Biotec

Installation and user manual

Product information

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

2

Risk of electric shock

Works with parts marked with this symbol are only

to be carried out by an electrician. Text passages

with this symbol hold information about electric connections.

Caution

Working on parts marked with this symbol can cause

injury or material damage. Text passages with this

symbol hold information about safety precautions.

Possible hand injuries

Working on parts marked with this symbol can cause

hand injuries.

Fire hazard

Flammable items may not be positioned near the boi ler. Text passages with this symbol hold information

about fi re prevention.

Danger of frost

Frost forming in the system pipes after a longer

period of downtime during the cold season can cause

severe damages. Text passages with this symbol hold information

about frost prevention.

Additional notices

Follow regional prescriptions on positioning, installation, operation and disposal of the boiler.

Every person with the intend of operating the boiler is prescribed

to carefully read this manual. This applies especially for the safety informations. Even persons intending to clean the boiler or

perform other maintenance must read this manual. Otherwise, the

guaranty expires.

This manual is to be stored safely.

Safety information

Basics

The boiler must be installed by a competent professional. The Biotec is produced according to current safety requirements. Incorrect

use can cause accidents, injury or even death of the user, if the

rules for safe use are ignored. This can also cause damages to the

boiler or to other items next to the boiler. The specialist responsible for the implementation must explain the proper handling of

the boiler to the user. Only use the boiler if it is installed properly.

Always follow the instructions of this manual. Every boiler failure

must be fi xed as soon as possible.

Use of the boiler

The manufacturer is not responsible for damages resulting from

an inappropriate use. In this case, the user is responsible.

The operation parameters can only be modifi ed in the range

prescribed in this manual. The use of parameters outside the range can cause damages or errors in the system.

Prescribed fuel

This boiler is designed for the combustion of wood pellets. The

use of other fuels is prohibited. Wood pellets are cylindrical and

made from wood scraps without additives or chemical binders. The

pellets must have specifi cal dimensions and a low moisture level.

STREBEL recommends pellets with a diameter of 6 to 8 mm and a

lenght of 10 to 30 mm. Quality and form are prescribed throughste standards ÖNORM 7135 and DIN 51731. Only use pellets that

comply with ÖNORM, DIN or equal regional stadards. More informations in chapter 3.

Possible risks

Carbon monoxyde

During boiler operation, carbon monoxyde can issue

through the boiler doors. Only leave them open as

long as necessary. Insuffi cient vent during operation is critical.

Closing the vent of the boiler room or the boiler is prohibited.

Signs and symbols

Surfaces with high temperatures

Touching such surfaces can cause burns. Surfaces

marked with this symbol may only be touched when

the system is cooled down. Text passages with this symbol hold

information about hot boiler parts.

Safety information

Caution

injury or material damage. Text passages with this

Working on parts marked with this symbol can cause

hand injuries.

Flammable items may not be positioned near the boi-

ler. Text passages with this symbol hold information

Frost forming in the system pipes after a longer

period of downtime during the cold season can cause

through the boiler doors. Only leave them open as

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

3

Contents

1 Boiler features ................................................................................................................................ 4

2 Technical data ................................................................................................................................ 5

3 Fuel ................................................................................................................................................. 7

4 Construction and funtion ................................................................................................................ 8

5 Installation...................................................................................................................................... 9

6 Boiler controller .............................................................................................................................. 18

7 Phases of operation........................................................................................................................ 22

8 Maintenance .................................................................................................................................. 23

9 Possible malfunctions .................................................................................................................... 24

10 First start-up ................................................................................................................................... 25

11 Disposal of the boiler ..................................................................................................................... 26

Terminal connections ..................................................................................................................... 27

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

4

1 Boiler features

1.1 General information

The boiler Biotec has a modern design and is made of high quality

material. The boiler testings were carried out conform to EN 3035, so the boiler fulfi lls all requirements for the connection to the

central heating system. The maximum permitted system pressure

is 2.5 bar.

This boiler is suitable as central heating system for single- or multi-family-homes, small businesses or workshops. The automatic

operation shows to be very user-friedly, because the only action

during operation is re-fi lling the pellet silo every day to every couple of days, depending on the current output. The Biotec includes

the silo and pellet screw. The basic design of the boiler features

the silo on its right side. On request and for additional charge,

the silo can be mounted on the left side resp. a bigger silo can be

installed.

Pellets make an excellent fuel. Wood pellets are zylindrical and

made from wood sraps. The ash-percentage after the combustion

is especially low with pellets and accounts for about 1 %. The

caloric value of pellets is approx. 18000 kJ/kg, wich means that 2

kg pellets comply to 1 l light heating oil.

The storing qualities and the high energy value of pellets make

them the ideal replacement for oil or gas. Additionally, they are

produced from wood, a regional renewable source.

Boiler features

1.2 Conformity declaration

The company STREBEL confi rms according to EN45014:1998 that

the boiler Biotec complies with the following standards:

EC-guidelines:

MD 98/37/EC

PED 97/23/EC

LVD 2006/95/EC

EMC 2004/108/EC

Harmonized standards:

EN 303-5:1999; EN 60204-1:2006; EN 60335-1:2002;

EN 50165:1997+A1; EN 61000-6-3:2001; EN ISO 12100-1:2003;

EN ISO 12100-2:2003; EN 1050:1997

Other standards and technical spezifi cations:

EN 287-1:2004, EN 288-3:1992; EN 10204:2004; EN ISO

7000:2004.

Used method for testing conformity: Modul B1

Grenzwert der Emission der Verbrennungsprodukte (Klasse) 3

Certifi cates: EC Control Type –Certifi kate Nr. 0745/350/09

Responsible laboratory: TÜV Thüringen e.V. Service-Center

Südthüringen, Industriestr.13, D-98544 Zella-Mehlis

We hereby declare that the mentioned products were produced

under safety- and norm prescriptions, guidelines and standards.

All working conditions and terms of use comply with this manual.

In case the product is changed in a way we are not informed of,

this confi rmation loses its validity.

Typographical and printing errors, changes

in construction and dimensions expected.

5

Biotec

Technical data

2 Technical data

Pelletskessel Biotec 25 Biotec 25 S Biotec 40

Rated output kW 25 25 40

Minimum output kW 8 8 13

Flow-/Return temperature °C 90/70 90/70 90/70

Flue gas temperature at rated output °C 135 - 140

Minimum fl ue gas temperature °C 95 95 95

Flue gas volume fl ow at rated output kg/s 0,0176 - 0,0280

Flue gas volume fl ow at min. output kg/s 0,0079 - 0,0140

Effi ciency % 88 91 85

Water volume l 70 74 118

Resistance on water side

t=10 K/t=20 K

hPa 7/2 7/2 7/2

Weight kg 320 340 459

Boiler class N 303-5 3 3 3

Maximum operating/testing pressure bar 2,5/5 2,5/5 2,5/5

Maximum fl ue draft Pa 12 - 15

Connection fl ow/return inch 1 1 5/4

Exhaust connection diameter mm Ø 130 130 130

Pellet silo volume l 200 500 400

Maximum volume of silo

(extra charge)

l 400 - -

Electric connection 230 V ~ 50 Hz (max. 1 A) 230 V ~ 50 Hz (max. 1 A) 230 V ~ 50 Hz (max. 1 A)

