Page 1

INSTALLATION INSTRUCTIONS

8G.51.21.01/11.99 changes reserved

Page 2

Page 3

Installation instructions S-HR series page 3

S-HR 15 S-HR 24/24T S-HR 35/35T S-HR 51/51T S-HR 60

Contents page

1 Description of the unit ................................................................................................................... 4

2 Scope of the delivery ..................................................................................................................... 4

3 Mounting of the unit ....................................................................................................................... 4

3.1 Dimensions ......................................................................................................................... 5

4 Connecting the unit ....................................................................................................................... 6

4.1 Central heating system .......................................................................................................7

4.2 Expansion tank.................................................................................................................... 8

4.3 Underfloor heating systems............................................................................................... 10

4.4 Gas pipe ............................................................................................................................ 10

4.5 Hot water supply (S-HR-T) ................................................................................................ 10

4.6 Condensation discharge pipe ............................................................................................ 10

4.7 Flue gas exhaust system and air supply system ............................................................... 11

5 External calorifiers ....................................................................................................................... 12

6 Electrical connection ................................................................................................................... 12

7 Control of the unit ........................................................................................................................ 14

7.1 Explanation of the function keys........................................................................................ 14

8 Filling and venting of unit and installation .................................................................................... 15

8.1 Central heating system ..................................................................................................... 15

8.2 Hot water supply ............................................................................................................... 15

9 Putting the unit into operation...................................................................................................... 16

9.1 Central Heating system ..................................................................................................... 16

9.2 Hot water supply ............................................................................................................... 16

9.3 Adjustments ...................................................................................................................... 16

10 Switching off the unit ................................................................................................................... 20

11 Commissioning and maintenance ............................................................................................... 20

11.1 Checking for contamination ............................................................................................... 20

11.2 Checking of the zero pressure control ............................................................................... 20

11.3 Checking the CO2 .............................................................................................................. 21

11.4 Maintenance...................................................................................................................... 22

11.5 Further checks .................................................................................................................. 22

11.6 The frequency of maintenance .......................................................................................... 22

12 Technical specifications .............................................................................................................. 23

13 Diagram showing various parts of the unit .................................................................................. 24

14 Example diagrams for connecting the unit .................................................................................. 26

14.1 Radiator installation without thermostat valves ................................................................. 26

14.2 radiator installation with thermostat valves only ................................................................ 27

14.3 radiator installation with an under floor heating zone ........................................................ 28

14.4 radiator installation and an independent underfloor heating zone ..................................... 29

14.5 two independent radiator zones ........................................................................................ 30

15 Error indication ............................................................................................................................ 31

Page 4

Installation instructions S-HR series page 4

1 Description of the unit

The STREBEL S-HR Boiler is a room sealed,

condensating and modulating central heating unit, with

or without an integrated hot water facility.

The built-in fan sucks the combustion air from outside

and provides full premixing of the gas and air. The gas

mixture is guided through the ceramic burner which is

fitted above the heat exchanger. As a result of the small

flame height a compact construction is possible. The

combustion gasses are exhausted after passing

through the stainless steel heat exchanger. The formed

condensation water is discharged through the waste

trap.

The unit has been tested according to valid CE*

standards and has a CE* certificate.

The operating efficiency of the unit is higher than 98%

(on top value). As a result of its compact construction the

radiation, convection and stand by losses are very low.

The emission of damaging substances is far below the

standard set for equipment with the gas quality-control

label for clean combustion.

The unit is provided with an automatic venting program.

In case of a recently topped up or filled up installation

this program takes care of the removal of any present

air. In this case the control will check the water pressure

and if it is too low, will report this on the display.

The unit anticipates the heat requirement of the central

heating installation or the hot water supply. As a result

the unit will adjust its capacity to the installation and will

switch on less often, which means that the unit will

operate longer and at a low level. It is possible that the

unit will only have to switch on once an hour. In this case

the aim is to obtain maximum comfort and efficiency.

In order to be able to anticipate installation noises the

unit has a so-called gradient control. After the unit goes

into operation this control provides a uniform increase of

power, instead of immediately burning at full power.

When the installation does require full power the control

will adjust as required. By this means a uniform increase

of the water temperature is effected.

If an outside sensor is connected, the control can

operate weather-dependent. This means that the

control measures the outside temperature and the flow

water temperature. On the basis of this data the control

calculates the optimal flow water temperature in the

installation.

The S-HR-T combination unit provides a hot water

supply by means of a high output calorifier fitted on the

right hand side of the unit. An adjustable thermostatic

mixing valve is fitted which provides a constant hot

water temperature (60

°

C factory setting).

2 Scope of the delivery

The unit is supplied ready for use. The supply kit is

composed as follows:

- Unit with casing;

- Automatic vent (inside the unit);

- Safety valve (inside the unit);

- Inlet combination and safety valve (only with S-HRT units);

- Suspension bracket

- Filling and draining valve with T-piece;

- Fixing material consisting of plugs and screws;

- Template on the package wrapper;

- Installation instructions

- Operating manual;

- Installation and user card.

3 Mounting of the unit

The unit can be mounted practically to every wall with

the mounting bracket and the included fixingequipment.

The wall must be flat and of sufficient strength in order

to be able to carry the unit weight.

Above the unit there must be at least 250 mm working

space in order to be able to fit a twin supply and exhaust

system or 500mm when fitting a horizontal coaxial flue

system. On the left side of the unit at least 50 mm and

on the right side 10 mm must be reserved in connection

with fitting or removing of the casing. The location of the

unit can be determined by using the template on the

inside of the wrapper.

