For the professional user

Mechanic‘s Instructions

Für den professionellen Anwender

Mechanikeranleitung

Class:

Klasse:

Model:

Ausführung:

Machine number:

Maschinen-Nr.:

Dated:

Stand:

141-23EV Ausf. 10

141-30 Ausf. 6

141-40 Ausf. 7

141-50 Ausf. 3

142-30 Ausf. 6

142-40 Ausf. 5

S p e z i a l m a s c h i n e n G m b H

The sign of quality

Y

ou nd the Strobel trademark on every Strobel

machine leaving our works. And with good reason.

This symbol is a guaranteen of the high quality of

our products. Quality which creates trust – trust

in our technology, our service and, not least of all,

in our good name.

Im Zeichen der Qualität

ie nden die Strobel-Schutzmarke auf jeder

S

Strobel-Maschine, die unser Werk verlässt.

Und das aus gutem Grund. Denn dieses Zeichen

garantiert Ihnen die hohe Qualität unserer

Produkte. Qualität, die Vertrauen schafft – in unsere

Technik, unseren Service und nicht zuletzt in unseren

guten Namen.

A decision with future

S

trobel clients know that they can expect a particularly high standard of performance from our company

and our machines. Now you have settled for one of

our products. For us this is a source of encouragement

and of obligation to Justify your trust.

If you wish to prot from the performance and

efciency of your Strobel machine as long as possible,

exact handling and thorough care is necessary. For this

reason we kindly request that you read the operating

instructions closely. It provides all the information you

need for trouble free operation.

And if you do happen to need a spare part the enclosed

spare parts list gives a complete overview. It is clearly

classied according to components so that you can nd

the required part quickly and easily. In order to avoid

errors we request you to quote machine class, machine

number and part number completely on your spare part

order.

We wish you lots of success in your work with your

new Strobel machine.

S p e z i a l m a s c h i n e n G m b H

Mechanic’s instructions

STROBEL Classes 141-23EV, -30, -40, -50, 142-30, -40

Contents

1 General notes on safety ............................................................................................ 5

2 General ..................................................................................................................... 7

2.1 Operating instructions ..................................................................................... 7

2.2 Class identification, serial number and orientation of the machine................. 7

2.3 Range of application and intended use .......................................................... 7

2.4 Technical Data ................................................................................................ 9

2.5 Brief setting instructions ............................................................................... 10

3 Disassemble the machine ....................................................................................... 11

3.1 Disassemble the main shaft (Fig. 1 and Fig. 2) ............................................ 11

4 Assemble the Machine ............................................................................................ 13

4.1 Mount the shaft (Fig. 1) ................................................................................ 13

4.2 Mount stitch regulating eccentric 353.0031 .................................................. 13

4.3 Adjust stitch regulating bolt 137.0014 for stitch adjustment .......................... 15

4.4 Adjust needle- and feed motion .................................................................... 15

4.5 Looper motion............................................................................................... 16

4.5.1 Adjust the looper motion .................................................................. 16

4.5.2 Adjust the looper eccentric (on single thread machines).................. 17

4.5.3 Adjust the looper eccentric (on two tread machines) ....................... 17

4.5.4 Adjust the front crank ....................................................................... 18

4.5.5 Set the looper in its front position to the feed cup ............................ 19

4.5.6 Adjust stroke of loop ........................................................................ 19

4.5.7 Adjust the front bearing block........................................................... 19

4.5.7.1 Basic dimensions for front and rear bearing block ........... 19

4.5.8 Adjust the rear bearing block ........................................................... 20

4.6 Adjust height of rear feed cups ..................................................................... 20

4.7 Mount the front feed cup .............................................................................. 20

4.8 Length adjustment of bar 133.0851 between stitch regulation rod and free

wheeling ....................................................................................................... 20

4.9 Thread lifting mechanism at needle bar head .............................................. 20

4.10 Spring tension at feed cup support arm 333.0114 ........................................ 21

4.10.1 Plate arm lifting ................................................................................ 21

4.11 Needle setting ............................................................................................... 22

4.11.1 Adjusting needle height (Fig. 10 and Fig. 11)................................... 22

4.12 Chaniging the looper .................................................................................... 23

4.13 Maintenance ................................................................................................. 24

4.14 General Data ................................................................................................ 24

1 MA_141_142_A10-6-7-3-6-5_130617_en

5 Notes on repair and adjustment .............................................................................. 27

5.1 Transport plate assembly ............................................................................. 27

5.2 Exchanging the transport plate ..................................................................... 27

5.3 Mounting and setting instructions for STROBEL gathering device No.

314.0399 ...................................................................................................... 28

