Pellet Boiler Varan 1.14., 1.20

Manual For Installation And Useage

Product Information

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

3

Operation

When staring the boiler for the first time, it is possible that a noticeable odour development caused by heat-resitant coatings or

painting of single boiler parts may occur. During operation, these

coatings will cure and the odour will fade out.

Note that certain surfaces of the boiler will heat up during operation. If you come in contact with parts of the boiler, make sure

that they have cooled down properly or use suitable protective

gloves. Make sure that pieces of clothing and other heat-sensitive

materials do not come in contact with the boiler.

Because of the changes in temperature during heating up and

cooling down, boiler parts may give out expansium noises (mostly

knocking or crackling). The ocurrence of such sounds is no manufacturing or operation defect.

If you open the combustion chamber door during operation or

when the boiler is still warm, particles of ember or ash may fall to

the floor. Remove them with heat-restistant tools and protective

gloves. .

The installation of a hydraulic group is mandatory with boilers of this type series.

Operation Parameters

The user may only modify the operation parameters in the range

that is prescribed by this manual. The use of other settings than

those listed in this manual can cause malfunctions in the system.

The operating pressure must never exceed 2,5 bar. A boiler temperatur of above 90˚C is not allowed.

Because of possible risk of frost inside the aquiferous heating

pipes, it is recommended to not switch-off the boiler at outdoor

temperatures below 0°C if the boiler is the only heating element

in the system.

Spare Parts

To replace defective parts of the boiler, only use original STREBEL

spare parts.

Prescibed Fuel

The boiler is construdef only for the combustion of wood

pellets. Using any other fuel is prohibited. In any case, do

not use pieces of wood, paper, oil, plastic or other materials as fuel.

More information in chapter 3.

Safety Instructions

This User Manual

Every person who is intending to operate this boiler is obligated to read this manual carefully,

especially the safety instructions. This includes individuals which

are cleaning or maintaining the boiler.

Otherwise, the legal warranty expires.

Please keep and preserve this manual.

Usage Of This Boiler

The manufacturer is not responsible for damages resulting from

improper installation, maintainence or operation. In this case, the

user is liable and the legal warranty expires.

Respect local provisions and legal guidelines when setting up,

installing, operating and disposing the boiler. The boiler must be

installed by expert personnel. Do not make unauthorized modifica

-

tions on the boiler or its water and exhaust connections.

To transport the boiler, make sure that the transport aids and the

underground that the boiler has to traverse over are able to sustain its weight. The underground on which the boiler is stored or

installed on should also have the suitable load capacity.

So not expose the boiler to weather conditions. The installation

and storage is only authorized indoors (VDE 0100 part 200). Do

not cover the boiler or lean/place objects directly beside it. The

installation in wet spaces/humidors is not permitted. The boiler is

not protected against spray water.

The person responsible for installation and/or implementation

must inform the user about the correct operation and cleaning of

the boiler. Only use the boiler if it is installed correctly. Always

adhere to this user manual. Malfunctions are to be repaired as

soon as possible.

This boiler may only be used for the purposes it is intended and

was manufactured according to current safety requirements. Incorrect use may cause damage to the boiler or to other objects in

in close proximity. Accidents, injury or even death of the usermay

occur if the safety instructions are violated.

The operation of this appliance by children or individuals with

restricted perception or motoric abilities, each without accompaniment, is prohibited. Pay attention that children or pets do not

comke in direct contact with the boiler or climb it.

It is prohibited to place heavy objects on the boiler or stepping

onto it.

Safety Instructions

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

4

Safety Instructions

Possible Risks

If the combustion chamber door or cleaning openings are left open

during operation, carbon monoxide is able to discharge from the

boiler. Do not leave them open longer than necessary. Insufficient

air supply during operation is lethal. It is prohibited to close the

openings of the boiler or the installation room that provide the

fresh air needed for operation.

This boiler has electric components which are live during operation, as well as movable parts on the inside. Under any circumstances do not stick a finger or other objects in the openings of the

boiler. There is a danger of electric shocks or burn injury, as well

as property damage.

In case water is leaking from the boiler, stop its operation immediately and have competent service personnel at the damage.

Minimum Distance Of Flammable Materials

Keep flammable materials and objects away from the boiler and

make sure that the insulation material below the boiler protects

the floor from harmful heat exposure. The minimum distance flammable objects have to be kept abway from the boiler is stringently

prescribed and is subject to regional directives. Ask your chimney

sweep for detail information.

In case the boiler is not installed in a seperate boiler room but in

the living space with an open flue, combustion air is taken from

the living space as well.

The minimum distance from the boiler and its exhaust pipe tomaterials with low or intermediate flammability is 100 mm. The

minimum distance from easily flammable objects is 200 mm. The

latter also counts for materials if their flammability is unknown.

Fresh Air Intake

Boilers need a suitable air supply to maintain combustion.

Open Flue: Under certain circumstances, if the fresh air is taken directly from the boiler room, an insufficient supply of oyxgen

needed for combustion may occur. This is especially prominent in

houses or flats with tightly sealed doors and windows. Operating

the boiler without constant supply of outside air can cause sevee

problems in operation. It is recommended to install an automatic

venting system in the builduing or use a balanced flue system.

Balanced Flue: The fresh air opening is connected with a sealed

pipe which takes air from the outside or a seperate room with

constant fresh air supply.

Keep the air supply pipe as short as pos-

sible. It is recommended to install the pipe with the capability to

be shut off (according to EnEV) to prevent humidity from entering

during longer operation pauses.

Avoid using combustion air from the flue. Because of the flue drau

-

ght, there is always negative pressure.

The simultaneous operation of artificial ventilation (e.g. cooking

hood) and the pellet boiler in the same room is prohibited. The air

suction may cause problems in boiler operation and discharge of

carbon monoxide.

Talk to your chimney sweep about regional prescriptions

regarding air supply.

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

5

Contents

Boiler Features

1 Boiler Features

1.1 General Information

The STREBEL Varan 2.20 is a pellet boiler for aquiferous central heating systems with radiators and/or underfloor heating. It

is designed to be set up directly in the living space (without an

external boiler room neded). During operation, heat is transmitted

directly into the room vis the boiler surface as well as into the

heating system.

Components

The integrated pellet tank is filled by hand and holds 45 kg or 75

litres of wood pellets. The pellet discharge takes place via auger,

a silent, energy-saving reduction gear and a downpipe.

An expansion vessel (10 litres), an electronically controlled Wilo

HE circulator pump and a safety group are already installed in the

compact boiler construction. The controller has a daily, weekly and

weekend programme as well as three programmable performance

levels.

1 Boiler Features ............................................................................................................................... 5

2 Technical Data ................................................................................................................................ 6

3 Fuel ................................................................................................................................................. 8

4 Construction .................................................................................................................................. 9

5 Installation...................................................................................................................................... 12

6 Controller ........................................................................................................................................ 18

7 Operating Phases ........................................................................................................................... 26

8 Maintenance .................................................................................................................................. 28

9 Possible Malfunctions .................................................................................................................... 30

10 First Start-Up .................................................................................................................................. 32

11 Boiler Disposal ............................................................................................................................... 32

