Strebel S-HQ, SHQ25s, SHQ38s, SHQ51s, SHQ60s Installation Instructions Manual

...

Installation Instructions Strebel Q-boiler range

2

Central heating on / off

Domestic hot water (DHW) on / off

Pump programme on / off

Reset key Unlocking the boiler

in case of error

Step key Selecting chapters

display

Explanations of symbols and signs on the Control Tower display.

1

2

No heat requirement

Ventilation phase

Ignition phase

Burner active on central heating

Burner active on hot water

Fan check

Burner off when room thermostat is demanding

Pump overrun phase for central heating

Pump overrun phase for hot water

Burner off because of to high flow water temperature

Automatic venting programme

3

4

5

6

7

8

9

A

Water pressure is to low (<1,0 bar),

flashing FILL will alternate with indication

of water pressure, boiler power of 50% is

possible. The installation needs to be

topped up.

Operation indication

(in the first display position by technical read out)

Mode key Selecting chapters

Water pressure is to high (>2,8 bar), if

HIGH indication remains continuously

visible, the boiler is taken out of operation.

The installation pressure needs to be

decreased by draining water.

Water pressure is to low (<0,7 bar), FILL

indication remains continuously visible,

the boiler is taken out of operation. The

installation needs to be topped up.

0

From Good-read out to Technical read out (and vice versa):

- Press 5 sec. on the STEP key.

Installation Instructions Strebel Q-boiler range

3

Content

Declaration of conformity ............................................................................................................. 3

1 Introduction .................................................................................................................................. 4

2 Regulations .................................................................................................................................. 4

3 Scope of the supply...................................................................................................................... 6

4 Description of the boiler ............................................................................................................... 6

5 Mounting the boiler....................................................................................................................... 6

