LAZERTM LITE

Owner’s Manual

STOP

Solo® Germany The registered Solo® trademark is licensed for use in the U.S. to the German company Solo Kleinmotoren Gmbh by the U.S. aliate, Solo incorporated.

ATTENTION: PRIOR TO FIRST USE

Avoid damage...

Read this manual

thoroughly before

using the auger.

To operate your engine you will need to use a

clean, high-quality, 2-cycle oil. We recommend

StrikeMaster 2-cycle Low Smoke Engine Oil

mixed with fuel at a ratio of 40:1 (3.2 fl. oz. to 1

gallon of gasoline).

!!

For best performance idle

engine for 1-2 minutes

before you start drilling.

®

STRIKEMASTER

Ice Augers

Ice Fishing has become one of the fastest growing and most popular winter sports, allowing the ardent

angler the opportunity to enjoy his or her favorite outdoor activity.

®

When you purchased a StrikeMaster

reputation as the quality leader since 1946. There is no doubt that this year’s model is the finest ever

produced by StrikeMaster Corporation.

Your new StrikeMaster ice auger has all of the most wanted features in a power ice auger, to assure many

years of enjoyable ice fishing. Some of these features such as workmanship, engineering excellence, and

dependability have long been standards at StrikeMaster. Your new power ice auger boasts many new

features while retaining the best features developed in previous years to enhance your ice fishing

experience and add to your satisfaction in selecting StrikeMaster.

We know that you are anxious to go fishing and use your new power ice auger, but before you go fishing,

it is important and to your advantage to spend a few minutes getting acquainted with your new

StrikeMaster power ice auger. There is no better way to acquaint yourself with the product than to read

the Owners Manual and operating instructions. A few minutes spent studying this manual before your

first ice fishing outing will be time well spent.

power ice auger, you selected a product that has gained a

Record the engine serial number, engine type and date purchased in the space below.

Also, please return the enclosed WARRANTY CARD or submit your information at

www.strikemaster.com to validate your limited warranty.

Model: Chipper Lite

Serial Number Engine Type

Spec # CC DOM

Date Purchased ______ / ______ / ______

ENGINE

TYPE

ATTENTION

!

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD ENDANGER

THE PERSONAL SAFETY AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS

IN THIS MANUAL AND ANY PROVIDED WITH OR ON THE EQUIPMENT ON WHICH THIS ENGINE IS USED BEFORE

ATTEMPTING TO OPERATE YOUR STRIKEMASTER® POWER ICE AUGER.

SPEC #

CC

!!

SERIAL

NUMBER

DOM

TABLE OF CONTENTS

Important Safeguards/Component & Control Locations 3

Assembly Instructions 4

Simple Start-Up Steps 4

Fueling: Oil/Fuel Instructions 5

Engine Start Preparations 6

Engine Start Instructions 6

Stop Engine 6

Maintenance 7

Storage 7

.................................................................................................................................................................

................................................................................................................................................................

...........................................................................................................................................................................

SOLO® Engines Limited Warranty 9-10

STRIKEMASTER Limited Warranty (back cover)

..............................................................................................................................................

..............................................................................................................................................

.................................................................................................................................

.......................................................................................................................................

........................................................................................................................................

..................................................................................................................

................................................................................................

............................................................................

IMPORTANT SAFEGUARDS

!!

STOP STOP

Avoid damage...Read this manual thoroughly before using the auger.

1. DO NOT use this product for any purpose other than cutting ice fishing holes. Ice augers are precision cutting

tools built for the ice fisherman, and must be properly maintained and handled with caution during both cutting

and transporting. When not in use, always store with blade guard attached.

2. DO NOT use attachments other than those available from the manufacturer.

3. DO NOT alter this product in any manner; doing so is dangerous and voids all warranties.

4. DO NOT allow children or adults weighing under 100 lbs. to operate this equipment.

5. DO NOT operate under the influence of drugs or alcohol.

6. DO NOT allow your body, loose clothing, drawstrings, scarves, hats or other materials to come in contact with

the Powerhead, Starter Assembly or Auger (Drill) unit at any time.