Power consumption

ignition/fan/screw motor

W 400/41/50 400/41/50 400/41/50

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

6

Technical data

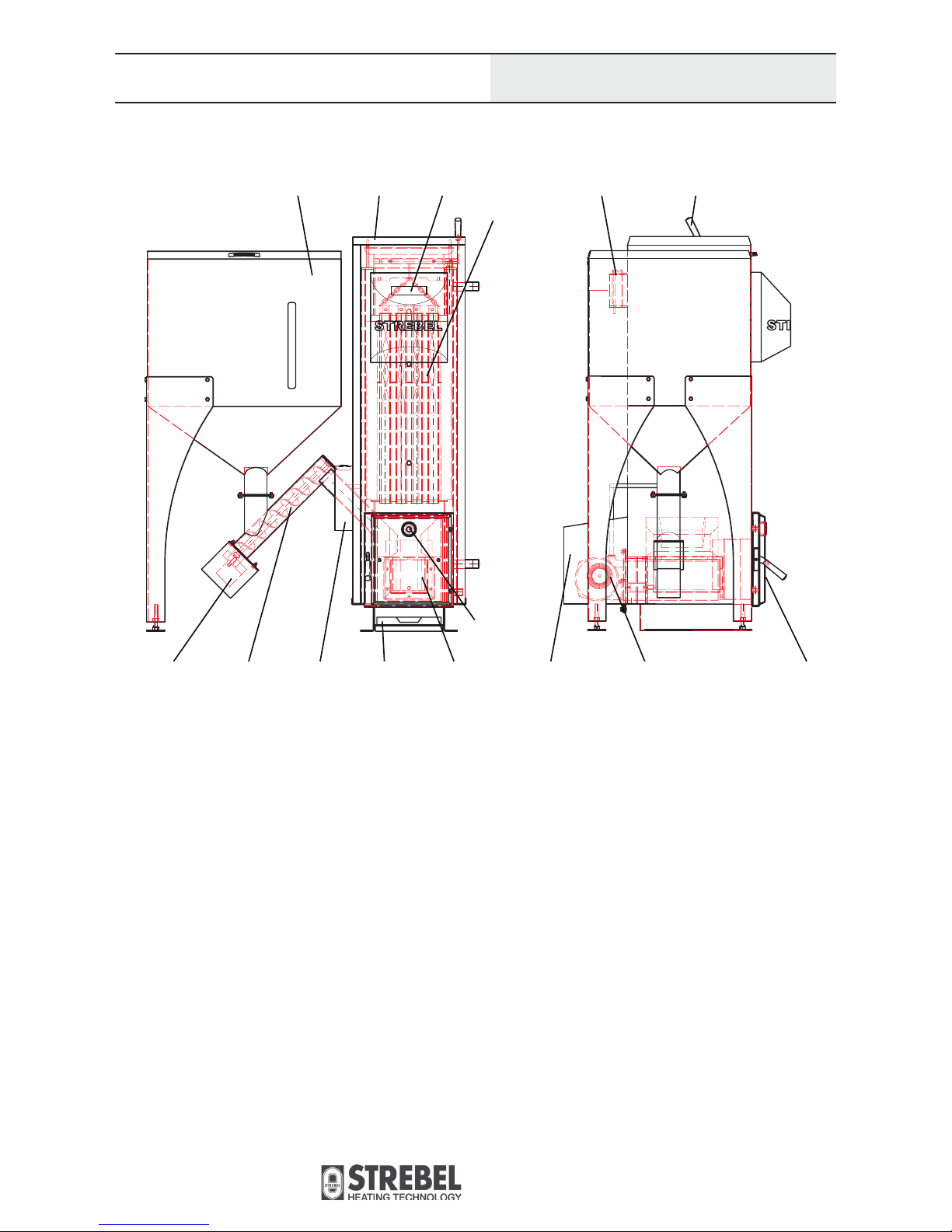

2.1 Dimensions

Boiler diameters (mm)

Overall width (W) Depth (D) Height (H)

Diameter

exhaust

conn. (DE)

Boiler width

(W2)

Height

return (R)

Height

fl ow (F)

Centre

exhaust

conn. (HE)

Biotec 25

1275 (200 L silo) 905 1435 130 500 269 1132 1130

Biotec 25 S

1443 (500 L silo) 905 1630 130 500 269 1132 1330

Biotec 40

1645 (400 l silo) 1070 1660 130 708 254 1301 1330

Connections (inch)

R1 R2 R3

Biotec 25

1 1/2 3/4

Biotec 25 S

1 1/2 3/4

Biotec 40

5/4 1/2 3/4

D

W

W2

R

F

H

HE

Pellet silo dimensions (mm)

Silo volume W. H. D.

Lid half-

height

Lid max

height

200 Litre

765 1350 650 - 1990

400 Litre

for Biotec 25

935 1350 750 1715 2100

400 Litre

for Biotec 40

935 1625 750 1990 2375

500 Litre

935 1545 750 1910 2295

DE

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

7

Fuel

3 Fuel

3.1 Required fuel-quality

DIN 51731

Pellet-size HP5, made from by-products of wood and woodshavings, without additives. The energy value of 2 kg pellets complies with the energy of 1 l light heating oil (10 kWh).

ÖNORM 7135

The Austrian standard comprises quality requirements of pellets,

testing regulations, supervision of pellet production and labelling.

DIN Plus

Standard DIN Plus combines Standard DIN 51731 and Standard

ÖNORM 7135. The certifi cation procedure at the manufacturer‘s

works is carried out by the responsible certifi ed DIN-inspector. The

quality of the pellets is supervised and checked regularly.

Standard DIN 51731 ÖNORM 7135 DIN Plus

Length mm max. 50 max. 5 x diameter max. 5 x diameter

Diameter mm 4-10 max. 10 max. 10

Chaloric value MJ/kg 17.5 - 19.5 min. 18 min. 18

Pellet density kg/m

3

1 - 1.4 min. 1.12 min. 1.12

Pellet bulk density kg/m

3

min. 650 min. 650 n.a.

Water content % max. 12 max. 10 max. 10

Ash content % max. 1.5 max. 1.5 max. 0.5

Abraison of the pellets % n.a. max. 2.3 max. 2.3

Sulphur content % n.a. max. 0.04 max. 0.04

Nitrogen content % n.a. max. 0.3 max. 0.3

Chlorine content % n.a. max. 0.2 max. 0.2

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

8

Construction and function

4. Construction and function

4.1 Construction

Construction of the boiler

Legend:

1 Burner

2 Heat exchanger w. turbulators

3 Pellet silo

4 Pellet screw

5 Gear motor

6 Case of heat exchanger

7 Case of burner

8 Fan

9 Combustion chamber door

10 Exhaust connection and exhaust probe

11 Cleaning lever

12 Controller panel

13 Ash drawer

14 Application box

15 Sight glas

4.2 Function

The application box (14) houses the main switch for turning the

boiler on and off. Boiler operation can be adjusted via pushbuttons on the controller panel (12). If the combustion process is

started, the gear motor (5) of the pellet screw (4) starts to run.

It conveys pellets from the silo (3) to the burner (1). Combustion

takes place in the combustion chamber and can be inspected via

the sight glass (15). The fan (8) provides primary and secundary

air for combustion. The pellet ash falls into the ash drawer (13)

through the openings of the combustion chamber fl oor. The turbulator-spirals within the heat exchanger tubes (2) can be moved up

and down with the cleaning lever (11) to remove cloggings from

the inside of the tubes.

Caution! The combustion chamber door (9) must be closed during

boiler operation. The ash drawer and the combustion chamber may

only be touched and cleaned when the boiler has cooled down.

