Strebel ATI SP 80, ATI SP 120, ATI SP 220, ATI SP 300, ATI SP 400 Installation, Operation And Maintenance Manual

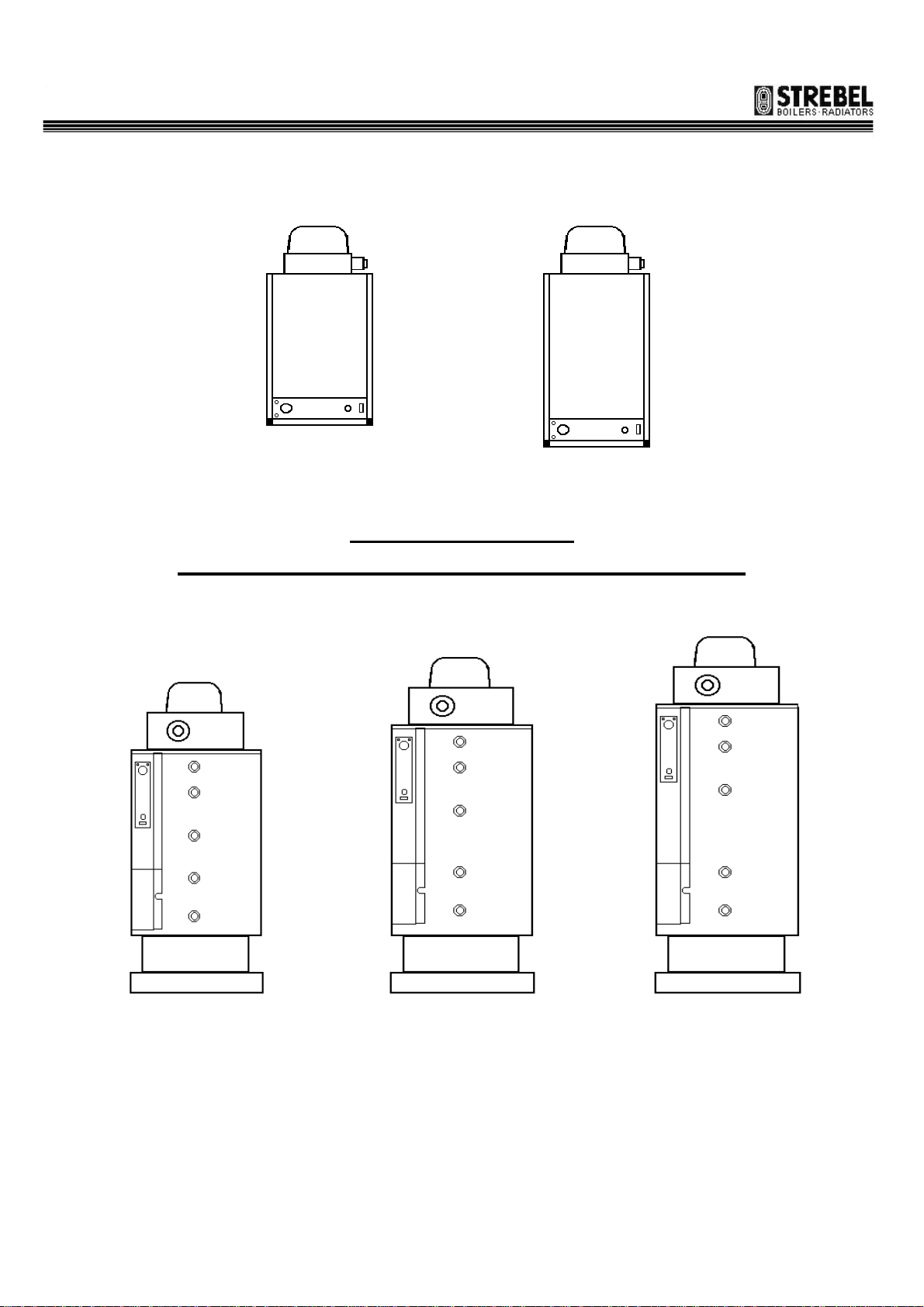

ATI SP 80 ATI SP 120

STREBEL ATI SP

DIRECT FIRED STORAGE WATER HEATER

ATI SP 220 ATI SP 400 ATI SP 300

INSTALLATION, OPERATING

AND MAINTENANCE MANUAL

Sept - 01

2

ATI SP 80, 120, 220, 300, 400 – INSTALLATION INSTRUCTIONS

Sept

-

01

• The following instruction book is integral and essential part of the appliance, and it has to be

kept with care near the appliance, for any further consultation.

• The appliance has been manufactured for hot water production: any other use of it has to be

considered dangerous and not suitable.

• The appliance is not to be installed in damp rooms, it has to be protected from water splashes

or other liquids, to avoid anomalies to electrical and thermal devices.

• Installation has to be made by professional qualified people, who are responsible and aware of

the safety regulations in force. A wrong installation, caused by not observing the manufacturer’s

instructions can cause danger to people, animals or things for which the manufacturer can not be

considered responsible.

• The guarantee for all devices is 12 months from the data of the installation, and however not

further 24 months from the manufactured period signed on the data label of the appliance.

• The appliance, as it is turned on, has to be checked by an Authorised Assistance Centre.

• Packaging parts (i.e. plastic bags, polystyrene, woods, clips, nails, etc.) can be harmful to

children and should be carefully disposed of immediately.

• Read carefully the instructions and the advice contained in this booklet, concerning safety,

installation, use and maintenance.

• If the appliance is sold or transferred to a new owner, make sure that this booklet stays with the

appliance, so that the new owner or installer can consult it.

• Do not place anything upon the appliance.