7. DO NOT operate if, upon pulling the starter rope or after drilling holes, the auger (drill) rotates or if the rope

pulls hard. Have the unit checked by a qualified mechanic.

8. DO NOT allow the engine to run or operate while moving or transporting to another location.

9. DO NOT continue to use this product in the event of mechanical or electrical failure.

10. This product produces considerable cutting force that is felt by the operator. Make sure your feet are firmly

planted and that the handles are held firmly while operating this product.

11. Always check the operation of the throttle system to ensure the carburetor control is completely returning to

the idle position when the throttle lever is released.

12. Check cutting blades and auger shaft screws before and after each use to make sure they are tight.

13. During operation, the auger unit could possibly stop. Be prepared at all times to release the throttle lever.

14. The cutting blades on the ice auger are razor sharp. Use extreme care when handling.

PACKAGING & DISPOSAL

! !

Please keep the original packaging in order to protect the equipment against damage in case you ever need to ship or

transport the auger. If the packaging materials are no longer required then they must be disposed of properly in accordance

with applicable local regulations. Cardboard packaging materials are raw materials which can be recycled or reused. At the end

of the equipments service life, please make sure that you dispose of it properly, in accordance with the ocial directives and

regulations that apply in your area.

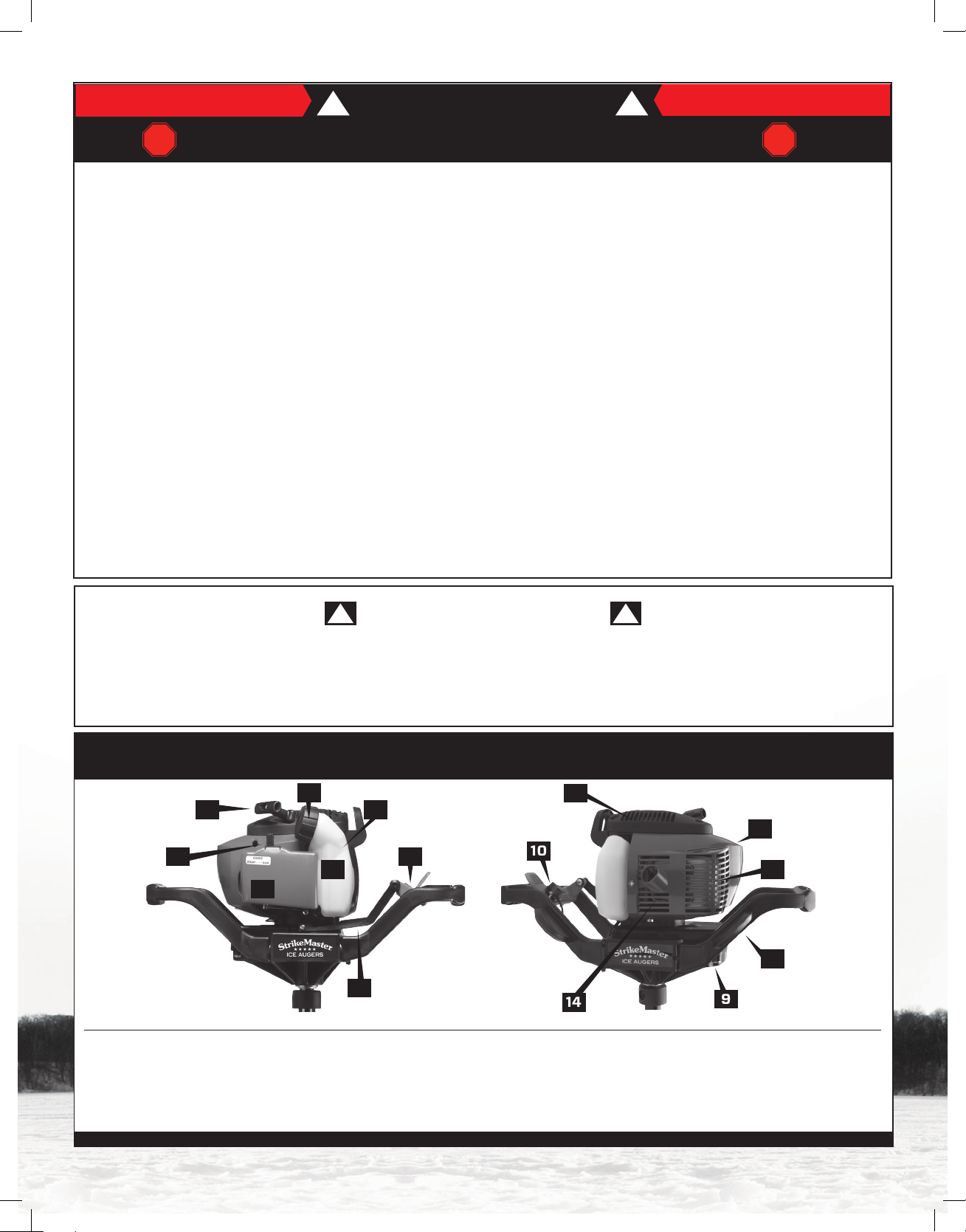

COMPONENT & CONTROL LOCATIONS

2

1

8

6

4

5

3

7

10

12

14

11

13

15

9

1. Recoil (starter) Handle

2. Fuel Cap

3. Fuel Tank

4. Fuel (FULL) Level

5. Throttle Lever

6. Air Filter Cover

7. Throttle Arm

8. Choke Lever

9. Transmission

10. Start/Stop Switch

11. Spark Plug Cover

12. Recoil Starter

3

13. Muer/Cylinder Guard

14. Muer

15. Handle Assembly

!

Carefully remove blade

1

guard and make sure

blade bolts are tight.

(Use 8mm closed end

wrench for Lazer blades)

Remove Metric Allen

