Strebel S-CB 60, S-CB 100, S-CB 80, S-CB 120, S-CB PX 120 Installation & Operating Manual

...

STREBEL

S-CB+ Cascade Kits

Models +60 - +80 - +100 - +120 – PX 120 - +150 - +180

Installation & Operating Manual

2x60 up to 12x180

Please read and understand before commencing installation and leave the manual with the customer for future reference.

2017-05-01 v1

INDEX

INTRODUCTION ....................................................................................................................................... 5

1.

2. CASCADE SELECTION TABLE .............................................................................................................. 6

3. MAIN DIMENSIONS.................................................................................................................................. 8

4. EXPLANATION OF PARTS AND GROUPS .......................................................................................... 10

5. FRAME GROUPS ................................................................................................................................... 11

6. MOUNTING THE BOILERS ON THE FRAME ....................................................................................... 13

7. MOUNTING THE CONNECTING SETS ................................................................................................. 14

8. MOUNTING THE HYDRAULIC GROUP ................................................................................................ 16

8.1 Hydraulic group for 2 boilers S-CB+ 60–120 and/or S-CB PX 120 ................................................. 17

8.2 Hydraulic groups for 3 and 4 boilers S-CB+ 60–120 and/or S-CB PX 120 ..................................... 18

8.3 Hydraulic groups for 2 and 3 boilers S-CB+ 150–180 ..................................................................... 19

8.4 Hydraulic group for 4 boilers S-CB+ 150–180 ................................................................................. 20

8.5 Hydraulic groups for 5 and 6 boilers S-CB+ 150–180 ..................................................................... 21

9. LOW VELOCITY HEADERS .................................................................................................................. 22

10. FLUE GAS AND AIR SUPPLY ............................................................................................................... 24

10.1 Individual or common flue systems ................................................................................................ 24

10.2 Individual flue systems .................................................................................................................... 24

10.3 Common flue systems .................................................................................................................... 24

10.4 Installation examples flue gas systems. ......................................................................................... 25

11. INSTALLATION ...................................................................................................................................... 26

12. PARAMETERS ....................................................................................................................................... 28

12.1 Parameter settings for cascaded boilers ........................................................................................ 28

12.2 Control panel / display unit ............................................................................................................. 29

12.3 Setting the parameters using the control panel .............................................................................. 30

12.4 Monitor screens .............................................................................................................................. 31

13. CASCADE CONTROL ............................................................................................................................ 32

13.1 Output control ................................................................................................................................. 32

13.2 Boiler sequence .............................................................................................................................. 32

14. OPTIONS ................................................................................................................................................ 33

