For the professional user

Operating Instructions

Für den professionellen Anwender

Betriebsanleitung

Class:

Klasse:

141-30 Ausf. 6

141-40 Ausf. 7

Model:

Ausführung:

Machine number:

Maschinen-Nr.:

Dated:

Stand:

S p e z i a l m a s c h i n e n G m b H

The sign of quality

ou nd the Strobel trademark on every Strobel

Y

machine leaving our works. And with good reason.

This symbol is a guaranteen of the high quality of

our products. Quality which creates trust – trust

in our technology, our service and, not least of all,

in our good name.

Im Zeichen der Qualität

ie nden die Strobel-Schutzmarke auf jeder

S

Strobel-Maschine, die unser Werk verlässt.

Und das aus gutem Grund. Denn dieses Zeichen

garantiert Ihnen die hohe Qualität unserer

Produkte. Qualität, die Vertrauen schafft – in unsere

Technik, unseren Service und nicht zuletzt in unseren

guten Namen.

A decision with future

trobel clients know that they can expect a particularly

S

high standard of performance from our company and our

machines. Now you have settled for one of our products.

For us this is a source of encouragement and of obligation

to Justify your trust.

If you wish to prot from the performance and efciency of

your Strobel machine as long as possible, exact handling

and thorough care is necessary. For this reason we kindly

request that you read the operating instructions closely.

It provides all the information you need for trouble free

operation.

And if you do happen to need a spare part the enclosed

spare parts list gives a complete overview. It is clearly

classied according to components so that you can nd the

required part quickly and easily. In order to avoid errors we

request you to quote machine class, machine number and

part number completely on your spare part order.

We wish you lots of success in your work with your new

Strobel machine.

Spez ia lm as ch in en G mb H

1 BA_141-30-40_A6-7_140416_en

2 BA_141-30-40_A6-7_140416_en

Operating Instructions

STROBEL – Single Thread Overseam Machines

Class 141-30, 141-40

Contents

1 General notes on safety ............................................................................................ 4

2 General ..................................................................................................................... 6

2.1 Operating instructions ..................................................................................... 6

2.2 Class identification, serial number and orientation of the machine ................. 6

2.3 Range of application and intended use .......................................................... 6

2.4 Technical Data ................................................................................................ 7

3 Installation and putting into service ........................................................................... 8

3.1 Unpacking the machine .................................................................................. 8

3.2 Installation ...................................................................................................... 8

3.3 Sense of rotation (Fig. 2) .............................................................................. 10

3.4 Motor drive via V-belts .................................................................................. 10

3.4.1 Tensioning the V-belt ....................................................................... 10

3.4.2 Positions of the machine .................................................................. 11

3.5 First lubrication (Fig. 6 and F ig. 7) ................................................................ 13

4 Instructions for use .................................................................................................. 15

4.1 Needles and threads (see chart, point “2.4 Technical Data”) ....................... 15

4.2 Inserting the needle (Fig. 8) .......................................................................... 15

4.3 Threading and thread course (Fig. 1 and Fig. 8) .......................................... 16

4.4 Thread tension .............................................................................................. 17

4.5 Setting the stitch length ................................................................................ 17

4.6 Adjustment of material guide ........................................................................ 18

4.7 Inserting and removing the material (Fig. 11) ............................................... 20

5 Machine maintenance ............................................................................................. 21

5.1 Oil drain pipe ................................................................................................ 22

6 Variable sewing tools .............................................................................................. 24

7 Optional extras ........................................................................................................ 28

7.1 Control panel ................................................................................................ 28

Subject to change without prior notice

3 BA_141-30-40_A6-7_140416_en

1

General notes on safety

The non-compliance wi th the fol l owing notes on safety can lead to bodily

injuries or to damages of the machine.

1. The machine must only be operated by persons familiar with the relevant

operating instructions and who have been instructed accordingly.

2. Before commissioning also read the notes on safety and the operating

instructions of the sewing drive manufacturer.

3. The machine must only be operated according to its designation and not

without the appropriate guards; all explicit safety regulations must also be

observed.

4. For threading, for changing the reels, for exchanging sewing tools such as

needles, grippers, stitch plate, transport devices, if necessary cutter and

cutting block, for cleaning, when leaving the workplace and for

maintenance work, switch off main switch or pull mains plug. With a

mechanically operated coupling motor without activation lock, wait until the

motor has stopped.

