Strebel S-CB+ Series, S-CB+80, S-CB+60, S-CB+100, S-CB+120 Installation Operating & Maintenance Manual

...

STREBEL

S-CB+ Boiler Range

Models +60 - +80 - +100 - +120 - +150 - +180

Wall hung high efficiency condensing boiler

Installation, Operating & Maintenance Manual

2015-07-21 v1

4

TABLE OF CONTENTS

INTRODUCTION…………………………………………………………………………………………….….…...7

1 SAFETY GUIDELINES ................................................................................................................................ 7

2 TECHNICAL DATA S-CB+ BOILERS ......................................................................................................... 9

2.1 FUNCTIONAL INTRODUCTION ............................................................................................................. 9

2.2 TECHNICAL SPECIFICATIONS DATASHEET......................................................................................... 10

3 DIMENSIONS .............................................................................................................................................12

3.1 S-CB

3.2 S-CB

+

60-120 .............................................................................................................................. 12

+

150-180 ............................................................................................................................ 13

4 ACCESSORIES AND UNPACKING ..........................................................................................................14

4.1 ACCESSORIES ............................................................................................................................... 14

4.2 UNPACKING ................................................................................................................................... 14

5 INSTALLATION OF THE S-CB+ ................................................................................................................15

5.1 GENERAL NOTES ........................................................................................................................... 15

5.2 MOUNTING THE BOILER .................................................................................................................. 16

6 CONNECTIONS WATER SIDE .................................................................................................................17

6.1 BOILER CONNECTIONS ................................................................................................................... 17

6.2 CONDENSATE DRAIN CONNECTION .................................................................................................. 17

6.3 FLOW AND RETURN CONNECTIONS .................................................................................................. 18

6.4 THE EXPANSION VESSEL................................................................................................................. 18

6.5 PRESSURE RELIEF VALVE ............................................................................................................... 18

6.6 BYPASS ........................................................................................................................................ 18

6.7 PUMP FUNCTIONALITY .................................................................................................................... 18

6.8 FROST PROTECTION ...................................................................................................................... 19

6.9 INSTALLING A STRAINER AND/OR DIRT SEPARATOR ........................................................................... 19

6.10 WATER QUALITY ............................................................................................................................ 19

6.11 PLASTIC PIPING IN THE HEATING SYSTEM ......................................................................................... 20

6.12 AUTOMATIC AIR VENT ..................................................................................................................... 20

6.13 AUTOMATIC WATER FILLING SYSTEMS ............................................................................................. 20

6.14 WATER PRESSURE ......................................................................................................................... 20

6.15 CHEMICAL WATER TREATMENT ....................................................................................................... 21

6.16 UNDER FLOOR HEATING ................................................................................................................. 21

6.17 FLUSH THE SYSTEM WITH FRESH WATER ......................................................................................... 21

6.18 INSTALLATION EXAMPLES ............................................................................................................... 21

