Striem OS-15, OS-75, OS-100, OS-25, OS-35 Instructions Manual

...

Striem

3100 Brinkerhoff

Kansas City, KS 66115

Tel: 913-222-1500

Fax: 913-291-0457

www.

striemco.com

Made in the U.S.A

OS-15

15 gpm, 15 gallons

10 gallon oil capacity

1 gallon sand capacity

OS-25

25 gpm, 21 gallons

15 gallon oil capacity

6 gallon sand capacity

OS-35

35 gpm, 38 gallons

28 gallon oil capacity

6 gallon sand capacity

OS-50

50 gpm, 57 gallons

40 gallon oil capacity

7 gallon sand capacity

OS-75

75 gpm, 110 gallons

93 gallon oil capacity

11 gallon sand capacity

OS-100

100 gpm, 250 gallons

144 gallon oil capacity

95 gallon sand capacity

OS-500

100 gpm, 500 gallons

288 gallon oil capacity

95 gallon sand capacity

Sheet Descriptions

Sheet #1 - Series overview and Warranty information

Sheet #2 - OS General installation guidelines and Operation/Maintenance guidelines

Sheet #3 - Below Grade installation guidelines

Sheet #4 - Below and Above Grade installation guidelines

Sheet #5 - Multiple unit systems. Setting the oil draw off

Sheet #6 - OCT General installation guidelines and Operation/Maintenance guidelines

Sheet #7 - TeleGlide Riser installation guidelines (SR24, LR24)

Sheet #8 - TeleGlide Riser installation guidelines (SR16)

Leak/Seal Testing

DO NOT AIR TEST UNIT OR TELEGLIDE RISER SYSTEM! Doing so may result in property damage, personal injury or death.

Base Unit:

To perform a leak/seal test on the base unit, cap/plug all plumbing connections, remove the cover, and fill the unit with water just above the

highest connection. Inspect unit and connections for leaks. Check water level at specific time intervals per local code.

TeleGlide Riser System:

If required by local code, the riser system may be leak/seal tested similar to the base unit.

CAUTION:

the riser(s) must be supported

before filling with water to keep from tipping over. Once riser system is in place and properly supported, cap/plug all plumbing connections on the main unit,

remove the cover from the top of the riser assembly and fill the unit and riser system with water to finished grade level. Carefully, as the riser(s) will be very

heavy from the weight of the water, inspect all gasket(s) and clamps (if applicable) for any leaks. Check water level at specific time intervals per local code.

Lifetime Warranty

Effective March 2, 2015 Striem represents and warrants that HDPE and PP products will be free from any

and all defects in material and workmanship, including corrosion, during the lifetime of the plumbing system in which the Products were originally

installed and will, at its option, agree to repair, replace, or supply credit to the original purchaser.

This warranty does not cover damage caused by the Products’ normal usage, or wear and tear, nor does it cover damage from naturally occurring

phenomenon, including, but not limited to UV, freeze-related damage, or natural disasters. This warranty does not cover the purchaser’s cost of routine

maintenance including replacement of parts required in routine maintenance.

This warranty does not cover fabricated steel products, or any monitoring equipment. This warranty shall be effective if, and only if, the Products:

* Were installed in accordance with Striem’s notes, specifications and instructions, for installation, operation, and maintenance;

* Were installed in conformance with all applicable building and plumbing codes, and passed all applicable testing methods immediately following installation;

* Have not been subjected to misuse or abuse, whether negligent or intentional;

* Were never modified, repaired, or altered by any individual(s) not authorized by Striem.

This warranty is the purchaser’s sole and exclusive remedy, and acceptance of this exclusive remedy is a condition of the contract for thepurchase of these

Products. In no event shall Striem be liable for any incidental, special, consequential or punitive damages, or for any costs, attorney fees, expenses, losses or

delays claimed to be as a consequence of any damage to, failure of, or defect in any products including, but not limited to, any claims for loss of profi ts,

transportation, removal and installation charges. This warranty is exclusive and in lieu of all other warranties or conditions, written or oral, expressed or implied.