Page 5

Installation instructions S-HR series page 5

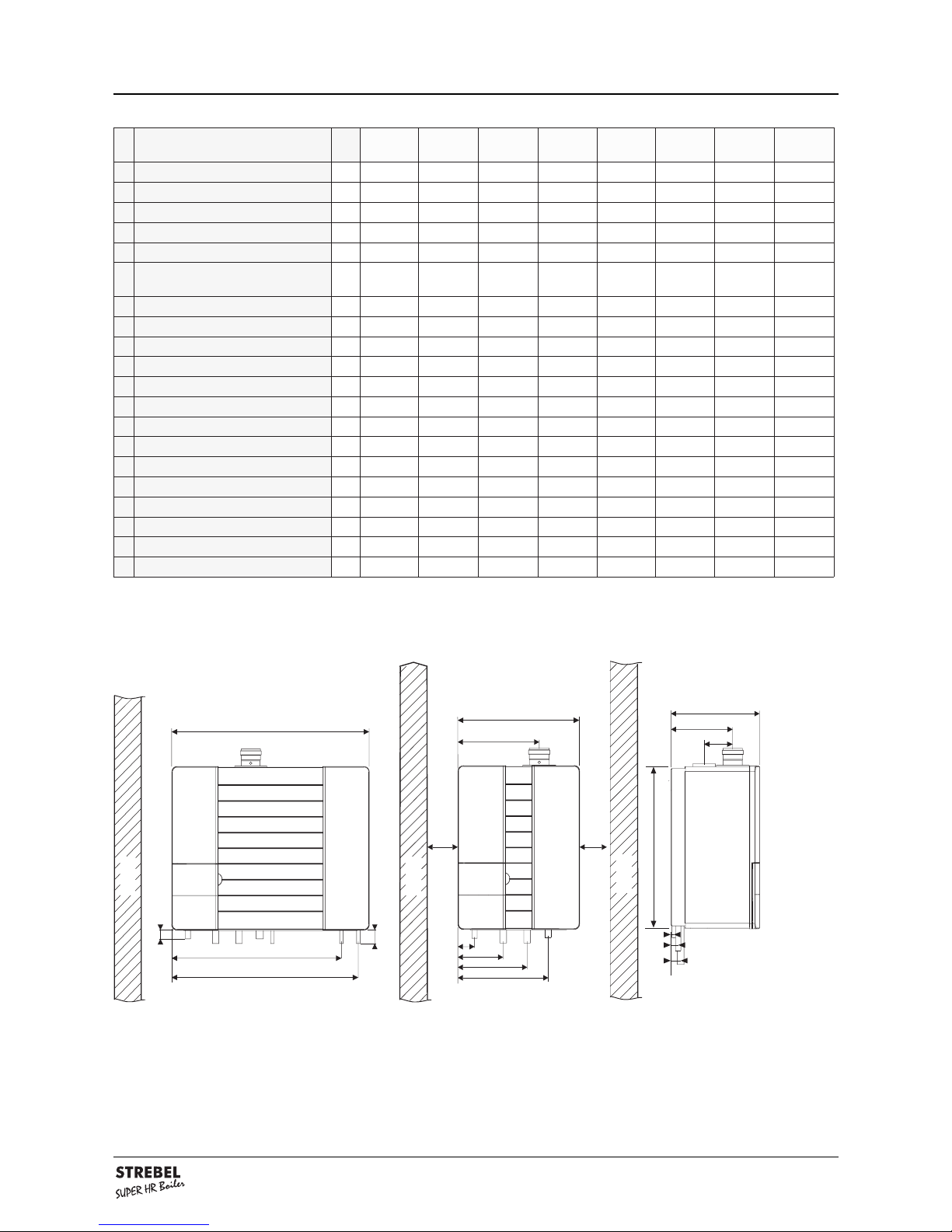

3.1 Dimensions

Dimensions (in mm) figure 1

wall

C

E

F

A

U

T

S

wall

B

M

N

P

Q

R

B

wall

D

H

J

K

1050

G

Dimensions table 1

tinufoepyt

RH-S

51

RH-S

42

RH-S

T42

RH-S

53

RH-S

T53

RH-S

15

RH-S

T15

RH-S

06

A thgieh

mm086086086086086086086086

B htdiw

mm0050050480050480660001066

C htped

mm073073073073073073073073

D tsuahxesageulf/edistfel

mm533533533533533594594594

E

tsuahxesageulf/ertnecotertnec

ylppusdna

mm021021021021021021021021

F tsuahxesageulf/kcab

mm072072072072072072072072

G epipsag/edistfel

mm5656565656565656

H epipwolf/edistfel

mm581581581581581581581581

J epipnruter/edistfel

mm582582582582582544544544

K epipnoitasnednoc/edistfel

mm073073073073073035035035

L epipknatnoisnapxe/edistfel

mm034034095

M epipretawdloc/edistfel

mm527527588

N epipretawtoh/edistfel

mm597597559

P *gfothgnelepip

mm8181818181818181

Q *kdnacfothgnelepip

mm0404040404040404

R *wdnae;r;afothgnelepip

mm0606060606060606

S *cepipfoertnec/kcab

mm5252525252525252

T *gepipfoertnec/kcab

mm0404040404040404

U *w;k;e;r;aepipfoertnec/kcab

mm0505050505050505

Page 6

Installation instructions S-HR series page 6

4 Connecting the unit

The unit has the following connection pipes;

- The central heating pipes, hot and cold water pipes

can be connected to the installation by means of

compression fittings;

- The gas pipe of the unit is provided with a female

thread into which the tail piece of the gas valve can

be screwed;

- The condensation discharge pipe consist of an oval

24 mm plastic pipe. The discharge pipe can be connected to this by means of an open connection. If the

open connection is fitted in a different location, then

the pipe can be lengthened by means of a 32 mm

PVC sleeve;

- The flue gas exhaust system and air supply system

consist of 2 x 80 mm connections.

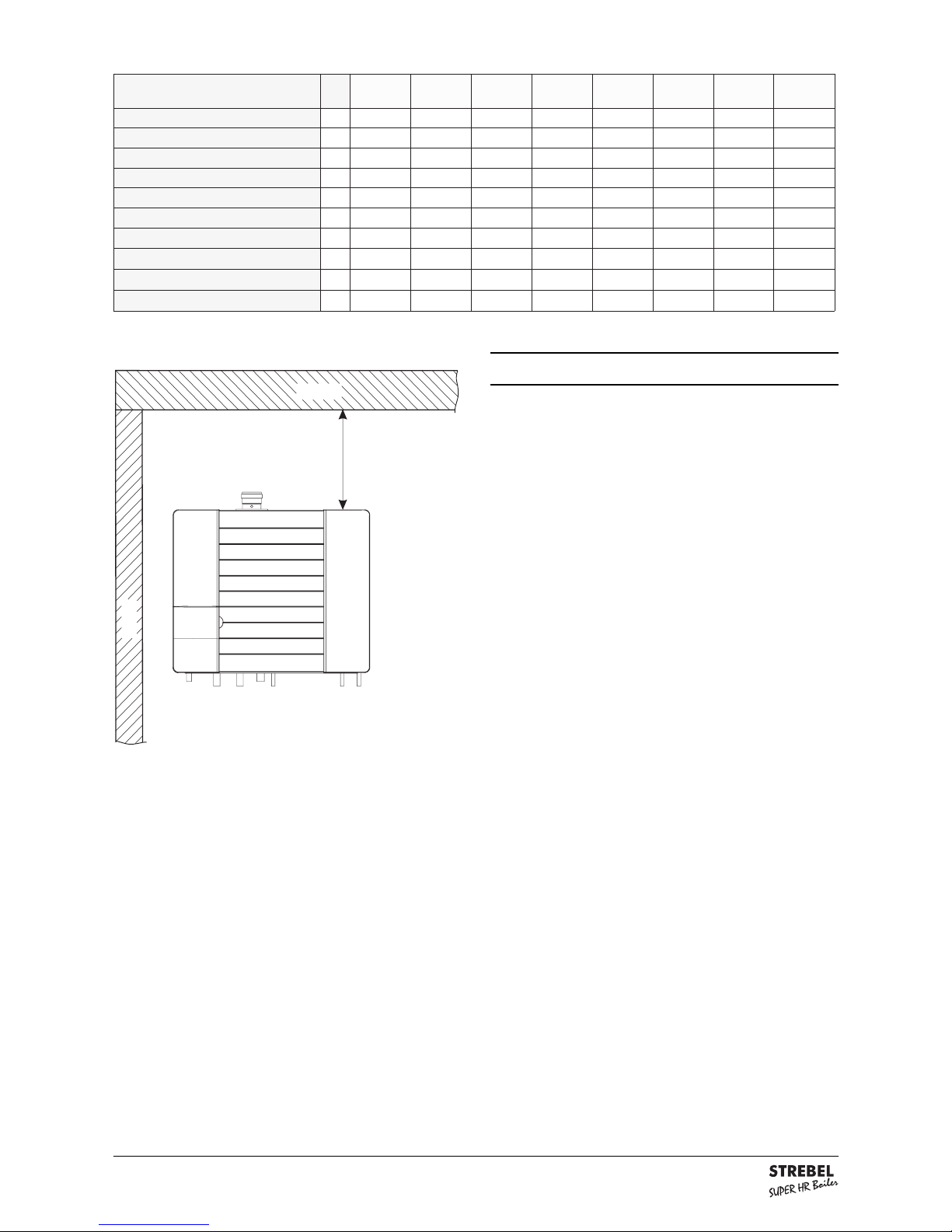

connection diameters table 2

unit pipes bottom figure 2

G A R C E K W

ceiling

wall

minimum

250 mm or

500 mm

tinufoepyt

RH-S

51

RH-S

42

RH-S

T42

RH-S

53

RH-S

T53

RH-S

15

RH-S

T15

RH-S

06

ylppusrianoitsubmoc

mm0808080808080808

tsuahxesageulf

mm0808080808080808

G-epipsag

edisni"½edisni"½edisni"½edisni"½edisni"½edisni"¾edisni"¾edisni"¾

A-epipwolfgnitaehlartnec

mm8282828282535353

R-epipnrutergnitaehlartnec

mm8282828282535353

C-epipegrahcsidnoitasnednoc

mm4242424242424242

E-epiplessevnoisnapxe

mm222222

K-epipretawdloc

mm515151

W-epipretawtoh

mm515151

Page 7

Installation instructions S-HR series page 7

4.1 Central heating system

The unit pipes can be connected to the installation by

means of compression fittings. Reducers should be

used for connecting to thick-walled pipe (welded or

threaded).

When removing the plastic sealing caps from the pipes,

contaminated testing water can be released.

The unit has a self-adjusting and self-protecting control

system for the load and the pump capacity. By this means

the temperature difference between the supply and return

water is checked. The circulation pump will be able to

supply the given water displacement with an installation

resistance of up to 20 kPa, for this see table 3.

If an unacceptable temperature is detected, then the

control will repeatedly try to achieve water flow, and if

this does not work then the unit will switch off.

The S-HR 60 unit has a circulation pump which has a

residual suction head for the installation of 12 kPa. This

means that the unit can function normally in installations

which have an installation resistance of up to 12 kPa and

in cascade installations.

If the installation resistance is higher than 12 kPa, the

unit will automatically reduce in power.

If the capacity of the unit pump is insufficient, an extra

external pump can be installed in series with the unit.

The electrical side of this external circulation pump can

be connected in the Control Tower, by which means this

pump switches at the same times as the unit pump.

The maximum absorbed current consumption of the

external circulation pump may be 230 W (1 Amp).

Use with a low velocity header can also be selected. In

this case a larger secondary sided water output has to

be taken into account, in order to affect the height of the

water temperature.

If the installation resistance is higher than the stated

value the pump will rotate at maximum pump capacity

and the load will be adjusted until an acceptable

temperature difference between supply and return water has been obtained. If, after this, the temperature

difference remains too much then the unit will switch

itself off and wait until an acceptable temperature has

arisen.

