Strebel S-HR 15, S-HR 24, S-HR 24T, S-HR 35, S-HR 35T Installation Instructions Manual

...

INSTALLATION INSTRUCTIONS

8G.51.21.01/11.99 changes reserved

Installation instructions S-HR series page 3

S-HR 15 S-HR 24/24T S-HR 35/35T S-HR 51/51T S-HR 60

Contents page

1 Description of the unit ................................................................................................................... 4

2 Scope of the delivery ..................................................................................................................... 4

3 Mounting of the unit ....................................................................................................................... 4

3.1 Dimensions ......................................................................................................................... 5

4 Connecting the unit ....................................................................................................................... 6

4.1 Central heating system .......................................................................................................7

4.2 Expansion tank.................................................................................................................... 8

4.3 Underfloor heating systems............................................................................................... 10

4.4 Gas pipe ............................................................................................................................ 10

4.5 Hot water supply (S-HR-T) ................................................................................................ 10

4.6 Condensation discharge pipe ............................................................................................ 10

4.7 Flue gas exhaust system and air supply system ............................................................... 11

5 External calorifiers ....................................................................................................................... 12

6 Electrical connection ................................................................................................................... 12

7 Control of the unit ........................................................................................................................ 14

7.1 Explanation of the function keys........................................................................................ 14

8 Filling and venting of unit and installation .................................................................................... 15

8.1 Central heating system ..................................................................................................... 15

8.2 Hot water supply ............................................................................................................... 15

9 Putting the unit into operation...................................................................................................... 16

9.1 Central Heating system ..................................................................................................... 16

9.2 Hot water supply ............................................................................................................... 16

9.3 Adjustments ...................................................................................................................... 16

10 Switching off the unit ................................................................................................................... 20

11 Commissioning and maintenance ............................................................................................... 20

11.1 Checking for contamination ............................................................................................... 20

11.2 Checking of the zero pressure control ............................................................................... 20

11.3 Checking the CO2 .............................................................................................................. 21

11.4 Maintenance...................................................................................................................... 22

11.5 Further checks .................................................................................................................. 22

11.6 The frequency of maintenance .......................................................................................... 22

12 Technical specifications .............................................................................................................. 23

13 Diagram showing various parts of the unit .................................................................................. 24

14 Example diagrams for connecting the unit .................................................................................. 26

14.1 Radiator installation without thermostat valves ................................................................. 26

14.2 radiator installation with thermostat valves only ................................................................ 27

14.3 radiator installation with an under floor heating zone ........................................................ 28

14.4 radiator installation and an independent underfloor heating zone ..................................... 29

14.5 two independent radiator zones ........................................................................................ 30

15 Error indication ............................................................................................................................ 31

Installation instructions S-HR series page 4

1 Description of the unit

The STREBEL S-HR Boiler is a room sealed,

condensating and modulating central heating unit, with

or without an integrated hot water facility.

The built-in fan sucks the combustion air from outside

and provides full premixing of the gas and air. The gas

mixture is guided through the ceramic burner which is

fitted above the heat exchanger. As a result of the small

flame height a compact construction is possible. The

combustion gasses are exhausted after passing

through the stainless steel heat exchanger. The formed

condensation water is discharged through the waste

trap.

The unit has been tested according to valid CE*

standards and has a CE* certificate.

The operating efficiency of the unit is higher than 98%

(on top value). As a result of its compact construction the

radiation, convection and stand by losses are very low.

The emission of damaging substances is far below the

standard set for equipment with the gas quality-control

label for clean combustion.

The unit is provided with an automatic venting program.

In case of a recently topped up or filled up installation

this program takes care of the removal of any present

air. In this case the control will check the water pressure

and if it is too low, will report this on the display.

The unit anticipates the heat requirement of the central

heating installation or the hot water supply. As a result

the unit will adjust its capacity to the installation and will

switch on less often, which means that the unit will

operate longer and at a low level. It is possible that the

unit will only have to switch on once an hour. In this case

the aim is to obtain maximum comfort and efficiency.

In order to be able to anticipate installation noises the

unit has a so-called gradient control. After the unit goes

into operation this control provides a uniform increase of

power, instead of immediately burning at full power.

When the installation does require full power the control

will adjust as required. By this means a uniform increase

of the water temperature is effected.

If an outside sensor is connected, the control can

operate weather-dependent. This means that the

control measures the outside temperature and the flow

water temperature. On the basis of this data the control

calculates the optimal flow water temperature in the

installation.

The S-HR-T combination unit provides a hot water

supply by means of a high output calorifier fitted on the

right hand side of the unit. An adjustable thermostatic

mixing valve is fitted which provides a constant hot

water temperature (60

°

C factory setting).

2 Scope of the delivery

The unit is supplied ready for use. The supply kit is

composed as follows:

- Unit with casing;

- Automatic vent (inside the unit);

- Safety valve (inside the unit);

- Inlet combination and safety valve (only with S-HRT units);

- Suspension bracket

- Filling and draining valve with T-piece;

- Fixing material consisting of plugs and screws;

- Template on the package wrapper;

- Installation instructions

- Operating manual;

- Installation and user card.