• To avoid damages caused by low temperatures, if the appliance has to be left unused for a

long period in a non-heated room, it is recommended the unit is drained down completely. The

manufacturer is not responsible for faults, breakdowns or for water leakage from the plant caused

by low temperatures.

• To comply with the Guarantee, we advise you to adhere to the following instructions and to use

only original spare parts and kits, supplied by the manufacturer.

INDEX page

1 - GENERAL INFORMATION AND CHARACTERISTICS

1.1 APPLIANCE’S CLASSIFICATION

1.2 PACKAGING CONTENT

1.3 CONSTRUCTIONAL AND OPERATIONAL DESCRIPTION

1.4 CONTROL AND SAFETY DEVICES

1.5 INSTRUMENT CONTROL PANEL

1.6 DIMENSIONS AND CONNECTIONS

1.8 TECHNICAL DATA

1.10 EXPLODED VIEW MOD. 80-120 (TAV. 105)

1.11 EXPLODED VIEW MOD. 220-300-400 (TAV. 106)

2 - INSTALLATION INSTRUCTIONS

2.1 REFERENCE REGULATIONS

2.2 INSTALLATION RECOMMENDATIONS

2.3 LOCATION OF THE APPLIANCE

2.4 INSTALLATION OF FLUE HOOD

2.5 WATER CONNECTIONS

2.6 GAS CONNECTIONS AND REGULATION

2.7 CHANGING THE GAS SUPPLY

2.8 ELECTRICAL CONNECTIONS

2.9 CONNECTION OF SEVERAL WATER HEATERS

2.10 STARTING THE WATER-HEATER

2.11 FAULT FINDING

3 - USER INSTRUCTIONS

3.1 RECOMMENDATIONS FOR THE USER

3.2 STARTING THE APPLIANCE

3.3 SWITCHING OFF

3.4 MAINTENANCE

3.5 WARRANTY VALIDITY

3.6 TECHNICAL DATA FOR THE USER

3

ATI SP 80, 120, 220, 300, 400 – INSTALLATION INSTRUCTIONS

Sept

-

01

1 - GENERAL INFORMATION AND

CHARACTERISTICS

1.1 APPLIANCE’S CLASSIFICATION

These appliances are classified as: “Gas fired water

heaters with sealed combustion circuit, with

atmospheric burner, equipped with a fan”.

The category of the appliance is II2H3B/P. This means

that the appliance can be supplied to operate with

gases of two different families. The atmospheric burner

can operate with a gas supply of the second family

(natural gas - group H) and of the third family (butane

and propane).

With reference to the European Regulation EN 483,

the type of the appliance can be C12, C32 or C52 (the

last one is just for models ATI SP 220, 300, 400)

according to the system of air supply and exhaust gas

evacuation used.

C12: “appliances with a sealed combustion circuit

connected to separate horizontal ducts

enabling combustion air to be admitted to the

burner and, at the same time, combustion

products to be discharged to the outside of

the room via orifices that are concentric or

sufficiently close to each other to be located

in almost identical wind conditions. The

appliance is assisted by a mechanical

means - a fan downstream of the

exchanger”.

C32: “appliances with a sealed combustion circuit

connected to separate vertical ducts enabling

combustion air to be admitted to the burner

and, at the same time, combustion products

to be discharged to the outside of the room

via orifices that are concentric or sufficiently

close to each other to be located in almost

identical wind conditions. The appliance is

assisted by a mechanical means - a fan

downstream of the exchanger”.

C52: “appliances with a sealed combustion circuit.

Flue duct orifices for air inlet and gas outlet

can be placed in different pressure

conditions. The appliance is assisted by a

mechanical means - a fan downstream of the

exchanger”.