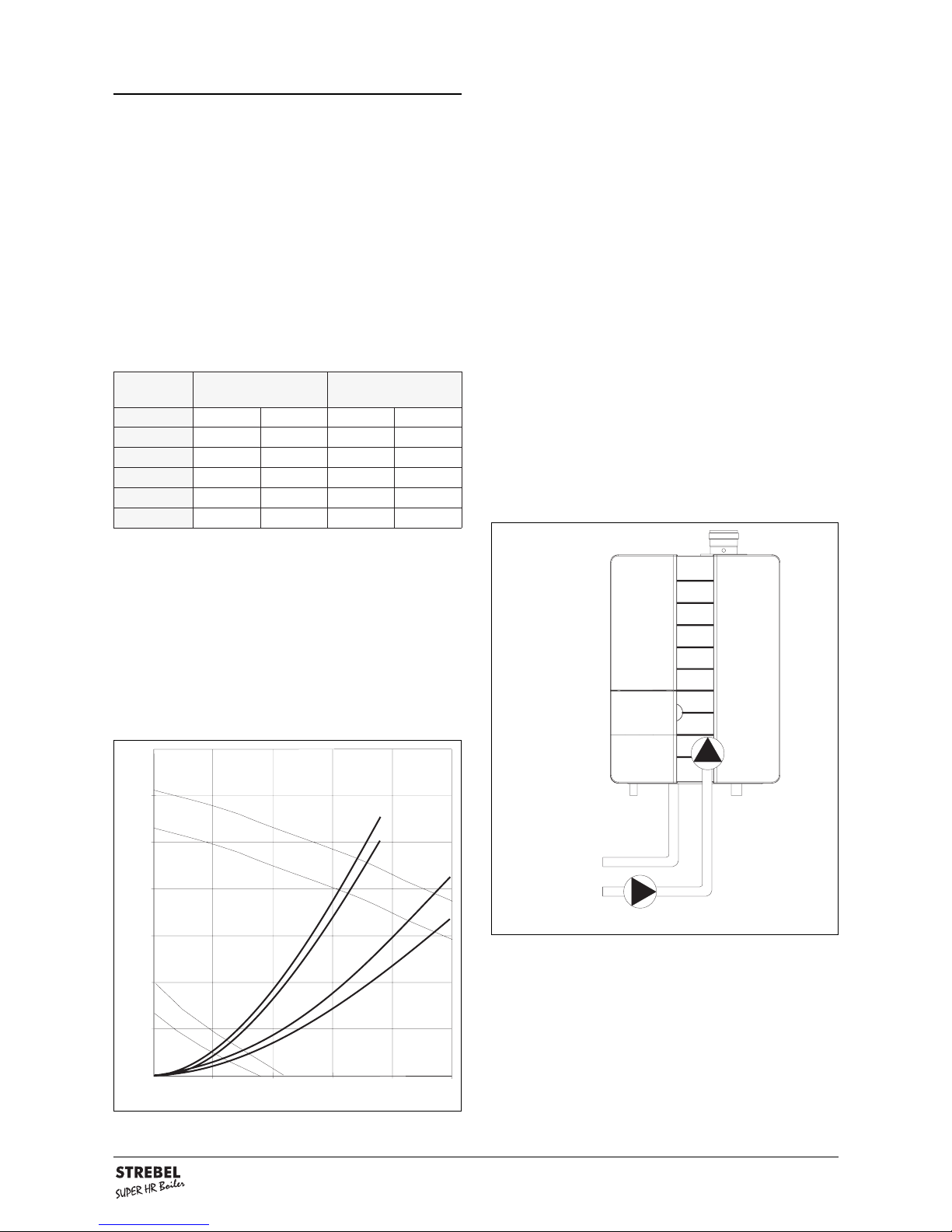

available water flow at full load table 3

external installation pump in series figure 3

tinufoepyt etarwolfretaw

D C°02T

elbissimrep

ecnatsisernoitallatsni

nim/lh/laPkrabm

51RH-S

9.900653053

T42/42RH-S

1,5108952052

T53/53RH-S

1,22423102002

T15/15RH-S

1,23929102002

06RH-S

9,73172221021

pump index lines graph 1

0 0,5 1 1,5 2 2,5

Q(m³/h)

7

6

5

4

3

2

1

0

H(m)

min (25%)

max (100%)

pump index line ARS 25-75

S-HR 15/24/35

S-HR 24T/35T

S-HR 51T

S-HR 51/60

pump index line ARS 25-70

Page 8

Installation instructions S-HR series page 8

As standard the unit is provided with a water filter in the

return pipe of the unit. With this, possible contamination

of the central heating water is prevented from ending up

in the unit. The unit is also provided with an internal

safety valve set at 3 bar. This is connected to the

discharge construction to the waste together with the

condensation discharge.

If all, or a large part of the radiators are provided with

thermostatic radiator valves it is advisable to use a

pressure difference control (by pass) in order to prevent

flow problems in the installation.

The unit is designed to be used on sealed

system only.

Additives in the installation water are only

permitted in consultation with STREBEL

LTD.

When using more than one unit in an installation please

refer to the cascade installation instructions.

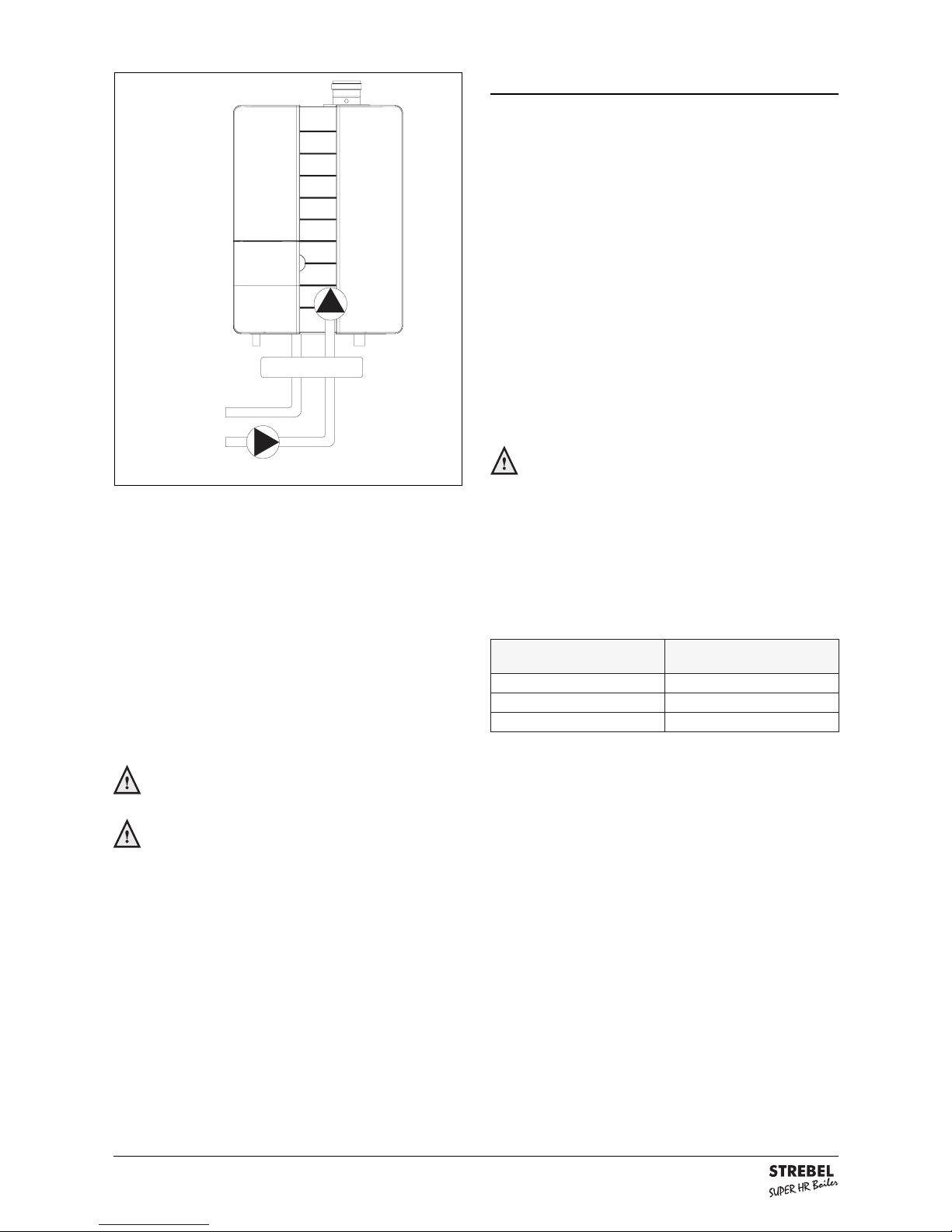

4.2 Expansion tank

All STREBEL S-HR-T units are provided with an

expansion tank on top of the calorifier. This expansion

tank is connected to the three-way valve and the

circulation pump. By this means the expansion water,

when functioning for the hot water supply, is prevented

from being shut off from the expansion tank when the

radiator thermostat valves are fully closed. A second

expansion tank in the installation is not a problem.

The STREBEL S-HR units are not equipped with an

expansion tank pipe. If a S-HR unit is combined with an

Comfort calorifier, the expansion tank connection is

included in the internal piping of the Comfort calorifier,

to which the expansion tank can be connected. If a

different calorifier is used then one has to take into

account that the expansion tank should be connected

between the three-way valve and the unit circulation

pump.

In connection with correct functioning of the

unit it is necessary for the expansion tank to

be connected to the expansion tank pipe of

the unit.

