Strebel CIS, CISM Installation Instructions Manual

STREBEL CIS BOILERS

BOILER INSTALLATION INSTRUCTIONS FOR STREBEL CISM BOILERS

INSTALLATION INSTRUCTIONS

General Instructions:

The STREBEL CIS & CIS boilers are special boilers for light oil or gasfired (forced) burners. They can be fitted in hot water heating

installations or low pressure steam installations, depending on the type.

Operating Conditions:

Hot water Heating installations boiler type STREBEL CIS

STREBEL CISM

Maximum high limit temperature 110ºC

Maximum Operating Temperature 95°C

Maximum working pressure 4 bar

Please note all relevant instructions when assembling the boilers.

The Installation: The connecting and initial setting in operation should

be carried out by a qualified heating specialist.

The boiler base is to be constructed in accordance with our diagrams.

Advantages of the STREBEL CIS AND CISM:

1. Long life of cast iron boiler body.

2. High efficiency of operation. Efficiency of combustion is higher

than 90.5 % for all kinds of fuels.

3. Possibility of delivery with burner.

4. Modern design.

5. Signalling of operation and defect of boiler.

6. It is possible to order a special variation of the boiler allowing a

water temperature of 115ºC (standard delivery is with boiler

water temperature up to 95ºC).

7. The ability to use a modular arrangement of connection.

8. Delivery fully assembled or in part form according to customer

requirements is available.

9. Door can be mounted to swing from either side (must be

specified in order).

10. Easily visible sight glass for viewing flame or for reading

combustion chamber pressure.