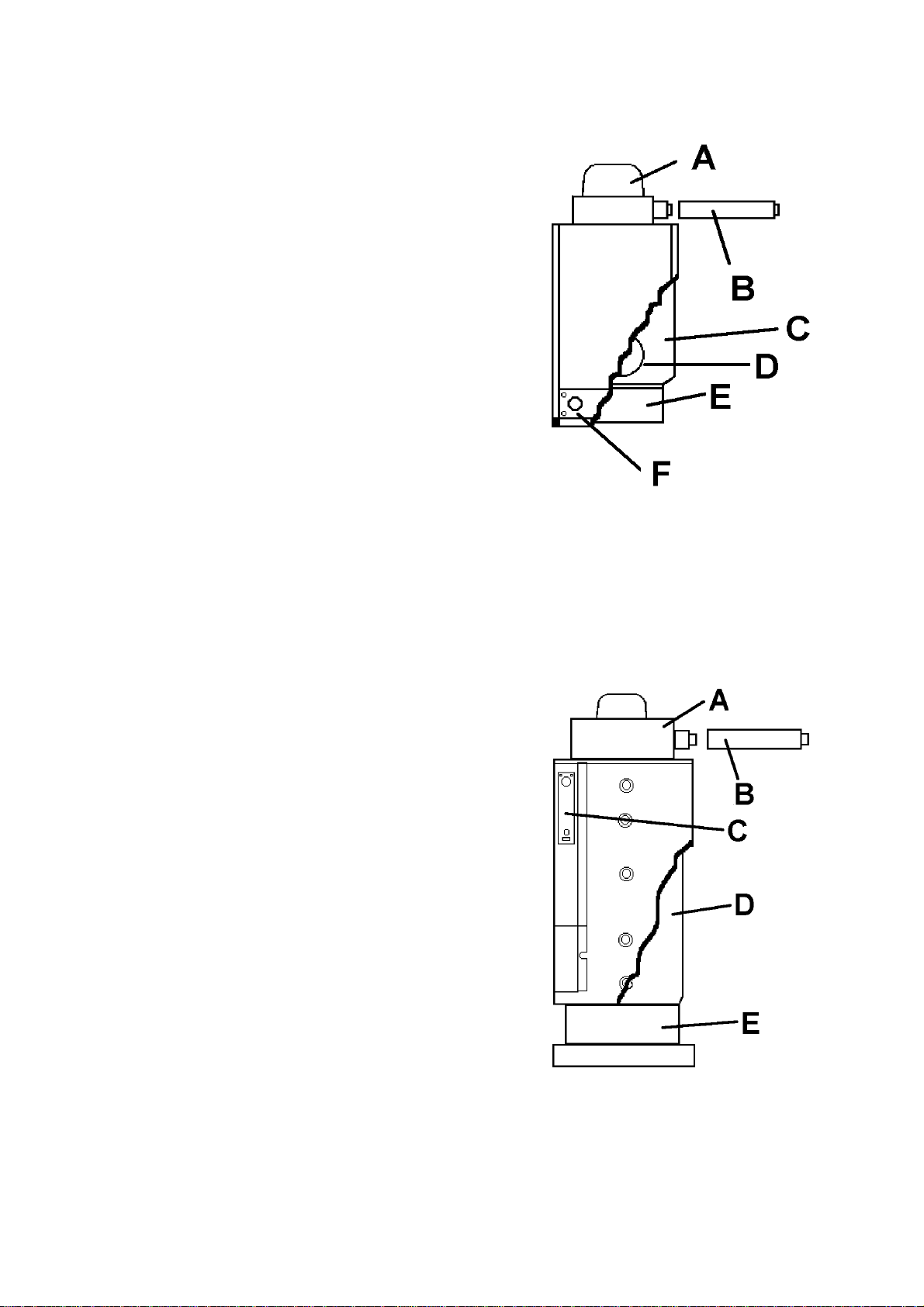

1a: ATI SP 80-120

a-flue hood; b-flue system kit; c-water tank;

d-inspection and cleaning flange;

e-combustion chamber; f-instrument control panel

1.2 PACKAGING CONTENT

For the ATI SP 80 & 120: the appliance is delivered

packaged in a cardboard box with appropriate

protection. Inside there is this booklet, the guarantee

certificate and the wall rosettes for coaxial flue pipes.

For the ATI SP 220, 300 & 400: the appliance is

delivered packaged in a wooden box with appropriate

protection. In a second cardboard box there is the flue

hood (inside which there is the fan for the forced draft

of exhaust gas), the flue outlet carrier, the wall rosette

for coaxial flue pipes and the screws to fix the flue

hood on the appliance and another plastic envelope

containing this booklet and the guarantee certificate.

Picture 1b: ATI SP 220, 300 & 400

a-flue hood; b-flue system kit;

c-instrument control panel; d-water tank;

e-combustion chamber;

4

ATI SP 80, 120, 220, 300, 400 – INSTALLATION INSTRUCTIONS

Sept

-

01

1.3 CONSTRUCTIONAL AND OPERATIONAL

DESCRIPTION

The purpose of the appliance is to allow the exchange

of heat between the gas combustion products, burned

in the combustion chamber, and the water held in the

tank.

The combustion is completely sealed inside the

combustion chamber, because the air supply and

exhaust gas outlet are made out of the room where the

appliance is installed. The sealed combustion chamber

is placed at the bottom of the appliance, under the

water tank. On the top there is the flue hood for the

forced draft of flue gases: a fan, placed after the

combustion chamber, assures the exhaust gas outlet

and the right air supply to the burner for the

combustion. Flue pipes which go through the water

tank, carry the air to the combustion chamber and the

exhaust gas back to the flue hood.

FLUE HOOD

The fan situated in the flue hood provides the air

supply and extracts the products of combustion. The

flue hood rotates through 360° for ease of positioning.

If the fan is not operating correctly or the flue pipes are

obstructed, a pressure switch, placed inside the flue

hood, stops the gas supply to the burner.

WATER TANK

It is made of thick sheet steel and assures great

resistance to pressure. The inside is coated with opal

glass (a vitreous coating baked at over 850°).

This allows a high chemical resistance (unassailable

from organically solvents and many other chemical

substances), excellent abrasion resistance (low

friction) and very good thermal stability (the opal glass

on steel resists up to 500°C; moreover frost and cold

have no effects). Moreover this allows a tank’s longlife and a higher healthy water. Inspection and

cleaning of the tank are allowed by an appropriate

clean our and inspection door.

COMBUSTION CHAMBER

It is situated at the bottom of the appliance, and this is

where the atmospheric burner, ignition and detection

electrodes are housed. The combustion chamber is

completely sealed.

INSTRUMENT CONTROL PANEL

On the instrument control panel there is all that is

required to control and to adjust the normal operating

of the appliance: control thermostat, ON/OFF switch,

lock-out lamp/reset push-button and the therm ometer

FLUE SYSTEM KIT (supplied separately)

It assures the connection between the flue hood and

the termination point, and for the air supply to the

burner. The flue kit required must be selected from the

various kits available, according to installation

requirements:

• horizontal coaxial system, with air supply and flue

outlet through the side wall.

• vertical coaxial system, with air supply and flue

outlet through the roof.

• vertical single wall system, with air supply through

the side wall and flue outlet through the roof.

• horizontal single wall system, with air supply

through the side wall and flue outlet in the chimney.