2

wrench attached to the

neck of the auger and

unscrew the collar bolt

from auger.

The large and small

2a

holes from each

component must line

up before installing

the collar bolt.

Push down and twist

to line up holes.

1

2

Plastic

Collar

2a

Large

Holes

ASSEMBLY

! !

It is recommended to

3

grease inside metal collar and

Lazer

Blade

transmission output shaft on the

powerhead. Standard automotive

wheel bearing grease is suggested.

Insert drive shaft into auger and

install collar bolt.

Collar bolt inserts into the large

Metal Collar

Allen

Wrench

3a

hole, passing through the drive

shaft and threads into small hole

of metal collar. Tighten bolt. Some

Collar Bolt

wiggle is normal between the power

head and auger. Tighten often.

After assembly is complete, you

4

can conveniently store your allen

wrench on the underside of the

throttle pedal.

It is recommended that the blade

and collar bolts be checked and

torqued firmly before and after

every use.

SIMPLE START-UP STEPS

! !

3

Output Shaft

3a

4

Allen Wrench

Storage

1. Turn kill switch to the “ON” position.

2. Pump the primer bulb until it is full of fuel.

3. Move the choke lever to the “START” position.

4. SLOWLY pull recoil handle out until the flywheel engages.

5. Pull the recoil with an assertive, short pull.

6. Pull the recoil until the first audible “fire” of the engine is heard (Should be 2-4 pulls).

7. Quickly move the choke lever to the “RUN” position.

8. If the engine dies, pull over 1-2 more times.

Light pressure on the throttle lever after startup may be needed in extremely cold conditions raising the engine’s

RPMs to warm up the motor.

After using this machine, STOP the engine by allowing the engine to

return to idle and moving the switch to the OFF position. If engine fails

to stop, move choke lever to start position. DO NOT OPERATE until this

issue has been repaired by a qualified mechanic. Always check to make

sure the throttle system is moving freely and returning to idle. Turn o

this machine when traveling from fishing site to fishing site. Always

store auger with blade guard attached.