1

15

1314 9874

5

2

3 106 12 11

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

9

A

B

AB

Hydraulische

Weiche

Rücklaufanhebung

Regumat RTA 130 DN 25

Netz 230 V / 50 Hz

Pelletskessel Biotec 25

Speicher

RTH

SF

SLP

HKP

RTH Raumthermostat

SF

Speicherfühler

SLP Speicherladepumpe

HKP Heizkreispumpe

AG Ausdehnungsgefäss

WW Warmwasser

KW Kaltwasser

Sicherheitsgruppe

Kaltwasser

Brauchwassermischer

Warmwasser

KW

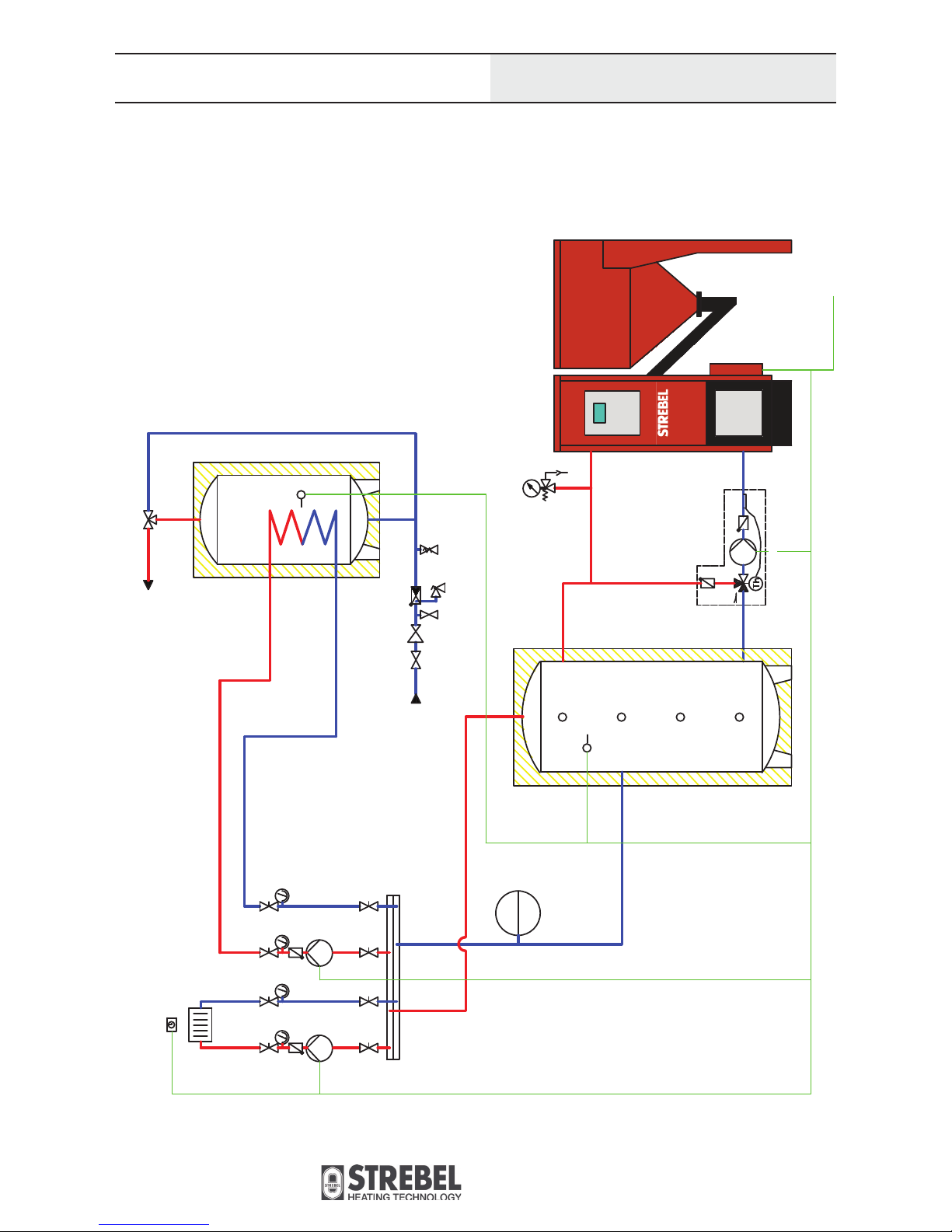

Connection scheme with domestic water tank

Installation

5 Installation

The installation of the boiler and other system components must be

carried out by qualifi ed technicians.

