STREBEL CIS BOILERS

BOILER INSTALLATION INSTRUCTIONS FOR STREBEL CISM BOILERS

INSTALLATION INSTRUCTIONS

General Instructions:

The STREBEL CIS & CIS boilers are special boilers for light oil or gasfired (forced) burners. They can be fitted in hot water heating

installations or low pressure steam installations, depending on the type.

Operating Conditions:

Hot water Heating installations boiler type STREBEL CIS

STREBEL CISM

Maximum high limit temperature 110ºC

Maximum Operating Temperature 95°C

Maximum working pressure 4 bar

Please note all relevant instructions when assembling the boilers.

The Installation: The connecting and initial setting in operation should

be carried out by a qualified heating specialist.

The boiler base is to be constructed in accordance with our diagrams.

Advantages of the STREBEL CIS AND CISM:

1. Long life of cast iron boiler body.

2. High efficiency of operation. Efficiency of combustion is higher

than 90.5 % for all kinds of fuels.

3. Possibility of delivery with burner.

4. Modern design.

5. Signalling of operation and defect of boiler.

6. It is possible to order a special variation of the boiler allowing a

water temperature of 115ºC (standard delivery is with boiler

water temperature up to 95ºC).

7. The ability to use a modular arrangement of connection.

8. Delivery fully assembled or in part form according to customer

requirements is available.

9. Door can be mounted to swing from either side (must be

specified in order).

10. Easily visible sight glass for viewing flame or for reading

combustion chamber pressure.

STREBEL CIS BOILER

V.1 - 03.08

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 2

V.1-03.08

INDEX : PAGE

ASSEMBLY TOOLS 3

BOILER BASE 3

TECHNICAL DATA 4 & 5

BOILER ERECTION

WALL CLEARANCES 6

COMPONENTS REQUIRED 6

IMPORTANT ASSEMBLY ADVISE 7

BOILER ASSEMBLY

BOILER BLOCK 8 & 9

FIXTURES 10

BURNER DOOR 10

UPPER FLUE-WAY DOOR 10

BOILER JACKETS 10

FLUE HOOD 10

FLOW AND RETURN CONNECTIONS 10

INSTRUMENT CONTROL PANEL ASSEMBLY

DESCRIPTION OF INSTRUMENT CONTROL PANEL 12

ASSEMBLING THE BURNER 12

INSTRUMENT CONTROL PANEL WIRING DIAGRAM 13

INSTRUMENT CONTROL PANEL TERMINAL DIAGRAM 14

BEFORE STARTING BOILER / BURNER 15

FAULT FINDING 15

MAINTENANCE 15

HAZARDS 15

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 3

V.1-03.08

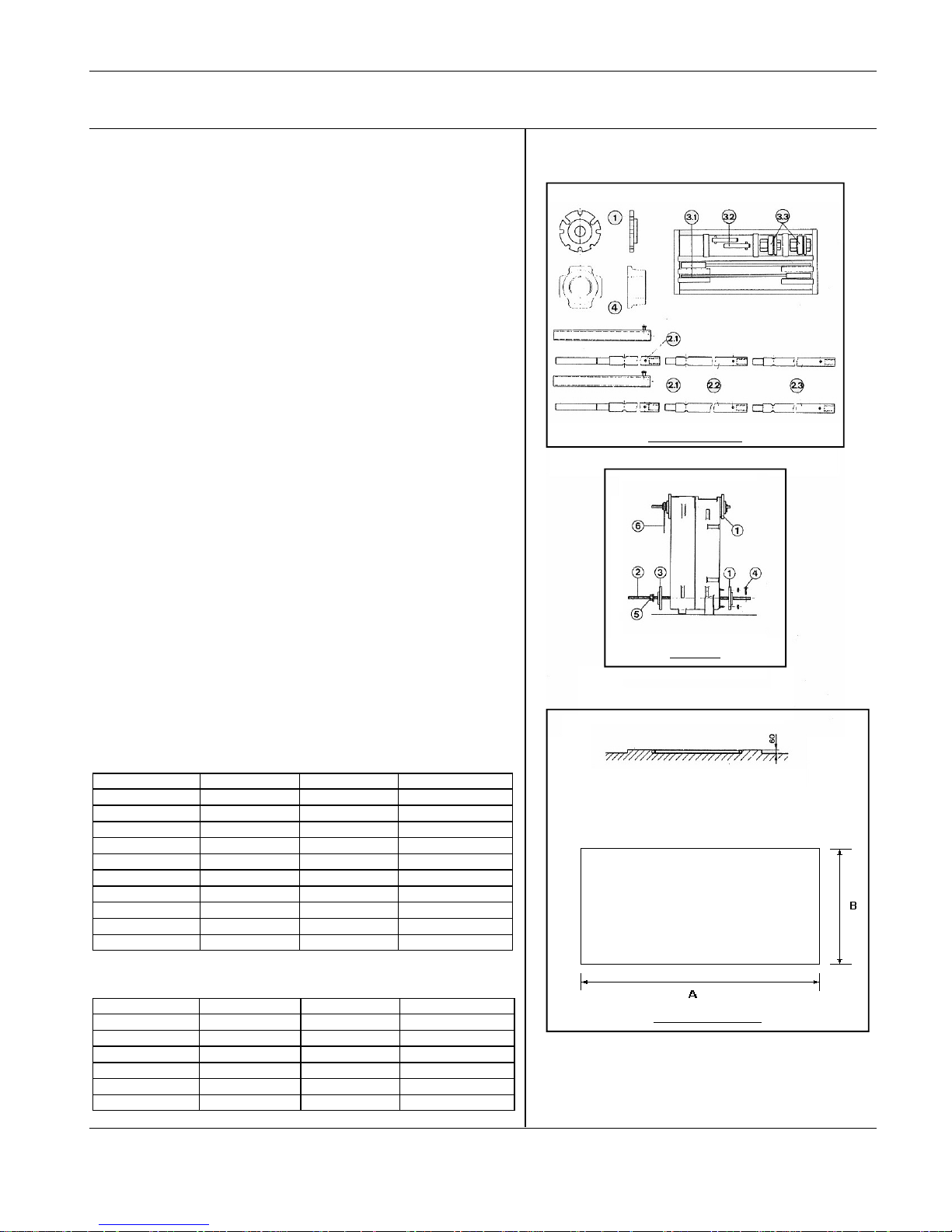

ASSEMBLY TOOL

A bar Pulling up tool, which is returnable after assembly has been successfully

completed, is made available for assembling the boiler block.