4

FUELING: OIL/FUEL INSTRUCTIONS

! !

Your new 2-stroke Solo auger engine does not come filled with a

fuel/oil mix. You will need to add a fuel/oil mix prior to your first use.

(See below) Fuel is highly flammable. Keep away from open flames

and never spill fuel. Do not smoke at the operating site or near the

refueling site.

• Stop the engine prior to refueling.

• Let the engine cool down before refueling.

• Open fuel cap slowly to allow any excess pressure in the tank to be

reduced without the risk of fuel spraying out.

• Fuel may contain substances similar to solvents. Wear protective

gloves during filling.

• Avoid breathing in fuel vapor.

• Immediately clean any spilled fuel on the machine.

• Firmly tighten fuel cap.

• Check for fuel leaks. Do not start the machine or work with the

machine if there is a fuel leak.

• Store fuel and oil in an approved and correctly labeled container.

1. The Solo engine has a non-vented gas cap which is not visible.

Air is supplied to the tank using an external venting system. (Fig 1)

2. You will notice the air line located under the fuel cap. The airline

needs to maintain this position in order to allow air to the tank. (Fig 2)

3. To prevent excessive fuel from collecting in the air line we have

the following suggestions. DO NOT OVER FILL THE GAS TANK.

4. When the auger is not in use, lay it down as shown. Position #1 (Fig 3)

is the best option followed by position #2. (Fig 4)

This will keep the air line out of the fuel.

Fig 1

AIR VENT PART #2700430

Fig 2

AIR LINE PART #64474

Fig 3

FUEL INFORMATION

• Use unleaded regular, unleaded premium or non-oxygenated

fuel. Do not use fuel with less than an octane rating of 87. For peak

performance use a 90-93 octane rated unleaded premium fuel.

• Do not use leaded fuel or E85.

• FUEL MUST BE FRESH AND CLEAN. NEVER use fuel left over

from last season or fuel that has been stored more than 30 days.

Do not use summer blend fuel; only use winter blend fuel which is

available after November 1st.

• Unsuitable fuel or deviations in mixing ratio may lead to serious

engine damage which is not covered under warranty.

2-CYCLE OIL/FUEL MIX

To operate your engine you will need to use a clean, high-quality,

2-cycle oil. We recommend StrikeMaster 2-cycle Low Smoke Engine

Oil mixed with fuel at a ratio of 40:1 (3.2 fl. oz. to 1 gallon of gasoline).

DO NOT use a fuel/oil mixture leaner than 50:1 (2.6 fl. oz. to 1 gallon

of gasoline).

• All 2-stroke engines will have some oil residue that slowly comes

from the muer area; this is normal.

• Full Synthetic 2-stroke oil may be used as long as fuel/oil mixture

ratio does not exceed 50:1 (2.6 fluid oz. oil to 1 gal. gas).

POSITION #1

When not in use

Fig 4

POSITION #2

When not in use

5

ENGINE START PREPARATIONS

!

!

• Check the complete machine for operational safety.

• The stop switch should function properly.

• The throttle must have freedom of movement and return to the idle

position on its own accord.

• The auger blades and collar bolt must be tightly secured and in

excellent working order.

• Ensure the spark plug cap and ignition cable are connected firmly.

• Remove fuel cap to ensure that the vent tube is up in the filler

tank neck and not pushed down or submersed in fuel.

ENGINE START INSTRUCTIONS

!

1. Turn the ON/OFF switch to ON. Make sure to read the

switch correctly. As shown above. (Fig 1)

2. Press the primer bulb (Fig 2) 5 to 8 times.

3. Slide the choke lever to START position. (Fig 3)

4. Pull the recoil slowly until engagement to flywheel is felt, then

continue pull with a slightly quicker motion until engine fires.