5.1 Hydraulic scheme examples

Room thermostat

Domestic water probe

Tank charging pump

Heating circuit pump

Expansion vessel

Hot water

Cold water

Pellet boiler Biotec 25

Power supply 230 V/50 Hz

Return riser

Hydraulic

compensator

Safety group

cold water

Tank

Domestic water mixer

Hot water

TCP

HCP

RTH

DWP

TCP

HCPEVHW

CW

CW

DWP

HW

EV

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

10

Installation

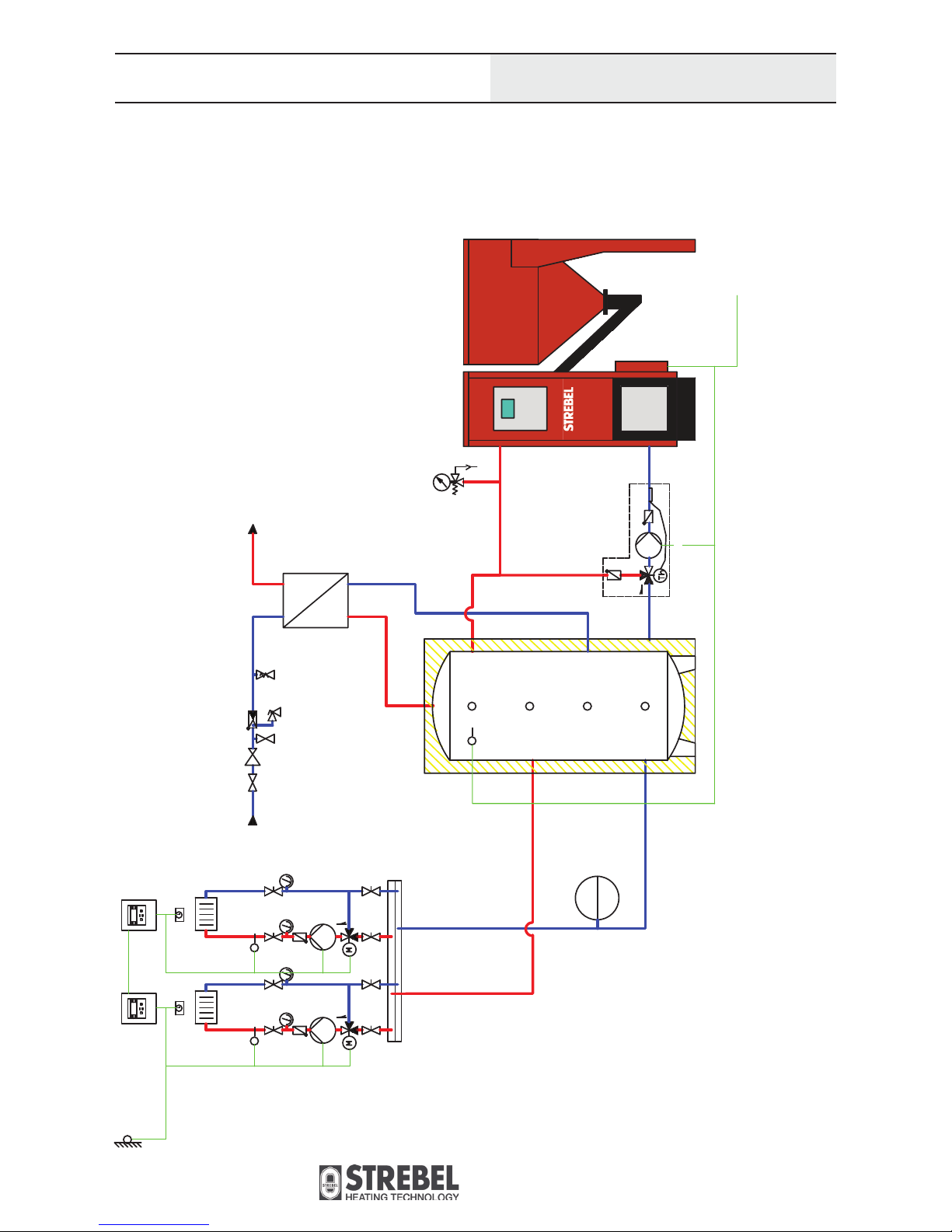

Connection scheme with domestic water tank and compensator tank

A

B

AB

Rücklaufanhebung

Regumat RTA 130 DN 25

Netz 230 V / 50 Hz

Pelletskessel Biotec 25

RTH

SLP

HKP

RTH

Raumthermostat

SF

Speicherfühler

PF Pufferfühler

SLP Speicherladepumpe

HKP

Heizkreispumpe

AG Ausdehnungsgefäss

WW Warmwasser

KW

Kaltwasser

Pufferspeicher

PF

Speicher

SF

Sicherheitsgruppe

Kaltwasser

Brauchwassermischer

Warmwasser

KW

Room thermostat

Domestic water probe

Compensator tank probe

Tank charging pump

Heating circuit pump

Expansion vessel

Hot water

Cold water

RTH

DWPCPTCP

HCPEVHW

CW

Pellet boiler Biotec 25

Power supply 230 V/50 Hz

Return riser

Compensator tank

TCP

HCP

EV

Safety group

cold water

Tank

Domestic water mixer

Hot water

CW

HW

DWP

CP

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

11

Installation

A

B

AB

Rücklaufanhebung

Regumat RTA 130 DN 25

Netz 230 V / 50 Hz

Pelletskessel Biotec 25

RTH

RTH Raumthermostat

AG

Ausdehnungsgefäss

Connection scheme with room thermostat

Return riser

EV

Room thermostat

Expansion vessel

RTH

EV

Pellet boiler Biotec 25

Power supply 230 V/50 Hz

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

12

Installation

A

B

AB

Rücklaufanhebung

Regumat RTA 130 DN 25

Netz 230 V / 50 Hz

Pelletskessel Biotec 25

Ceta 106 Regelgerät

Ceta RC

Raumgerät

VF Vorlauffühler

AF

Aussenfühler

PF

Pufferfühler

MIMO

Mischermotor

MKP

Mischerkreispumpe

AG

Ausdehnungsgefäss

WW Warmwasser

KW

Kaltwasser

Speicher im Speicher System

PF

Ceta 106

Ceta 106

VF VF

Ceta RC Ceta RC

AF

MKP

MIMO

MKP

MIMO

Sicherheitsgruppe

Kaltwasser

Brauchwassermischer

Warmwasser

Connection scheme with tank-in-tank system and 2 heating circuits

Pellet boiler Biotec 25

Power supply 230 V/50 Hz

Controller

Room remote controller

Flow probe

Outside probe

Compensator tank probe

Mixer motor

Mixer circuit pump

Expansion vessel

Hot water

Cold water

Ceta 106

Ceta RCFPOPCPMMO

MCPEVHW

CW

Return riser

HW

FP

FP

MCP MCP

EV

OP

Safety group

cold water

Tank-intank system

Domestic water mixer

Hot water

CW

CP

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

13

Installation

A

B

AB

Rücklaufanhebung

Regumat RTA 130 DN 25

Netz 230 V / 50 Hz

Pelletskessel Biotec 25

Ceta 106

Regelgerät

Ceta RC Raumgerät

VF

Vorlauffühler

AF

Aussenfühler

PF

Pufferfühler

MIMO Mischermotor

MKP

Mischerkreispumpe

AG

Ausdehnungsgefäss

FRIWA Frischwassermodul

WW

Warmwasser

KW

Kaltwasser

Ceta 106

Ceta 106

VF

VF

Ceta RC

Ceta RC

AF

MKP

MIMO

MKP

MIMO

KW

WW

FRIWA

PF

Sicherheitsgruppe

Kaltwasser

Connection scheme withcompensator tank, 2 heating circuits and freshwater-module

Cobtroller

Room remote controller

Flow probe

Outside probe

Compensator tank probe

Mixer motor

Mixer circuit pump

Expansion vessel

Fresh water module

Hot water

Cold water

Ceta 106

Ceta RCFPOPCPMMO

MCPEVFREWAHWCW

FREWA

CW

HW

CP

Safety group

cold water

Pellet boiler Biotec 25

Power supply 230 V/50 Hz

Return riser

FPFP

MCP MCP

EV

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

14

A

B

AB

Rücklaufanhebung

Regumat RTA 130 DN 25

Netz 230 V / 50 Hz

Pelletskessel Biotec 25

Ceta 106 Regelgerät

Ceta RC

Raumgerät

VF Vorlauffühler

AF

Aussenfühler

PF Pufferfühler

MIMO

Mischermotor

MKP Mischerkreispumpe

AG Ausdehnungsgefäss

WW Warmwasser

KW Kaltwasser

Ceta 106

Ceta 106

VF VF

Ceta RC

Ceta RC

AF

MKP

MIMO

MKP

MIMO

PF

Kombipufferspeicher

Brauchwassermischer

Warmwasser

Brauchwasser-

Ausdehnungsgefäss

Sicherheitsgruppe

Kaltwasser

Installation

Connection scheme with combined compensator tank and 2 heating circuits

Controller

Room remote controller

Flow probe

Outside probe

Compensator tank probe

Mixer motor

Mixer circuit pump

Expansion vessel

Hot water

Cold water

Ceta 106

Ceta RCFPOPCPMMO

MCPEVHW

CW

HW

HW

CP

CW

EV

EV

Safety group

cold water

Combined compensator tank

Domestic water mixer

Hot water

Domestic water

expansion vessel

Pellet boiler Biotec 25

Power supply 230 V/50 Hz

Return riser

FP

FP

MCP MCP

OP

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

15

Installation

A

B

AB

Rücklaufanhebung

Regumat RTA 130 DN 25

Netz 230 V / 50 Hz

Pelletskessel Biotec 25

SLP

Pufferspeicher

PF

Speicher

SF

Sicherheitsgruppe

Kaltwasser

Brauchwassermischer

Warmwasser

KW

Ceta 106

VF

Ceta RC

AF

MKP

MIMO

Ceta 106

Regelgerät

Ceta RC Raumgerät

VF

Vorlauffühler

AF Aussenfühler

SF

Speicherfühler

PF Pufferfühler

MIMO

Mischermotor

MKP

Mischerkreispumpe

AG

Ausdehnungsgefäss

WW

Warmwasser

KW

Kaltwasser

Connection scheme with combined compensator tank, 1 heating curcuit and DW-circuit

