Strebel ASCONA A, ASCONA APV Installation, Operating And Maintenance Manual

STREBEL

ASCONA ‘A’ & ‘APV’

ATMOSPHERIC GAS BOILER

INSTALLATION, OPERATING AND

MAINTENANCE MANUAL

JUNE 2000

12/06/00Page 2

ASCONA ‘A’ & ‘APV’ INSTALLATION INSTRUCTIONS

SECTION TITLE PAGE

1 GENERAL 5

2 LOCATION 5

3 VENTILATION 5

4 GAS SUPPLY 6

5 FLUE SYSTEM 7

6 WATER CIRCULATION 7

7 INSTALLATION 7

8 ELECTRICAL SUPPLY 8

9 COMMISSIONING AND TESTING 8

10 SERVICING 9

11 FAULT FINDING 10

12 GAS VALVE ADJUSTMENT 11

13 L.P.G CONVERSION 13

14 WIRING DIAGRAM 14

15 USERS INSTRUCTIONS 16

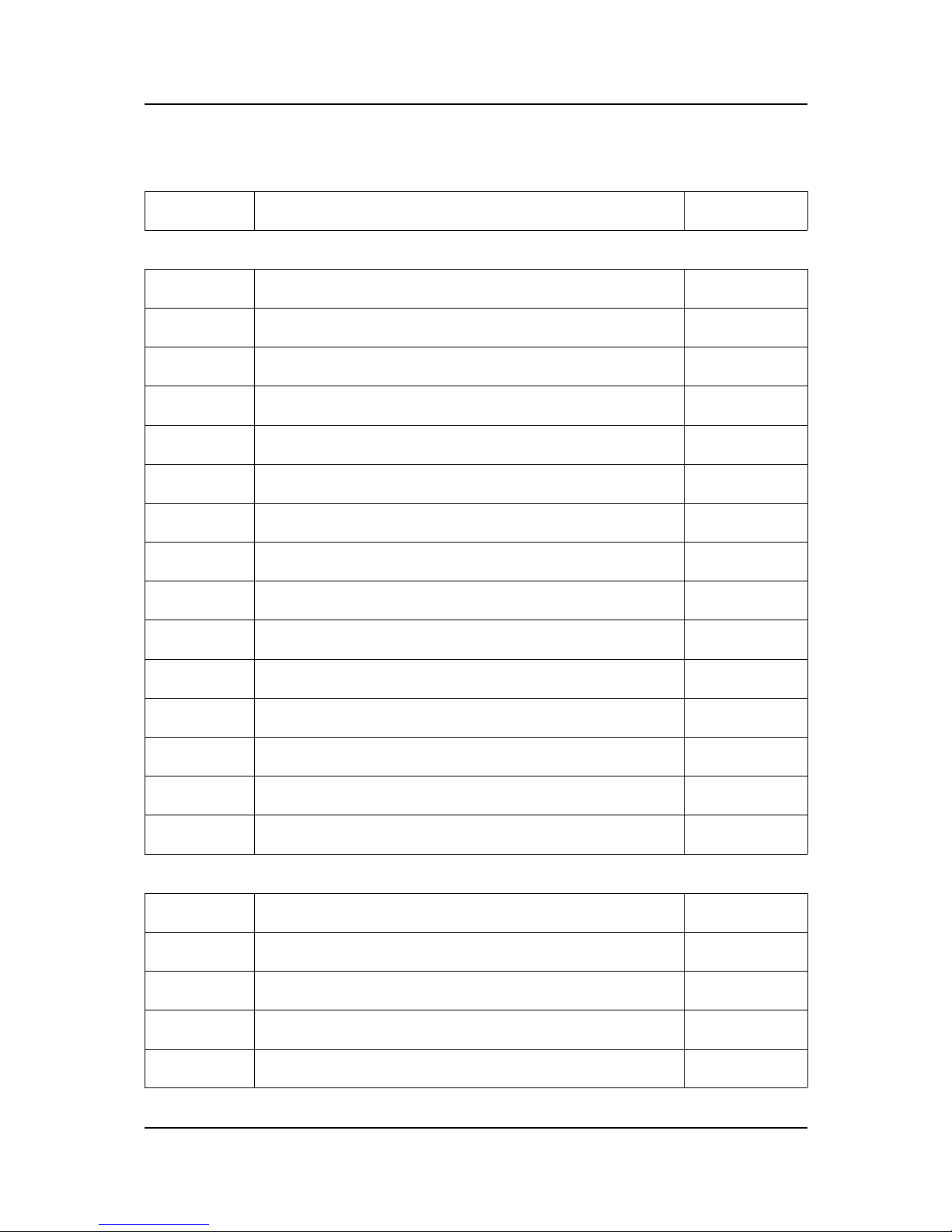

TABLE 1 TECHNICAL DATA ASCONA ‘A’ 3

TABLE 2 TECHNICAL DATA ASCONA ‘APV’ 4

TABLE 3 VENTILATION REQUIREMENTS A3 – A6 6

TABLE 4 VENTILATION REQUIREMENTS A3 – A6 6

TABLE 5 VENTILATION REQUIREMENTS A7 – A9 6

PAGE INDEX

12/06/00Page 3

ASCONA ‘A’ & ‘APV’ INSTALLATION INSTRUCTIONS