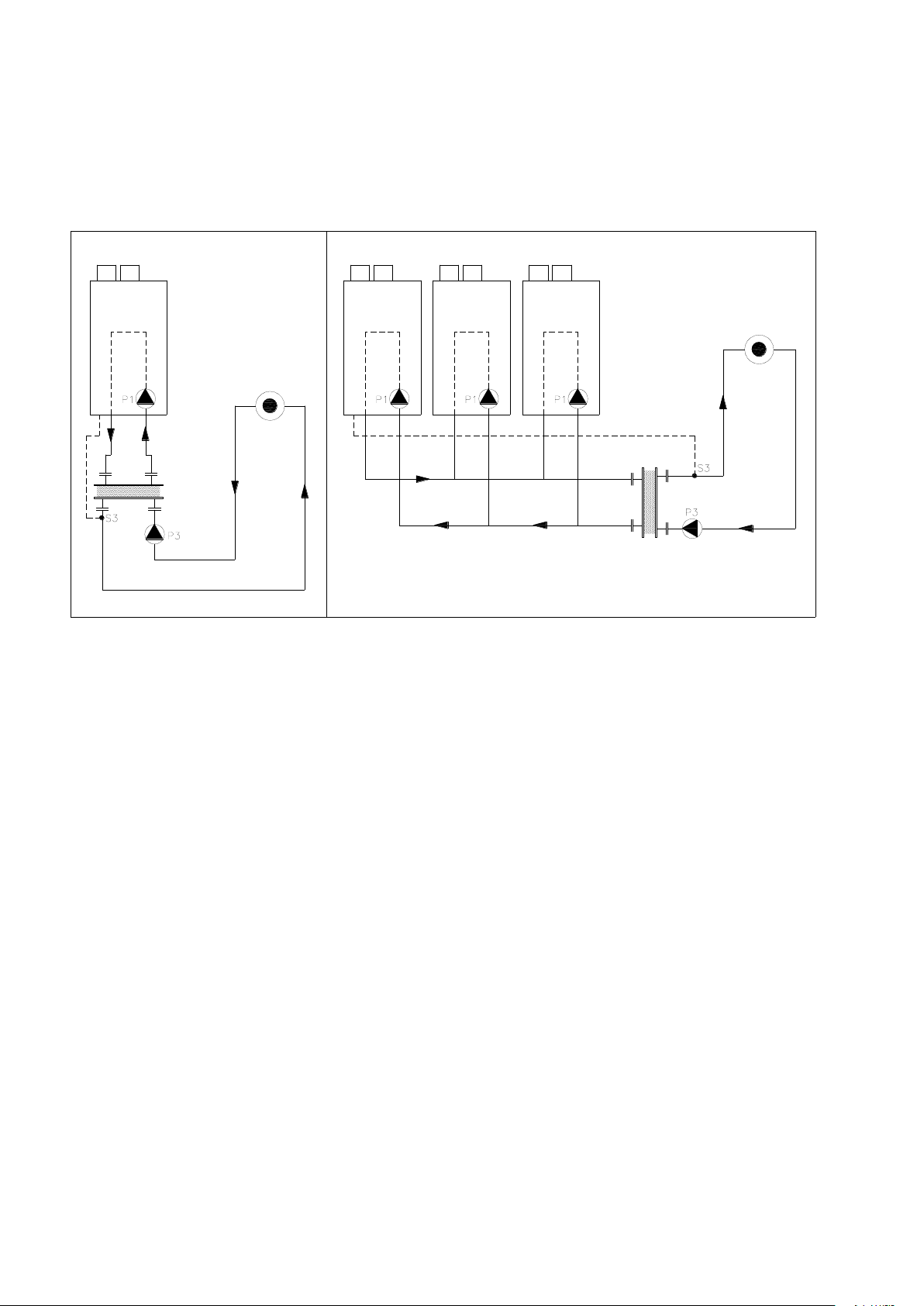

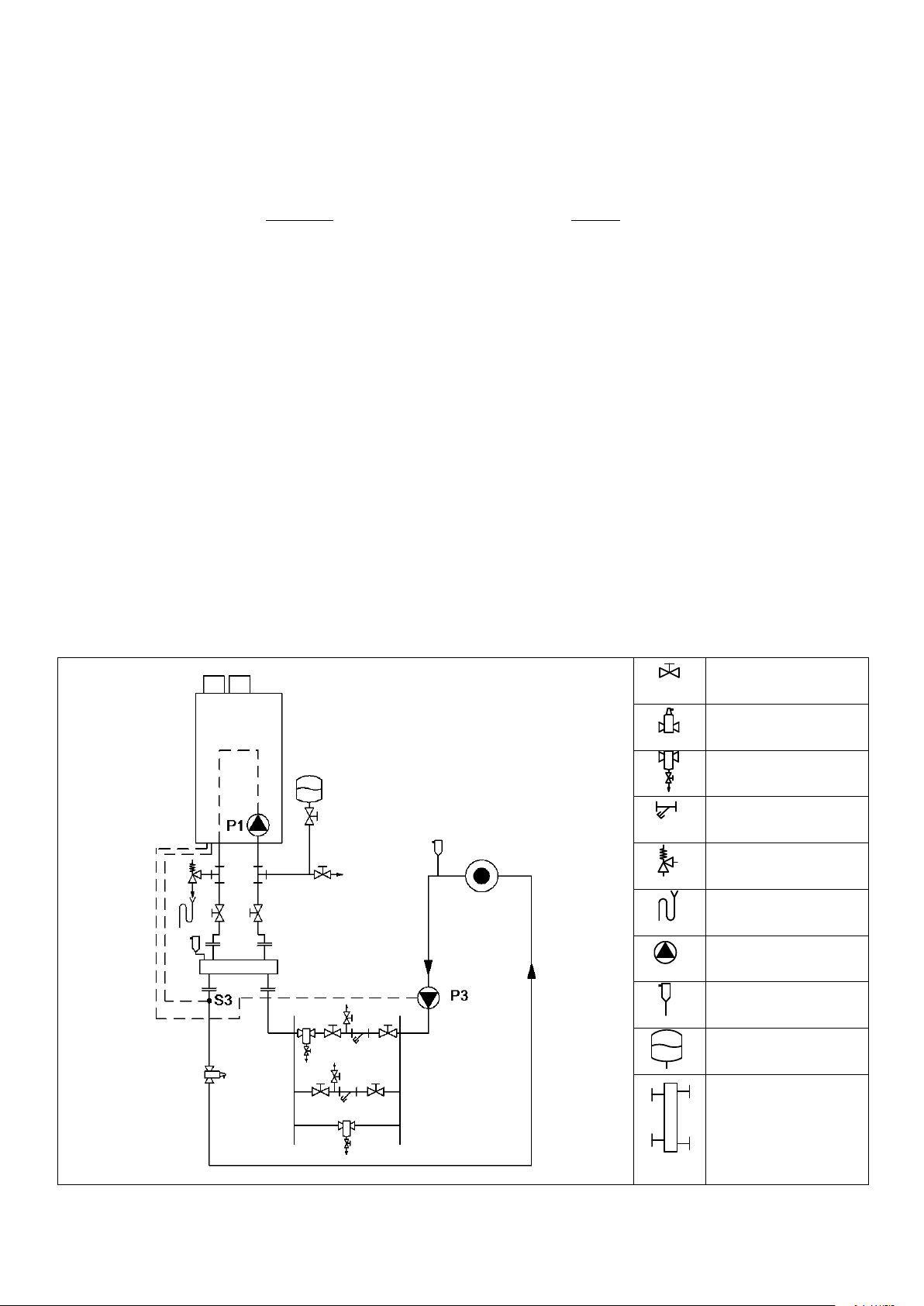

6.18.1 Example of a standard single boiler heating circuit with low loss header ......................... 21

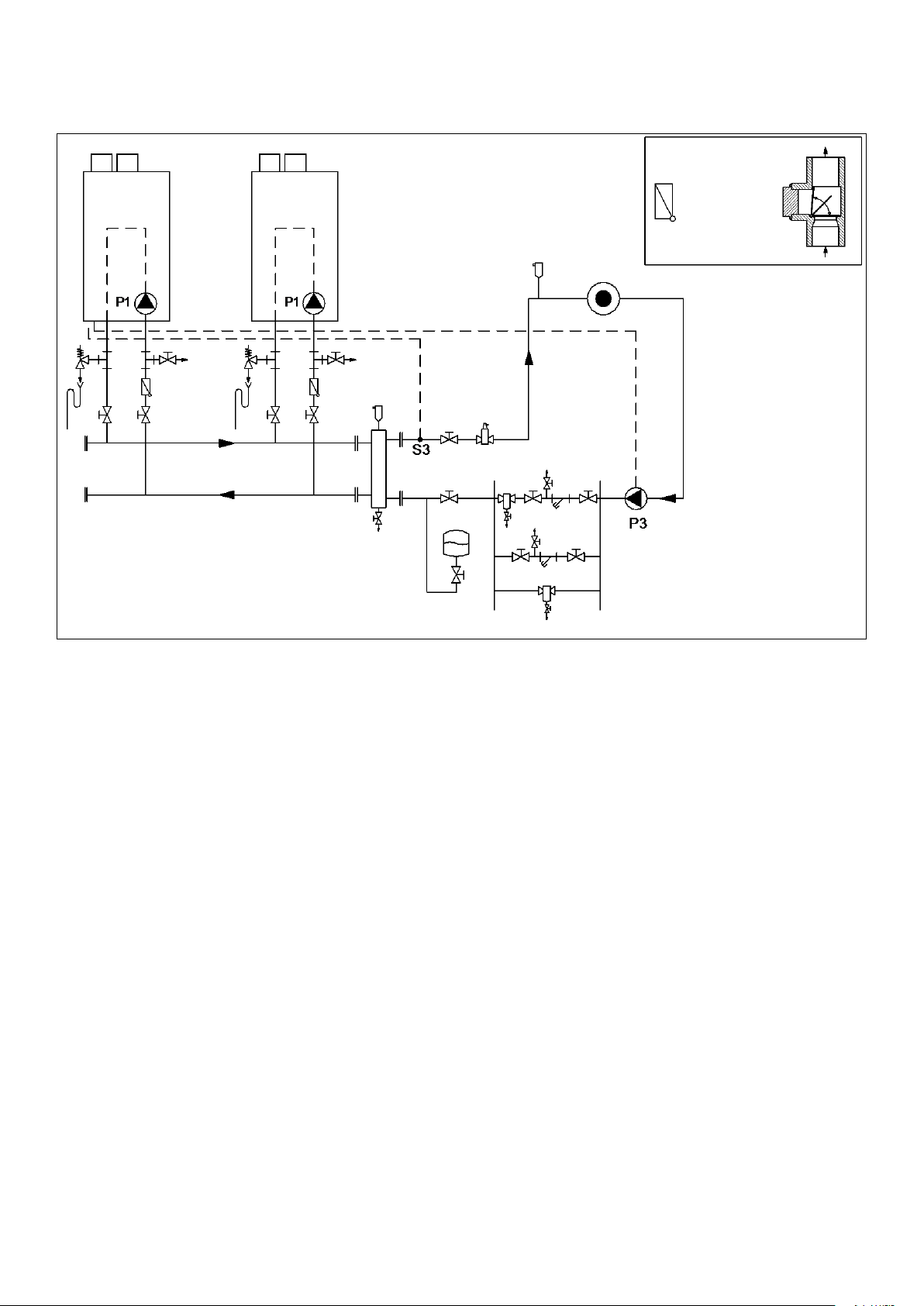

6.18.2 Example of a multiple boiler heating circuit with low loss header ..................................... 23

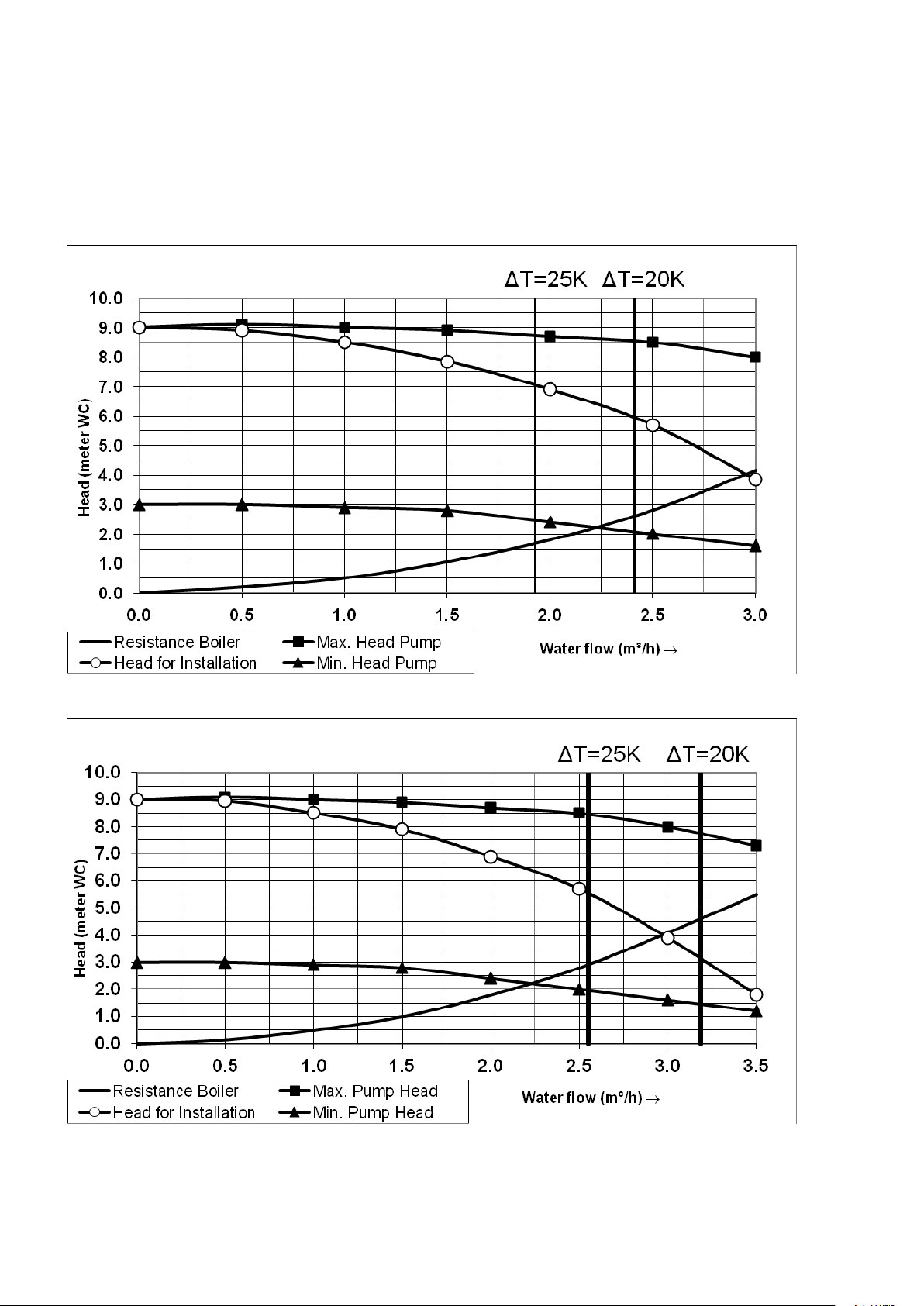

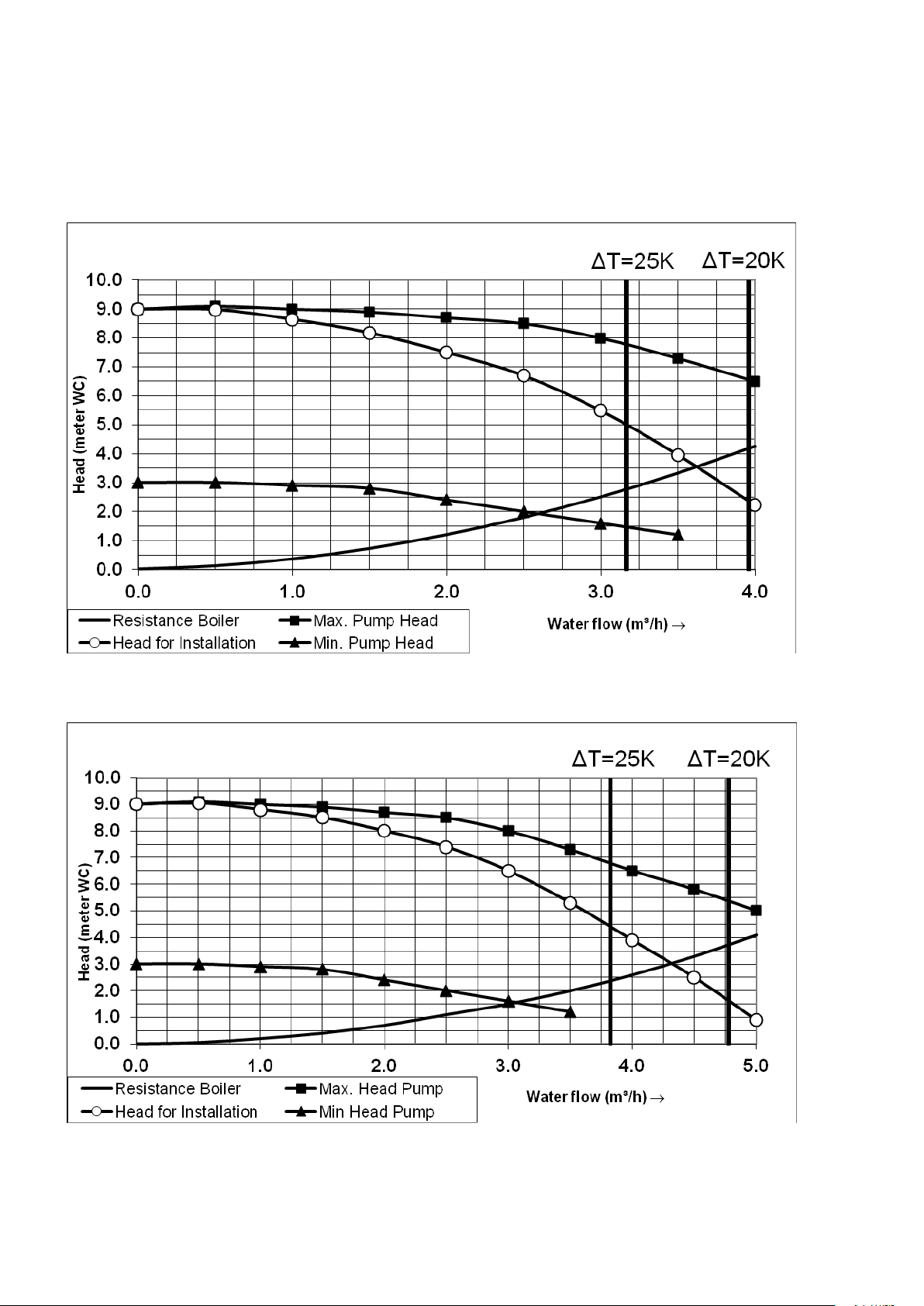

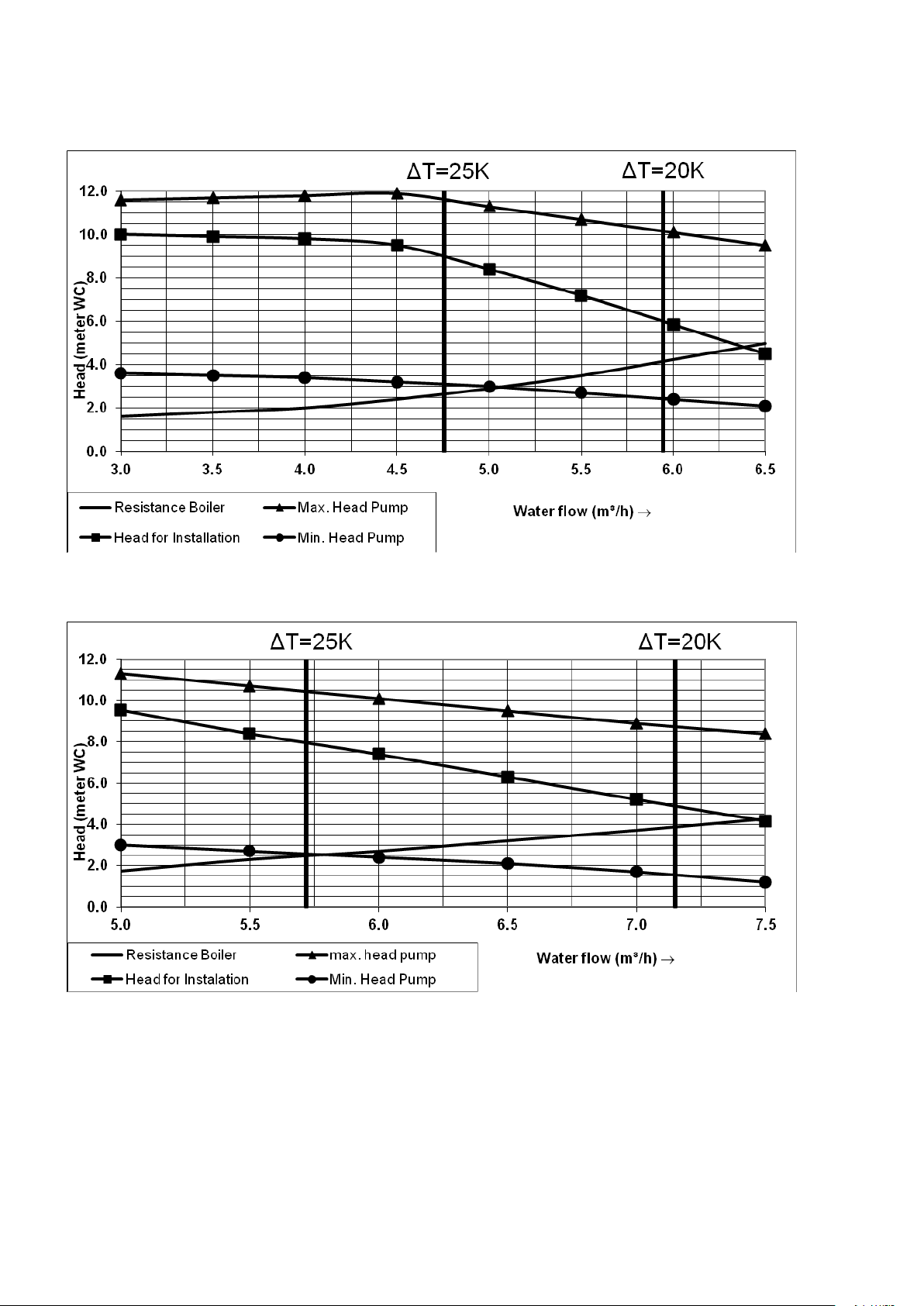

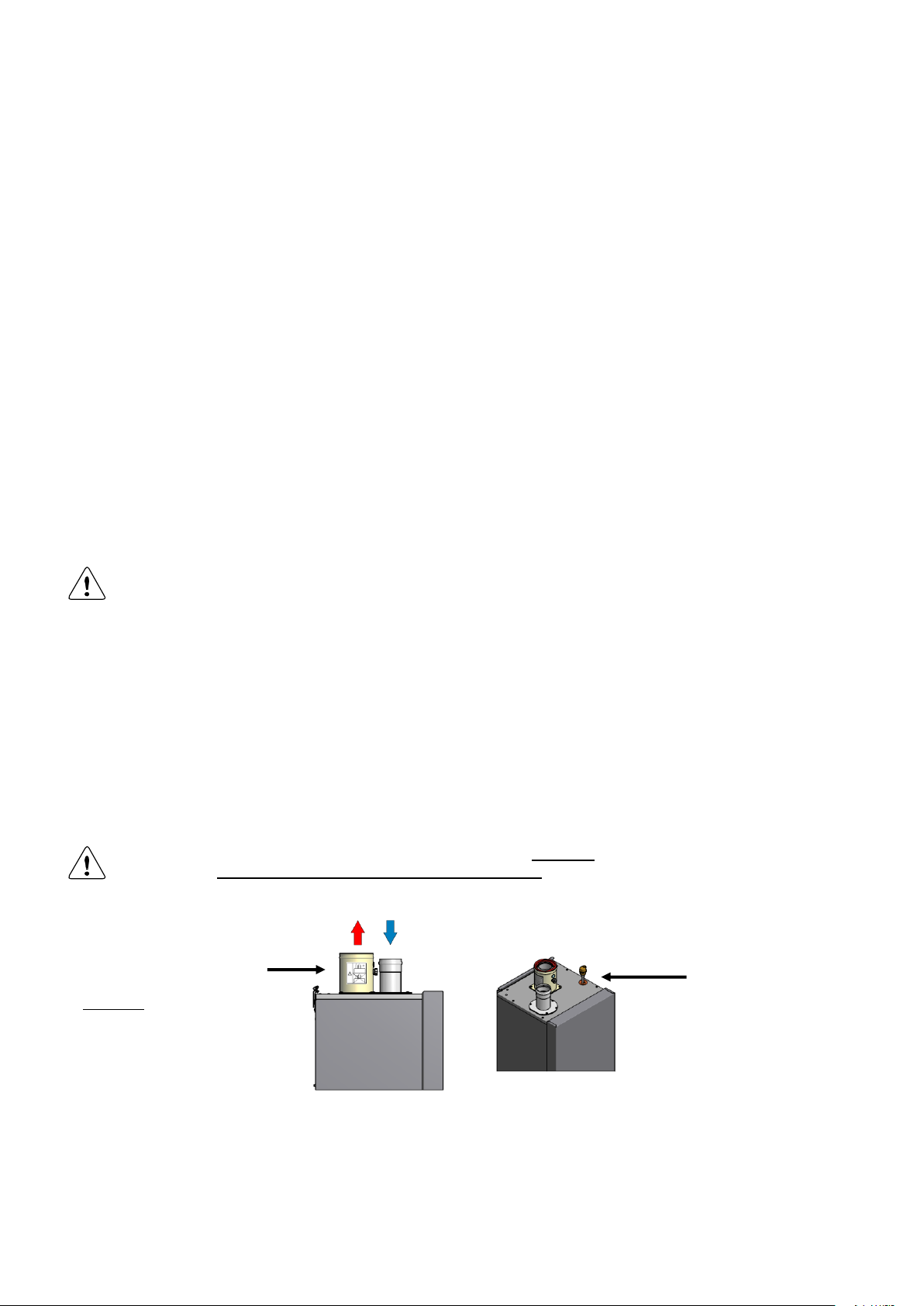

7 PUMP CHARACTERISTICS ......................................................................................................................24

7.1 HYDRAULIC GRAPHS ...................................................................................................................... 24

7.2 PUMPS: MAXIMUM ELECTRICAL POWER............................................................................................ 27

8 FLUE GAS AND AIR SUPPLY SYSTEM ..................................................................................................27

8.1 GENERAL ...................................................................................................................................... 27

8.2 AIR SUPPLY ................................................................................................................................... 28

8.2.1 Combustion air quality ...................................................................................................... 28

