Strebel RU 1S Series, BRU 1 Series, RU 3S Series, RU 2S Series, BRU 2 Series Installation Instructions Manual

11/07/00

BOILER INSTALLATION INSTRUCTIONS FOR RU 1S / BRU 1

RU 2S / BRU 2

RU 3S

ASSEMBLY INSTRUCTIONS

General Instructions:

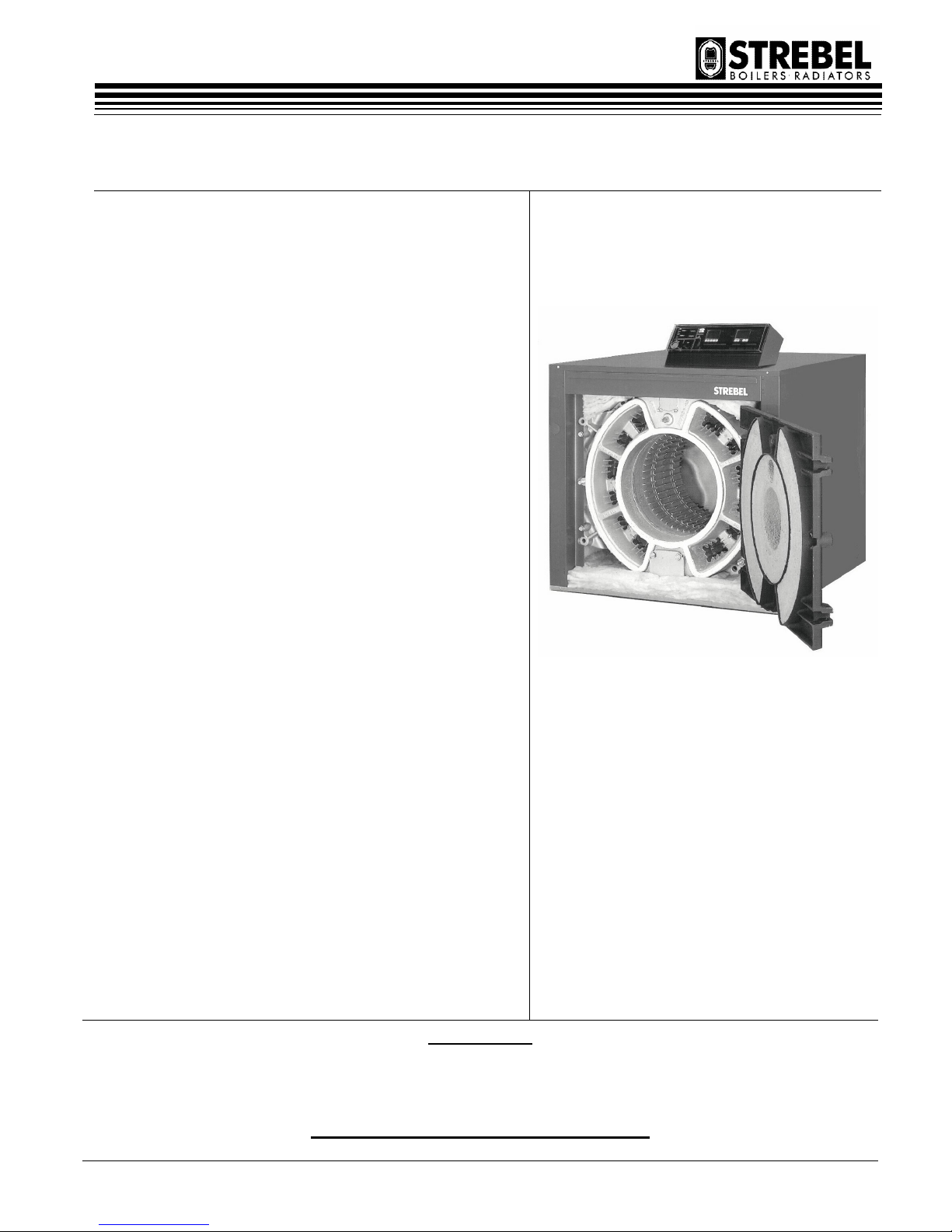

The STREBEL RU boilers are special boilers for oil or gas-fired

(forced) burners. They can be fitted in hot-water heating

installations.

Operating Conditions:

Hot-water Heating installations boiler

Maximum Heat limit Temperature 110ºC / 130ºC

Operating excess pressure normal working 4 bar

Operating excess pressure multi-storey working 6 bar

Please note all relevant instructions when assembling the boilers

The Installation: The connecting and initial setting in operation

should be carried out by a qualified heating specialist.