5. General maintenance work must only be carried out by appropriately

instructed persons in accordance with the operating instructions.

6. Repair, modification and maintenance work must only be carried out by

qualified staff or by appropriately instructed persons.

7. During maintenance and repair work at pneumatic devices, the machine

must be disconnected from the pneumatic supply network. Exceptions are

only admissible during adjusting work and function test by appropriately

instructed qualified staff.

8. Work at the electrical equipment must only be carried out by qualified

staff.

9. Work at parts and devices under voltage is not allowed. Exceptions are

regulated by the regulation EN50110 (DIN VDE0105).

10. Modification or alteration at the machine must only be undertaken under

consideration of all explicit safety regulations.

11. Only spare parts released by us for use are to be used during repairs.

12. The commissioning of the upper part is prohibited until it has been

determined that the entire sewing unit complies with the regulations of the

EC guidelines.

4 BA_141-30-40_A6-7_140416_en

13. Warning notes in the operating instructions of the machine, which point

out special points of danger, are marked at the appropriate positions with

the safety symbol.

Warning notes in the operating instructions of the machine which point out

special dangers of injury for operating or qualified staff, are marked at the

appropriate positions with the symbol

It is essential that you observe and follow these notes as well as the

generally valid safety regulations.

5 BA_141-30-40_A6-7_140416_en

2

2.1

2.2

2.3

General

Operating instructions

Any person involved in the installation, operation, maintenance and repair of

the machine must have read and understood the operating instructions and

mainly the safety instructions before starting the machine. Please open the

illustrations at the beginning of these operating instructions, so you can follow

the illustrations step by step while reading the instructions.

Class identification, serial number a nd orientation of the machine

The operating side of the machine is the basis for descriptions referring to

sides. The class identification (type) as well as serial and model number (after

the dash) are located below the left handwheel. These data are also shown on

the front page of the operation instructions.

Range of applicati on a nd intended use

Class 141-30

Single Thread Overseaming Machine for sewing fur facings, heavy furs such as

lambskin, imitated furs and polishing wheels.

Class 141-40

High Speed Single Thread Overseaming Machine for fine fur stranding (let-out)

and general sewing operations.

6 BA_141-30-40_A6-7_140416_en

2.4

Technical Data

Number of stitches: Max mechanically admissible

Cl. 141-30 2800 min-1

Cl. 141-40 4200 min-1

Recommended rated speed:

Cl. 141-30 2300 min-1

Cl. 141-40 3600 min-1

Machine pulley diameter dw 80 mm

V-belt profile 10 x 6 mm

Stitch length Cl. 141-30 3 - 6 mm adjustable

Cl. 141-40 0.6 – 2.5 mm adjustable

Kind of stitch Single Thread Overseam

Needle system 459R

Needle size Cl. 141-30 110 - 130

Cl. 141-40 40 - 120

Recommended thread twisted polyester filament

Recommended thread size

Cl. 141-30 50 -10

Cl. 141-40 130 – 80, 40 - 10

Stitch type 501

Kind of feed rear cup drive

Pneumatic connection 10 bar

Operating pressure 5 – 6 bar

Required space 0.6 m x 1.06 m

Noise:

Average noise level at a speed of

Cl. 141-30 n = 2300 min-1 LpAm 84 dB(A)

Cl. 141-40 n = 3200 min-1 LpAm 85 dB(A)

Noise test according to DIN 45635-48-1 KL3

7 BA_141-30-40_A6-7_140416_en

instructions.

3

3.1

3.2

Installati on a nd put t ing into service

Unpacking the machine

Strobel machines are supplied either as complete units with head, stand and

motor, or head with motor only, or the head only.

Due to the high weight and to avoid damages during transport, complete units

are packed in several smaller cartons.

Machine head and motor are removed from the stand. Reel stand, rods, oil and

other accessories are packed into the stand packing. Make sure that all

accessories have been unpacked before throwing away any packing material.

Installation

ATTENTION!

Danger of bodily injuries or finger bruises through pulling in

of garments or hairs!

The machine may not be operated without belt guards for

head and motor.

