Optional

Standard

Optional

Needle plate

Plunger

Pressure spring

380.0265

281.0131

Standard

161.0157

380.0266

281.0125

Fabric qualitiy

Stitch formation

Feed dog

182.0140

182.0319

8 mm

(or 6 mm or 4 mm)

under the hem edge

182.0131

282.0320

39 BA_310D-R_3100D-R_A16-3_180117_en

Cl. 3100D-R

Optional

Optional

at 500g

only lining hems

Optional

182.0131

Needle plate

280.0267

10,0 mm Opening

281.0126

Plunger

Pressure spring

Fabric qualitiy

Stitch formation

Optional

161.0047

8 mm

(or 6 mm or 4 mm)

under the hem edge

40 BA_310D-R_3100D-R_A16-3_180117_en

Feed dog

282.0320

8 Optional Extras

The following equipment is additionally available for the machine and can be

ordered from the works with the machine or as attachment:

8.1 Plunger

181.0070 Side plunger, round shape

(for delicate lining)

8.2 Additional parts for hemm ing half lined jack e t s

386.0347 Additional parts for hemming half lined jackets

(for cl. 31OD only - for all needle plates)

incl.

174.0204 Flat head screw

182.0319 Feed dog

183.0136 Presser foot

186.0347 Height adjustment (4 mm under the hem edge)

186.0348 Height adjustment (6 mm under the hem edge)

41 BA_310D-R_3100D-R_A16-3_180117_en

Und wir können noch mehr für Sie tun!

Unser Lieferprogramm bietet für jede Branche und

jegliche Anforderung genau die richtige Problemlösung.

And we can do a lot more for you!

Our range offers the correct problem solution for

every branch and for all requirements.

Für die Bekleidungsindustrie:

Ein- und ZweifadenHochleistungs-Saummaschinen

DoppelblindstichSaummaschinen

Zweifaden-BlindstichStafermaschinen

Roll- und Flachpikiermaschinen

Pikier-Automat

und

weitere Spezial-Nähmaschinen

For the clothing

industry:

Single and two thread high

performance hemming

machines

Bluff edge hemming machines

Two thread blind stitch felling

machines

Roll and at padding machines

Automatic lapel padding

machine

Für die Schuhverarbeitung:

Einfaden-Überwendlichmaschinen mit und ohne

Differentialtransport

For the shoe industry:

Single-thread overseaming machines with and without differential feed

Für Kürschnereien

und Pelzkonfektion:

Pelzschnellnäher

For the fur industry:

High-speed fur sewing machines

Für Heimtextilien:

Ein- und ZweifadenBlindstichmaschinen

For the home textiles

industry:

Single and two thread

blind stitch machines

Für die Polsterverarbeitung:

Ein- und ZweifadenÜberwendlichmaschinen

Ein- und ZweifadenBlindstichmaschinen

For the upholstery

industry:

Single and two thread

overseaming machines

Single and two thread

blind stitch machines

Für die Konfektion

technischer Textilien:

Ein- und ZweifadenÜberwendlichmaschinen

For the processing

of technical textiles:

Single and two thread

overseaming machines

and other special sewing

machines

Noch Fragen?

Dann rufen Sie uns an, schreiben Sie uns oder

kommen Sie einfach bei uns vorbei.

Sie können jederzeit weitere Informationen über

unsere Produkte anfodern oder die StrobelNähmaschinen in unserem Ausstellungsraum live

erleben. Wir freuen uns auf Sie!

Any further questions?

Then phone, write or simply come and see us. You

can have further information about our products at

any time, or experience the Strobel machines live in

our show room. We’re looking forward to meeting you!

Sp ez ia l ma sc hi ne n G mb H

Postfach 1242

82168 Puchheim

Siemensstraße 3

82178 Puchheim

DEUTSCHLAND

www.strobel.biz

Telefon: +49 89 80096-0

Telefax: +49 89 80096-190

Loading...

Loading...