3

4

1. Introduction

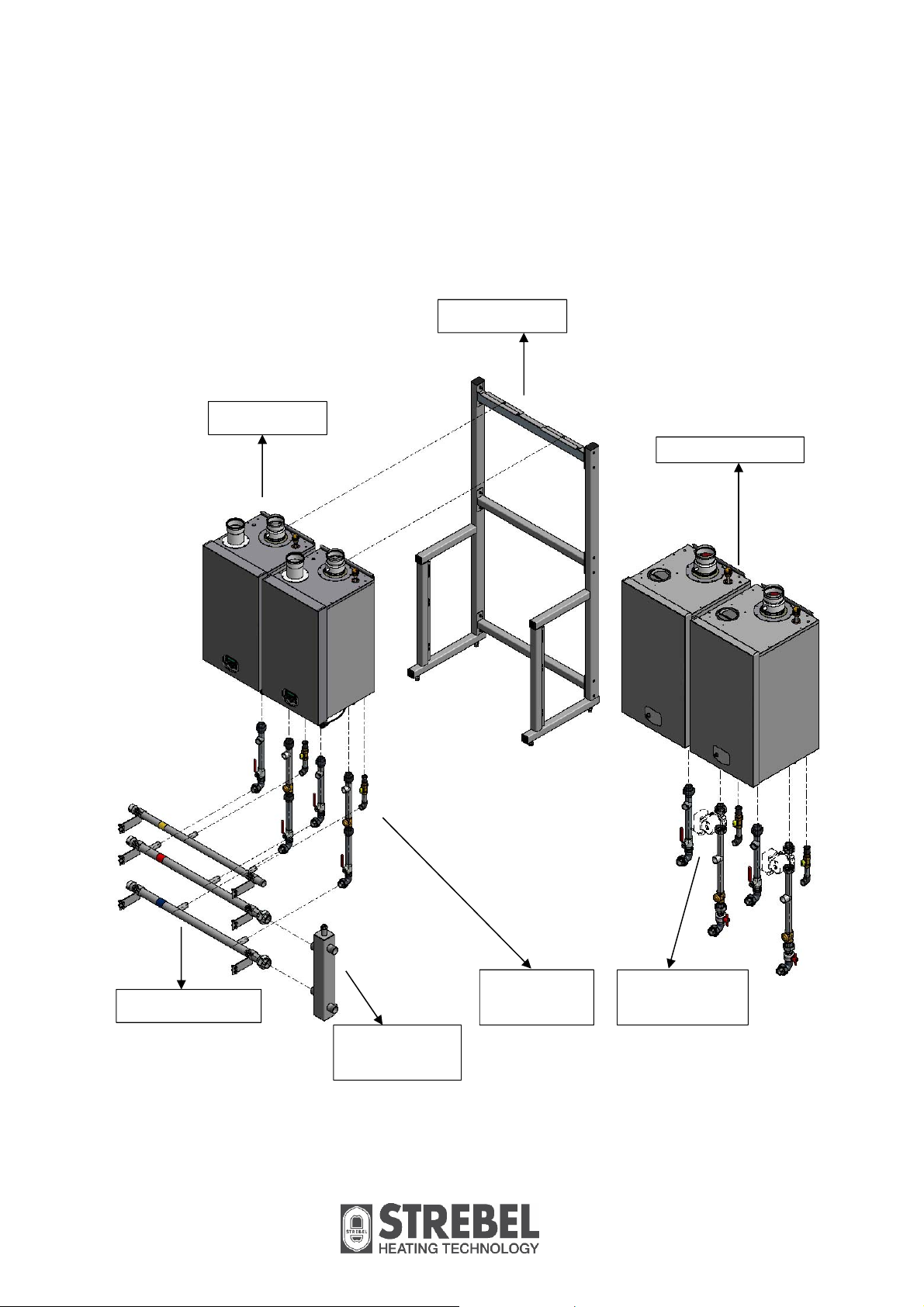

Figure 1 - Typical cascade configuration (S-cb PX 120 Above).

+

This Cascade manual is intended for the S-CB

by Strebel Ltd. These boilers are available, in order of ascending output, as S-CB

PX120,

+

150 and +180.

and the S-CB PX 120 wall-hung high efficiency CH boilers

+

60, +80, +100, +120,

The S-CB 60+ - 120+ (Not including the PX models) can be combined in one cascade set, as can the S-cb+

150-180 boilers, but the S-CB PX 120 models can only be combined with the PX 120 model.

Strebel Ltd can supply standard cascade systems with mounting frame, piping and low loss headers for up to

four boilers in the 60-120 range, four boilers in the PX 120 range and even six in the 150-180 range. For

cascades with more boilers, a dedicated system must be designed.

The Strebel S-CB+ boilers are standard equipped with an internal cascade manager for up to twelve boilers.

No extra controllers are necessary, only connect a 2-wire cable between all boilers.

The low-loss header can be fitted on the right-hand side as well as on the left-hand side without making any

alterations to the delivered parts. The gas connection can also be fitted on one of both sides, independently

from the side chosen for the low loss header.

To commission the cascade installation, it is necessary to set a number of parameters on the boilers, see

chapter 12.1.