Varan 1.14, 1.20

6

Technical Data

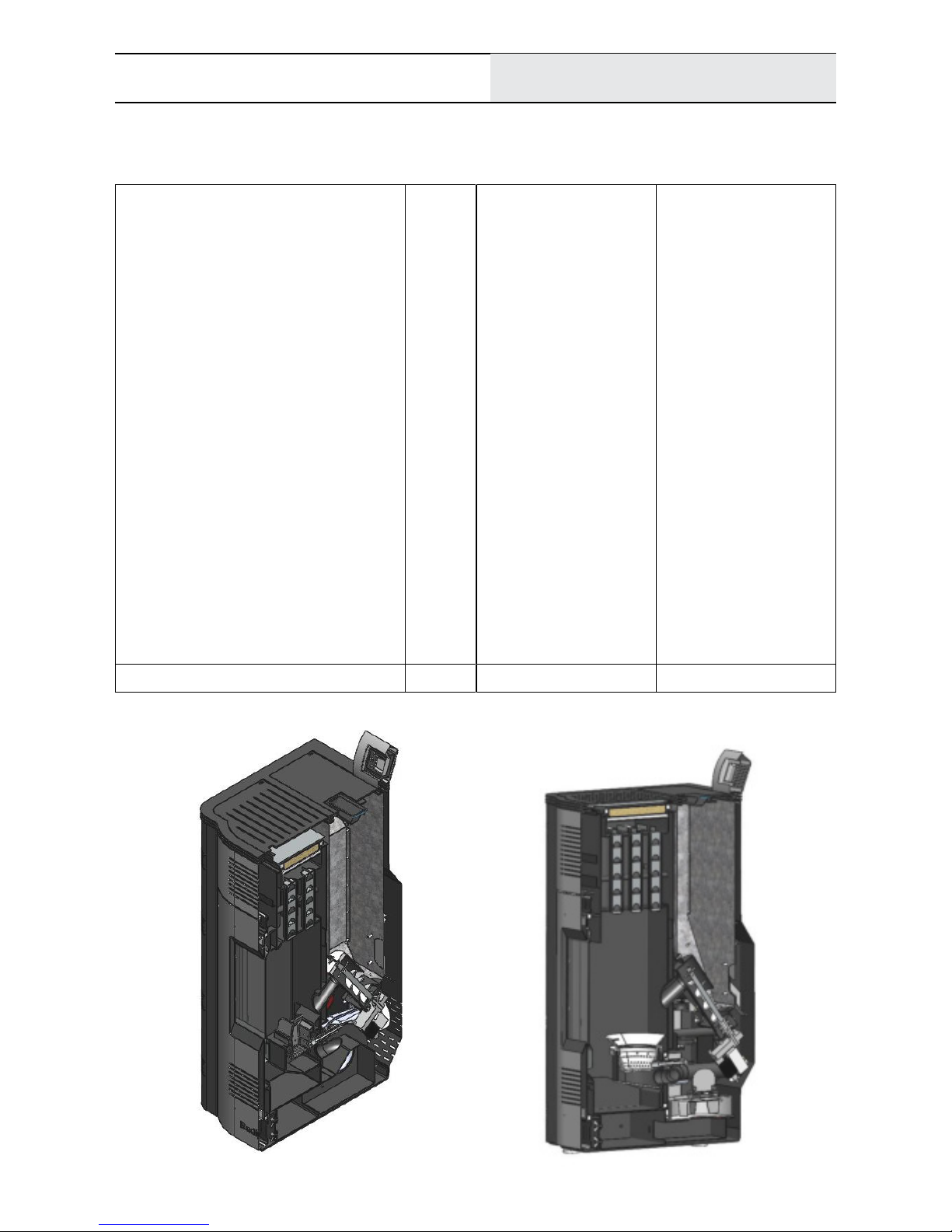

2 Technical Data

Pellet Boiler

Rated heat output kW

Rated output into the heating system kW

Rated output directly from surface kW

Distance from floor to centre of exhaust connection mm

Exhaust connection mm

Flue draught Pa

Efficiency %

Pellet tank volume kg/Litres

Weight kg

Water volume Litres

Operating/testing pressure bar

Boielr temperature min./max. °C

Return temperature min. °C

Power supply

Connections flow/return Inch

Flue gas temperature (rated output, min. output) °C

Energy label (Range A++ to G)

Changes in models reserved. Dimensions not binding!

Varan 1.14 Varan 1.20

11.9 20

10.45 18.7

1.45 1.3

180 134

80 80

11 11

>91 >91

45/75 45/75

192 235

24 38

2.5/5 2.5/5

60/90 60/90

55 55

230 V /50 Hz 230 V /50 Hz

1“ 1“

135/90 135/90

A++ A++

Schematic section Varan 1.20

Schematic section Varan 1.14

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

7

Technical Data

2.1 Dimensions (in mm)

mics, ceramic-based insulation etc.). Such plates have to be

larger than the floor area of teh boiler itself.

- Keep furniture and other objects at leat 1 metre away from

the boiler.

- The distance between the boiler and immobile, solid objects

(walls pillars etc) has to be at least 40 cm (measure B), 20 cm

from the backside (measure C) and 100 cm from the front

(measure A). These distances are necessary to allow cleaning

and maintenance of the boiler.

2.2 Recommended Space For Service And Maintenance

When placing the boiler prior to installation, make sure of the following:

- The boiler must be installed as close to the flue and fresh air

connections as possible.

- For the operation of the appliance, a power supply of 230 V

and 50 Hz is needed. Keep the connection line as short as

possible and avoid using extension cords.

- If possible, install the boiler in the largest, most central room

of the building.

- The boiler must not be installed in bedrooms or rooms that

are inseperatable from the beedroom througha door.

- Do not operate other boilers (for wood or pellets) inside the

room where the Varan boiler is installed to keep up the

necessary air supply.

- The installation room must have windows or doos that can

be opened for additional fresh air supply or there should be

at least an adjacent room connected to the installation room

trough a non-flammable pipe that is open at any given time

during operation. This adjacent room must have windows or

doors that can be opened to provide fresh air.

- In case the boiler is placed on flammable underground

(e.g. laminate, parquet, carpet), it must be insulated with

a plate consisting of non flammable material (steel, cera-

Der integrierte Pelletsbehälter befindet sich

im hinteren Teil des Kessels und ist über

eine Klappe an der Geräteoberseite zugäng-

lich. Der Behälter wird von Hand befüllt und

fasst 45 kg bzw. 75 Liter Pellets. Eine schräg

ansteigende Pellets-Zubringerschnecke mit

Getriebemotor transportiert den Brennstoff

zum Fallrohr, über das er in die Brennertasse

fällt. Diese Bauweise verhindert, dass Flam-

men aus dem Brennraum auf den Brennstoff

im Behälter übergreifen können.

Der Abgasventilator regelt die Verbrennung

und hält die Flamme mit einem kontinuierli-

chen Luftstrom konstant. Je nach Bedarf und

eingestellter Leistung variiert die Laufge-

schwindigkeit und der Pelletseintrag in den

Brennraum. Die automatische Zündung sorgt

jedes Mal für einen sicheren Betriebsstart.

Reinigung

Für eine unkomplizierte und schnelle Reini-

gung lässt sich die Brennerschale im abge-

kühlten Zustand mit einem Handgriff aus der

Ausnehmung im Brennraum herausnehmen.

Die Asche wird in einen feuerfesten Behäl-

ter ausgeklopft. Danach die Schale wieder

einsetzen.

Brennstoff

Als Brennstoff für alle Modelle eignen sich

handelsübliche Holzpellets (nach ISO 17225-

2:2014 Qualität A1, ENplus-A1, ÖNORM M

7134). Pellets in Form von Sackware (übli-

cherweise 15 kg/Sack) lassen sich gut sta-

peln und an einem trockenen Ort über viele

Jahre lagern.

Pellets – kleine Umrechnungstabelle

1 Kubikmeter Pellets wiegt ca. 650 kg.

1000 kg Pellets brauchen ca. 1,5 m³ Raum.

1 kg Pellets liefert ca. 5 kWh.

Der Heizwert von 1 kg Pellets entspricht

jenem von ca. 0,5 Liter Heizöl.

STREBEL Pellets erhalten Sie als Sackware

(15 kg) einzeln oder auf Palette. Abholung in

unserem Werk in Wr. Neustadt oder Haus-

zustellung zwischen Wien und Gloggnitz.

Falls wir Ihr Interesse geweckt haben, neh-

men Sie Kontakt zu uns auf. Sie erhalten

eine kostenlose und unverbindliche Beratung

durch unsere Außendienstmitarbeiter in der

jeweiligen Region – auf Wunsch auch vor

Ort.