2 MA_141_142_A10-6-7-3-6-5_130617_en

Appendix

Circuit diagrams

Connecting the sewing ma chine:

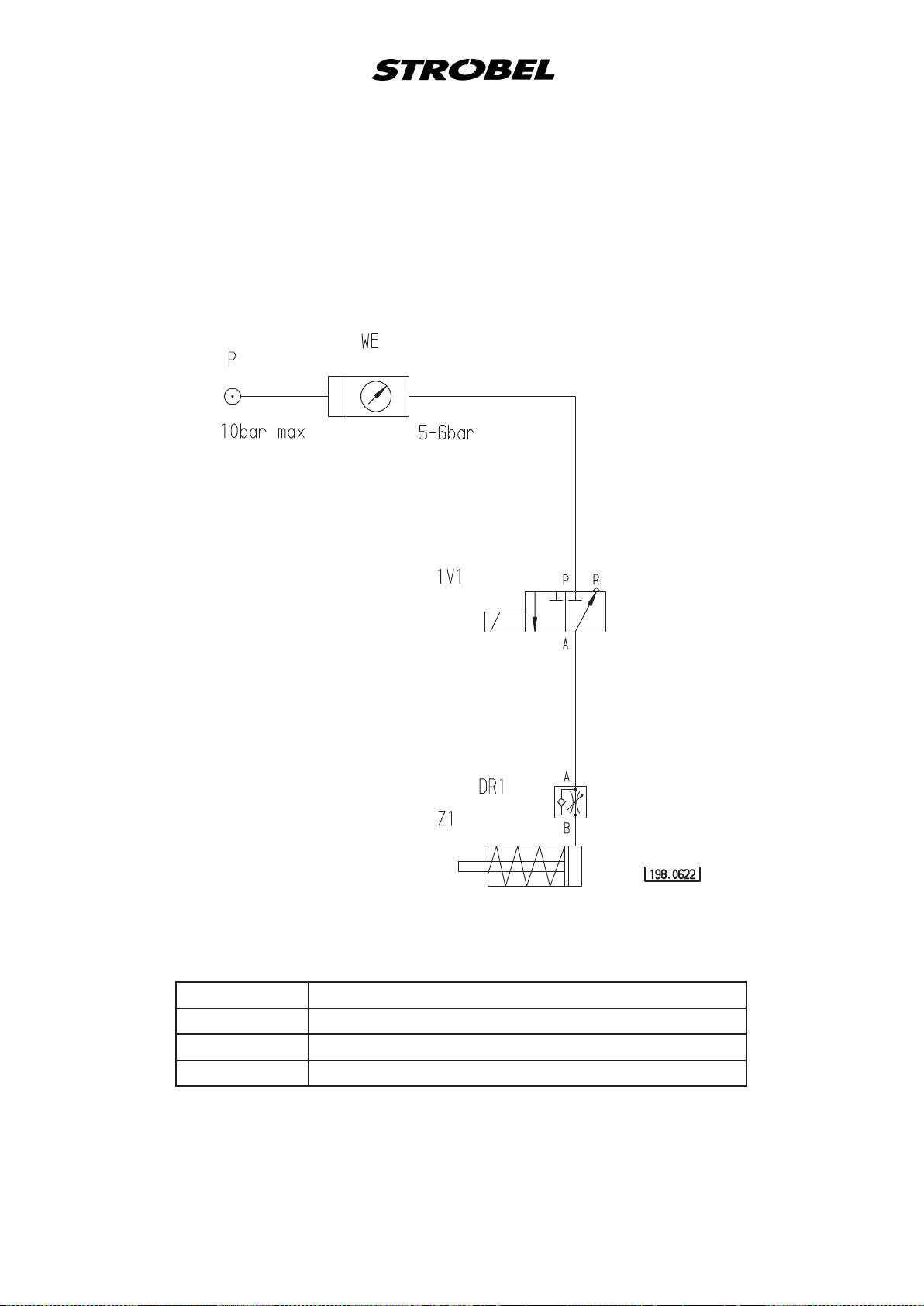

259.00.16 Pneumatic circuit diagram Cl. 142

259.10.16 Pneumatic construction circuit diagram Cl. 142

Connecting digital display:

258.21.27 Electric connection diagram Cl. 141 – digital display

Subject to change without prior notice

3 MA_141_142_A10-6-7-3-6-5_130617_en

4 MA_141_142_A10-6-7-3-6-5_130617_en

1 General notes on safety

The non-compliance wi th the fol l owing notes on safety can lead to bodily

injuries or to damages of the machine.

1. The machine must only be operated by persons familiar with the relevant

operating instructions and who have been instructed accordingly.

2. Before commissioning also read the notes on safety and the operating

instructions of the sewing drive manufacturer.