3 Mounting of the unit

The unit can be mounted practically to every wall with

the mounting bracket and the included fixingequipment.

The wall must be flat and of sufficient strength in order

to be able to carry the unit weight.

Above the unit there must be at least 250 mm working

space in order to be able to fit a twin supply and exhaust

system or 500mm when fitting a horizontal coaxial flue

system. On the left side of the unit at least 50 mm and

on the right side 10 mm must be reserved in connection

with fitting or removing of the casing. The location of the

unit can be determined by using the template on the

inside of the wrapper.

Installation instructions S-HR series page 5

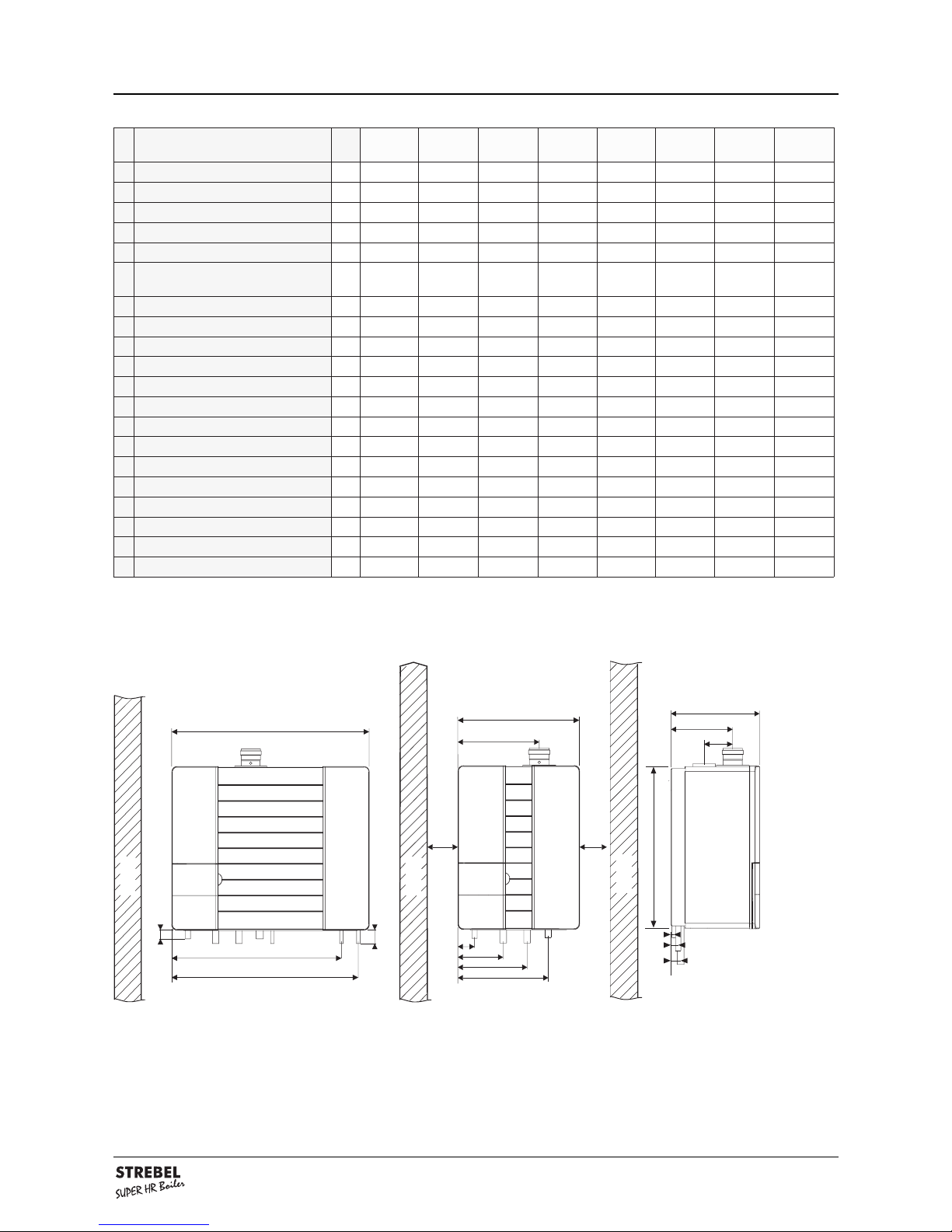

3.1 Dimensions

Dimensions (in mm) figure 1

wall

C

E

F

A

U

T

S

wall

B

M

N

P

Q

R

B

wall

D

H

J

K

1050

G

Dimensions table 1

tinufoepyt

RH-S

51

RH-S

42

RH-S

T42

RH-S

53

RH-S

T53

RH-S

15

RH-S

T15

RH-S

06

A thgieh

mm086086086086086086086086

B htdiw

mm0050050480050480660001066

C htped

mm073073073073073073073073

D tsuahxesageulf/edistfel

mm533533533533533594594594

E

tsuahxesageulf/ertnecotertnec

ylppusdna

mm021021021021021021021021

F tsuahxesageulf/kcab

mm072072072072072072072072

G epipsag/edistfel

