Strebel SP 150, SP 170, SP 300, SP 400, SP 220 Installation Manual

...

21 0- 03 88 - O c to be r 20 12

0694

SP 150

SP 170

SP 220

SP 300

SP 400

SP 600

SP 800

Gas fired storage water heaters

with sealed combustion chamber (C type)

and forced flue draft

MANUAL OF INSTALLATION

GENERAL INFORMATION AND CHARACTERISTICS

INSTRUCTIONS TO THE INSTALLER

INSTRUCTIONS TO THE USER

210-0388 - Edition October 2012

WARNING

••••

The following instruction book is an integral and essential part of the

appliance and it has to be kept with care near the appliance, for any

further consultation.

••••

The appliance has been conceived for hot water production: any

other use of it has to be considered dangerous and not suitable.

••••

The appliance is not to be installed in damp rooms and it has to be

protected from water splashes and other liquids, to avoid anomalies to

electrical and thermal devices.

••••

The installation has to be made by professional qualified people, who

are responsible for the respect of all safety regulations in force. An

incorrect installation, caused by a non-observance of manufacturer’s

instructions, can cause damages to people, animals or things for which

the manufacturer cannot be considered responsible.

••••

The appliance, as switched on, has to be tested by an Authorised aftersale service.

••••

Packaging parts (plastic bags, polystyrene, wood, clips, nails,..) can be

harmful to children and should be carefully disposed of

immediately.

••••

Read carefully the instructions and the advice concerning safety,

installation, use and maintenance contained in this booklet.

••••

If the appliance is sold or transferred to a new owner, make sure that

this booklet stays with the appliance, so that the new owner or the

installer can consult it.

••••

Do not place anything upon the appliance.

••••

To avoid damages caused by low temperatures, if the appliance has to

be left unused for a long period in a non-heated room, it is

recommended to empty the unit completely. The manufacturer is not

responsible for faults, break downs or for water leakage from the plant

caused by low temperatures.

••••

To comply with the warranty terms, we advise you to adhere to the

following instructions and to use only original spare parts and kits,

supplied by the manufacturer.

210-0388 - Edition October 2012

INDEX ........................................................................ page