(Audible sound)

Once the motor has fired, slide the choke lever to RUN (Fig 4)

(no choke), and continue. Repeat step 4 until engine starts.

If engine fails to start, repeat steps 1-4.

Fig 1

Fig 2

Fig 3

!

Primer

Bulb

Choke Lever

(Start Position)

STARTING TIPS: As you know, very cold temperatures make all engines

a little harder to start. Whenever possible, keeping your machine in a

warm environment will ALWAYS make it easier to start.

Fig 4

If the engine fails to start after several attempts, check that all

adjustments described above have been done correctly.

Be sure the on/o switch is NOT in the o position and start once

again. If the engine still fails to start, contact your local Solo

authorized repair center located on our website.

Choke Lever

www.strikemaster.com

STOP ENGINE

! !

(Run Position)

After completing the cutting of an ice fishing hole, STOP the engine by allowing the engine to return to idle and

moving the ON/OFF switch to the OFF position. If engine fails to stop, slide choke lever to start (full choke). Do not

operate until this issue has been repaired by a qualified mechanic.

6

MAINTENANCE

! !

AIR FILTER

Contaminated air filters cause a reduction in engine

performance and increase fuel consumption with more

pollutants in the exhaust gas. Engines are less likely to

start readily with a contaminated air filter.

As a basic principle therefore, the air filter should be

cleaned as follows before starting work, and

intermittently in very dusty conditions:

Use spark plugs with the following description:

BOSCH: Super R10 USR4AC (Original plug included,

gap .020 inch)

NGK: CMR6H or comparable (Replacement/

Service plug .025 inch.)

Only use spark plugs where the contact nut has been

firmly fitted. Loose connections may produce sparks,

which can cause fire. Before restarting the engine,

check the high-tension ignition cable for any damage to

it’s insulation and ensure the cable is connected

securely to the spark plug cap.

• Insert the spark plug into the cylinder head and

tighten it.

• Push the spark plug cap firmly over the spark plug.

• Position the spark plug cover onto the housing by

aligning it with the guiding pins, push down and click

into place.

Before opening the air filter, close the choke to prevent

dirt entering the carburetor.

• Push tab (a) in, only slightly open air filter lid (11) and

remove by rotating gently back and forth.

• Remove foam filter (c) from the lid and clean the area

around the filter.

• Thoroughly clean air filter casing (d) and air filter

cover (11) on the inside, using a paintbrush or by

carefully blowing on them.

• Clean filter insert (c) by shaking it out or carefully

blowing on it.

If the filter insert is damaged or so contaminated that it

is impossible to clean, replace it with the original spare

part (part no. 20 48 406).

• Insert the new or cleaned foam filter into the

air filter lid.

• Position the air filter cover with both tabs (b) [inside,

opposite tab (a)] in the corresponding two pockets

(b’) of the filter casing.

• Press air filter cover against the filter casing until tab

(a) clicks audibly into place.

SPARK PLUG

Check the spark plug annually.

• Engine must be cool.

• Press the top tab of the spark

plug cover (16) down (a),

push back (b) and remove.

• Disconnect the

spark plug cap.

• Unscrew the spark plug

and dry electrodes.

The spark plug should be replaced after 50 hours of

operation or if the electrodes are badly worn.

Do not turn the engine over while the spark plug has

been removed or the spark plug cap has been

disconnected from the ignition cable.

.025 inch

TRANSMISSION

Transmissions are maintenance free, they require no

adding of grease or checking.

SECURING YOUR AUGER DURING TRANSPORT

With your purchase of a StrikeMaster power auger, you

have acquired one of the world’s best precision cutting

machines. A little prevention goes a long way. Whether

you transport this machine in a truck, snowmobile, ATV

or sled be sure to secure it down to prevent damage.

STORAGE

! !