mm5656565656565656

H epipwolf/edistfel

mm581581581581581581581581

J epipnruter/edistfel

mm582582582582582544544544

K epipnoitasnednoc/edistfel

mm073073073073073035035035

L epipknatnoisnapxe/edistfel

mm034034095

M epipretawdloc/edistfel

mm527527588

N epipretawtoh/edistfel

mm597597559

P *gfothgnelepip

mm8181818181818181

Q *kdnacfothgnelepip

mm0404040404040404

R *wdnae;r;afothgnelepip

mm0606060606060606

S *cepipfoertnec/kcab

mm5252525252525252

T *gepipfoertnec/kcab

mm0404040404040404

U *w;k;e;r;aepipfoertnec/kcab

mm0505050505050505

Installation instructions S-HR series page 6

4 Connecting the unit

The unit has the following connection pipes;

- The central heating pipes, hot and cold water pipes

can be connected to the installation by means of

compression fittings;

- The gas pipe of the unit is provided with a female

thread into which the tail piece of the gas valve can

be screwed;

- The condensation discharge pipe consist of an oval

24 mm plastic pipe. The discharge pipe can be connected to this by means of an open connection. If the

open connection is fitted in a different location, then

the pipe can be lengthened by means of a 32 mm

PVC sleeve;

- The flue gas exhaust system and air supply system

consist of 2 x 80 mm connections.