The expansion tank which is used should be geared to

the water content of the installation. The pre-pressure

depends on the installation height above the mounted

expansion tank.

external installation pump with low velocity header figure 4

choice of expansion tank table 4

evobathgiehnoitallatsni

lessevnoisnapxeeht

ehtfoerusserp-erp

lessevnoisnapxe

m5rab5,0

m01rab0,1

m51rab5,1

Page 9

Installation instructions S-HR series page 9

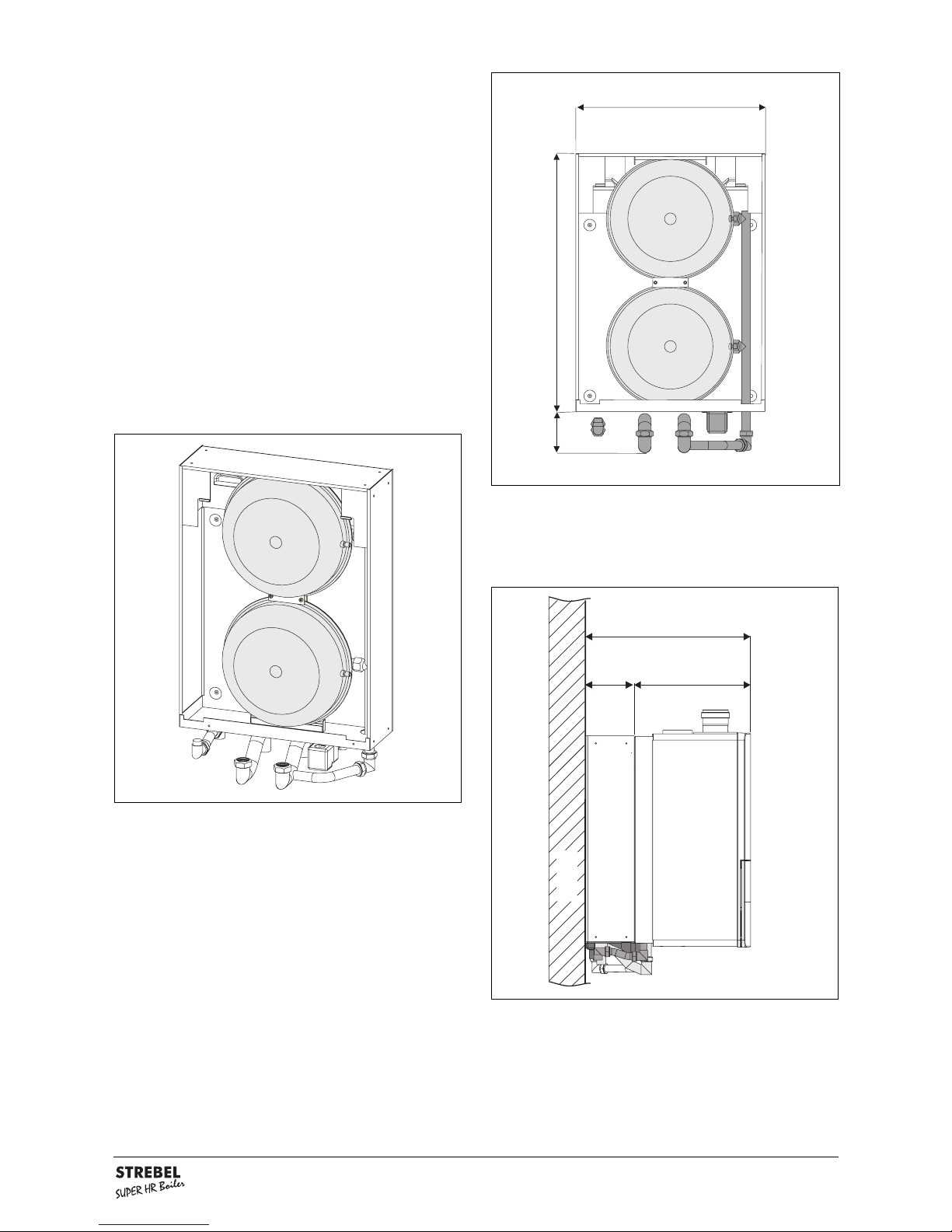

The STREBEL S-HR24 and S-HR35 units can be

provided with an expansion tank module. By this means

the external expansion tank is cancelled. This

expansion tank module is placed behind the S-HR unit,

by which means the expansion tank is not noticeable. If

the S-HR unit is provided with a STREBEL Comfort

calorifier the overall depth will be equal. The content of

the two expansion tanks is 20 litres. The pre-pressure is

1 bar.

The expansion tank module can be supplied with the

necessary pipes to connect with the S-HR unit. The

connecting pipes for the installation correspond with

those of the unit and have the same centre-to-centre

distance to the wall. When checking the expansion

tanks these are accessible via the left, right and upper

sides. From these sides the tanks are also removable

and the unit does not have to be dismantled.

The space which is required for mounting the expansion

tank module corresponds with the required space for

mounting a S-HR unit. The included template and

mounting strip for the S-HR unit can be used for the

expansion tank module. The S-HR unit is fitted on to this

after the expansion tank module has been mounted.

The necessary mounting strip for the unit is present on

the module.

expansion tank module figure 5

side view of the module with S-HR unit figure 7

(dimensions in mm)

515

wall

145

370

front view of the expansion tank module figure 6

(dimensions in mm)

480

660105

Article numbers:

- the expansion tank module without pipe connections AEMO209U

- pipe connections for expansion tank module ALE0004U

Page 10

Installation instructions S-HR series page 10

4.3 Underfloor heating systems

When connecting or using an underfloor heating system

fitted with plastic pipes one has to take into account that

the plastic pipes used meet the DIN 4726/4729

standard. It is stated in this standard that the pipes may

not have a higher oxygen transmittance than 0.1 g/m³.d

at 40°C. If the system does not meet this DIN standard,

then the underfloor heating section will have to be

separated from the central heating unit by means of a

plate heat exchanger.

In case of non-compliance with the

regulations concerning plastic underfloor

heating pipes, no claims can be made against

the guarantee conditions.

4.4 Gas pipe

The unit pipe is equipped with a female thread, into

which the tail piece of the gas valve can be screwed.

The Gas Safety (Installation and Use) Regulations

1994:

It is the law that all gas appliances are installed by

CORGI registered contractors in accordance with the

above regulations. Failure to install appliances correctly

could lead to prosecution. It is in your own interest, and

that of safety, to ensure that the law is complied with.

For good operation of the unit it is necessary that the

pre-pressure of the unit is higher than 20 mbar.

Make sure that the gas pipe work does not

contain dirt, particularly with new pipes.

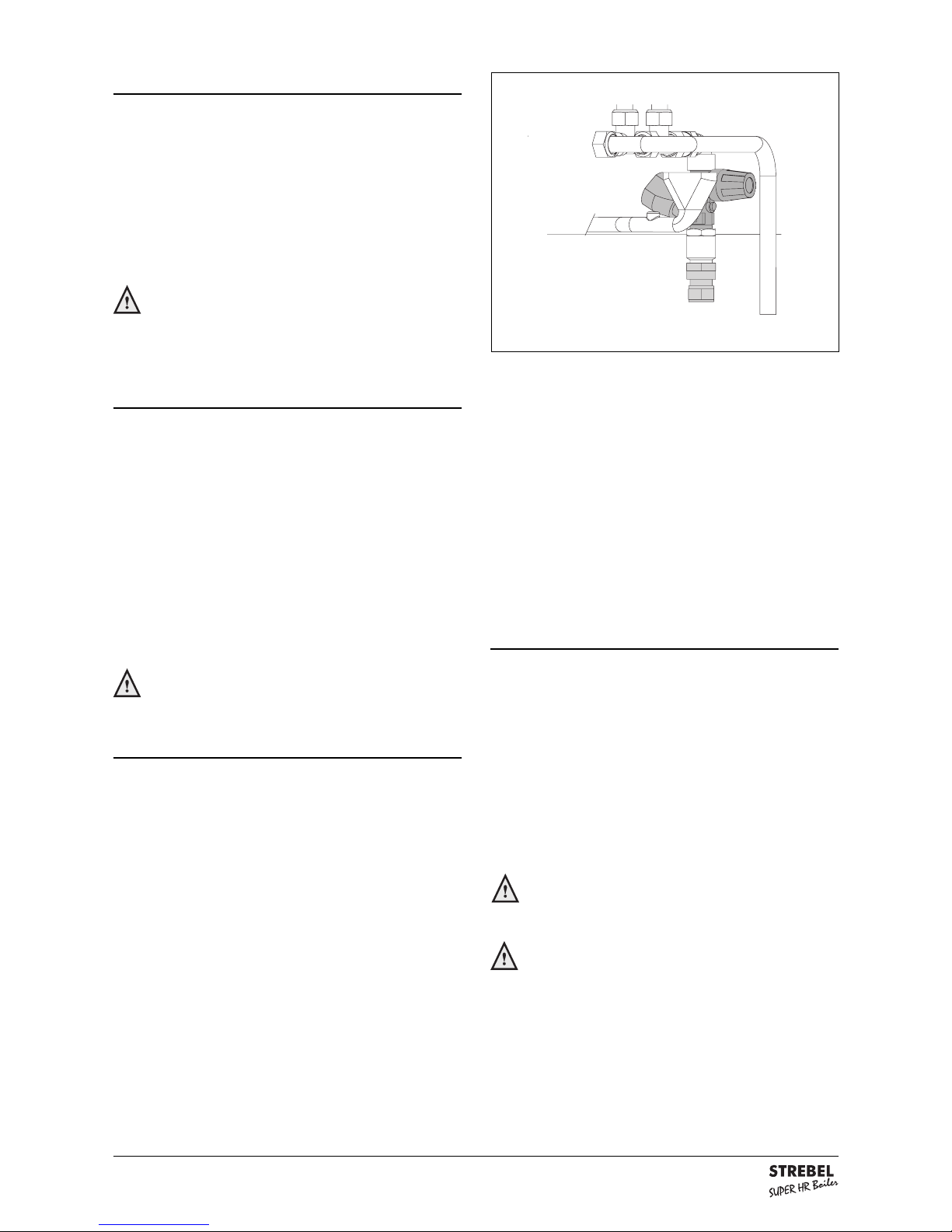

4.5 Hot water supply (S-HR-T)

The unit pipes can be connected to the installation by

means of compression fittings. The unit is provided with

an inlet combination and safety valve set at 8 bar.