The boiler base is to be constructed in accordance with our

diagrams.

IMPORTANT

THERE IS A STOP NUT BETWEEN THE BOILER DOOR AND THE DOOR SEAL

(TO PROTECT THE DOOR SEAL DURING TRANSIT)

THIS NUT MUST BE REMOVED ON SITE.

ASSEMBLY INSTRUCTIONS FOR:

Page 2

11/07/00

CONTENTS:

Assembly instructions & tools

Boiler base details & Important assembly advice

Wall clearance dimensions

Pulling up sections

Pulling up sections

Positioning & Influence of baffles

Diagram of RU1 injector tube

Fitting the flue-gas collector hood

Fitting the rear wall protective refractory

Converting the burner door hinge

Assembly of boiler connections

Assembling the jackets and insulation

BRU 1s Bicalor assembly completion

BRU 1s Bicalor jacket & insulation assembly

Assembling the burner

Gas connections

Opening & closing burner door

Wiring details for control panel

RU 2s Assembly section

Fig. 1.2 through to Fig. 8.2 with corresponding notes

RU 2s Jacket assembly

RU 3s Assembly section

Fig. 1.3 through to Fig. 8.3 with corresponding notes

RU 3s Jacket assembly

Page :

3

4

5

6

7

8

9

10

10

10

11

12

13

14

15

16

17

18

22 & 23

27 & 28

ASSEMBLY INSTRUCTIONS FOR:

Page 3

11/07/00

ASSEMBLY INSTRUCTIONS

Please follow the installation instructions very carefully.

The installation of all RU and BRU boilers are very similar

through the RU 1, RU 2, RU 3, & BRU 1, & BRU 2.

For all installations please follow the instructions for the

RU1 model and, if installing the RU 2 or RU 3 models, refer

to the relevant information in the appendix at the rear of this

manual when prompted.

Information given in the appendix will allow for the

differences between models and guide installers through the

entire RU and BRU range of boilers.