Caution: Screw oil drain pipe 133.0764 to the lid 112.0085 before setting the

top part on the table top. (See point “5.1“)

If the frame is not delivered by us as well, but rather the machine set on a

different frame, then the table top needs to be prepared as can be seen in the

table-top diagram.

ATTENTION!

Before putting the machine into service make sure

that the electrical connecting data on the motor’s

name plate, your electric network, and all other connecting

values, e. g. for the air, correspond to

the data shown on the machine and the operating

8 BA_141-30-40_A6-7_140416_en

Fig. 1

All rust protection agents, such as Vaseline and similar agents have to be

wiped off carefully from the sewing tools before putting the machine into

service.

9 BA_141-30-40_A6-7_140416_en

3.3

Sense of rotation (Fig. 2)

The correct sense of rotation of the right hand wheel is clockwise in line of

vision on the hand wheel.

Fig. 2

3.4

3.4.1

Motor drive via V-belts

Tensioning the V-belt

Caution! Danger of injury!

When checking the belt tension, switch off the machine at

the mains. Do not operate the machine without the belt

guard. Otherwise there is a DANGER of crushing

fingers, of injuries to the body and of pulling in parts of

clothing.

The tensioning of the V-belt is carried out by swivelling the motor underneath

the table plate after releasing the retaining nut with SW 24.

The V-belt must not be tensioned too much, especially with the stop motor. You

should be able to depress it with light thumb pressure by about 2 cm.

Too little V-belt tensioning can impair the positioning of the machine and

therefore impair the function sequence.

10 BA_141-30-40_A6-7_140416_en

3.4.2

Positions of the machine

CAUTION! Danger of injury!

Danger of crushing fingers and needle through stitching as

well as pulling in of parts of clothing.

Keep fingers and hands away from moving parts when

setting the position generator and checking the positions

with switched-on machine.

General:

Stop motors require a position generator, which takes the mechanical setting of

the machine from the main screw and transmits this to the control of the motor.

(Fig. 2)

The correct position of the position generator to the flange is marked with a

spot of paint.

To adjust or to remove, release the two clamping screws (2), Fig. 2. tighten

these firmly prior to commissioning.

All Machines:

The machine requires two needle positions and, depending on the sewing

drive, possibly also a reference position.

Reference position (if required, i.e. sewing drive DC1500-ST220A (Fig. 3)):

The reference position must be set in such a way, that the point of the

needle in the direction of the insertion stitch closes with the outer table

edge.

Fig. 3

11 BA_141-30-40_A6-7_140416_en

Needle position (with stop outside the seam with pedal position "-2"

(Fig. 4)):

The needle position must be set in such a way, that the distance between

the outer table edge in the stitch direction and the tip of the needle is

about 10 mm.

Needle position is position 2 at the sewing drive.

Fig. 4

Needle position (with stop in and outside the seam with pedal position "0" (Fig.

5)):

The needle position must be set in such a way, that the distance between

the tip of the needle in the stitch direction and outer table edge is about 4

mm.

Needle position is position 1 at the sewing drive.

Fig. 5

12 BA_141-30-40_A6-7_140416_en

3.5

First lubrication (Fig. 6 and Fig. 7)

Remove outer and inner machine cover and pour in original STROBEL oil

supplied with the machine from above.

To take off the inner cover first pull out the small oil pipe in the oil rising pipe of

the pump.

The soecial STROBEL oil (viscositiy 46 c St) supplied with the machine should

always be used.

The required oil quantity is 0,5 liter. It is recommended to change the oil after

approx. six month operation.

The oiling points are automatically lubricated, therefore no maintenance

required.

Fig. 6

13 BA_141-30-40_A6-7_140416_en

When remounting the inner cover make sure that the lower part of the oil pipe is

pushed into the oil rising pipe of the pump. Otherwise the automatic lubrication

does not work and the machine will be heavily damaged through blocking of the

shafts in the bearings, etc.

Therefore follow the instructions carefully and, after filling the machine with new

oil, operate the machine for a short while and control the working of the

automatic lubrication through the oil inspection glass in the outer cover.

Fig. 7

14 BA_141-30-40_A6-7_140416_en

for using different needle types.

4

4.1

4.2

Instructions for use

Needles and threads

(see chart, point “2.4 Technical Data”)

The needle size to be used depends on the material to be sewn and on the

thread respectively. Needle type to be used is 459R.