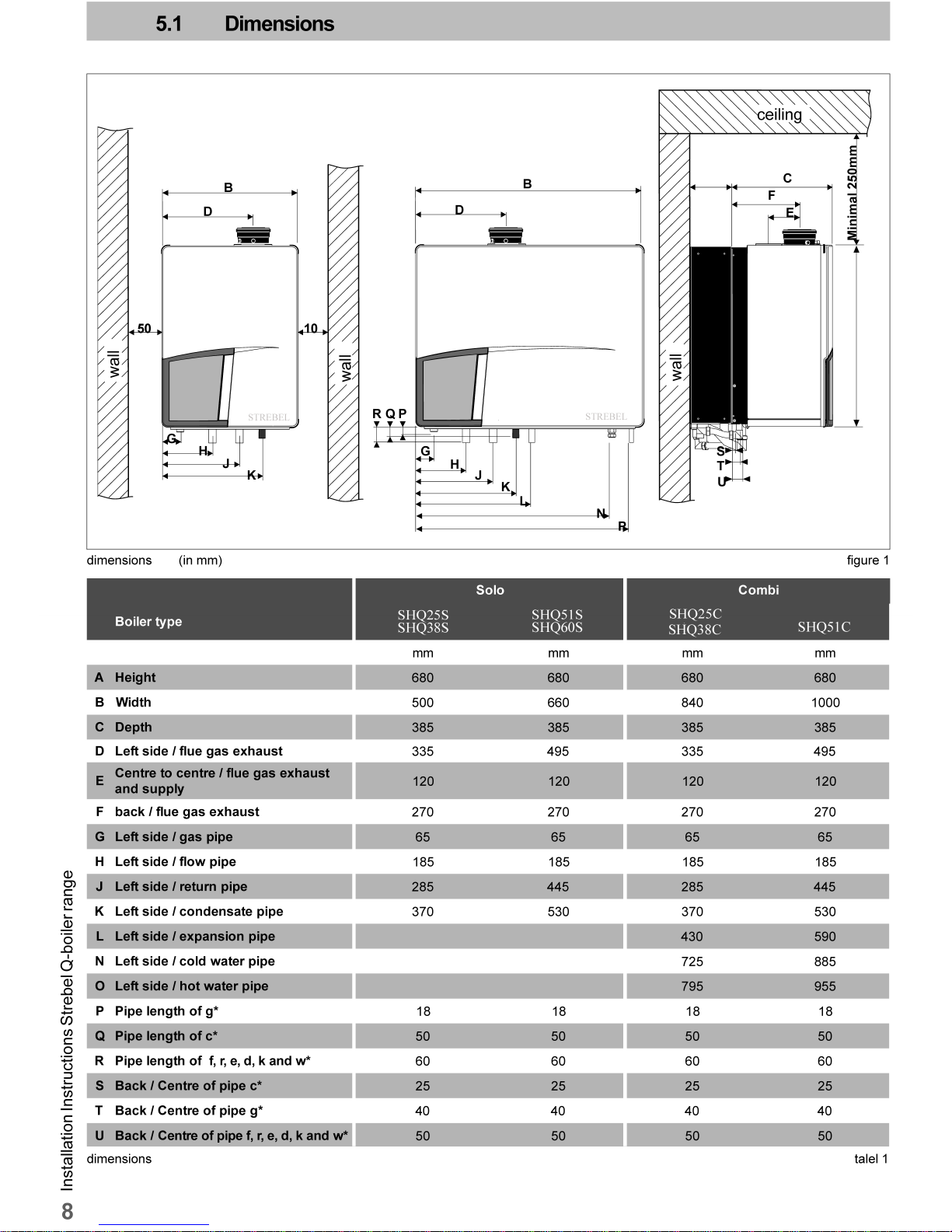

5.1 Dimensions ....................................................................................................................... 7

6 Connecting the boiler ................................................................................................................... 9

6.1 Central heating system ..................................................................................................... 9

6.2 Expansion vessel ............................................................................................................ 11

6.2.1 Expansion vessel module ............................................................................................... 12

6.3 Underfloor heating system (plastic pipes) ....................................................................... 13

6.4 Gas connection ...............................................................................................................13

6.5 Hot water supply .............................................................................................................13

6.6 Condensation drain pipe ................................................................................................. 14

6.7 Flue gas exhaust system and air supply system............................................................. 15

6.7.1 Dimensions of the flue gas and air intake duct................................................................ 18

7 External hot water cylinders ....................................................................................................... 19

8 Electrical connection .................................................................................................................. 20

9 Boiler controls ............................................................................................................................ 22

9.1 Explanation of the function keys ..................................................................................... 23

10 Filling and venting the boiler and installation.............................................................................. 24

10.1 Hot water supply ............................................................................................................. 24

11 Commissioning the boiler........................................................................................................... 25

11.1 Central heating system ................................................................................................... 25

11.2 Hot water supply ............................................................................................................. 25

11.3 Adjustments .................................................................................................................... 26

11.4 Activating factory settings (green key function)............................................................... 28

12 Isolating the boiler ..................................................................................................................... 29

13 Commissioning........................................................................................................................... 29

13.1 Checking for contamination............................................................................................. 29

13.2 Checking of the zero pressure control ............................................................................ 30

13.3 Checking the CO2............................................................................................................ 31

14 Maintenance............................................................................................................................... 32

14.1 Frequency of maintenance.............................................................................................. 32

14.2 Maintenance activities..................................................................................................... 33

14.3 Warranty ......................................................................................................................... 33

15 Technical specifications ............................................................................................................. 34

16 Parts of the boiler ....................................................................................................................... 35

17 Installation examples.................................................................................................................. 36

17.1 Radiator installation without thermostatic radiator valves................................................ 36

17.2 Radiator installation with underfloor heating zone........................................................... 37

18 Error indication ........................................................................................................................... 38

19 Declaration of conformity ........................................................................................................... 39

The appliance should only be installed by a Competent Gas Installer.

Work on the boiler must be carried out by a competent person, (Ref: Gas

Safety Installation and Use ) using correctly calibrated instruments with

current test certification.

Installation Instructions Strebel Q-boiler range

4

1 Introduction

These instructions describe the functioning, installation, use and primary maintenance

of STREBEL central heating units for the United Kingdom and Ireland. Where necessary

the different regulations for each country are separately described.

These instructions are intended for the use by Corgi registered installers or registered

Bord Gais installers in connection with the installation and putting into operation of

STREBEL units. It is advisable to read these instructions thoroughly, well in advance of

installation. Separate instructions for use are supplied with the unit for users of STREBEL

central heating units. STREBEL is not liable for the consequences of mistakes or

shortcomings which have found their way into the installation instructions or user’s

manual. Further, STREBEL reserves the right to alter its products without prior

notification.

When delivering the unit, give the customer clear instructions concerning its

use; present the customer with the user’s manual and card.

Each unit is fitted with an identification plate. Consult the details on this plate to verify

whether the unit is compliant with its intended location, e.g.: gas type, power source

and exhaust classification.