5

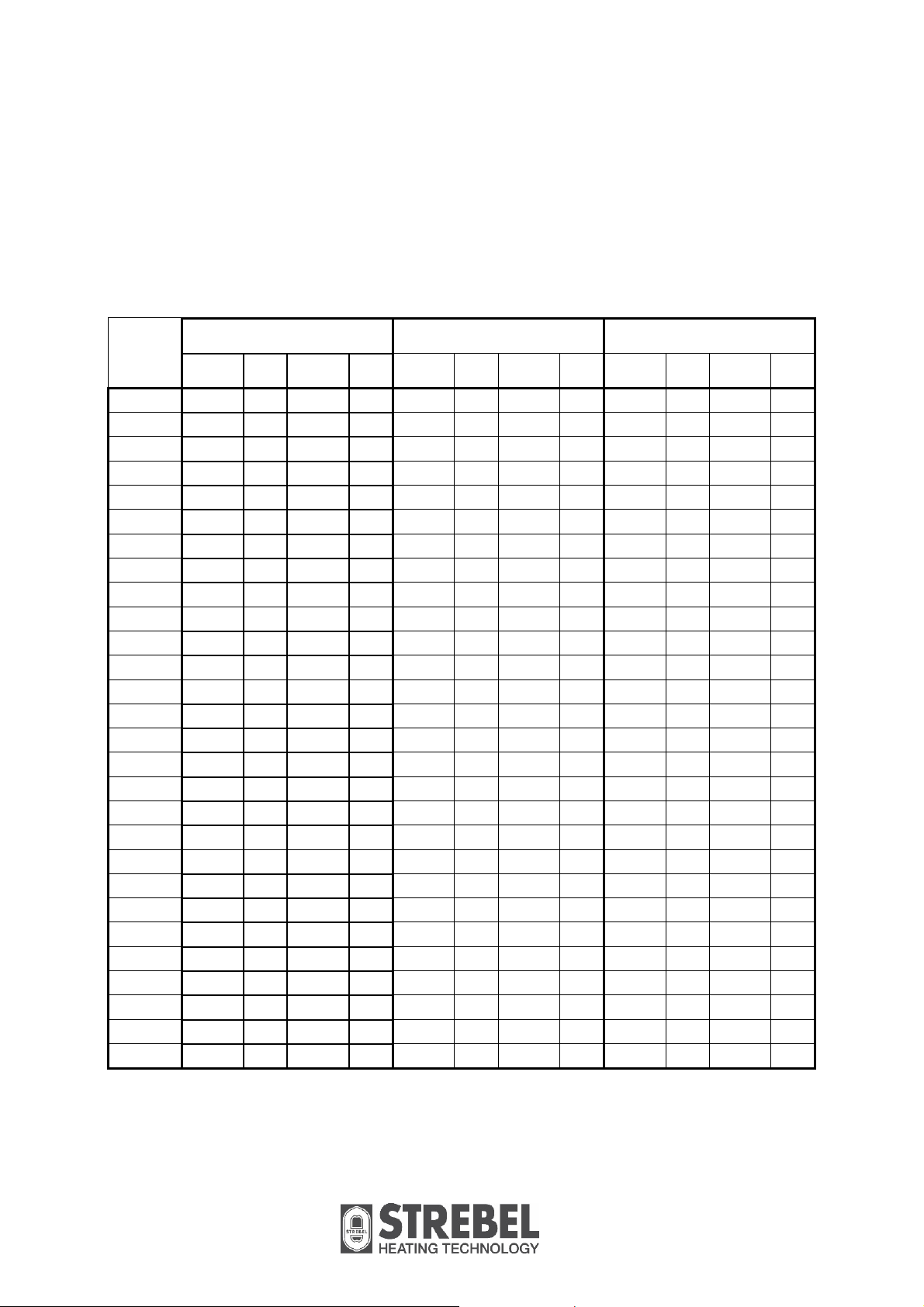

2. Cascade Selection Table

When selecting a cascade set-up, follow the next steps:

1. First determine the total required power of the set.

2. Determine the best number of boilers required (q. in the table(quantity)).

3. Choose one of the combinations in the table below (even more combinations are available).

4. Determine the required space for the set in the main dimensions’ tables and check this with the

planned location.

5. Determine the required flue gas and air supply lines.

6. Choose all the required accessories in the Options-chapter.

Total

Kw

Input

120

140

160

180

200

220

240

260

280

300

320

330

340

360

380

400

420

440

450

460

480

510

540

600

630

660

690

720

Model q. Model q. Model q. Model q. Model q. Model q.