The complete pulling up kit CIS/CISM consists of the following:

1) Pulling up flange at the top rear section

1) Pulling up flange at the bottom rear section

1) Pulling up flange at the intermediate section

1) Pulling up flange at the bottom front section

4) Pulling up flange at the top front section

5) Pulling up piping

2.1) Basic bar

2.2) Extension

2.3) End piece

Case containing press tool

3.1) Free running ratchet spanner

3.2) Stop pins

3.3) Pulling up nut with thrust bearing

Items needed for construction: flat chisel, mallet, brush, small round smoothing

file, emery cloth, cleanser (e.g. petroleum), inspection lamp, spanner.

Advice on the use of the pulling-up tools.

1) The pulling up flanges at the rear section are screwed onto the boiler flow

and return connections.

2) The basic bars are inserted through the openings of the press flanges and

ports so that the screw ends are situated out of the ports at the front. (The

basic bars can be extended, as necessary.)

3) The pulling up flanges at the intermediate section or front section are pushed

over the basic bar screw end from the front.

4) The Stop pins are inserted at the back through one of the transverse borings

of the pulling up bar.

5) The pulling up nuts are screwed onto the basic bar screw end, from the front

until they take up the slack on the pulling up tool flanges.

6) The free-running ratchet spanners are put on the starting nuts.

Boiler base

The boiler base is to be constructed in accordance with our base plans. The boiler

block may stand on an iron frame set in concrete. The boiler base must stand on a

level, non combustable base which is capable of supporting the weight of the

boiler, water content and any ancillary equipment. These dimensions provide a

50mm excess around the boiler jackets.

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR STREBEL CISM

STREBEL CISM

No. of sections Width (B) (mm) Length (A) (mm) Min. Thickness (mm)

10 904 1862 60

11 904 2012 60

12 904 2162 60

13 904 2312 60

14 904 2462 60

15 904 2612 60

STREBEL CIS

No. of sections Width (B) (mm) Length (A) (mm) Min.Thickness (mm)

5 850 860 60

6 850 970 60

7 850 1080 60

8 850 1190 60

9 850 1300 60

10 850 1410 60

11 850 1520 60

12 850 1630 60

13 850 1740 60

14 850 1850 60

Pulling-up tools

Boiler base details

Tool use

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 4

V.1-03.08

S

T

R

E

B

E

L

C

I

S

–

T

E

C

H

N

I

C

A

L

D

A

T

A

No. of Sections

5 6 7 8 9 10 11 12 13 14

Nominal Output kW 103 126 149 172 195 218 241 264 287 310

Nominal Input kW 113.2 138.5 163.7 189 214.3 239.6 264.8 290.1 315.4 340.7

Efficiency % 90.5

Fuel Consumption:

Natural Gas m³/hr 11.5 14.1 16.7 19.3 21.9 24.5 27.1 29.7 32.2 34.9

Extra Light Heating Oil kg/hr 9.59 11.74 13.87 16.02 18.16 20.31 22.44 24.58 26.73 28.87

Max. Working Pressure bar 4

Max. Boiler Operating Temp. ºC 90

Combustion Chamber Pressure mbar 2

Approx. Flue Gas Temp. ºC 185

Flue Gas Volume kg/sec 0.053 0.065 0.077 0.088 0.100 0.112 0.124 0.136 0.148 0.149

Water Volume of Boiler litres 56.4 65.4 74.4 83.4 92.4 101.4 110.4 119.4 128.4 137.4

Combustion Chamber Volume cm³ 81.79 100.73 119.68 138.62 157.56 176.51 195.45 214.39 233.33 252.27

Hydraulic Resistance @ 10°C ∆ T mbar 0.20 0.24 0.25 0.31 0.37 0.43 0.50 0.55 0.63 0.71

Dimensions:

Height mm 1355

Width mm 750

Depth mm 737 847 957 1067 1177 1287 1397 1507 1617 1717

Depth of Combustion Chamber mm 475 585 695 805 915 1025 1135 1245 1355 1465

Flue Spigot Diameter mm 225

Flow & Return Connections mm 80

Weight of Boiler kg 505 585 665 745 825 905 985 1065 1145 1225

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 5

V.1-03.08

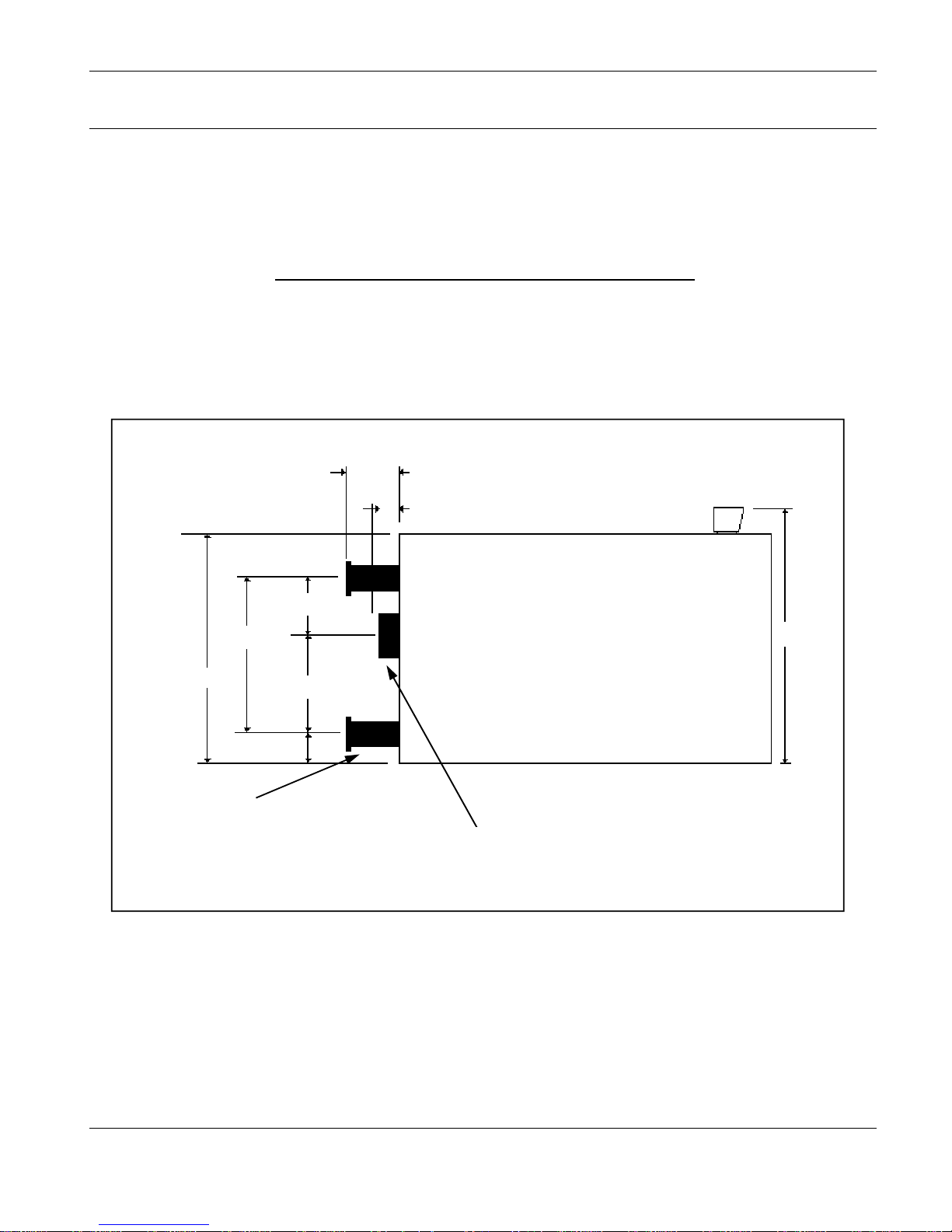

STREBEL CIS Series - Connection Dimensions

1185mm

125mm

Flue spigot 220mm

outside diameter

Flow & Return connections

80mm I.d pipe

Mating weldneck flanges

supplied

STREBEL CIS BOILER

80mm

275mm

670mm

95mm

945mm

1355mm

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 6

V.1-03.08

STREBEL CISM – TECHNICAL DATA

No. of Sections

10 11 12 13 14 15

Nominal Output kW 330 400 470 550 620 690

Nominal Input kW 360 438 512 600 678 754

Efficiency % 91.5

Fuel Consumption:

Natural Gas m³/hr 36.1 43.9 51.4 60.2 71.1 82.3

Extra Light Heating Oil kg/hr 30.2 36.8 43.1 50.5 58.0 65.5

Max. Working Pressure bar 4

Max. Boiler Operating Temp. ºC 90

Combustion Chamber Pressure mbar 0.9 1.4 2.2 3.2 5 6.2

Approx. Flue Gas Temp. ºC 165 - 190

Flue Gas Volume kg/sec 0.088 0.100 0.120 0.135 0.156 0.180

Water Volume of Boiler litres 252 277 302 327 352 377

Combustion Chamber Volume cm³ 314 347 381 414 449 485

Hydraulic Resistance

@ 20°C ∆ T mbar 0.90 1.35 1.90 2.60 3.34 4.20

@ 10°C ∆ T mbar 3.40 3.90 5.30 8.60 12.40 16.70

Dimensions:

Height mm 1237

Width mm 904

Depth mm 1762 1912 2062 2212 2362 2512

Depth of Combustion Chamber mm 1377 1527 1677 1827 1977 2127

Flue Spigot Diameter mm 250 250 250 300 300 300

Flow & Return Connections mm 100

Weight of Boiler kg 1660 1815 1970 2125 2280 2435

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 7

V.1-03.08

Boiler erection.

Wall clearances.

There must be free space around the boiler to access the boiler for servicing

purposes. The space in front of the boiler must be of distance equal to 1.5 times

the depth (L).

Access at one side should be a minimum of 500mm allowing free movement to

the rear of the boiler again for servicing purposes.

These areas around the boiler must be kept free from debris, especially, free from

combustible materials.

Components required:

→ Number of sections: front, rear and from 3 to 12 intermediate sections

(according to boiler size).

→ Boiler nipples: 8 to 26 (according to boiler size).

→ Boiler sealing mastic.

→ Nipple jointing oil.

→ Tie bars.

→ Injector.

→ 2 “ Plug

→ 2” x 1/2” bush.

→ Thermometer pocket.

→ Thermostat poket.

→ 1/2” self-closing valve for altitude (pressure) gauge.

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 8

V.1-03.08

Important Assembly Advice:

Please read through before starting the assembly!

The boiler is normally delivered in individual sections, which are assembled as a

boiler block by means of tapered nipples.

The watertight joint between two boiler sections is a high-precision press fit

between the boiler nipple and nipple port. The block assembly must be carried

out accordingly with precision.

The following points should be observed during assembly:

No damage to the nipple and borings should be apparent.

Before a nipple is inserted and a section fitted, the nipple and the boring should

be inspected. Any damage, e.g. to the face of the boring, destroys the nipple seal

and leads to leakage.

Attention! Minor damage (transport damage) to the faces of the boiler nipple or

to the nipple ports (A) can be corrected with a small smoothing file and emery

cloth without affecting the water tightness of the joint.

→ The accompanying nipple jointing oil sealing compound serves as a lubri

cant as well as a waterproof seal and must be used.

→ During the assembly no dirt should be allowed to remain on the nipples

or in the boring. These should be inspected during each assembly

phase, but particularly before fixing on the pulling–up flanges. Particles of

dirt, which are not removed, can lead to leakage.

→ During the boiler block assembly take care that the various boiler sec tions are fitted to the various positions, depending on the model.

→ Boiler nipples and nipple ports must align exactly at all stages of the as-

sembly.

→ An inclined inserted nipple leads to leakage.

A boiler section is built on basically in three stages: In addition, certain specific

points should be observed at each stage:

Stage 1: Drive nipple into boring with care

Inspect nipple and boring for damage.

Smear linseed oil sealing compound over nipple and boring. Gently drive nipple

into flow and return nipple ports using a mallet or synthetic hammer. The nipples

must remain firm and exactly vertical in the nipple ports and must be able to take

the next boiler section without twisting from nipple port. Take care, inclined

nipples lead to leakage.

