Strebel Geneva C3, Geneva C4, Geneva C5, Geneva C6, Geneva C7 Installation, Operating And Maintenance Manual

...

STREBEL

GENEVA CE

ATMOSPHERIC GAS BOILER

INSTALLATION, OPERATING AND

MAINTENANCE MANUAL

INDEX

TABLE 1 TECHNICAL DATA

SECTION 1 GENERAL

SECTION 2 LOCATION

SECTION 3 VENTILATION

SECTION 4 GAS SUPPLY

SECTION 5 FLUE SYSTEM

SECTION 6 WATER CIRCULATION SYSTEM

SECTION 7 ELECTRICAL SUPPLY

SECTION 8 INSTALLATION

SECTION 9 COMMISSIONING AND TESTING

SECTION 10 SERVICING

SECTION 11 FAULT FINDING

FIGURE 1 CONTROL PANEL LAYOUT

FIGURE 2 NOVA SIT 822 GAS VALVE

FIGURE 3 ELEKTROGAS VM-L GAS VALVE

FIGURE 4 LPG CONVERSION

2

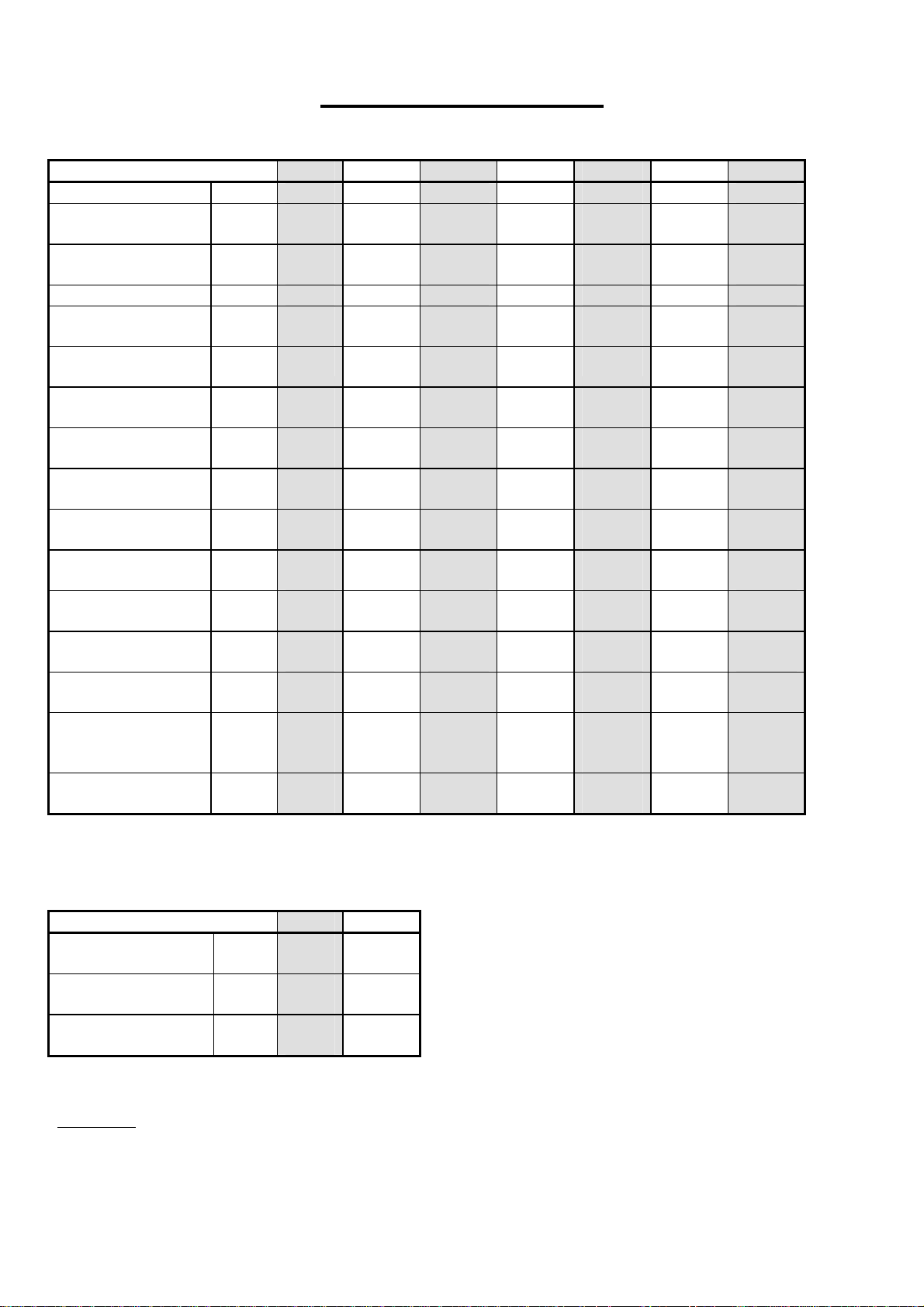

TECHNICAL DATA

BOILER MODEL C3 C4 C5 C6 C7 C8 C9

Number Of Sections 3 4 5 6 7 8 9

Input

Output

Water Content Lits 10 12.5 15 17.5 20 22.5 25

Maximum Working

Pressure

Maximum Working

Temperature

Flow Rate 10°C

Differential

Water Resistance

10°C Differential

Gas Consumption

Natural

Gas Consumption

LPG

Burner Pressure

Natural

Supply Pressure

Natural

Burner Pressure

LPG

Supply Pressure

LPG

Main Injectors

Natural

LPG

Shipping Weight

kW

Btu/hr

kW

Btu/hr

Bar

Psi

°C

Lt/sec

M³/h

mbar

in Wg

M³/h

Ft³/h

Kg/h

Lbs/h

mbar

in Wg

mbar

in Wg

mbar

in Wg

mbar

in Wg

mm

mm

Kg

Lbs

21.4

73,017

19.3

65,852

4

58

90 90 90 90 90 90 90

0.47

1.70

9.5

3.7

2.0

70.21

1.54

3.40

14.8

5.8

18

7

31.8

12.5

37

14.5

2.6

1.75

87

192

31.7

108,160

28.6

97,583

4

58

0.71

2.55

20

7.8

2.9

104.00

2.29

5.04

14.5

5.7

18

7

30.8

12.1

37

14.5

2.6

1.75

110

243

42

143,304

37.7

128,632

4

58

0.95

3.42

36.5

14.4

3.9

137.79

3.03

6.68

13.2

5.2

18

7

30.3

11.9

37

14.5

2.7

1.75

136

300

52.3

178,448

47.1

160,705

4

58

1.10

3.96

23

9.1

4.9

171.58

3.77

8.31

14.5

5.7

18

7

29.7

11.8

37

14.5

2.6

1.75

164

362

62.7

213,932