Because of today’s fuels STRIKEMASTER cannot

guarantee results. For summer storage or any period of

time exceeding four weeks, the following steps should

be carried out:

WET/NORMAL STORAGE : (recommended)

• Empty fuel tank contents and dispose of properly

• Fill fuel tank to 1/4 capacity with fresh fuel,

oil and stabilizer

• Start and run engine for 2-3 minutes, varying throttle

input, then turn switch to the OFF positron

• If possible, run engine every 30 days for 2-3 minutes.

DRY STORAGE:

• Empty fuel tank contents and dispose of properly

• Fill fuel tank to 1/4 capacity with fresh fuel,

oil and stabilizer

• Start and run engine for 2-3 minutes, varying throttle

input, then turn switch to the OFF position

• Empty fuel tank contents

• Restart engine and allow engine to idle until engine

stalls (due to lack of fuel)

Suggested steps for general cleaning and storage:

• Spray WD-40 or apply oil onto the blades and blade

screws to reduce rust and corrosion

• Clean the engine thoroughly with a clean cloth

• Place a cover over engine assembly

• Store indoors in a well-ventilated low humidity area

• Store auger with blade guard attached

7

Tony Roach

Ice Force Pro Angler

®

Solo® Germany-The registered Solo® trademark is licensed for use in the U. S from the

German company Solo Kleinmotoren Gmbh by the U.S. aliate, Solo incorporated.

Transmission: Transmissions are maintenance free, they require no adding of grease or checking.

LIMITED WARRANTY

The manufacturer warranties trouble-free quality and will cover the cost of replacing parts which are found to be

faulty in material or workmanship within the prescribed warranty period after the date of purchase. Please note

that specific warranty conditions may vary from country to country. If in doubt, ask your equipment vendor. They are

responsible for warranty matters. Solo Inc. provides the initial purchaser with a 2 year engine warranty.

We hope you will understand that we cannot be liable for damage resulting from the following causes:

• Non-compliance with the operating instructions.

• Neglecting essential maintenance and repair work.

• Damage caused by incorrect carburetor adjustment.

• Wear and tear from normal use.

• Obvious overload by continuously exceeding the maximum performance limit of the product.

• Using non-authorized tools.

• Use of force, incorrect treatment, misuse and accidents.

• Damage from excessive heat due to dirt buildup around the cooling fan housing.

• Attempted adjustments and repairs by unqualified persons.

• Use of unsuitable spare parts or third party parts, if these are the cause of the defect.

• Use of unsuitable or stale fuel.

• Damage caused by using the product in the hire or rental industry.

Normal cleaning, adjustments or maintenance work fall outside the warranty provisions. A service center authorized

by the manufacturer must carry out all warranty work.

!!

9

EC DECLARATION OF CONFORMITY

In accordance with EG Directives 98/37/EC,

2000/14/EC and 89/336/EEC (amended by

92/31/EEC), SOLO Kleinmotoren GmbH,

Stuttgarter Strasse 41, D-71069 Sindelfingen,

being solely responsible, states that the product

referred to in this declaration complies with the

requirements of the Machinery Directive.

Description of product: Ice Auger

Model/Type description 111 142 154

Sound power level

Guaranteed sound

Actual sound 94 111 111 dB(A)

105 112 112 dB(A)

PARTS SUBJECT TO WEAR AND TEAR

Various parts are subject to application-specific or

normal wear and must be replaced when required.

The following parts are subject to normal wear and

are not covered by the manufacturer’s warranty:

• Air filter

• Fuel filter

• All rubber parts which come into contact with fuel

• Clutch

• Spark plug

• Starter (Recoil)

• Blades

(EN ISO 3744, EN ISO 22868)

Applied standards: EN ISO 12100, EN 11806,

ISO 14865, EN ISO 14982

Conformity assessment procedures

(98/37/EG) - Appendix V

(2000/14/EG) - Appendix V

Serial number, Build year - Type plate

This declaration of conformity loses its validity, if the

equipment is converted or modified without the

manufacturer’s consent.