Type and No of Sections A-3 A-4 A-5 A-6 A-7 A-8 A-9

Nominal output kW 18.2 27.5 37.7 47.1 56.5 66.4 75.6

Nominal input kW 20.2 30.5 42.0 52.3 62.7 73.7 83.8

Supply Pressure – Natural gas mbar 20 20 20 20 20 20 20

Supply Pressure – LPG mbar 37 37 37 37 37 37 37

Burner Pressure – Natural gas mbar 14.8 14.5 13.2 14.5 14.5 14.5 14.5

Burner Pressure – LPG mbar 31.5 30.8 30.3 29.7 29.4 29.1 31

Burner injectors – Natural gas mm 2.6 2.6 2.7 2.6 2.6 2.6 2.6

Burner injectors – LPG mm 1.75 1.75 1.75 1.75 1.75 1.75 1.65

Gas consumption – Natural M³/h 2.33 3.44 4.55 5.63 6.72 7.80 8.87

Gas consumption – LPG Kg/h 1.71 2.52 3.43 4.13 4.93 5.72 6.50

Water Resistance 10ºC differential mbar 9.5 20 36.5 23 34 46 57

Water content Litres 10 12.5 15 17.5 20 22.5 25

Flue gas volume G/s 0.017 0.021 0.026 0.037 0.039 0.053 0.053

Flue gas temperature ºC 106 119 134 117 128 112 120