3. The machine must only be operated according to its designation and not

without the appropriate guards; all explicit safety regulations must also be

observed.

4. For threading, for changing the reels, for exchanging sewing tools such as

needles, grippers, stitch plate, transport devices, if necessary cutter and

cutting block, for cleaning, when leaving the workplace and for

maintenance work, switch off main switch or pull mains plug. With a

mechanically operated coupling motor without activation lock, wait until the

motor has stopped.

5. General maintenance work must only be carried out by appropriately

instructed persons in accordance with the operating instructions.

6. Repair, modification and maintenance work must only be carried out by

qualified staff or by appropriately instructed persons.

7. During maintenance and repair work at pneumatic devices, the machine

must be disconnected from the pneumatic supply network. Exceptions are

only admissible during adjusting work and function test by appropriately

instructed qualified staff.

8. Work at the electrical equipment must only be carried out by qualified

staff.

9. Work at parts and devices under voltage is not allowed. Exceptions are

regulated by the regulation EN50110 (DIN VDE0105).

10. Modification or alteration at the machine must only be undertaken under

consideration of all explicit safety regulations.

11. Only spare parts released by us for use are to be used during repairs.

12. The commissioning of the upper part is prohibited until it has been

determined that the entire sewing unit complies with the regulations of the

EC guidelines.

5 MA_141_142_A10-6-7-3-6-5_130617_en

13. Warning notes in the operating instructions of the machine, which point

out special points of danger, are marked at the appropriate positions with

the safety symbol.

Warning notes in the operating instructions of the machine which point out

special dangers of injury for operating or qualified staff, are marked at the

appropriate positions with the symbol

It is essential that you observe and follow these notes as well as the

generally valid safety regulations.

6 MA_141_142_A10-6-7-3-6-5_130617_en

2 General

2.1 Operating instructions

Any person involved in the installation, operation, maintenance and repair of

the machine must have read and understood the operating instructions and

mainly the safety instructions before starting the machine. Please open the

illustrations at the beginning of these operating instructions, so you can follow

the illustrations step by step while reading the instructions.

2.2 Class identification, s e rial number and or ientation of the machine

The operating side of the machine is the basis for descriptions referring to

sides. The class identification (type) as well as serial and model number (after

the dash) are located below the left handwheel. These data are also shown on

the front page of the operation instructions.

2.3 Range of applicati on a nd intended use

Class 141-23EV

Single Thread Overseaming Machine with gathering device for sewing insoles

to uppers of heavy weight textile and leather shoes up to total thickness

of 7 mm.

With appropriate optional features also suitable for "string lasting" and

California processing.

Class 141-30

Single Thread Overseaming Machine for sewing fur facings, heavy furs such

as lambskin, imitated furs and polishing wheels.

Class 141-40

High Speed Single Thread Overseaming Machine for fine fur stranding (let-out)

and general sewing operations.

Class 141-50

High Speed Single Thread Overseaming Machine for very fine stranding

(let-out) operations at fur.

7 MA_141_142_A10-6-7-3-6-5_130617_en

Class 142-30

Two Thread Cup Seaming Machine for sewing and overedging soft rubber

foam. Material thickness compressed state up to 4 mm. Also suitable for

clothing quilts and for decorative stitches of fur and leather garments.

Special version Class 142-30N

Two Thread Cup Seaming Machine for sewing of coated material for diving and

surfing suits (e.g. neoprene) for material thickness of 4 – 7 mm.

Class 142-40

Two Thread Cup Seaming Machine for sewing and overedging soft rubber

foam. Material thickness compressed state up to 2 mm. Also suitable for

clothing quilts and for decorative stitches of fur and leather garments.

8 MA_141_142_A10-6-7-3-6-5_130617_en

2.4 Technical Data

Recommended rated speed min-1

1800

2300

3600

2300

2400

Machine

dw 80

V-belt profile

10 x 6 mm

Stitch length (adjustable in mm)

3 - 6.5

3 - 6

0.6 - 2.5

3 - 6

1 - 4

Kind of stitch: Overseam

Single thread

Two thread

Needle system

134

459R

1738

Needle size

140

110 -

40 - 120

90, 100

55

Recommended thread

Twisted Polyester filament

Recommended thread size

40 - 20

50 -

130 - 80

40 - 20

120/2

Stitch type

501

502

Kind of feed

Back plate transport

Pneumatic connection

10 bar

Operating pressure

5 - 6 bar

Required space

0.6 x 1.06 m

of number of stitches n min-1

1800

2300

3200

2300

Number of stitches

Max mechanically admissible min

Machine pulley diameter

141-23EV

-1

2300

141-30

2800

130

10

141-40

4200

40 - 10

141-50

142-30

142-30N

2800

142-40

2800

Noise:

Average noise level at a speed

9 MA_141_142_A10-6-7-3-6-5_130617_en

LpAm

73 dB

LpAm

84 dB

LpAm

85 dB

LpAm

76 dB

2.5 Brief setting instructions

Setting data

141-23EV

141-30

141-40

141-50

142-30

142-40

A

Stitch length

3 - 6.5

3 - 6

0.7 - 2.7

0.6 -2.5

2.3 – 5.3

1 - 4

B

Stroke of loop

4.7

4.5 - 5

3.5

3.5

4.2

4.5

Needle point front

edge

Looper front position

edge

K

Looper movement

9.5 9 5.3

4.8

8.2

6.7

Looper movement to

center to looper point

Class

C

measured from cup

Looper height

L

inclusive shaft

H

measured from cup

22.6 20.5 18.5 16.8 18.8 17

11.5 8.2 7.5 5.5 11.5 9.7

142-30N

37 30.5 31.5 30.8 28.3 31

H + J Total looper travel 17.7 12.7 11 10.1 12.5 11.3

F

the right from needle

5.5 3 4.2 3.2 2.8 5.9

The clearence between the feed cups amount 12 – 14 mm.

10 MA_141_142_A10-6-7-3-6-5_130617_en

3 Disassemble the machine

3.1 Disassemble the main shaft (Fig. 1 and Fig. 2)

Before disassembling the main shaft, it is advisable to mark the exact position

of each part or screw, and to take the measures of both bearing support blocks

by means of a gauge, measuring from the front edge of the machine column.

(Measures a + b).

This will save you a lot of time when you assemble and adjust the machine.

(Fig. 1)

Not until now should the screws of the parts attached to the shaft be loosened

and the right handwheel be removed and the shaft, too, be pushed out to the

left by a withdrawal device.

Loosen the screws of the parts. Take off the right hand wheel. Pull the shaft

about 20 to 30 mm to the left and remove the remaining glue without displacing

the ball bearings. Then take off shaft.

The left handwheel with the stitch-regulating eccentric bolt does not need to be

removed. Be sure that the set screws 176.0632 located on both sides of the

regulating eccentric bolt (A) 132.0074 are removed; on machines that were built

before 1986, the screws 176.0620, 176.0619, and the setbolts 135.0078.

(Fig. 1 and Fig. 2)

NOTE! If not done yet, mark the position of guide disc 153.0031 and

regulating eccentric 132.0074.

The remaining glue can easily be removed from the shaft by using a cleanser,

e. g. Clorothene.

11 MA_141_142_A10-6-7-3-6-5_130617_en

Fig. 1

Fig. 2

12 MA_141_142_A10-6-7-3-6-5_130617_en

4 Assemble the Machine

4.1 Mount the shaft ( Fig. 1)

First, remove any grease from the shaft. Mount the parts in correct order onto

the shaft and put it into the machine column so that it sticks out about 30 mm

on the left. Then put a drop of “Loctite” on either end of the shaft, that is, on the

left end sticking out from the column, and on the ball bearing on the right.

(Loctite, Kapillar 290)

NOTE! The surfaces to be joined must be absolutely clean. Only then

you may fit the shaft completely into the machine column. Turn

it slightly, so that the glue on the ball bearing is evenly

absorbed. Fix stitch regulating eccentric (A) (fig.1).

See chapter “4.2 Mount stitch regulating eccentric 353.0031”.

Push the shaft to the left up to the stop, and fasten setting ring

246.0103 on the right of the shaft in order to eliminate any axial

play.

About an hour later when the glue (Loctite, Kapillar 260) is hard, you may

continue to assemble and adjust the machine. When assembling after a repair,

it is not necessary to take off the left hand wheel.

4.2 Mount stitch regulating eccentric 353.0031

Fit the left handwheel onto the shaft so that the first screw in direction of sewing

fits into the drill hole on the left of the shaft and point upwards.

Turn guide disc 153.0031 so that you can easily slide down set eccentric

132.0074. Then screw the first screw 176.0632 into the regulating eccentric, but

ensure that regulating bolt 137.0026 can still freely be turned in the shaft. Then

turn hand wheel with shaft by 180 degrees. Screw second screw 176.0532 into

the regulating eccentric right to the stop. Fasten guide disc 153.0031.

Push the shaft to the left up to the ball bearing, slide set collar 246.0103 on the

right shaft side all the way to the ball bearings, and tighten. The shaft is now

fastened.

Let stitch-regulating eccentric 137.0014 level out and tighten.

Fix two lubricated springs 161.0063 and bolts 135.0062 into the drill hole of the

hand wheel (Fig. 2, Fig. 3 und Fig. 4).