Stage 2: Joining the boiler section to both inserted nipples.

Inspect nipple and nipple port for damage.

Smear linseed oil sealing compound over nipple and nipple port. Cover one

section with boiler mastic sealing strand. Place boiler section in front of both

inserted nipples. Raise the boiler section with the inserted nipples using a flat

chisel at all times under the section feet. The inserted nipples must stand approx.

1 to 2 mm higher than the boring of the section, which is to be joined. Using a

crowbar, raise boiler section to the inserted nipples until nipple and nipple ports

mate and hold.

Inspect boring once again for any dirt deposits before fixing the pulling-up

flanges. Remove dirt deposits if necessary.

Stage 3: To assemble boiler sections using bar pulling-up tool.

Take care during the pulling-up process that the clearance between both boiler

and section is even. If the clearance is uneven insert a flat chisel into the narrow

point and continue pulling-up until the clearance is even again.

Nipples and Nipple ports

Driving in nipple

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 9

V.1-03.08

Assembly of the boiler block from individual sections

Starting with the rear section to the front, the boiler block is assembled on the

boiler base.

1. Erect and support the rear section (A).

2. Clean the rear section sealing grooves and place boiler mastic sealing strand

into the sealing grooves.

3. Clean nipple and port. Inspect and smear with nipple jointing oil

4. Drive nipple into flow and return ports

5. Level the first intermediate section onto both rear section nipples.

6. Pull on intermediate section with pulling up tool. Fix on pulling up flanges,

starting nuts and ratchet spanners; tighten the starting nuts evenly (C). The

clearance between the two sections must be equal when pulling-up. If

clearance is unequal insert a flat chisel in the narrower point and continue

pulling-up until clearance is equal again.

Avoid using excessive force

and smooth out excess mastic.

Add on only one section at a time in each case.

Further sections are added accordingly.

7. On completion of the boiler block. Push pulling up bars through the lugs on

the ready assembled boiler block. Slide a flat washer and nut onto the tie

bars at the front and rear respectively and screw on hexagonal nut. Hold fast

one nut and draw on the other nut until tight.

Boiler Block Alignment

Any unevenness between boiler base and section feet can be levelled out by

laying metal shims underneath the boiler section feet.

A

B

C

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 10

V.1-03.08

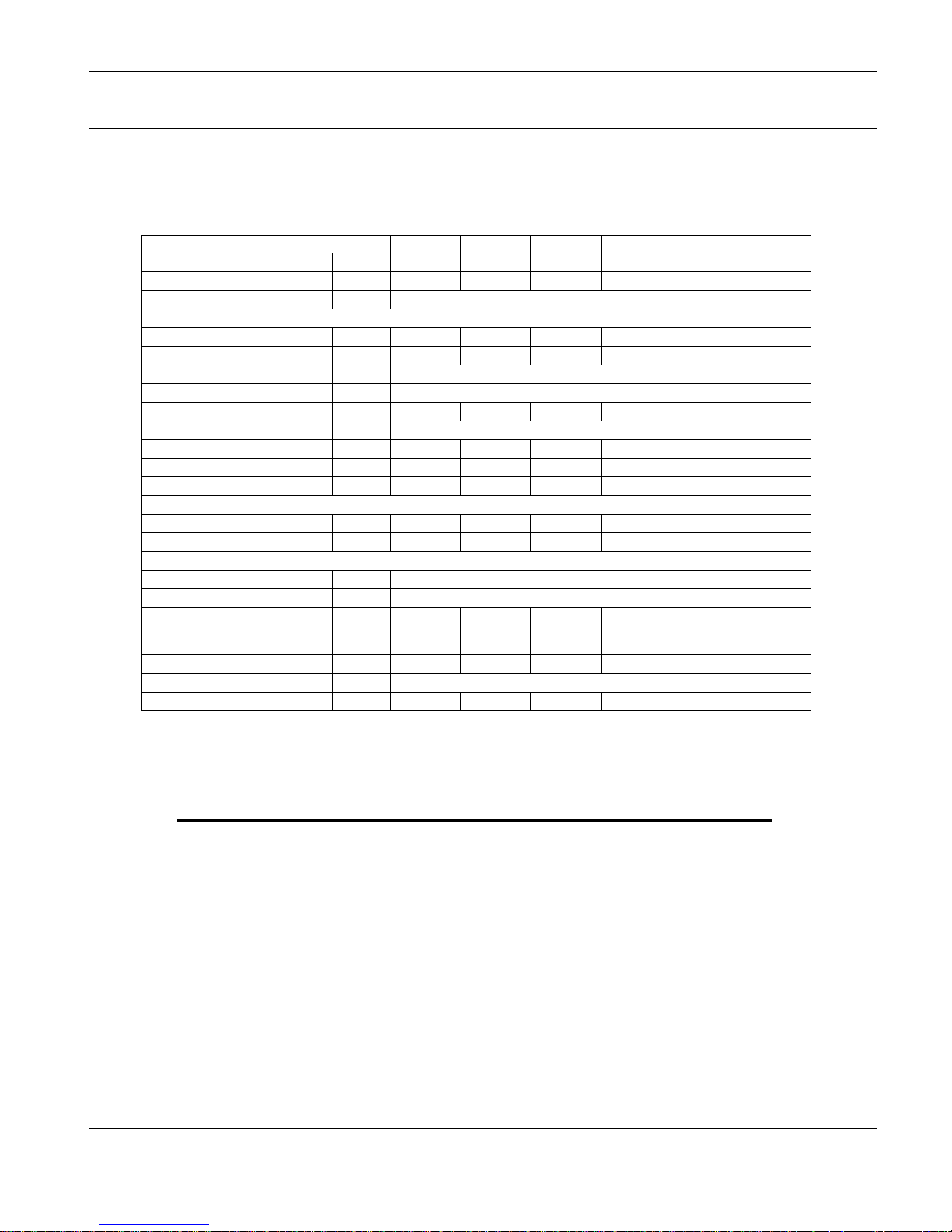

Front view showing the first three intermediate

sections after ‘pulling up’.

Front view showing the

complete boiler block without

the burner door or flue pass

door.

Rear view of the complete boiler block.