Relevant Installation, Service and User manuals:

- BrainQ Digital room thermostat

- MadQ Cascade-/Zone controller

2 Regulations

The following regulations apply to installation of STREBEL central heating units:

Legislation and Regulations.

Gas Safety (Installation and Use). All gas appliances must by law, be installed by a

competent person, eg. Members of CORGI and in accordance with the current Gas Safety

Regulation. Failure to install appliance correctly could lead to prosecution.

In addition to the above regulations this appliance must be installed in compliance with the

current IEE Regulations, the Building Standards (Scotland Consolidation) Regulations.

Regulations and bye laws of the Local Water Authority and the Current Health and Safety

Regulation.

The current, Electricity at Work Regulation must be complied with and also be in

accordance with the relevant and current editions of the British Standards.

The STREBEL S-HQ boiler is a certified appliance and must not be modified or installed

in any way contrary to this Installation Manual.

Manufacturers instructions must not be taken in any way as overriding statutory

obligations.

Installation Instructions Strebel Q-boiler range

5

The STREBEL S-HQ is a central heating unit with an optional integrated hot water

function. These units must be connected according to these instructions and all

installation norms in respect of the part of the unit to be connected.

Observe the following rules of safety:

- All work on the unit must take place in a dry environment.

- STREBEL units may never be in operation without their housing, except in

connection with maintenance or adjustments (see Chapter 13 and 14).

- Never allow electrical or electronic components to come into contact with water.

Carry out the following tasks in connection with maintenance, etc. to an already-

installed unit:

- Shut down all programmes

- Close the gas tap

- Remove the plug from the wall socket

- Close the stop cock of the unit’s intake connection

Take note of the following when maintenance or adjustments are needed:

- The unit must be able to function during these activities; for this reason, the unit’s

supply voltage, gas pressure and water pressure must be maintained. Ensure that

these is not a source of potential danger during these activities.

Following maintenance or other activities; always check the installation of all

parts through which gas flows (using leak-search spray).

Following maintenance or other activities, always replace the housing and

secure it with the screw behind the door at the front of the casing.

The following (safety) symbols may be encountered in these installation instructions

and on the unit:

This symbol indicates that the unit must be stored away from frost.

This symbol indicates that the packaging and/or contents can be damaged as

a result of insufficient care taken during transport.

This symbol indicates that, whilst still in its packaging, the unit must be

protected from weather conditions during transport and storage.

KEY-symbol. This symbol indicates that assembly or dismantling, must be

carried out.

ATTENTION symbol. This symbol indicates that extra attention must be paid

in connection with a particular operation.

Useful tip or advice

Installation Instructions Strebel Q-boiler range

6

3 Scope of the supply

The boiler is supplied ready for use. The supply kit is composed as follows:

• Boiler with casing; • Template on the package wrapper;

• Automatic vent (inside the boiler); • Installation instructions

• Safety valve (inside the boiler); • Operating manual;

• Suspension bracket • Warranty card;

• Draining valve with T-piece; • Benchmark logbook.

• Fixing material consisting of plugs and

screws;

4 Description of the boiler

The STREBEL S-HQ boiler is a room sealed, condensing and modulating central heating

boiler, with or without an integrated hot water facility.

The boiler is provided with a compact stainless steel heat exchanger with smooth

tubes. A well thought out principal using durable materials.

The boiler burns gas for supplying warmth. The heat is transferred in the heat

exchanger to the water in the central heating system. By cooling down the flue gasses

condensate is formed. This results in high efficiency. The condensate, which has no

effect on the heat exchanger and the function of the boiler, is drained through an

internal siphon.

The boiler is provided with an intelligent control system (CMS Control Management

System). The boiler anticipates the heat demand of the central heating system or the

hot water facility.

When an outside sensor is connected to the boiler works weather dependantly. This

means that the boiler control measures the outside temperature and flow temperature.

With this data the boiler calculates the optimal flow temperature for the installation.

Explanation of the type indication: STREBEL Q 51C

Q = Type

51 = Nominal load in kW

C = Combi (S = Solo)

Room sealed boiler

The boiler retreives its

combustion air from

outside then discharges

the flue gasses to the

outside.

Condensing

Retrieves heat from the

flue gasses. Water

condensates on the

heat exchanger.

Modulating

Higher or lower burning

according to the heat

demand.

Stainless Steel

Super solid kind of

steel which keeps its

quality for life. It will not

rust or erode in contrast to composition

materials, like aluminium.