When joining fused parts it may happen that the needle eye conglutinates,

which may affect the loop formation.

Thicker and harder material requires thicker needles.

Guaranteed remark!

This machine has been set and sewn off with genuine

Strobel needles.

No guarantee can be granted if the settings are modified

Inserting the nee dle (Fig. 8)

ATTENTION!

Switch off machine electrically and confirm that the

machine is really in standstill position by operating the

treadle for the motor control before changing the needle.

Otherwise danger of finger bruises and needle

throughstitches.

Introduce the needle with is horizontal groove pointing downwards, push it to

the rear until it strikes against needle stop 134.0205 (Fig. 8). Then the needle is

clamped by means of screw 171.0406 (Fig. 9).

15 BA_141-30-40_A6-7_140416_en

4.3

Threading and thread c ourse (Fig. 1 and Fig. 8)

ATTENTION!

Switch off machine electrically and confirm that the

machine is really in standstill position by operating the

treadle for the motor control before changing the needle.

Otherwise danger of finger bruises and needle

throughstitches.

After putting the bobbin on the supporting bolt of the reel stand, the thread is

guided through the eye of thread guiding arm. (Fig. 1)

Further pass it through thread guide 184.0078 (depending on thread and

material through 1 to 3 holes) and thread tension discs 184.0049 to thread

guide 184.0161 and through thread eye 184.0125.

Fig. 8

Fig. 9

16 BA_141-30-40_A6-7_140416_en

Then guide the thread beneath pin 160.0079 at needle bar head and put it

round thread clamping screw 138.0081. After hooking it into needle set plate

285.0054 (Cl.141-30), 285.0147 (Cl. 141-40) from the left to the right, the

thread is passed through the eye of the needle from below (Fig. 8).

Thread guide 184.0078 should always be in a vertical position to obtain a large

looping angle between the thread tension discs.

4.4

4.5

Thread tension

Depending an quality, nature and thickness of the thread, thread tension is set

by means of tension nut 279.0624 (

tight tension.

Fig. 2). A thick and strong thread requires

Setting the stitch length

ATTENTION!

Switch off machine electrically and make sure that it is

really in standstill position by healing the tradle for the

motor control before setting the stitch length. Otherwise

danger off finger bruises and needle thoughstitches.

As shown in Fig. 7, the stitch length can be adjusted by means of stitch

adjusting knob 344.0089 in the inside of the left handwheel, which is equipped

with pointer 124.0080 showing through the “S” slot in the handwheel.

The handwheel has a scale according to which pointer 124.0080 has to be set.

The figures of this scale do not represent a certain stitch length in mm, but

serve as reference figures only. However, low figures mean smaller stitch

length and viceversa.

17 BA_141-30-40_A6-7_140416_en

4.6

Adjustment of material guide

Class 141-40

This machines are used for finest stranding operations.

(see point “2.3 Range of application and intended use”)

Attention!

Switch off machine electrically and confirm that the

machine is really in standstill position by operating the

treadle for the motor control.

Otherwise danger of finger bruises and needle

throughstitches.

As already mentioned, a height limit stop can be attached (see feed cup chart)

which, depending on the material to be sewn, can be set to the desired height.

It is important that the looper passes the material guide without striking it. (Fig.

10)

Fig. 10

18 BA_141-30-40_A6-7_140416_en

Fig. 11

19 BA_141-30-40_A6-7_140416_en

4.7

Inserting and re m ovi ng t he m a t e rial (Fig. 11)

ATTENTION! Danger!

The operating personnel should observe the sewing range

carefully during swing. Otherwise danger of finger bruises

and needle throughstitches.

When the machine is in standstill position and the needle is placed approx. 3

mm within the feed cup, by opening the front cup up to approx. 14 mm, by

either actuating the treadle or the pneumatic cup opening (depending on the

machine class) the sewing material can be inserted or removed easily.

Put the sewing material edge to edge and place it then up to the height limit

stop of the material guide, close the front cup and start sewing.

When using a stop motor the needle is positioned automatically after the

sewing process when heeling the treadle.

Only then the thread can be torn over the edge of the feed cup and then the

material can be removed, or the material is removed and the thread is cut using

scissors.

20 BA_141-30-40_A6-7_140416_en

5

Machine maintenance

Attention!