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 11

V.1-03.08

Assembly of fixtures

1. Fit 2” plug into the bottom tapping on the front section of the boiler (A).

2. Fit the 2” x 1/2” bush to the upper tapping of the boiler front section for the

thermostat pocket (B+C).

3. Next fit the thermostat pocket (1/2” diameter) into the bush (B).

4. Fit the thermometer pocket into the tapping immediately to the right of the self

closing valve (C)

5. Fit the 1/2” self-closing valve for the altitude (pressure) gauge into the upper

left hand tapping (D)

6. Fit the injector into the return connection with joggle to the bottom.

7. Connect flange to the lower return connection.

8. Connect the flow header to the upper tapping of the rear section.

Burner door assembly

1. Attach M12 screw with eye into the tapping on the front section ensuring that

there is a 40mm gap between the centre of the eyelet to the edge of the front

section and tighten locking nut (J).

2. Attach the threaded bolts M12 x 80 mm into the right hand tappings on the

lower half of the front section.

3. Put ceramic sealing cord into the groove on the lower part of the front section

(I).

4. Place burner door with insulation onto the eyelets and insert hinge pins 12 x

63 mm.

5. Close burner door, check alignment and tighten nuts M12 with washers.

6. Attach burner flange plate onto burner door.

7. Repeat procedure swapping eye bolt fixings with threaded bolts fitting the

hinge on the right hand side, if required.

Upper flue-way door

Use the same procedure as above to fit the flue-way door.

Boiler jacket assembly

1. Hang the insulated side jackets on the upwardly protruding jacket supports on

the front and rear sections.

2. Fit the rear bottom jacket to the side jackets by pushing the spring clips into

the side jackets and securing further up with M6 self tapping screws.

3. Repeat procedure with the rear upper jacket.

4. Fit the upper jacket and insulation by sliding over the side jackets and

securing with M6 self-tapping screws.

5. The lower front jacket is fitted by pushing together using spring clips.

Assembly of Flue Hood

1. Put the ceramic fibre sealing cord (900mm) into the groove in the rear section

of the boiler (G).

2. Align the complete flue hood casting and bolt on using the M8 nuts (H).

Flow and return connections

1. These are bolted onto the rear section of the boiler using the M12 nuts and

washers (E+F).

J

A

I

B

D

C

F

H

E

G

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 12

V.1-03.08

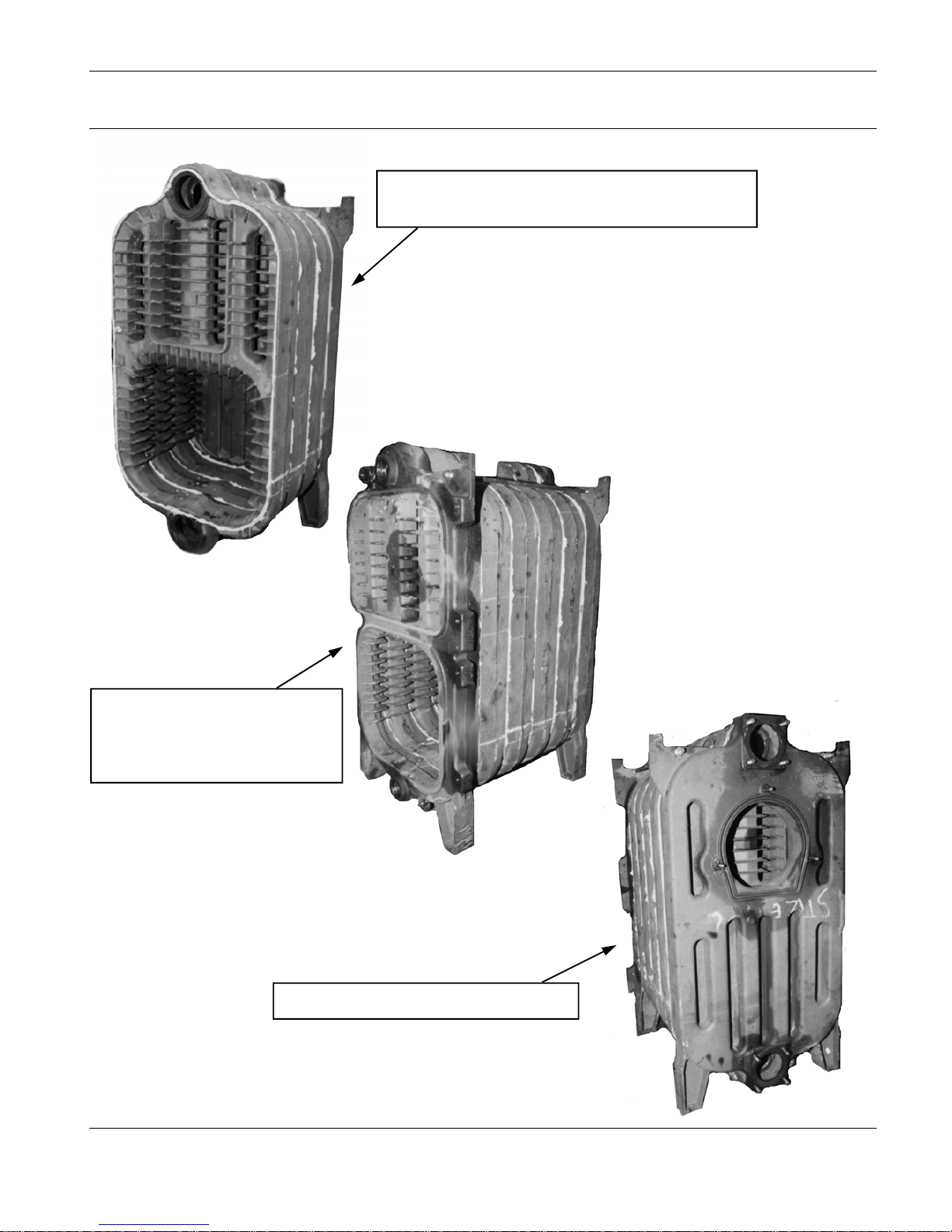

Completed boiler block with burner door and

flue pass door hinged on the right.

Front view showing the side jackets

and the doors bolted closed.

Top view showing insulation prior to fitting the top jacket.