+

+

+

+

+

+

+

+

+

+

2 Boilers 3 Boilers 4 Boilers

60 2x

80 1x

80 2x

100 1x

100 2x

120 1x +100 1x

120 2x

150 2x

180 1x +150 1x

180 2x

+

60 1x

+

80 1x

+

60 3x

+

80 1x

+

80 2x

+

80 3x

+

100 1x

+

100 2x

+

100 3x

+

120 1x +100 2x

+

120 2x +100 1x +100 1x

+

120 3x

+

150 3x

+

180 1x +150 2x +120 4x

+

180 2x +150 1x

+

180 3x

+

60 2x

+

60 1x

+

60 4x

+

80 2x

+

80 1x

+

80 1x

+

80 2x

+

80 3x

+

80 4x

+

100 2

+

100 3x

+

100 4x

+

120 1x +100 3x

+

120 2x +100 2x

+

120 3x +100 1x

+

150 4x

+

180 1x +150 3x

+

180 2x +150 2x

+

180 3x +150 1x

+

180 4x

+

60 3x

+

60 2x

+

60 1x

+

80 3x

+

80 2x

+

80 1x

* Figures in this column are the gross calorific values in kW at 100% load

Table continues next page

6

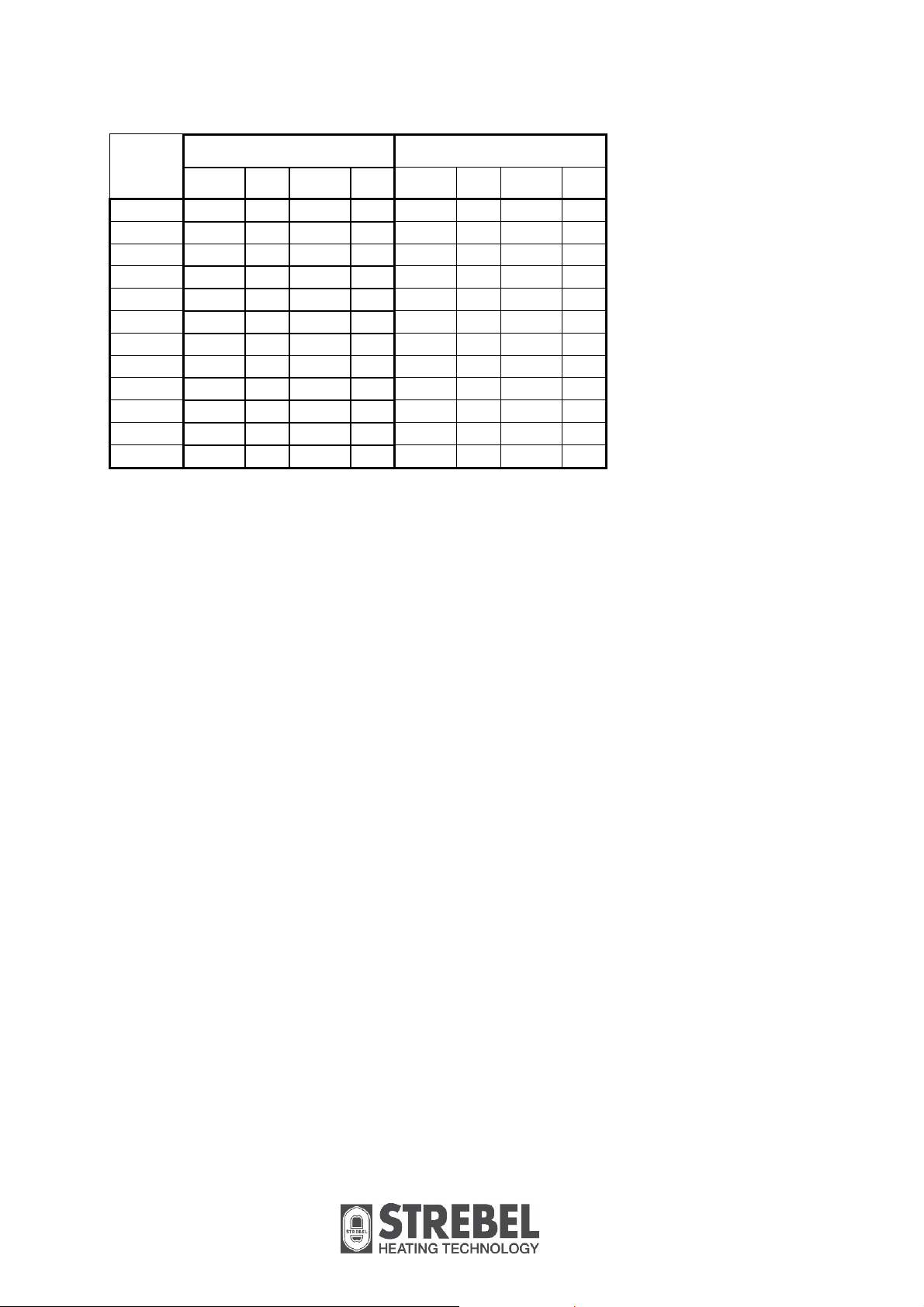

Continuation from previous page

Total

5 Boilers 6 Boilers

Kw

Input

750

780

810

840

870

900

930

960

990

1020

1050

1080

Model q. Model q. Model q. Model q.