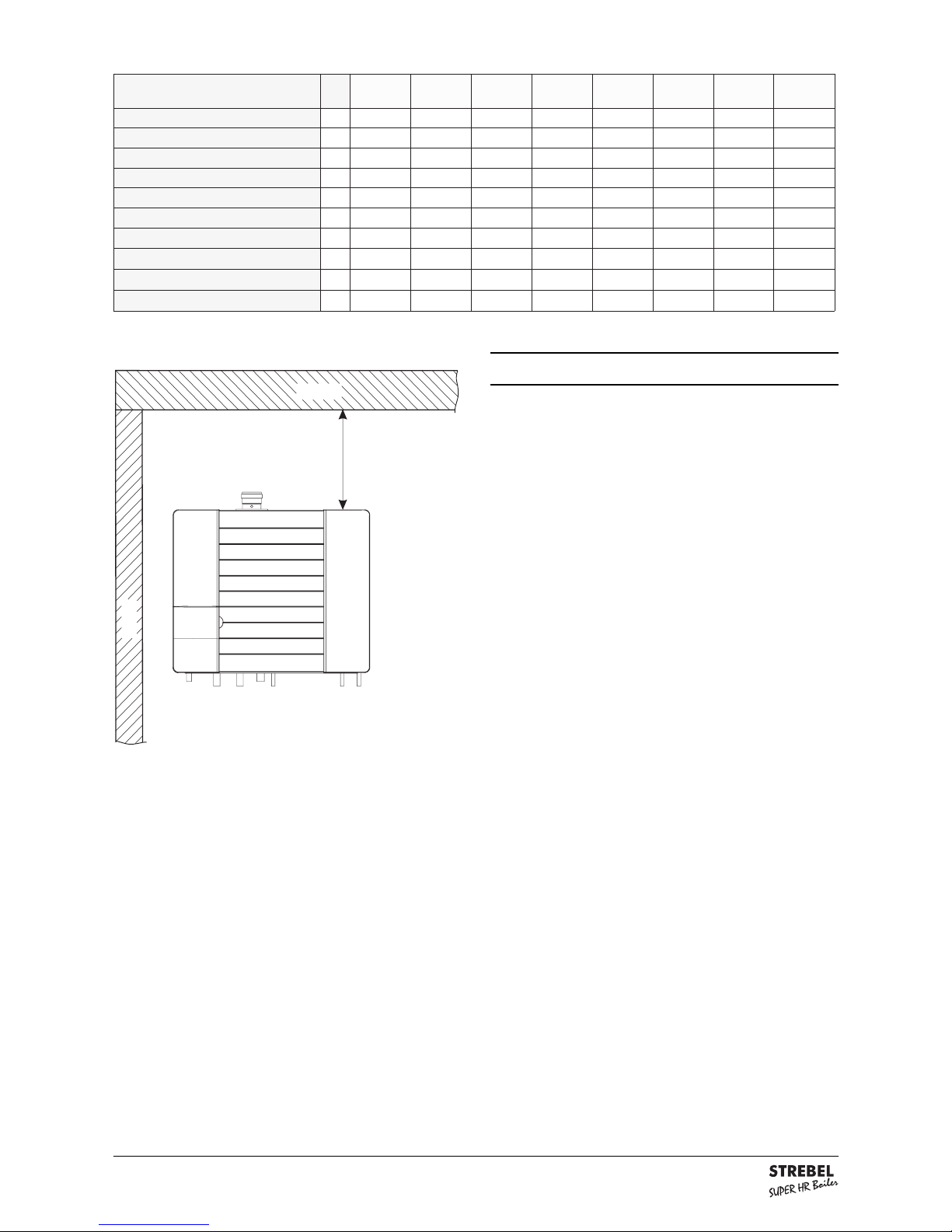

connection diameters table 2

unit pipes bottom figure 2

G A R C E K W

ceiling

wall

minimum

250 mm or

500 mm

tinufoepyt

RH-S

51

RH-S

42

RH-S

T42

RH-S

53

RH-S

T53

RH-S

15

RH-S

T15

RH-S

06

ylppusrianoitsubmoc

mm0808080808080808

tsuahxesageulf

mm0808080808080808

G-epipsag

edisni"½edisni"½edisni"½edisni"½edisni"½edisni"¾edisni"¾edisni"¾

A-epipwolfgnitaehlartnec

mm8282828282535353

R-epipnrutergnitaehlartnec

mm8282828282535353

C-epipegrahcsidnoitasnednoc

mm4242424242424242

E-epiplessevnoisnapxe

mm222222

K-epipretawdloc

mm515151

W-epipretawtoh

mm515151

Installation instructions S-HR series page 7

4.1 Central heating system

The unit pipes can be connected to the installation by

means of compression fittings. Reducers should be

used for connecting to thick-walled pipe (welded or

threaded).

When removing the plastic sealing caps from the pipes,

contaminated testing water can be released.

The unit has a self-adjusting and self-protecting control

system for the load and the pump capacity. By this means

the temperature difference between the supply and return

water is checked. The circulation pump will be able to

supply the given water displacement with an installation

resistance of up to 20 kPa, for this see table 3.

If an unacceptable temperature is detected, then the

control will repeatedly try to achieve water flow, and if

this does not work then the unit will switch off.

The S-HR 60 unit has a circulation pump which has a

residual suction head for the installation of 12 kPa. This

means that the unit can function normally in installations

which have an installation resistance of up to 12 kPa and

in cascade installations.

If the installation resistance is higher than 12 kPa, the

unit will automatically reduce in power.

If the capacity of the unit pump is insufficient, an extra

external pump can be installed in series with the unit.

The electrical side of this external circulation pump can

be connected in the Control Tower, by which means this

pump switches at the same times as the unit pump.

The maximum absorbed current consumption of the

external circulation pump may be 230 W (1 Amp).

Use with a low velocity header can also be selected. In

this case a larger secondary sided water output has to

be taken into account, in order to affect the height of the

water temperature.

If the installation resistance is higher than the stated

value the pump will rotate at maximum pump capacity

and the load will be adjusted until an acceptable

temperature difference between supply and return water has been obtained. If, after this, the temperature

difference remains too much then the unit will switch

itself off and wait until an acceptable temperature has

arisen.