Switch off machine electrically and confirm that the

machine is really in standstill position by operating the

treadle for the motor control.

Otherwise danger of finger bruises and needle

throughstitches.

The machine is maintenancefree due to automatic lubrication (see “First

lubrication” point 0), only once a week dirt and hairs should be removed from oil

drain hole “D” to allow the oil coming from the needle bar to drain off. Also oil

splashing protector “C” should be cleaned (remove small cover at looper shaft),

to avoid that the oil is soaked up by the dirt and thus spoiling the material.

Checking the oil level:

Make sure that there is always

to submerge in the oil and to always bring the oil upwards.

A plastic receptacle with a capacity of exactly 1 liter is supplied with the

machine. After having filled the machine with one liter oil, the oil pump’s suction

piece is submerged in the oil.

Oil quantity and cleanness should be checked every six to twelve month

maximum.

sufficient

oil in the machine to enable the pump

If the oil is still clean enough, the oil quantity can be checked using the plastic

receptacle. Drain the oil into this receptacle an re-fill it into the machine if the oil

quantity is still correct. It is recommended to order a second oil container to

complete the oil quantity to one liter, if necessary.

The first oil change should be realized after about six month operation.

21 BA_141-30-40_A6-7_140416_en

5.1

Oil drain pipe

To facilitate machine maintenance, at the machine body or at the lower cover

respectively there is oil drain pipe 133.0764 going through the table top, thus

enabling to drain the oil without removing the machine head.

The oil drain pipe 133.0764 is sealed by means of seal ring 193.0530 and

screw 173.0772 (Fig. 13).

For machine assembly and for shipment the screw borings in cover 112.0085

are sealed by means of ring 193.0530 and screw 193.0772 as well as three

rings 190.0010 and screws 172.0521 each (Fig. 12).

Before mounting head to the table top screws 193.0772 and 172.0521 with the

seal rings have to be removed and the oil drain pipe with sealing washer

190.0178 has to be mounted and sealed (Fig. 13).

To drain the waste oil put a receptacle under the pipe and remove screw

193.0772 only. After having drained the oil screw on screw 193.0772 and seal

it.

Dispose of old oil properly!

ATTENTION! Danger!

Observe safety instructions under 1.3 and operating

instructions before starting any maintenance or repair

works. Failure to do so can result in serious bodily injuries.

After having drained the oil rinse the machine thoroughly with petroleum and

then refill with new oil.

When removing the inner cover, also oil pipe 196.0716 for the automatic

lubrication which comes from the oil pump through the inner cover with oil, is

removed (Fig. 6)

When re-mounting the inner cover please observe that the lower end of the

main oil pipe is put into the conical opening of the oil outlet piece of the oil

pump (Fig. 6). If you fail to do so the automatic lubrication does not work and

the machine may be damaged seriously by jamming of the shafts in the

bearings.

Therefore these instructions should be observed carefully and after refilling new

oil make sure the automatic lubrication works properly by briefly operating the

machine and controlling the class at the outer cover.

Before operating the machine make sure that all protection devices (e. g. cover,

belt-guard, etc.) are effective and that all screws are tightened.

22 BA_141-30-40_A6-7_140416_en

Fig. 12

Fig. 13

23 BA_141-30-40_A6-7_140416_en

6

Variable sewing tools

Attention!

Switch off machine electrically and confirm that the

machine is really in standstill position by operating the

treadle for the motor control.

Otherwise danger of finger bruises and needle

throughstitches.

