Strebel TN 220, TN 300, TN 400 Installation, Operation & Maintenance Manual

TN 220/300/400

heater for

sanitary hot water production with

Gas fired storage water-

atmospheric burner.

TN 220 – 34 TN 300 – 44 TN 400 – 44

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

Page 1 11/07/00

INDEX Page.

GENERAL INFORMATION AND CHARACTERISTICS

1.1 APPLIANCE’S CLASSIFICATION 3

1.2 PACKAGING CONTENT 3

1.3 CONSTRUCTIONAL AND OPERATIONAL DESCRIPTION 3

1.4 CONTROL AND SAFETY DEVICES 4

1.5 CONTROL PANEL 5

1.6 DIMENSIONS AND CONNECTIONS 6

1.7 TECHNICAL DATA 7

1.8 ELECTRICAL DIAGRAM 7

1.9 EXPLODED VIEW 8

INSTALLATION INSTRUCTIONS

2.1 GENERAL PRECAUTIONS 10

2.2 INSTALLATION RECOMMENDATIONS 10

2.3 LOCATION OF THE APPLIANCE 11

2.4 DRAUGHT DIVERTER INSTALLATION 11

2.5 WATER CONNECTIONS 12

2.6 GAS CONNECTION AND REGULATIONS 12

2.7 GAS SUPPLY CONVERSION 14

2.8 ELECTRICAL CONNECTIONS 15

2.9 STARTING THE WATER-HEATER 15

2.10 CONNECTION OF SEVERAL WATER-HEATERS 15

2.11 FAULT FINDING 15

USER INSTRUCTIONS

3.1 RECOMMENDATIONS FOR THE USER 16

3.2 STARTING THE APPLIANCE 16

3.3 SWITCHING OFF 17

3.4 MAINTENANCE 17

3.5 WARRANTY APPLIES 17

Page 2 11/07/00

1.1 APPLIANCE’S CLASSIFICATION

DEFINITION

These appliances are classified as: “Direct gas fired

storage water -heater.

CATEGORY

The category of the appliance is:

II

2H3+……………..

This means that the appliance is suitable for gas of 2nd

family (G20/25) and 3rd family (G30/31).

TYPE

Following the European Regulation EN 483, the appliance is of kind B

be connected to a flue gas system for the gas exhausting

outside the room in which it is installed and where the

combusting air is taken directly from the room where

the appliance is installed”. The appliance:

• is supplied with draught diverter in the combustion

products circuit;

• is supplied with a control device for flue gas spill-

age.

•

Great Britain & Ireland

, that means an “appliance settled to

11BS

1.2 PACKAGING CONTENT

The appliance is delivered packaged in a wooden crate

with appropriate protections.

The draught diverter is delivered in a separate cardboard

box, not assembled.

An envelope contains this booklet, the warranty paper

and screws to fix the draught diverter.

1.3 CONSTRUCTIONAL AND OPERATIONAL DESCRIPTION

The appliance is manufactured according to the EC

regulation 90/396(CEE for gas appliances, and has

therefore, the CE agreement. In particular the manufacturing process and the components satisfy the technical

European regulation EN 89.

The purpose of this appliance is to allow the heat exchange between the gas combustion products, burned in

the combustion chamber and the water inside the tank.

The combustion chamber is placed in the lower part of

the appliance, under the water tank. On the top is the

draught diverter.

Flue pipes, which go through the water tank, allow the

exhausting of the gas of the combustion chamber into

the chimney flue and for the thermal exchange. Turbulators have been installed inside the flue exhaust pipes in

order to improve the thermal exchange.

DRAUGHT DIVERTER

It is placed on the combustion products circuit and its

purpose is to keep into pre-set limits the combustion quality

and the combustion stability within min. and max. conditions.

ATMOSPHERIC BURNER

It is composed of two parts: a principal burner, which ensures

the thermal function of the appliance, and a pilot burner

needed to light the principal burner.