Pellet boiler Biotec 25

Power supply 230 V/50 Hz

Return riser

FP

FP

MCP MCP

EV

CW

CP

DW-tank

OP

HW

DP

Domestic water mixer

Hot water

Controller

Room remote controller

Flow probe

Outside probe

Domestic water tank probe

Compensator tank probe

Mixer motor

Mixer circuit pump

Expansion vessel

Hot water

Cold water

Ceta 106

Ceta RCFPOPDPCP

MMO

MCPEVHW

CW

Safety group

cold water

Compensator tank

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

16

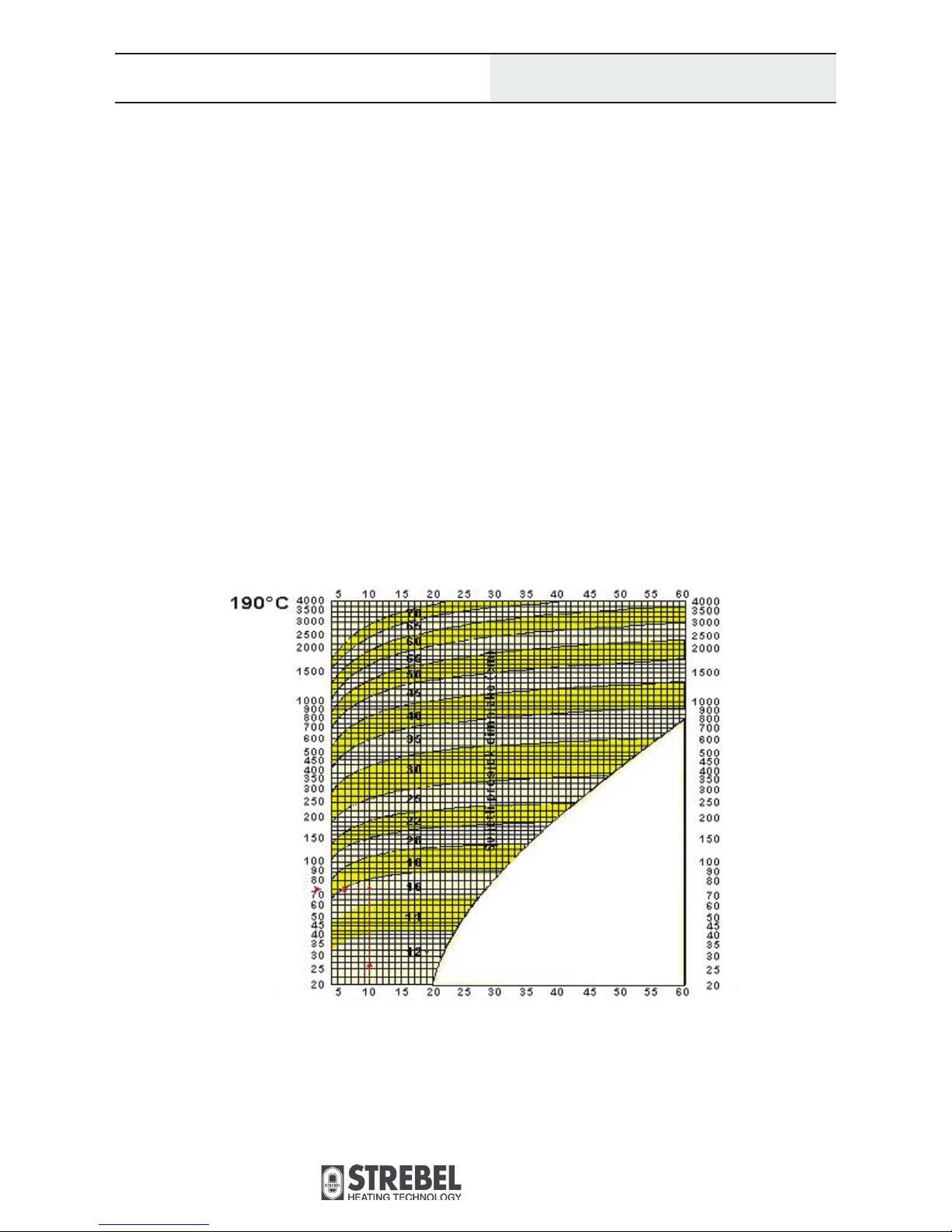

5.2 Installation place and chimney

The boiler must be installed near a chimney. It is prohibited to

close air vents.

WARNING!

1.) The boiler must be placed on a solid and stable fl oor.

2.) The installation must be carried out by qualifi ed technicians.

3.) The boiler room must be equipped with water- and grounded

electrical connection. A waste water draw-off is advantage ous.

4.) The boiler room must be vented in a suffi cient way.

5.) Floor, walls, ceiling, door and equipment of the room must be

made of non-fl ammable material.

Installation

Additional notes:

1.) Humidity should be kept at a low level to avoid corrosion of

metal parts.

2.) For the fi lling of the boiler we advise to use soft water.

3.) The circulation pump must not operate before the heating

system is completely fi lled with water. The system must be

bled.

4.) When connecting the boiler to the fl ue it is necessary to put

the fl ue pipe inhorizontally or vertically. All connections

must be sealed up properly.

5.) Before the fi rst start-up, check the position of the chamotte

bricks to make sure they fi t correctly and were not shifted

during transportation of the boiler.

6.) The chimney must be layed out according to diagram below.

An insuffi cient fl ue draft holds a fi re risk. In that case, the fi re

can spread from the burner on to the screw and the pellets in the

silo.

Rated output [kW]

Chimney height [m]

Rated output [kW]

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

17

Installation

Examples of correct chimney installation

5.3 Connection of the boiler parts

Connect the electric wire of the pump to the power supply. (max.

current 1 A).

Connection of the controller

Connect the electric wire of the controller to the power supply.

The installation of the electric accessories of the boiler needs a

power supply with 230 V/50 Hz.

Connection of the room thermostat

A room thermostat can be connected to the controller. Before starting up the boiler, check the following:

1.) Water pressure in boiler and system.

2.) System must be bled.

3.) The wires of the boiler are installed correctly, undamaged

and not touching surfaces that heat up during operation.

4.) The chamotte-bricks are correctly positioned in the burner.

5.) The pellet silo is properly clean.

A certifi ed safety valve (2.5 bar) and an expansion vessel must

be installed in the heating system. Do not install other valves

between the safety valve and the vessel. The return temperature

must not fall below 60 °C to prevent the build of condensate inside the boiler.

Installation scheme of the thermo-chamotte-bricks

inside the burner.

To prevent system freeze or if the boiler will not be

used for a longer period of time, we advise to fi ll the

system with a an antifreeze or to drain the system.

To prevent system freeze or if the boiler will not be

used for a longer period of time, we advise to fi ll the

system with a an antifreeze or to drain the system.

5.3 Connection of the boiler parts

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

18

6.2 Basic display

In the line „Boiler operation phase“ (13), information about the

current phase of boiler operation (Boiler OFF, First ignition-phase,

Combustion-phase, Cool-down phase, Room thermostat OFF, etc.)

The symbol „Boiler operation“ shows if the boiler is active or not.

If the boiler is set to run in a pre-programmed operation mode, the

display shows „TIME“.

The symbols in the bottom line show the operational availability

of the controller outputs resp. if the elemets (fan, pump, screw,

ingniter, boiler pump) are active or not. If the symbol shows, that

component is active.

Boiler controller

6 Boiler controller

6.1 Control panel

The controller is used for regulating the pellet boiler operation.

The design of the control panel is shown in the scheme below:

The controller has an LCD display and 6 buttons on the right side

of the display.

Functions of the buttons

Increase of parameter values

Escape, boiler power off

Browse menu – go back

Browse menu – go forward

Decrease of parameter values

Enter, confi rm selected parameter

Inputs

- Boiler probe (Pt 1000)

- Flue gas probe (Pt 1000)

- Domestic water probe (NTC, 10 kΩ)

- Compensator tank probe (NTC, 10 kΩ)

- Room thermostat

- Input – GSM controller

Outputs

- Ignition electrode (relay, 8A, NO)

- Pellet screw (relay, 5A, NO)

- Fan (PWM)