Abmessungen und Anschlüsse

966

866

81

360

270

55

55

55

80

221

600 530

620

600

1050

1020

Rauchrohr

Rauchrohr

Rauchrohr

Frischluft

Frischluft

Füllhahn

Frischluft

800

740

785

241

356

100

Varan 1.14 Varan 1.20

Varan 2.20

126

126

VL VL

VL

RL

RL

RL

696

1130

1110

134

180

134

1265

1285

628

336

600

Füllhahn

Füllhahn

ÖNORM

M 7135

PELLE TS

Qualität A1

für alle gängigen

Pelletskessel

Exhaust connection

Exhaust connection

Return

Return

Filling valve

Filling valve

Flow

Flow

Fresh air

Fresh air

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

8

Fuel

3 Fuel

3.1 Required Fuel Quality

The boiler is construdef only for the combustion of wood pellets. Using any other fuel is prohibited. In any case, do not use

pieces of wood, paper, oil, plastic or other materials as fuel.

Wood pellets are zylindrical and made from wood scraps without additives or chemical binders. The pellets must show standard simensions and a low moisture content.

For the best possible combustion use pellets with the quality A1 according to ISO 17225-2:2014, with the seal ENplus-A1 and ÖNORM.

These standards comprise requirements in pellet quality, test regulations, control of production and labelling.

Parameter Unit Quality A1

Length mm 3.15 – 40*

Diameter mm 6 (+/- 1)**

Chaloric value MJ/kg min. 16.5

Mechanical strength % (Mass) min. 97.5

Dust (<3,15 mm) % (Mass) max. 1

Bulk density kg/m

3

min. 600

Water content % (Mass) max. 10

Ash content % (Mass) max. 0.7

Cinder softening temperature °C min. 1200

Arsenic content mg/kg** max. 1

Led content mg/kg** max. 10

Cadmium content mg/kg** max. 0.5

Chloine content % (Mass)** max. 0.02

Chrome content mg/kg** max. 10

Copper content mg/kg** max. 10

Nickel content mg/kg** max. 10

Mercury content mg/kg** max. 0.1

Sulphur content % (Mass)** max. 0.03

Nitrogen content % (Mass)** max. 0.3

Zinc content mg/kg** max. 100

* Max. 1% of the pellets (regarding mass) may exceed a length of 40 mm. More than 45 mm are not permitted.

** in anhydrous condition

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

9

Construction

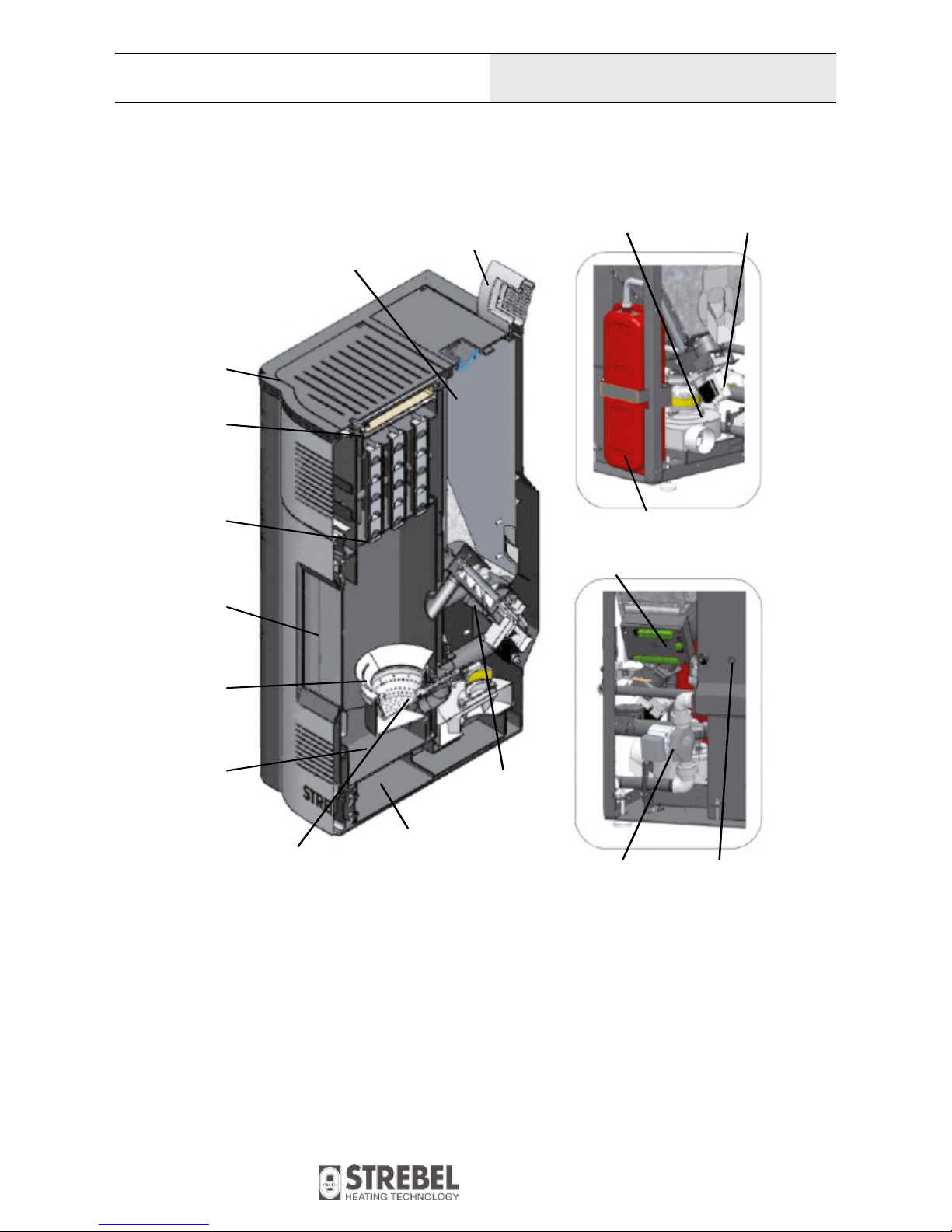

4. Construction

4.1 Boiler Main Parts

Heat exchanger

with turbolators

Cover

Cleaning opening

Pellet tank

Combustion

chamber

Ash tray

Door with

special glass

Pellet auger

Controller processor

Flue gas fan Gear motor

Pressure switch

Circulator

pump

Flue gas channel

Igniter

Controller

Expansion vessel (10 litres)