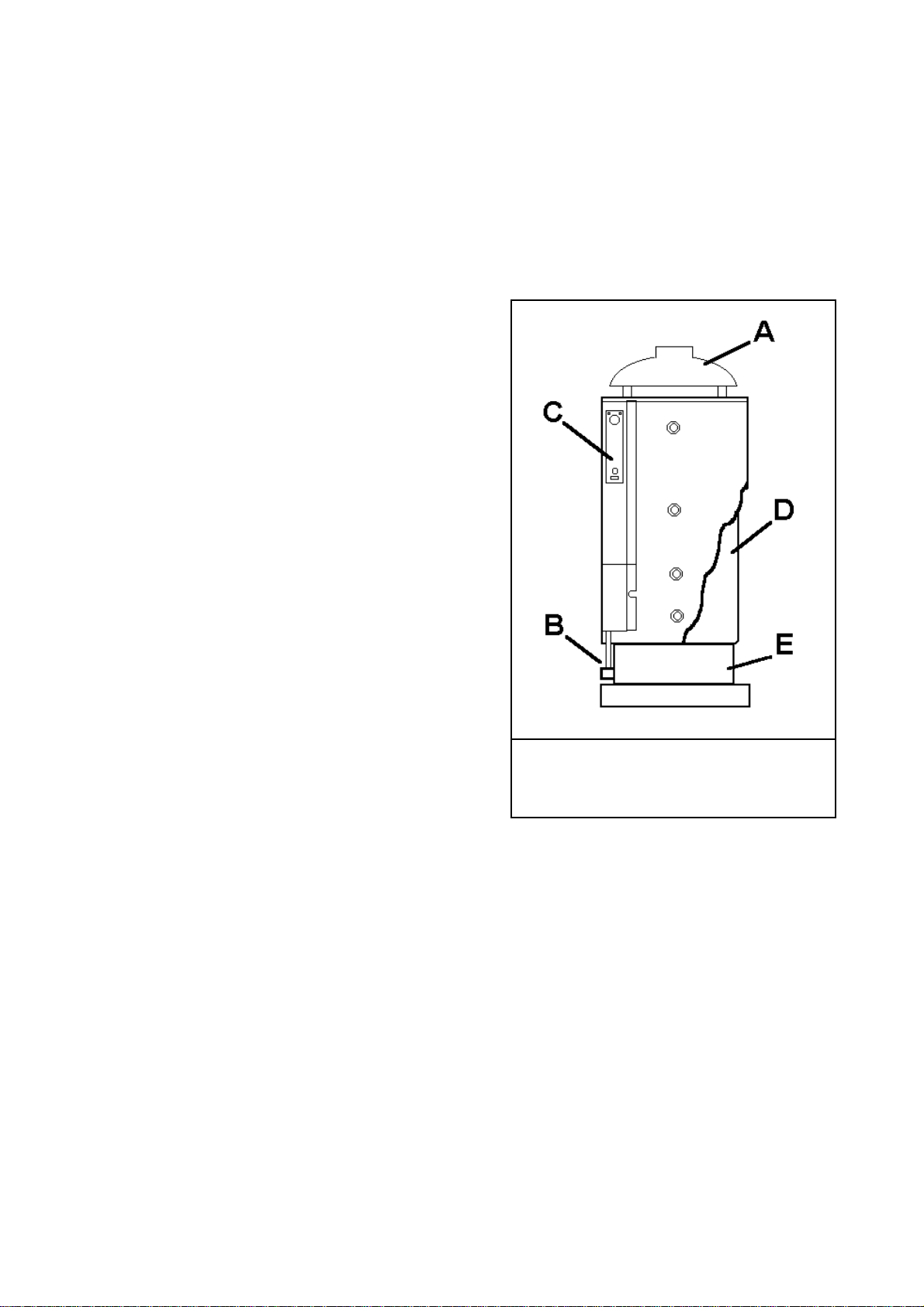

fig. 1.3 / 1

A draught diverter B atmospheric burner

C control panel D tank E combustion chamber

CONTROL PANEL

On the instrument control panel there is all required to control

and adjust the normal operation of the appliance: On/Off

switch, water temperature thermostat, water temperature thermometer. There is also the security flue gas spillage thermostat

in case of improper combustion (manual reset) and a red light

which lights up when this thermostat has operated.

TANK

It is made of thick sheet steel and assures great resistance to

pressure. The inside is coated with opal glass (a vitreous coating baked at over 850°).

This allows a high chemical resistance to organic solvents and

many other chemical substances, excellent abrasion resistance

(low friction) and very good thermal stability. This allows

long-life and a higher quality water. Inspection and cleaning of

the tank are allowed by an appropriate clean out and inspection

door.