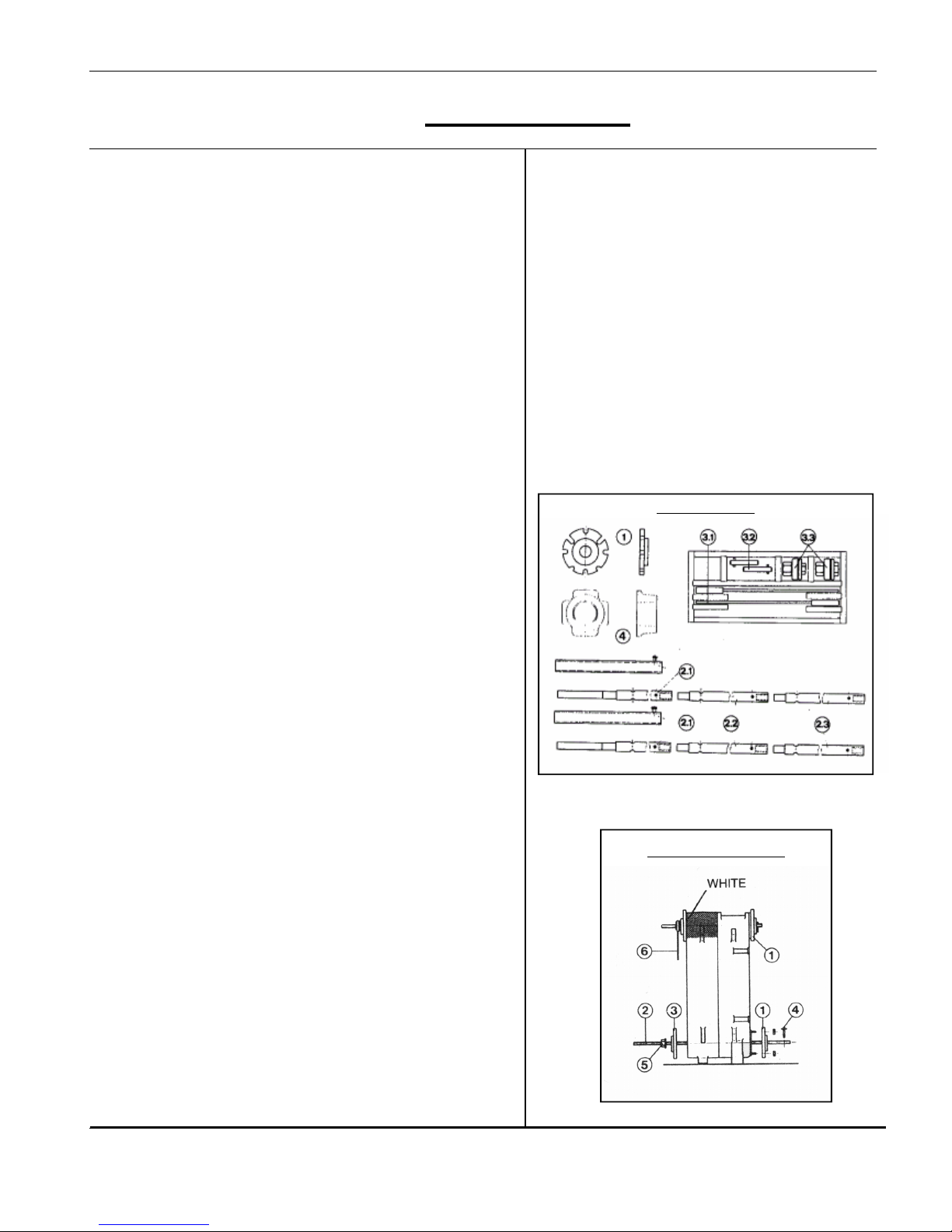

ASSEMBLY TOOL

A bar pulling-up tool, which is returnable after assembly has

been successfully completed, is made available for assembling

the boiler block.

The complete pulling-up tool RU 1S consists of the following

1) Pulling-up flange for the rear, intermediate & top front section

4) Pulling-up flange at the top front section

2.1) Basic bar

2.2) Extension

2.3) End piece

3.1) Free running ratchet spanners.

3.2) Stop pins

3.3) Pulling-up nut with thrust bearing

Items needed for construction: flat chisel, mallet, brush, small

round smoothing file, emery cloth, cleanser (e.g. petroleum),

inspection lamp, spanner.

Note: RU 2s Pulling-up tools shown in Fig. 4.2 and RU 3s

tools in Fig. 8.3.

Advice on the use of the Pulling-up tool.

1) The pulling-up flanges (1) at the rear section are screwed

onto the boiler flow and return connections.

2) The basic bars (2) are inserted through the openings of the

pulling-up flanges and ports so that the screw ends are

situated out of the ports at the front. (The basic bars can be

extended, as necessary.)

3) The pulling-up flanges (1) at the intermediate section or front

section are pushed over the basic bar screw end from the

front.

4) The Stop pins (3.2) are inserted at the back through one of

the transverse borings of the pulling-up bar.

5) The pulling-up nuts (3.3) are screwed onto the basic bar

screw end, from the front until they take up the slack on the

pulling up tool flanges.

6) The free-running ratchets (3.3) are on the pulling-up nuts.

Pulling-up Tools

Using Pulling-up Tools

ASSEMBLY INSTRUCTIONS FOR:

RU 1s Assembly

ASSEMBLY INSTRUCTIONS FOR:

Page 4

11/07/00

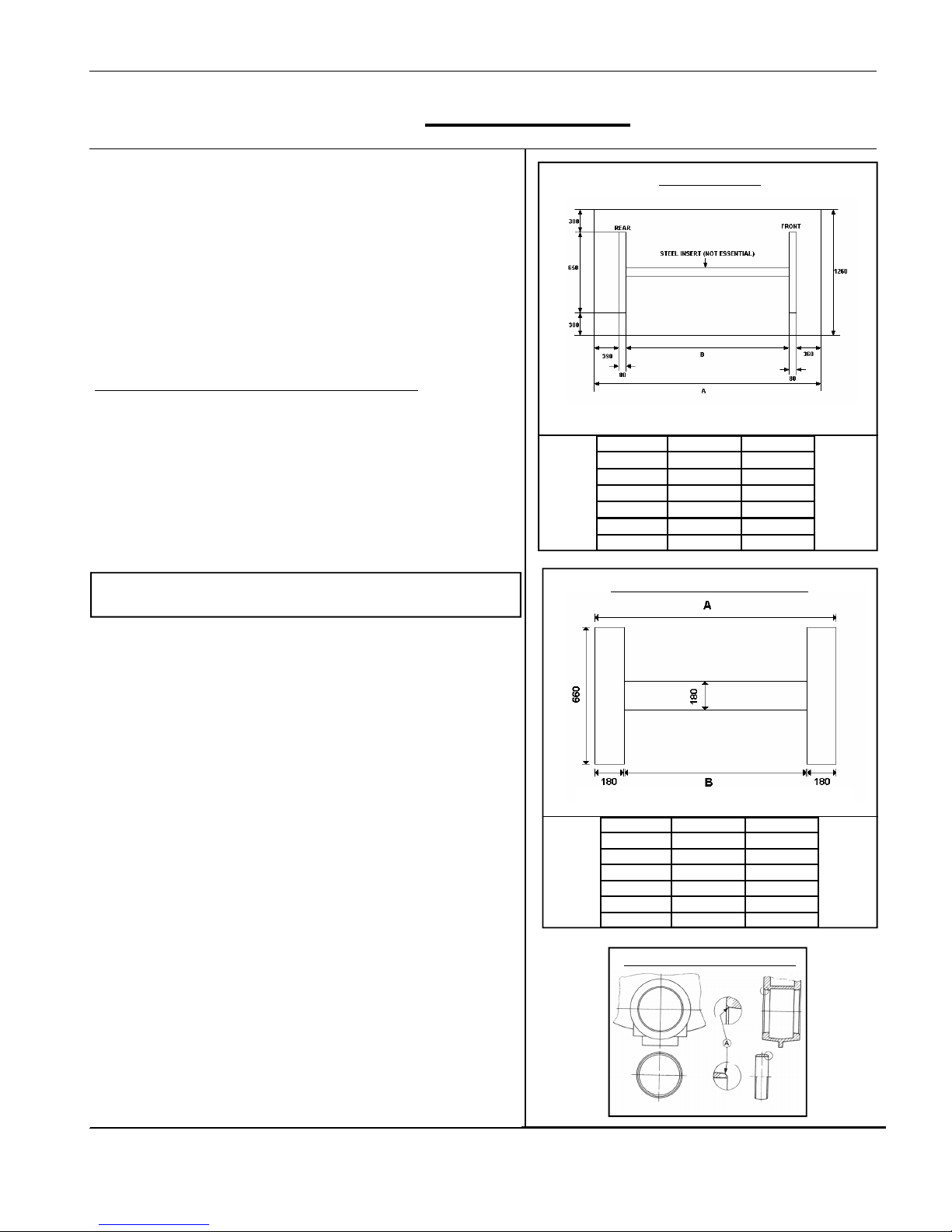

Boiler base

The boiler base is to be constructed in accordance with the base

plans. The boiler block may stand on an iron frame set in

concrete but is not essential. The boiler must stand on a level

non-combustible base which is capable of adequately supporting

the weight of the boiler, water content and any ancillary

equipment. (Dimensions for optional TICO Sound reducing

framework shown opposite). (Fig 2.2 & Fig 3.2 are for RU 2s

and Fig 2.3 & Fig 3.3 are for RU 3s).

Important Assembly Advice:

Please read through before starting the assembly!

The boiler is normally delivered in individual sections, which are

assembled on site as a boiler block using tapered nipples.

The individual weights of the boiler components are as follows:

Rear section approx. 195kg

Intermediate section approx. 185kg

Front section with burner door approx. 285kg

Front section without burner door approx. 192kg

Burner door approx. 93kg

Flue gas collection housing approx. 39kg

NOTE: Weights for RU 2s (Fig 1.2) & RU 3s (Fig 1.3) are

shown in appendix at rear.

The watertight joint between two boiler sections is a highprecision press fit between the boiler nipple and nipple port. The

block assembly must be carried out accordingly with precision.

The following points should be observed during assembly:

No damage to the nipple and borings should be apparent.

Before a nipple is inserted and a section fitted, the nipple and the

boring should be inspected. Any damage, e.g. to the face of the

boring, destroys the nipple seal and leads to leakage.

Attention! Slight damage (transport damage) to the faces of the

boiler nipple or to the nipple ports (A) can be corrected with a

small smoothing file and emery cloth without affecting the water

tightness of the joint.

− The accompanying nipple jointing oil sealing compound

serves as a lubricant as well as a waterproof seal and

must be used.

− During the assembly no dirt should be allowed to remain

on the nipples or in the boring. These should be inspected

during each assembly phase, but particularly before fixing

on the pulling-up flanges. Particles of dirt, which are not

removed, can lead to leakage.

− During the boiler block assembly take care that the various

boiler sections are fitted to the various positions,

depending on the model.

− Boiler nipples and nipple ports must align exactly at all

stages of the assembly. An inclined inserted nipple leads

to leakage.

In addition, certain specific points should be observed at each

stage.

Diagram showing nipple and boring.

Thickness of base = 60mm min.