Legend

1 Time

2 Boiler operation

3 DW-tank temperature

4 Fan activated

5 Pump

6 Pellet screw

7 Ignition electrode

8 Boiler pump

9 Preset power output

10 Flue gas temperature

11 Current boiler temperature (desired)

12 Program

13 Boiler operation phase

1

2

3

4

5 6 7 8

10

9

11

12

13

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

19

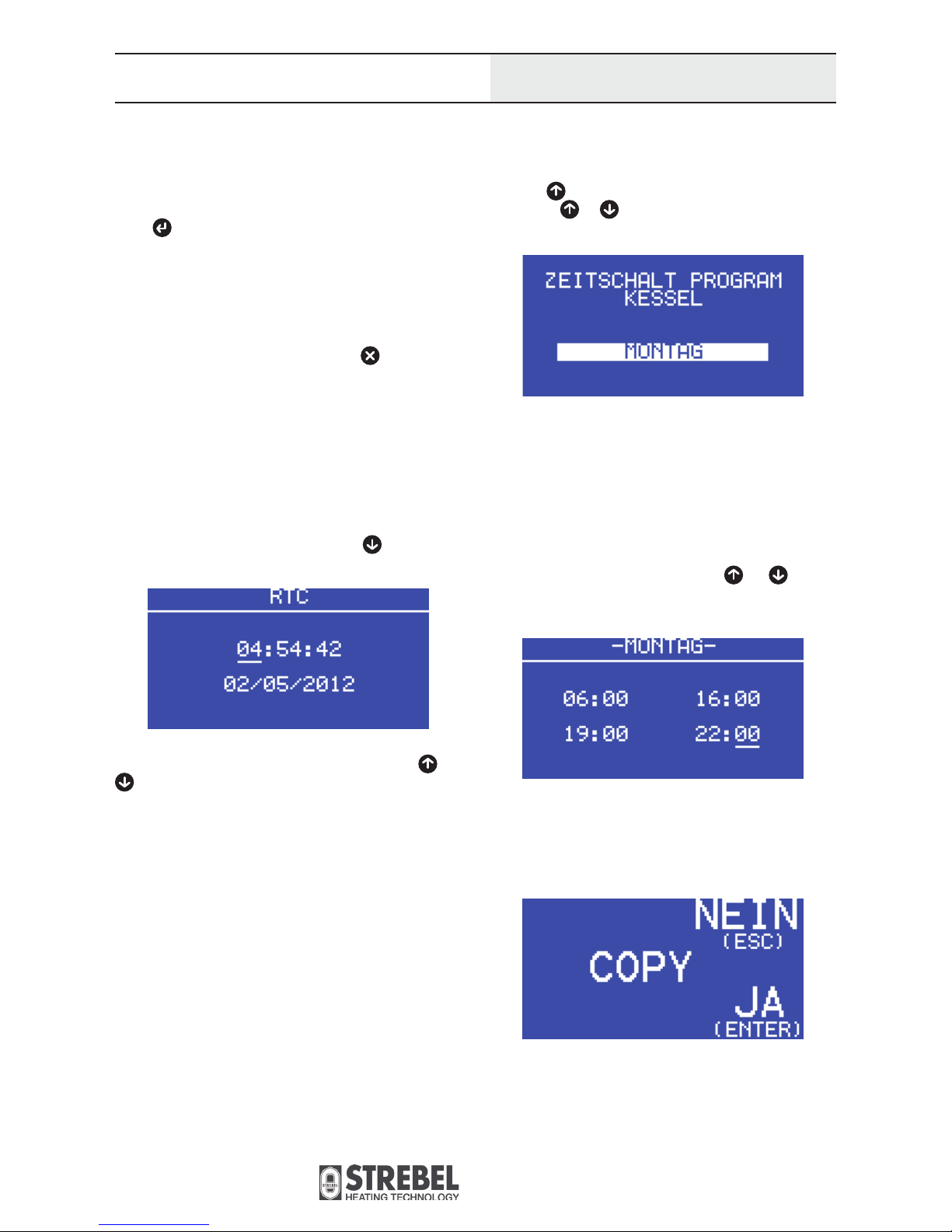

6.5 Automatic operation

To set the hours of operation for the automatic operation, press

the button for about 2 seconds. The weekday can be selected

by pressing or . To change the operating hours for the

selected day, press the enter button.

The display shows two rows of each two time-sets, the fi rst is the

start of operation, the second is the time for operation stop. In the

example below, the boiler starts up at 06:00 am and deactivated

at 04:00 pm. After a pause, operations starts again at 07:00 pm

and stops at 10:00 pm. Then the boiler is deactivated until the next

day. The operation times can be set individually for every day of

the week.

The values can be changed with the buttons and and confi rmed with the enter button. After confi rming, the selection shifts

ahead one position.

After all four sets are confi rmed, the display shows „COPY“. If this

is confi rmed with the enter button, the settings are copied to the

next day. Pressing the escape button leads to the settings for the

next weekday, without copying the changes.

Boiler controller

6.3 Start and stop of the boiler

To start the boiler, activate the red main switch on the right side

of the boiler. After activation, the boiler controller turns on and

shows the basic display. To start boiler operation, press the enter

button for about 2 seconds. The display shows „ON“ and the

boiler switches into the pre-pulse phase with maximum fan power.

To switch to automatic operation, the enter button is again pressed

for about 2 seconds. Then, the display shows „TIMER PROGRAM

BOILER“.

To shut down the boiler, the escape button is pressed for

about 2 seconds until the display shows „OFF“. The boiler switches to the cool-down phase with decreased fan power. To deactivate the boiler, the escape button is again pressed for about 2

seconds. By deactivating the main switch, the boiler is powered

down completely.

6.4 Setting of time and date

For the setting of date and time the button

is pressed for

about 2 seconds.

The current selection can be changed with the buttons and

. With the enter button, the selection is confi rmed and shifts

ahead one position. The seconds can not be set. When all positions are set, the user reaches the basic display. To escape the

setting without making changes, press the escape button.

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

20

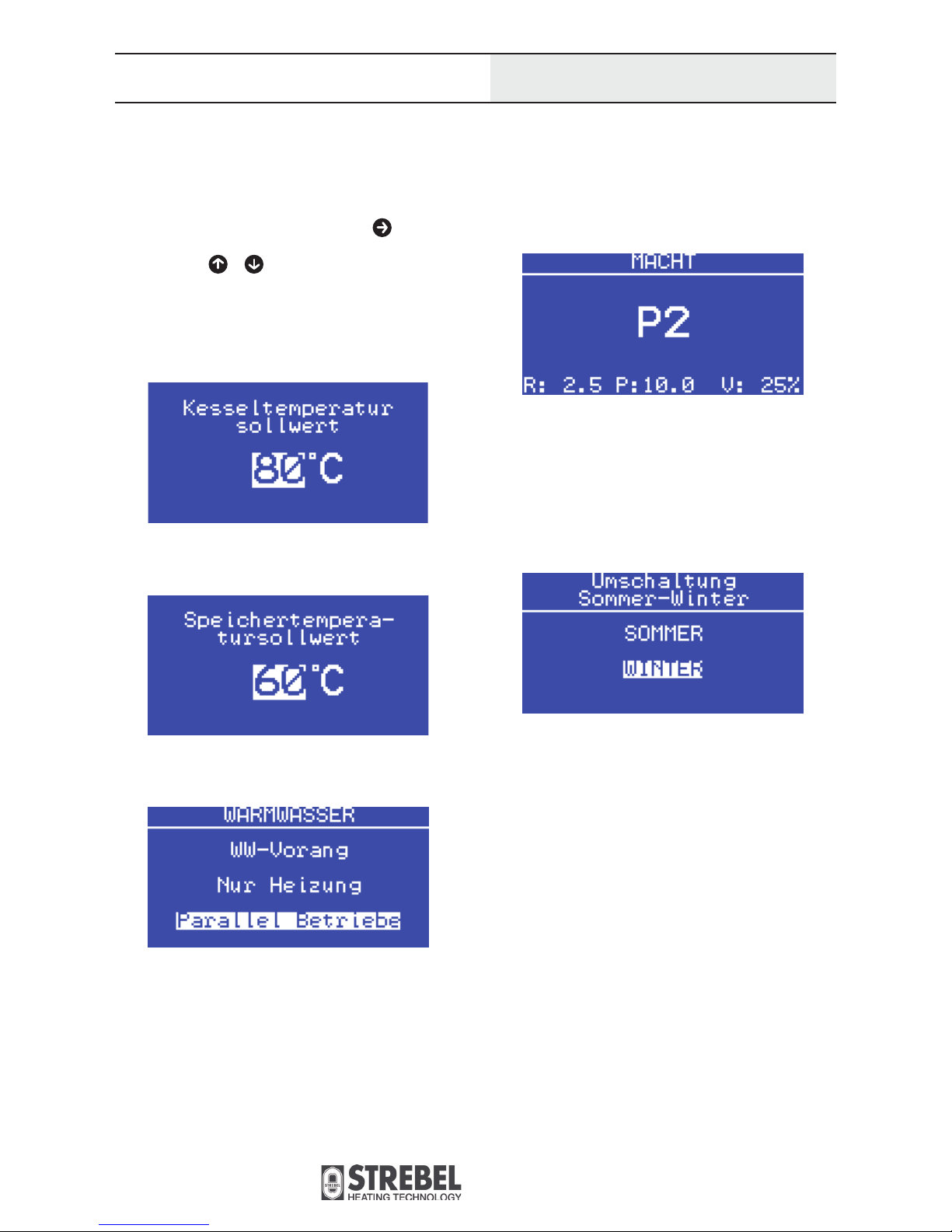

4.) POWER:

The large position in the middle shows the set power stage. The

row below shows the set values of the Operating duration of

screw (R), the Pausing duration of screw (P) and the - Fan-power

during heating operation (V).