available water flow at full load table 3

external installation pump in series figure 3

tinufoepyt etarwolfretaw

D C°02T

elbissimrep

ecnatsisernoitallatsni

nim/lh/laPkrabm

51RH-S

9.900653053

T42/42RH-S

1,5108952052

T53/53RH-S

1,22423102002

T15/15RH-S

1,23929102002

06RH-S

9,73172221021

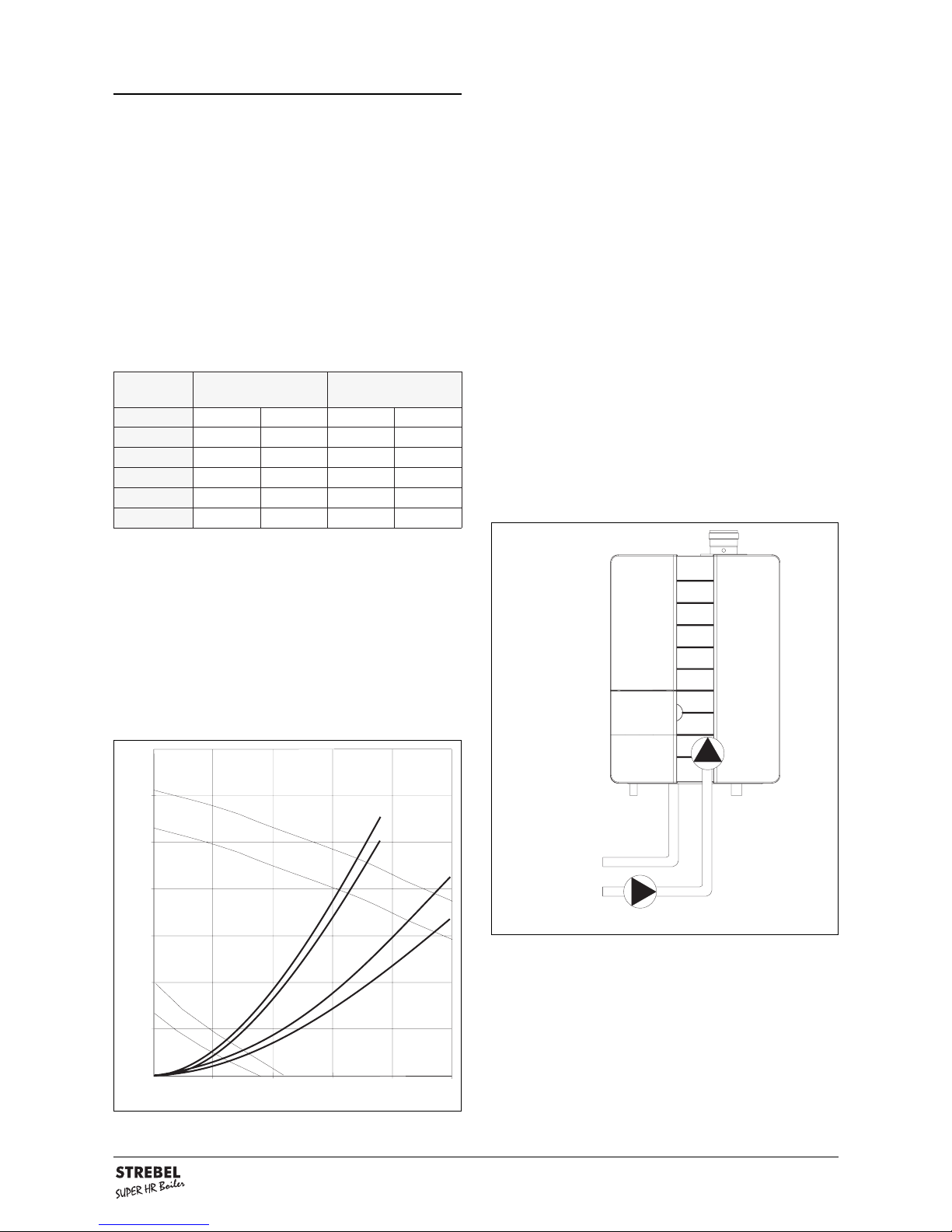

pump index lines graph 1

0 0,5 1 1,5 2 2,5

Q(m³/h)

7

6

5

4

3

2

1

0

H(m)

min (25%)

max (100%)

pump index line ARS 25-75

S-HR 15/24/35

S-HR 24T/35T

S-HR 51T

S-HR 51/60

pump index line ARS 25-70

Installation instructions S-HR series page 8

As standard the unit is provided with a water filter in the

return pipe of the unit. With this, possible contamination

of the central heating water is prevented from ending up

in the unit. The unit is also provided with an internal

safety valve set at 3 bar. This is connected to the

discharge construction to the waste together with the

condensation discharge.

If all, or a large part of the radiators are provided with

thermostatic radiator valves it is advisable to use a

pressure difference control (by pass) in order to prevent

flow problems in the installation.

The unit is designed to be used on sealed

system only.

Additives in the installation water are only

permitted in consultation with STREBEL

LTD.

When using more than one unit in an installation please

refer to the cascade installation instructions.

4.2 Expansion tank

All STREBEL S-HR-T units are provided with an

expansion tank on top of the calorifier. This expansion

tank is connected to the three-way valve and the

circulation pump. By this means the expansion water,

when functioning for the hot water supply, is prevented

from being shut off from the expansion tank when the

radiator thermostat valves are fully closed. A second

expansion tank in the installation is not a problem.

The STREBEL S-HR units are not equipped with an

expansion tank pipe. If a S-HR unit is combined with an

Comfort calorifier, the expansion tank connection is

included in the internal piping of the Comfort calorifier,

to which the expansion tank can be connected. If a

different calorifier is used then one has to take into

account that the expansion tank should be connected

between the three-way valve and the unit circulation

pump.

In connection with correct functioning of the

unit it is necessary for the expansion tank to

be connected to the expansion tank pipe of

the unit.

The expansion tank which is used should be geared to

the water content of the installation. The pre-pressure

depends on the installation height above the mounted

expansion tank.