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 13

V.1-03.08

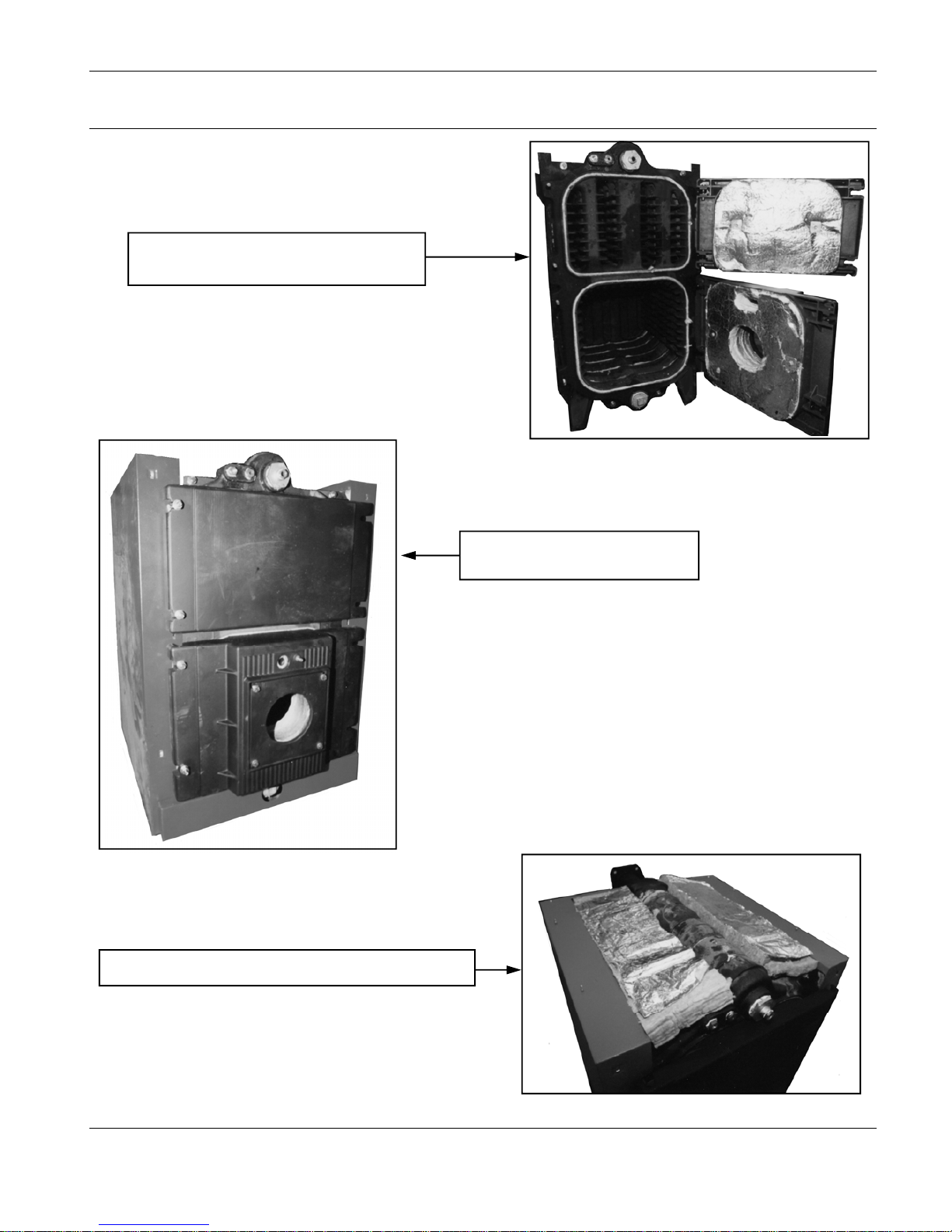

Instrument control panel assembly.

Description of the instrument control panel

Instrument control panel OS-04 consists of the following parts:

→ Instrument panel casing.

→ Altitude (pressure) sensor.

→ Thermometer.

→ Stage 1 control thermostat.

→ Stage 2 control thermostat.

→ Limit thermostat.

→ Hours run counter for stage 1 & 2.

→ Stage 1 and stage 2 ON/ OFF lamps.

→ Burner lockout lamp (reset button).

→ Terminal connections.

Assembly of instrument control panel

1. Attach instrument control panel casing to the upper jacket on the

boiler.

2. Push the altitude (pressure) sensor, thermometer, stage 1&2

thermostats and the limit thermostat, wiring through the slotted hole

in the upper jacket.

3. Push connection wires through into the control panel and connect

according to the wiring diagram.

4. The burner connections run from the burner to the conduits on the

side jackets and again up through the slotted hole in the upper jacket

to the control panel.

5. Ensure unused holes in the control panel casing are plugged with

rubber stoppers.

WARNING: The length of the wires should be such that there is enough

wire to fully open and close the burner door.