8.2.2 Air supply through humid areas ........................................................................................ 28

8.3 FLUE TERMINAL ............................................................................................................................. 28

8.4 S-CB+ 60 TWIN PIPE VERSION ........................................................................................................ 28

8.5 PIPE HEIGHTS AND MUTUAL DISTANCES ON A FLAT ROOF .................................................................. 29

8.6 B23P CERTIFIED ............................................................................................................................ 29

8.7 C63 CERTIFIED .............................................................................................................................. 29

8.8 FLUE GAS AND AIR SUPPLY RESISTANCE TABLE ................................................................................ 30

8.9 FIVE TYPICAL EXAMPLES ................................................................................................................ 31

8.9.1 Example A: Twin pipe system ........................................................................................... 31

8.9.2 Example B: Twin pipe system with concentric roof terminal ............................................. 31

8.9.3 Example C: Single flue gas outlet. Air supply from boiler room ........................................ 33

8.9.4 Example D: Concentric flue gas/air supply pipe (roof-mounted) ...................................... 35

8.9.5 Example E: Concentric flue gas/air supply pipe (wall-mounted) ...................................... 35

9 ELECTRICAL INSTALLATION .................................................................................................................37

9.1 GENERAL ...................................................................................................................................... 37

S-CB+ Boiler Range Manual

5

9.2 ELECTRICAL CONNECTIONS ............................................................................................................ 37

9.3 EXPLANATION OF THE CONNECTIONS .............................................................................................. 37

9.4 ELECTRICAL SCHEMATICS .............................................................................................................. 39

9.5 SENSOR VALUES ............................................................................................................................ 42

10 USER INTERFACE ....................................................................................................................................43

10.1 CONTROL PANEL / DISPLAY UNIT ..................................................................................................... 43

10.2 CONTROL PANEL MENU STRUCTURE................................................................................................ 44

10.3 DISPLAY DURING OPERATION .......................................................................................................... 46

10.4 MONITOR SCREENS ....................................................................................................................... 47

10.5 SERVICE FUNCTION ........................................................................................................................ 49

10.6 SCHORNSTEINFEGER FUNCTION ..................................................................................................... 50

10.7 PROGRAMMING IN STANDBY MODE .................................................................................................. 51

10.8 SETTING THE TIME & DATE ............................................................................................................. 51

10.9 SET POINTS ................................................................................................................................... 52

10.10 SETTING THE TIMER PROGRAMS ..................................................................................................... 53

10.11 SETTING THE OUTDOOR SPECIFICATIONS ........................................................................................ 56

10.12 CHECKING THE OPERATING HISTORY ............................................................................................... 60

10.13 CHECKING THE FAULT HISTORY ...................................................................................................... 61

10.14 SETTING THE MAINTENANCE SPECIFICATIONS .................................................................................. 62

10.15 SETTING THE USER LOCK ............................................................................................................... 66

10.16 SETTING THE PARAMETERS AT THE CONTROL PANEL ........................................................................ 67

10.17 FAULT CODES DISPLAY ................................................................................................................... 74

10.17.1 Lock-out codes .................................................................................................................. 74

10.17.2 Blocking codes .................................................................................................................. 76

10.17.3 Messages .......................................................................................................................... 77

11 CONTROLLING OPTIONS AND SETTINGS ............................................................................................78

11.1 GENERAL ...................................................................................................................................... 78

11.1.1 Extra boiler control ............................................................................................................ 78

11.1.2 Max cooling time ............................................................................................................... 78

11.1.3 Temperature display on/off ............................................................................................... 78

11.1.4 Water pressure ................................................................................................................. 78

11.1.5 Gas type selection ............................................................................................................ 78

11.1.6 Soft start option ................................................................................................................. 79

11.1.7 Pump mode (EC technology) ............................................................................................ 79

11.2 HEATING ....................................................................................................................................... 80

11.2.1 Controlling behaviour settings........................................................................................... 80

11.2.2 Room thermostat on/off .................................................................................................... 81

11.2.3 Room thermostat OPEN-THERM ..................................................................................... 81

11.2.4 Outdoor temperature related flow control ......................................................................... 81

11.2.5 0-10 Vdc remote flow temperature set point ..................................................................... 81

11.2.6 0-10 Vdc Remote burner input control .............................................................................. 82

11.2.7 Timer contact function ....................................................................................................... 82

11.3 INDIRECT HOT WATER/CALORIFIER .................................................................................................. 83

11.3.1 Pump and 3-way valve control .......................................................................................... 83

11.3.2 Tank thermostat ................................................................................................................ 83

11.3.3 Tank sensor ...................................................................................................................... 83

11.3.4 Low/high flow temperature to tank coil ............................................................................. 84

11.3.5 Heating and hot water switching time ............................................................................... 85

11.3.6 Heating and hot water switching at sudden temperature drop ......................................... 85

11.3.7 Anti-Legionnaires’ disease function (pasteurisation) ........................................................ 86

11.4 CASCADE CONTROL ....................................................................................................................... 87

11.4.1 Parameter settings for cascaded boilers .......................................................................... 87

11.4.2 Monitor screens ................................................................................................................ 89

11.4.3 Output control and boiler sequence .................................................................................. 89

12 COMMISSIONING THE BOILER ...............................................................................................................90

12.1 FIRST: FLUSHING THE BOILER WITH WATER ...................................................................................... 90

12.2 SECOND: FILLING & VENTING THE BOILER AND THE SYSTEM .............................................................. 90

12.3 THIRD: CHECK THE WATER FLOW .................................................................................................... 90

13 STARTING THE BOILER ..........................................................................................................................92

13.1 GENERAL ...................................................................................................................................... 92

13.2 FIRING FOR THE FIRST TIME ............................................................................................................ 92

S-CB+ Boiler Range Manual

6

14 ADJUSTING AND SETTING THE BURNER ............................................................................................93

14.1 INTRODUCTION .............................................................................................................................. 93

14.1.1 Adjustment tables ............................................................................................................. 93

14.1.2 Setting screws gas valve(s): drawings .............................................................................. 95

14.1.3 Gas valve classes A+C and B+J (B+J only for Poland) .................................................... 96

14.1.4 Adjustment actions: general scheme ................................................................................ 97

14.2 ADJUSTING IN CASE OF A NEW BOILER, OR AFTER MAINTENANCE (CASE A) ........................................ 98

14.2.1 General remark ................................................................................................................. 98

14.2.2 Checking and adjusting at maximum load ........................................................................ 98

14.2.3 Checking and adjusting at minimum load ......................................................................... 98

14.3 ADJUSTING IN CASE OF VALVE REPLACEMENT OR GAS CONVERSION (CASE B) ................................... 98

14.3.1 General remarks ............................................................................................................... 98

14.3.2 Checking and adjusting at maximum load A+60 / A+80 / A+100 ....................................... 98

14.3.3 Checking and adjusting at minimum load A+60 / A+80 / A+100......................................... 98

14.3.4 Checking and adjusting at maximum load A+120 / A+150 / A+180 ................................... 99

14.3.5 Checking and adjusting at minimum load A+120 / A+150 / A+180 .................................... 99

14.4 ADJUSTING PROCEDURES ............................................................................................................ 100

15 PUTTING THE BOILER OUT OF OPERATION ......................................................................................101

15.1 OUT OF OPERATION: ON/OFF FUNCTION ........................................................................................ 101

15.2 OUT OF OPERATION: POWER OFF .................................................................................................. 101

16 FAULT CODES. BLOCKING CODES .....................................................................................................102

16.1 FAULT CODES .............................................................................................................................. 102

16.2 BLOCKING CODES: ....................................................................................................................... 109

16.3 MAINTENANCE ATTENTION FUNCTION ............................................................................................ 112

17 MAINTENANCE .......................................................................................................................................113

17.1 GENERAL .................................................................................................................................... 113

17.2 INSPECTION & MAINTENANCE........................................................................................................ 113

18 USER INSTRUCTIONS ...........................................................................................................................117

19 INSTALLATION EXAMPLES ..................................................................................................................118

20 INDEX .......................................................................................................................................................123

S-CB+ Boiler Range Manual

7

INTRODUCTION

Warning: important information concerning the safety of persons and/or the appliance.

The manufacturer/supplier is not liable for any damage caused by inaccurately following these mounting

instructions. Only original parts may be used when carrying out any repair or service work.

This appliance is not intended for use by persons (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance.

This manual is written for:

The installer

System design engineer

The service engineer

The following symbol is used in this manual:

Strebel Ltd is not accountable for any damage caused by incorrect following the mounting instructions. For service

and repair purposes use only original Strebel spare parts.

All documentation produced by the manufacturer is subject to copyright law.

1 SAFETY GUIDELINES

Carefully read all the instructions before commencing installation.

Keep these instructions near the boiler for quick reference.

The appliance should be installed by a skilled installer such as GAS SAFE registered person, electrical work car-

ried out by a qualified person, all according to national and regional standards.

Failure to comply with these regulations could deem the warranty invalid. This appliance must be installed in ac-

cordance with the rules that apply and only be used in an adequately ventilated space conforming to standards in

place.

Without written approval of the manufacturer the internals of the boiler may not be changed. When changes are

executed without approval, the boiler certification becomes invalid.

Commissioning, maintenance and repair must be done by a skilled installer/engineer, according to all applicable

standards and regulations.

What should one do when there is the smell of gas: -

Don't use any electrical equipment.

Don't press any switches.

Close the gas supply.

Ventilate the room (open the windows and/or outdoor boiler room doors).

Immediately warn the responsible person.

S-CB+ Boiler Range Manual

8

These instructions are written for the installer of Strebel products and contain all necessary information on the installation and adjustment of S-CB+ Ranges of boilers. Please read these instructions fully before installation to ensure that all work is carried out correctly.

We suggest that you keep a copy of these instructions near the boiler.

These instructions together with those in any supplemental instruction booklet cover the basic principles to ensure

the satisfactory installation of the boiler, although detail may need slight modification to suit particular local site

conditions.

It is the law that all gas appliances and fittings are installed by a competent person (such as a Gas Safe registered

installer) and in accordance with The Gas Safety (installation and Use) Regulations.

The relevant British standards for installation, codes of practice or rules in force and in accordance with the Manufactures’ instructions.

The installation must be carried out in accordance with the following regulations plus relevant codes & standards:

- Due consideration must be given to current Health & Safety Legislation while this product is being installed.

- Key Approved Documents to the Building Regulations, in the region of the United Kingdom that this product is

being installed.

- The Local Building Regulations and Local water by-laws, the gas services area and the Local Authority recommendations.

- The appropriate British & European Standards for the type of installation and fuel used, including but not exclusively the following standards: -

o BS 5440: Parts 2 (Flues and Ventilation).

o BS 6644: Installation of gas-fired hot water boilers of rated inputs between 70kW & 1.8MW

- The clean air act as defined by the local authority.

- The appropriate documents as produced by the Institution of Gas Engineers and Managers Documents

(IGEM) for the type of installation and fuel used, including but not exclusively the following documents: -

o IGE/UP1

o IGE/UP2

o IGE/UP4

o IGE/UP10

- If the product is being fuelled with LPG then the appropriate UKLPG Codes of Practice (CoP) should be referred to.

- Wiring to the appliance must be in accordance with the IEE (BS 7671) Wiring Regulations the Health and

Safety Document No 635 “The Electricity at Work Regulations 1989” and any local regulations that apply.

- CP 342: Part 2, 1994. Code of practice for centralised hot water supply – buildings other than individual dwellings.

- CIBSE, Guides A, B and C.

Adhere to all regulations that are in force at the time of installation or service.

S-CB+ Boiler Range Manual

9

2 TECHNICAL DATA S-CB+ BOILERS

2.1 Functional introduction

The S-CB+ boilers are central heating boilers with a maximum high efficiency. Such a performance can be reached

by, amongst other things, using a special heat exchanger made of stainless steel. This allows the flue gases to cool

down below the condensation point, and so release extra heat. This has an immediate positive impact on the efficiency, exceeding the 100%.

The S-CB+ boiler is standard set for Natural gas G20

Gases used must meet the European standard EN 437.

Fuel used should have sulphur rates according to the European standard, a maximum annual peak over a short

period of time of 150 mg/m3 and an annual average of 30 mg/m3.

Boiler control includes:

Cascade control for up to twelve boilers

Remote operation and heat demand indication from each boiler

Weather compensation control

Hot water cylinder control

Connections for:

0-10 VDC remote flow temperature (set point) control

0-10 VDC remote burner input control

Outdoor temperature sensor

External hot water cylinder pump or diverter valve

Cascade control

When using the integrated cascade control, a maximum of twelve boilers can be controlled in a cascade configuration. By the use of an appropriate external control, this number may be increased at will.

0-10 VDC connection available

The boiler flow temperature or power input can be controlled by an external 0-10 VDC signal. When a number of

boilers are cascaded, and controlled by the integrated cascade control, the signal should be directed to the master

boiler only. If an alternative control is used, more than one boiler may be controlled by a 0-10 VDC signal. A signal

of 1,48 Volt will switch on the boiler(s), less than 1,4 Volt will switch off the boiler(s).

Time program

For both central heating and hot water function of the boiler, time programs with three programmable periods per

day are available. These time programs are set and activated by entering the desired settings directly at the boiler

control panel.