1.1 TECHNICAL DATA 3

1.2 APPLIANCE CLASSIFICATION 3

1.3 PACKAGING CONTENT 4

1.4 OPERATIONAL AND FUNCTIONAL DESCRIPTION 4

1.5 CONTROL AND SAFETY DEVICES 5

1.6 DIMENSIONS AND CONNECTIONS 7

2.1 REFERENCE REGULATIONS 9

2.2 RECOMANDATIONS FOR THE INSTALLATION 9

2.3 FLUE HOOD INSTALLATION 9

2.4 WATER CONNECTIONS 10

2.5 GAS CONNECTIONS 11

2.6 GAS SUPPLY SETTING 11

2.7 GAS SUPPLY CONVERSION 11

2.8 WIRING 12

2.9 CONNECTION OF SEVERAL APPLIANCES 12

2.10 FLUE SYSTEMS 13

2.11 WIRING 15

2.12 STARTING THE APPLIANCE 16

2.13 FAULT FINDING 16

3.1 RECOMMENDATIONS FOR THE USER 17

3.2 STARTING THE APPLIANCE 17

3.3 TURNING OFF THE APPLIANCE 17

3.4 MAINTENANCE 17

3.5 WARRANTY 17

3.6 FREQUENTLY ASKED QUESTIONS 18

1 – GENERAL INFO RMAT IO N AN D CHARACTERISTICS

-

3 -

210-0388 - Edition October2012

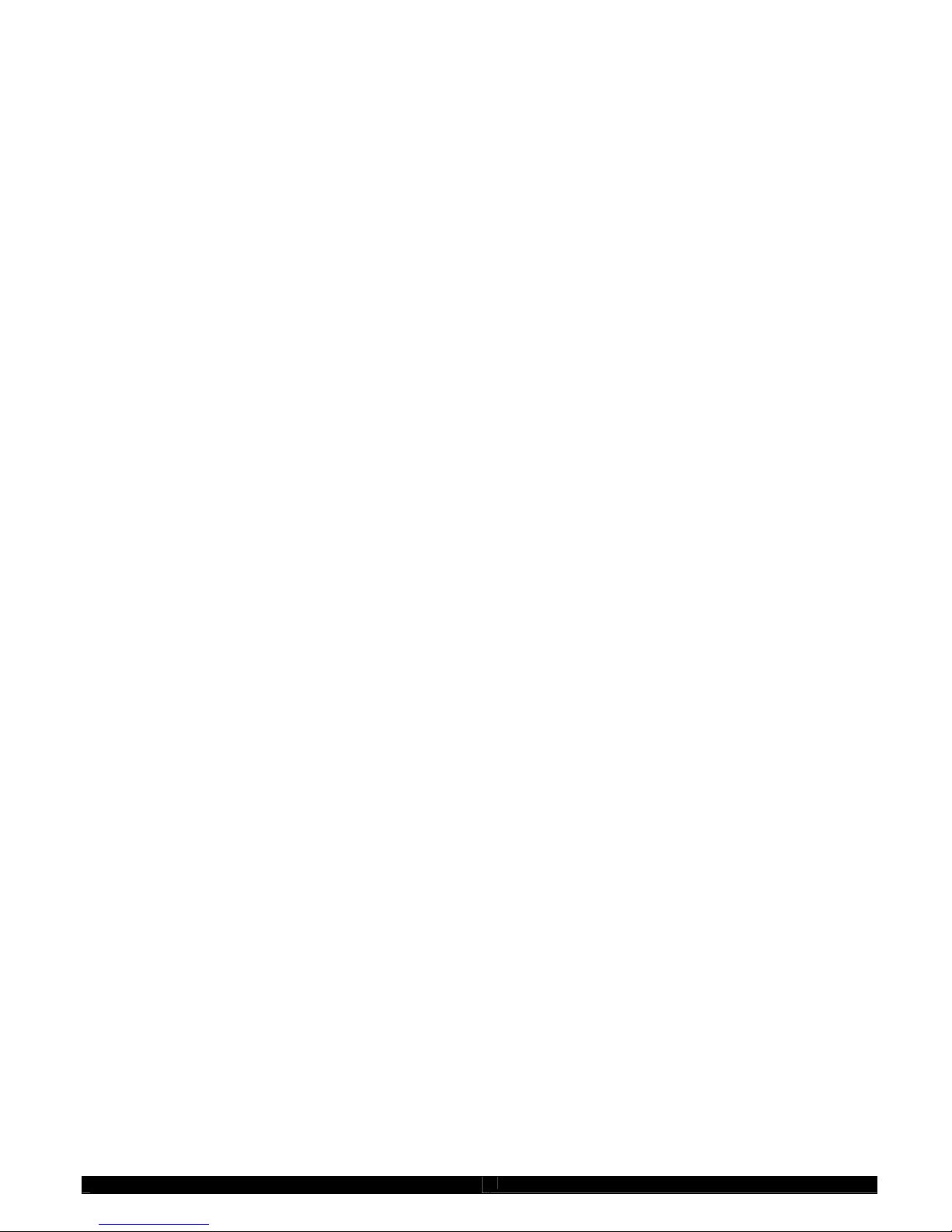

1.1 TECHNICAL DATA

mod.

150 170 220 300 400 600 800

Nominal storage capacity litres 145 160 220 300 395 585 740

Nominal input kW 18.0 19.0 25.0 29.0 29.0 31.0 31.0

Nominal output kW 16.9 17.9 23.5 27.3 27.3 29.1 29.1

Combustion efficiency - 94% 94% 94% 94% 94% 94% 94%

Flue mass g/s 9,0 9,5 12,5 14,0 14,8 16,0 16,4

Flue temperature °C 109 95 109 115 97 104 103

Recovery time (∆T = 25 °C)

min 16 17 16 19 26 35 44

Recovery time (∆T = 45 °C)

min 28 30 29 35 46 64 79

Continuous output (∆T = 25 °C)