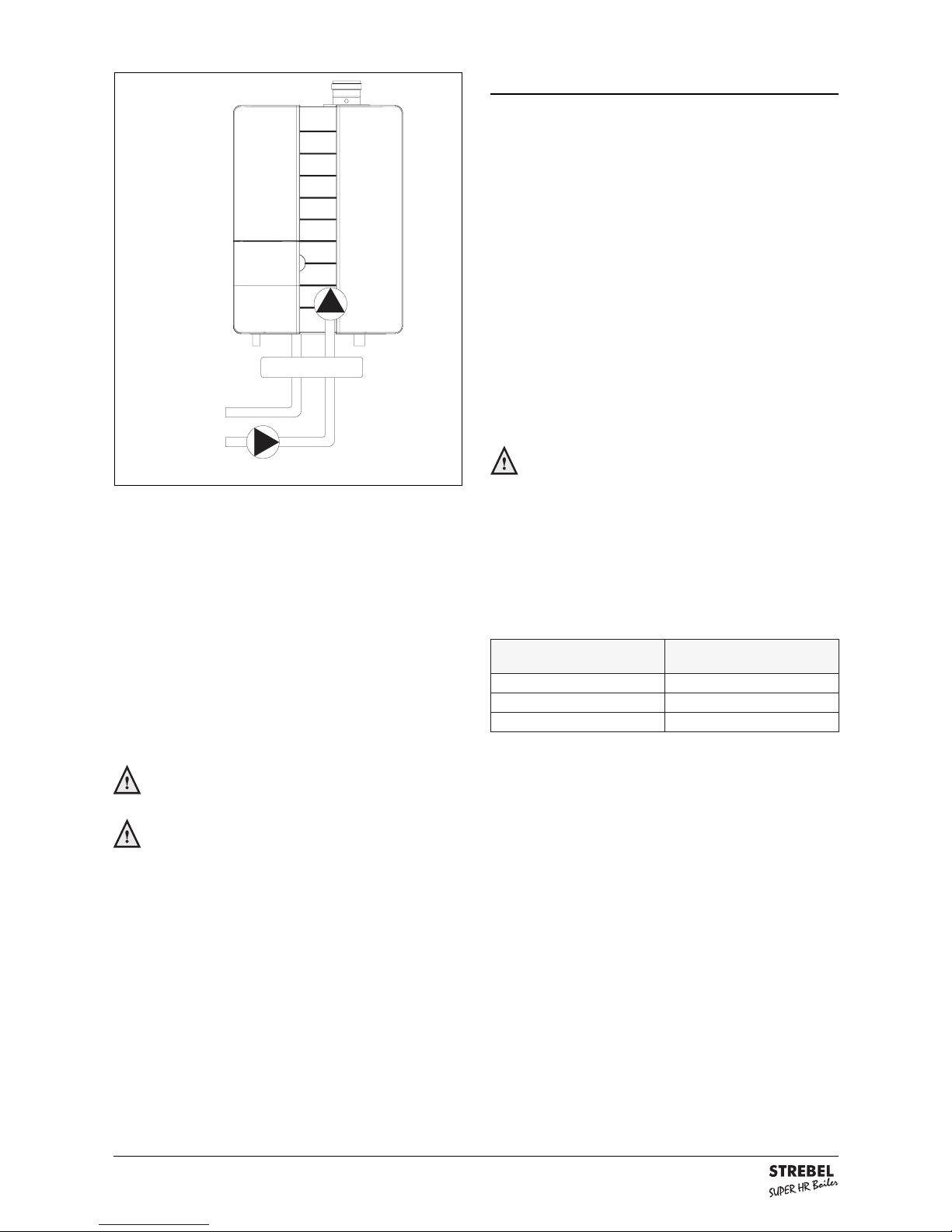

external installation pump with low velocity header figure 4

choice of expansion tank table 4

evobathgiehnoitallatsni

lessevnoisnapxeeht

ehtfoerusserp-erp

lessevnoisnapxe

m5rab5,0

m01rab0,1

m51rab5,1

Installation instructions S-HR series page 9

The STREBEL S-HR24 and S-HR35 units can be

provided with an expansion tank module. By this means

the external expansion tank is cancelled. This

expansion tank module is placed behind the S-HR unit,

by which means the expansion tank is not noticeable. If

the S-HR unit is provided with a STREBEL Comfort

calorifier the overall depth will be equal. The content of

the two expansion tanks is 20 litres. The pre-pressure is

1 bar.

The expansion tank module can be supplied with the

necessary pipes to connect with the S-HR unit. The

connecting pipes for the installation correspond with

those of the unit and have the same centre-to-centre

distance to the wall. When checking the expansion

tanks these are accessible via the left, right and upper

sides. From these sides the tanks are also removable

and the unit does not have to be dismantled.

The space which is required for mounting the expansion

tank module corresponds with the required space for

mounting a S-HR unit. The included template and

mounting strip for the S-HR unit can be used for the

expansion tank module. The S-HR unit is fitted on to this

after the expansion tank module has been mounted.

The necessary mounting strip for the unit is present on

the module.