Page 3 11/07/00

COMBUSTION CHAMBER

It is placed in the lower part of the appliance and holds

the atmospheric burner, flame control sensor

(thermocouple) and the pilot burner with ignition electrode.

1.4 CONTROL AND SAFETY DEVICES

MAGNESIUM ANODE

The water heater is protected against metal-to-metal corrosion by a magnesium anode. It has to be replaced every

year in order to extend the working life of the appliance.

The anode is placed in the inspection flange, on the front

of the tank.

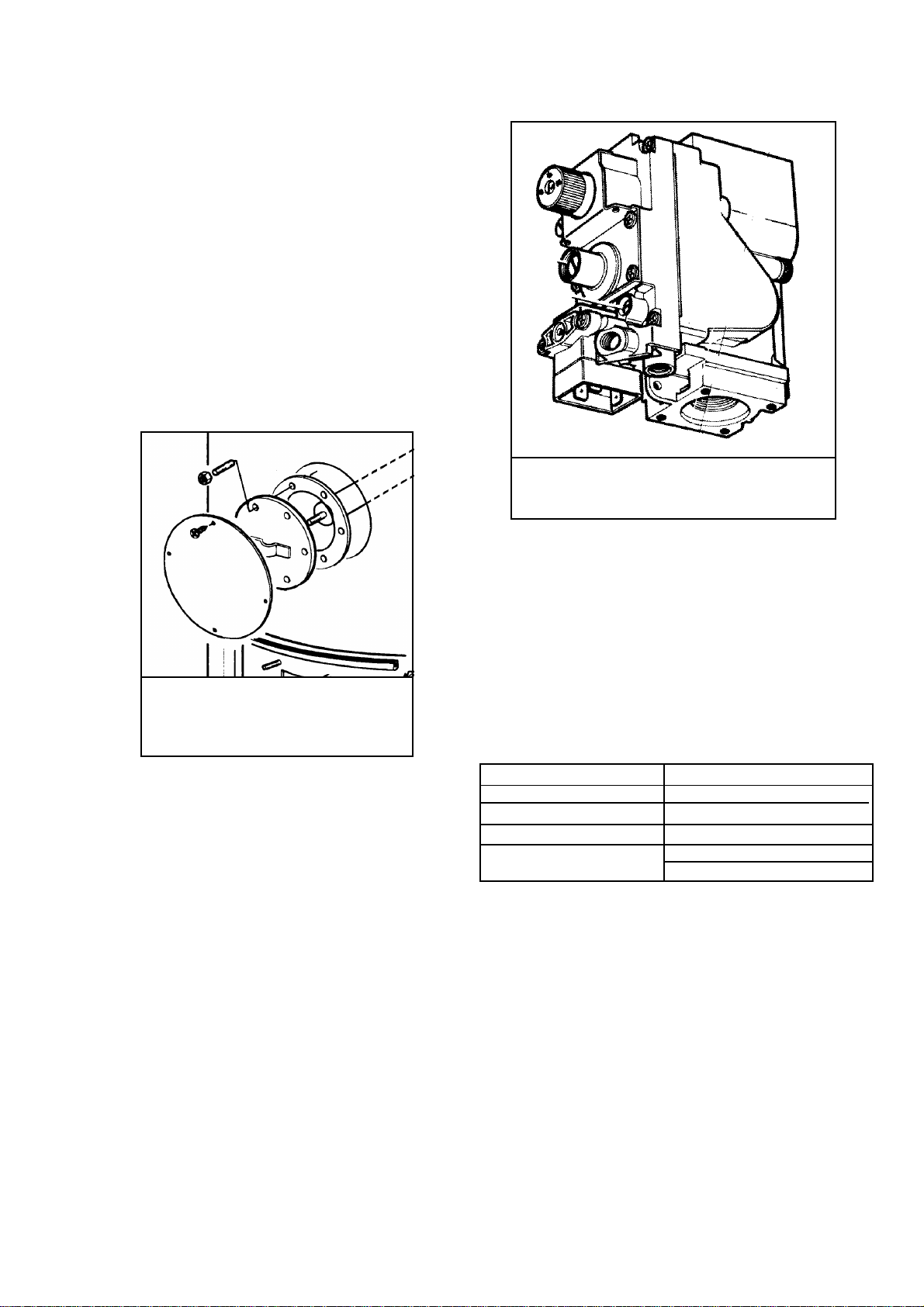

fig. 1.4 / 1

Anode position

GAS VALVE

It is GASTEC approved following the EN 126 regulation.