S-CB+ Boiler Range Manual

10

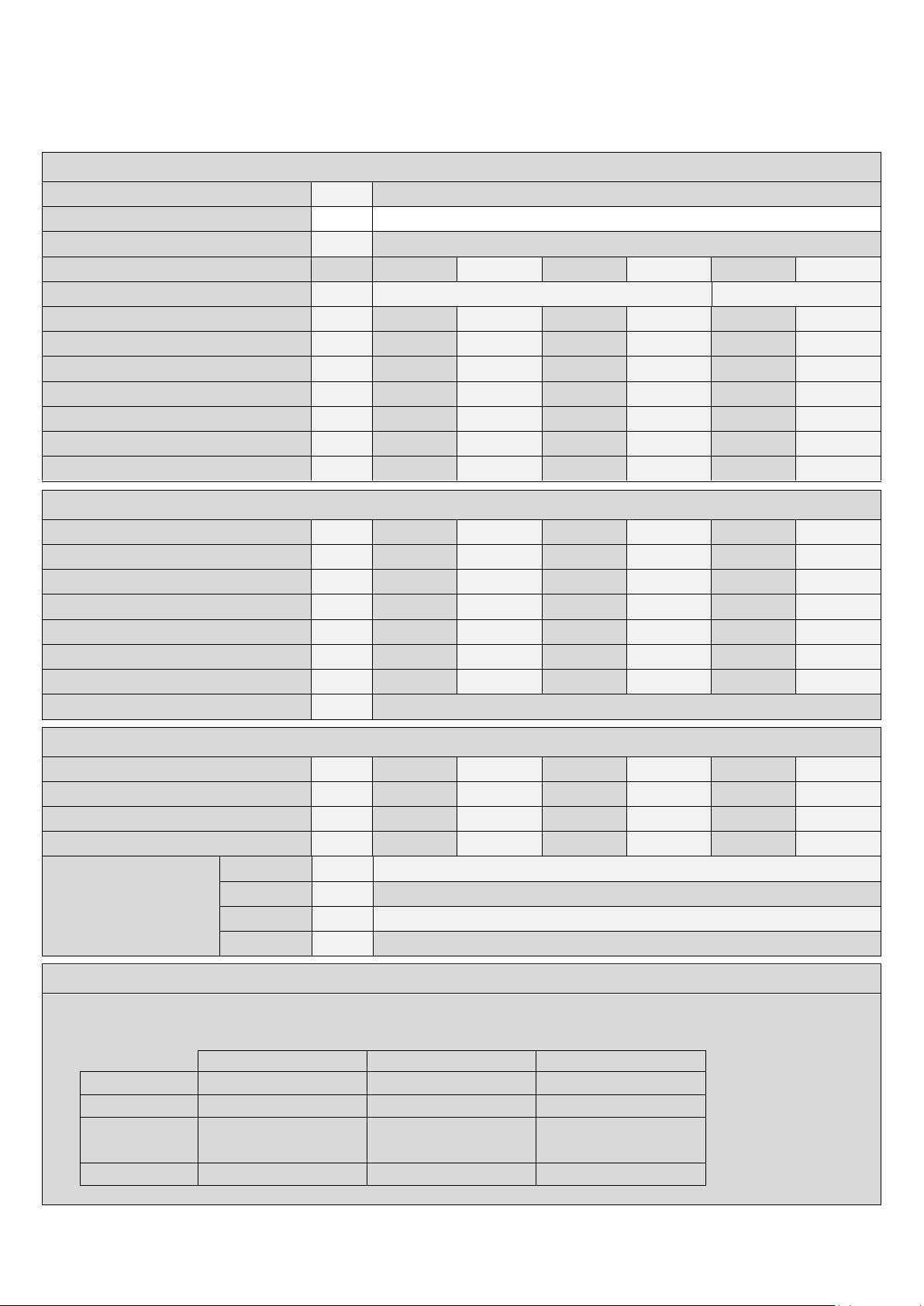

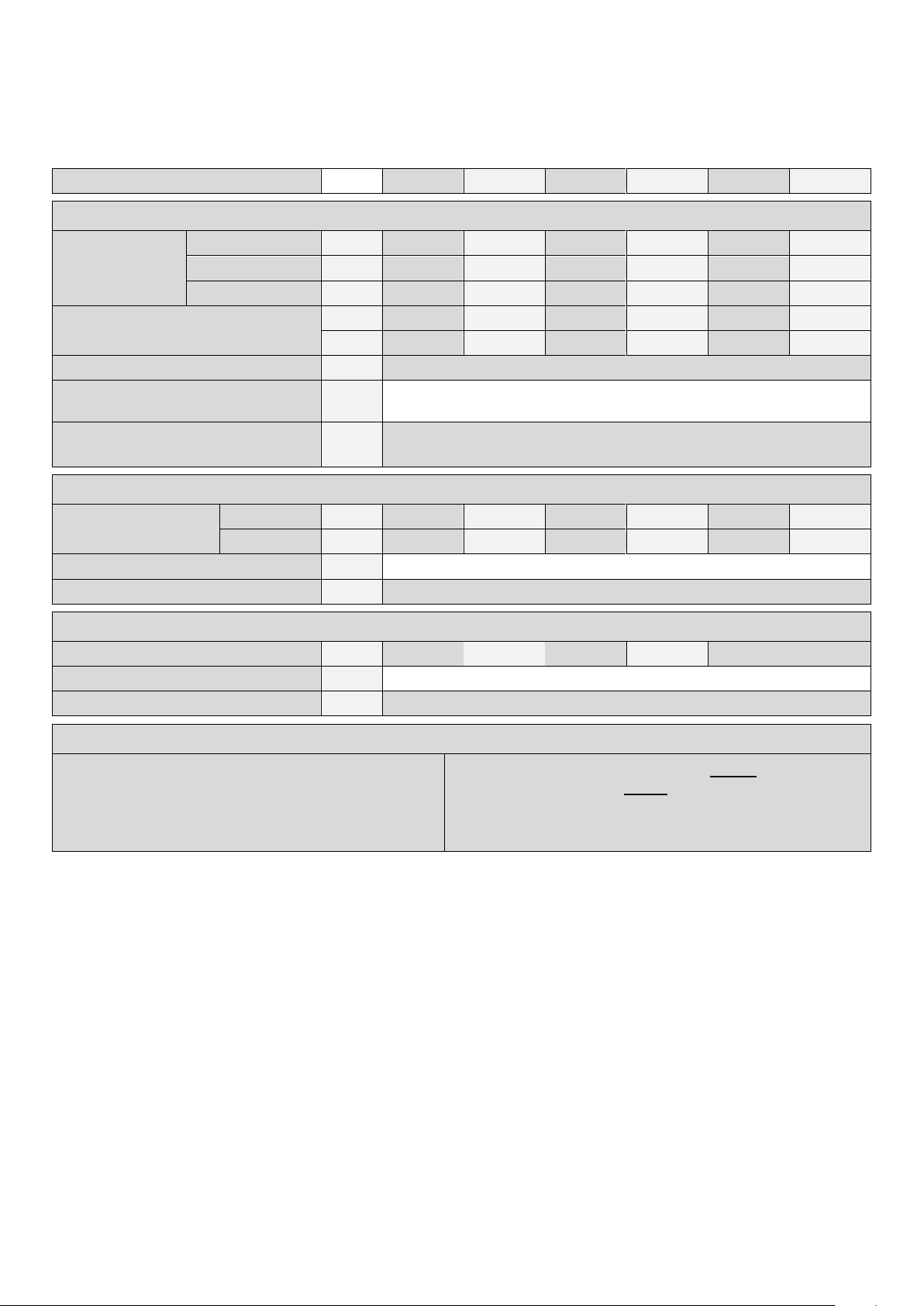

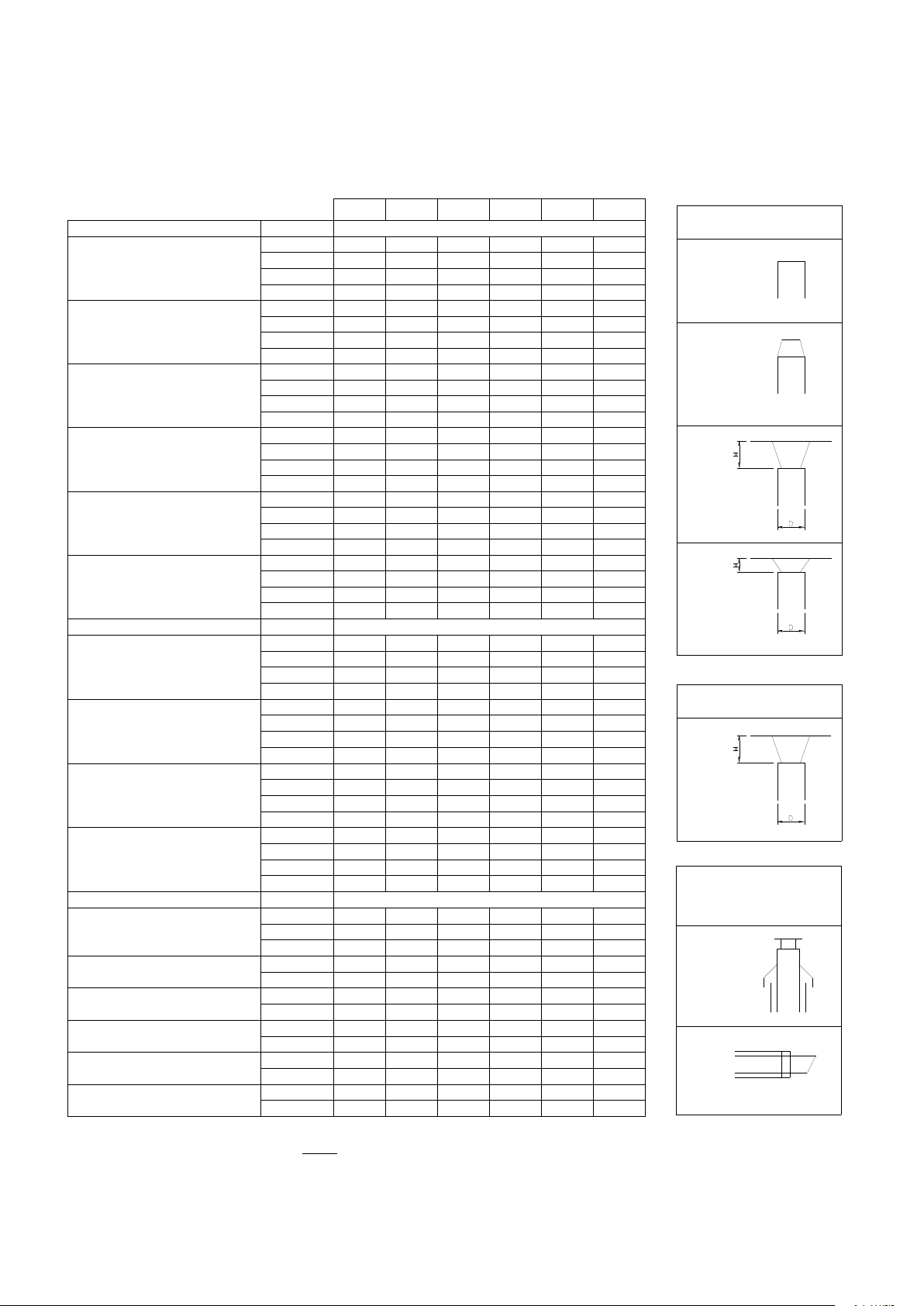

2.2 Technical specifications datasheet

GENERAL

Product Identification Number

-

CE 0063 BP3254

Classification

-

II2H3P (for NL II2L3P)

Gas Appliance Type

-

B23, B23P; C13X, C23X, C33X, C43X, C53X, C63X, C83X

Type boiler

S-CB+60

S-CB+80

S-CB+100

S-CB+120

S-CB+150

S-CB+180

Dimensions (h x w x d)

mm

842 x 476 x 486

898 x 476 x 677

Water content estimated

litre

3,9

5,0

6,5

8,3

10,4

12,9

Weight (empty)

kg

46

73

78

83

92

101

Flow/return connection (boiler)

inch

R 1”

R 1”

R 1”

R 1”

R 1¼”

R 1¼”

Flow/return connection (T-piece)

inch

Rp 1¼”

Rp1¼”

Rp 1¼”

Rp 1¼”

Rp 1½”

Rp 1½”

Gas connection

inch

R ¾”

R ¾”

R ¾”

R ¾”

R 1”

R 1”

Flue duct flue/air inlet (* as supplied)

mm

80/125*

80/125*

100/150*

100/150*

100/150

100/150

Parallel connection (* as supplied)

mm

80-80

80-80

100-100

100-100

130-130*

130-130*

HEATING Values min-max:

Nominal input (Net)

kW

12,5 - 55,6

14,6 - 74,3

17,2 - 92,2

26,0 - 111

34,0 - 138

45,0 - 166

Nominal input (gross) (G20, G25)

kW

13,9 - 61,8

16,2 - 82,5

19,1 - 102

28,9 - 123

37,8 - 153

50,0 - 184

Nominal input (gross) (G31)

kW

13,6 - 60,4

15,9 - 80,8

18,7 - 100

28,3 - 121

37,0 - 150

48,9 - 180

Nominal input (gross) (G30)

kW

13,5 - 60,3

15,8 - 80,2

18,6 - 99,7

34,7 - 120

36,8 - 150

48,8 - 180

Nom. output 80/60°C

kW

12,0 - 53,5

14,0 - 71,2

16,5 - 88,4

24,7 - 106

32,6 - 132

43,3 - 160

Nom. output 50/30°C

kW

12,9 - 57,4

15,2 - 77,5

18,0 - 96,2

27,2 - 116

35,5 - 144

47,3 - 175

Nom. output 37/30°C

kW

13,5 - 59,8

15,7 - 80,1

18,6 - 99,5

28,1 - 120

36,7 - 149

48,5 - 179

Efficiency 40/30°C DIN 4702-8

%

up to 110,6 % within the S-CB+ range

GAS CONSUMPTION [EN437] Values min-max:

Natural gas G25

m³st/h

1,54 - 6,84

1,80 - 9,14

2,12 - 11,4

3,20 - 13,7

4,18 - 17,0

5,54 - 20,4

Natural gas G20

m³st/h

1,32 - 5,88

1,54 - 7,86

1,82 - 9,76

2,75 - 11,8

3,60 - 14,6

4,76 - 17,6

Propane gas G31 1

m³st/h

0,51 - 2,27

0,60 - 3,04

0,70 - 3,77

1,06 - 4,54

1,39 - 5,65

1,84 - 6,79

Butane gas (B/P) G30 1

m³st/h

0,39 - 1,72

0,45 - 2,29

0,53 - 2,85

0,99 - 3,44

1,05 - 4,28

1,40 - 5,15

Gas supply pressure

nom. 2

G25

mbar

25

G20

mbar

20

G31 1

mbar

30/37

G30 1

mbar

50

NOTES

1

Using propane or butane/propane mixtures (B/P), maximum fan speed needs to be reduced (parameter P4BD)

2

Min. and max. gas supply pressures according to EN437:

p nominal [mbar]

p min [mbar]

p max [mbar]

G25

25

20

30

G20

20

17

25

G31

30

25

35

37

25

45

G30

50

43

57

S-CB+ Boiler Range Manual

11

Type boiler

S-CB+60

S-CB+80

S-CB+100

S-CB+120

S-CB+150

S-CB+180

EMISSION [EN437] Values min-max:

CO2 flue gas 3

G25/G20

%

8,7 - 9,0

8,7 - 9,0

8,7 - 9,0

8,7 - 9,0

8,7 - 9,0

8.7 - 9.0

G31

%

9,3 - 10,3

9,3 - 10,3

9,3 - 10,3

9,3 - 10,3

9,3 - 10,4

9.3 - 10.5

G30 (B/P)

%

9,3 - 10,4

9,3 - 10,4

9,3 - 10,4

9,3 - 10,4

9,3 - 10,5

9.3 - 10.6

NOx at 0% O2, year emission

ppm

21,0

31,5

24,6

27,4

25,3

16,5

mg/kWh

37,7

56,6

44,2

49,2

45,4

29,7

NOx class [EN483 / EN15420]

-

5

Flue gas temperature at combustion

air temperature = 20°C

°C

~ 85-95

Available pressure for the flue system 4

Pa

200

INSTALLATION

Available pressure for

the installation at

T = 20 K

mWC

3,8

1,3

1,5

1,0

0,7

0,1

T = 25 K

mWC

5,1

3,7

3,7

3,0

3,2

2,5

Pressure boiler min-max.