56.5

192,778

4

58

1.40

5.04

34

13.4

5.8

205.70

4.52

9.97

14.5

5.7

18

7

29.4

11.6

37

14.5

2.6

1.75

186

410

73.7

251,464

66.4

226,557

4

58

1.60

5.76

46

18.1

6.8

241.79

5.31

11.71

14.5

5.7

18

7

29.1

11.4

37

14.5

2.6

1.75

213

470

83.8

285,926

75.6

257,947

4

58

1.90

6.84

57

22.6

7.8

274.93

6.04

13.32

14.5

5.7

18

7

31

12.2

37

14.5

2.6

1.65

234

516

Geneva ‘PV’ as above with these changes.

BOILER MODEL ‘PV’ PV 3 PV 4

Maximum Working

Pressure

Expansion Vessel

Capacity

Shipping Weight

Bar

Psi

Lits

Gal

Kg

Lbs

3

44

8

1.76

94

207

2.20

118

260

TABLE. 1

3

44

10

3

INSTALLATION INSTRUCTIONS

1.0 GENERAL

1.1 The STREBEL GENEVA ‘PV’ & ‘C’ range of Gas Fired Boilers are floor mounted open flued units for

connection to indirect heating and hot water systems.

The Geneva heat exchanger body is constructed of cast iron sections with a stainless steel atmospheric gas

burner suitable for Natural Gas and LPG (site conversion) the boilers as standard are fitted with electronic

ignition. The boilers are fitted with full safety devices including “Spillage Control System” (SCS) which

shuts down the boiler if Spillage is occurring and so prevents any escape of flue gases out the flue diverter,

also on the C60 & C68 models there is a Gas pressure switch for low gas inlet pressure.

The boilers are delivered completely assembled jackets fitted and fully insulated.

The Geneva ‘PV’ range is also fitted with three speed circulating pump, expansion vessel for use with a

sealed systems, 3 Bar safety valve, pressure gauge and water fill point (manual).

1.2 The installation of this boiler must be carried out in accordance with the relevant requirements of the gas

safety (installation and use) Regulations 1984, the I.E.E. Wiring Regulations and the Bylaws of the Local

Water Undertaking, and the Building Regulations 1985.