Installation Instructions Strebel Q-boiler range

7

5 Mounting the boiler

The room where the boiler will be placed must always be frost free.

It is NOT necessary to have a purpose provided air vent in the room or internal space in

which the boiler is installed. Neither is it necessary to ventilate a cupboard or

compartment in which the boiler is installed, due to the extremely low surface

temperature of the boiler casing during operation. Therefore the requirements of BS 6798,

Clause 12, and BS5440:2 may be disregarded.

The boiler can be mounted practically to any wall with the suspension bracket and the

enclosed fixing equipment. The wall must be flat and of sufficient strength in order to be able

to carry the boiler weight with its water content.

Above the boiler there must be at least 250 mm working space in order to be able to fit

a coaxial flue system or a twin supply. On the left side of the boiler at least 50 mm and

on the right side 10 mm must be reserved to allow fitting or removing of casing. The

location of the boiler can be determined by using the template located inside the boiler

packaging.

Lift the boiler only by the boilers rear wall

Installation Instructions Strebel Q-boiler range

10

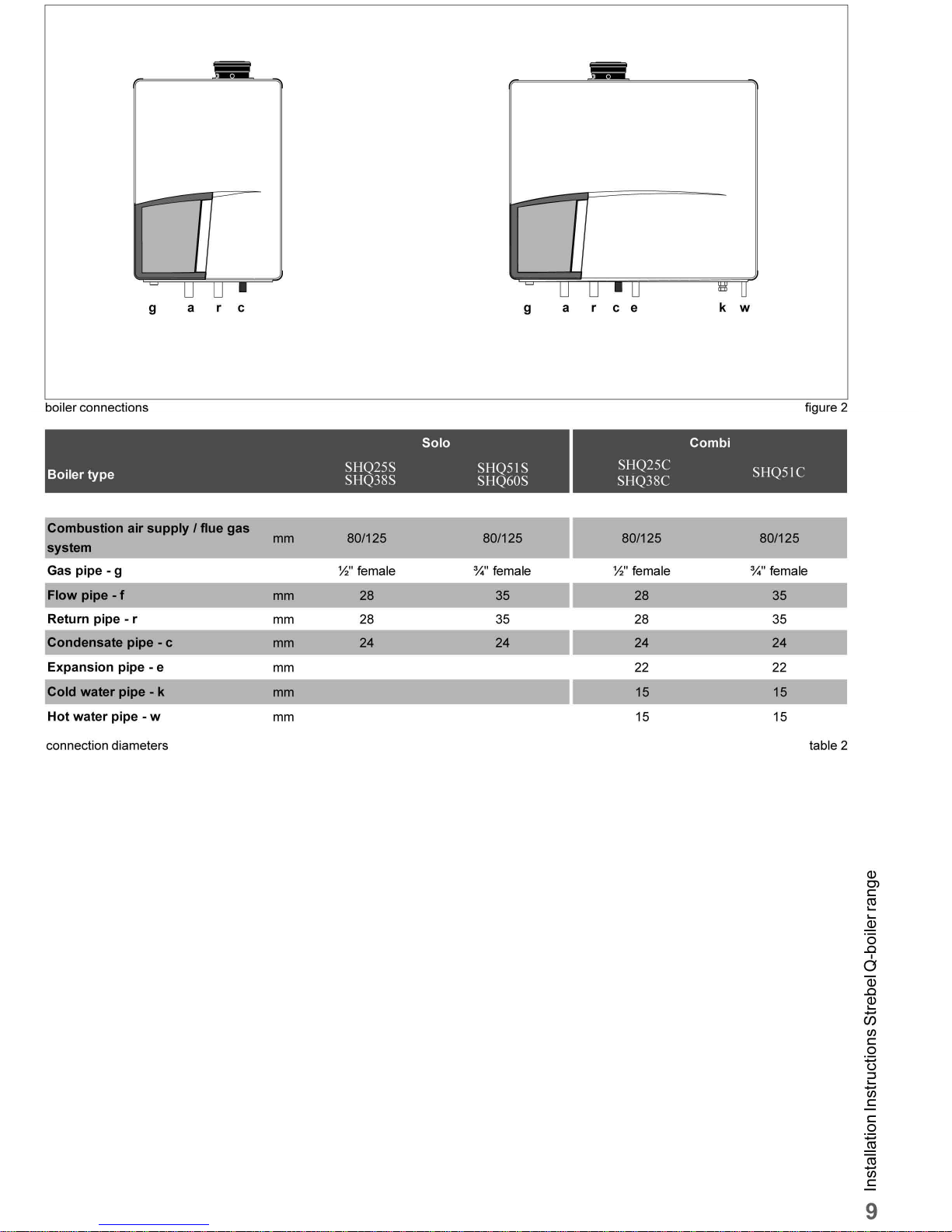

6 Connecting the boiler

The boiler has the following connection pipes;

- The central heating pipes.