bar

1,0 - 4,0 5

Max. flow temperature

°C

90

ELECTRIC

Power consumption

W

355

355

355

370

600

Power supply

V/Hz

230/50

Protection class

-

IPX4D

NOTES

3

CO2 of the unit measured/set without the boiler

front panel in place

4

Maximum allowed combined resistance of flue

gas and air supply piping at high fire

5

When the built-in water pressure sensor is replaced

by a water pressure switch, water pressure may go

up to 6,0 bar

S-CB+ Boiler Range Manual

12

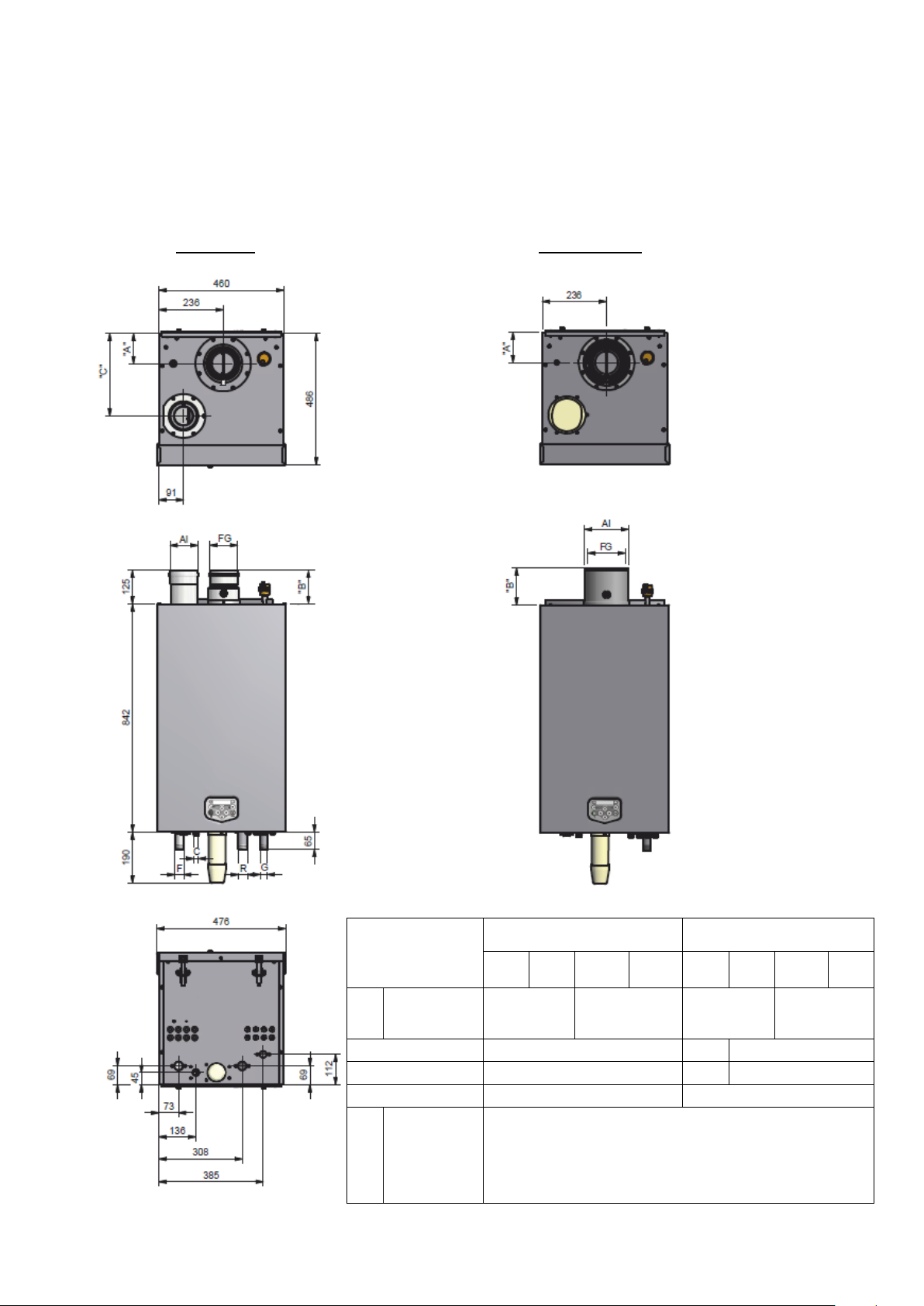

3 DIMENSIONS

Connections

twin pipe

Concentric

(Standard Delivery)

+

60 +80 +100 +120 +60 +80 +100 +120

FG

AI

flue gas

air inlet

80-80

100-100

80/125

100/150

size "A"

112

155

112

size "B"

135

150

135

size "C"

308

N.A.

F

C

R

G

flow

condensate

return

gas

R 1¼" (male)

flexible hose Ø25/21 x 750 mm

R 1¼" (male)

R ¾" (male)

3.1 S-CB+ 60-120

TWIN PIPE CONCENTRIC (Standard Delivery)

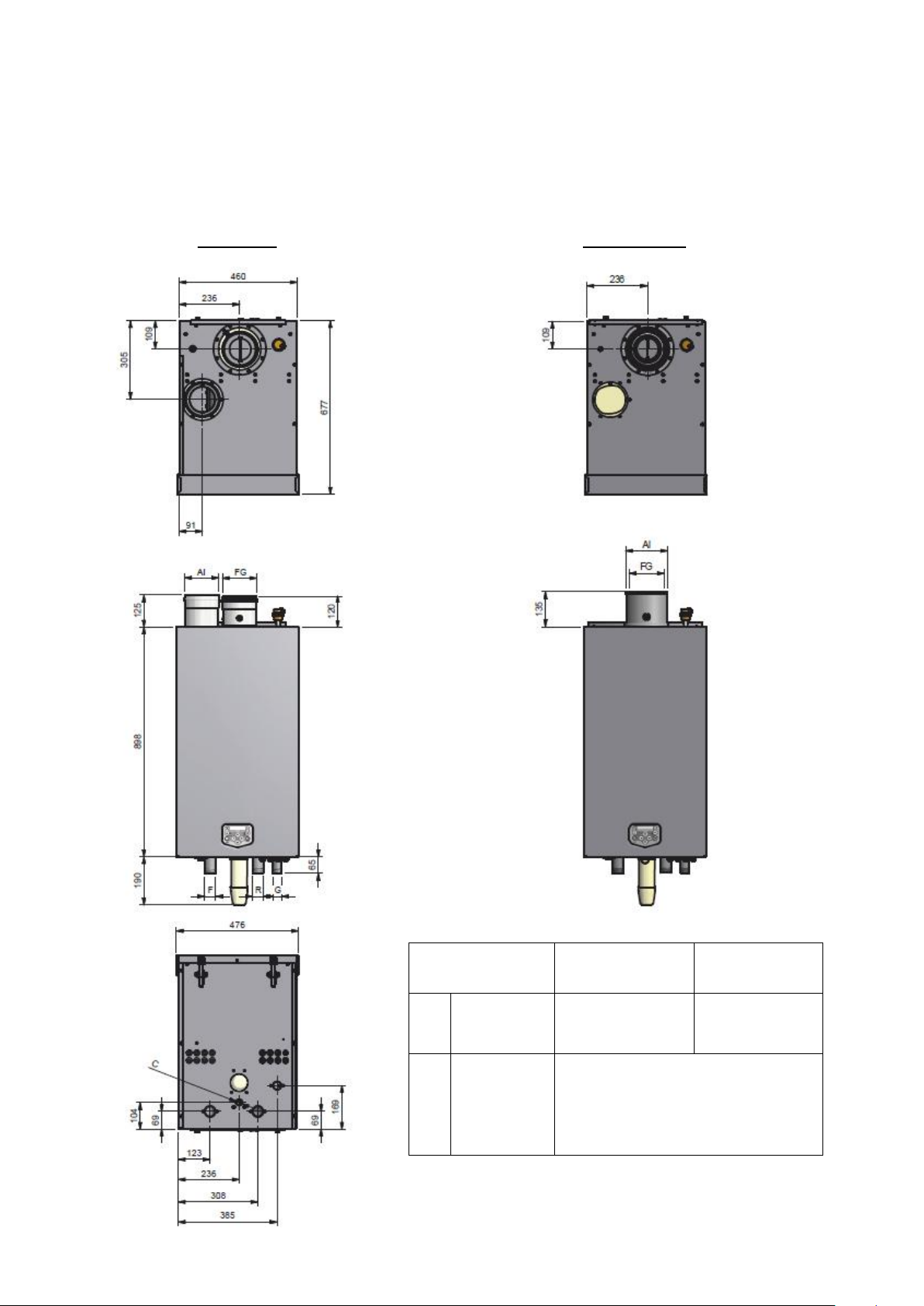

S-CB+ Boiler Range Manual

13

Connections

twin pipe

(Standard Delivery)

concentric

FG

AI

flue gas

air inlet

130-130

100/150

F

C

R

G

flow

condensate

return

gas

R 1½" (male)

flexible hose Ø25/21 x 750 mm

R 1½" (male)

R 1” (male)

3.2 S-CB+ 150-180

TWIN PIPE (Standard Delivery) CONCENTRIC

S-CB+ Boiler Range Manual

14

4 ACCESSORIES AND UNPACKING

Item

Part Nº.

Outdoor (air) temperature sensor: 12kOhm@25°C (to be connected to the boiler connections)

E04.016.585

External flow temperature sensor for system side of the low loss header: 10kOhm@25°C (to

be mounted to the boiler connections)

E04.016.304

Calorifier temperature sensor: 10kOhm@25°C (to be connected to the boiler connections)

S04.016.303

Conversion sets flue and air terminals

S-CB+60: concentric to twin pipe 80/125→80-80

E61.001.162

S-CB+60: twin pipe to concentric 80-80→80/125

E61.001.187

S-CB+80: concentric to twin pipe 80/125→80-80

E61.001.163

S-CB+80: twin pipe to concentric 80-80→80/125

E61.001.170

S-CB+100-120: concentric to twin pipe 100/150→100-100

E61.001.164

S-CB+100-120: twin pipe to concentric 100-100→100/150

E61.001.171

S-CB+150-180: concentric to twin pipe 100/150→130-130

E61.001.165

S-CB+150-180: twin pipe to concentric 130-130→100/150

E61.001.172

Room Controller “OpenTherm” RC (Modulating) with room sensor

S04.016.355

Room Controller “OpenTherm” RC (Modulating) no room sensor/to be used with E04.016.359

S04.016.358

External room sensor for the RC and RCH controller: 5kOhm@25°C

E04.016.359

Room thermostat (modulating) RCH with e-bus interface, to control one heating zone (Thermostat includes room sensor).

S04.016.357

EBC heating zone controller to control 2 different heating zones. This EBC will include the wall

housing unit, for an easy installation and connection.

S04.016.550

Interface IF to convert an OpenTherm signal to an E-bus signal (One interface for each boiler

or one interface for cascaded boilers).

S04.016.552

External flow sensor for one heating zone: 5 kOhm@25°C

E04.016.363

Software + interface cable for programming the boiler with a computer/laptop

S04.016.586

4.1 Accessories

Depending on the selected controlling behaviour for the central heating system and/or the optional use of a calorifier, the following items can be supplied with the boiler. Ask your supplier for the specifications.

4.2 Unpacking

The S-CB+ boiler will be supplied with the following documents and accessories:

One “Mounting Instructions” manual for the installer

One suspension bracket with locking plate and bolts

Three spare nuts for mounting the burner plate, two spare fuses for the boiler control and a gas conversion

sticker (all in a bag attached to the front of the gas valve)

Bottom part of the siphon

Two T-pieces for the flow and return connections of the boiler

After delivery, always check the boiler package to see if it is complete and without any defects. Report any imperfections immediately to your supplier.

S-CB+ Boiler Range Manual

15

5 INSTALLATION OF THE S-CB+

5.1 General notes

At every side of the boiler at least 50 mm of clearance should be applied to walls or wall units, 350 mm above the

top side of the boiler and 250 mm from the bottom of the boiler.

The installation area/room must have the following provisions:

230 V - 50 Hz power source socket with earth connection.

Open connection to the sewer system for draining condensing water.

A sound-deadening wall.

Note:

The wall used for mounting the boiler must be able to hold the weight of the boiler. If not, it is recommended to

mount the boiler by means of a (cascade) frame.

Other considerations related to the boiler location.

The ventilation of the boiler room must meet local and national standards and regulations, regardless of the

selected supply of fresh air to the boiler.

Both the air supply and the flue gas pipes must be connected to the outside wall and/or the outside roof.

The installation area must be dry and frost-free.

The boiler has a built-in fan that will generate noise, depending on the total heat demand. The boiler loca-

tion should minimise any disturbance this might cause. Preferably mount the boiler on a brick wall.

There must be sufficient lighting available in the boiler room to work safely on the boiler.

When a boiler is positioned at the highest point of the installation, the supply and return pipes must first

protrude 0.5 m above the top of the boiler, before these pipes go to the installation side. In other words, the

water level must always be 0.5 meter above the top of the boiler and an automatic air vent must be installed in the supply or return pipe. A low-water level protection should also be installed at the installation

side.

Remind the positioning of electrical components in relation to the temperature sensitivity.

Make sure there is an open connection with the sewer to drain the condensate. This connection should be

lower than the condensate drain level of the boiler.

The boiler must be positioned and installed by a skilled installer in accordance with all applicable standards and

regulations. Commissioning of the boiler must be done by a skilled service/commissioning engineer, who is trained

for this type of boiler.