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

10

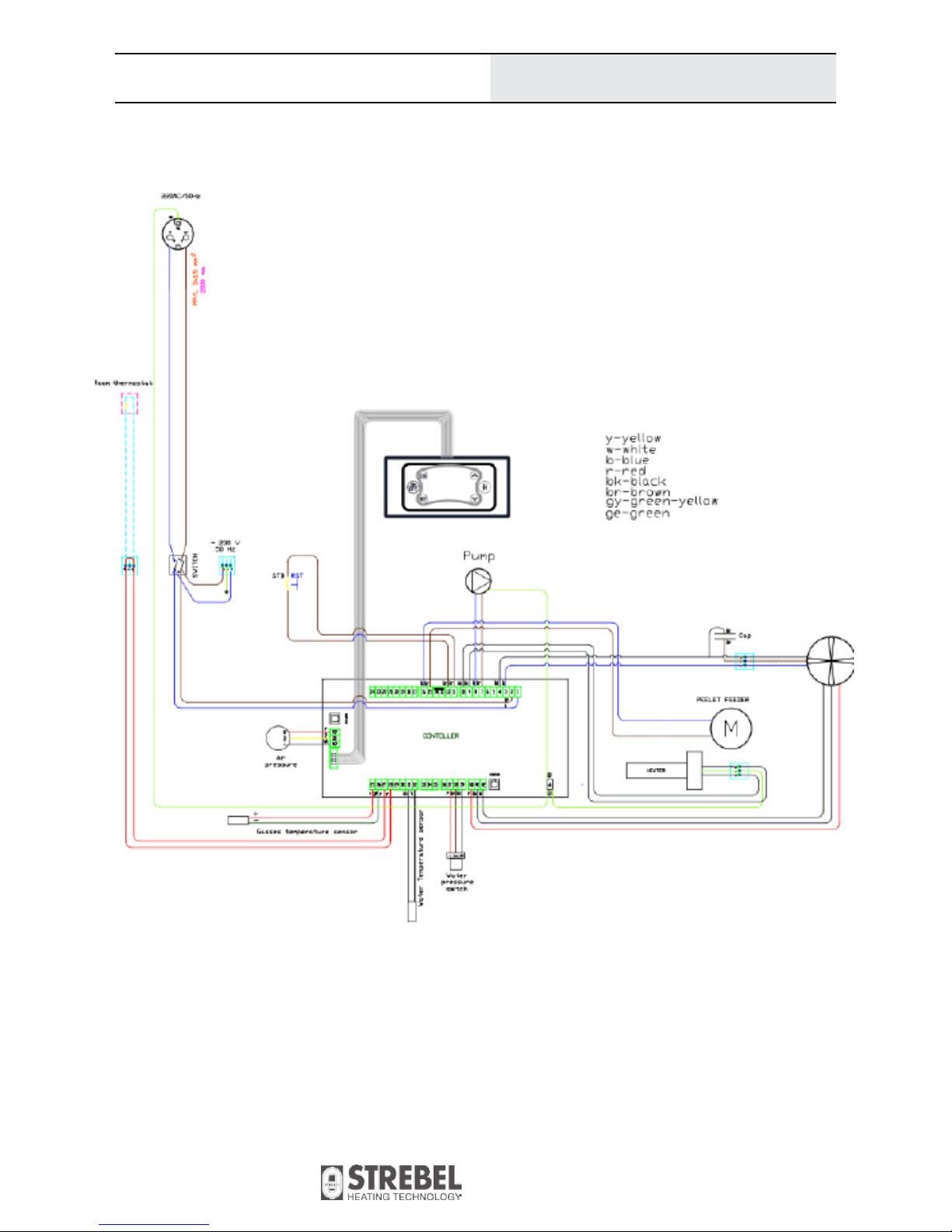

4.2 Electrical Scheme

Construction

The hatched lines are wires which the qualified personnel must connect to the controller during installation. Connectors of additional

appliances have to pass via two connectors on the boiler backside. The connectors are bi-pole or tri-pole. The tri-pole connector is used

to connect a room thermostat.

Only use battery powered room thermostats! On the thermostat itself, the connection with an NC (normal closed contact) is used.

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

11

Construction

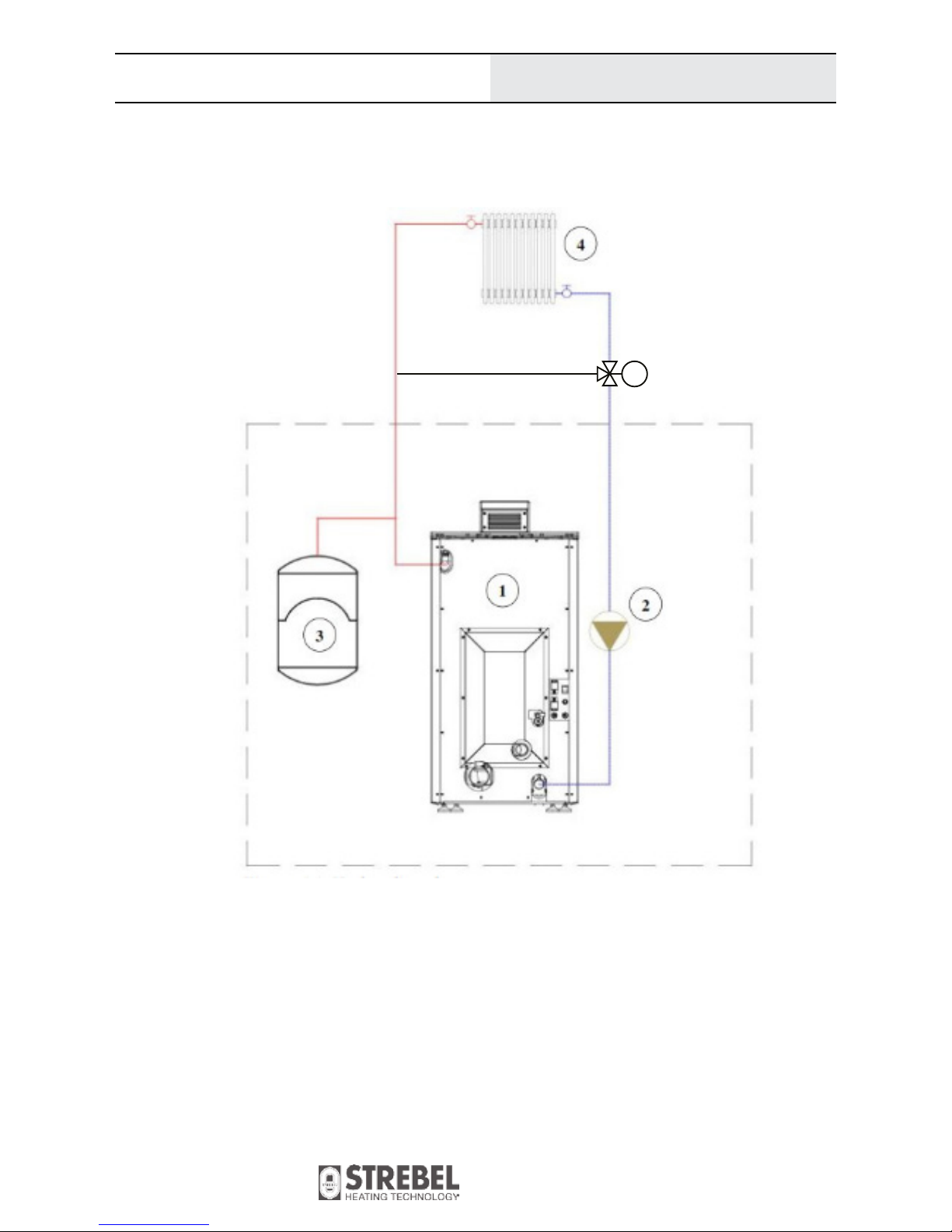

4.3 Hydraulic Scheme

Key:

1. Boiler

2. Circulator pump (integrated in boiler)

3. Expansion vessel 10 litres (integrated in boiler)

4. Radiators, underfloor heating system (via temperature limiter)

5. Thermal valve (min. 55°C)

Always make sure to comply with regional prescriptions when installing a boiler.

STREBEL does not take responsibility for damages caused by a faulty installation of the boiler.

th

5

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

12

This safety element constantly measures the pressure inside the

heat exchanger and transmits the information to the controller.

In case the pressure sinks below 0,5 bar or exceeds 2,7 bar, the

boiler stops operation. The limit values are programmed into the

controller.

This component measures the draught in the exhaust channel and

transmits the data to the controller. In case the draught value sinks

below or exceeds the parameter, teh boiler stops operation and

shows an alert message.

NOTE: The flue draught may change due to cloggings or heavy

pollution of the flue or the boiler, or defective boiler sealings. Also,

bad weather conditions may influence the flue draught.

The controller is connected to an independent thermostat which is

used to limit the boiler temperature.

This safety thermostat interrupts the operation of the fan. The

temperature is limited to 95°C. This safety thermostat is located

below the main switch.

Installation

5 Installation

5.1 General Warnings

Mind regional prescriptions and legal guidelines during installation, operation and disposal of the boiler. The boiler must be installed by qualified personnel.