1.4 CONTROL AND SAFETY DEVICES

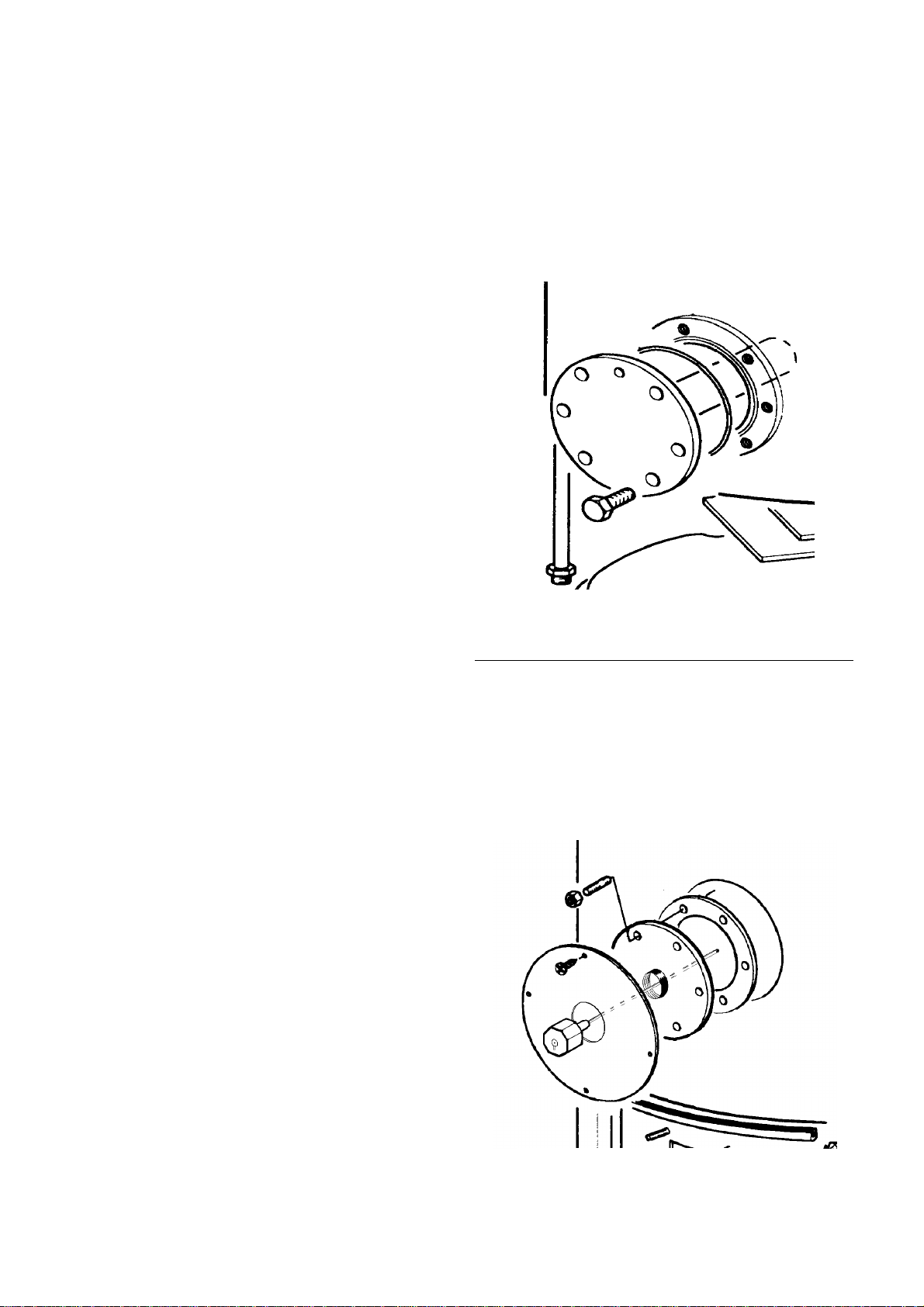

MAGNESIUM ANODE (ATI SP 80 & 120 ONLY)

The water heater is protected against metal-to-metal

corrosion by a magnesium anode. This has to be replaced each year in order to extend the working life of

the appliance. The anode is placed in the inspection

flange.

Picture 2a

Magnesium anode position

On ATI SP 80 & 120

CORREX ELECTRONIC ANODE

(ATI 220, 300 & 400 ONLY)

The water heater is protected against metal-to-metal

corrosion by an electronic anode. This requires a permanent 230 volt electrical supply in order to give full

protection and extend the working life of the appliance. The anode is fitted in a 3/4" connection in the

clean out and inspection flange.

Picture 2b

Correx electronic anode position

on ATI SP 220, 300 & 400

5

ATI SP 80, 120, 220, 300, 400 – INSTALLATION INSTRUCTIONS

Sept

-

01

ELECTRONIC CONTROL BOX

This controls the opening and closing of the gas valve

and the ignition of the burner.

If the pressure switch is in the “no air” position when

the control thermostat calls for heat, the fan is

switched on. When sufficient air flow is proven by the

pressure switch, a pre-purge period elapses before the

built-in ignite and gas valve are energised. The ignition

spark ignites the gas and the resulting flame is

detected by the flame detection electrode. Ignition

sparking is switched off immediately after a flame is

established. If the flame is not established within the

safety time, the control box locks out. In this case, wait

a few seconds and reset the control box, by

depressing the reset push-button on the instrument

panel. A new ignition cycle will start.

CONTROL BOX - TECHNICAL DATA

supply voltage 220/240 V

50/60 Hz

ambient temperature 0 - 60 °C

pre-purge time 30 sec

safety time 10 sec

minimum flame current 0,7 uA

response time off < 1 sec.