S-CB+ Boiler Range Manual

16

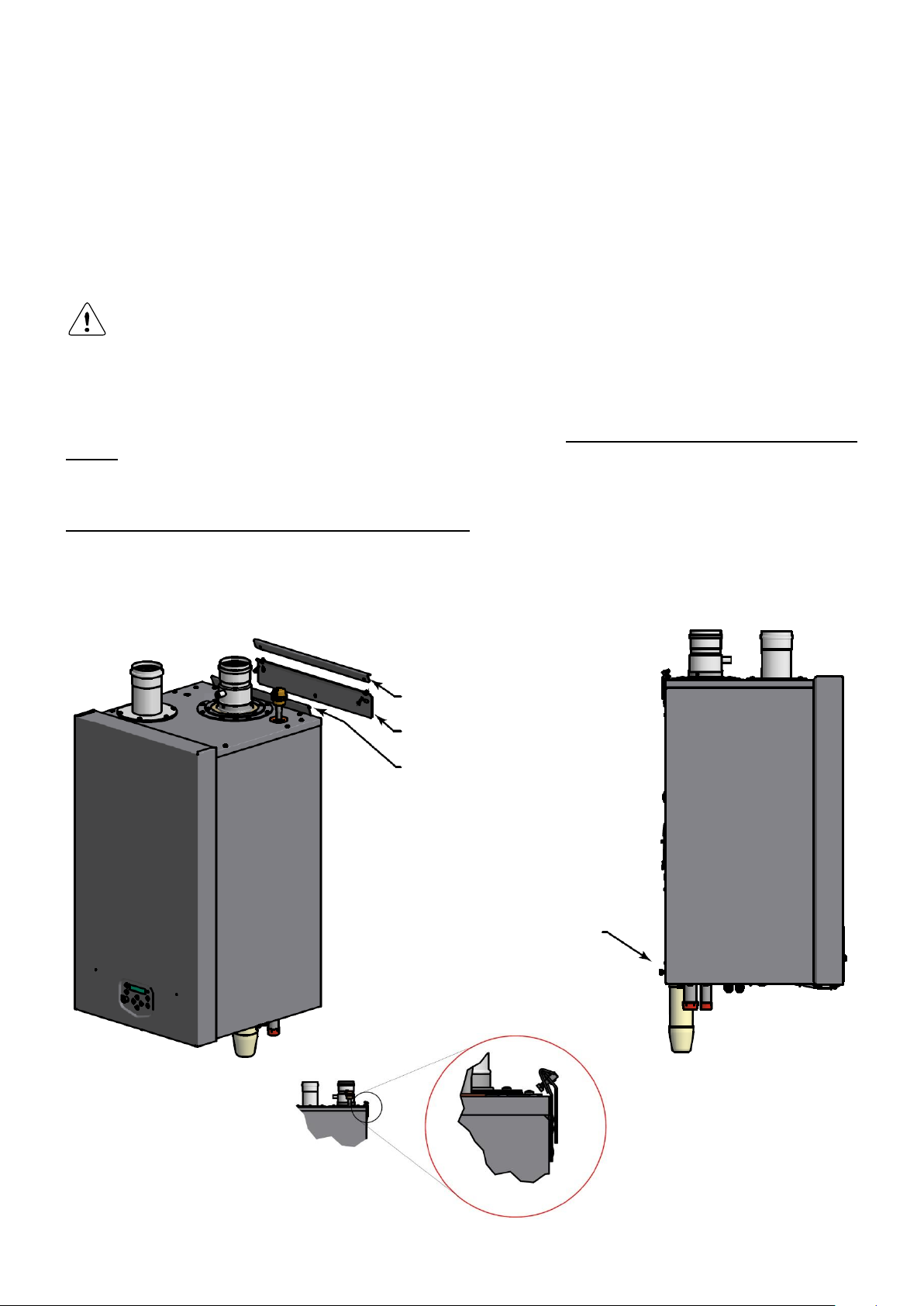

5.2 Mounting the boiler

All lines/piping must be mounted free of tension. The weight of the installation components should be supported separately from the boiler so there will be no standing forces on the connections.

This might influence the mounting position of the boiler.

1. Attach mounting bracket to wall

with inclined side facing upwards

3. Lock boiler with locking plate

and two bolts

2. Suspend boiler with suspension

bracket on mounting bracket

4. Level boiler using

adjusting bolts

Before mounting and installing the boiler the following connections should be considered:

Flue gas system and the flue gas pipe connections

Air supply system and connections

Flow and return pipe connection

Condensate and pressure relief valve drainage

Power supply (preferably the power connection positioned above the boiler)

Determine the position of the flow and return pipes by using the included suspension bracket or a suspension

frame (when supplied).

While marking the holes, ensure that the suspension bracket or frame is perpendicular and the boiler does not lean

forward. If necessary adjust the position with the adjusting bolts at the lower rear side of the back panel (see drawing). When the adjusting bolts aren’t sufficient, fill the gap behind the bolts to get the boiler in position. The exact

boiler position lies between the boiler hanging level and hanging slightly backwards.

The boiler should not lean forward in the mounted position.

Lock the suspension bracket with the security cover before making any other connections to the boiler. This secu-

rity cover will prevent the boiler from falling off the bracket. Don't use excessive force during the mounting of the

boiler connections.

suspension detail

S-CB+ Boiler Range Manual

17

6 CONNECTIONS WATER SIDE

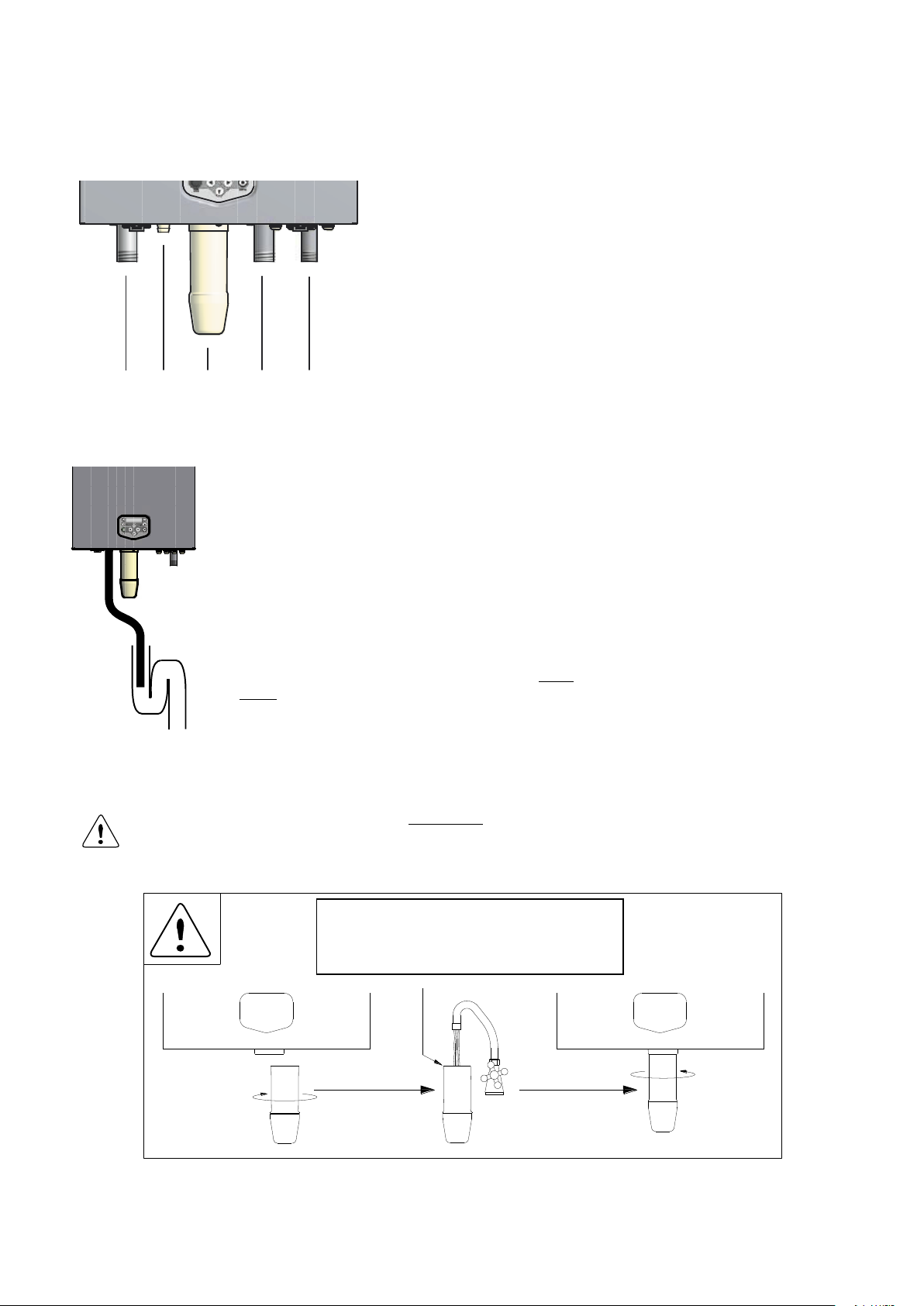

FRONT VIEW

1 2 3 4 5

6.1 Boiler connections

1 – Flow CH

2 – Condensate drain

3 – Siphon cleaning point

4 – Return CH

5 – Gas

Open connection

to the sewer.

6.2 Condensate drain connection

The condensate drain is placed at the centre and at the bottom of

the boiler and has a ¾ inch hose discharge. Connect this flexible

hose to the sewer system.

Use only plastic parts with the condensate drain. Metal lines are not

allowed.

Blockage of this drain might damage the boiler. The drain connection is correct when the condensate can be seen flowing away, e.g.

using a funnel. Any damage that might occur, when the drain is not

installed correctly, is not covered by the warranty of the boiler.

There should be an open connection of the condensate hose into

the sewage system. A possible vacuum in the sewage system must

never give the opportunity to suck on the boiler’s condensate drain

hose.

When mounting the bottom part of the siphon, before commissioning the boiler and/or after maintenance, the siphon must ALWAYS be completely filled with water.

This is a safety measure: the water in the siphon keeps the flue gases from leaking out of the

heat exchanger via the condensate drain.

The siphon must always be filled to the

edge with water, before placing back on

the unit.

S-CB+ Boiler Range Manual

18

6.3 Flow and return connections

Two separate T-pieces are shipped with the boiler.

These are applied for externally mounting the pressure

relief valve and the boiler bleed valve for servicing the

boiler. We advise to install two service valves in the

flow and return pipes underneath the boiler, so the

boiler can be isolated from the heating system and

eventually disconnected, when needed.

When using a system pump, this pump should always

be mounted in the return pipe of the heating system.

Do not use chloride-based fluxes for soldering any

pipes of the water system.

6.4 The expansion vessel

The capacity of the expansion vessel must be selected

and based on the capacity of the central heating system

and the static pressure. Suggested is to fit the expansion vessel in the return pipe of the central heating system. It can be combined with the drain valve for service.

See the above drawing.

P1

supplied

with

boiler

supplied

with

boiler

BOILER

boiler bleed

valve for service

boiler service valves

pressure

relief valve

expansion

vessel

6.5 Pressure relief valve

The boiler has no internal pressure relief valve. This should be installed close to the boiler in the flow pipe of the

heating system. When having cascaded boilers, each boiler should have its own pressure relief valve. It is advised

to use the T-piece that is supplied with the boiler, for this.

Advice is always to install service valves, so the boiler can be isolated from the heating system, when needed.

Make sure that the pressure relief valve is mounted between the boiler and the service valves.

The specifications and size of the relief valve should be determined by the installer and must comply with all applicable regulations and boiler capacity.

6.6 Bypass

The boiler has no internal bypass. When many thermostatic valves are being used, the system should have a bypass to allow an adequate flow when all thermostatic valves are closed. Instead of a bypass also a low-loss header

can be used for this function.

The boiler flow will also be influenced when a pipe of the heating system is frozen / blocked. Make sure all heating

pipes are free from the risk of frost. If there is the risk of freezing of the heating system, all the pipe section must be

insulated and/or protected with the help of a tracing.

6.7 Pump functionality

Controlling the pump:

The pump speed is controlled by a PWM signal provided by the burner controller at a value causing a Delta T

across the heat exchanger of 20°C at the whole burner modulation range.

When the boiler modulates down or up, also the pump speed decreases or increases, keeping delta T at 20°C until

it reaches the end of its modulation range.

Delta T monitoring:

The delta T monitoring parameters are active. A malfunctioning of the pump, burner controller or a high resistance

in the hydraulic system will cause a high Delta T and will therefore be detected by the burner controller. The display

shows “dT Block” or “FlowReturn dTfault”.

S-CB+ Boiler Range Manual

19

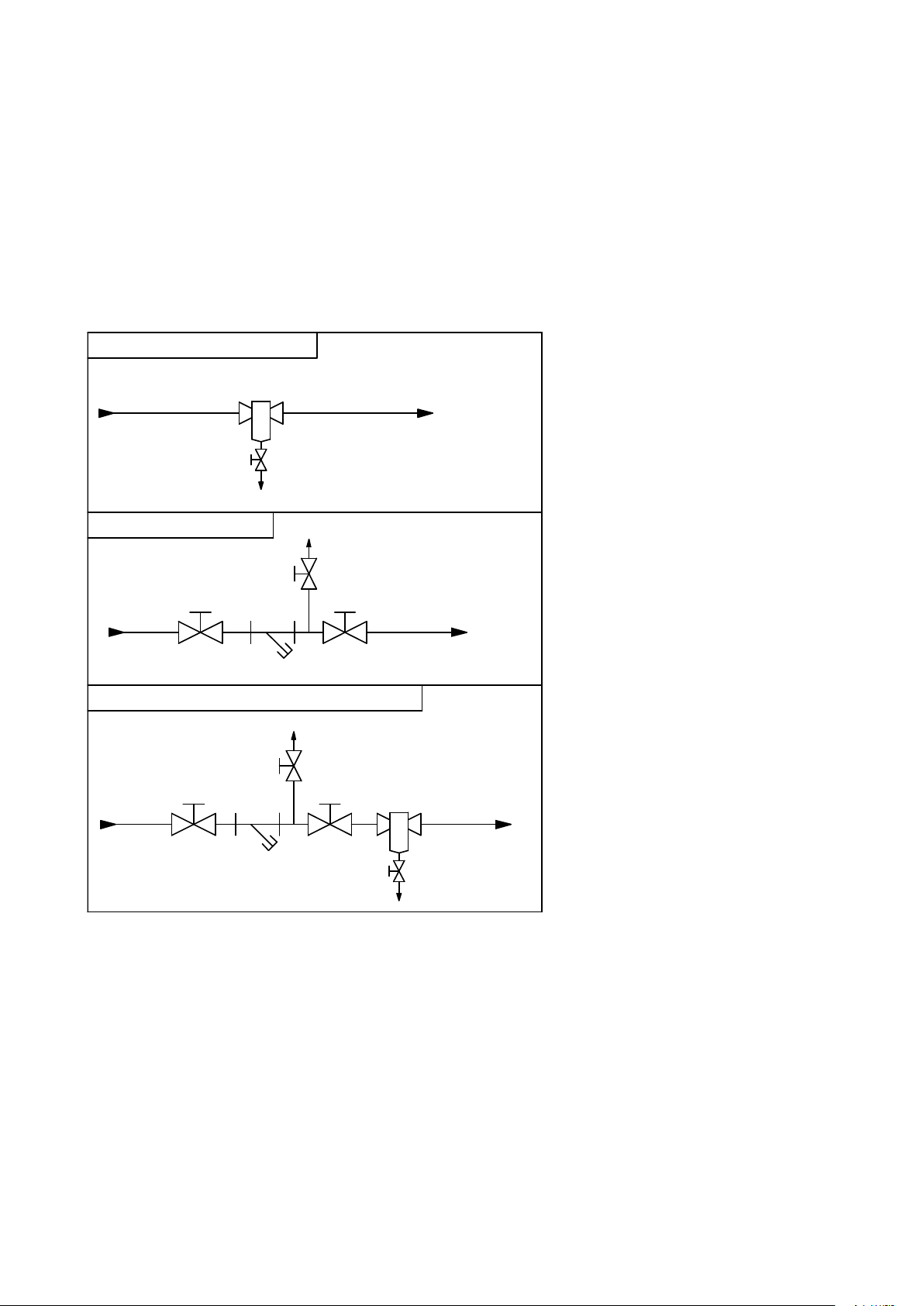

6.8 Frost protection

Always install a strainer (water filter)

and/or a dirt separator in the return pipe

of the boiler; in such a way that the water going to the boiler is free of any debris/particles. When using a water filter

always check a week after installation to

determine the strainer cleaning interval.