lt/hr 551 575 817 938 908 981 1013

lt/min 9,2 9,6 13,6 15,6 15,1 16,4 16,9

Continuous output (∆T = 45 °C)

lt/hr 306 320 454 521 504 545 563

lt/min 5,1 5,3 7,6 8,7 8,4 9,1 9,4

Natural gas input rate (G20 - 20 mbar) m3/h 1,91 2,01 2,65 3,07 3,07 3,28 3,28

n° injectors - 11 11 16 16 16 16 16

injectors diameter mm 1.20 1.25 1.25 1.25 1.25 1.25 1.25

Burner pressure mbar 10.3 10.5 10.0 12.2 12.2 12,1 12,7

LPG input rate (G30/31 28-30/37 mbar) Kg/h 1,40 1,50 2,00 2,30 2,30 2,40 2,40

n° injectors - 11 11 16 16 16 16 16

injectors diameter mm 0.70 0.70 0,65 0.72 0.75 0.75 0.75

Power consumption 230 V ~ 50 Hz (IP20) W 67 67 67 67 67 67 67

Max working head Mpa 0,6 0,6 0,6 0,6 0,6 0,6 0,6

Empty weight Kg 128 141 220 265 309 278 324

Filled weight Kg 273 301 440 565 704 863 1064

Tests carried out in standard conditions (15 °C / 1013 mbar)

1.2 APPLIANCE CLASSIFICATION

DEFINITION

These appliances are classified as: "Gas fired water

heaters with sealed combustion chamber and atmospheric

burner, equipped with fan in the combustion circuit”.

TYPE

As classed by the European Regulation EN483, the type of

the appliance can be C12, C32, C42, C52, C62, C82

depending on the system used for the air supply and the

exhaust gas evacuation.

Here below a short description of the different types:

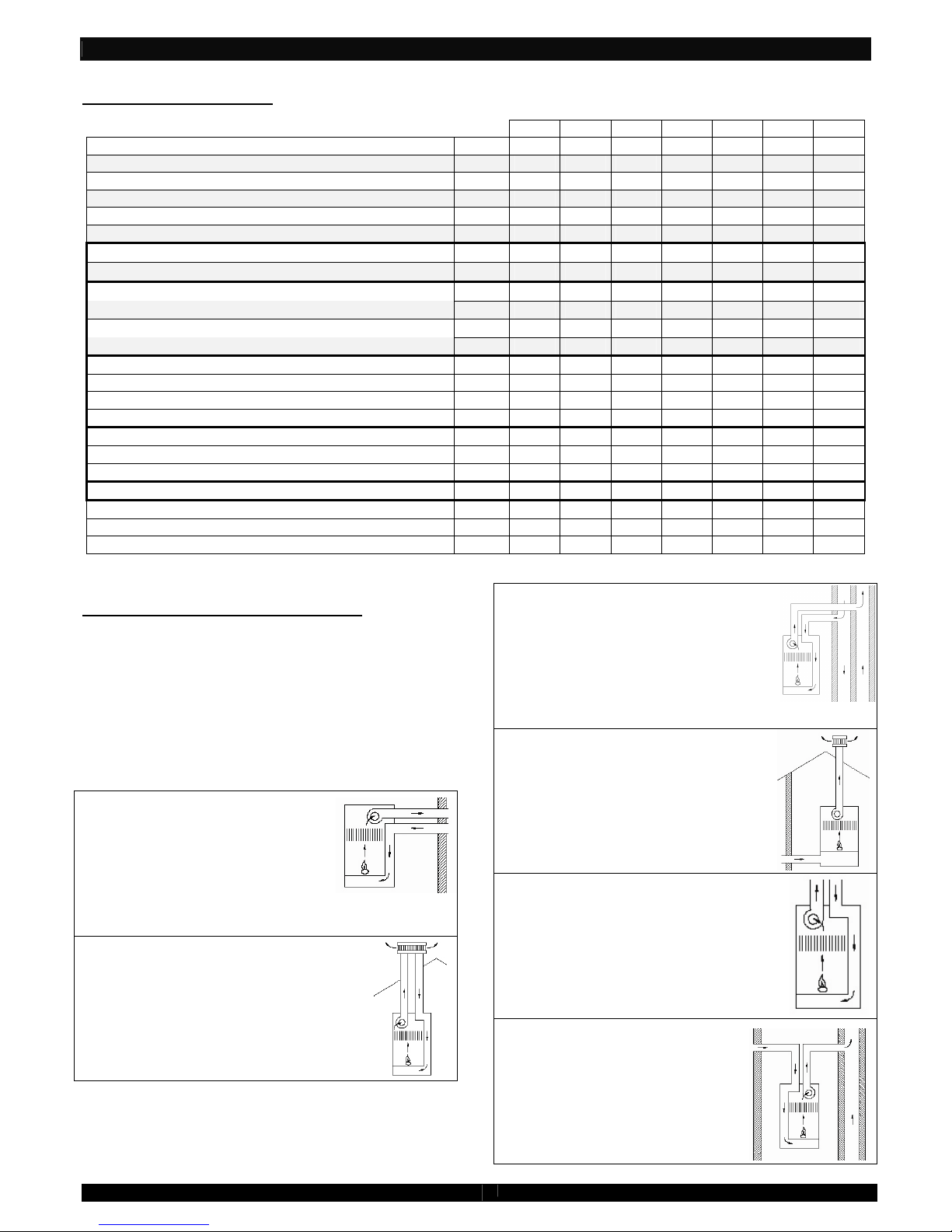

C12

The air intake and the flue outlet are

done by means of a horizontal coaxial

duct or through orifices sufficiently

close one to the other to be located in

almost identical wind conditions.

C32

The air intake and the flue outlet are done

by means of a vertical coaxial duct.

C42

The appliance is connected to a collective

duct consisting of a duct for the air supply

and a duct for the flue discharge. The

orifices of this system are concentric or

sufficiently close one to the other to be

located in almost identical wind

conditions.

C52

The air intake and the flue outlet have to

be located in different pressure

conditions.

C62

The appliance has to be connected to an

external system for the air supply and the

flue outlet. This external device has to be

approved and sold separately.

C82

The air intake is done by means of

an air terminal, whereas the flue

outlet is done through an individual

or collective chimney.

1 – GENERAL INFO RMAT IO N AN D CHARACTERISTICS

-

4 -

210-0388 - Edition October2012

CATEGORY

The countries of destination and the categories are listed

in the chart here below.