This boiler is designed to run in aquiferous central heating installations with an operating pressure of max. 2.5 bar an max. water

temperature of 90°C.

The combustion chamber door must remain closed during normal

heating operation.

All electrical components of the boiler need a power supply of 230

V. An improper connection can result in electrical shocks.

Prior to installation, check the boiler for visible damages.

5.2 Safety Devices

Make sure that the following components are always in function:

- safety valve, vent valve,

- electro-mechanic water pressure switch

- vacuum actuator

- boiler thermostat.

Safety valve vent valve

Water pressure switch

Vacuum actuator

Thermostat

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

13

5.3 Flue Connection

When connecting the boiler with the flue, there are two stages

of montage:

- Montage of the flue pipes and air supply for combustion.

- Connection to the flue.

Montage of the flue pipes and air supply for combustion:

- The STREBEL Varan has an exhaust and an air supply

connection on its back side.

- Only use certified, stainless pipes for the flue connection.

The exhaust connection has a diameter of 80 mm. It is prohi bited to reduce the diameter in the following flue pipes.

- The flue gas pipe must not be used for multiple applianes at

once.

- Only use a maximum of two 90° angle pipe pieces. The

maximum length of a horizontal pipe distance is 2 metres.

- In case the pipes are near flammable materials or lead through

them, the pipes must be insulated.

Installation

For safety reasons, the circulator pump is connected to

the controller. In case the water temperature reaches

the critical value of 95°C, the fan ceases operation.

The pump continues running constantly and derives the excess

heat to the radiators, until the temperature is in normal range.

The heating system is to be filled slowly, allowing it to be vented

well. During filling of the installation, check if there are leaks in

the system.

- The pipes and connection elements usually show o-rings

made from silicone. If they do not have this kind of seal,

use fireproof sealing agent.

- The flue pipe must be detachable when necessary or have an

revision opening installed.

- In case the flue pipe does nor lead directly into the flue, but

vertically upwards, the installation of a condensate collector

is prescribed.

- The air supply from outside of the building for combustion

must be guaranteed. Use a pipe consisting of black or Inox

steel. The minimum diameter for this pipe is 50 mm.

- If it is not possible to take fresh air from the outdoors, the

intake must be carried out from an adjecent room with contant

fresh air ventilation. This fresh air connection must be

designed in a way that is is impossible to shut off (e.g. when

closing doors or windows)

Note: The safety valve of the current version is located not

in front of the boiler like in this picture, but on the boiler

backside.

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

14

Situation 1 Chimney Connection Varan 1.14

Connection To The Flue

Montage Possibilities

- Situation 1: The boiler is connected to a standard chimney

(stone-walled or metal), which has a fundament and a whole

cross section of the fundament plate to the upper end point.

- Situation 2: The boiler is connected to a stainless steel flue

which is mounted to the facade.

Installation

Situation 1:

- The chimney uses ceramic or metal pipes of circular cross section of 130 mm diameter. The flue pipe must be insulated.

- If the chimney already exists and is of square cross-section,

then the minimum dimension of the intersection is

130x130 mm.

- It is not allowed to use one chimney for connecting multiple

boilers.

- It is not allowed to use the air vents like a chimney.

- The top of the chimney must be protected with a chimney

cap due for the impact of rain and winds.

Distance of chimney to cap is 200 mm.

- The chimney should come out above the roof according to

the recommendations in the image on page 17.

If other objects are near the chimney, take this into account

and increase the height of chimney.

- The chimney must have a connection to extract condensation

and an inspection door. The door should always be sealed

well during the operation.

Air supply connection Exhaust connection

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

15

Installation

Air supply connection

Exhaust connection

Situation 1

Chimney connection Varan 1.20

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

16

Installation

Situation 2:

- In this situation flue pipe must go at least 1.5 meters

vertically upwards in the very room where the boiler is

placed. Penetrate through the wall and connect the pipe

onto the chimney.

- The flue pipe must have a T-piece for condensation at the

outlet of the boiler and the possibility of dismantling for

cleaning.

WARNING: Failure to follow the rules during the execution

of flue and chimney can lead to malfunction of the boiler and

danger to objects and to human health. The most notable danger

is from the toxic gases (carbon monoxide) which are the products

combustion process.

Important: We recommend to perform a chimney evaluation

prior to installation.

1 Condensate collector

2 T-piece

3 Flue pipe

4 Knee 90° female-male fittings

5 Rosetta female-female fittings

6 Rosetta male-female fittings

7 Knie 90° male-male fittings

8 Wall brackets

9 Cover

Outdoor parts must

be insulated

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

17

Installation

0 to 1,5 m 1,5 to 3 m over 3 m

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

18

6 Controller

The operating parameters the user has access to are visible on the screen. Additional parameters which influence boiler operation are

reserved for qualified personnel ans must not be changed without reasons.

6.1 Controller Display

Controller

Controller panel with buttons and screen

Button Functions Description

P2 (ON/OFF) Activating/Deactivating,

reset alarm

Hold button (about 3 sec.) until a sound is audible.

P4 (

^

)

P6 (v )

Sub menu selection,

parameter selection

change of parameter

Move through the menu.

Change the values of parameters (increase/decrease).

P1 (ESC) Leave, cancel Leave current menu.

P3 (SET) Confirm Confirm/Access the current selection. Save changes.

P5 (#) Time programme Activating/Deactivating of the individual time programmes.

Summer/Winter mode

Time programme

Date/Time

Current operation phase

Service display

Alarm

Preset temperatureCurrent temperatureActivated parts

Pellet auger

Power level and operation mode (auto/man)

P1 P4

P2 P5

P3 P6

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

19

Scheme of the controller panel with all possible activated parts, dots L1–L12

Controller

Function Description Part

Electrical igniter Dot visible: The igniter is active L1

Pellet auger Dot visible: The auger motor is active. The auger transports pellets into the combus-

tion chamber.

L2

Circulator pump Dot visible: The circulator pump is running. L3

Three way switch valve Dot visible: The three way switch valve (mixing valve) is active (only with domestic

hot water module)

L4

Output V2 Not used. L5

Fanr Not used. L6

Exit Aux2 Not used. L7

Not used. Not used. L8

Not used. Not used. L9

Filling level Not used. L10

Room thermostat Dot visible: Preset room temperature reached (contact open) L11

Flow meter Not used. L12

Hold button P6 to see this display of current operating values.

[°C]

[°C]

[°C]

(optional room temperatur sensor) [°C]

(water) [mbar]

[cm/s]

[s]

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

20

Controller

6.2 Aufrufen des Menüs

Hold button P3 (SET) to open the menu. Use the arrow keys to select a menu item and confirm the choice with P3 (SET).

Menu item Description

Combustion Power Modification of the combustion programmes: AUTO, P1, P2 oder P3

Heating Power Not used.

Boiler Thermostat Set the desired boiler temperature.

Buffer Thermostat Set the desired buffer or domestic hot water tank temperature.

Not visible if P26 = 2, 3 or 4.

Room Thermostat Set the desired room temperature (if a room sensor is present).

Only visible if A19 = 1.

Chrono Modality Select programme: Day, week, weekend, deactivated

Chrono Program Adjust 3 switching cycles per day.

Time and Date Set time and date.

Remote Control Not used.

Calibration Set auger run time and fan RPM

Load Select this menu item to transport a starting load of pellets into the combustion

chamber (after pellet tank has been emtied completely. After selection, the auger

will run continously until a manual stop.

Summer-Winter Select between winter or summer mode.

Summer mode only provides domestic hot water.

Language Select the language shown on the controller menu.

Keyboard Menu Set contrast and min. backlighting.

System Menu Allows settings reserved for qualified personnel.

6.3 Menu Use

- To activate the menu, press P3 (SET).

- The display will show a list of menu items. Use the buttons

P4 (^) and P6 (v) and select – for example – ‚Combustion

Power‘.