P1: Minimum output operation

P2: Intermediate output operation

P3: Maximum output operation

5.) Switching between summer- and winter-mode

In summer-mode, the boiler only produces heat for domestic

water.

6.6 Operation parameters

The following parameters are relevant for boiler operation, pellet

combustion, and fl ue gas temperature. The parameters are set by

the technician before the fi rst start-up (see 6.7). The operation parameters are displayed by pressing the button in the basic

display.

Press the buttons or to set the value for the selected parameter. Press the escape button to go back to the basic display.

Press the enter button to confi rm the selection.

1.) Boiler temperature rated value:

2.) Tank temperature rated value:

3.) DOMESTIC WATER:

Boiler controller

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

21

Boiler controller

6.7 Setting parameters

Changes of particular parameters can be done by pressing

the buttons

and at the same time. Below, a list of the

parameters with the factory settings in brackets (value Biotec 25/

value Biotec 40).

The parameters can be altered by pressing

or . The setting

is confi rmed with the enter button and the menu directs the user

back to the basic display.

S1: Duration of start-up fan (30 s/30s)

S2: Fan-power (100 %/100 %)

S3: Duration of screw start-up dose (30 s/30 s)

S4: Fan-power during start-up (30 %/30 %)

S5: Delayed start of ignition (60 s/60 s)

S6: Duration of start-up ignition (60 s/60 s)

S7: Fan-power during ignition (80 %/80 %)

S8: Duration of second ignition (600 s/600 s)

S9: Duration of stabilisation (200 s/200 s)

S10: Operating duration of screw during stabilisation (1,5 s/1,5 s)

S11: Pausing duration of screw during stabilisation (10,0 s/10,0 s)

S12: Fan-power during stabilisation (90 %/90 %)

S13: Stabilisation delay (300 s/300 s)

S14: Operating duration of screw P1 (2,5 s/4,0 s)

S15: Pausing duration of screw P1 (10,0 s/10,0 s)

S16: Fan-power during heating operation P1 (40 %/55 %)

S17: Operating duration of screw P2 (3,0 s/4,5 s)

S18: Pausing duration of screw P2 (10,0 s/10,0 s)

S19: Fan-power during heating operation P2 (45 %/60 %)

S20: Operating duration of screw P3 (3,0 s/5,0 s)

S21: Pausing duration of screw P3 (10,0 s/10,0 s)

S22: Fan-power during heating operation P3 (46 %/62 %)

S23: Duration of cool-down phase (240 s/240 s)

S24: Power of fan during cool-down phase (50 %/50 %)

S25: Boiler delay with room thermostat OFF (0 s/0 s)

S26: Max. fl ue gas temp. for ignition (100 °C/100 °C)

S27: Min. fl ue gas temp. (7,0 °C/7,0 °C)

S28: Min. Abgastemperatur (50 °C/50 °C)

S29: Max. decrease of fl ue gas temp. (20 °C/min / 20 °C/min)

S30: Duration of disregarded fl ue gas temp. in partial load opera tion (30 min./30 min)

S31: Minimum operation (5 °C/5 °C)

S32: Factor of boiler rated value for modulation (10 x/10 x)

S33: Fan-power reduction permitted (5 %/5 %)

S34: Hysteresis (5,0 °C/5,0 °C)

S35: Turn-on temp. for return increase pump (55 °C/55 °C)

S36: Diff. between turn-on and -off temp. (10 °C/10 °C)

S37: Pump overrun with RT OFF (0 s/0 s)

S38: Difference boiler to tank (5,0 °C/5,0 °C)

S39: Boiler probe adjustment (0,0 °C/0,0 °C)

S40: Flue gas probe adjustment (0,0 °C/0,0 °C)

S41: Compensator tank probe adjustment (0,0 °C/0,0 °C)

S42: Domestic water probe adjustment (0,0 °C/0,0 °C)

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

22

The pump is activated if the boiler temperature rises beyond the

required temperature and if the room thermostat is activated.

If the room thermostat is not activated, the pump runs for a period

of time (5 minutes) after deactivation. After that period, the pump

stops until the room thermostat is activated again.

7 Operation phases

7.1 Ignition phase

If the fl ue gas temperature rises beyond the limit for triggering ignition, the controller registers that the burner room holds enough

ember to successfully continue combustion. In this case, the ignition electrode is deactivted. The dosage of pellets continues.

If the fl ue gas temperature falls below the limit for triggering ignition, the boiler switches to ignition phase. In this phase the fan

is activated to clean the burner room, especially the vents below

the ignition electrode. After that, the pellet screw starts working.

It despenses the starting amount of pellets for ignition. When the

duration of screw start-up dose is over, the ignition electrode is

activated. After a successful igntion, the fl ue gas temperature rises and the boiler switches to warm-up phase.

7.2 Warm-up phase

The ignition electrode is deactivated and the dosage of pellets

reduced. The fan is running with increased speed in comparison to

combustion phase (according to the setting). The warm-up phase

has the purpose to fan the fi re and let it spread across the pellets

in the burner. The duration of the warm-up phase is temporary.

After this phase, the combustion phase starts.

In the case that the fl ue gas temperature does not rise beyond

the set point, the controller registeres that the pellets can not be

ignited and the boiler stops operation. The display shows „Failed

ignition“.

7.3 Combustion phase

During combustion phase, the pellet and air supply are regulated

based on the parameter settings. The controller aims for the boiler

to increase the temperature up to the „Maximum boiler temperature“. After that is done, the boiler slowly reduces its output to

prevent repeated turing off and on of the burner. The boiler shifts

to pause mode when the temperature reaches the „Maximum boiler temperature“. On the top row the display shows „Rated temp.

reached“.

The boiler continues operation when the temperature of the fl ow

water drops below the parameter „Maximum boiler temperature“.

The current fl ue gas temperature determines if the boiler operation starts with the warm-up phase or ignition.

If a room thermostat is used, it is possible to activate the setting

that turns off the boiler resp. sends it into a phase of afterrun if

the room thermostat is turned off. If the afterrun-function is used,

the boiler will quickly reach the required temperature and stops

operation.

Operation phases

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

23

When cleaning the burner room with a vacuum clea ner, the ash inside must be cooled down to prevent

accidents.

When removing the front brick of the burner, there

is a risk of burn when handling it shortly after

deactivation of the boiler because it may still be hot.

Allow the boiler to cool down an adequate period of time until the

bricks can be touched safely.

There is a risk of burns when cleaning the exhaust passes because

these surfaces can reach a temperature of up to 200 °C during

operation. Wait until these parts cool down before cleaning.

8 Maintenance

8.1. Intervals of maintenance and cleaning

The maintenance work performed periodically is very important

for a problem-free operation und guarantee a long life of the boiler

and other system components.

The maintenance periods relate to the pellet quality and boiler

output. Soot and tar cling to the burner room walls, so the burner

room must be cleaned periodically by hand.

Before you start the cleaning, turn off the boiler controller and

deactivate the main switch.

Maintenance

Interval Components Application

Every 3 days

Clean heat exchanger and

burner room

Move the lever of the heat exchanger cleaning system back and forth 5 to

6 times. Remove the front chamotte brick and clean the burner room with

a vacuum cleaner.

Every month Clean pellet silo Empty out the pellet silo and remove the wood dust with a vacuum cleaner.