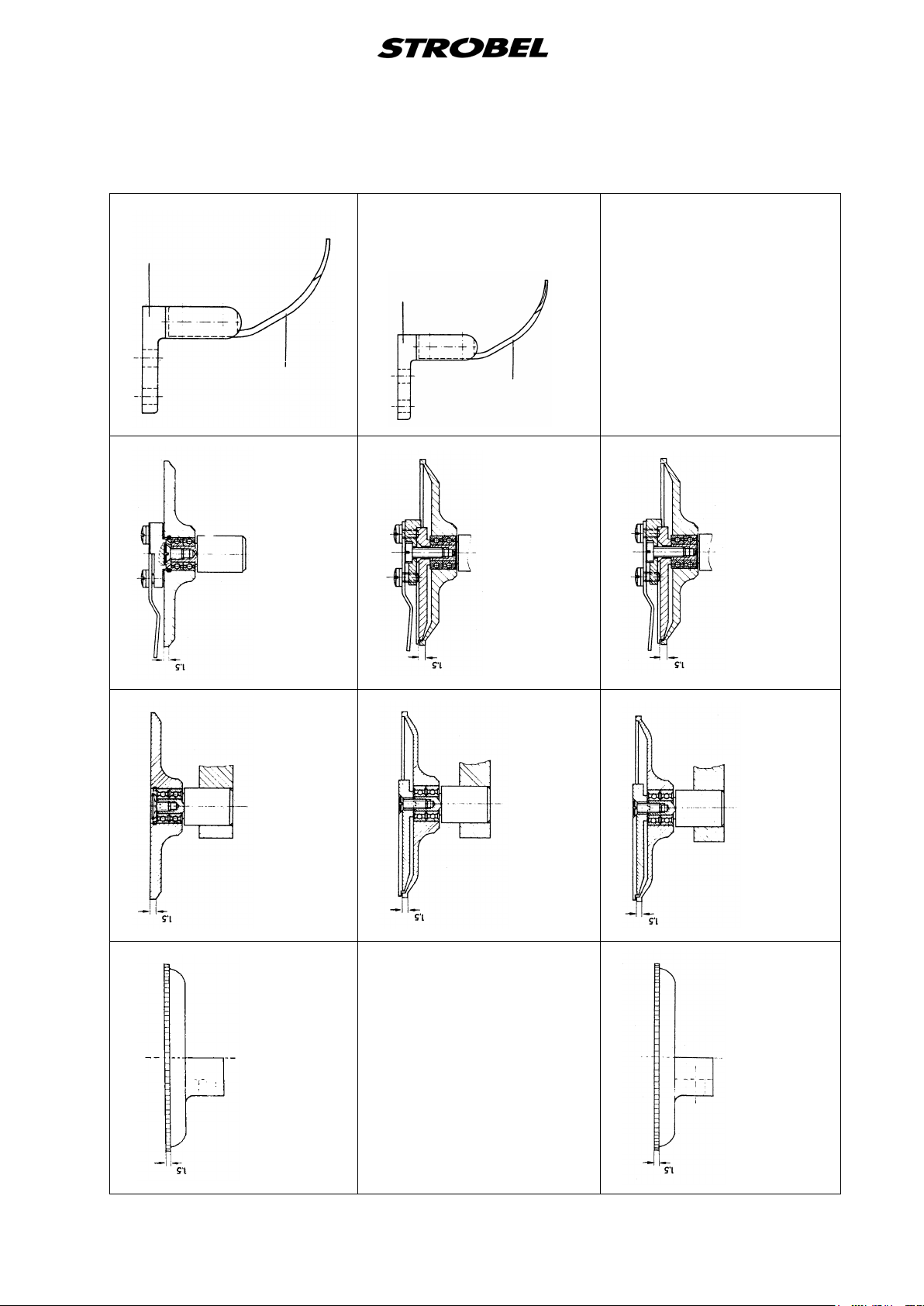

The following charts show all feed cups, front cups and material guides

available.