These can be connected to the installation by means of compression fittings;

- The gas pipe.

It is provided with a female thread into which the tail piece of the gas valve can be

screwed;

- The condensation drain pipe.

It consists of an oval 24 mm plastic pipe. The drain pipe can be connected to this

by means of an open connection. If the open connection is fitted in a different

location, then the pipe can be lengthened by means of a 32 mm PVC sleeve;

- The flue gas exhaust system and air supply system.

It consists of a concentric connection 80/125 mm.

- Cold and hot water pipes.

Only Combi boilers: These consist of 15 mm copper pipe and can be connected

to the installation by means of compression fittings.

It is recommended that isolation valves are fitted to all heating and hot water

connections to facilitate ease of future maintenace.

It is advisable to spray-clean all of the unit’s connecting pipes and/or to

spray-clean/blow-clean the installation before connecting it to the unit.

6.1 Central heating system

Connect the central heating system according to the actual regulations.

The boiler pipes can be connected to the installation by means of compression fittings.

Reducers should be used for connecting to thick-walled pipe (welded or threaded).

When removing the plastic sealing caps from the pipes, contaminated testing

water can be released.

The boiler has a self-adjusting and self-protecting control system for the load and the pump

capacity. By this means the temperature difference between the flow and return water is

checked. Table 3 shows the water displacement which supplies th e circulation pump at

certain installation resistance.

A low velocity header must be connected to the Q51C, Q51S and Q60S to

prevent flow problems over the boiler.

STREBEL supplies the AA1OV09U Low velocity header for 1 boiler. This can be

connected directly under the boiler on the flow and return pipe.

Boiler type pump type water flow rate permissible installation

resistance

UPER l/min l/h kPa mbar

Combi

Q25C

20-60 16,2 972 29 290

Q38C

20-70 24,6 1478 20 200

Q51C

20-70 30,1 1803

Solo

Q25S

20-60 9,7 583 47 470

Q25S

20-60 1 6,2 972 32 320

Q38S

20-70 24,6 1478 22 220

Q51S

20-7030,11803

Q60S

20-70 38,9 2333

Installation resistance table 3

Installation Instructions Strebel Q-boiler range

12

6.2 Expansion vessel

The central heating system must be provided with an expansion vessel. The expansion

vessel which is used should be geared to the water content of the installation. The precharge pressure depends on the installation height above the mounted expansion vessel.

See table 4.

All Combi boilers are provided with an expansion vessel connection. This pipe is

connected with the three way valve and boiler pump. This prevent the expanding water,

during hot water production, is being closed off from the expansion vessel, when the

thermostatic radiator valves are fully closed. A second expansion vessel in the installation

is not a problem.

In connection with correct functioning of the boiler it is necessary for the

expansion vessel to be connected to the expansion vessel pipe of the boiler.

The Solo boilers are not provided with an expansion vessel connection. When one of

these Solo boilers is combined with a cylinder then one has to take into account that the

expansion vessel should be connected between the three-way valve and the boiler

circulation pump.