Country

Category

Country

Category

AT I2H,I

3B/P

,II

2H3B/P

BE I

2E+,I3+

,II

2+3+

BG I2H,I

3B/P

, I

3

P

,II

2H3B/P

,II

2H3P

CH I2H,I

3B/P,I3+

,II

2H3B/P

,II

2H3+

CY I2H,I

3B/P,I3B,I3+

,II

2H3B/P

,II

2H3

+

CZ I2H,I

3B/P,I3+

,II

2H3B/P

,II

2H3+

DE I2E,I

3B/P

,II

2E3B/P

DK I2H,I

3B/P

,II

2H3B/P

EE I2H,I

3B/P

, I3P,II

2H3B/P

,II

2H3P

ES I2H,I3+,II

2H3+

FI I2H,I

3B/P

,II

2H3B/P

FR I

2E+,I3+

,II

2+3+

GB I2H,I3+,II

2H3+

GR I2H,I

3B/P,I3+

,II

2H3B/P

,II

2H3+

HU I2H,I2S,I

3B/P

,II

2HS3B/P

IE I2H,I3+,II

2H3+

IT I2H,I

3B/P,I3+

,II

2H3B/P

,II

2H3+

LT I2H,I

3B/P,I3+,I3P

,II

2H3B/P

,II

2H3+

,II

2H3P

LU I2E,I3P,II

2E3P

LV I2H,I

3B/P,I3P

,II

2H3B/P

,II

2H3P

MT I2H, I

3B/P,I3B

,II

2

H3B/P

,II

2H3B

NL I2L,I

3B/P

,II

2L3B/P

NO I2H,I

3B/P

,II

2H3B/P

PL I2E,I

3B/P,I3P

,II

2E3B/P

,II

2E3P

PT I2H,I

3B/P,I3+

,II

2H3B/P

,II

2H3+

RO I2E,I2H,I

3B/P

,II

2E3B/P

,II

2H3B/P

SE I2H,I

3B/P

,II

2H3B/P

SI I2H,I

3B/P,I3P,I3+

,II

2H3B/P

,II

2H3

P

,II

2H3

+

SK I2H,I

3B/P,I3P,I3+

,II

2H3B/

P

,II

2H3P

,II

2H3+

TR I2H,I

3B/P

,II

2H3B/P

The atmospheric burner can operate on gas:

Of the second family (group E, E+, H, L, S)

Of the third family (group B, P, B/P, 3+)

IMPORTANT

This installation, use and maintenance manual is valid

only for Italy.