Base Dimensions

A B

RU 1s-4 1350 440

RU 1s-5 1550 640

RU 1s-6 1750 840

RU 1s-7 1950 1040

RU 1s-8 2150 1240

RU 1s-9 2350 1440

Thickness = 20mm

TICO Sound reducing framework

A B

RU 1s-4 780 420

RU 1s-5 980 620

RU 1s-6 1180 820

RU 1s-7 1380 1020

RU 1s-8 1580 1220

RU 1s-9 1780 1420

ASSEMBLY INSTRUCTIONS FOR:

RU 1s Assembly

ASSEMBLY INSTRUCTIONS FOR:

Page 5

11/07/00

WALL CLEARANCE DIMENSIONS

KEY:

A = Boiler length + min. 200mm

B = Projection of burner + min. 100mm

ASSEMBLY INSTRUCTIONS FOR:

RU 1s Assembly

ASSEMBLY INSTRUCTIONS FOR:

Page 6

11/07/00

Stage 1: Drive nipple into nipple port with care

Inspect nipple and nipple port for damage.

Smear nipple jointing oil sealing compound over nipple and

boring. Gently drive nipple into flow and return nipple ports using

a mallet or synthetic hammer. The nipples must remain firm and

exactly vertical in the nipple ports and must be able to take the

next boiler section without twisting from nipple ports. Take care,

twisted nipples lead to leakage.

Stage 2: Before offering up the boiler section to both inserted

nipples.

Inspect nipple and nipple port for damage.

Smear nipple jointing oil sealing compound over nipple and

nipple port. Place boiler mastic sealing strand into sealing

grooves as shown in diagram opposite (see Fig. 6.2 For RU 2s

and Fig. 7.3 For RU 3s). Place boiler section in front of both

inserted nipples. Raise the boiler section onto the inserted

nipples using a flat chisel under the section feet. The inserted

nipples must stand approx. 1 to 2 mm higher than the boring of

the section, which is to be joined. Using a crowbar, raise the

boiler section onto the inserted nipples until nipple and nipple

ports mate and hold.

Inspect boring once again for any dirt deposits before fixing the

pulling-up flanges. Remove dirt deposits if necessary.

Stage 3: To assemble boiler sections using pulling-up tool.

Take care during the pulling-up process that the clearance

between both boiler and section is even. If the clearance is

uneven insert a flat chisel into the narrow point and continue

pulling-up until the clearance is even again.

Driving Nipple into Boring

Diagram showing mastic placement

Raising sections to ensure nipples and borings mate

ASSEMBLY INSTRUCTIONS FOR:

RU 1s Assembly

ASSEMBLY INSTRUCTIONS FOR:

Page 7

11/07/00

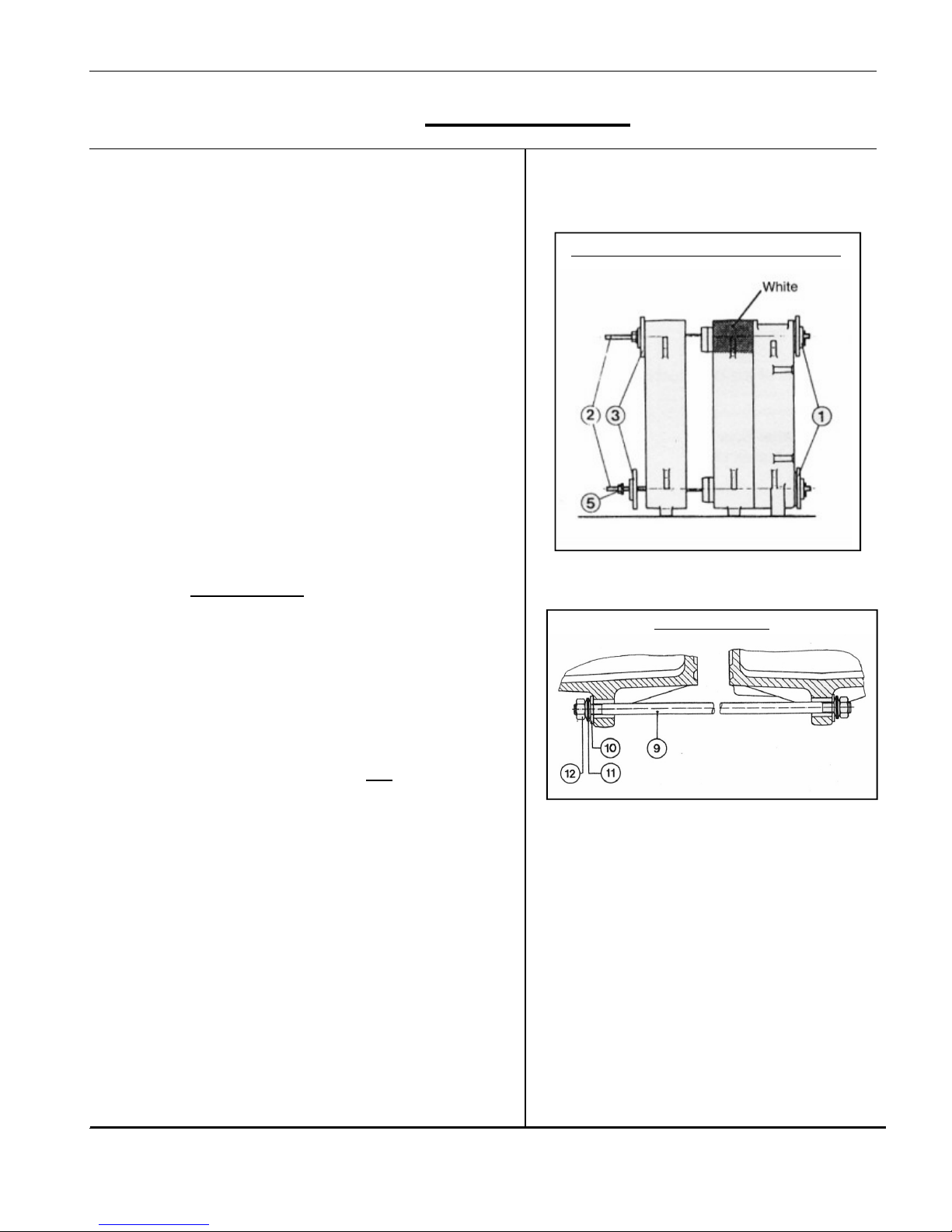

Assembly of the boiler block from individual sections

Starting with the rear section to the front, the boiler block is

assembled on the boiler base, or on the boiler base sound

reducing framework.

1: Erect and support the rear section.

2: Place boiler mastic sealing strand into the sealant grooves.

3: Clean nipple and port. Inspect and smear with nipple jointing

oil sealing compound (note assembly advice on page 4)

4: Drive nipple into flow and return ports (note assembly advice

on page 5)

5: Fix first intermediate section, marked with a white patch of

paint at the top (on RU1s only), to both rear section nipples.

(Note assembly advice on page 3)

6: Pull up intermediate section with pulling-up tool. Fix on pulling up flanges, starting nuts and free running ratchets; tighten the

starting nuts evenly. The clearance between the two sections

must be equal when pulling up. If clearance is unequal insert

a flat chisel in the narrower point and continue pulling-up

until clearance is equal again.

Avoid using excessive force.

Add on only one section at a time in each case.

Further sections (not marked with white patch) are added

accordingly.

7: Push tie bars (9) through the lugs on the ready a s s e m b l e d

boiler block. Slide a flat washer (10) and 2 disc springs (11)

with concave sides facing each other onto the tie bars at the

front and rear respectively and screw on hexagonal nut (12).

Hold fast one nut and draw on the other nut until disc springs

lie flat against each other.

After that turn back one hexagonal nut one

revolution.

RU 1S-4: 4 tie bars M 12 x 680

RU 1S-5: 4 tie bars M 12 x 880

RU 1S-6: 4 tie bars M 12 x 1080

RU 1S-7: 8 tie bars M 12 x 680

RU 1S-8: 4 tie bars M 12 x 680

And 4 tie bars M 12 x 880

RU 1S-9: 8 tie bars M 12 x 880

Boiler Block Alignment

Any unevenness between boiler base and section feet can be

levelled out by inserting metal shims underneath.

Diagram of Tie Bar

Assembling boiler block (NB: White section)

ASSEMBLY INSTRUCTIONS FOR:

RU 1s Assembly

ASSEMBLY INSTRUCTIONS FOR:

Page 8

11/07/00

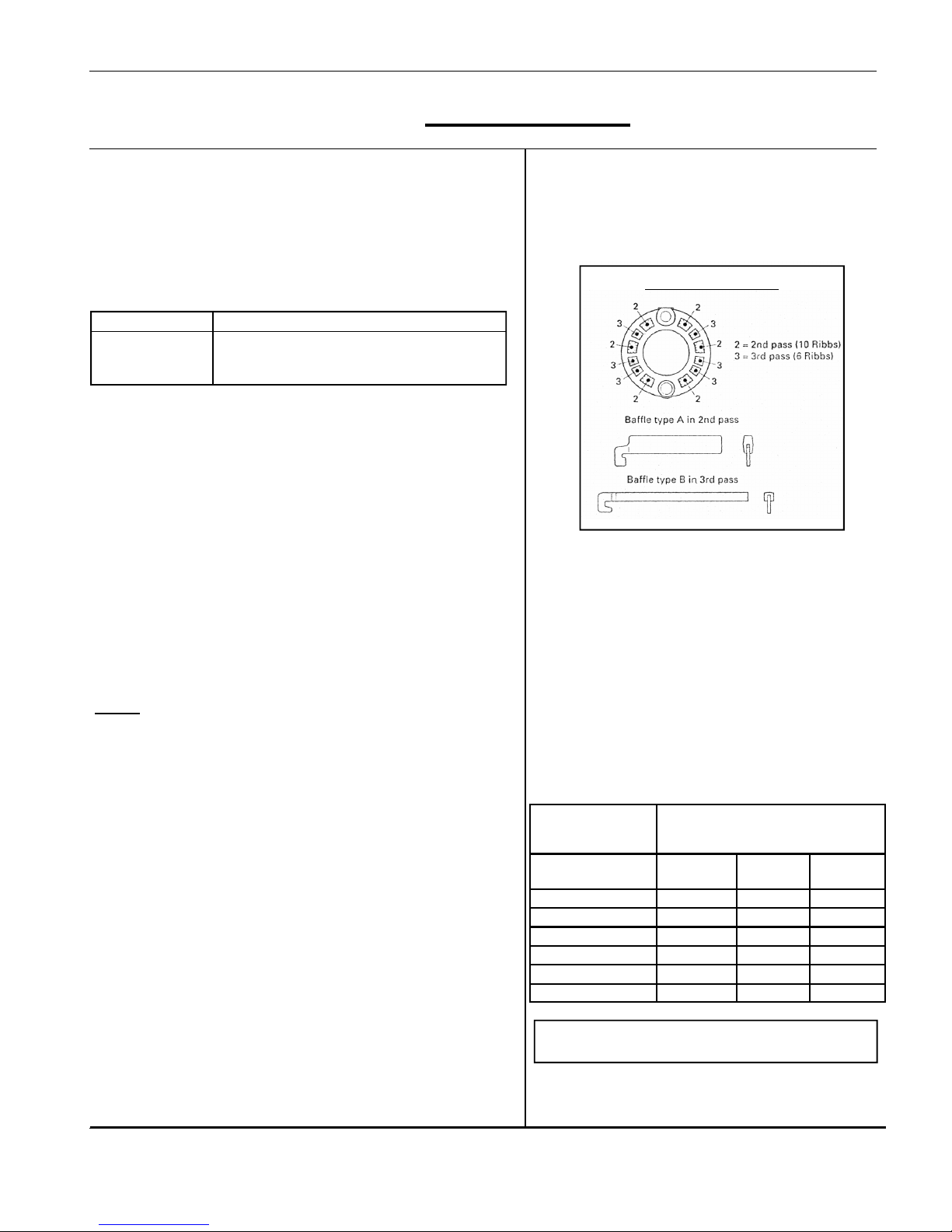

Positioning the baffles

Push the Baffles into the flue–ways as far as the stop Fit

standard equipment in accordance with table below.

Flue gas temperature can be raised by removing the baffles.

Standard boilers are equipped with the following baffles.

Boiler sections 4 5 6 7 8 9

2nd Pass 6xA 6xA 6xA 6xA 6xA 6xB

3rd Pass 6xB 6xB 4xB 4xB

With less than 6 baffles the lower passes remain free.

The flue gas temperature of a boiler depends on boiler water

temperature and boiler capacity. If boiler water temperature is

reduced the flue gas temperature is also reduced. If boiler

capacity is reduced by means of a different burner setting or by

the first stage of a two-stage burner, the flue gas temperature is

also reduced. The flue gas temperature rises by some 20ºC –

40ºC in the case of dirty flue-way surfaces, depending on the

degree of fouling.

Influence of baffles

If the baffles in the 3rd flue pass are removed, the flue gas

temperature rises by approx. 20ºC; if the baffles in the 2nd flue

pass are also removed, the flue gas temperature rises by a total

of approx. 40ºC.

NOTE:

RU 2s baffle details in Fig 8.2.

The RU 3s range of boilers do NOT use flue gas baffles.

Alternatively they have ribbed intermediate sections

denoted by the section legs painted in green.

Influence of water temperature

A change of 10ºC in the water temperature produces a change in

flue gas temperature of approx. 5ºC– 8ºC.

Boiler water and return temperatures

The boiler is operated with low flue-gas temperatures in order to

achieve maximum efficiency. If the boiler water or return

temperatures are too low, there is a danger that heating surfaces

will become fouled and encrusted this results in higher flue gas

temperatures, making boiler cleaning difficult, and in extreme

cases cause damage.