It is a multi-functional valve with on -off gas flow control

with double electro-valve. The operation happens through

one of 3 positions of control (ignition-workingextinguish).

The inlet and outlet gas connections are threaded 1/2 RP”

UNI-ISO 7, whereas the fitting for the thermocouple is

M9x1. There also are two (inlet and outlet) Two pressure

test point are in the inlet and outlet. Gas valve has a gas

filter at the entry.

fig. 1.4 / 2

Gas valve

All the setting and regulation operations have to be made

by professional qualified people. In case of valve replacement, be sure that the gas flow is in the direction of the arrow on the body the valve and while installing care should

be taken to ensure no foreign matter enters into the valve.

MAINTENANCE: the only operation allowed is the solenoid replacement, which has to be carried out by qualified

personnel..

Gas inlet max. pressure 60 mbar

Pressure outlet range 3 - 30 mbar

Voltage rating 220/240V 50 Hz

Pressure setting B class

Flame detection ignition time < 10 sec

switching time < 60 sec

Pressure safety valve.

We recommend a suitable safety valve is installed.

ADJUSTABLE CONTROL THERMOSTAT 40-80 °C

(VDE (Germany) and IMQ (Italy) approved).

It controls the operation of the appliance switching the

burner on and off, according to the water temperature set.

This is a single pole liquid filled sensing bulb with operating switch contacts.

SAFETY LIMIT THERMOSTAT

(Flue gas spillage control)

It cuts off the burner operating (by cutting the current to

Page 4 11/07/00

Control thermostat – Technical data

Temperature range 40º / 80º

Contacts rating 250 V ~ / 2.5 A

Temperature differential 8º ± 2º K

Bulb max. temperature 150º C

the gas valve) in case of improper exhausting of the combustion gas. To restore the normal operation it has to be

manually reset. It is a single pole, liquid filled type, temperature limiter with manual reset and positive cut off

safety in case of capillary breakage.

SAFETY LIMIT THERMOSTAT

(WATER MAX. TEMPERATURE)

It cuts off the burner in case of overheating of the water

tank, due to non-working of the adjustable control thermostat. The operation is automatic (automatic reset) as soon

as the water temperature reaches standard levels/values. It

is a single pole liquid filled type thermostat and two contacts (On/Off switch), safety limit temperature with automatic reset, with positive cutoff safety in case of capillary

breakage. The high limit temperature is factory set at 90°.

Safety limit thermostat (flue gas spillage control)

- Technical data

Intervention temperature 70º ±3º

Differential 15º

Contacts rating 250 V ~ / 2.5 A

Bulb max. temperature 125 ºC

1.5 CONTROL PANEL

Safety limit thermostat (max. water temp.)

Technical data

Intervention temperature 90º ±3º

Differential 12º

Contacts rating 250 V ~ / 2.5 A

Bulb max. temperature 125 ºC

Contacts resistance < 8 mO

KEY:

A – ON/OFF Switch

B – Adjustable water control

thermostat

C – Safety limit thermostat

D – Water temperature

thermometer

E – Safety limit thermostat (on)