13 MA_141_142_A10-6-7-3-6-5_130617_en

Fig. 3

Fig. 4

Screw knob 344.0089 onto regulating bolt 137.0026 until it touches the hand

wheel. Then hold the knob while screwing out the regulating bolt until index

124.0080 stops at the knob (mark 5) long stitch, (Fig. 4) and easily visible

between handwheel and stand.

When properly adjusted, you can easily turn the regulation knob from the fixed

stop “long stitch” to the fixed stop “short stitch”.

Regulating eccentric 132.0074 must be set to the upper dead point, the index at

the hand wheel to mark 5. Finally, screw in lock nut 179.0614. (Fig. 4)

14 MA_141_142_A10-6-7-3-6-5_130617_en

4.3 Adjust stitch regulating bolt 137.0014 for stitch adjustm e nt

Eccentric (A) 353.0031 (Fig. 1) and bolt (B) 137.0014 (Fig. 4) have to be

adjusted to the specific stitch length required for each machine (See chart).

Make sure that wing 223.0045 and rod 120.0082 are correctly set. Bolt

137.0014 must be mounted with the grain mark facing upwards because this

mark indicates the stitch length; in other words, it moves - in direction of arrow to the right (-) when at its smallest, and to the left (+) when the longest stitch is

being formed. (Fig. 4 and Fig. 5)

4.4 Adjust needle- and feed motion

If the machine is set to produce the longest stitch (see chart), the feed motion

stops when the point of the needle placed approx. 1.5 mm within the cup edge

before penetrating the fabric.

The feed motion starts when the needle is placed approx. 1 mm behind the cup

edge.

Needle- and feed motion are adjusted at needle bar eccentric (E) (Fig. 1), note

the foremost needle position (table).

When adjusting the needle bar, make sure that the needle clamp device at the

needle bar head stands exactly rectangular to the rear feed cup.

Fig. 5

15 MA_141_142_A10-6-7-3-6-5_130617_en

4.5 Looper motion

The looper motion is determined by the stroke of the looper eccentric (F)

(Fig. 1 and Fig. 6), by the crank distance, and by the distance between drill

holes in the clamp lever. These parts are different for each machine class. The

looper motion must start and end at the same time as the needle bar motion.

The lateral looper movement is determined by the control cam and must be in

accordance with the needle motion.

The looper shaft must be mounted exactly in the center of the needle bar.

We recommend to fit the parts onto the shaft so that they can still be moved,

and to fasten them tightly only after the final adjustment.

4.5.1 Adjust the looper motion

Mark the upper dead point of needle bar eccentric (E) (Position 1).

Find and mark the top dead centre of the needle bar eccentric (equals position

"1"). (E)

The top dead centre of the needle bar eccentric is equal to the bottom dead

centre of the gripper eccentric offset by 180° (see chapter “4.5.2 Adjust the

looper eccentric (on single thread machines)”).

In this position, turn the control cam until the looper – moving to the right –

takes up the loop and reaches the turning point.

Make sure that a play of approx. 1 mm remains between control cam and

setting ring at the looper shaft, because a lateral displacement of the cam also

influences the looper movement.

If the distance is enlarged, the deflection of the gripper to the right is reduced.

The total path of the gripper hardly changes.

16 MA_141_142_A10-6-7-3-6-5_130617_en

Fig. 6

4.5.2 Adjust the looper eccentri c (on single thread m a c hines)

Set looper eccentric (in position 1) so that ist surface stands horizontally

(Fig. 6). For setting the needle in its utmost rear position, turn the hand wheel

about 100 degrees (position 2). In this position, the looper is set about 2 mm on

the left of and about 3 mm above the needle, but this varies according to stroke

of loop (Fig. 7a). When the needle has moved forth to the looper’s right hand

edge, its point moves past the looper approx. 1 mm above it (Fig. 7b). At the

utmost dead point of the looper’s lateral and longitudinal movement, the point

of the needle is at 1 to 3 mm within the feed cup, which depends on how the

stroke of loop had been adjusted.

4.5.3 Adjust the looper eccentri c (on two tr e a d m a c hines)

Set looper eccentric (in position 1) so that ist surface stands horizontally

(Fig. 6). For setting the needle in its utmost rear position, turn the hand wheel

about 100 degrees (position 2). In this position, the looper is placed in front of

and above the needle; the distance varies according to looper motion and

stroke of loop. (See chart)

When moving forth, the needle moves closely below the looper without actually

touching it (Fig. 8a) and takes up the thread from the looper’s groove. The

looper motion stops when the point of the needle reaches its center (Fig. 8b).