The flame sensing is based on the rectification

principle (an AC signal is sent from the control box to

the detection electrode, where it is converted to a DC

signal and returned to the control box).The control box

is approved by Gastec, Holland and VDE and DINDVGW, Germany.

GAS VALVE

For ATI SP 80-120: This is a compact multi-functional

and multi-gas control, with 2 direct-acting solenoid

valves (class B, group 2) with high sealing force. It has

an integral electronic packages for quiet operation with

cushioned solenoid stops, and it incorporates an

adjustable direct acting pressure regulator, and

approved by DIN-DVGW Germany.

Picture 3

Gas Valve for ATI SP 80 & 120

The aluminium body has 3/8” x 3/8” (BSP P.I.) inlet

and outlet and inlet screen (protected from potential

pipe damage). Commissioning and any adjustments

should be carried out by a qualified combustion

engineer. Care should be takes to prevent foreign

matter from entering valve during valve replacement.

MAINTENANCE: the only maintenance operation

allowed is the solenoid replacement, which has to be

carried by qualified personnel only.

GAS VALVE FOR ATI SP 80 – 120

Maximum pressure inlet 50 mbar

Voltage rating 220/240 V 50/60 Hz

Ambient temperature range 0 - 60 °C

Opening time < 0.25 seconds

Closing time < 0.25 seconds

For ATI 220 – 300 – 400 This is a multi-functional and

multi-gas gas control, with double silent

directly operated solenoid valve in class 2, adjustable

pressure regulator and low rate ignition with ignition

rate adjuster (factory set). Tis is approved by BRITISH

GAS (UK) and GASTEC (Holland).

The aluminium body has 1/2” x 1/2” RP UNI-ISO 7 gas

inlet and outlet, inlet and outlet pressure test points

and inlet filter. The solenoids are connected in series,

with a single electrical connector for both.

Commissioning and any adjustments should be carried

out by a qualified combustion engineer. Care should

be takes to prevent foreign matter from entering valve

and ensure that gas flow follows arrow on valve body

during valve replacement.

MAINTENANCE: the only maintenance operation

allowed is the solenoid replacing, which has to be

carried out by qualified personnel only.