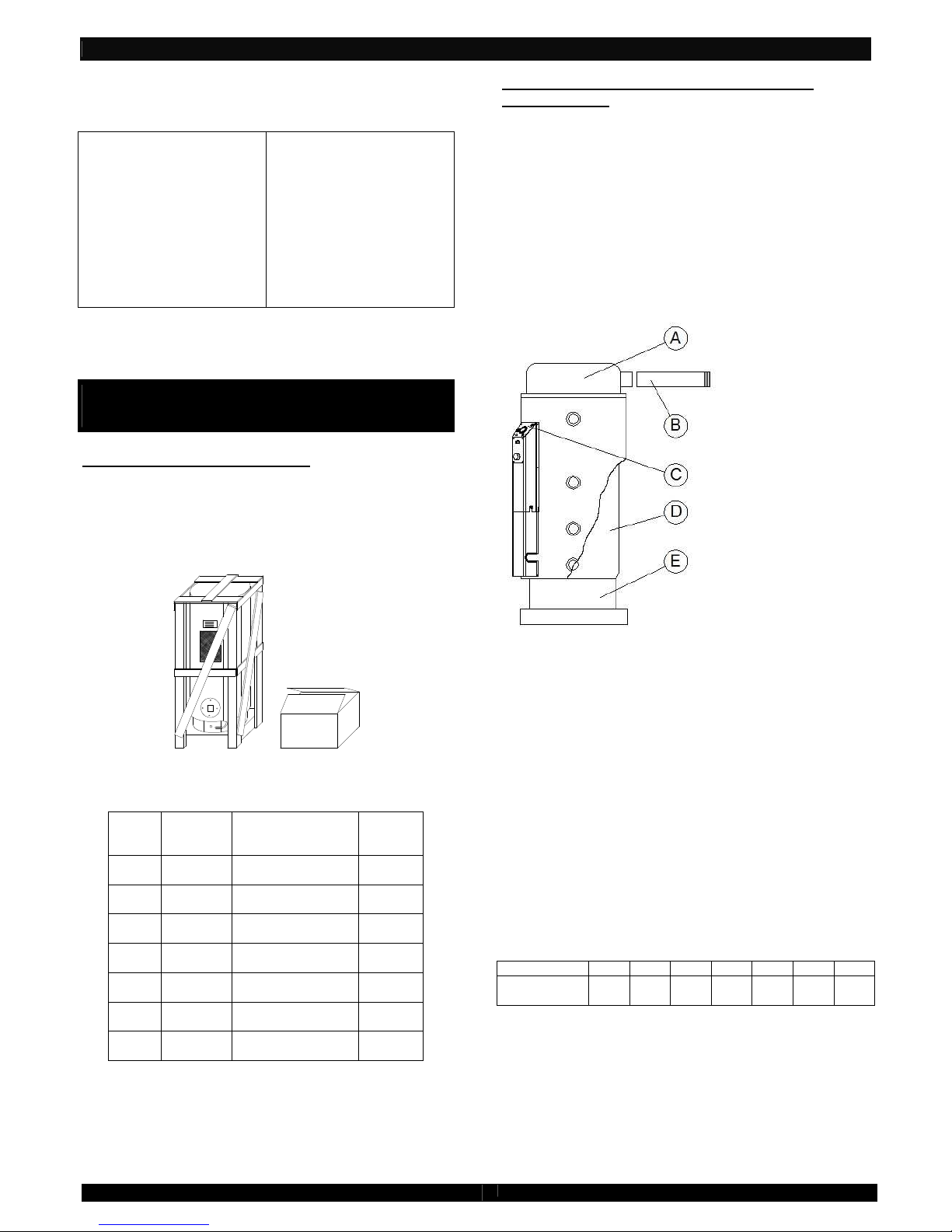

1.3 PACKAGING CONTENT

The appliance is delivered packaged in a wood cage with

appropriate protection. A second cardboard box contains

the flue hood (with the inside fan), the flue outlet carrier

and the screws necessary for the flue hood installation.

An envelope, provided on the frontal casing of the

appliance, contains this manual and the warranty

certificate.

fig_1-03: packaging

Dimensions and gross weight of the heaters

mod. parcels

n°

dimensions

LxPxH

(cm)

weight

(kg)

150 2

58 x 58 x 175

46 x 46 x 23

119

9

170 2

58 x 58 x 195

46 x 46 x 23

132

9

220 2

78 x 78 x 141

67 x 67 x 23

211

9

300 2

78 x 78 x 176

67 x 67 x 23

256

9

400 2

78 x 78 x 211

67 x 67 x 23

300

9

600 2

98 x 98 x 180

67 x 67 x 23

289

9

800 2

98 x 98 x 210

67 x 67 x 23

335

9

1.4 OPERATIONAL AND FUNCTIONAL

DESCRIPTION

The purpose of the appliance is to allow the heat exchange

between the gas combustion products, burned inside the

combustion chamber, and the water stored in the tank.

The combustion is completely sealed inside the

combustion chamber: the air supply and exhaust gases

outlet are made outside the room where the appliance is

located. The sealed combustion chamber is placed at the

bottom of the heater, under the water tank.

A flue hood is placed on the top of the heater: a fan,

placed afterwards the combustion chamber, ensures the

flue gases evacuation and the proper air supply to the

burner. Inside the tank there are some flue tubes that carry

air to the combustion chamber and flue gases back to the

flue hood, increasing also the heat exchange.

LEGEND:

A. Flue hood

B. Flue kit

C. Instrument

control panel

D. Tank

E. Combustion

chamber

fig_1-04:

FLUE HOOD

A fan, placed inside the flue hood, ensures the air supply

and flue gases outlet. The flue hood can be orientated with

any angle. In case of bad operation of the fan or

obstruction of the flue pipes, a differential pressure switch,

which the flue hood is equipped of, turns off the gas supply

to the burner.

TANK

The tank is made of thick sheet steel highly resistant to

pressure. Each storage tank is internally lined with a

vitreous enamel coating (baked at more than 850° C). This

coating ensures a high chemical resistance (unassailable

from organic solvents and many other chemical

substances), an excellent abrasion resistance (low friction)

and a very good thermal stability (the opal glass on steel

resists up to 500°C; moreover frost and cold have no

effects). Generally speaking, the coating makes the

working life of the tank longer and water healthier.

A clean out and inspection door allows an easy inspection

and cleaning of the tank.

mod. 150 170 220 300 400 600 800

Ø Flange

(mm)

85 85 120 120 120 120 120

COMBUSTION CHAMBER

The combustion chamber is placed at the bottom of the

heater. The atmospheric burner and the flame detection

system are housed inside the combustion chamber that is

completely sealed.

INSTRUMENT CONTROL PANEL

All the devices needed to control and adjust the normal

operation of the heater are located on the instrument

control panel: control thermostat, ON / OFF switch, lockout lamp/reset push-button and thermometer.