Together with the condensation discharge and the

discharge of the central heating safety valve (3 bar) this

is connected to one waste connection pipe.

A flow regulation valve is fitted in the cold water pipe.

The flow regulation valve provides that a quantity of

water is supplied which has a guaranteed outlet

temperature of 60°C (assuming a cold water

temperature of 10°C). The quantity of water is virtually

unaffected by the water pressure. With a water pressure

lower than 1.5 bar it is advisable to remove the inside

mechanism of the flow regulation valve. Connecting of

the drinking water installation should be done according

to the water BYE-laws.

4.6 Condensation discharge pipe

The collective condensation discharge pipe should be

connected to the waste by means of an open

connection. By this means the possibility of sewer

gases ending up in the unit is prevented. The waste

connection should have a minimum diameter of 25 mm.

The following components are connected to the

collective condensation discharge pipe:

- Condensation discharge;

- Safety valves;

- Inlet combination (S-HR-T)

Discharging of the condensation water to the

precipitation discharge is not permitted in

view of the danger of it freezing.

Before putting the unit into operation fill the

trap with 300 ml of water.

inlet combination and safety valve figure 8

Page 11

Installation instructions S-HR series page 11

4.7 Flue gas exhaust system and air

supply system

The unit connection diameter is Ø 80 mm. to which the

flue gas discharge and air supply system can be fitted

with or without bends.

The maximum usable pipe length is stated in table 5.

It is advisable to use stainless steel discharge

equipment for the flue gas discharge. By using the

STREBEL icicle-free trough the roof kit, ice-forming

around the flue terminal is prevented. For the air supply

plastic can be chosen. If a plastic discharge system is

installed the unit has to be equipped with a flue gas

thermostat. This flue gas thermostat is available from

STREBEL LTD.

With the flue gas discharge system and air supply

system the following is meant:

- the flue gas discharge pipe;

- the air supply pipe;

- through the roof kit or wall terminal.

The flue gas exhaust and the air supply installation must

be installed in accordance with British Standards.

The exhaust system should always be installed sloping

towards (30 mm/m) the unit, in order for condensation

water not to gather in the exhaust system. With

condensation water flowing back to the apparatus the

chance of ice forming on the trough the roof kit is

minimal. In case of horizontal outlets the supply system

has to be installed sloping outside in order to prevent

rain coming in.

It is superfluous to install an extra condensation

collecting unit.

In operation, the unit produces a white

condensation plume. This condensation

plume is harmless but can be experienced as

disturbing especially in the case of outlets in

the wall. For this reason it is advisable to exit

at roof level.

The apparatus is not suitable as an open

unit. This means that the combustion air

always has to be brought from outside.

Where the unit is installed in a compartment,

ventilation is required as per BS 5440.

For further information regarding the supply range of the

exhaust and supply system please contact STREBEL

LTD.

supply and exhaust system figure 9

length supply and exhaust system table 5

ehthtobrofsisertemnihtgnelepipdetatsmumixamehT

ecnatsidehtsidnametsystsuahxeehtsallewsaylppus

.lanimretllawrofoorehtdnatinuehtneewteb

tinufoepytepipmumixam

htiwsertemnihtgnel

mm08foretemaida

epipmumixam

htiwsertemnihtgnel

mm09foretemaida

51RH-S

0304

T42/42RH-S

5204

T53/53RH-S

8163

T15/15RH-S

0102

06RH-S

631

eht,metsystsuahxeroylppusehtnisdnebgnisunehW

ecnatsiserehthtiwsdnopserrocsiht,wolebdenoitnemhtgnel

.htgnelepipehtotdeddaebotsah,dnebehtfo

dnamm08øtcudtsuahxesertem01htiw42RH-S:elpmaxE

5,21=ertem52,1x2+sertem01:snaemsihT.sdneb°09x2

.ertem

°09dneb

52,15,1

°54dneb

152,1

Page 12

Installation instructions S-HR series page 12

5 External calorifiers

Various external calorifiers can be connected to a S-HR

unit, depending on the comfort requirements. The

wiring of the calorifier thermostat can be connected to

the connection block in the Control Tower by means of

the relevant plug.

Calorifiers which are used together with the S-HR boiler

should be of the quick recovery type.

S-HR51 and S-HR60

Consult STREBEL when using calorifiers

with lower absorption than 20kW or primary

pipe and/or coil size less than 3/4 inch.

S-HR with calorifier figure 14

6 Electrical connection

The unit complies with the CE machine guidelines 89/

392/EEC.

The installation must be in accordance with:

- Current I.E.E. Regulations;

- Local Regulations;

- A visible electrical isolation switch must be fitted

adjacent to the boiler complete with an earth.

The apparatus complies with the following regulations:

- low-voltage guideline 73/23/EEC

- EMC guideline 89/336/EEC

Furthermore the following general regulations are valid:

- no modifications may be made to the wiring of the

unit;

- all connections must be made to the connection

block.

The Brain room thermostat and controls must be

connected to their allocated connections. All other types

or makes of room thermostats or controls which are

used must have a potential-free contact

When using an on/off thermostat or control, it is possible

that an anticipating resistance must be installed in order

to prevent too high temperature fluctuations. As a standard rule this means mercury thermostats. This resistance wire is present in the Control Tower and must be

connected to clamps 23 and 27. The anticipating resistance in the room thermostat has to be set at 0.11 A.

For more detailed questions regarding the components

which are not supplied by STREBEL, the supplier

concerned should be contacted.

The connections of the Brain Interface and

the wiring of the three-way valve with the

calorifier sensor are only applicable if they

are installed in the Control Tower.

230 Volts for

external pump

mains power

supply

230 Volts for

external control

230 Volts

internal or external

three-way valve motor

and calorifier sensor

Brain

clock thermostat

On/off thermostat or

control

Connection block in the Control Tower

STREBEL outside

sensor

External safety

contact

24 Volts

maximum 100 mA

Page 13

Installation instructions S-HR series page 13

electrical connecting diagram figure 11

Page 14

Installation instructions S-HR series page 14

7 Control of the unit

The unit is provided with a self-adjusting control called

the Control Tower. This control takes over a large part

of the manual adjustments which means putting the unit

into operation has been extensively simplified. After

plugging the plug into the wall socket the unit will not

undertake any operating action and no operating lamps

will be lit.

On the display the relevant status will be shown. Reading out of the status can be done in two ways.

The first way is a simple read out called the Good status.

The unit will only show the indication. During this

read out the unit can be in normal operation without this

showing in any other way. If it is necessary to show a

report it will be shown on the display.

The second way is the technical way which shows a

more extensive read-out with, among others, the

position in which the unit is active with the flow water

temperature and the water pressure of the central

heating system.

The second level is reached from the indication

after pressing the STEP key for 5 seconds. Returning to

the indication is done the same way.

Only when activating the operating program pump

circulating after filling up the installation, will the

automatic venting program start as standard after

pressing the PC program key. This automatic

venting program takes 15 minutes and stops

automatically. After this the unit will function for the

activated part.

In case of a heat requirement, which arises for central

heating or hot water, a certain flow water temperature

will be calculated. This calculated water temperature is

called the T-set value. This value becomes active in

case of a demanding room thermostat after which the

unit power will be adjusted. With a recently started unit

a build-up delay of the T-set valve is active. The main

purpose of this is to prevent the unit going into operation

at full power due to which disturbing noises and

unnecessary temperature peaks can arise. In the case

of heat requirement from the hot water supply the T-set

valve on the central heating return water temperature is

adjusted. Depending on the amount of domestic water

which is withdrawn from the calorifier, the central

heating return water temperature, which adjusts the

load of the unit, will vary.

Each time the mains power supply to the

boiler is broken, the automatic venting program will re-start once there is power to the

boiler.

7.1 Explanation of the function keys

Key functions from the and the extensive

indication are:

-

Central Heating program key, see chapter

10.1;

- Hot Water program key, see chapter 10.2;

- PC program key, adjusts the pump to continuous

water circulation in the central heating system, or

according to the pump overrun times on the relevant

programs;

- Mode key, after briefly pressing, a selection of the

data chapters can be retrieved. After pressing for 5

seconds it is possible to enter the code as described

in chapter 10.3;

- Step key, after briefly pressing, the water pressure

can be retrieved and pages per chapter can be

retrieved. After pressing for 5 seconds it switches

from indication to technical indication and the

other way round;

- Reset key, after briefly pressing, for:

unlocking errors;

ending the access code;

ending the automatic venting program, only when

the access code is entered and the reset key is

pressed briefly.

After pressing for 5 seconds an operating stop is

made, for example, for activating the automatic

venting program.

Other key functions from the other indications are:

- Central Heating key then has the + function;

- Hot Water key then has the - function;

- PC key then has the store function, which means

that by means of this key a modified setting is

confirmed;

- Step key for scrolling in a data chapter.

Page 15

Installation instructions S-HR series page 15

8 Filling and venting of unit and

installation

Filling of the installation can be carried out according to

the usual method. In order to read out the central

heating water pressure the unit plug should be plugged

into the socket.