24 BA_141-30-40_A6-7_140416_en

186.0179

Extras

282.0203

front cup

∅ 60 – 1,5 pitch

with needle guard185.0123

Extras

382.0160

front cup ∅ 41 – 1,5 pitch

with nose 185.0128

186.0191

Material guide for

Extras

thicker material

Extras

282166

front cup

∅ 40 – 0,6 pitch

with needle guard 185.0125

682.0162

front cup

∅ 40 – 0,6 pitch

with height limit stop 186.0275

282.0160

front cup for thicker material

∅ 41 – 1,5 pitch

182.0015

feed cup for attaching fur

collars and fur trimmings

∅ 60 – 1,5 pitch

Cl. 141-30

214.0463

feed cup arm

complete, suitable

for front cup 282.0203

of Cl. 141-30

Cl. 141-40

282.0162

182.0025

front cup

∅ 40 – 0,6 pitch

feed cup

∅ 60 – 0,6 pitch

25 BA_141-30-40_A6-7_140416_en

186.0179

186.0179

Extras

Extras

Extras

186.0200

482.0161

front cup

material guide

Extras

∅ 60– 0,6 pitch

with height limit stop 186.0276

Extras

186.0315

482.0163

material guide

Extras

front cup ∅ 60 – 0,6 pitch

with needle guard 185.0123

and height limit stop 186276

Extras

482.0164

front cup ∅ 60 – 1,0 pitch

with needle guard 185.0149

and height limit stop 186.0276

282.0161

Cl. 141-40

front cup

∅ 60 – 0,6 pitch

214.0463

feed cup arm

182.0025

feed cup

∅ 60 – 0,6 pitch

complete, suitable

282.0163

front cup

∅ 60 – 0,6 pitch

with needle guard 185.0123

Extras

for all front cups

of Cl. 141-40

282.0164

182.0024

front cup

∅ 60 – 1,0 pitch

with needle guard 185.0149

feed cup

∅ 60 – 1,0 pitch

26 BA_141-30-40_A6-7_140416_en

Extras

482.0214

front cup

∅ 40– 0,6 pitch

Extras

Extras

with height limit stop 186.0275

Extras

382.0219

front cup ∅ 60 – 0,6 pitch

with needle guard 185.0123

and height limit stop 186.0276

Extras

282.0219

front cup

∅ 60 – 0,6 pitch

282.0214

Extras

Cl. 141-40

front cup

∅ 40 – 0,6 pitch

182.0215

feed cup

∅ 60 – 0,6 pitch

with needle guard 185.0123

Extras

282.0180

182.0179

front cup

∅ 60 – 1,0 pitch

with needle guard 185.0123

feed cup

∅ 60 – 1,0 pitch

27 BA_141-30-40_A6-7_140416_en

7

7.1

Optional extras

Control panel

298.0542 Control panel for a more comfortable controlling of the compact drive

28 BA_141-30-40_A6-7_140416_en

Und wir können noch mehr für Sie tun!

Unser Lieferprogramm bietet für jede Branche und

jegliche Anforderung genau die richtige Problemlösung.

And we can do a lot more for you!

Our range offers the correct problem solution for

every branch and for all requirements.

Für die Bekleidungsindustrie:

Ein- und ZweifadenHochleistungs-Saummaschinen

DoppelblindstichSaummaschinen

Zweifaden-Blindstich-

Stafermaschinen

Roll- und Flachpikiermaschinen

Pikier-Automat

und

weitere Spezial-Nähmaschinen

For the clothing

industry:

Single an two thread high

performance hemming

machines

Bluff edge hemming machines

Two thread blind stitch felling

machines

Roll and at padding machines

Automatic lapel padding

machine

and other special sewing

machines

Für die Schuhverarbeitung:

Einfaden-Überwendlichmaschinen mit und ohne

Differentialtransport

For the shoe industry:

Single-thread overseaming machines with and without differential feed

Für Kürschnereien

und Pelzkonfektion:

Pelzschnellnäher

Pelzpikiermaschine

Futterstafermaschine

For the fur industry:

Rapid fur sewing machines

Fur padding machine

Lining felling machine

Für Heimtextilien:

Ein- und ZweifadenBlindstichmaschinen

For the home textiles

industry:

Single and two thread

blind stitch machines

Für die Polsterverarbeitung:

Ein- und ZweifadenÜberwendlichmaschinen

Ein- und ZweifadenBlindstichmaschinen

For the upholstery

industry:

Single and two thread

overseaming machines

Single and two thread

blind stitch machines

Für die Konfektion

technischer Textilien:

Ein- und ZweifadenÜberwendlichmaschinen

For the processing

of technical textiles:

Single and two thread

overseaming machines

Noch Fragen?

Dann rufen Sie uns an, schreiben Sie uns oder

kommen Sie einfach bei uns vorbei.

Sie können jederzeit weitere Informationen über

unsere Produkte anfodern oder die StrobelNähmaschinen in unserem Ausstellungsraum live

erleben. Wir freuen uns auf Sie!

Any further questions?

Then phone, write or simply come and see us. You

can have further information about our products at

any time, or experience the Strobel machines live in

our show room. We’re looking forward to meeting you!

Spezi a l m a s c hinen G m b H

Postfach 1242

82168 Puchheim

Siemensstraße 3

82178 Puchheim

DEUTSCHLAND

www.strobel.biz

Telefon: +49 89 80096-0

Telefax: +49 89 80096-190

Loading...

Loading...