OIL RESERVE OIL SEPARATORS

(Models OS-15, OS-25, OS-35, OS-50, OS-75, OS-100, and OS-500)

OS & OCT SERIES INSTALLATION,

OPERATION AND MAINTENANCE GUIDE

ECO:

8/15/18MJREV:

DATE:

DWG BY:

DESCRIPTION:

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

STRIEM, LLC.

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

STRIEM, LLC.

IS

PROHIBITED.

NOTES:

Striem oil separators are rated and manufactured with an internal flow control system already in

place. They do not require an external flow control system or air intake vent.

Striem oil separators are not to be installed in any other manner except as shown. Consult local

codes for separate trapping requirements, cleanout locations and additional installation instructions.

SHEET NUMBER:

1 of 7

Striem

3100 Brinkerhoff

Kansas City, KS 66115

Tel: 913-222-1500

Fax: 913-291-0457

www.

striemco.com

Made in the U.S.A

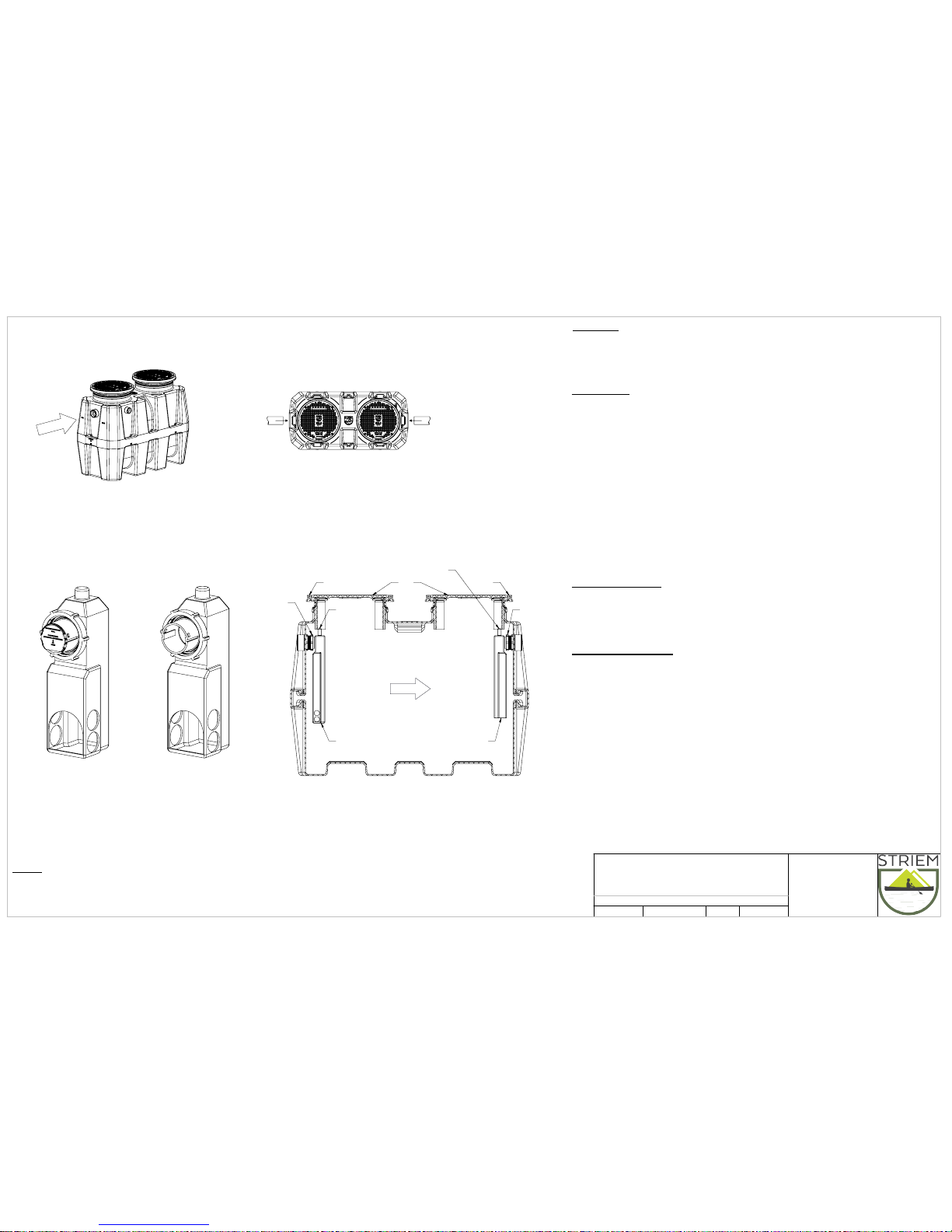

Connect inlet and outlet drainage lines to

unit. Mechanically couple pipes to

unit.