STREBEL CIS BOILER

V.1 - 03.08

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 2

V.1-03.08

INDEX : PAGE

ASSEMBLY TOOLS 3

BOILER BASE 3

TECHNICAL DATA 4 & 5

BOILER ERECTION

WALL CLEARANCES 6

COMPONENTS REQUIRED 6

IMPORTANT ASSEMBLY ADVISE 7

BOILER ASSEMBLY

BOILER BLOCK 8 & 9

FIXTURES 10

BURNER DOOR 10

UPPER FLUE-WAY DOOR 10

BOILER JACKETS 10

FLUE HOOD 10

FLOW AND RETURN CONNECTIONS 10

INSTRUMENT CONTROL PANEL ASSEMBLY

DESCRIPTION OF INSTRUMENT CONTROL PANEL 12

ASSEMBLING THE BURNER 12

INSTRUMENT CONTROL PANEL WIRING DIAGRAM 13

INSTRUMENT CONTROL PANEL TERMINAL DIAGRAM 14

BEFORE STARTING BOILER / BURNER 15

FAULT FINDING 15

MAINTENANCE 15

HAZARDS 15

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 3

V.1-03.08

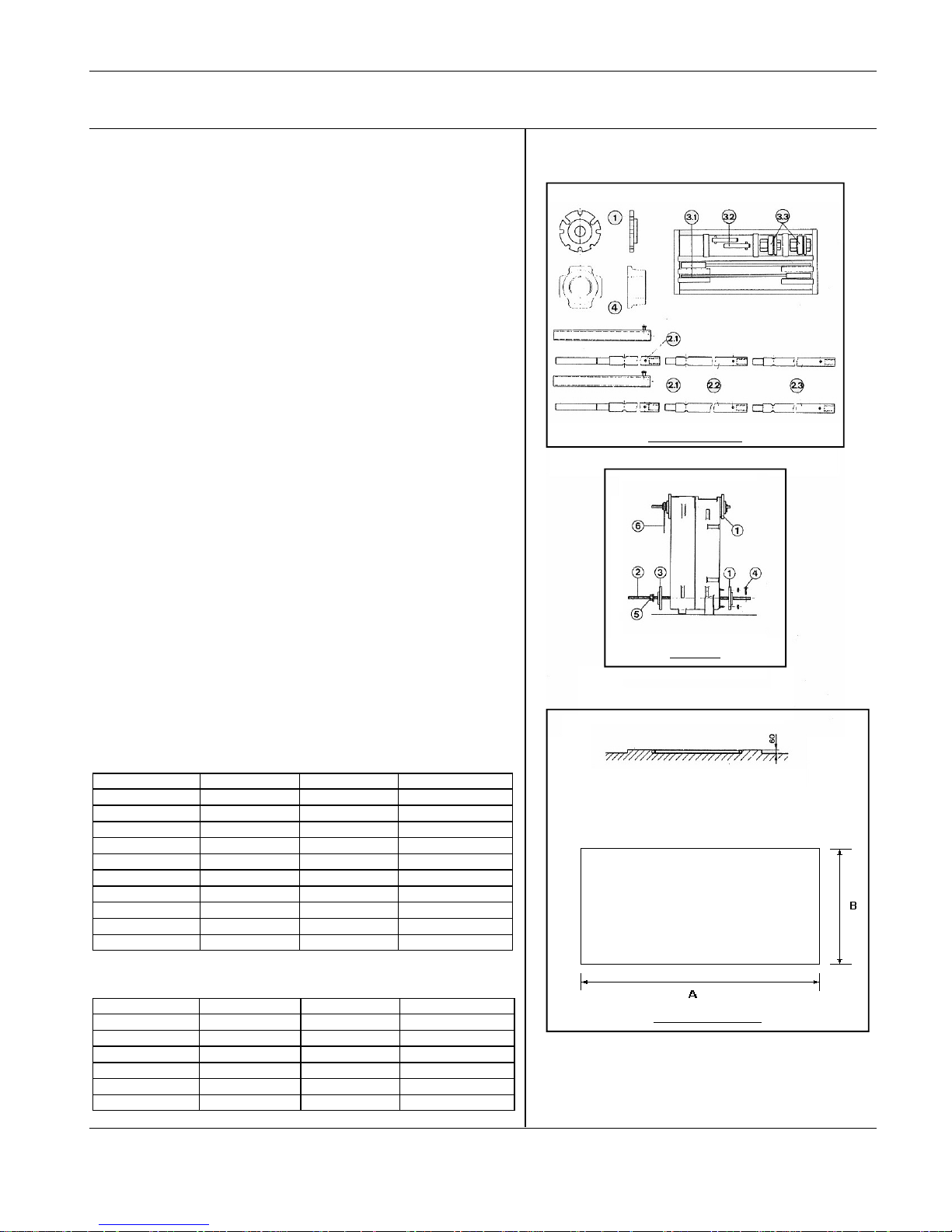

ASSEMBLY TOOL

A bar Pulling up tool, which is returnable after assembly has been successfully

completed, is made available for assembling the boiler block.

The complete pulling up kit CIS/CISM consists of the following:

1) Pulling up flange at the top rear section

1) Pulling up flange at the bottom rear section

1) Pulling up flange at the intermediate section

1) Pulling up flange at the bottom front section

4) Pulling up flange at the top front section

5) Pulling up piping

2.1) Basic bar

2.2) Extension

2.3) End piece

Case containing press tool

3.1) Free running ratchet spanner

3.2) Stop pins

3.3) Pulling up nut with thrust bearing

Items needed for construction: flat chisel, mallet, brush, small round smoothing

file, emery cloth, cleanser (e.g. petroleum), inspection lamp, spanner.

Advice on the use of the pulling-up tools.

1) The pulling up flanges at the rear section are screwed onto the boiler flow

and return connections.

2) The basic bars are inserted through the openings of the press flanges and

ports so that the screw ends are situated out of the ports at the front. (The

basic bars can be extended, as necessary.)

3) The pulling up flanges at the intermediate section or front section are pushed

over the basic bar screw end from the front.

4) The Stop pins are inserted at the back through one of the transverse borings

of the pulling up bar.

5) The pulling up nuts are screwed onto the basic bar screw end, from the front

until they take up the slack on the pulling up tool flanges.

6) The free-running ratchet spanners are put on the starting nuts.