Gas Valve for ATI SP 220, 300 & 400

Picture 4

6

ATI SP 80, 120, 220, 300, 400 – INSTALLATION INSTRUCTIONS

Sept

-

01

GAS VALVE FOR ATI SP 220, 300 & 400

TECHNICAL DATA

Maximum pressure inlet 50 mbar

Voltage rating 220/240 V 50/60 Hz

Ambient temperature range 0 - 60 °C

Opening time < 0.25 seconds

Closing time < 0.25 seconds

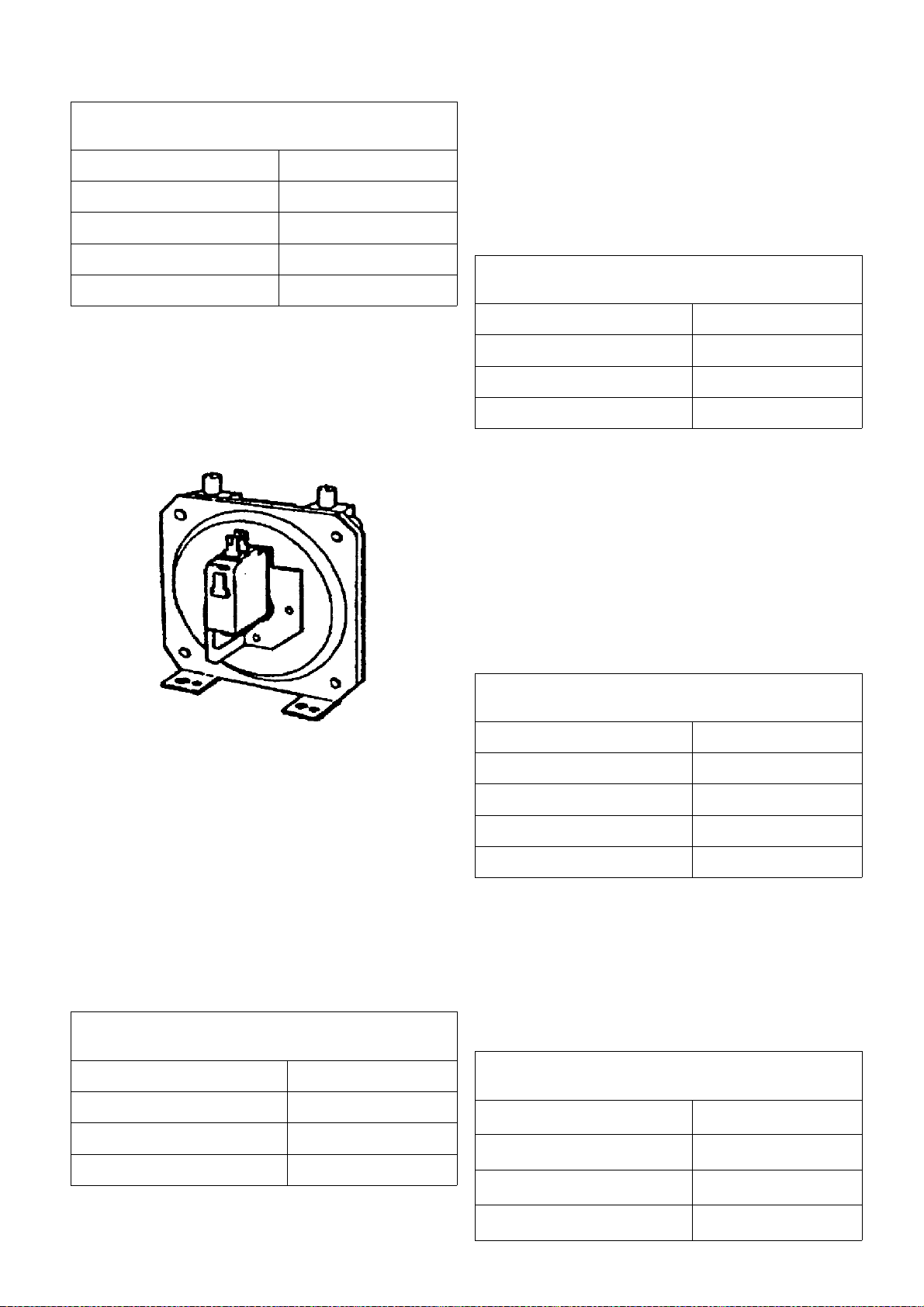

DIFFERENTIAL PRESSURE SWITCH

The pressure switch functions as a (combustion)

airflow supervisor with a safe start

interlock. If the airflow is not enough it will cut-off the

gas flow to the burner. This occurs for a fan failure or

for an obstruction in the combustion circuit.

Differential Pressure Switch

Picture 5

It is placed in the flue hood and it is connected by two

silicon pipes to two probes inside the flue hood, to test

the pressure difference on the flue outlet when the fan

is operating. In front of the device there is an

adjustment screw for setting, which is factory set. It

has three

terminals (common, normally closed NC and normally

open NO).It is approved by UL (USA), TÜV and DINDVGW (Germany).

DIFFERENTIAL PRESSURE SWITCH

TECHNICAL DATA

Maximum sustained pressure 6 mbar

Ambient temperature -10/ + 70°C

Contact terminals resistance < = 300m?

Electrical rating 250V ~ / 1.5A

ADJUSTABLE CONTROL THERMOSTAT 0-70°

This controls the operation of the appliance,

switching the burner on and off, according to the water

temperature set. This is a single pole liquid filled

sensing bulb with operating switch contacts. It is

approved by VDE (Germany) and IMQ (Italy).

ADJUSTABLE CONTROL THERMOSTAT

TECHNICAL DATA

contacts rating 250 V ~/2,5 A

temperature differential 4° ±/- 1°K

max. bulb temperature 150 °C

temperature range 40° / 80°

SAFETY LIMIT THERMOSTAT

Cuts off the burner operating in case the appliance

overheats, caused by control thermostat failure or lack

of circulation. To switch the appliance on again it is

necessary to press the manual reset button. The

cause of the safety lock should be investigated.

For ATI SP 80 & 120: This is a single pole thermostat

with snap action contacts and temperature control by

surface contact.It is approved by VDE (Germany),

SEMKO (Sweden), UL (USA), ASEV (Switzerland),

KEMA (Holland).

SAFETY LIMIT THERMOSTAT (ATI SP 80 & 120)

TECHNICAL DATA

intervention temperature 85°C

tolerance intervention +5° / -5°K

differential 14°K

contacts resistance £ 5 mW

capacity 250 V ~/10A

For ATI 220, 300 & 400: This is a single pole liquid

filled type, temperature limited with manual reset and

positive cut-off in case of capillary breakage. The high

limit temperature is factory set at 90°.It is approved by

VDE and DIN (Germany), SEMKO (Sweden) and IMQ

(Italy

SAFETY LIMIT THERMOSTAT

(ATI SP 220, 300 & 400)