+

150 5x

+

180 1x +150 4x

+

180 2x +150 3x

+

180 3x +150 2x

+

180 4x +150 1x

+

180 5x

+

150 6x

+

180 1x +150 5x

+

180 2x +150 4x

+

180 3x +150 3x

+

180 4x +150 2x

+

180 5x +150 1x

+

180 6x

7

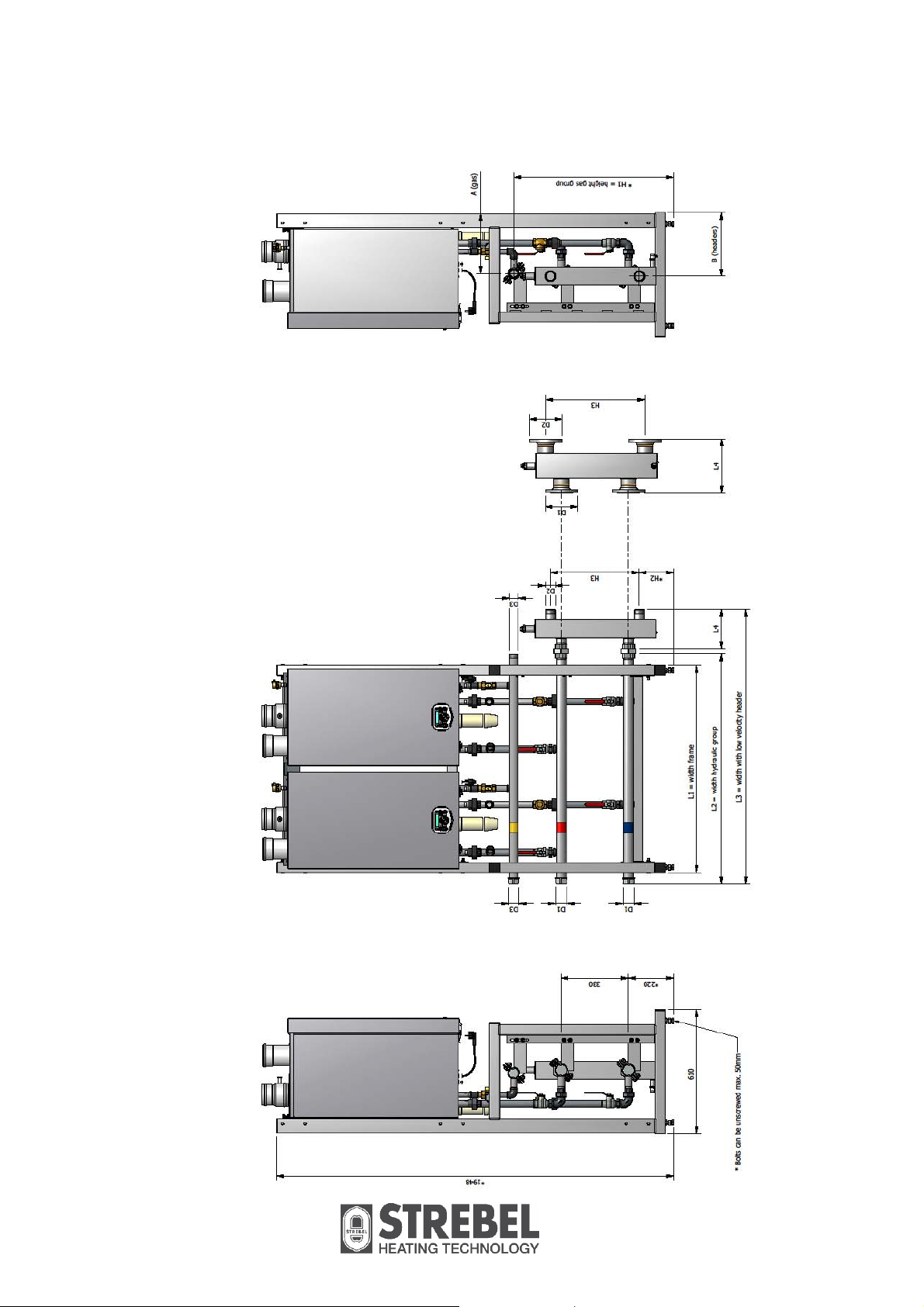

3. Main dimensions

boilers – for the S-CB PX boilers the connecting sets are different.

+

8

Figure 2. Cascade dimensions. The picture shows connecting sets for S-CB

1980

4 boilers

889

770

3045

3162

6 boilers

2489

5 boilers

290

791

768

2084

2393

440

DN 80 PN6 (3")

DN 80 PN6 (3")

R 2"

283

283

1980

4 boilers

4071

2607

2090

889

3516

355

2465

220

1000

DN 125 PN6 (5")

DN 125 PN6 (5")

770

220

1000

DN 125 PN6 (5")

DN 125 PN6 (5")

768

168

440

DN 100 PN6 (4")

DN 100 PN6 (4")

335

294

DN 80 (3")

335

294

DN 80 (3")

338

283

DN 80 (3")

1520

3 Boilers

1015

2 Boilers

120

+

60 -

+

265

789

766

1630

1914

190

1140

1358

787

487

DN 65 PN6 (2½")

DN 65 PN6 (2½")

766

436

R 1½"

RP 1½"

283

R 1½"

271

R 1¼"

283

3 boilers

283

2 boilers

180

+

150 -

+

290

766

165

1520

1630

1940

265

1015

1125

1408

766

440

DN 80 PN6 (3")

DN 80 PN6 (3")

144

487

DN 65 PN6 (2½")

DN 65 PN6 (2½")

R 2"

R 2"

338

283

338

283

S-CB Boilers

L1 (frame)

L2 (standards)

L3 (total)

L4 (open header)

H1 (gas)

H2 (open header)

H3 (open header)

D1 (Header Connections Sizes)

D2 (Header Connections Sizes)

D3 (gas)

A (gas)

B (headers)

S-CB Boilers

L1 (frame)

L2 (standards)

L3 (total)

L4 (open header)

H1 (gas)

H2 (open header)

H3 (open header)

D1 (Header Connections Sizes)

D2 (Header Connections Sizes)

D3 (gas)

A (gas)

B (headers)

9

Table 1. Main dimensions (mm and " ).