Advice is to mount valves before and

after the strainer, including an air bleed

valve, so the strainer can be isolated

from the heating circuit for service operations. Clean water is very important,

blocked and/or polluted heat exchangers, including failures and/or damages

caused by this blockage are not covered

by the warranty.

SYSTEM WITH DIRT SEPARATOR

SYSTEM WITH STRAINER

SYSTEM WITH STRAINER AND DIRT SEPARATOR

DIRT SEPARATOR

DIRT SE-

PARATOR

WATER RETURN FROM

SYSTEM

WATER

RETURN

FROM

SYSTEM

WATER

RETURN

FROM

SYSTEM

WATER FLOW

TO BOILER(S)

WATER FLOW

TO BOILER(S)

WATER

FLOW TO

BOILER(S)

DIRT

BLEED

VALVE

DIRT

BLEED

VALVE

AIR

BLEED

VALVE

AIR

BLEED

VALVE

VALVE

VALVE

VALVE

VALVE

STRAINER

(WATER FILTER)

STRAINER

(WATER FILTER)

The boiler has a built-in frost protection that is automatically activating the central heating pump when the boiler

return (water) temperature drops below the 5°C (programmable). When the boiler return temperature drops below

the 3°C (programmable), the burner is also ignited. The pump and/or burner will shut down as soon as the return

temperature has reached the 10°C (programmable). The mentioned temperatures are related to the temperatures

measured by the RETURN sensor of the boiler. This frost protection function will not fire up the boiler in case of a

“general blocking” of the burner demand.

NOTICE: This “Frost Protection” function is only useable for the boiler and not for the whole central heating system.

Because it concerns a programmable setting, a boiler damaged by frost is not covered under warranty.

6.9 Installing a strainer and/or dirt separator

6.10 Water quality

The pH value of the water must be within the following limits: 7,5 < pH < 9,5. This pH value is reached with the

steady conditions. These steady conditions will occur, when after filling the heating system (pH around 7) with fresh

water, the water will lose its air because of the air bleeding operation and heating up (dead water conditions).

Water hardness must be within the following limits:

3,5° Clark (50 ppm CaCO3) < total hardness < 10,5° Clark (150 ppm CaCO3)

When the water might contain aluminium particles, this should be of a maximum of 0.2 mg/litre. If there is the risk of

contamination of the water by any kind of debris/chemicals in the period after installing, a plate heat exchanger

should be used to separate the boiler circuit from the heating circuit (see drawing below).

It is advised to prevent the possible air intake and water leakage of the central heating system. Fresh oxygenated

water might damage the heat exchanger of the boiler and should therefore be prevented! Usual spots where air is

most likely to seep in are: suction gaskets, pumps, air valve working as a venting pipe, O-rings / gaskets in stuffing

box, under floor heating pipes.

S-CB+ Boiler Range Manual

20

6.11 Plastic piping in the heating system

BOILER

BOILER

BOILER

BOILER

HEATING

ZONE

HEATING

ZONE

PLATE HEAT EX-

CHANGER

PLATE HEAT

EXCHANGER

When plastic pipes are used in the central heating system, these should be separated from the boiler system by

using a plate heat exchanger. Diffusion (through the plastic) can cause air to enter the heating system. This could

damage the boiler, pumps and other components in the system. Be aware that plastic piping is often used in under

floor heating systems. When no measures have been taken to prevent the entrance of air into the boiler system,

the warranty of the boiler and any boiler part may be deemed invalid.

6.12 Automatic air vent

An automatic air vent is mounted on the boiler to remove the air from the water circuit.

NOTICE: This automatic air vent is only used for bleeding the air in the heat exchanger of the boiler. One or more

external automatic air vent(s) and/or air separators must always be mounted in the heating system to take out the

air trapped in the heating circuit.

DE-AERATION PROGRAM. When the unit is fired for the first time the unit starts a de-aeration program. One cycle

means 5 seconds pump running and 5 seconds pump off. A complete de-aeration program consists out of three

cycles. The de-aeration program can be interrupted/stopped by briefly pressing the service button.

6.13 Automatic water filling systems

When using an automatic water refill system some precautions should be taken (fresh water is bringing fresh oxygen into the system), like installing a water meter to measure and evaluate the total water volume that is added to

the system. This to detect and eliminate any water leakage as soon as possible.

When an automatic water refill system is used, some form of logging should take place to prevent continuously

filling of the system with large amounts of oxygenated fresh water. This can happen when a leak in the system is

not detected and the total added water amount is not being logged.

6.14 Water pressure

First and for all, the installation should be designed and built conform all applicable regulations and standards, including the right safety valves. IMPORTANT: Always keep the pressure in the boiler lower than the value at which

its safety valve opens.

Sensor

A water pressure sensor has been built into the boiler. With this sensor, the minimum water pressure in the boiler is

0,8 bar and the maximum pressure is 4,0 bar (sensor values). The normal water pressure is supposed to be between 1,5 and 2,0 bar.

The pressure sensor will stop the boiler from firing when the water pressure drops below 0,8 bar, and start the

boiler firing again when the water pressure reaches above the 1,0 bar. These values can be changed in the boiler

control settings.

S-CB+ Boiler Range Manual

21

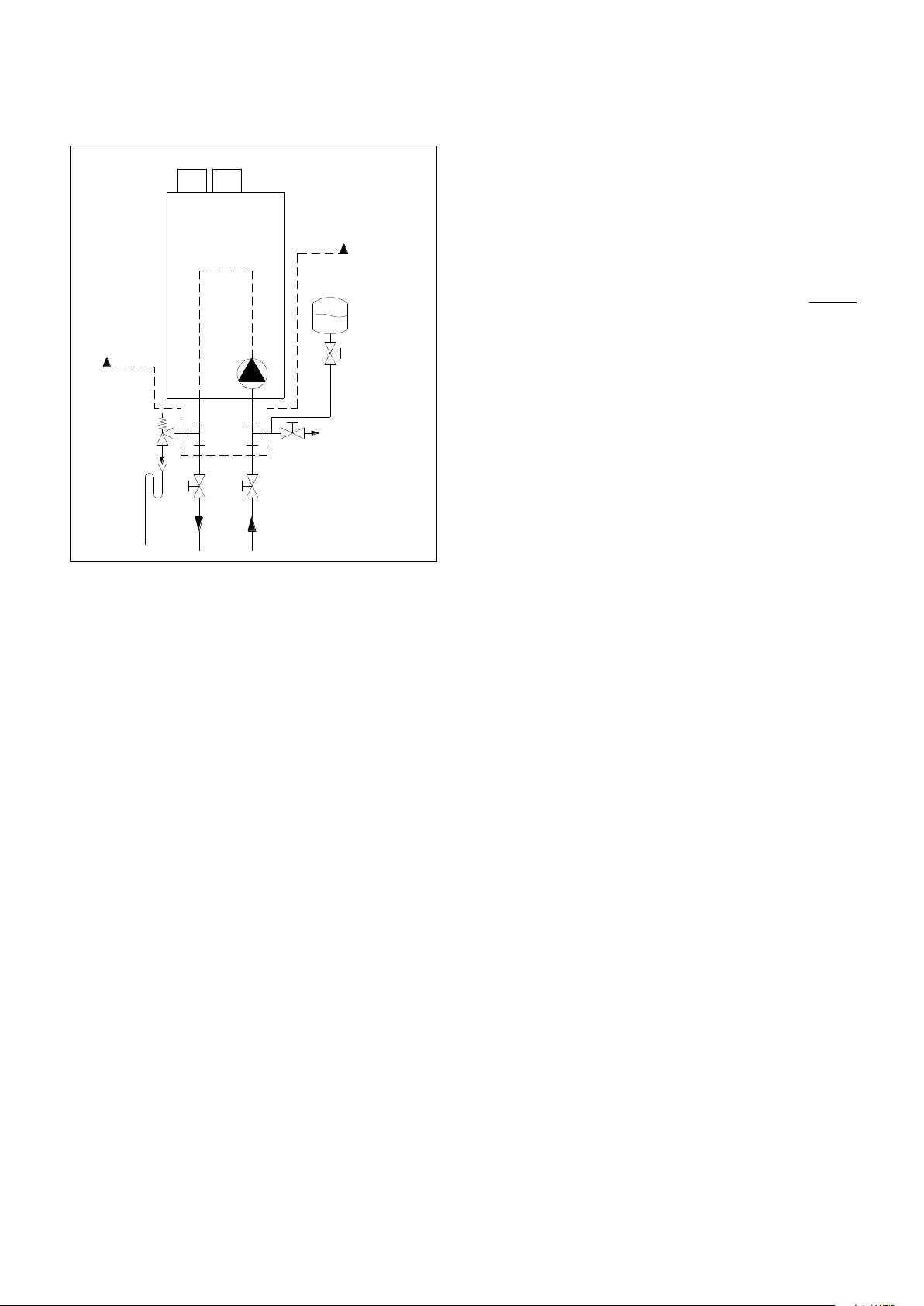

valve

air separator

dirt separator

strainer (water filter)

pressure relief valve

siphon

pump

automatic air vent

expansion vessel

low loss header

BOILER

HEATING ZONE

Higher pressure systems (e.g. in high buildings)

If pressures higher than 4,0 bar occur in the heating system, the best solution is to separate the system from the

boiler by means of a plate heat exchanger. Now the boiler pressure can still be under 4,0 bar and the boiler control

remains as described above.

Without plate heat exchanger, above 4,0 bar, a water pressure switch has to be built into the boiler instead of the

water pressure sensor - the maximum allowed value in the boiler now is 6,0 bar and the boiler control needs to be

adjusted.

6.15 Chemical water treatment

The chemical compatibility of several products for treatment of the central heating equipment has been tested on

the heat exchangers and the boilers. A list with the corrosion inhibitors in preventative and curative treatment for

gas fired central heating boilers can be supplied by Strebel Ltd.

6.16 Under floor heating

When using an under floor heating system, the boiler circuit must be separated from the heating circuit with a plate

heat exchanger.

6.17 Flush the system with fresh water

The water of the boiler and heating circuit should be free of any particles, debris and pollution. Therefore the complete installation must always be thoroughly flushed with clean water before installing and using the boiler(s).

6.18 Installation examples

6.18.1 EXAMPLE OF A STANDARD SINGLE BOILER HEATING CIRCUIT WITH LOW LOSS HEADER

S-CB+ Boiler Range Manual

22

S-CB+ Boiler Range Manual

23

6.18.2 EXAMPLE OF A MULTIPLE BOILER HEATING CIRCUIT WITH LOW LOSS HEADER

NON RETURN

VALVE

(low resistance

type)

NOT SPRING

LOADED

HEATING

ZONE

BOILER

BOILER

S-CB+ Boiler Range Manual

24

7 PUMP CHARACTERISTICS

7.1 Hydraulic graphs

Boiler and pump graph S-CB

+

60. UPML 25-105PWM:

Boiler and pump graph S-CB

+

80. UPML 25-105PWM:

S-CB+ Boiler Range Manual

25

Boiler and pump graph S-CB

+

100. UPML 25-105PWM:

Boiler and pump graph S-CB

+

120. UPML25-105 PWM:

S-CB+ Boiler Range Manual

26

Boiler and pump graph S-CB

+

150. Wilo Stratos Para 30/1-12 PWM:

Boiler and pump graph S-CB

+

180. Wilo Stratos Para 30/1-12 PWM:

Explanation pump graph:

The S-CB+ range is equipped with high efficiency pumps, in the hydraulic graph there is a minimum and maximum

head for the pump. This is the range in which the pump will modulate.

The pump speed is controlled by a PWM signal provided by the burner controller at a value causing a Delta T

across the heat exchanger of 20°C at the whole burner modulation range.

S-CB+ Boiler Range Manual

27

7.2 Pumps: maximum electrical power

General

- The start current of a conventional pump is approximately 2½ x its nominal current.

- The maximum switch current of the PCB is 5 A.

When the two statements are combined, the conclusion is that nominal currents of pumps, controlled by the PCB,

may not exceed 2 A.

Pump P1 - boiler pump.

This modulating pump is part of the appliance. The speed and power consumption depends on the Delta T across

the heat exchanger and is controlled by the burner controller.

Pump P2 - calorifier pump.

Pump P2 is a DHWi pump and is used when P4AA = 1, meaning the appliance is an indirect calorifier.

Pumps P1 and P2 are connected to one fuse of 5 A, so their total nominal current may not exceed 5 A. To limit the

inrush current, the switching sequence has been modified so pump P2 always switches 100 ms later than pump

P1.

The maximum nominal current of pump P2 must also be 2 A, again due to the inrush current.

3 way valve.

The combined nominal current of pump P1 and the 3 way valve must be smaller than 5 A.

So, the inrush current of the 3 way valve must be lower than 3 A.

Pump P3 - system pump.

The nominal current of pump P3 must be equal to or lower than 2 A.

Warning (EC pumps):

In case of using an electronic commutating pump, the relays 1, 2 or 3 may not be used for the power connection,

because of the inrush current of the electronics of the pump.

Directly connect the pump to an external power supply.

Control connections of an EC pump can be established in several ways, set by parameter P5BN.

See § 11.1.7 on page 79.

8 FLUE GAS AND AIR SUPPLY SYSTEM

8.1 General

The boiler has a positive pressure flue system. The available combined pressure drop for the inlet and outlet system is 200 Pa for the complete boiler range.

Notice:

Install the horizontal flue components with an angle of 3° downwards in the direction of the boiler (roughly

equal to five centimetres for every linear meter). When not installed accordingly, it may result in condensate

building-up in the flue gas tube, eventually causing component failure.

Wall flue terminals are generally used up to 60-80 kW. Using these terminals with larger capacities will give

unpleasant large condensate clouds.

When using a wall terminal, there is the possible risk of ice building-up on surrounding parts/structures, be-

cause the condensate will freeze. This risk should be taken into account during the design phase of the heating installation.

Note

Because the flue gases can have a low temperature, the boiler needs to have a high efficiency approved stainless

steel or plastic flue system. These materials, including the gaskets, should be usable for positive pressure flue gas

systems and have a temperature class of T120.

S-CB+ Boiler Range Manual

28

8.2 Air supply

Never use aluminium (containing) flue gas materials for this boiler.

The S-CB+ 60 boiler as shown in the picture below, is a twin pipe boiler with separate air inlet and flue

outlet pipes. Do NOT connect a concentric pipe to this boiler.

Note the sticker on the flue

pipe, indicating that this is

a twin pipe boiler.

The twin pipe version

is recognized by the

two pipes, one of

which has a RED ring

cap.

When an air supply duct is connected from the outside of the building to the boiler, the boiler will operate as a

room-independent boiler (closed boiler).

The air supply duct can be made of:

PVC / PP

Thin-walled aluminium

Stainless steel

8.2.1 COMBUSTION AIR QUALITY

Combustion air must be free of contaminants. For example: chlorine, ammonia and/or alkali agents, dust, sand and

pollen. Remind that installing a boiler near a swimming pool, a washing machine, laundry or chemical plants does

expose combustion air to these contaminants.