- Confirm the selection with P3 (SET). It is now possible to

change the setting..

- The now visible screen (see scheme on the right side)

allows to change the setting using the buttons P4 (^) and

P6 (v); switching between Auto, 1, 2, 3.

- Confirm and safe your selection with P3 (SET).

- To return to the main screen, press P1 (ESC).

- If the controller did not successfully apply the new setting, the

display will read ‚Transmission not successful‘.

In this case, repeat the previous steps.

Parameter

Current setting

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

21

6.9.1 ‚Modality‘ sub menu

- Choose between ‚Modality‘ and ‚Program‘ and confirm the

selection with P3 (SET).

- ‚Modality‘ lets you choos between:

‚Daily‘, ‚Weekly‘, ‚Weekend‘ and ‚Disable‘.

- Use P4 (^) and P6 (v) to select the desired menu item and

confirm the selection with P3 (SET).

6.9.2 ‚Program‘ sub menu

To programme the ON/OFF heating cycles, choose the item

‚Program‘ and confirm the selection with P3 (SET).

- Use P4 (^) and P6 (v) to select the time value. Confirm the

selection with P3 (SET) and the cursor moves to the next

value. Use P1 (ESC) to return to the previous value if necessary.

The three programmes are saved seperately. For example – making changes in the ‚Daily‘ programme will not affect any other

programming.

Important: To start operation with the programmed heating cycles, activate them using P5 (#). An active programme is marked

with a ‚V‘.

To deactivate an active programme, select it with the cursor (P4

(^) and P6 (v)) and press P5 (#) again.

Programming Over Midnight

For example, if a heating cycle is supposed to last from 6

pm/18:00 to 5 am/05:00, apply the following steps:

- Set the desired time on which the boiler should start heating

operation (e.g. ‚ON‘ to 18:00). Now, for the same day, set the

operation at 23:59 to ‚OFF‘.

- Now open the programming for teh following day and set the

operation at 00:00 to ‚ON‘. On the same day set the time at

which the boiler should cease operation.

Controller

6.4 Change Combustion Power

Parameter Description

3

Operation with power level 3

2

Operation with power level 2

1

Operation with power level 1

Auto

Operation starts with ‚level 3‘ and modulated

after reaching the control temperature

6.6 Boiler Temperature

Allows to set the temperature between a maximum and a minimum value (parameters Th26 and Th27).

6.7 Buffer Temperature

This sub menu is only visible if a tank probe is connected and

parameter P26 = 2,3,4.

6.8 Room Thermostat

Only visible if A19 = 1.

6.9 Chrono

(only use this option AFTER SETTING THE CORRECT TIME

AND DATE!)

Coose between the options ‚Modality‘ and ‚Program‘.

The ‚Modality‘ option is used to select the time programmes:

- „Daily“: seperate programming of every weekday (monday,

tuesday, wednesday, ... sunday);

- „Weekly“: from monday to sunday,

- or „Week-end“: from monday to friday and saturtay to

sunday seperately,

Completely disable the time programmes with the item ‚Chrono

(Disable)‘. The item ‚Program‘ allows to set the switching cycles.

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

22

Controller

Examples for possible programming in the ‚Program‘ sub menu

6.10 Time And Date

Choose the current time resp. the date with P4 (^) and P6 (v) and

confirm yourcelection with P3 (SET).

Use P1 (ESC) to leave this setting.

6.11 Remote Control

Activate or deactive the connection with the

remote control.

8.2.8 Combustion Recipe Menu

Menu to select the Combustion Recipe. The maximum value is the number of recipes visible to the user. This

value can be set in System Menu Default Settings (parameter P04). If the parameter P04 = 1 the Menu

isn’t visible.

8.2.9 Time and Date Menu

This Menu allows to set time and date. Push the button P4 and P6 to select hours, minutes, year, month

and day. Push P3 to enter editing, P4 and P6 button to change the value. Push P3 to save and P1 to exit.

8.2.10 Remote Control Menu

This Menu allows to enable or disable the Remote Control SYTX.

Time and Date

Remote Control_______

Calibration

Load

Language

Remote Control

Enable

Disable

8.2.8 Combustion Recipe Menu

Menu to select the Combustion Recipe. The maximum value is the number of recipes visible to the user. This

value can be set in System Menu Default Settings (parameter P04). If the parameter P04 = 1 the Menu

isn’t visible.

8.2.9 Time and Date Menu

This Menu allows to set time and date. Push the button P4 and P6 to select hours, minutes, year, month

and day. Push P3 to enter editing, P4 and P6 button to change the value. Push P3 to save and P1 to exit.

8.2.10 Remote Control Menu

This Menu allows to enable or disable the Remote Control SYTX.

8.2.11 Calibration Menu

This Menu allows to modify the Combustion Fan’s speed and the Auger’s work time set by factory. It has two

Submenu.

Time and Date

Remote Control

Calibration _____

Load

Language

Auger Calibration

Fan Calibration

Time and Date

Remote Control_______

Calibration

Load

Language

Remote Control

Enable

Disable

6.12 Calivration

Set the running time of the auger and the RPM of the

fan. Coose from 10 calibration levels (the setting ex

factory is ‚0‘). Increasing or decreasing the value by

‚1‘ relates to an increase or decrease of 1%. This relative percentage can be adjusted (‚Calibration Step‘

in the system menu). The calibration effect is only

active in operating mode and in pellet modulation.

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

23

Modelländerungen vorbehalten.

Maße unverbindlich!

6.13 Load

This item allows the manual activation of the pellet

auger. To activate the auger, select ‚ON‘ usingt P4 (^)

resp. P6 (v) and confirm your selection with P3 (SET).

To stop it, select ‚OFF‘ and confirm.

600 seconds after manual activation, the auger will

automatically stop.

The boiler must not be in operating mode during load phase!

Controller

8.2.8 Combustion Recipe Menu

8.2.9 Time and Date Menu

8.2.10 Remote Control Menu

8.2.11 Calibration Menu

8.2.12 Load Menu

Time and Date

Remote Control

Calibration _____

Load

Language

Auger Calibration

Fan Calibration

Time and Date

Remote Control_______

Calibration

Load

Language

Remote Control

Enable

Disable

Time and Date

Remote Control

Calibration

Load __________

Language

Load

ON

OFF________________

6.14 Summer-Winter

In Winter mode, the boiler will produce heating water as well as

domestic hot water (if the optional DHW module is attached). In

Sommer mode, it will only produce domestic hot water (if the optional DHW module is attached). If the Winter mode is active, the

display will show

8.2.13 Summer - Winter Menu

. In Summer mode, the symbol

is visible.

6.15 Language

Set the desired language of the display menu. Use

P4 (^) resp. P6 (v) to select a language and confirm

the selection with P3 (SET).

6.16 Keyboard Menu

Set the desired display contrast and the minimum

display backlight. Use P4 (^) resp. P6 (v) to select a

language and confirm the selection with P3 (SET).

8.2.13 Summer - Winter Menu

Menu to modify the plumbing plant functioning according to the season. On display appears one of these

symbols: , .

8.2.14 Language Menu

This Menu allows to change the language of LCD panel.

Time and Date

Remote Control

Calibration

Load

Language____________

Español

Française

Deutsch

English

Italiano______________

8.2.13 Summer - Winter Menu

Menu to modify the plumbing plant functioning according to the season. On display appears one of these

symbols: , .

8.2.14 Language Menu

This Menu allows to change the language of LCD panel.

8.3 Keyboard Menu

Menu to set the contrast and light of LCD panel.

Keyboard Menu_______

System Menu

Set Contrast

Set Minimum Light

Time and Date

Remote Control

Calibration

Load

Language____________

Español

Française

Deutsch

English

Italiano______________

8.2.13 Summer - Winter Menu

Menu to modify the plumbing plant functioning according to the season. On display appears one of these

symbols: , .

8.2.14 Language Menu

This Menu allows to change the language of LCD panel.