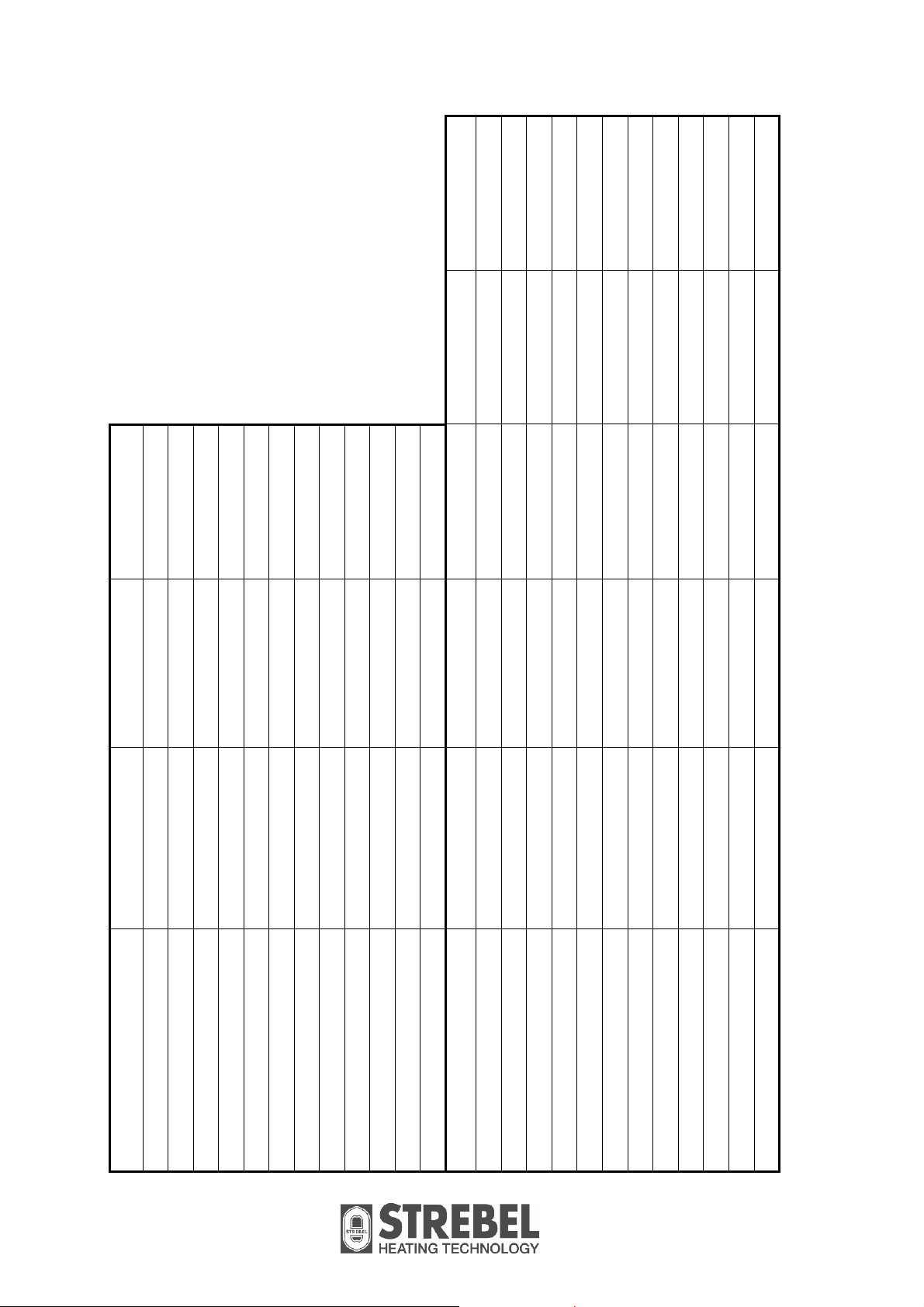

4. Explanation of parts and groups

Each cascade set exists of the following parts and groups:

1. The number of S-CB

2. The frame group (with locking plates) as determined by the number of boilers.

3. Connecting groups to connect the boilers to the hydraulic groups (one group for each boiler, each group

existing of 1 gas, 1 flow and 1 return connecting set).

4. Hydraulic group, existing of 1 gas, 1 flow and 1 return header with all fixing and connecting parts.

5. Low-loss header to connect hydraulic group to your heating installation.

+

type boilers as selected in chapter 2.

S-CB+ Model

Frame group

-

Hydraulic Group

Connecting

sets S-CB

+

Connecting

sets S-CB PX

Low Velocity

Header

Figure 3. Cascade parts and groups. For the S-CB PX boilers, the return connecting sets are different from the S-CB

10

+

.