Boiler base

The boiler base is to be constructed in accordance with our base plans. The boiler

block may stand on an iron frame set in concrete. The boiler base must stand on a

level, non combustable base which is capable of supporting the weight of the

boiler, water content and any ancillary equipment. These dimensions provide a

50mm excess around the boiler jackets.

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR STREBEL CISM

STREBEL CISM

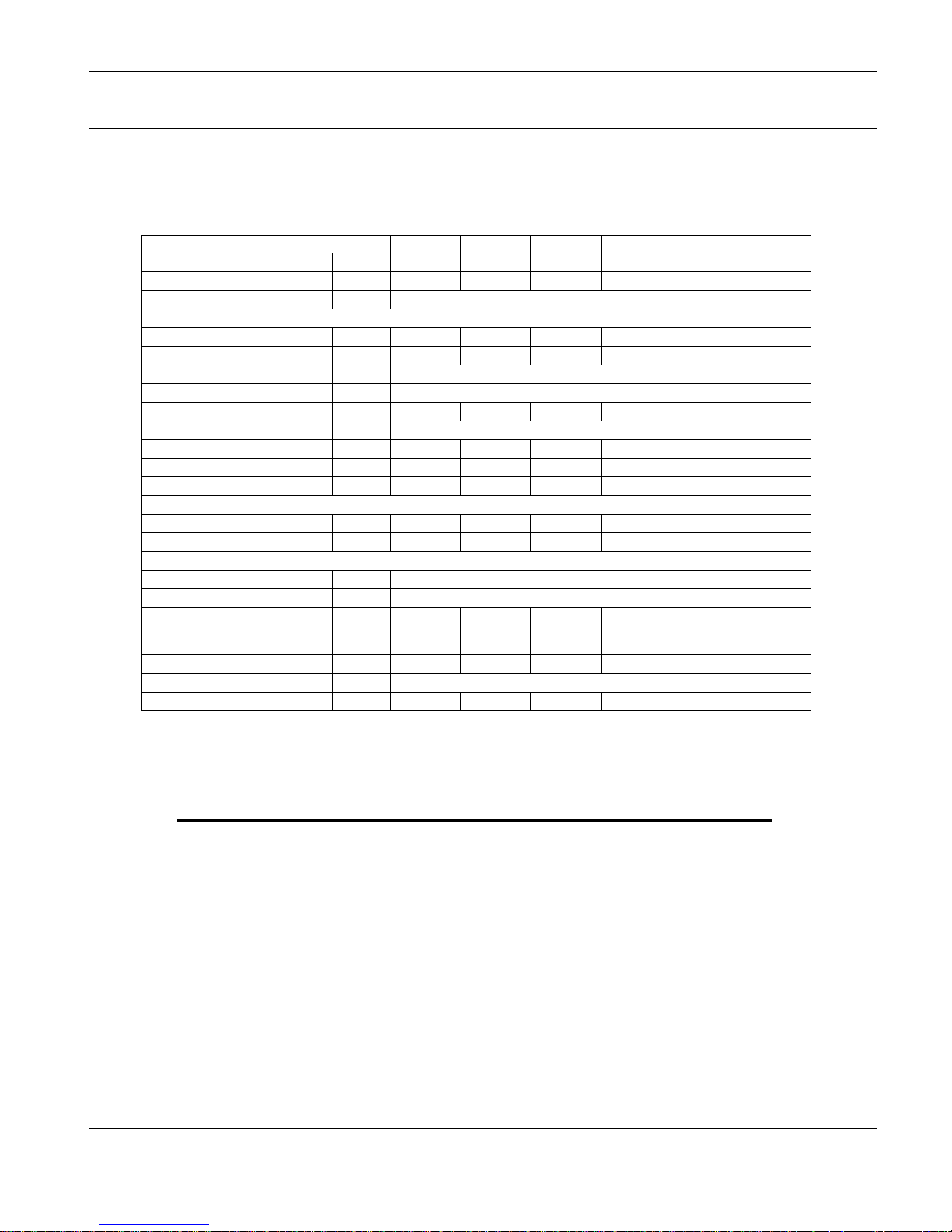

No. of sections Width (B) (mm) Length (A) (mm) Min. Thickness (mm)