8.3 Keyboard Menu

Menu to set the contrast and light of LCD panel.

8.3.1 Set Contrast

This Menu allows to set the display contrast.

Set Contrast _____

Set Minimum Light

Set Contrast _____

+

15

-

Keyboard Menu_______

System Menu

Set Contrast

Set Minimum Light

Time and Date

Remote Control

Calibration

Load

Language____________

Español

Française

Deutsch

English

Italiano______________

8.2.13 Summer - Winter Menu

Menu to modify the plumbing plant functioning according to the season. On display appears one of these

symbols: , .

8.2.14 Language Menu

This Menu allows to change the language of LCD panel.

8.3 Keyboard Menu

Menu to set the contrast and light of LCD panel.

8.3.1 Set Contrast

This Menu allows to set the display contrast.

Push the buttons P4 and P6 to increase or decrease the contrast; P3 to save and exit, P1 to exit without

save.

8.3.2 Set Minimum Light

This Menu allows to set the display light when you don’t push any button.

Set Contrast

Set Minimum Light

Set Minimum Light

+

9 5

-

Set Contrast _____

Set Minimum Light

Set Contrast _____

+

15

-

Keyboard Menu_______

System Menu

Set Contrast

Set Minimum Light

Time and Date

Remote Control

Calibration

Load

Language____________

Español

Française

Deutsch

English

Italiano______________

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

24

6.17 System Menu

This menu allows settings reserved for qualified personnel. Because of this, the menu is keyword protected.

Ex factory, the keyword is 2111.

To enter the keyword, confirm the selection ‚System Menu‘ with P3 (SET). Now it is possible to use P4 (^) and P6 (v) to increase or decrease

the displayed digit. Confirm the desired digit with P3 (SET). After that, the cursor moves to the next position until all 4 digits are filled in.

After the fourt digit is confirmed with P3 (SET) and the keyword is correct, the system menu will open.

Important: Changes in the system menu can cause malfuntions or damages to the boiler and the system!

6.18 operation Parameters

Pellet Auger

Parameter Recommended Description

C01 0.5 Ignition

C02 0.8 – 1.0 Stabilisation

C03 0.8 Power level 1

C04 1.6 Power level 2

C05 1.8 – 2.0 Power level 3

Boiler Fan (RPM)

Parameter Recommended Description

U01 1250 – 1400 Ignition

U02 1600 Stabilisation

U03 1550 Power level 1

U04 1600 Power level 2

U05 1650 – 1700 Power level 3

P23 1700 Burn out

Time Programme

Parameter Recommended Description Additional

T02 40 Igniter preheat time

T03 40 – 50 Auger r un time prior to ignition (for pellet

starting load)

There have to be enough pellets in front of the

igniter hole!

T04 450 Timespan between start and normal ope-

ration

T06 250 Stabilisation time Durin this time span, the boiler temperature

has to rise 7°C.

Controller

Keyboard Menu

System Menu _____

PASSWORD?________

- - - -

Modelländerungen vorbehalten.

Maße unverbindlich!

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

25

Thermostat Menu

Parameter Recommended Description

Th01 55 – 65 The boiler switches off if the flue gas temperature sinks below the set value.

Th02 45 – 50 The ignition switches of when the flue gas temperature reaches the set point.

TH06 46 – 51 A the set flue gas temperature, the boiler switches from ignition phase to stabilisation phase.

Th19 50 The circulator pump starts running at the set temperature.

Ih19 2 Pump hysteresis

Th28 55 – 65 The boiler switches to standby mode if the flue gas temperature sinks below the set point.

Funktion Menu

Parameter Parameter Description

A01 0 The boiler switches to burnout at this temperature (room thermostat).

1 The boiler starts modulation at this temperature (room thermostat).

2 The boiler switches to standby at this temperature (room thermostat).

3 The pump is blocked at this temperature (room thermostat).

Forced switch on, wehen the set value in Th21 is exceeded.

A06 0 In modulation phase, der boiler runs with ‚P1‘

1 In modulation phase, der boiler runs with individually programmable parameters U11 and C11

Differencial Temperature Menu

Parameter Ex Factory Description

D01 7 Difference for stabilising

54°C (restart) – 60°C (preset temperature) – 66°C (standby):

results in hysteresis of +/- 6°C

D08 6 Difference for modulation

55°C (modulation start) – 60°C (preset temperature) – 66°C (standby):

Furter Important Parameters

Parameter Ex Factory Description

A24 0 Vacuum actuator

Controller

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

26

7 Operating Phases

7.1 Start

7.1.1 Filling Tank With Pellets

Open the lid of the pellet tank on the top rear of the boiler and fill it with pellets. Only fill it to a level where the lid can still be closed

tightly.

7.1.2 Switch-on

Press the main switch on the boiler backside to switch on the boiler.

Make sure it is conected to the power supply.

The pellet tank lid is open

Operating Phases

Main switch

Backside

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

27

7.2 Switching Off

To switch off the boiler, hold P2 (ON/OFF) for 2 to 3 seconds until

a conformation sound is audible. The boiler is now switched off.

Operating Phases

7.1.3 Starting Pellet Load

Activate the pellet dosing system for loading fuel into the combustion plate. This procedure can only be activated if the controller

display shows ‚OFF‘ on the main screen.

- Press P3 (SET);

- The display will read a list. Use the buttons P4 (^) and P6 (v) to select ‚Load‘.

- Confirm the selection with P3 (SET).

- Use P4 (^) resp. P6 (v) to select ‚ON‘ and confirm with P3 (SET).

- After pressing the button, the pellet auger starts running. Let it run until the first pellets fall into the combustion plate (visually

inspect through the inner combustion chamber door.)

- To stop this procedure, select ‚OFF‘ and confirm the selection.

- Press 1 (ESC) to leave the sub menu.

7.1.4 Starting Combustion

Hold P2 (ON/OFF) for 2 to 3 seconds until a conformation sound is

audible. The display will now read ‚Ignition‘. The boiler is now in

operation.

When using standard pellets and if the air-flue-installation has

been carried out correctly, the combustion process starts after 5

to 10 minutes.

When starting up a new Varan boiler, there may be an increased

amount of smoke and combustion odour. This occurs because of

coatings which protect the boiler against corrosion. After several

hours of operation, the coating is burned out and stops emitting

odours.

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

28

8 Maintenance

8.2 Intervals Of Cleaning And Mainenance

The regular cleaning and maintenance works are very important

for a problem-free operation and guarantee a long boiler lifetime.

The timespan between the periodical maintenance depends on

pellet quality and power level of the boiler. On the combustion

chamber walls and the heat exchanger tubes, soot and tar will

form over time. Because of this, these parts have to be cleaned

mechanically.

Prior to starting the cleaning work, switch off the boiler on the

controller panel and on the main switch.

8.3 Daily Cleaning

During normal boiler runtime, ash is piling up inside the combustion chamber. To ensure a problem-free operation, the combustion

chamber should be cleaned out from ash every day. At standard

combustion parameters, the boiler will produce 1 kg of ash from

100 kg of pellets.

8.4 Every 3 To 4 Days

See images on the following page. Two times a week, thoroughly

clean out the burner plate. Scrape any coating off the combustion

chamber walls using a proper cleaning tool. A combustion chamber that is cree from soot coatings has the advantage of a better

heat transmission and therefore better efficiency. Approximately,

a coating thickness of 1 mm will reduce boiler efficiency by 5%.

8.5 Every 2 Weeks

Open the cleaning cover on the front top side of the boiler. Take

out the turbulator spirals and remove deposits from the sorals and

the heat exchanger tubes. The residues will fall down into the

combustion chamber where they can be cleaned out along with

the ashes. Use the revision openings on the flue pipe to clean out

gross contaminations.