Do not solvent weld

. If connecting

multiple units for an engineered oil

separator system refer to multiple unit

installation sheet. (sheet #5)

Top View

FLOW

Isometric View

Set unit on level solid surface as close as

possible to fixtures being served. If unit is

to be installed below grade refer to below

grade installation instructions. (sheet #3)

FLOW

OS-100 SHOWN

Locking Collar

Cover

Adapter

Locking Collar

Inlet Disffuser

Outlet Diffuser

Open Top

Closed top outlet diffuser

to provide sewer gas trap

Adapter

MAINTENANCE

For most thorough cleaning contact a professional pumper contractor.

1.

Wear appropriate safety equipment when cleaning. Do not smoke near separator or clean near open

2.

flame or sparks.

Remove cover(s).

3.

Remove coalescing media (if applicable) and thoroughly wash down into appropriate container.

4.

Remove all contents of the separator including oil, sediment

5.

and wastewater.

To access the inlet and outlet lines for cleaning as needed:

6.

a.) 4" connections: Remove the inlet and outlet diffusers

(inside unit(s)) by hand loosening

green locking collars.

b.) 6" connections: Remove threaded clean-out plug from the back

of the inlet and outlet diffusers.

Clean the drain lines, diffusers and air relief thoroughly of all

7.

debris before replacing diffusers to original positions or reinstalling

threaded clean-out plug.

Fill unit(s) with water.

8.

Inspect gasket for wear and tear. Replace cover(s).

9.

Dispose of oil per local code.

10.

PUMPING FREQUENCY:

Frequency depends on the capacity of the separator and the amount of oil and sediment in the wastewater.

After initial installation, it is recommended that the unit is fully pumped every 3 to 4 weeks. Monitor each pumping

to establish an adequate maintenance schedule Striem Products recommends pumping frequency to exceed no

more than 6 months.

TROUBLESHOOTING TIPS:

In the case of a clog, inlet and outlet diffusers may be removed for line cleaning. Slower than usual drainage may

indicate the need to pump/clean oil separator. Units with 6" connections have a removable plug on the back of the

diffuser as the diffuser itself is not removable.

Always take proper care to ensure a safe and healthy environment while cleaning separator. For best cleaning and

maintenance service, call your local sewer and drain contractor.

GENERAL SEPARATOR INSTALLATION INSTRUCTIONS

(OS-100 SHOWN)

OPERATION

Striem Oil Separators are engineered to separate oil and other lighter-than-water contaminants from

wastewater to keep them from entering the sewage system. This is accomplished using Striem's patented

Diffusion Flow design. The inlet diffusor distributes the wastewater through the separator in a smooth, even

flow pattern which eliminates dead spots. This diffused flow assures that the oil and sediment layers are

undisturbed and increases the efficiency of the separator.

To maintain proper flow rate,

when interceptor is installed

in a high flow or increased head

pressure application keep

calibrated flow plate installed.

Flow plate calibrated to

rated GPM at 13 foot water column.

Flow Plate Installed

To maintain proper flow rate,

when interceptor is installed in

a low flow or reduced head

pressure application remove

and discard calibrated flow

plate.

Flow Plate Uninstalled

OS & OCT SERIES INSTALLATION,

OPERATION AND MAINTENANCE GUIDE

ECO:

8/15/18MJREV:

DATE:

DWG BY:

DESCRIPTION:

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

STRIEM, LLC.

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

STRIEM, LLC.

IS

PROHIBITED.

NOTES:

Striem oil separators are rated and manufactured with an internal flow control system already in

place. They do not require an external flow control system or air intake vent.

Striem oil separators are not to be installed in any other manner except as shown. Consult local

codes for separate trapping requirements, cleanout locations and additional installation instructions.