10 904 1862 60

11 904 2012 60

12 904 2162 60

13 904 2312 60

14 904 2462 60

15 904 2612 60

STREBEL CIS

No. of sections Width (B) (mm) Length (A) (mm) Min.Thickness (mm)

5 850 860 60

6 850 970 60

7 850 1080 60

8 850 1190 60

9 850 1300 60

10 850 1410 60

11 850 1520 60

12 850 1630 60

13 850 1740 60

14 850 1850 60

Pulling-up tools

Boiler base details

Tool use

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 4

V.1-03.08

S

T

R

E

B

E

L

C

I

S

–

T

E

C

H

N

I

C

A

L

D

A

T

A

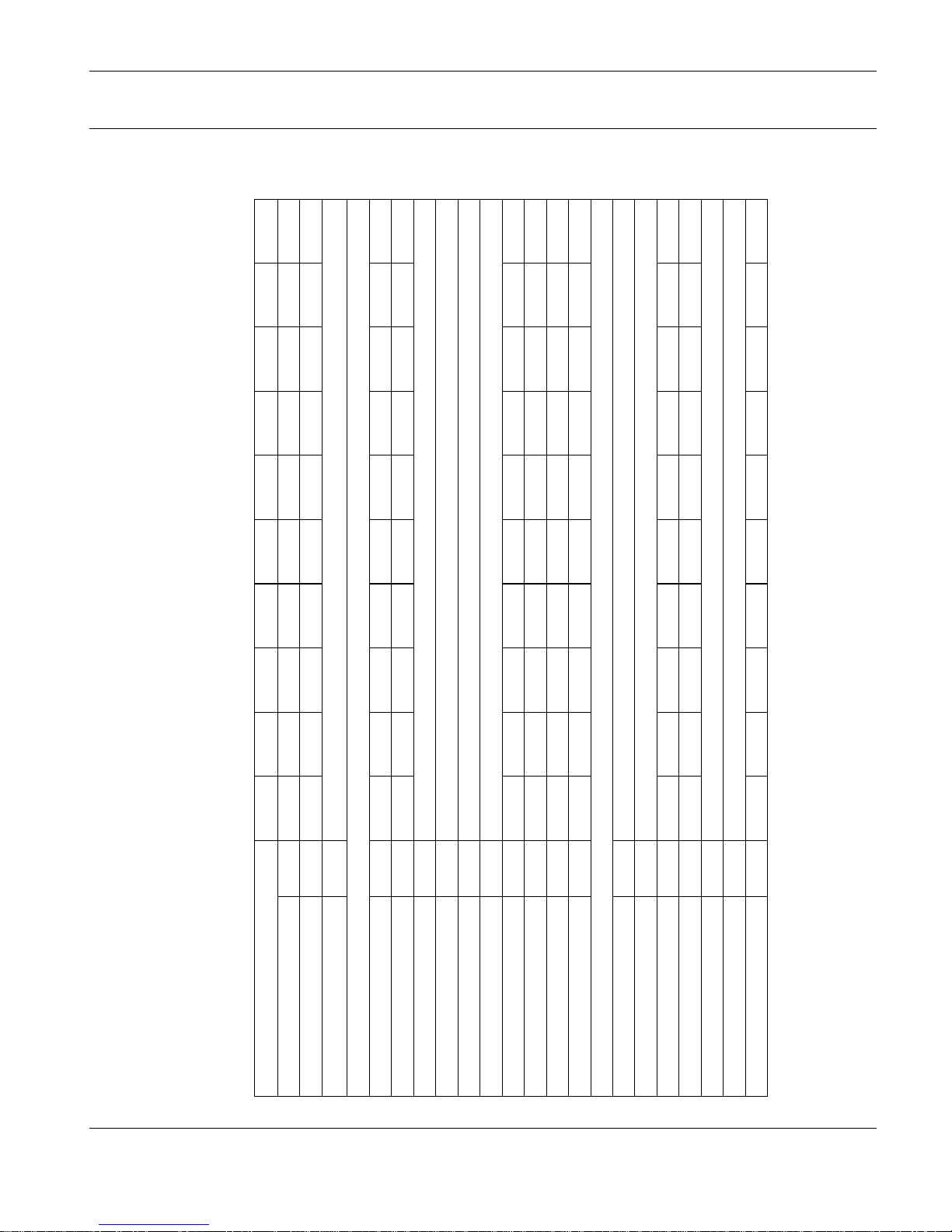

No. of Sections

5 6 7 8 9 10 11 12 13 14

Nominal Output kW 103 126 149 172 195 218 241 264 287 310

Nominal Input kW 113.2 138.5 163.7 189 214.3 239.6 264.8 290.1 315.4 340.7

Efficiency % 90.5

Fuel Consumption:

Natural Gas m³/hr 11.5 14.1 16.7 19.3 21.9 24.5 27.1 29.7 32.2 34.9

Extra Light Heating Oil kg/hr 9.59 11.74 13.87 16.02 18.16 20.31 22.44 24.58 26.73 28.87

Max. Working Pressure bar 4

Max. Boiler Operating Temp. ºC 90

Combustion Chamber Pressure mbar 2

Approx. Flue Gas Temp. ºC 185

Flue Gas Volume kg/sec 0.053 0.065 0.077 0.088 0.100 0.112 0.124 0.136 0.148 0.149

Water Volume of Boiler litres 56.4 65.4 74.4 83.4 92.4 101.4 110.4 119.4 128.4 137.4

Combustion Chamber Volume cm³ 81.79 100.73 119.68 138.62 157.56 176.51 195.45 214.39 233.33 252.27

Hydraulic Resistance @ 10°C ∆ T mbar 0.20 0.24 0.25 0.31 0.37 0.43 0.50 0.55 0.63 0.71

Dimensions:

Height mm 1355

Width mm 750

Depth mm 737 847 957 1067 1177 1287 1397 1507 1617 1717

Depth of Combustion Chamber mm 475 585 695 805 915 1025 1135 1245 1355 1465

Flue Spigot Diameter mm 225

Flow & Return Connections mm 80

Weight of Boiler kg 505 585 665 745 825 905 985 1065 1145 1225

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 5

V.1-03.08

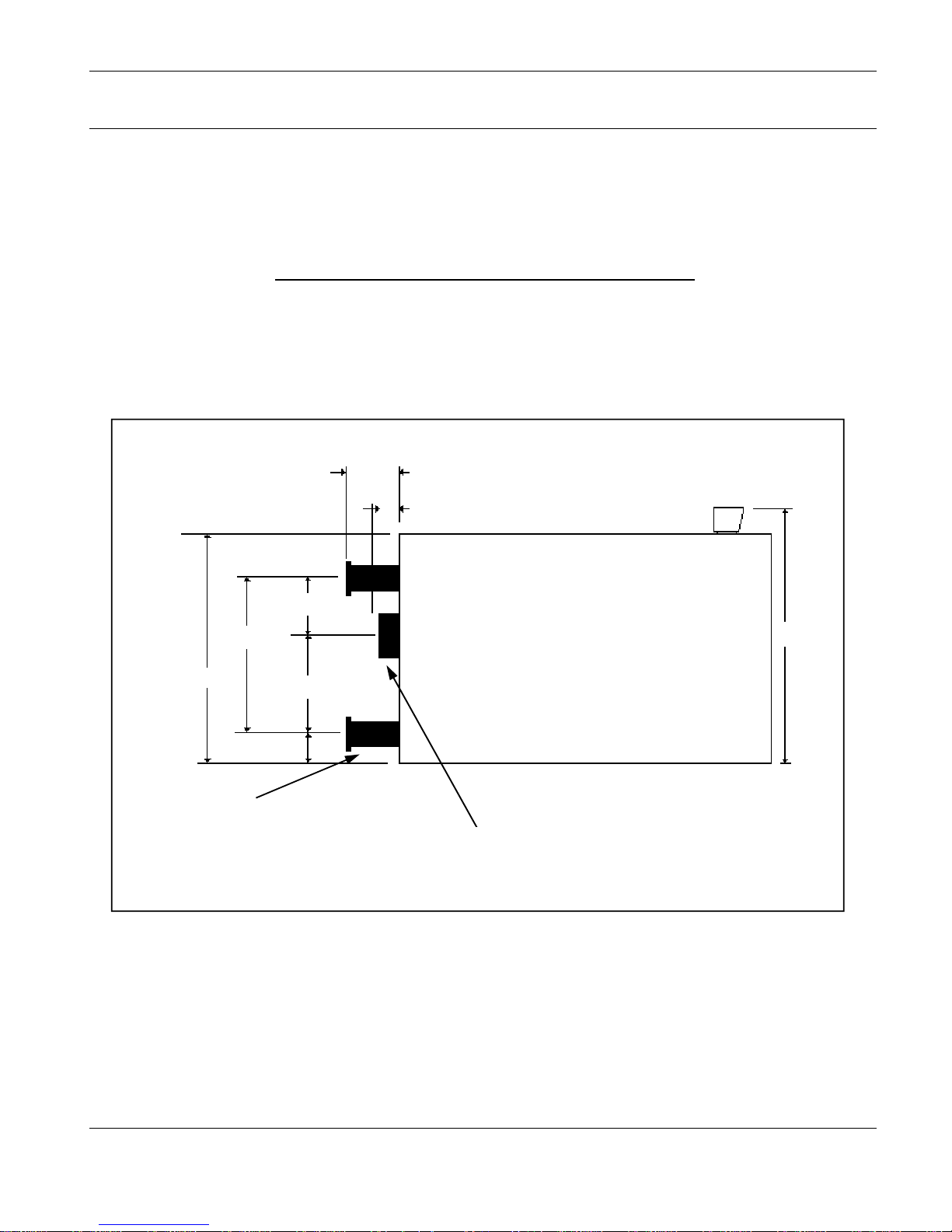

STREBEL CIS Series - Connection Dimensions

1185mm

125mm

Flue spigot 220mm

outside diameter

Flow & Return connections

80mm I.d pipe

Mating weldneck flanges

supplied

STREBEL CIS BOILER

80mm

275mm

670mm

95mm

945mm

1355mm

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 6

V.1-03.08

STREBEL CISM – TECHNICAL DATA

No. of Sections

10 11 12 13 14 15

Nominal Output kW 330 400 470 550 620 690

Nominal Input kW 360 438 512 600 678 754

Efficiency % 91.5

Fuel Consumption:

Natural Gas m³/hr 36.1 43.9 51.4 60.2 71.1 82.3

Extra Light Heating Oil kg/hr 30.2 36.8 43.1 50.5 58.0 65.5

Max. Working Pressure bar 4

Max. Boiler Operating Temp. ºC 90

Combustion Chamber Pressure mbar 0.9 1.4 2.2 3.2 5 6.2

Approx. Flue Gas Temp. ºC 165 - 190

Flue Gas Volume kg/sec 0.088 0.100 0.120 0.135 0.156 0.180

Water Volume of Boiler litres 252 277 302 327 352 377

Combustion Chamber Volume cm³ 314 347 381 414 449 485

Hydraulic Resistance

@ 20°C ∆ T mbar 0.90 1.35 1.90 2.60 3.34 4.20

@ 10°C ∆ T mbar 3.40 3.90 5.30 8.60 12.40 16.70

Dimensions:

Height mm 1237

Width mm 904

Depth mm 1762 1912 2062 2212 2362 2512

Depth of Combustion Chamber mm 1377 1527 1677 1827 1977 2127

Flue Spigot Diameter mm 250 250 250 300 300 300

Flow & Return Connections mm 100

Weight of Boiler kg 1660 1815 1970 2125 2280 2435

Loading...

Loading...