light

Page 5 11/07/00

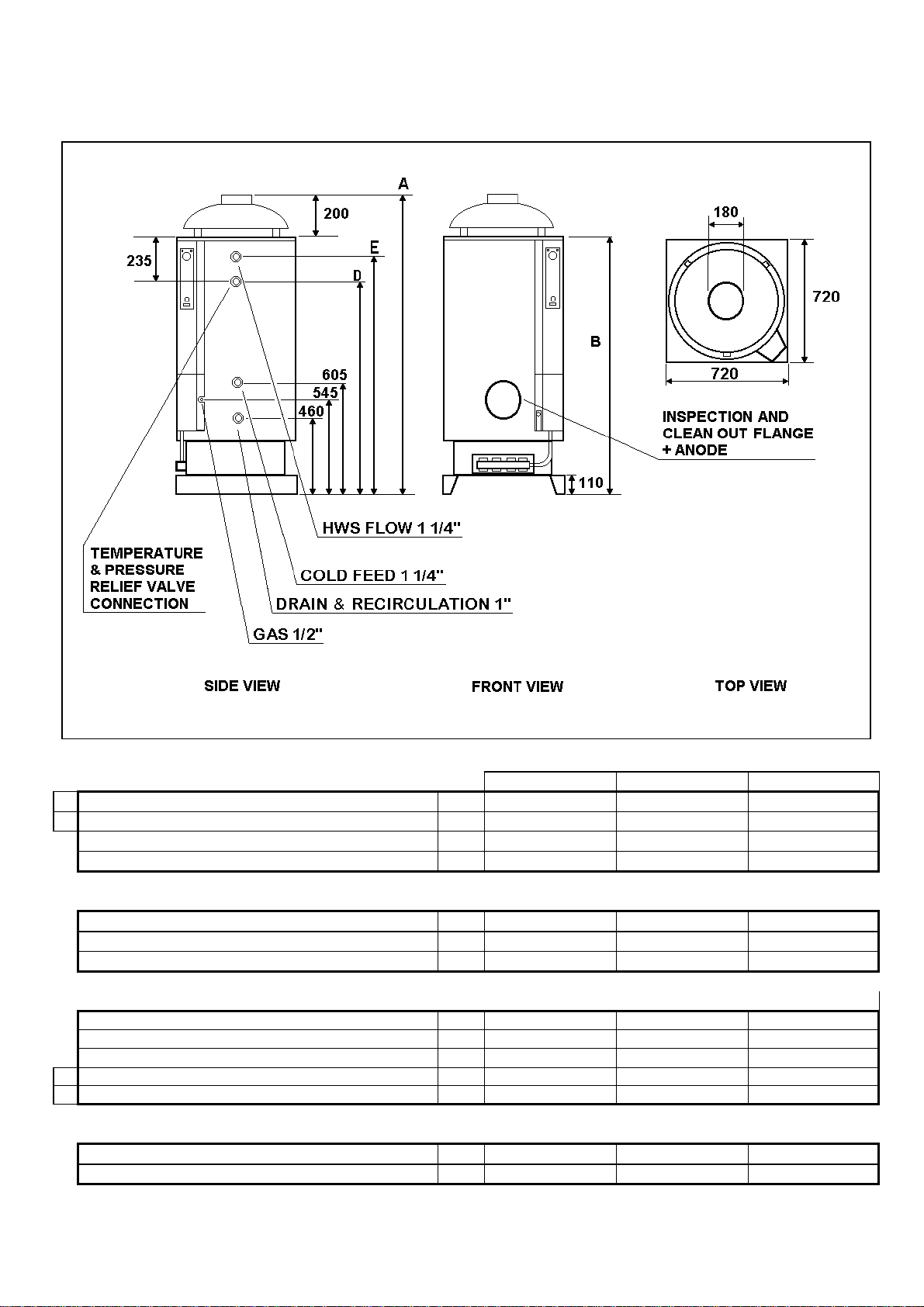

1.6 DIMENSIONS AND CONNECTIONS

Fig. 1.6/1

A

OVERALL HEIGHT

B

HEIGHT WITHOUT DRAUGHT DIVERTER

WIDTH

DEPTH

BASE

HEIGHT

WIDTH

DEPTH

HEIGHT FROM FLOOR:

DRAIN CONNECTION

GAS CONNECTION

COLD WATER FEED CONNECTION

D

RECIRCULATION CONNECTION

E

HOT WATER CONNECTION

1" 460 mm 460 mm 460 mm

1/2" 545 mm 545 mm 545 mm

1"1/4 605 mm 605 mm 605 mm

1" 1010 mm 1010 mm 1175 mm

1"1/4 1330 mm 1680 mm 2030 mm

INSPECTION AND CLEANING FLANGE

DIAMETER

HEIGHT FROM FLOOR

MOD. 220 MOD. 300 MOD. 400

1600 mm 1960 mm 2310 mm

1400 mm 1750 mm 2100 mm

720 mm 720 mm 720 mm

720 mm 720 mm 720 mm

110 mm 110 mm 110 mm

720 mm 720 mm 720 mm

720 mm 720 mm 720 mm

120 mm 120 mm 120 mm

620 mm 620 mm 620 mm

Page 6 11/07/00

Loading...

Loading...