SHEET NUMBER:

2 of 7

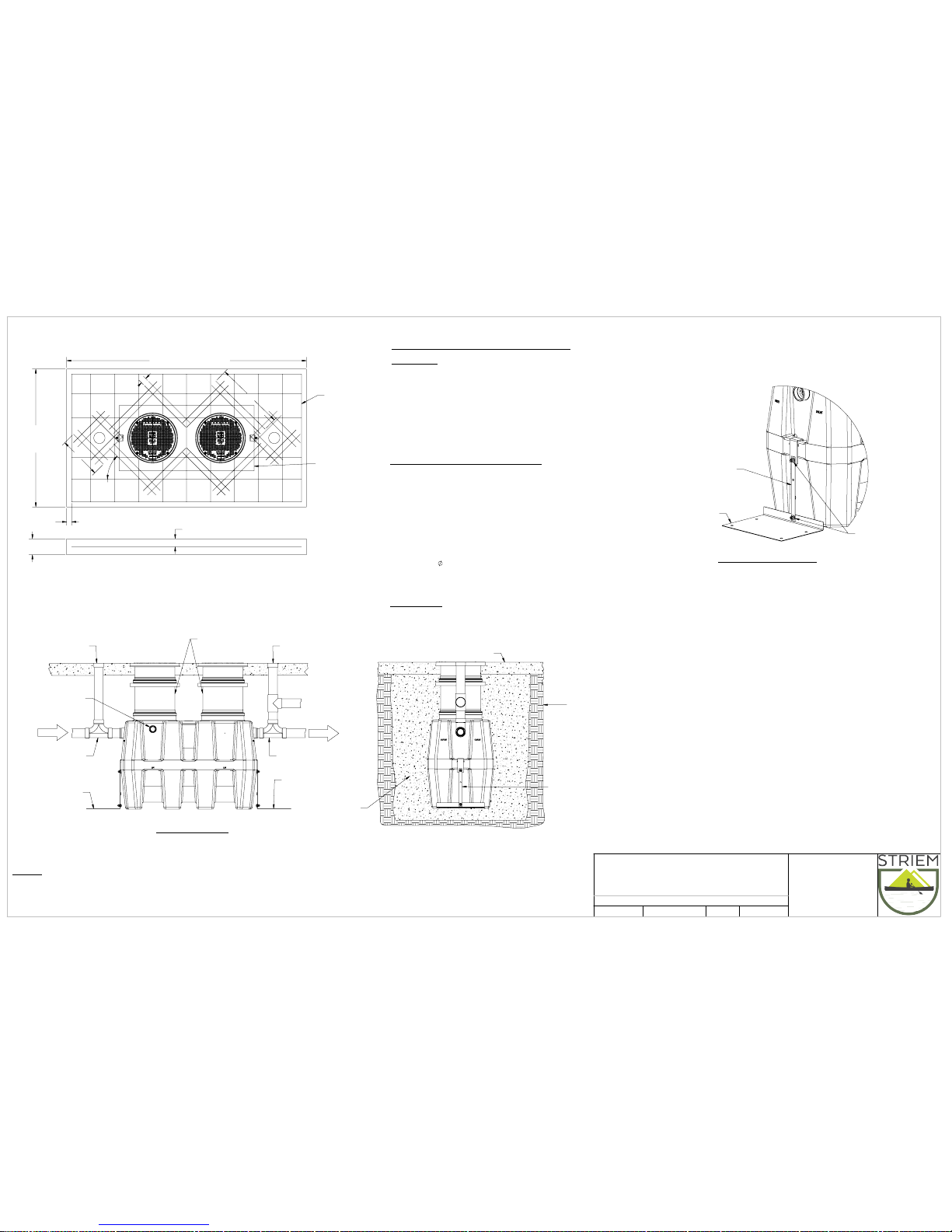

Clean out to grade

on inlet pipe of each

unit (by others)

Clean out to grade

on outlet pipe of each

unit (by others)

Risers to grade

EXCAVATION AND BACKFILL DETAIL

(INTERIOR OR EXTERIOR)

2-Way cleanout

tee (by others)

2-Way cleanout

tee (by others)

SIDE VIEW DETAIL

Optional Anchor kit

see detail

Optional Anchor kit

see detail

VENT

Concrete slab

Native soil

Crushed aggregate

or sand

Optional Anchor kit

see detail

30"

60"

4"

the unit footprint

Concrete Pad

must extend

18" outside

45.00°

2 1/2"

Min.