The circulation pump will not begin to operate as long as

the operating lamps are off. The control display will

show a indication, which means that the control

is signalling insufficient water pressure. If the

installation is filled and the water pressure rises then the

water pressure will automatically be shown with an

alternating text. If the water pressure rises to

above 1.5 bar then after a short stop text the

indication will appear, which means the water pressure

is sufficient and the unit is ready for operation.

In order to be able to read out a constant water pressure

the Step key should be pressed in and in order to obtain

a constant readout the Step key should be

pressed briefly again.

If the water pressure in the unit becomes too high (>3.5

bar) a text appears, by which means the burner

is switched off. After draining the water from the

installation, by which means the water pressure arrives

below 3 bar, the text disappears and the burner

is activated.

In order to go from a read-out to a technical

readout the Step key should be pressed for 5

seconds. This read-out can be selected if the user

requires a technical read out. In order to return to the

read-out the Step key must be pressed again for

5 seconds.

8.1 Central heating system

For filling the central heating installation you use the

filling and draining valve.

Filling is done as follows:

- Plug the unit plug into the wall socket and leave the

operating lamps off;

- Connect the filling hose to the cold water tap and let

it fill with water;

- Connect the filled filling hose to the filling and

draining valve and open this valve;

- Open the cold water tap and fill the installation

slowly;

- The unit has an automatic vent which removes the

air which is present;

- Start venting the radiators and pipes at the lowest

point;

- Bring the installation to pressure (1.5 to 2 bar) after

all radiators and pipes have been vented;

- Close the cold water tap and the filling and draining

valve;

- Activate the automatic venting program by pressing

the pump key which means the pump lamp will be

lit. Allow the control to finish its venting program. The

pump will circulate a number of times around the

boiler as well as the central heating installation.

Also, if a three-way valve, if present, this will be

adjusted to the boiler and central heating installation

a number of times. The pump will be stopped

regularly in order to allow possible present air to

escape.

- Check the water pressure and if required top up. The

working pressure in the installation should be between 1.5 and 2 bar in cold state.

- After finishing the automatic venting program the key

can be switched off again.

It can take a while before all air has disappeared from a filled installation. Especially

in the first week noises can be heard which

indicate the presence of air. The automatic air

vent in the unit will make this air disappear, by

which means the water pressure can reduce

during this period and therefore topping up

with water will have to be done.

8.2 Hot water supply

Apply the water pipe pressure to the calorifier (open

main valve and/or stop valve of the inlet combination

valve).

Vent the calorifier and the hot water installation by

opening a hot water tap. Leave the tap open for as long

as required until all air has disappeared from the

calorifier and the pipes and only water is flowing from the

tap.

Page 16

Installation instructions S-HR series page 16

9 Putting the unit into operation

Before putting the unit into operation make sure, that the

unit and the installation are well vented. Vent the gas

pipe and open the gas valve for the unit. The unit does

not require adjustment of burner pressure and air

quantity because it is self-adjusting and is factory-set at

the correct value.

9.1 Central Heating system

Provided there is a heat requirement from the

thermostat or control, the central heating program will

be put into operation by means of the

key (central

heating program). The circulation pump will start

circulating and the unit will start the burner.

9.2 Hot water supply

Provided there is a heat requirement from the boiler the

hot water program will be put into operation by means of

the key (hot water program).

9.3 Adjustments

In the Control Tower a number of adjustments can be

made. These adjustments can be fed in easily by means

of the keys on the unit. However, a distinction is made

between adjustments which are done by the user and

adjustments done by the installer.

At users level adjustments can only be made from the

technical read-out in other words from the display readout with the operating function and the water

temperature. Adjustments can not be made from the

indication.

The next two chapters are accessible after pressing the

Mode key:

Chapter 1

The normal operating functions such as the simple

read out or the technical with the

read out.

Chapter 2

The chapter in which adjustments can be made.

Page 17

Installation instructions S-HR series page 17

User adjustments

To switch from the

level to the opera-ting

status level with the read out of the operating

functions , the water tempe-rature and

the water pressure , the following acts

must be carried out. From the display read-out,

press the Step key for 5 seconds after which the

operating status and the water temperature will

be shown for 8 seconds and the water pressure

for 2 seconds. If, after this, the Mode key is

pressed briefly the adjustments chapter is

displayed by means of the text . By

pressing the Step key briefly the adjustment

facilities are shown. Adjustment of the fixed

value can be done by means of the + or the -

key. Confirmation of the new setting is done with

the Store key.

* Brain thermostat

Most of the adjustments which are stated in

tables 6 and 7 are unnecessary when in

combination with the Brain and will be taken

care of by the Brain itself and do not have to

be adjusted. Most of the data in table 8 can be

requested by the Brain. For further

information with regard to the Brain

thermostat we refer to the Brain thermostat

installation manual.

In order to gain access to the adjustments at

installers level the entrance code has to be fed

in first. For this the following operations have to

be carried out.

Press the Mode key for 5 seconds. The text

is shown, after which a random number

appears on the display. By means of the + or the

- key the code can be fed in. After

pressing the Store key the code is confirmed.

With this entrance to the installers level is given.

The next chapters are shown after pressing the

Mode key:

Chapter 3

The chapter where information can be retrieved.

Chapter 4

The chapter in which adjustments can be made

for service purposes.

Chapter 5

The chapter in which error data can be retrieved.

user adjustment possibilities table 6

stnemtsujdaretemarapresU

petS noitpircsed yrotcaf egnar

1

gnitaehlartnec.pmetretawwolfmumixamC°58C°09-02

2

metsysgnitaehlartnecfoepyt104-1

10

srotcevnoc;gnitaehria;srotaidar

retawwolfxamTC°58.motua

enilgnitaehrotcafK3.2.motua

tneidargnim/C°5.motua

laitnereffidraegC°6.motua

20

lanoitiddasagnitaehroolfrednurosaeraecafrusegralhtiwsrotaidar

gnitaeh

retawwolfxamTC°07.motua

enilgnitaehrotcafK8.1.motua

tneidargnim/C°5.motua

laitnereffidraegC°5.motua

30

gnitaehlanoitiddasasrotaidarhtiwgnitaehroolfrednu

retawwolfxamTC°06.motua

enilgnitaehrotcafK5.1.motua

tneidargnim/C°4.motua

laitnereffidraegC°4.motua

40

gnitaehroolfrednulluf

retawwolfxamTC°05.motua

enilgnitaehrotcafK0.1.motua

tneidargnim/C°3.motua

laitnereffidraegC°3.motua

*01

erutarepmetyadenilgnitaehtnemtsujdaenif05tot5-

*11

erutarepmetthginenilgnitaehtnemtsujdaenif05tot5-

32

erutarepmetytefastsorfC°3-C°01tot02-

13

rednilyclanoitiddafoerutarepmetffo-hctiws

reliobRH-Shtiw

C°36C°08-04

84

)06/15RH-S(yticapacpmupmuminim)%05(%52%001-52

Page 18

Installation instructions S-HR series page 18

Installers adjustments

Adjustments whereby technical knowledge is

required have been classified under the installers

level. Access to this level is obtained after feeding

in a code, after which adjustments for user and

installer are visible. For going to the Adjustments

Parameters chapter the Mode key should be

pressed once after which it is shown with the

text. Scrolling in the Parameter chapter can be done

by means of the Step key. Adjusting the fixed value

can be done by means of the + or the - key.

Confirming the new adjustment is done with the

Store key.

Information chapter.

After feeding in the access code the information

can be read out according to table 8. In order to

select the information chapter the Mode key must

be pressed twice after feeding in the code. New

adjustments can not be done in this chapter.

Scrawling in the information chapter is possible by

means of the Step key.

installer adjustment possibilities table 7

rellatsnistnemtsujdaretemarapartxE

petS noitpircsed yrotcaf egnar

3

Wknignitaehlartnecrewopxammumixamxam-nim

*4

elpicnirplortnoc

tatsomrehtffo/nohtiw

01-0

0

tatsomrehtffo/no%001

1

tnednepedrehtaewffo/no%001

*5

rotcafKenilgnitaeh3.25.3-2.0

*6

tnenopxeenilgnitaeh4.14.1-1.1

*7

enozetamilcenilgnitaeh01-0-02-

*41

deepstneidarg751-0

*51

noitcuderthginretfaretsoob01fo0

0

on

1

sey

63

evlavyaw-eerhtfoepyt03-0

0

0102CV

1

gnitaludom0496CV

34

Wkniretawtohrewoprewopxammumixamxam-nim

94

yticapacpmupxam

gnitaehlartnec

%001%001-04

98

ecafretnignittessserdda07-1-

1-

eraps

0

niarB

7-0

edacsaCni8-1reliob

installer information possibilities table 8

rellatsniedomnoitamrofnI

petS noitpircsed eulav

1

1TerutarepmetretawwolfC°

4

2TerutarepmetretawnruterC°

5

3TerutarepmetretawreifirolacC°

7

4TerutarepmetedistuoC°

8

5TerutarepmetsageulfC°

61

%nirewoptneserp%

71

WknirewoptneserpWk

81

WknidaoltneserpWk

02

noitacinummocsublortnoc

12

latotnoitpmusnocJGJG

22

gnitaehlartnecnoitpmusnocJGJG

32

retawtohnoitpmusnocJGJG

42

sruohnurrenrubforebmunlatotruoh

52

gnitaehlartnecsruohnurrenrubforebmunruoh

62

retawtohsruohnurrenrubforebmunruoh

23

retnuocsruohforebmunlatotruoh

64

deriuqerecivressisruohynamwohnihtiwruoh

Page 19

Installation instructions S-HR series page 19

Service chapter.