When the needle has taken up the thread and is about to penetrate the sewing

material (approx. 2 mm in front of the cup edge), the looper moves about

0.7 mm to the left, then past the sewing material to the front turning point

(stroke of loop) on the right. (See chart)

17 MA_141_142_A10-6-7-3-6-5_130617_en

Fig. 7

a b

Fig. 8

4.5.4 Adjust the front crank

Set the front crank (131.0010, 131.0019, according to machine class) vertically

in position “1”.

The regulation of the front crank influences the looper’s upwards movement. In

its front position, the looper moves upwards, and should move very closely over

the needle (0.1 to 0.15 mm) to ensure that the loop is properly taken up. You

also have to consider the different needle sizes. In its utmost rear position, the

looper is placed below the needle, and the needle about 1 mm above the

looper’s bevelled edge. (Fig. 7b)

18 MA_141_142_A10-6-7-3-6-5_130617_en

4.5.5 Set the looper in its front position to the feed cup

The looper reaches its utmost front position on moving approx. 45 degrees

opposite to direction of sewing. To be set as per measures (H) – see chart. It is

important that the height of looper and shaft is properly adjusted. (See chart)

It has to be controlled if measure (L) consides with looper shaft set as

described at chart page 30 and 31, readjust, if necessary.

4.5.6 Adjust stroke of loop

Each machine requires a certain stroke of loop (B) (see chart), which is

regulated by turning the control cam and the looper eccentric; measured from

the needle’s front dead point to the point where the looper stands above the

center of the needle.

To obtain a large stroke of loop - turn cam and looper eccentric opposite

to the machine’s direction of sewing.

To reduce the stroke of loop - turn cam and looper eccentric in

direction of sewing.

Then the looper takes up the loop and puts it – as straight as possible –

backwards on the sewing material.

4.5.7 Adjust the front bearing bloc k

The height of the front bearing block (M) (Fig. 1 and Fig. 6) is specifically set for

each machine. The looper motion depends on the control cam and can be

altered as follows: To increase the looper motion to the right, put a distance

plate under the bearing block. To reduce it, take off the distance plate.

4.5.7.1 Basic dimensions f or front and rear be a ring block

Manufacturing constructs the machine housing to a certain dimension. To get to

a different basic dimension for the various sub-classes, spacer plates of the

required thickness are placed underneath the bearing block when necessary.

19 MA_141_142_A10-6-7-3-6-5_130617_en

4.5.8 Adjust the rear bearing block

The looper movement may be altered in the final positions by shifting the rear

bearing block (N) (Fig. 1 and Fig. 6). On its return movement, the looper gets

close to the needle in its vertical- and front position, without essentially

changing its height in the rear position. (Ratio approx. 10:1). When moving

forth, the distance between looper and needle increases.

4.6 Adjust height of rear feed cups

Fit bushings 150.0170 and 150.0281 so that the lower bushing is on a level with

the surface on which the free wheeling is screwed, that the bottom socket is

4 mm within the bolting surface for the free wheel; the top socket needs to

provide the distance for the transport plate. In the mounted state with the

transport shaft head the distance between needle shaft middle and transport

plate top edge is the measurement “a” from Fig. 6.

4.7 Mount the front f e e d cup

When mounting the front feed cup onto the machine, make sure to fix it

horizontally and 0.1 mm lower than the rear feed cup. If the machine is

equipped with a needle guard, the needle groove must be another 0.1 mm

below the upper edge of the front feed cup.

4.8 Length adjustment of bar 133.0851 between s t itch regulation rod and free wheeling

The distance between the two drill holes ∅6 must be 111 mm. (Fig. 5)

4.9 Thread lifting mechanism at needle bar head

Class 141: Adjust lifting bar 124.0053 so that the thread is lifted – on the

needle’s backwards movement – when the looper is placed vertically above the

needle and has taken up the loop. Then – while the needle moves forth – until

the looper’s point reaches the center of the needle. (Fig. 1)

The same applies to class 142. In other words, the thread must be loose

(without tension) from the moment the looper takes it up until the looper’s right

hand turning point. Make sure that thread clamping bolt 138.0081 at the needle

bar head releases the thread just about 0.3 mm. You should also consider that

threads vary according to machine class and application.

(Fig. 9)

The thread drag on the needle bar is 0.35 - 0.4 N.

20 MA_141_142_A10-6-7-3-6-5_130617_en

Fig. 9

4.10 Spring tension at feed cup support arm 333.0114

The tension of spring 162.0034 should be adapted to each specific fabric. For

diver’s suits, it is approx. 70 N, for shoes up to 200 N. (Fig. 1 and Fig. 9)

4.10.1 Plate arm lifting

The plate arm lifting is about 12 - 14 mm for all machines. Lever 221.0194 and

lever 121.0033 have to be appropriately adjusted to each other (Fig. 9)

21 MA_141_142_A10-6-7-3-6-5_130617_en

4.11 Needle setting

Concerning the setting of the needle bar, refer to table containing setting data.