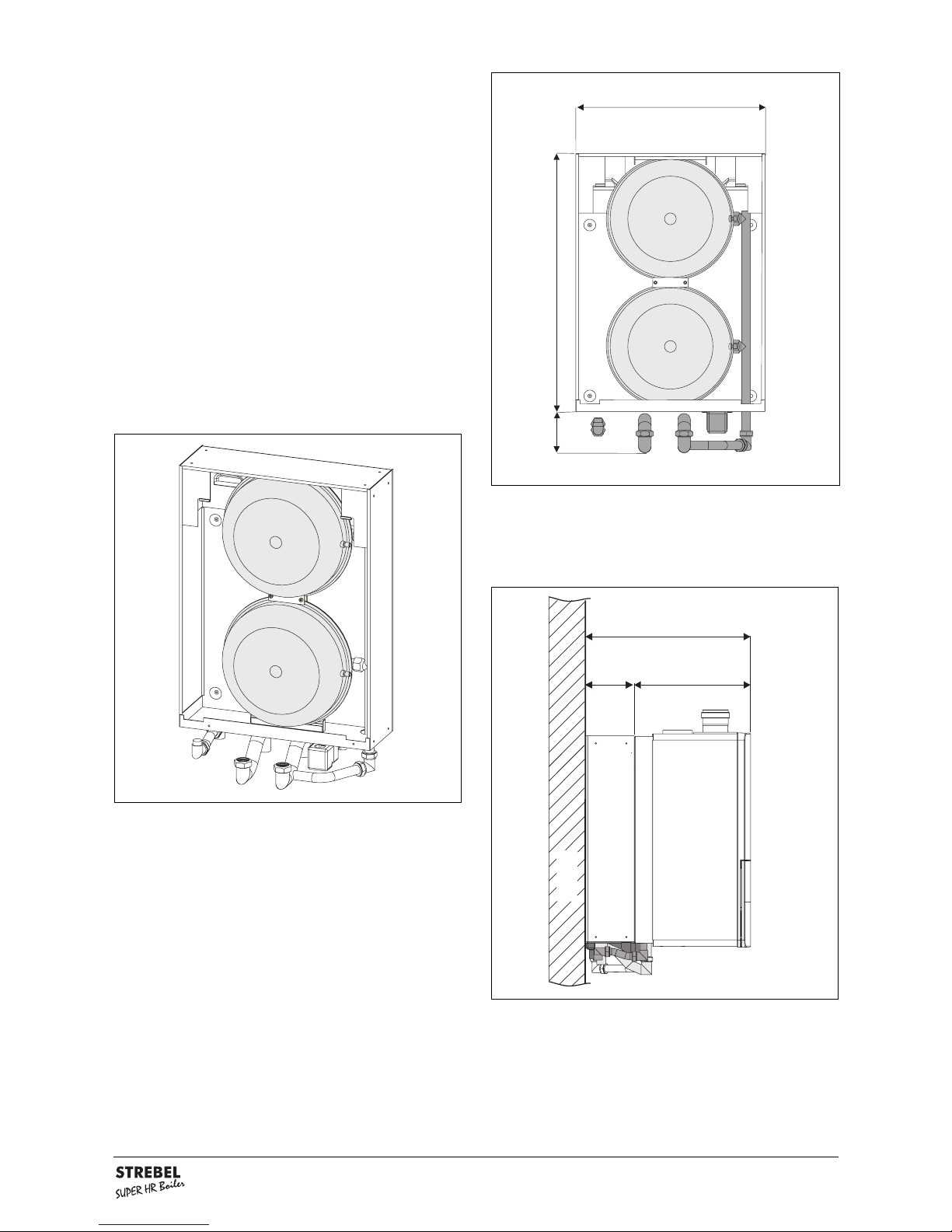

expansion tank module figure 5

side view of the module with S-HR unit figure 7

(dimensions in mm)

515

wall

145

370

front view of the expansion tank module figure 6

(dimensions in mm)

480

660105

Article numbers:

- the expansion tank module without pipe connections AEMO209U

- pipe connections for expansion tank module ALE0004U

Installation instructions S-HR series page 10

4.3 Underfloor heating systems

When connecting or using an underfloor heating system

fitted with plastic pipes one has to take into account that

the plastic pipes used meet the DIN 4726/4729

standard. It is stated in this standard that the pipes may

not have a higher oxygen transmittance than 0.1 g/m³.d

at 40°C. If the system does not meet this DIN standard,

then the underfloor heating section will have to be

separated from the central heating unit by means of a

plate heat exchanger.

In case of non-compliance with the

regulations concerning plastic underfloor

heating pipes, no claims can be made against

the guarantee conditions.

4.4 Gas pipe

The unit pipe is equipped with a female thread, into

which the tail piece of the gas valve can be screwed.

The Gas Safety (Installation and Use) Regulations

1994:

It is the law that all gas appliances are installed by

CORGI registered contractors in accordance with the

above regulations. Failure to install appliances correctly

could lead to prosecution. It is in your own interest, and

that of safety, to ensure that the law is complied with.

For good operation of the unit it is necessary that the

pre-pressure of the unit is higher than 20 mbar.

Make sure that the gas pipe work does not

contain dirt, particularly with new pipes.

4.5 Hot water supply (S-HR-T)

The unit pipes can be connected to the installation by

means of compression fittings. The unit is provided with

an inlet combination and safety valve set at 8 bar.