Electrical supply for unit V/Hz 230/50 230/50 230/50 230/50 230/50 230/50 230/50

Wattage W 40 40 40 40 40 110 110

Shipping weight Kg 87 110 136 164 186 213 234

ASCONA ‘A’ TECHNICAL DATA – TABLE 1

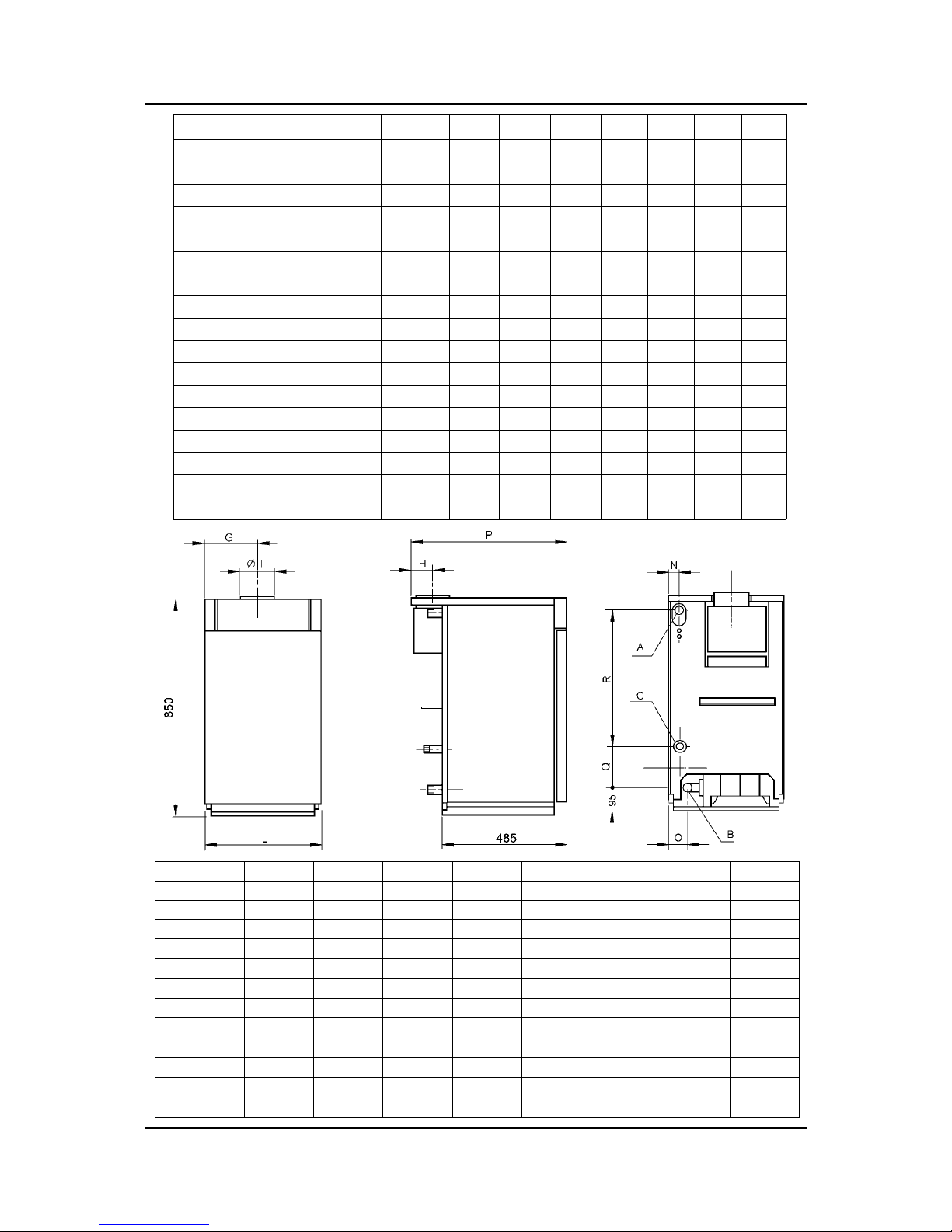

A-3 A-4 A-5 A-6 A-7 A-8 A-9

L mm 365 450 600 750 750 900 900

P mm 600 600 600 650 650 705 705

ØA Flow inches 1" 1" 1" 1¼" 1¼" 1¼" 1¼"

ØB Return inches 1" 1" 1" 1¼" 1¼" 1¼" 1¼"

ØC Gas supply inches ½" ½" ½" ½" ½" 1" 1"

G mm 135 205 205 335 335 405 405

H mm 80 80 90 105 105 125 125

ØI Flue size mm 130 130 150 180 180 220 220

N mm 40 40 115 55 55 55 55

O mm 70 70 150 55 55 55 55

Q mm 160 160 160 160 160 150 150

R mm 540 540 540 540 540 550 550

12/06/00Page 4

ASCONA ‘A’ & ‘APV’ INSTALLATION INSTRUCTIONS

A-3 A-4

L mm 365 450

P mm 600 600

ØA Flow inches 1" 1"

ØB Return inches 1" 1"

ØC Gas supply inches ½" ½"

G mm 135 205

H mm 80 80

ØI Flue size mm 130 130

M mm 40 40

ØS mm ½” ½”