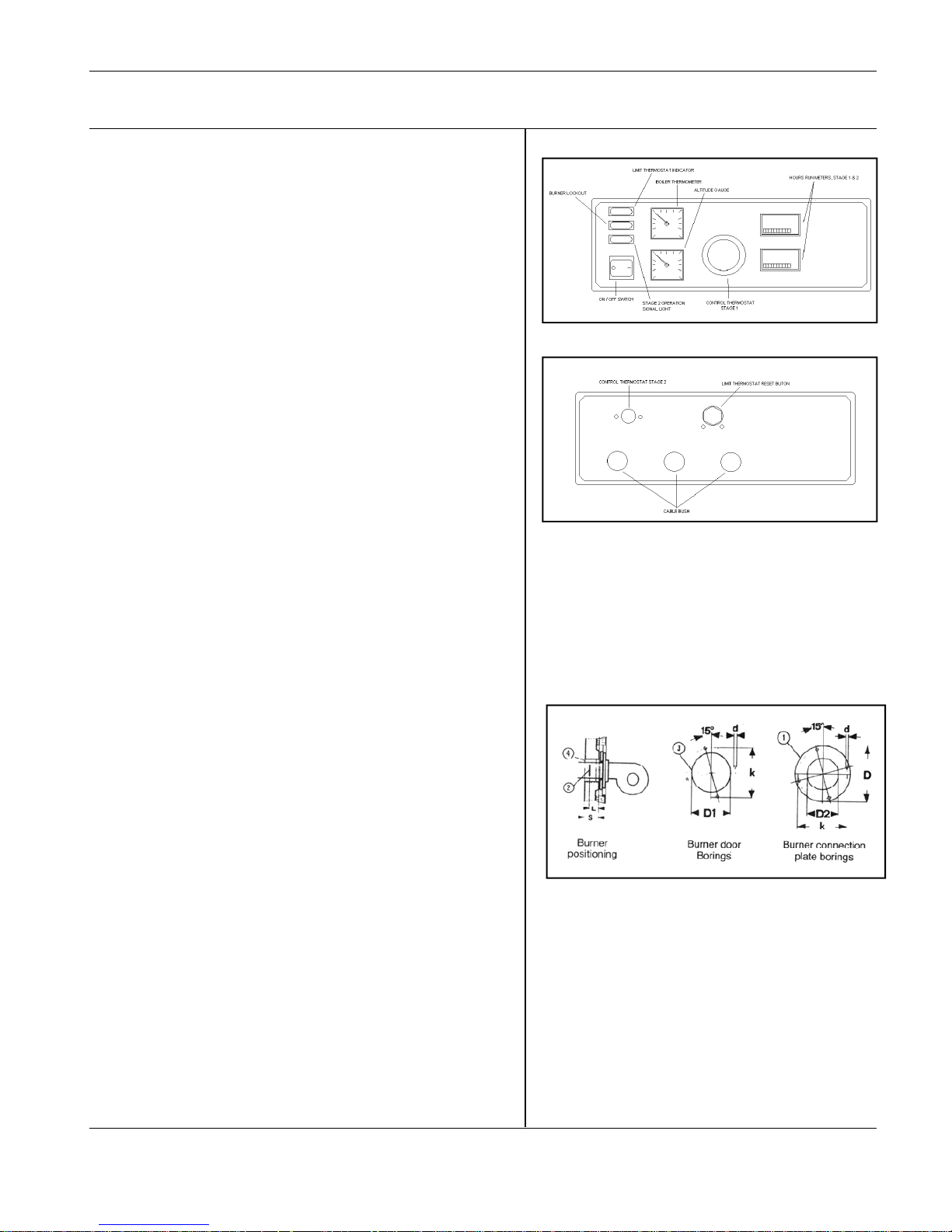

Assembling the burner

1. Only have the burner commissioned by a qualified combustion

engineer. Cables and pipes for electricity and oil should be fitted

flexible to allow full swing of door.

2. Fit burner to burner door with a suitable burner plate

3. When assembling the burner, the position of the diffuser disc (2)

should be observed.

4. The largest possible diameter of the burner is limited by the boring

(3) in the burner door

5. With regard to the choice of burner, the burner head equipment

stipulated by the manufacturer concerned should be used

6. Wrap burner draught tube with cerafelt fibre to insulate gap (4)

7. Electrical connection should be made according to the circuit

diagram in the instrument panel and IEE regulations. Please follow

operating instructions for details regarding burner setting.

The burner should only be commissioned by a Qualified Combustion

Engineer

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 14

V.1-03.08

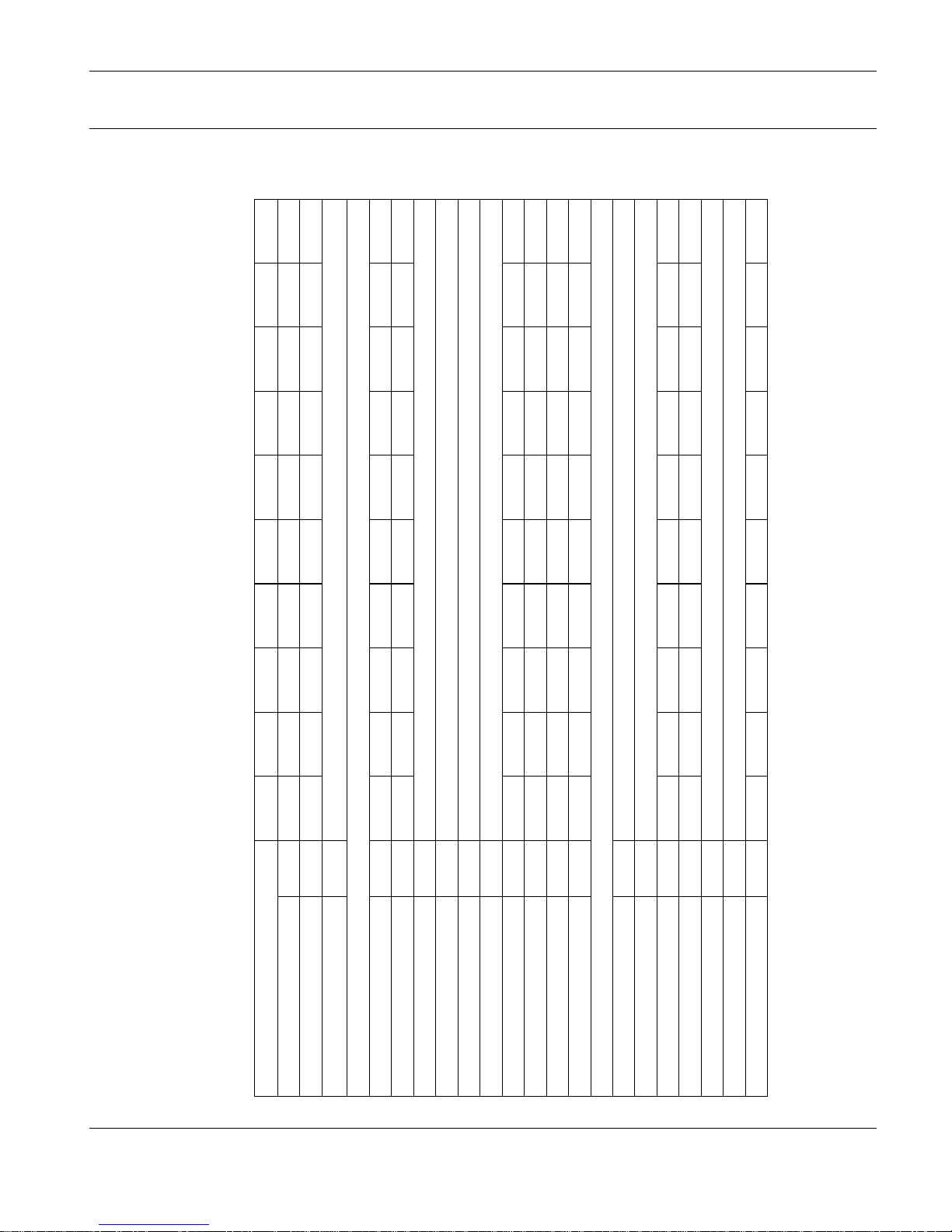

W

I

R

I

N

G

D

I

A

G

R

A

M

LEGEND: 1.1 ON /OFF SWITCH.