18" outside the unit footprint

Concrete Pad must extend

8"

4"

Rebar

Finished Grade

Rebar

OS-100

Shown

CONCRETE SLAB DETAIL FOR TRAFFIC LOADING

(INTERIOR OR EXTERIOR)

(OS-100 Shown)

Top View

Elevation View

Stainless steel

Anchor strap

Stainless steel

Anchor plate

Stainless hardware

ANCHOR KIT INSTALLATION DETAIL

Anchor Kit Installation Steps

Slide "Anchor Strap" over tie down point on end wall and

1.

bolt together using provided hardware.

Bolt "Anchor Strap" to "Anchor Plate" using provided hardware

2.

3. Hold down force achieved by backfill weight acting on Anchor Plate.

4. Anchor Plate may be bolted to concrete slab, if required, by using

holes provided in Anchor Plate.

FLOW

FLOW

Striem

3100 Brinkerhoff

Kansas City, KS 66115

Tel: 913-222-1500

Fax: 913-291-0457

www.

striemco.com

Made in the U.S.A

For unit details see specification sheet for selected unit

(Connecting pipe and fittings by others)

INTERIOR OR EXTERIOR BELOW GRADE INSTALLATION INSTRUCTIONS

(OS-35, OS-50, OS-75, OS-100, OS-500)

CONNECTIONS

Connect waste piping to the unit. When connecting OS-75 (2), and OS-500, install

units in series, not parallel.

Connect vent piping to vent connection on sidewall of tank per local code.

BELOW GRADE INSTALLATION INSTRUCTIONS

EXCAVATION

Install unit(s) as close as possible to fixtures being serviced.

1.

Width and length of excavation shall be minimum 12" greater

2.

than the tank on all sides.

Depth of excavation shall be 6" deeper than tank bottom.

3.

Set the tank in well-packed crushed aggregate material

4.

approximately 3/4" size rock, or sand, with no fines. When setting OS-75 (2) and

the OS-500 all units must be level.

Anchor kit is recommended for installations in high water table conditions to

5.

prevent float out. To be determined by specifying engineer. If necessary,

order optional "Anchor Kit". See detail on this sheet.

BACKFILLING & FINISHED CONCRETE SLAB

Preparation of sub grade per geotech recommendations.

1.

Stabilize and compact sub grade to 95% proctor.

2.

Fill tank with water before backfilling to prevent float out during piping installation.

3.

Before backfilling and pouring of slab secure cover(s) and riser/s (if necessary) to the unit(s)

4.

Backfill using crushed aggregate material approximately 3/4" size rock, or sand,

5.

with no fines.

6. Place 6" aggregate base under slab. Aggregate should be 3/4" size rock, or sand, with no fines.

7. Thickness of concrete around cover to be determined by specifying engineer. If traffic

loading is required the concrete slab dimensions shown are for guideline

purposes only.

8. Concrete to be 28 day compressive strength to 4000 PSI.

9. NO. 4 rebar (

1/2") grade 60 steel per ASTM A615: connected with tie wire.

10. Rebar to be 2 1/2" from edge of concrete.

11. Rebar spacing 12" grid. 4" spacing around access openings.

12. All pipe penetrations to be sleeved or have slip connections.

VENT

OS & OCT SERIES INSTALLATION,

OPERATION AND MAINTENANCE GUIDE

ECO:

8/15/18MJREV:

DATE:

DWG BY:

DESCRIPTION:

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF

STRIEM, LLC.

ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

STRIEM, LLC.

IS

PROHIBITED.

NOTES:

Striem oil separators are rated and manufactured with an internal flow control system already in

place. They do not require an external flow control system or air intake vent.

Striem oil separators are not to be installed in any other manner except as shown. Consult local

codes for separate trapping requirements, cleanout locations and additional installation instructions.

SHEET NUMBER:

3 of 7

Loading...

Loading...