4.11.1 Adjusting needle height (Fig. 10 and Fig. 11)

A special device permits needle height adjustment, a feature particularly

advantageous if needles of different sizes are used. Turn the eccentric

132.0069, provided with a slit, and placed on front of the head of the needle

bar. Make sure that the needle of the respective thickness always goes with a

distance of about 0.1 mm over the transport plate. Loosen screw 171.0407 of

the needle set plate 285.0054 (or 285.0055, 285.0147, or 285.0159, different

depending on class), adjust height of needle and retighten screw 171.0407.

Fig. 10

Fig. 11

22 MA_141_142_A10-6-7-3-6-5_130617_en

4.12 Chaniging the looper

The looper can be removed after loosening clamping screw 175.0403 (Cl. 14140/-50) (Fig. 12) and 172.0403 (Cl. 141-23/-30 and 142-30/-40) (Fig. 12a)

respectively, at looper shaft head.

Upon mounting a new looper, take care that it touches the needle neither in its

front position nor in its rear position. (Also refer to setting data)

The wide gripper back should be standing as parallel as possible to the needle.

Fig. 12

23 MA_141_142_A10-6-7-3-6-5_130617_en

4.13 Maintenance

Since the machines feature fully automatic lubrication, they need no

maintenance in this regard. Never the less, we would recommended an oil

change approx. every six months, which depends on how many hours the

machine is used per day, and on its degree of soiling. You should use approx.

¾ of a litre of oil with a viscosity of 46 cSt (Recommended oil: Shell Voltol 46)

4.14 General Data

All further informations – technical data, application and operating instructions –

are included in the manual we provide with each machine.

24 MA_141_142_A10-6-7-3-6-5_130617_en

Setting data for Single Thread Over seaming machines

Class Dim. 141-23 141-30 141-40 141-50

Needle type

Needle size

Stitch length

Stroke of loop

Needle point front

measured from cup edge

Needle stop at needle bar

until cup edge

Stroke of needle bar

eccentric

Looper movement to the

right from needle center to

looper point

Looper movement to the

left

A

B

C

D

E

F

G

134 459R 459R 459R

120- 140 90-130 40-55 40-55

3.5-6.5 3.6 0.7-2.7 0.6-2.5

4.7 4.5-5 3.5 3.5

22.6 20.5 18.5 16.8

20.5 19 21 22.7

32.4 30.4 25 24

5.5 3 4.2 3.2

10.2 9 8.2 8

Looper front position

measured from cup edge

Looper rear position

Looper movement

Looper height

inclusive shaft

H

J

K

L

11.5 8.2 7.5 5.5

6.2 4.5 3.5 4.6

9.5 9 5.3 4.8

37 30.5 31.5 30.8

25 MA_141_142_A10-6-7-3-6-5_130617_en

Setting data for Tw o Thread Overseaming machines

Class Dim. 142-30 142-40

Needle type

Needle size

Stitch length

Stroke of loop

Needle point front

measured from cup edge

Needle stop at needle bar

until cup edge

Stroke of needle bar

eccentric

Looper movement to the

right from needle center to

looper point

Looper movement to the

left

A

B

C

D

E

F

G

1738 1738

55 - 100 55

2.3 – 5.3 1-4

4.2 4.5

18.8 17

19 21

28 24

2.8 5.9

8 6.8

Looper front position

measured from cup edge

Looper rear position

Looper movement

Looper height

inclusive shaft

H

J

K

L

11.5 9.7

1 1.6

8.2 6.7

28.36 31

26 MA_141_142_A10-6-7-3-6-5_130617_en

5 Notes on repair and a djustment

5.1 Transport plate assembly

Refer to the table for the transport and pressure plates needed for the various

classes.

In addition to the transport and pressure plates featured in the normal models,

optional transport and pressure plates with appropriate teeth and edge heights

are offered to handle various materials to be processed.

5.2 Exchanging the trans port plate

Exchanging the transport plate is done by loosening the screw 171.0609.

(Fig. 12)

If a pressure plate needs to be exchanged, loosen screw 171.0502, which

holds the whole plate set in the bearing arm. Make sure when inserting each

pressure plate that the edge of the pressure plate is always about 0.1 mm lower

than the edge of the transport plate so that the needle can move over the edge

of the pressure plate without hitting it. (Fig. 12)

27 MA_141_142_A10-6-7-3-6-5_130617_en

5.3 Mounting and sett ing instructions for STROBEL gathering devic e No. 314.0399

(see operating instructions – Working instructions)

The gathering device EV (Fig. 14) is fixed to the machine housing by two

screws 171.0607. In the housing you will find two threads which are closed by

two blind screws if the EV is not used.