Every 6 months

Clean display Carefully clean with slightly damp cloth.

Check and clean exhaust

passes

The exhaust pipes can be removed and cleaned with the cleaning tool

when the system is cooled down.

Check and clean boiler

and fl ue gas probe

Pull out the probes, remove soot and lime.

Once a year

Clean all parts mentioned

above

When cleaning the burner room with a vacuum clea-

ner, the ash inside must be cooled down to prevent

accidents.

When removing the front brick of the burner, there

is a risk of burn when handling it shortly after

deactivation of the boiler because it may still be hot.

While cleaning, mind that there is a choking hazard

due to carbon monoxyde passing out if the boiler is

in operation. In this case, carbon monoxyde extits the

opened boiler doors. Do not leave the boiler doors open longer

than necessary.

The ash mass in the burner room depends on the pellet quality.

High quality pellets case less ash in the burner room and less

wood dust in the pellet silo.

To prolong the livetime of the ignition electrode which ignites teh

pellets, the electrode itself and the air vent must be cleaned regularly.

Thoroughly clean the system at the end of the heating season to

prolong its livetime and raise its effi ciency.

While cleaning, mind that there is a choking hazard

due to carbon monoxyde passing out if the boiler is

in operation. In this case, carbon monoxyde extits the

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

24

9 Possible malfunctions

Possible malfunctions

Malfunction/error Possible cause Solution

The boiler is working but does not reach

the set temperature.

1.) Boiler is polluted.

2.) Not enough fuel in burner.

3.) The chamotte bricks in the burner room

are not placed correctly.

1.) Clean the boiler.

2.) Set the screw to longer running time.

3.) Place the bricks correctly.

The boiler is wet.

Flue gas condensation.

The radiator power is too high or the

boiler output is to low. Meaning: replace

the boiler with an other that has a higher

output or adjust the number of radiators to

the boiler output.

Defects in the boiler.

Weld leaking parts on the boiler. This

is carried out by customer service or an

installler.

The fl ue gas is escaping insuffi ciently.

Flue gas pipes or heat exchangers are dirty. Clean the parts.

The chimney opening is too small.

Adjust chimney diameter to the boiler

output.

The boiler does not start operation. No power supply or blackout.

1.) Check electric connections.

2.) Check fuse in domestic electrical

installation.

The boiler reaches set temperature but the

radiators stay cold.

The circuit pump is not working (this pump

is not delivered with the boiler).

De-block the circuit pump by opening the

cover and turn shaft with a screw driver.

No potential on the circuit pump. Check fuse of circuit pump.

The fan does not work.

1.) Blown fuse.

2.) Foreign substance in the fan.

1.) Replace fuse.

2.) Check if fan can be turned without

resistance.

Failed pellet ignition.

1.) No power supply or blackout.

2.) Ignition electrode error.

3.) Burner is dirty.

4.) Pellet silo is empty.

5.) Ignition not callibrated correctly.

6.) Fan error.

7.) Screw error.

8.) Flue gas probe error.

1.) Check fuse.

2.) Replace ignition electrode.

3.) Clean burner room.

4.) Refi ll pellet silo.

5.) Callibrate ignition.

6.) Fix malfunction of fan.

7.) Fix malfunction of gear motor or screw.

8.) Replace probe.

Blocked screw.

1.) No power supply or blackout.

2.) Foreign substance in the screw.

3.) Pellets are damp.

4.) Gear motor of the screw is defective.

1.) Check fuse.

2.) Clean pellet silo and screw channel.

3.) Use dry pellets or pellets of higher

quality.

4.) Replace gear motor.

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

25

9.1 Fire prevention of the silo

In the case that the boiler is not connected to a suitable fl ue gas

system (not enough height, wrong diameter of the chimney, decreased diameter because of dirt or heavily polluted boiler), there is a

possibility that fi re spreads from the burner into the silo.

A part of the combustion air supply is led through the screw channel and thus prevents backfi re in the pellet silo. This air current is

present at all times during operation.

If the fl ue gas system is badly designed or heavily polluted, the

air supply may not be enough to stop a backfi re. In this case, the

thermal valve is activated which releases tempering water if a

temperature of 95 °C or more is measured. The fi re is extinguished

that way. The thermal valve and the probe are mounted on the

boiler ex factory.

The buyer is obligated to provide a water supply to the thermal

valve (1/2“ connection) and to comply with the prescriptions regarding dimension and quality of the fl ue gas system. If the fl ue

gas system is designed incorrectly or heavily polluted or if the boiler is not cleaned regularly, the manufactorer is not liable for fi re

caused by such failures.

9.2 Measures after thermal valve release

1.) Disconnect boiler from power supply.

2.) Remove screw and gear motor.

3.) Clean out damp pellets from the silo and the screw channel.

4.) Mount screw and gear motor.

5.) Remove residual water and dry damp system parts. Moisture

can cause electrical shorts.

6.) Connect to power supply.

If the damp pellets are not removed completely, screw and motor

may jam. The manufactorer rejects responsibility and the guaranty

expires if material damage occurs because of such failures.

Possible malfunctions,

First start-up

9.1 Fire prevention of the silo

Scheme of thermal valve

10 First start-up

The fi rst start-up of the boiler Biotec may only be carried out by a

professional of the company STREBEL or an experienced installer.

If the start-up is not carried out correctly, the boiler and the system

can be damaged or destroyed or injury and material damage can

occur.

10.1 Precautions for the fi sr start-up

1.) Disconnect boiler from power supply.

2.) Check if the red main switch on the boiler side is activated.

3.) Check if the following parts are installed professionally and

working.

- All mechanical parts of the boiler,

- burner and chamotte bricks,

- fan,

- circuit pump,

- safety valve.

4.) Check of all electrical connections:

- Correct installation of all electric components (gear motor,

fan, controller, display),

- Protection of unused connections,

- ground,

- power supply.

10 First start-up

Thermal valve

Probe

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

26

11 Disposal of the boiler

11.1 Removal

The boiler removal must be carried out by qualifi ed technicians.

Otherwise, injury or material damage can occur.

Procedure of the removal

1.) Stop boiler operation.

2.) Wait until the pellets in the burner room are burnt up and the

boiler is cooled down.

3.) Disconnect the boiler from power supply.

4.) Disconnect the boiler from the rest of the heating installation

with a turncock and drain the water from the boiler.

5.) Remove pellet silo.

6.) Remove boiler shell.

7.) Remove mineral wool insulation from the boiler body.

11.2 Disposal

The steel parts of the boiler are delivered to a recycling centre:

- Boiler body,

- boiler shell,

- pellet silo,

- screw,

- gear motor,

- burner.

The electrical parts as well as glas parts, mineral wool and plastic

parts are seperately delivered to the recycling centre.

The boiler parts must not be disposed in the domestic waste bin.

Disposal of the boiler,

Guaranty

11 Disposal of the boiler

Biotec

Typographical and printing errors, changes

in construction and dimensions expected.

27

Terminal connections

COMPENSATOR TANK

PROBE NTC10K

DOMESTIC WATER

TANK NTC10K

ROOM THERMOSTAT

SCREW

230 VAC, 50 Hz, 50 W

FAN

230 VAC, 50 Hz, 41 W

IGNITION

230 VAC, 400 W

RETURN RISER

230 VAC, < 500 W

TANK CHARGER PUMP

230 VAC, < 500 W

CIRCUIT PUMP

230 VAC, <500 W

POWER SUPPLY

230 VAC, 50 Hz

3 x 1,5 mm

2

A - 2700 Wiener Neustadt, Wiener Strasse 118

Teleph. +43 (0)2622 235 55-0

Fax +43 (0)2622 253 46

verkauf@strebel.at

www.strebel.at

Strebelwerk GmbH

STREBEL customer service:

Teleph. +43 (0)2622 23555 70-72,93,94

Fax +43 (0)2622 84344

kundendienst@strebel.at

Loading...

Loading...