The following conditions must be maintained:

Oil fired: boiler water temperature min: 60ºC

Return water temperature min: 50ºC

Gas fired boiler water temperature min: 70ºC

Return water temperature min: 60ºC

RU 1s max. kW oil kg/h Nat. gas

m /h

4 190 17.5 22

5 250 23 29

6 320 29.5 37

7 390 36 46

8 460 42 54

9 525 47.8 61

Type and

no. of sections

Output and fuel consumption

Refer to Fig. 7.2 for technical data on the RU 2s and

Fig. 6.3 for the RU 3s

Positioning the Baffles

ASSEMBLY INSTRUCTIONS FOR:

RU 1s Assembly

ASSEMBLY INSTRUCTIONS FOR:

Page 9

11/07/00

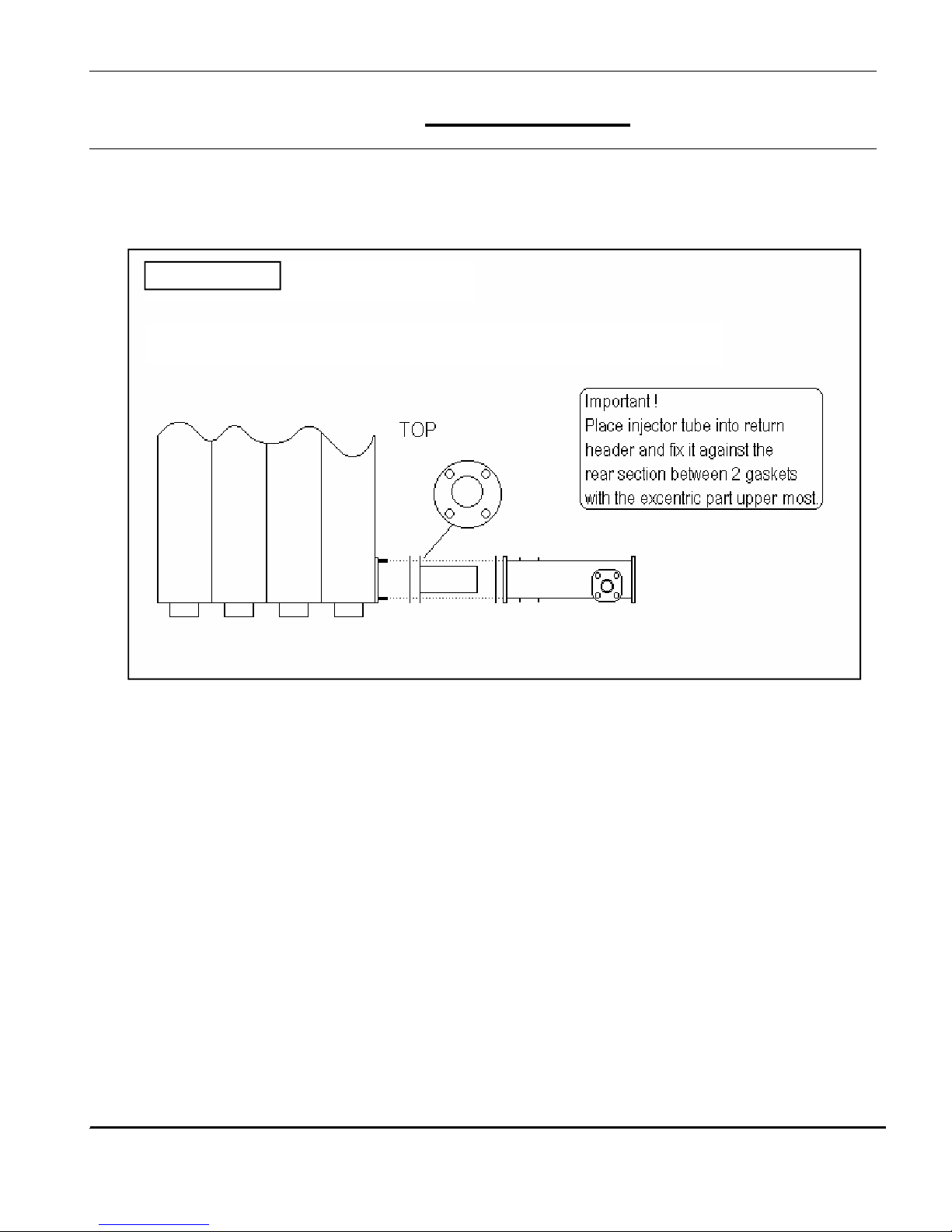

NOTE: Injector tube is not a requirement for the RU 2s and RU 3s boilers.

STREBEL RU 1s

Injector tube in the STREBEL RU 1s return

ASSEMBLY INSTRUCTIONS FOR:

RU 1s Assembly

Loading...

Loading...