Type and No of Sections PVA-3 PVA-4

Nominal output kW 18.2 27.5

Nominal input kW 20.2 30.5

Supply Pressure – Natural gas mbar 20 20

Supply Pressure – LPG mbar 37 37

Burner Pressure – Natural gas mbar 14.8 14.5

Burner Pressure – LPG mbar 31.5 30.8

Burner injectors – Natural gas mm 2.6 2.6

Burner injectors – LPG mm 1.75 1.75

Gas consumption – Natural M³/h 2.33 3.44

Gas consumption – LPG Kg/h 1.71 2.52

Water Resistance 10ºC differential mbar 9.5 20

Water content Litres 10 12.5

Flue gas volume G/s 0.017 0.021

Flue gas temperature ºC 106 119

Electrical supply for unit V/Hz 230/50 230/50

Wattage W 40 40

Shipping weight Kg 94 118

ASCONA ‘APV’ TECHNICAL DATA – TABLE 2

ASCONA ‘APV’ Heating pump curve

12/06/00Page 5

ASCONA ‘A’ & ‘APV’ INSTALLATION INSTRUCTIONS

1.0 GENERAL

1.1 The STREBEL ASCONA ‘APV’ & ‘A’ range of Gas Fired Boilers are floor mounted open flued

units for connection to heating and indirect hot water systems.

The Ascona heat exchanger body is constructed of cast iron sections with a stainless steel

atmospheric gas burner suitable for Natural Gas and LPG (site conversion) the boilers as

standard are fitted with electronic ignition. The boilers are fitted with full safety devices including

“Spillage Control System” (SCS) which shuts down the boiler if Spillage is occurring and so

prevents any escape of flue gases out the flue diverter, also on the A-8 & A-9 models there is a

Gas pressure switch for low inlet gas pressure.

The boilers are delivered completely assembled with jackets fitted and fully insulated.

The ASCONA ‘APV’ range is also fitted with three speed circulating pump, expansion vessel for

use with a sealed systems, 3 Bar safety valve, pressure gauge and water fill point (manual).

1.2 The installation of this boiler must be carried out in accordance with the relevant requirements of

the gas safety (installation and use) Regulations 1998, the I.E.E. Wiring Regulations and the

Bylaws of the Local Water Undertaking, and current Building Regulations

Detailed recommendations are contained in the following:

British Standard Code of Practice:

BS 6880 parts 1, 2 & 3 1988.

BS 6700 1987; CP. 342 : Part 2 :

BS 5440 parts 1 & 2 :

BS 5854 : BS. 6644 :

BS 6798 :

BS 6891 and British Gas Publications :- IM/11 Flues for Commercial and Industrial Gas Fired

Boilers and Air Heaters

"The Gas Safety (Installation and Use) Regulations 1998:

It is the law that all gas appliances are installed by CORGI registered contractors in accordance

with the above regulations. Failure to install appliances correctly could lead to prosecution. It is

in your own interest, and that of safety, to ensure that the law is complied with".

2.0 LOCATION

2.1 The boiler must stand on a level non combustible base, which is capable of adequately supporting

the weight of the boiler, water content an any ancillary equipment.

The location chosen for the boiler must permit the provision of a satisfactory flue and termination.

the boiler should be positioned to allow 50 mm between boilers and 500 mm at one end for

access to the pipework etc. 600 mm is required above to clean the flue-ways.

There should be 350 mm at the front of the boiler for maintenance and the draught diverter should

be at least 50 mm clear of the wall behind the boiler.

The location must also permit an adequate space for combustion and ventilation air purposes

(seeSection3on

Ventilation) and adequate space for servicing and air circulation around the

boiler.

3.0 VENTILATION

3.1 It is important that there are sufficient areas of air inlet and ventilation provided to the boiler room

detailed recommendations for air supply are given in BS 5440 part 2 & BS 6644.