After the access code has been fed in it is possible to

temporarily manually adjust the number of revolutions

of the fan in the service chapter (table 9). In order to

select the service chapter the Mode key has to be

pressed 3 X after feeding in the access code. By means

of the Step key the first function is displayed with the text

Off. By means of the + or - key a required number of

revolutions for the fan can be selected while the unit is

operating.

With Step 4 it is possible to activate the showroom

position by pressing the + key after which the text on

appears in the display.

After this a simulated water pressure of 1.9 bar and a

water temperature will be indicated. Pump or burner

action is not possible. After a voltage interruption or a

reset the showroom position is switched off.

Error chapter.

After the access code has been fed in the Error chapter

can be read (table 10). In order to select the Error

chapter it is necessary to press the Mode key 4 X after

feeding in the access code. By means of the Step key

the functions are shown which were stored when the

unit went into an error state. The first error which is

shown is the last, the next error is the second last, etc.

In order to return to the normal technical read out

whereby the water temperature and water pressure are

shown, the Standby chapter must be requested by

means of the Mode key. After a few seconds the text

standby will be replaced by the technical read-out.

Other wise returning to the Good read-out

automatically occurs after 20 minutes in the event that

no more keys have been used.

Green key function

The green key function can be used in order to activate

the factory settings. By this means the modified settings

are cancelled. The following actions must be carried

out. Make sure that chapter is shown in the

display by means of the Mode key. After this press the

Store key. The word Copy becomes visible and the

factory settings will be active again.

installer service possibilities table 9

installer error possibilities table 10

rellatsniedomrorrE

petS noitpircsed eulav

1

rebmunrorre

2

tinusutatsgnitarepo

3

1TerutarepmetretawwolfC°

4

2TerutarepmetretawnruterC°

5

daolWk

6

yticapacpmup%

rellatsniedomecivreS

petS noitpircsed

1

nonoitcnufrenrubhtiwnoitareponireliob

2

fforenrubdnaelbatsujdanaf

3

norenrubhtiwelbatsujdapmup

4

evitcanon=FFOdnaevitca=NOnoitisopmoorwohs

Page 20

Installation instructions S-HR series page 20

10 Switching off the unit

In some situations it may be that the entire unit must be

switched off. By switching off the three keys with the

lamps for central heating, hot water and pump program,

the unit is switched off. STREBEL advise to leave the

plug in the wall socket, by which means the circulation

pump and the three-way valve are activated once every

24 hours in order to prevent jamming.

In the event of frost danger it is advisable to

drain the unit and/or the installation.

11 Commissioning and

maintenance

The top of the casing is hooked behind a locking edge

and is locked behind the door on the front of the casing

with a screw. After removing this screw the casing must

be lifted at the bottom by which means it is released from

the locking edge. Then the casing can be removed

forward.

With the S-HR settings such as burner pressure and

adjustment of the air quantity are unnecessary, due to

the fact that the unit operates with a so-called zero

pressure control. By this means the correct gas quantity

is controlled by the suction operation of the fan. The fine

adjustment which is carried out at the factory is onceonly, which means that adjusting of these values is

unnecessary.

11.1 Checking for contamination

In order to be able to check the unit for contamination in

the following running years it is advisable to measure

the maximum air displacement in the unit when putting

the unit into operation. This value can be different with

each type of unit.

In order to be able to measure this value the following

operations must be carried out:

- in order to enter the service chapter feed in the

access code as described on page 18;

- select the manual fan setting without burner action

Step , by means of the Step key which will

indicate that the fan is off ;

- connect the digital pressure gauge hose to the

uppermost measuring nipple of the gas block

according to figure 12 (open it before fitting the

hose);

- take the fan to its maximum number of revolutions by

means of the + key;

- measure the pressure difference and write down this

value;

- when next servicing the unit the value of the fan

output may not have reduced by more that 20%

compared to the value during commissioning. If this

value is lower than 20% the unit does not require

maintenance.

11.2 Checking of the zero pressure control

The zero pressure control is set at the factory. This can

be checked by means of the following action;

- make sure that the unit is in operation and that it can

discharge the heat which it produces;

- in order to enter the service chapter feed in the

access code as described on page 18;

- select the manual fan adjustment with burner action

Step by means of the Step key, which will

indicate that the manual operation is off ;

measuring point air pressure difference figure 12

Page 21

Installation instructions S-HR series page 21

- connect the digital pressure gauge hose to the

uppermost measuring nipple of the gas block

according to figure 13;

- activate the manual control by briefly pressing the

- key;

- take the fan to minimum load by means of the - key,

after which the measured pressure difference must

be between 0 and -4 Pa ;

- ending the manual selection is done by pressing the

- key until the minimum load is displayed. After

pressing this key again the text

is shown

which means that the manual selection is off.

If it is determined that the zero pressure control deviates

too much, then it can be corrected by means of the

adjustment screw on the gas block.

- place the lance of the CO

2

gauge in the location

according to figure 14;

- adjust to maximum load by means of the + key;

- ending the manual selection is done by pressing the

- key until the minimum load is shown. After

pressing this key again the text

is shown

which means that the selection is off.

11.3 Checking the CO

2

The CO2 percentage is factory-set. This can be checked

by means of the following actions:

- put the unit into operation by means of the service

chapter as described in chapter 11.2;

- adjust the CO2 percentage according to table 11.

The CO2 percentage can be adjusted by means of

the adjustment screw according to figure 15.

adjustment screw zero pressure control figure 13

measuring point for CO

2

figure 14

adjustment screw CO

2

figure 15

Page 22

Installation instructions S-HR series page 22

11.4 Maintenance

If it is necessary to clean the unit the following actions to

the following components must be carried out:

The air unit

Dirt which is sucked in by the air supply pipe will end up

in the bottom of the air box. This dirt can be cleaned with

a cloth with a simple (non-abrasive) cleaning agent.

Do not use an abrasive agent for cleaning,

this causes disturbing scratches in the air

box.

The burner ceramic bricks and heat exchanger

These components should only be cleaned if it is

determined that the maximum Pa is no longer obtained

as described in chapter 12.1.

The fan unit must be removed in order to be able to

inspect the heat exchanger. In this case the following

actions must be carried out:

- close the gas valve and isolate the units electrical

supply;

- turn the Control Tower forward around its left hinge

point and remove the plastic air box;

- loosen the nut of the gas pipe under the gas block;

- loosen the small crosshead screw on the red

electrical connection adaptor of the gas block;

- remove the electrical connection plug from the fan

motor;

- loosen the front crosshead screw of the black plastic

air inlet damper;

- after this turn the two clamping rods ¼ turn and

remove them by pulling them forward;

- slightly lift the fan unit and remove it towards the front

of the heat exchanger;

- the fan unit and the air inlet damper can be checked

for contamination and if necessary cleaned;

- now remove the burner ceramic bricks by slightly

lifting them upward and removing them in the same

direction as the heat exchanger fan unit;

- the burner ceramic bricks and the heat exchanger

can be cleaned by means of a soft brush;

Refitting of the components is done in reverse.

The following components require extra attention

before and after refitting:

- make sure that the gasket for the ceramic bricks is

fitted onto the heat exchanger precisely;

- make sure that the fan unit clamping rods have been

pushed backward sufficiently and that they have

again been turned ¼ turn;

- make sure that the gas connection under the gas

block is tightened;

The waste trap

In order to check the waste trap for contamination the

following actions must be carried out:

- make sure that the unit is off by isolating the units

electrical supply;

- turn the Control Tower forward around its left hinge

point;

- turn the waste trap cup to the left until it is released

from the screw thread;

Do not use pliers or wrenches for removing

the waste trap cup

Refitting is done in reverse order.

11.5 Further checks

Checking the ionisation current.

- ionisation determines if there is a flame present with

correct combustion. The measurement is done by

means of connecting a Micro ampere gauge in

series with the ionisation thread. The minimum

allowed ionisation is 2 µA. The unit will modify its load

anyway if the ionisation reaches the bottom limit of 2

µA.

Checking by means of a visual inspection.

- A visual inspection entails viewing and checking of a

number of components with regard to their

functioning.

The safety valve may not show any traces of leaks.

The waste trap should be clean.

The central heating water filter only requires

cleaning if the circulation pump is adjusted at maximum speed and the maximum DT is exceeded.

11.6 The frequency of maintenance

STREBEL advise to carry out an inspection to the unit

every two years and an overhaul every four years. When

doing this the circumstances of the units location must

be taken into account, From this one can determine

whether to deviate from this advice.