choice of expansion vessel table 4

insta lla tio n height a bove

the expansion vessel

pre-charge pressure

of the expansion vessel

5 m 0,5 bar

10 m 1,0 bar

15 m 1,5 bar

Installation Instructions Strebel Q-boiler range

13

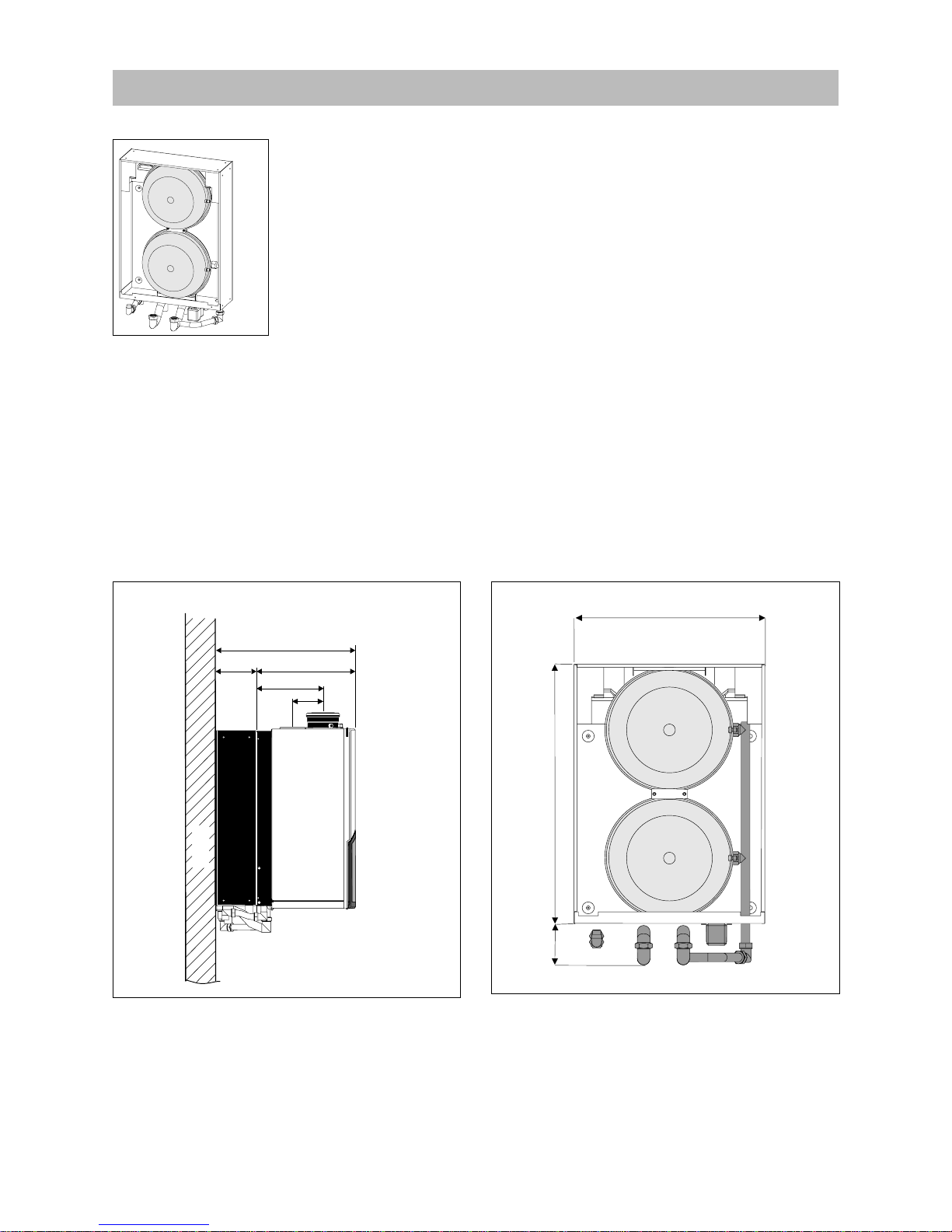

side view of the module with boiler (dimensions in mm) figure 5

540

wall

155

385

front view of the module with boiler (dimensions in mm) figure 6

660

105

6.2 Expansion vessel module

The STREBEL Q25S and Q38S boilers can be provided with an expansion vessel

module. By this means the external expansion vessel is not required. This expansion

vessel module is placed behind the STREBEL S-HQ boiler, by which means the

expansion vessel is not noticeable. The content of the two expansion vessels is 20 litres.

The pre-charge pressure is 1 bar.

The expansion vessel module can be supplied with the necessary pipes to connect with

the STREBEL S-HQ boiler. The connecting pipes for the installation correspond with

those of the boiler and have the same centre-to-centre distance to the wall.

When checking the expansion vessels these are accessible via the left, right and upper

sides. From these sides the tanks are also removable and the boiler does not have to

be dismantled.

The space which is required for mounting the expansion vessel module corresponds

with the required space for mounting an STREBEL S-HQ boiler. They included template

and mounting strip for the boiler which can be used for the expansion vessel module.

The boiler is fitted on to this after the expansion vessel module has been mounted. The

necessary mounting strip for the boiler is present on the module.

Article numbers:

- the expansion vessel module without pipe connections AEM0209U

- pipe connections for expansion vessel module ALE0004U

480

expansion vessel module

figure 4

Loading...

Loading...