Detailed recommendations are contained in the following:

British Standard Code of Practice CP. 341 : 300-307 ; CP 342 : Parts I and 2 : BS. 5440 parts 1 & 2 :

BS.5854 : BS. 6644 :BS. 6798 : BS. 6891 and British Gas Publications :- IM/11 Flues for Commercial and

Industrial Gas Fired Boilers an Air Heaters

"The Gas Safety (Installation and Use) Regulations 1984:

It is the law that all gas appliances are installed by CORGI registered contractors in accordance with the

above regulations. Failure to install appliances correctly could lead to prosecution. It is in your own

interest, and that of safety, to ensure that the law is complied with".

2.0 LOCATION

2.1 The boiler must stand on a level non combustible base, which is capable of adequately supporting the weight

of the boiler, water content an any ancillary equipment.

The location chosen for the boiler must permit the provision of a satisfactory flue and termination.

The location must also permit an adequate space for combustion and ventilation purposes (see Section 3 on

Ventilation) and adequate space for servicing and air circulation around the boiler.

3.0 VENTILATION

3.1 It is important that there are sufficient areas of air inlet and ventilation provided to the boiler room detail

recommendations for air supply are given in BS. 5440 part 2 & BS. 6644. The following notes are intended

to give general guidance.

3.2 Natural Ventilation.

Where both low- and high-level openings are used, the grilles shall have a total minimum free area as

follows:

Low level (inlet): 540 cm² plus 4.5 cm² per Kilowatt in excess of 60 kW total rated input;

High level (inlet): 270 cm² plus 2.25 cm² per Kilowatt in excess of 60 kW total rated input.

4

3.3 Mechanical Ventilation.

The minimum quantity of air required for combustion and boiler house ventilation shall be supplied at a

minimum flow rate in accordance with BS. 6644.

All air inlet and extract fans shall be fitted with automatic controls causing safety shut-down or lockout of

the boiler(s) in the event of the inlet or extract air flow failing.

4.0 GAS SUPPLY

4.1 An existing meter should be checked preferably by the Gas Supplier, to ensure the meter is adequate to deal

with the rate of gas required.

4.2 Pipework from the meter to the boiler must be of adequate size. Pipes of smaller size than the boiler inlet gas

connection should not be used. All gas pipework should be fitted and on completion of installation tested, in

accordance with BS. 6891 : IGE/UP/2 Gas Installation Pipework, Boosters and Compressors on Industrial

and Commercial Premises.

4.3 Gas supply connections is as follows:

Geneva PV 3 & PV 4 = 1/2" BSP

Geneva C 3, C 4, C 5, C 6 & C 7 = 1/2" BSP

Geneva C 8 & C 9 = 1" BSP.

4.4 A gas service cock must be fitted immediately adjacent to the boiler.

5.0 FLUE SYSTEM

5.1 Detail recommendations for flueing are given in B.G.C. Publications:- “Flues for commercial and Industrial

Gas Fired Boilers and Air Heaters” 1M/11.

Reference should also be made to BS. 5440 Part 1 : BS. 6644 where applicable.

The following notes are intended to give general guidance.

5.2 The nominal flue size should not be less than that of the boiler flue connection, and must be at least

equivalent to a vertical height above the boiler outlet of 1 M (3 ft 3 in), due allowance being made for any

horizontal or inclined length, and consideration being given to the position of the outlet.

The boiler flue hood is not load bearing and the flue must be supported independently. The flue should be

easily disconnected for servicing.

6.5 WATER CIRCULATION SYSTEM

6.1 Flow and return connections are from the back of the boiler with BSP connections.

6.2 In combined heating and hot water systems the hot water storage vessel must be of the indirect cylinder or

calorifier type.

6.3 The boiler maximum working pressure is 3 Bar (43.5 Psi) for ‘PV’ models and 4 Bar (58 Psi) for ‘C’ models

which includes pump circulation head. The minimum head being 1 meter above the top of the boiler.

6.5 Hydraulic Resistance and Flow Rates

The differential temperatures across the flow and return water connections to the boiler is recommend as

10°C temperature difference (Max. temperature difference 20°C).

Water flow rates and water pressure drops across the boilers are detailed on Table 1.

6.6 If three-way mixing or diverting vales are installed in the systems they should not be of such a type that the

flow through the boiler is totally closed. If such valves are used, a by-pass should be fitted.

5

Loading...

Loading...