When mounting EV note, that, after swivelling down guide 186.0195, this must

stop abt. 1 mm below the cup edge and abt. 5 – 6 mm on the right side of the

needle.

When mounting the EV to a machine originally supplied without EV, drill a

24 dia. boring for rod 133.0286 in the table top, according to Fig. 13.

Fig. 13

28 MA_141_142_A10-6-7-3-6-5_130617_en

Fig. 14

29 MA_141_142_A10-6-7-3-6-5_130617_en

259.00.16en

Pneumatic circuit diagram cl. 142

DR1 One-way ow restrictor for lifting

MV1 3/2-solenoid-way valve

Z1 Cylinder for lifting (LÜ)

WE Service unit

259.10.16en

Pneumatic construction circuit diagram cl. 142

Wartungseinheit

service unit

Magnetventil

solenoid valve

198.0623

Lüftung

lifting

293.0469 1 Schalldämpfer R1/8

293.0470 1 Doppelnippel R1/8

193.0473 1100 PA-Schlauch Ø6x1

193.0478 3000 PA-Schlauch Ø8x1

193.0530 1 Dichtung R1/8

193.0658 1 Muffe R1/8

293.0731 1 Wartungseinheit

293.0841 1 L-Einschraubanschluss R1/8x8

293.0850 4 L-Einschraubanschluss R1/8x6

297.0170 1 Kupplungsstecker Ø8

298.0075 1 Spannzylinder

298.0077 1 Drosselrückschlagventil R1/8

298.0179 1 3/2 Wege-Magnetventil

Electric connection diagram cl. 141

Steck-Adapter EA 9044

Socket adapter EA 9044

258.21.27en

Digital display

R2

30,9kΩ

Widerstand

Resistor

Kippschalter

Flip switch

Batterie

Battery

R1

5kΩ lin.

Drehpotentiometer

Trimming potentiometer

398.0466

Und wir können noch mehr für Sie tun!

Unser Lieferprogramm bietet für jede Branche und

jegliche Anforderung genau die richtige Problemlösung.

And we can do a lot more for you!

Our range offers the correct problem solution for

every branch and for all requirements.

Für die Bekleidungsindustrie:

Ein- und ZweifadenHochleistungs-Saummaschinen

DoppelblindstichSaummaschinen

Zweifaden-Blindstich-

Stafermaschinen

Roll- und Flachpikiermaschinen

Pikier-Automat

und

weitere Spezial-Nähmaschinen

For the clothing

industry:

Single an two thread high

performance hemming

machines

Bluff edge hemming machines

Two thread blind stitch felling

machines

Roll and at padding machines

Automatic lapel padding

machine

and other special sewing

machines

Für die Schuhverarbeitung:

Einfaden-Überwendlichmaschinen mit und ohne

Differentialtransport

For the shoe industry:

Single-thread overseaming

machines with and without

differential feed

Für Kürschnereien

und Pelzkonfektion:

Pelzschnellnäher

Pelzpikiermaschine

Futterstafermaschine

For the fur industry:

Rapid fur sewing machines

Fur padding machine

Lining felling machine

Für Heimtextilien:

Ein- und ZweifadenBlindstichmaschinen

For the home textiles

industry:

Single and two thread

blind stitch machines

Für die Polsterverarbeitung:

Ein- und ZweifadenÜberwendlichmaschinen

Ein- und ZweifadenBlindstichmaschinen

For the upholstery

industry:

Single and two thread

overseaming machines

Single and two thread

blind stitch machines

Für die Konfektion

technischer Textilien:

Ein- und ZweifadenÜberwendlichmaschinen

For the processing

of technical textiles:

Single and two thread

overseaming machines

Noch Fragen?

Dann rufen Sie uns an, schreiben Sie uns oder

kommen Sie einfach bei uns vorbei.

Sie können jederzeit weitere Informationen über

unsere Produkte anfodern oder die StrobelNähmaschinen in unserem Ausstellungsraum live

erleben. Wir freuen uns auf Sie!

Any further questions?

Then phone, write or simply come and see us. You

can have further information about our products at

any time, or experience the Strobel machines live in

our show room. We’re looking forward to meeting you!

S pe z ia l ma s c hi n en Gm b H

Postfach 1242

82168 Puchheim

Siemensstraße 3

82178 Puchheim

DEUTSCHLAND

www.strobel.biz

Telefon: +49 89 80096-0

Telefax: +49 89 80096-190

Loading...

Loading...