Page 23

Installation instructions S-HR series page 23

12 Technical specifications

unit specifications table 11

epytecnailppa

RH-S

51

RH-S

42

RH-S

T42

RH-S

53

RH-S

T53

RH-S

15

RH-S

T15

RH-S

06

)sH(tupni

Wk0,510,420,420,530,530,150,150,06

)iH(tupni

Wk5,316,126,125,135,139,549,540,45

)C°06/08yticapac(egnarnoitaludom

Wk3,31-5,32,12-5,32,12-5,39,03-9,49,03-9,40,54-8,80,54-8,89,25-8,8

)C°03/05yticapac(egnarnoitaludom

Wk4,41-9,30,32-9,30,32-9,36,33-3,56,33-3,59,44-5,99,44-5,92,75-5,9

)daollluftaC°06/08(ycneiciffe

%8989898989898989

)daollluftaC°03/05(ycneiciffe

%701701701701701601601601

776NEhtiwecnadroccaniycneiciffe

%901901901901901901901901

xONfonoissimeylraey

mpp2121212121212121

OCfonoissimeylraey

mpp1111111111111111

OC

2

%99999 5,95,95,9

)daollluftaC°06/08ta(erutarepmetsageulf

C°5656567676868686

)daolwoltaC°03/05ta(erutarepmetsageulf

C°1313131313131313

lortnocrenrub

noitaludomsselpets

02G)C°0/rabm3101ta(noitpmusnocsag

h/³m23,101,201,270,370,374,474,462,5

epytrenrub

cimareccimarecmaof

epyttnerruc

zH/V05/03205/03205/03205/03205/03205/03205/03205/032

dedrocerrewopcirtcelemumixam

W221221221541541091091091

dedrocerrewopcirtceleybdnats

W55555555

92506NEotgnidroccanoitcetorpfoeerged

04PI04PI04PI04PI04PI04PI04PI04PI

)ten(thgiew

gk0505373567366836

desab-HCyticapacretaw

l5,35,35,3 55777

desab-WHDyticapacretaw

l414131

HCemitnurrevopmup

nim5151515151515151

WHDemitnurrevopmup

nim 111

muminimerusserpretaw

rab11111111

mumixamerusserpretaw

rab33333333

erutarepmetretawwolfmumixam

C°0909090909090909

C°06taetarwolfpat

nim/l65,85,21

C°54taetarwolfpat

nim/l5,85,215,71

epytpmup

oliW

SRA

07/52

SRA

07/52

SRA

07/52

SRA

07/52

SRA

07/52

SRA

57/52

SRA

57/52

SRA

57/52

daehpmupelbaliava

aPk5352520202020221

tnetnoclessevnoisnapxe

l2121

erusserp-erplessevnoisnapxe

rab11

Page 24

Installation instructions S-HR series page 24

G gas pipe

A flow connection central heating

R return connection central heating

C condensation pipe

E expansion tank pipe (S-HR-T)

K cold water pipe (S-HR-T)

W hot water pipe (S-HR-T)

T1 flow sensor

T2 return sensor

T3 calorifier sensor HWS (S-HR-T)

T5 flue gas sensor (if fitted)

P1 water pressure sensor

13 Diagram showing various parts of the unit

unit diagram figure 16

GAR CE KW

T1

T2

P1

10

11

12

13

2

1

8

14

4

5

3

T5

6

7

18

T3

16

15

9

17

Page 25

Installation instructions S-HR series page 25

P1 4T12 13195187 6 T3920

T2 C 11 E K13 14 15 16 17WG21 A10 RT5

1 heat exchanger

2 ignition unit

3 fan unit

4 air inlet damper

5 gas block

6 safety valve

7 automatic air vent

8 ceramic burner bricks

9 calorifier HWS (S-HR-T)

10 operating panel

unit description figure 17

11 Control Tower

12 water filter return central heating

13 three-way valve (S-HR-T)

14 circulation pump

15 inlet combination valve (S-HR-T)

16 safety valve (S-HR-T)

17 thermostatic mixing valve (S-HR-T)

18 flue gas discharge

19 combustion air supply

20 air unit

21 type plate

Page 26

Installation instructions S-HR series page 26

1 STREBEL S-HR unit

2 expansion tank

3 outside sensor ARV1205U

4 drain points

5 Brain thermostat AA1RT15G

14 Example diagrams for connecting the unit

14.1 Radiator installation without thermostat valves

connecting of the unit to a radiator installation without thermostat valves figure 18

1

2

3

4

5

Page 27

Installation instructions S-HR series page 27

1 STREBEL S-HR unit

2 expansion tank

3 outside sensor ARV1205U

4 drain points

5 Brain thermostat AA1RT15G

6 by-pass

tra thermostatic radiator valve

14.2 radiator installation with thermostat valves only

connecting of the unit to a radiator installation with thermostat valves only figure 19

1

2

3

4

5

6

Page 28

Installation instructions S-HR series page 28

14.3 radiator installation with an under floor heating zone

connecting of the unit to a radiator zone and an underfloor heating zone figure 20

1

2

3

4

5

6

7

8

9

10

11

12

13

1 STREBEL SUPER HR unit

2 expansion tank

3 outside sensor ARV1205U

4 drain points

5 Brain thermostat AA1RT15G

6 underfloor heating

7 2-core sleeve cable

8 zone controller AA1RR15G

9 zone three-way valve

10 zone pump

11 zone non return valve

12 zone flow sensor

13 adjustment valve

Page 29

Installation instructions S-HR series page 29

14.4 radiator installation and an independent underfloor heating zone

connecting of the unit to a radiator installation and an independently controlled underfloor heating zone figure 21

1

2

3

4

5

6

7

8

9

10

11

12

14

13

1 STREBEL S-HR unit

2 expansion tank

3 outside sensor ARV1205U

4 drain points

5 Brain thermostat Master AA1RT15G

6 underfloor heating

7 2-core sleeve cable

8 group controller AA1RR15G

9 three-way valve group controller

10 pump group controller

11 return valve group controller

12 flow sensor group controller

13 adjustment valve

14 Brain thermostat zone controller AA1RT15G

Page 30

Installation instructions S-HR series page 30

14.5 two independent radiator zones

connecting of the unit to two independently controlled radiator zones figure 22

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1 STREBEL S-HR unit

2 expansion tank

3 outside sensor ARV1205U

4 draining possibility

5 Brain thermostat Master AA1RT15G

6 2-core sleeve cable

7 group controller AA1RR15G

8 three-way valve group controller

9 pump group controller

10 return valve group controller

11 flow sensor group controller

12 Brain thermostat group AA1RT15G

13 adjustment valve

14 low velocity header

Page 31

Installation instructions S-HR series page 31

15 Error indication

A detected error is indicated on the display by means of blocking or error messages. A distinction should be made

between these two messages due to the fact that blocking can be of a temporary nature, however, error messages

are fixed lockings. The control will try its utmost to prevent locking and will temporarily switch off the unit by blocking

it. Hereunder is a list of some messages.

Blocks with a number in the last 2 positions.

Block 01:

External safety contact cut off

Block 11:

Maximum DT of flow and return sensor in central heating has repeatedly been exceeded. During the

block normal operation of the hot water supply is possible. The pump continues to operate at minimum

capacity during the block.

Block 12:

Maximum DT of flow and return sensor in domestic hot water has repeatedly been exceeded. During

the block normal operation of the central heating installation is possible. During the block the pump

continues to operate at minimum capacity.

Block 60:

Incorrect parameter setting of the minimum or maximum power.

Block 67:

A DT has been detected between flow and return sensor whereas the burner is not in operation. After

the DT has disappeared the block will disappear.

Block 80:

Maximum flue gas temperature has been exceeded (if present). The block will not be cancelled until

the flue gas temperature has arrived below the temperature.

Block 81:

The flue gas sensor is not connected although it was connected to the control. The burner is blocked

until the flue gas sensor is reconnected.

Block 82:

The flue gas sensor has short-circuited, heat requirement blocked and pump capacity at minimum.

Block 85:

The control has not detected a water flow. The venting cycle is started. If during this cycle water flow

is detected, the venting cycle is ended and the burner is released.

Error with a number in the last two positions.

Error 00: Poor flame-forming

Error 01: short-circuit of 24 volt circuit

Error 02: no flame-forming

Error 04: adjustment or error for voltage interruption

Error 05: adjustment

Error 12: fuse 24 volt/3AT faulty

Error 18: maximum flow temperature exceeded

Error 19: maximum return temperature exceeded

Error 28: number of revolutions not reported back from fan

Error 69: no or incorrect display

Error 80: maximum flue gas sensor temperature exceeded

Page 32

This renewed publication cancels all previous installation instructions.

The company reserves the right to change the specifications and dimensions without prior notice

E. & O. E.

Page 33

central

heating

progr. on / off

hot water

progr.

on / off

pump progr.

on / off

Reset key

Step key

display

Explanations of symbols and signs on the

Control Tower display.

0

1

2

No heat requirement

Ventilation phase

Ignition phase

Burner active on central heating

Burner active on hot water

Fan check

Burner off when room thermostat is demanding

Pump overrun phase for central heating

Pump overrun phase for hot water

Burner off because of too high flow water temperature

Automatic venting programme

3

4

5

6

7

8

9

A

Water pressure is too low (<1,0 bar), flashing FILL will be

altered with indication of water pressure, unit power of 50% is

possible. The installation needs to be topped up.

Water pressure is too low (<0,7 bar), FILL indication remains

continuously visible, the unit is taken out of operation. The

installation needs to be topped up.

Water pressure is too high (>3,5 bar), HIGH indication remains

continuously visible, the unit is taken out of operation. The

installation pressure needs to be decreased by draining water.

Operation indication (in the first display position)

Mode key ~ Selecting chapters

Step key ~ Scrolling in a chapter

Reset key ~ Unlocking the unit in case of error

Mode key

STREBEL LTD.

1F, Albany park industrial estate

frimley road, camberley

surrey GU15 2PL

Telephone: (01276) 685422

Fax: (01276) 685405

Loading...

Loading...