adjustable limit temperature 90°/110°

tolerance +0° / - 6°K

contacts rating 250 V ~/2,5 A

max. bulb temperature 125 °C

7

ATI SP 80, 120, 220, 300, 400 – INSTALLATION INSTRUCTIONS

Sept

-

01

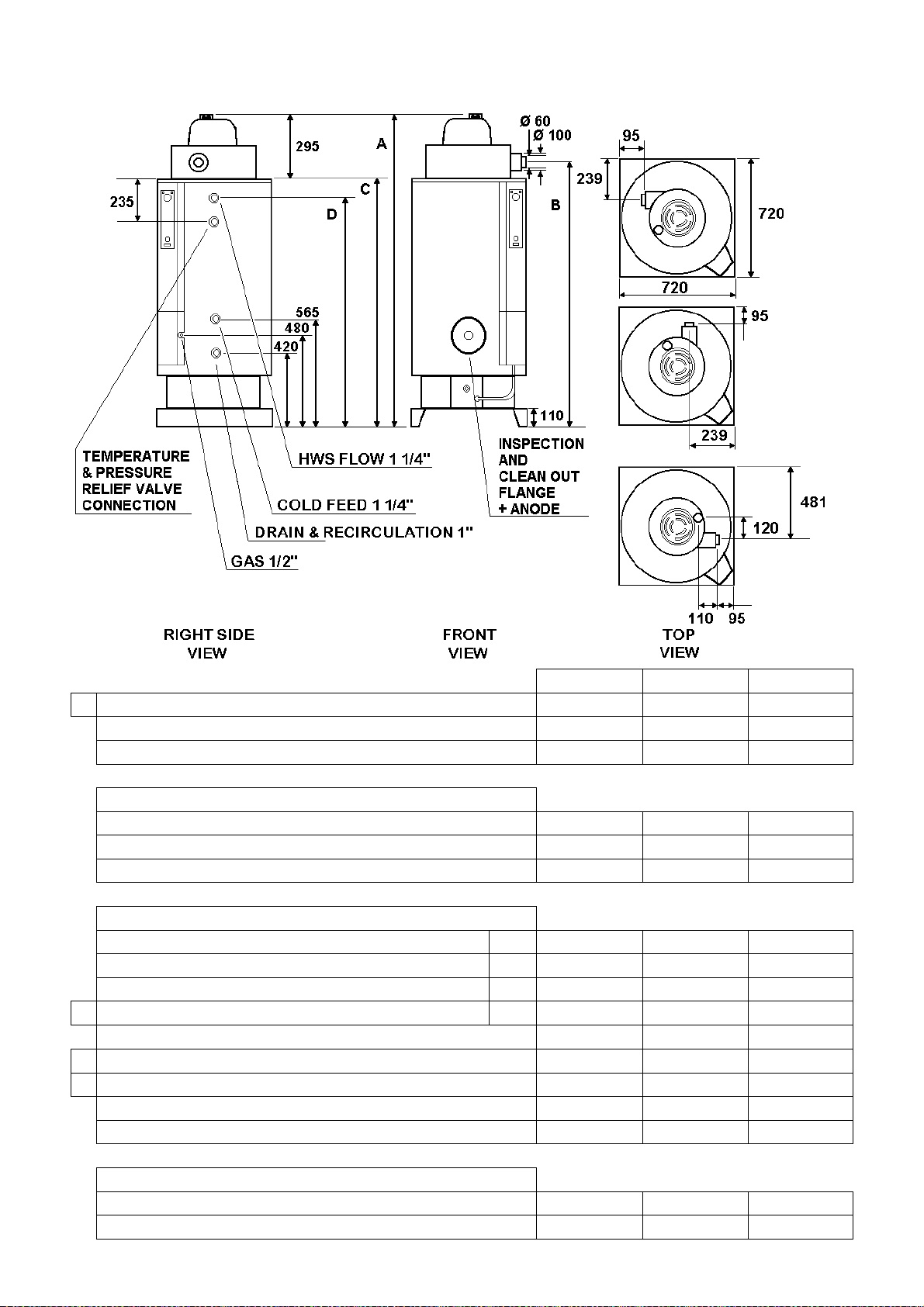

DIMENSIONS AND CONNECTIONS

ATI SP 80 & 120

ATI SP 80 ATI SP 120

OVERALL HEIGHT

A

WIDTH

DEPTH

HEIGHT OF FAN UNIT

HEIGHT WITHOUT FAN UNIT

B

HEIGHT TO FLUE CONNECTION

C

FLUE CONNECTION DIAMETER (INNER PIPE)

FLUE CONNECTION DIAMETER (OUTER PIPE)

FLANGE DIAMETER FOR INSPECTION AND CLEAN OUT AND

ANODE REPLACEMENT

1040 mm 1400 mm

450 mm 450 mm

460 mm 460 mm

190 mm 190 mm

850 mm 1210 mm

895 mm 1255 mm

38 mm 38 mm

60 mm 60 mm

85 mm 85 mm

8

ATI SP 80, 120, 220, 300, 400 – INSTALLATION INSTRUCTIONS

Sept

-

01

DIMENSIONS AND CONNECTIONS ATI SP 220, 300 & 400

A OVERALL HEIGHT 1660 mm 2015 mm 2365 mm

WIDTH 720 mm 720 mm 720 mm

DEPTH 720 mm 720 mm 720 mm

BASE

BASE HEIGHT 110 mm 110 mm 110 mm

BASE WIDTH 720 mm 720 mm 720 mm

BASE DEPTH 720 mm 720 mm 720 mm

HEIGHT FROM FLOOR OF:

GAS CONNECTION 1/2" 480 mm 480 mm 480 mm

COLD WATER FEED CONNECTION 1"1/4 565 mm 565 mm 565 mm

DRAIN & RECIRCULATION CONNECTION 1" 420 mm 420 mm 420 mm

D HOT WATER OUTLET CONNECTION 1"1/4 1300 mm 1655 mm 2005 mm

HEIGHT OF FAN UNIT 295 mm 295 mm 295 mm

B HEIGHT TO FLUE CONNECTION 1495 mm 1840 mm 2190 mm

C HEIGHT WITHOUT FAN UNIT 1365 mm 1720 mm 2070 mm

FLUE CONNECTION DIAMETER (INNER PIPE) 60 mm 60 mm 60 mm

FLUE CONNECTION DIAMETER (OUTER PIPE) 100 mm 100 mm 100 mm

INSPECTION AND CLEAN OUT FLANGE

DIAMETER 120 mm 120 mm 120 mm

HEIGHT FROM FLOOR 460 mm 460 mm 460 mm

ATI SP 220 ATI SP 300 ATI SP 400

9

ATI SP 80, 120, 220, 300, 400 – INSTALLATION INSTRUCTIONS

Sept

-

01

TECHNICAL DATA

ATI SP Model

Storage Capacity Litres 75 115 220 300 400

Nominal Input Btu/h 17,060 17,060 97,242 105,772 105,772

kW/h 5.0 5.0 28.5 31.0 31.0

Nominal Output Btu/h 16,036 16,036 88,029 95,536 95,536

kW/h 4.7 4.7 25.8 28.0 28.0

Combustion Efficiency 94% 94% 92% 92% 92%

10 Minute Output at 54°C

(Storage Water at 60ºC - Cold Water at 10ºC)