8.6 Cleaning And Maintenance Trough Qualified Personnel

Adhere to locar prescriptions and legal guidelines when it comes

to periodical, professional cleaning and maintenance of the boiler

and the flue system. A yearly cleaning carried out by our customer

service is recommended.

When cleaning the combustion chamber with a

vacuum cleaner, the ash has to be cooled down

completely. Otherwise there is a risk of fire.

When taking the burner plate out of the combustion

chamber for cleaning, there is a risk of burn injuries

if handled improperly. Shortly after deactivating the

boiler, the combustion chmaber and ashes are still hot. Wait a

proper amount of time for the boiler parts have cooled down so

they may be touched safely. There is also a risk of burn injury

when cleaning the heat exchanger tubes, because they will heat

up to 200°C in operation.

Maintenance

During all cleaning work, there is a risk of suffoca tion (from carbon monoxide) if the boiler is still in

operation and the doors are opened. Do not leave

the boiler doors and lids open longer than necessary.

The amount of ash in the combustion chamber is related to the

pellet quality. High quality, dry pellets produce less ask andless

dust inside the pellet tank.

To prolong the lifetime of the igniter, regularily clean the air deduction and de igniter itself.

At the end of the heating season, the boiler have to be cleaned

thoroughly to prolong its lifetime and keep top efficiency. Close all

boiler doors and openings to minimise moisture build-up.

8.1 Special Instructions

Varan 1.14, 1.20

Combustion plate

Varan 1.14

Varan 1.20

Ash plate with wing nuts

Ash plate with wing nuts

Removable Parts When Cleaning

Maintenance

29

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

30

9 Possible Malfunctions

All possible malfuntions in the operation of this device can be divided into two major groups.

Gruppe I: Error during the initial start of the boiler or the first start

after a short deactivation period.

Gruppe II: The boiler switches off during run mode. After reaching set temperatures and a forced pause, the boiler will not

start again without manual reset.

9.1 Group I

Adhere to the installation guidelines in the ‚Montage‘ part – especially the flue system (diameter, number of bends, sealing, ...),

as well as the chimney (diameter, height, sealing of revision openings, pullution etc.).

The most common error message of this group is „E12“. In case

of insufficient flame formation after ignition and if the flue gas

temperature failes to rise, the igniter will be displayed as active,

but the boielr will switch to extingushing phase. If this happens,

check the following:

- Bad pellet quality or wet pellets.

Solution: only use, dry, high quality pellets.

Combustion air temperature is too low (below 0°C).

Solution: set a longer ignition time t02 to 30 – 40

seconds.

- Power supply voltage is low (much below 230 V);

the igniter output is insufficient.

Solution: set a longer ignition time t02 to 30 – 40

seconds. If this measure is unsuccessful, install an AC

adapter that provides 230 V.

- Pellet starting load insufficient, no flame formation.

Solution: Have qualified personnel check for mechanical

problems on the auger or the motor.

- Flame formation is successful, but the boiler remains

in stabilisation phase and does not enter run mode.

Solution: The boiler needs more fuel in the combustion

chamber. Set a longer timespan in parameter t03 – increase

it step by step for a few seconds each. Please also mind the

following reference.

- There is flame formation after the timespan set in t03,

but the boiler does not switch to stabilisation phase

t04. The flame is getting weaker and the flue gas tem perature is sinking. The boiler switches to extingu ishing phase.

Solution: Decrease the timespan set in parameter t04

(stabilisation phase) it step by step for a few seconds each.

Please also mind the previous reference.

The boiler controller may display the following messages resulting from a malfuntion.

Er01 Error – High voltage (even when boiler is not in operation)

Er02 Error – High voltage (only when fan is in operation)

Er03 Error – Low flue gas temperature; boiler ceases operation

Er04 Error – High boiler temperature; boiler ceases operation

Er05 Error – High flue gas temperature; boiler ceases operation

Er07 Error – Signal error between encoder and controller

Er08 Error – Encoder encouters problems with counter

Er09 Error – Low water pressure

Er10 Error – High water pressure

Er11 Error – Wrong time-setting

Er12 Error – Ignition failed

Er15 Error – Low power supply voltage

Er17 Error – Error in vacuum actuator

Er18 Error – Low pellet level (not used)

Er39 Error – Vacuum actuator defective

Er41 Error – Minumum negative pressure could not be reached

Er42 Error – Negative pressure to high

Possible Malfunctions

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

31

- The boiler is connected to a room thermostat, but does

not switch to ignition mode

Solution: Check the current room temperature and compare

it to the related preset temperature on the boiler. Make sure

that the heating cycle is currently in operation. Test the room

thermostat for possible malfunction.

9.2 Group II

The most common error message of this group is Er03.

- The boiler has already been in run mode but ceased

operation. During a new heating demand (from boiler

or room thermostat), it will not start operation again.

the combustion chamber is filled with unburned pel lets.

Solution: Check the values in the parameters A26, Th28 and

Th06. They may have been altered.

The parameter A26 must be set to ‚1‘.

The parameter Th06 must be between ‚60‘ to ‚65,

and parameter Th28 must be at least 2°C lower than Th06.

Adjust the parameters, clean the combustion chamber and

restart the boiler.

- The boiler has already been in run mode, but unburnt

pellets are piling up in teh combustion chamber. The

flames are getting smaller and are extinguished.

Solution: Increase exhaust the fan RMP in all phases using

the calibration menu.

- The boiler is operating, but is stops unexpectetly and

starts modulationg. After that, a safety switch-off

occurs. (Extingishing) (Error Er05).

Solution: The flue gas temperature is too high – possibly

resulting from a polluted boiler, too much draught, high fan

power, too many pellets in the combustion chamber, bad

pellet quality, etc. This problem can be solved usually by

adjusting one of the parameters for the transmission to

modulation or the safety switch-off (resulting from high flue

gas temperature): Parameters Th07, Th08.

Possible Malfunctions

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

32

First Start-Up

Boiler Desposal

10 First Start-Up

The first start-up of this boilermay only be carried out by a professional of the company STREBEL or an experienced installer. If the

start-up is not carried out correctly, the boiler and the system can

be damaged, destroyed or injury and material damage can occur.

10.1 Precautions for the fisr start-up

1.) Disconnect boiler from power supply.

2.) Check if the red main switch on the boiler side is activated.

3.) Check if the following parts are installed professionally and

working.

- All mechanical parts of the boiler,

- burner and chamotte bricks,

- fan,

- circuit pump,

- safety valve.

4.) Check of all electrical connections:

- Correct installation of all electric components (gear motor,

fan, controller, display),

- Protection of unused connections,

- ground,

- power supply.

11 Boiler Disposal

11.1 Removal

The boiler removal must be carried out by qualified technicians.

Otherwise, injury or material damage can occur.

Procedure of the removal

1.) Stop boiler operation.

2.) Wait until the pellets in the burner room are burnt up and the

boiler is cooled down.

3.) Disconnect the boiler from power supply.

4.) Disconnect the boiler from the rest of the heating installation

with a turncock and drain the water from the boiler.

5.) Remove pellet silo.

6.) Remove boiler shell.

7.) Remove mineral wool insulation from the boiler body.

11.2 Disposal

The steel parts of the boiler are delivered to a recycling centre:

- Boiler body,

- boiler shell,

- pellet silo,

- screw,

- gear motor,

- burner.

The electrical parts as well as glas parts, mineral wool and plastic

parts are seperately delivered to the recycling centre.

The boiler parts must not be disposed in the domestic waste bin.

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

33

Space For Notes

Varan 1.14, 1.20

34

Space For Notes

Varan 1.14, 1.20

Changes in models reserved.

Dimensions not binding!

Varan 1.14, 1.20

35

Space For Notes

2700 Wiener Neustadt, Wiener Strase 118, AUSTRIA

Telefon +43 (0)2622 235 55-0

Fax +43 (0)2622 253 46

verkauf@strebel.at

www.strebel.at

Strebelwerk GmbH

NAK, 0217

Loading...

Loading...