1 – GENERAL INFO RMAT IO N AN D CHARACTERISTICS

-

5 -

210-0388 - Edition October2012

FLUE SYSTEMS

(Installing the original kits supplied by the

manufacturer of the appliance is compulsory)

The flue system has to be chosen according to the

installation requirements. It connects the flue hood to the

outside of the building, supplying air to the burner and

discharging flue gases.

1.5 CONTROL AND SAFETY DEVICES

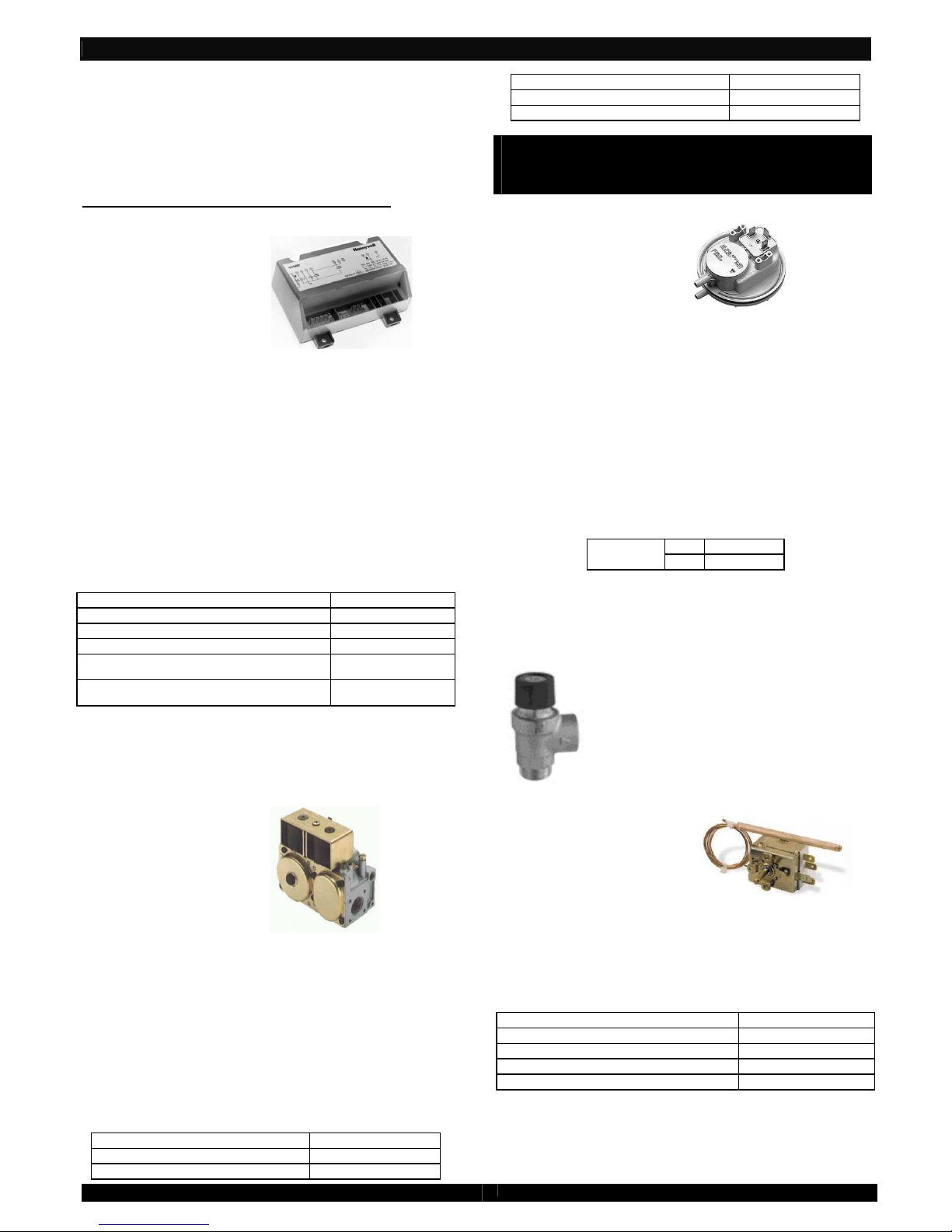

CONTROL BOX

fig_1-05-01:

Control box

The control box supervises the opening and closing of the

gas valve and the burner ignition. As it gets power supply

from the adjustable thermostat, first of all it checks if the

differential pressure switch is operating correctly.