Continuous Output With a 44°C Temperature

Difference

Time To Recover With a 44°C Temperature

Difference

Gas Input Rate (Natural Gas G20) m³/h

Injector Diameter mm 2.00 2.00 1.25 1.25 1.25

Gas Pressure At Injector mbar 11.5 11.5 10.0 12.2 12.2

in Wg 4.5 4.5 4 4.8 4.8

Gas Input Rate (LPG G30/31 28-30/37 mbar) kg/h

Injector Diameter mm 1.15 1.15 0.72 0.75 0.75

Gas Pressure At Injector mbar 28.2 28.2 28.2 28.4 28.4

in Wg 11 11 11 11.1 11.1

Electrical Supply For Unit

Electrical Supply For Electronic Anode

Maximum Working Pressure

Minimum Working Pressure bar

Shipping Weight kg 49 74 202 245 286

Filled Weight kg 124 189 422 545 686

Lits/10 mins

Gals/10 mins

Lits/h

Gals/h

mins 44 71 26 34 43

ft³/h

lbs/h

bar

psi

psi

80 120 220 300 400

91

20

91

20

0.53

18.71

0.39

0.85

230 Volt - 50Hz - Single Phase - 3 Amp Fuse

N/A N/A

6

87

0.1

1.5

140

30

91

20

0.53

18.71

0.39

0.85

6

87

0.1

1.5

305

67

502

110

3.01

106.29

2.24

4.93

Permanent 230 Volt- 50Hz

Single Phase -3 Amp Fuse

6

87

0.1

1.5

401

88

568

125

3.28

115.82

2.44

5.37

6

87

0.1

1.5

515

113

568

125

3.28

115.82

2.44

5.37

6

87

0.1

1.5

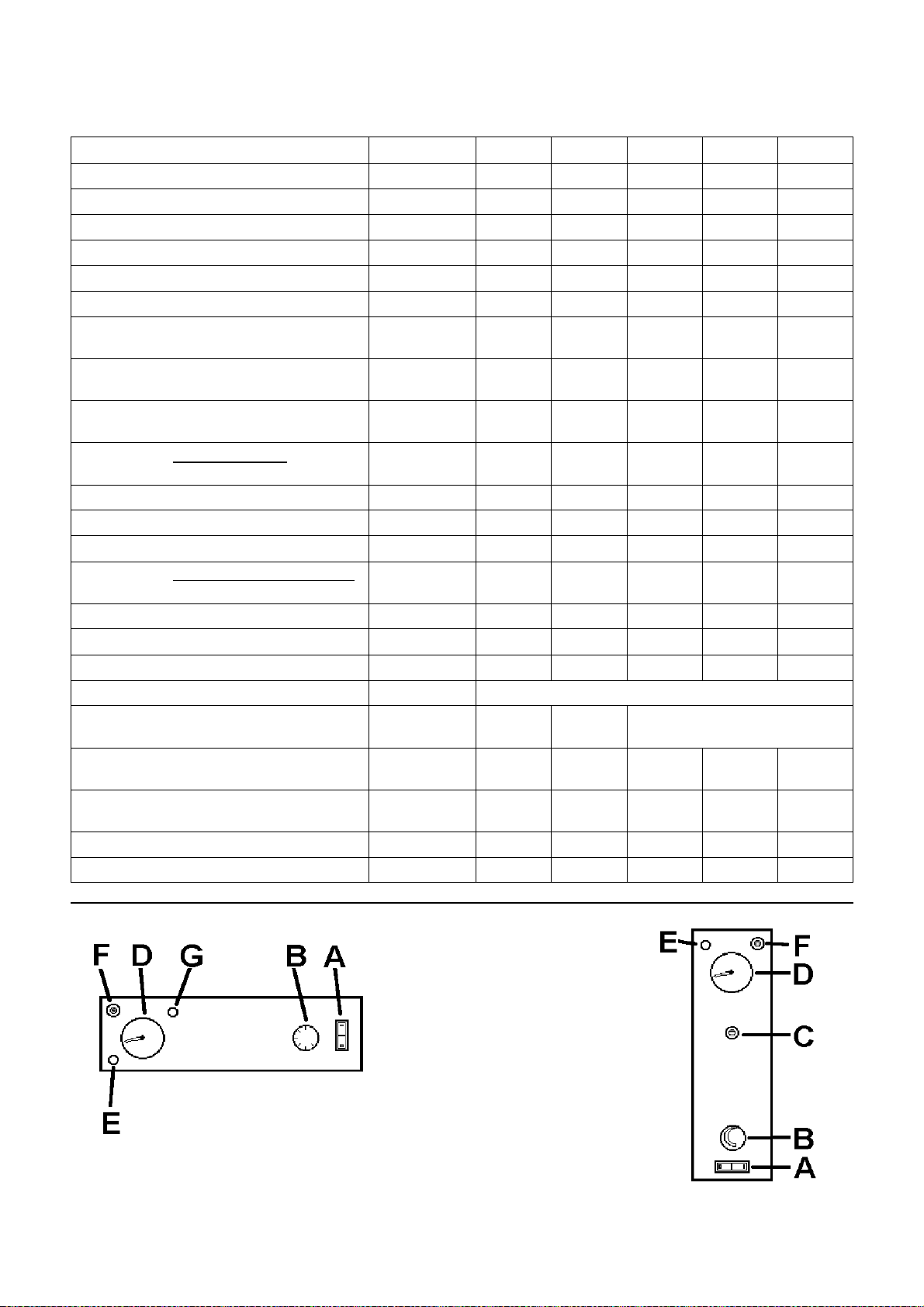

INSTRUMENT CONTROL PANEL

Picture 9a

ATI SP 80-120

A ON/OFF SWITCH

B ADJUSTABLE CONTROL

THERMOSTAT 0-70°C

C SAFETY LIMIT THERMOSTAT

(MANUAL RESET)

D THERMOMETER

E GREEN BURNER (ON) LIGHT

F LOCK OUT LIGHT + RESET

BUTTON

G HOLE FOR INSPECTION

OF THE COMBUSTION

Picture 9b

ATI SP 220-300-400

Loading...

Loading...