Together with the condensation discharge and the

discharge of the central heating safety valve (3 bar) this

is connected to one waste connection pipe.

A flow regulation valve is fitted in the cold water pipe.

The flow regulation valve provides that a quantity of

water is supplied which has a guaranteed outlet

temperature of 60°C (assuming a cold water

temperature of 10°C). The quantity of water is virtually

unaffected by the water pressure. With a water pressure

lower than 1.5 bar it is advisable to remove the inside

mechanism of the flow regulation valve. Connecting of

the drinking water installation should be done according

to the water BYE-laws.

4.6 Condensation discharge pipe

The collective condensation discharge pipe should be

connected to the waste by means of an open

connection. By this means the possibility of sewer

gases ending up in the unit is prevented. The waste

connection should have a minimum diameter of 25 mm.

The following components are connected to the

collective condensation discharge pipe:

- Condensation discharge;

- Safety valves;

- Inlet combination (S-HR-T)

Discharging of the condensation water to the

precipitation discharge is not permitted in

view of the danger of it freezing.

Before putting the unit into operation fill the

trap with 300 ml of water.

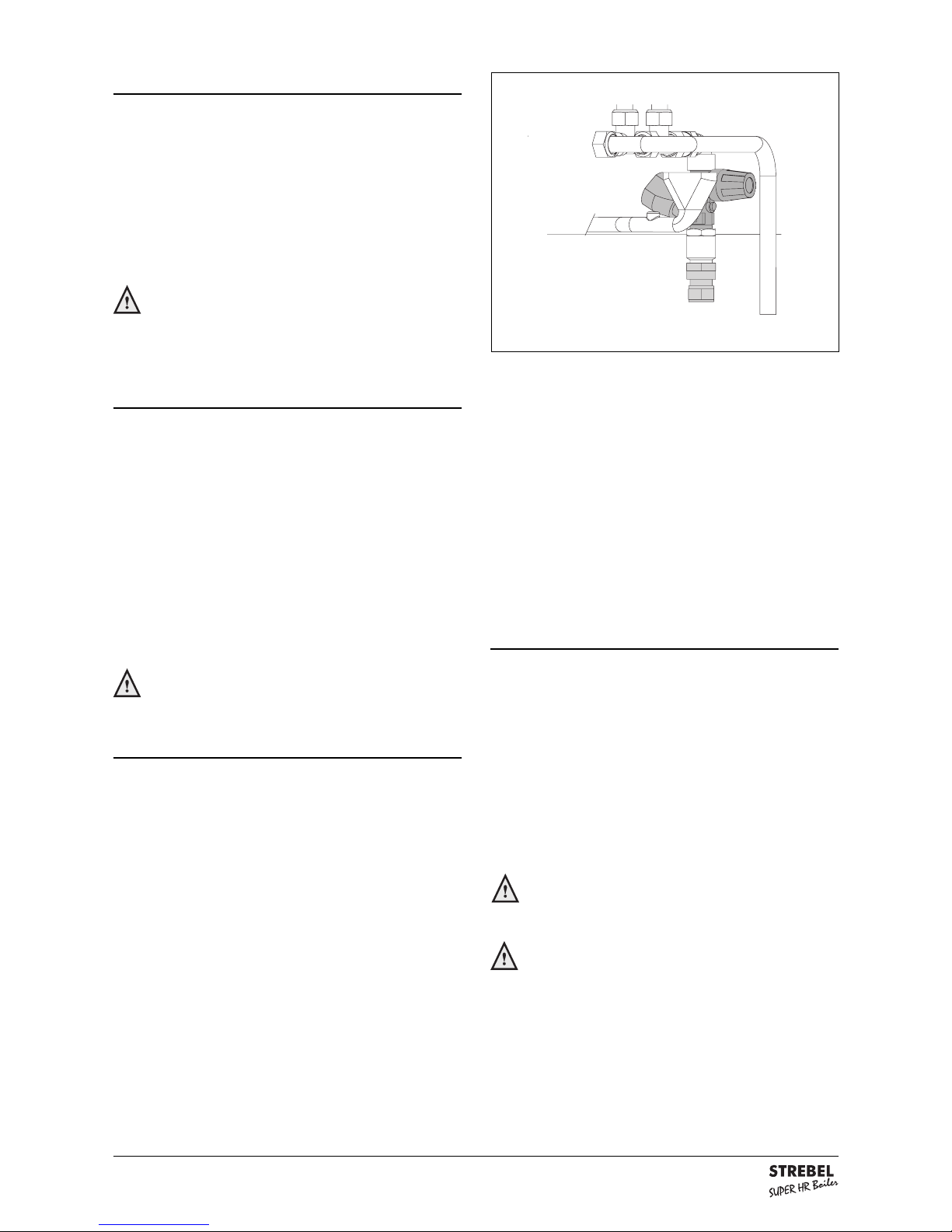

inlet combination and safety valve figure 8

Loading...

Loading...