If the differential pressure switch is operating badly, the

burner ignition is not allowed. Otherwise, a pre-purge

period of the combustion chamber elapses before the builtin igniter and gas valve are energised. If the flame is not

established within the safety time, the control box LOCKS

OUT. In this case, in order to relight the heater, wait a few

seconds and then reset the control box, pressing the reset

push-button on the instrument control panel. Flame is

detected by ionisation, by means of a special detection

electrode placed on the burner.

It is EC approved (according to EN 298).

Technical features

Electrical supply 220/240 V - 50 Hz

Room temperature 0÷60 °C

Pre-purge time 26 sec

Safety time at the ignition 10 sec

Minimum flame current 0,7 µA

Response time off < 1 sec

GAS VALVE

The gas assembly is a multi-functional and multi-gas valve

with double safety silent operating solenoid valves (class B

- 2). It is equipped with an adjustable pressure regulator

and a low rate ignition device with ignition rate adjuster

(factory set). It is EC approved (according to EN 126).

fig_1-05-02

Gas valve

The valve body is made of die-casted aluminium. Gas inlet

and outlet connections are ½” RP” UNI-ISO 7 threads. The

valve is provided with pressure test points on both gas

inlet and outlet. The valve assembly is also equipped with

a gas inlet filter. The two solenoids are connected in series

to the main gas line and they are supplied by a single tripolar connector, which avoids false connections. Any

adjustment intervention must be carried out only by

qualified and professional technicians. In case of gas valve

replacement, care must be taken to prevent dirt and

foreign material from entering the valve. Gas must flow in

the direction of the arrow on the gas valve body.

Technical features

Max gas inlet pressure 60 mbar

Pressure outlet range 3÷50 mbar

Room temperature 0÷60 °C

Electrical supply 220/240 V - 50 Hz

Power consumption 15 W

Electrical protection degree IP 54

IMPORTANT

The only maintenance operation allowed is the

solenoid replacement, which has to be carried out by

qualified and professional technicians.

DIFFERENTIAL PRESSURE SWITCH

fig_1-05-03:

Differential pressure switch

The differential pressure switch acts as a combustion

(airflow) supervisor, turning off the burner in case of bad

operation of the draft hood. This can occur in case of fan

failure or obstruction in the combustion circuit.

The differential pressure switch is placed in the flue hood.

Two silicone tubes, resistant to the flue gases high

temperatures, connect the differential pressure switch to

two probes that are placed inside the flue hood, where flue

gas flows. In this way, it is possible to test the pressure

difference inside the flue pipe when the fan is operating.

The differential pressure switch has three terminals (with

two positions: normally open NA and normally closed NC).

It is EC approved (Directive 90/396/EEC and

73/23/EEC).

Technical features

Calibration

ON 110 ± 5 Pa

OFF 122 ± 5 Pa

PRESSURE RELIEF VALVE

This device allows the water discharged from the tank

through a suitable drain, in case of excessive pressure of

the water stored inside the tank.

It is EC approved (Directive 97/23/EEC).

Technical features

Body in brass (Ot 58 UNI5705/65)

Spring in special steel

Membrane in elastomer

Fixed setting 6,5±0,2 bar

fig_1-05-04:

Pressure relief valve

ADJUSTABLE THERMOSTAT

fig_1-05-05:

Adjustable thermostat (water

temperature)

An adjustable thermostat controls the general operation of

the appliance, switching the burner on and off according to

the desired water temperature. The thermostat is a single

pole liquid filled sensing bulb with operating switch

contacts.

It is BEAB approved (according to EN 60730)

Technical features

Contacts rating 250 V~ / 16 A

Temperature differential 8±2 °C

Max bulb temperature 130 °C

Max body temperature 85 °C

Temperature setting 41÷80 ±3 °C

Loading...

Loading...