1.2 TERMINAL BLOCK.

1.3 SOLENOID SAFETY VALVE.

1.4 HIGH LIMIT THERMOSTAT.

1.5 BOILER CONTROL THERMOSTAT STAGE 1.

1.6 HIGH TEMPERATURE LIMIT INDICATION LAMP.

1.7 BOILER CONTROL THERMOSTAT, STAGE 2.

1.8 BURNER CONNECTORS.

1.9 ROOM THERMOSTAT*.

* IF ROOM THERMOSTAT IS NOT FITTED, LINK TERMINALS 9 & 10. T1 CONTROL CIRCUIT FEED.

T2 CONTROL CIRCUIT RETURN TO BOILER .

S3 BURNER LOCK-OUT LAMP.

S4 STAGE 2 INDICATOR LAMP.

B4 HOURS RUN METER, STAGE 1.

B5 HOURS RUN METER, STAGE 2.

T6 HIGH/LOW CONTROL CIRCUIT FEED.

T7 HIGH/LOW CHANGEOVER CONTROL CIRCUIT .

T8 HIGH/LOW CONTROL CIRCUIT RETURN.

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 15

V.1-03.08

T

E

R

M

I

N

A

L

D

I

A

G

R

A

M

LEGEND: 1.1 ON /OFF SWITCH.

1.2 TERMINAL BLOCK.

1.3 SOLENOID SAFETY VALVE.

1.4 HIGH LIMIT THERMOSTAT.

1.5 BOILER CONTROL THERMOSTAT STAGE 1.

1.6 HIGH TEMPERATURE LIMIT INDICATION LAMP.

1.7 BOILER CONTROL THERMOSTAT, STAGE 2.

1.8 BURNER CONNECTORS.

1.9 ROOM THERMOSTAT*. * IF ROOM THERMOSTAT IS NOT FITTED, LINK TERMINALS 9

& 10. T1 CONTROL CIRCUIT FEED.

T2 CONTROL CIRCUIT RETURN TO BOILER .

S3 BURNER LOCK-OUT LAMP.

S4 STAGE 2 INDICATOR LAMP.

B4 HOURS RUN METER, STAGE 1.

B5 HOURS RUN METER, STAGE 2.

T6 HIGH/LOW CONTROL CIRCUIT FEED.

T7 HIGH/LOW CHANGEOVER CONTROL CIRCUIT .

T8 HIGH/LOW CONTROL CIRCUIT RETURN.

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 16

V.1-03.08

Before start-up check whether:

1. There is sufficient water in the boiler and the heating system;

the pointer on the altitude (pressure) gauge is in the green

sector.

2. All valves in the heating flow and return are open.

3. The heating system has been fully vented.

4. The burner door is closed securely.

5. The burner plug is wired in correctly.

6. The fresh air supply to the boiler room is open.

7. Oil or gas supply is sound and purged.

8. All fuses are intact.

9. The mains switch is turned on.

Fault finding

Heating is cold

• Is boiler up to temperature? Check correct heat settings of

heating circuit controls.

• If automatic control does not operate ie is faulty, switch off

“control” switch off “control” switch and regulate via “manual”

control. Consult specialist.

• If boiler temperature has dropped and burner indicates

malfunction, refer to the burner suppliers’ instructions (press

malfunction button).

General check on whether:

• Fuse is intact.

• Mains switch is turned on and other controls are calling for

heat.

• Burner plug is correctly plugged in.

• Heating pump and filling pump are operating.

• Burner indicates malfunction.

• Control is switched on and displays the correct time.

• All valves are open.

• Fuel is available.

• All switches and knobs are set as per instructions.

• Boiler has switched off due to excess temperature.

Maintenance

• Clean the boiler regularly, proceed as follows:

− Turn off mains switch and control.

− Open burner door.

− Clean heating gas flue-ways and combustion chamber.

− Close burner door and tighten nuts firmly.

• Never tap water from the boiler for domestic use.

• If the system is to be out of operation for an extended period

of time, clean the boiler thoroughly , spray it out with a

mixture of oil and graphite and close the door firmly.

• If there is a frost hazard when the system is out of operation,

drain the boiler. Leave the stop-cock open (unless it contains

anti-freeze).

• Perform maintenance of heating controls and burner

according to the manufacturers’ instructions.

Hazards:

• Operate the boiler at a maximum temperature of 95ºC. If the

boiler overheats as a result of incorrect operation, switch the

burner off immediately. Do not refill with water until the boiler

has cooled off.

• Never fill the hot boiler with cold water.

• Flue gas temperature of less than 160ºC can cause sooting in

masonary chimneys.

• Consult the heating installers’ service department if heating

gas flue-ways become severely fouled or condensation

occurs.

• Only refill the oil tank when the system is switched off. Start up

no earlier than the next day, so the dirt which has been

disturbed in the tank can settle again.

• Inspect the door seal gasket between the front section and the

door. If the gasket is damaged, a specialist should fit a

replacement. Close the cleaning door ensuring it is firmly

sealed. Check all the door bolts are firmly tightened.

STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR: STREBEL CIS

Page 17

V.1-03.08

STREBEL LTD

1F ALBANY PARK INDUSTRIAL ESTATE

FRIMLEY ROAD, CAMBERLY

SURREY GU16 7PL

TELEPHONE : (01276 685422) FAX: (01276 685405)

E-mail address: info@strebel.co.uk

Website: www.strebel.co.uk

THE COMPANY RESERVES THE RIGHT TO CHANGE SPECIFICATIONS AND DIMENSIONS WITHOUT NOTICE

E. & O.E.

Loading...

Loading...