Sindelfingen, 1st January 2006

SOLO Kleinmotoren GmbH Wolfgang Emmerich

Executive Director

FOR USA ONLY

Emissions Control Warranty Statement

The Environmental Protection Agency and Solo are

pleased to explain the emission control system on your

small non-road power equipment engine. In the US new

small non-road engines must be designed, built, and

equipped to meet the Environmental Protection

Agency’s standards. Solo must warrant the emission

control system on your small non- road engine for the

period of time listed below provided there has been no

abuse, neglect, or improper maintenance of your small

non-road engine.

Your emission control system includes parts such as the

carburetor, the ignition system and the exhaust system.

Where a warrantable condition exists Solo will repair

your small non-road power equipment engine at no cost

to you including diagnosis, parts, and labor.

10

LIMITED WARRANTY

The warrantor’s obligation shall be limited to repairing or replacing any part, which upon examination by StrikeMaster, is determined to be defective. This obligation

begins on the date of purchase (as evidenced by a product receipt) and continues for a period of ONE YEAR after purchase (“warranty period”), with the exception of

engines and parts subject to wear and tear. This warranty is non-transferrable; warranty registration must be completed online or via USPS within 30 days of purchase

to validate warranty. The warranty does not apply if product has been negligently used, misused, altered, damaged in an accident or if periodic maintenance has not

Company warrants that Product, other than engines and parts subject to wear and tear, will perform substantially in accordance with the accompanying written

materials [owner’s manual] for a period of ONE YEAR. In the case of engines and parts subject to wear and tear, please refer to the chart below. Parts subject to

normal wear and tear are not covered by warranty including: air filter, fuel filter, any rubber part that comes in contact with fuel, clutch, spark plug, starter (recoil), 12

volt batteries and blades. In the event applicable law imposes any implied warranties, the implied warranty period is limited to ONE YEAR from the date reflected on the

product receipt. Some jurisdictions do not allow such limitations on the duration of an implied warranty, so the above limitation may not apply.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, THE COMPANY AND AUTHORIZED SERVICE CENTERS DISCLAIM ALL OTHER WARRANTIES, EITHER

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH REGARD TO

THE PRODUCT AND WRITTEN MATERIALS [OWNER’S MANUAL]. THIS LIMITED WARRANTY GIVES CUSTOMER SPECIFIC LEGAL RIGHTS. CUSTOMER MAY HAVE OTHER

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, IN NO EVENT SHALL THE COMPANY OR AUTHORIZED SERVICE CENTER BE LIABLE FOR ANY DAMAGES

WHATSOEVER (INCLUDING WITHOUT LIMITATION, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL OR INDIRECT DAMAGES FOR PERSONAL INJURY, LOSS OF BUSINESS

PROFITS, BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION OR ANY OTHER PECUNIARY LOSS) ARISING OUT OF THE USE OF OR INABILITY TO USE THIS

PRODUCT, EVEN IF THE COMPANY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN ANY CASE, THE COMPANY’S AND AUTHORIZED REPAIR CENTER’S

ENTIRE LIABILITY UNDER ANY PROVISION OF THIS AGREEMENT SHALL BE LIMITED TO THE AMOUNT ACTUALLY PAID BY YOU FOR THE PRODUCT. BECAUSE SOME

JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT

been performed. Customer is responsible for shipping and transportation charges to the nearest warranty repair center.

RIGHTS DEPENDING ON THE JURISDICTION.

APPLY TO YOU.

Continued satisfying performance from your StrikeMaster power ice auger may be assured by applying a minimum amount

of preventive maintenance.

Limited Warranty coverage

(with receipt/proof of registration)

Wear & tear parts X

12-Volt Battery X

StrikeMaster parts X

Solo engine X

Honda engine X

Lithium Lazer motor X

Lithium Lazer battery X

30-Day

Warranty

90-Day

Warranty

1-Year

Warranty

2-Year

Warranty

3-Year

Warranty

Visit our website for up to date warranty service centers.

www.strikemaster.com

Loading...

Loading...