8.2.2 AIR SUPPLY THROUGH HUMID AREAS

When the supply duct will be placed in a boiler room with moist air (for example: greenhouses), a double walled

supply duct or an insulated duct must be used to prevent the possible condensation at the outside of the duct. It is

not possible to insulate the internal air pipes of the boiler and therefore condensation at the internal air canals must

be prevented.

When roof mounted, the air supply duct needs to be protected against rain, so no water will be entering the boiler.

8.3 Flue terminal

The flue terminal duct can be made of:

Stainless steel in combination with T120 gaskets

PP temperature class T120

Multiple boilers can be connected to a common duct. These flue gas systems for multiple boiler installations must

always be engineered as zero or negative pressure systems; this to prevent the risk of recirculation of the flue

gases. Consult the flue gas supplier for detailed information and engineering. See also the cascade manual for

these multiple boiler installations.

8.4 S-CB+ 60 Twin pipe version

S-CB+ Boiler Range Manual

29

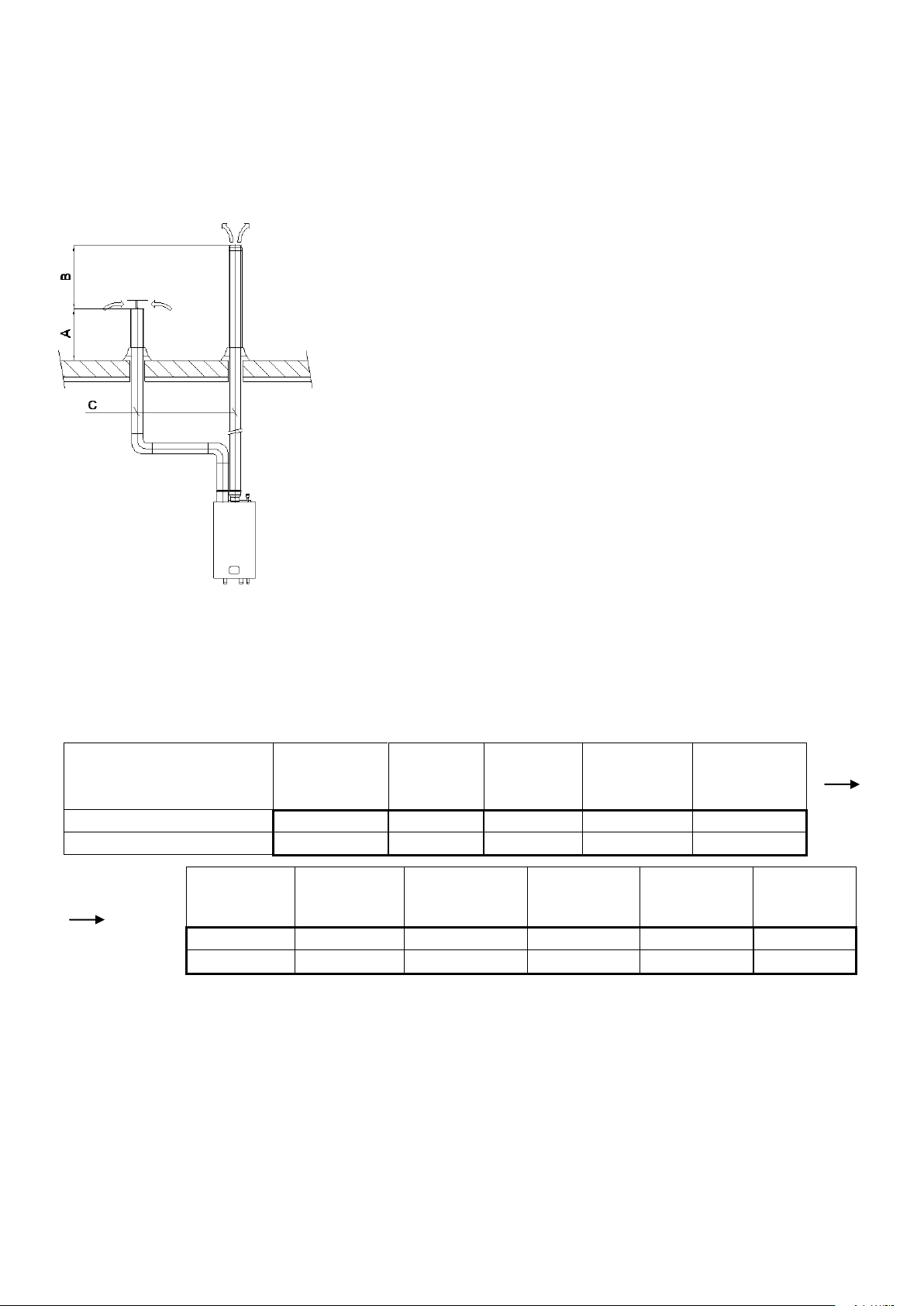

8.5 Pipe heights and mutual distances on a flat roof

Height A

This is the height of the air inlet. A rain hood should prevent

rainwater entering the air supply system.

When the inlet and outlet are mounted on a flat roof, the inlet should

be at least 60 cm above the roof surface and at least 30 cm above the

maximum snow level.

Example 1:

When the maximum snow level on the roof surface is 45 cm then the

air inlet should be at 45+30=75 cm. 75 cm is more than the minimum

60 so the height will be 75 cm.

Example 2:

When the maximum snow level on the roof surface is 15 cm then the

air inlet should be at 15+30=45 cm. 45 cm is less than the minimum

60 cm so the height will be 60 cm.

Height difference B

This is the distance between the flue outlet and the air inlet.

The flue gas outlet should be at least 70 cm above the air inlet. It is

advised to be equipped with a conical outlet.

When no air inlet connection is applied on the roof, the flue outlet should be situated at least 100 cm above the roof surface.

Distance C

The horizontal mutual distance at roof level.

This distance should be at least 70 cm.

CE string flue gas

material (B23P)

European standard

Temperature class

Pressure

class

Resistance to

condensate

Corrosion resistance class

min. requirement PP

EN 14471

T120

P1 W 1

min. requirement StS

EN 1856-1

T120

P1 W 1

Metal: liner

specifications

Soot fire resistance class

Distance to

combustible

material

Plastics:

location

Plastics: fire

behaviour

Plastics:

enclosure

O 30

I or E

C/E

L

L20040 O 40

8.6 B23P certified

Overpressure flue gas systems

For boiler classification B23P and for overpressure flue gas systems the minimum requirements of the flue gas

material for Eco Boilers can be determined in a designation string according to the EN1443 (see table):

A few examples of flue gas material suitable for ECO boilers:

CE String for Plastic PPs: EN14471 T120 P1 W 2 O(30) I C/E L

CE String for Stainless Steel: EN1856-1 T250 P1 W V2-L50040 O (50)

When selecting flue gas systems, be aware that the minimum requirements are met. So only select flue gas materials having the same or better properties than this table.

8.7 C63 certified

In general, boilers are certified with their own flue gas material. If a boiler is C63 certified, no specific type flue gas

material has been certified in combination with the boiler. In this case the flue gas material does not need to be

certified in combination with the boiler but should be fit for purpose, and comply with the applicable European standards. It must be able to handle the condensate forming and transport, overpressure and must have a minimum

temperature class of T120.

S-CB+ Boiler Range Manual

30

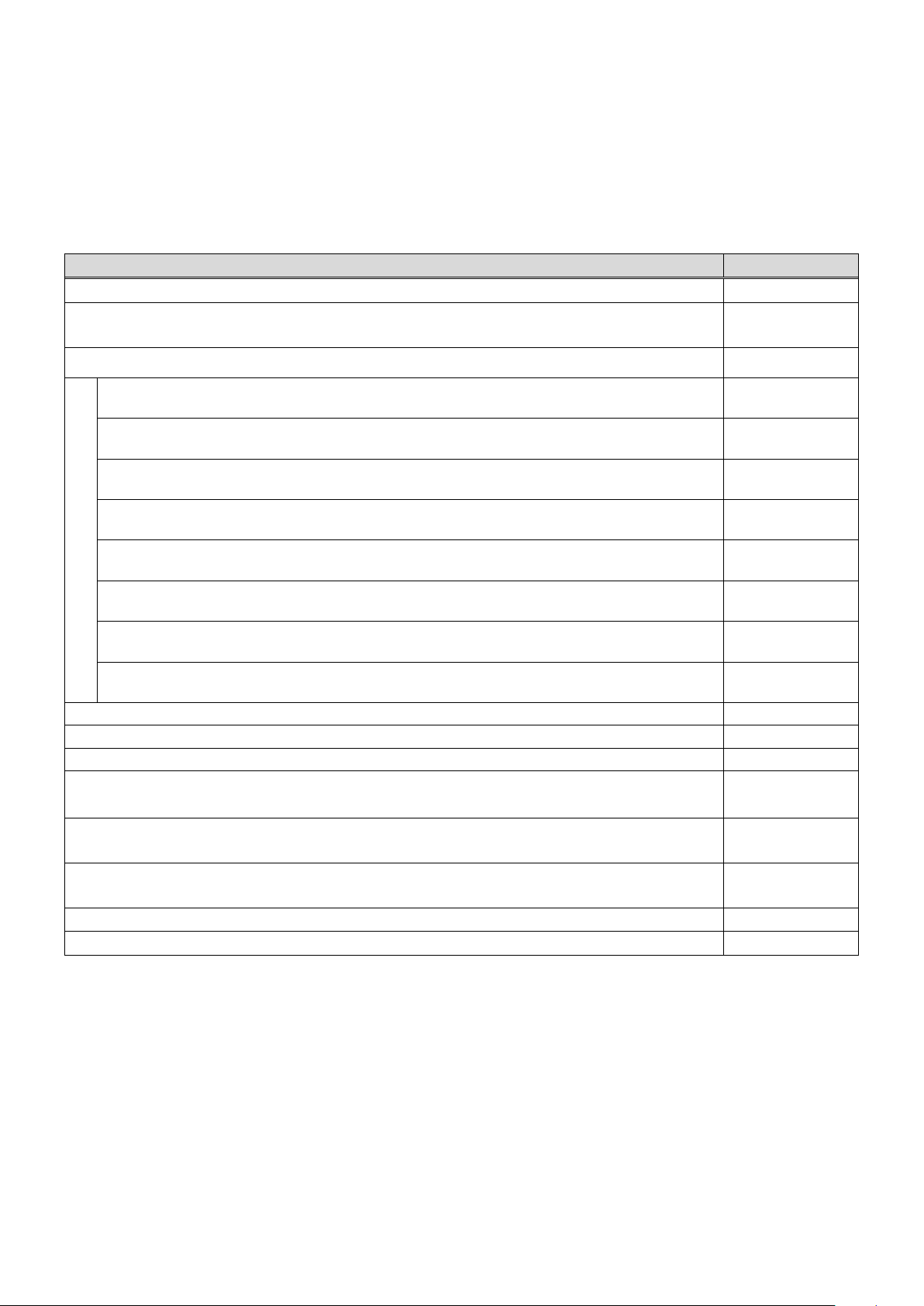

8.8 Flue gas and air supply resistance table

* Never reduce pipe diameters relative to boiler connections

Values printed in grey applicable for larger pipe diameters than boiler connection

+60 +80 +100 +120 +150 +180

FLUE GAS PIPING

Ø [mm] *

RESISTANCE [Pa]

straight tube/m

80

5,0

8,0

-

-

-

-

100

2,0

3,5

4,0

6,5

-

-

130

0,45

0,8

1,2

1,8

3,8

6,0

150

-

-

0,5

0,8

1,7

3,0

45° bend

80

2,5

4,0

-

-

-

-

100

1,0

1,7

2,0

3,2

-

-

130

0,2

0,4

0,6

0,8

1,9

3,0

150

-

-

0,2

0,4

0,8

1,5

90° bend

80

5,0

8,0

-

-

-

-

100

2,0

3,5 4 6,5

-

-

130

0,4

0,8

1,2

1,8

3,8

6,0

150

-

-

0,5

0,7

1,7

3,0

Flue outlet zeta=0,05

80

0,7

1,2

-

-

-

-

100

0,3

0,5

0,8

1,1

-

-

130

0,1

0,18

0,3

0,4

0,6

0,9

150

-

-

0,15

0,2

0,35

0,5

Flue outlet zeta=1

80

13,8

24,0

-

-

-

-

100

5,6

9,8

15,2

22,1

-

-

130

2,0

3,5

5,3

7,8

12,0

17,3

150

-

-

3,0

4,4

6,8

9,8

Flue outlet zeta=1,5

80

20,6

36,0

-

-

-

-

100

8,5

14,8

22,8

33,2

-

-

130

3,0

5,2

8,0

11,6

18,0

26,0

150

-

-

4,5

6,6

10,2

14,7

AIR SUPPLY PIPING

Ø [mm] *

RESISTANCE [Pa]

straight tube/m

80

4,0

7,5

-

-

-

-

100

1,2

3,0

3,5

4,0

-

-

130

0,35

0,75

0,8

1,1

1,2

2,0

150

-

-

0,3

0,4

0,6

1,2

45° bend

80

2,0

3,5

-

-

-

-

100

0,6

1,5

1,7 2 -

-

130

0,2

0,4

0,4

0,5

0,6

1,0

150

-

-

0,15

0,2

0,3

0,6

90° bend

80

4,0

7,0

-

-

-

-

100

1,2

3,0

3,5

4,0

-

-

130

0,3

0,7

0,8

1,1

1,2

2,0

150

-

-

0,3

0,4

0,6

1,2

Air inlet zeta =1

80

10,4

18,1

-

-

-

-

100

4,2

7,4

11,4

16,7

-

-

130

1,5

2,6

4,0

5,8

9,1

13,1

150

-

-

2,3

3,3

5,1

7,4

CONCENTRIC PARTS

Ø [mm] *

RESISTANCE [Pa]

roof terminal

80/125

34

61

-

-

-

-

100/150

-

-

39

45

69

86

130/200

-

-

-

-

15

23

outside wall terminal

80/125

13

22

-

-

-

-

100/150

-

-

19

24

40

48

straight tube/m

80/125

9

12

-

-

-

-

100/150

-

-

8

10

14

16

45° bend concentric

80/125

5

7

-

-

-

-

100/150

-

-

8

9

14

16

90° bend concentric

80/125

8

13

-

-

-

-

100/150

-

-

11

13

22

28

conc./par. adaptor

80/125

10

14

-

-

-

-

100/150

-

-

16

22

40

56

CONCENTRIC

FLUE GAS OUTLET

AIR INLET

ROOF

WALL

AIR INLET

H/D=1,0

zeta=1,0

FLUE GAS OUTLET

zeta=0

open outlet

zeta=0,05

conical outlet

H/D=1,0

zeta=1,0

H/D=0,5

zeta=1,5

In the next section, for five typical flue gas outlet & air inlet configurations the maximum lengths of the straight

pipes will be calculated. First all component resistance values are given in the next table:

NOTICE: This table may only be used for a single flue/air system for one boiler. Do NOT use this table for common

flue systems with cascaded boilers.

S-CB+ Boiler Range Manual

Loading...

Loading...