5. Frame groups

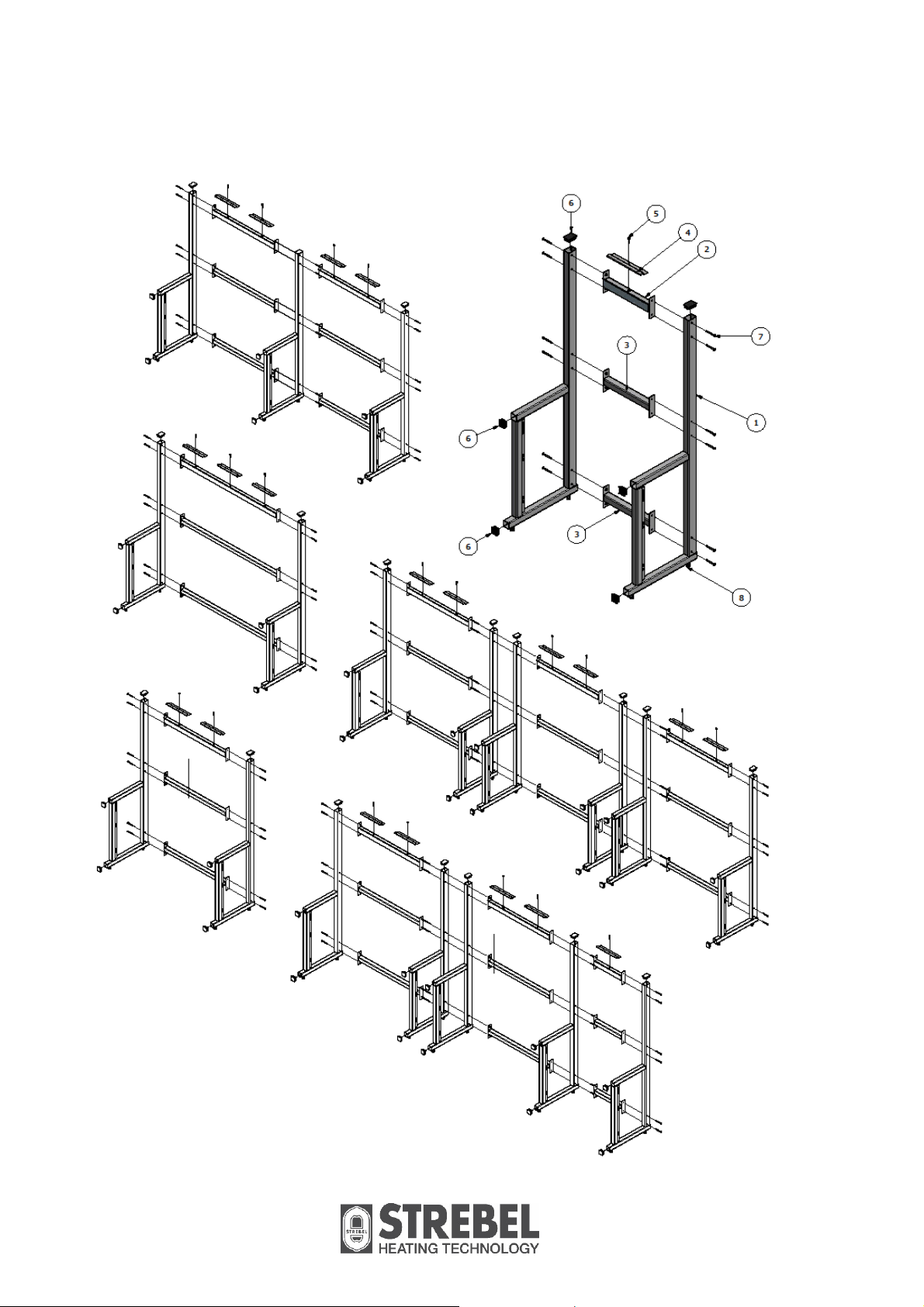

Figure 4. Cascade frame groups for 1, 2, 3, 4, 5 and 6 boilers.

11

Loading...

Loading...