12/06/00Page 6

ASCONA ‘A’ & ‘APV’ INSTALLATION INSTRUCTIONS

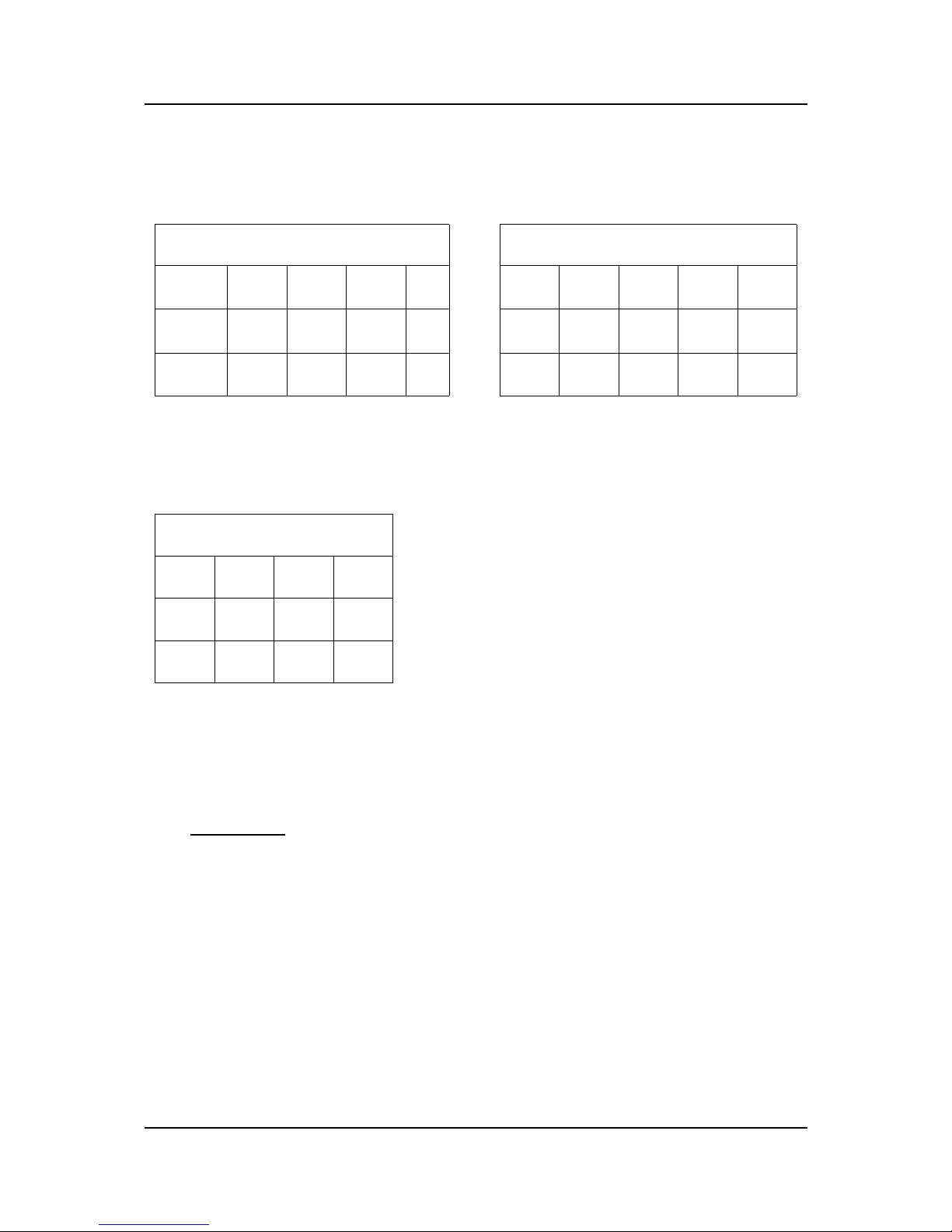

VENTILATION INTO A ROOM

OR INTERNAL SPACE IN CM²

A3 &

APV 3

A4 &

APV 4

A5 A6

HIGH

LEVEL

182 275 378 471

LOW

LEVEL

364 549 756 942

VENTILATION DIRECT TO

OUTSIDE AIR IN CM²

A3 &

APV 3

A4 &

APV 4

A5 A6

HIGH

LEVEL

91 138 189 236

LOW

LEVEL

182 275 378 471

VENTILATION DIRECT TO

OUTSIDE AIR IN CM²

A7 A8 A9

HIGH

LEVEL

277 301 324

LOW

LEVEL

553 602 648

TABLE3 TABLE4

TABLE5

3.3 Mechanical Ventilation.

The minimum quantity of air required for combustion and boiler house ventilation shall be supplied at a minimum flow rate in accordance with BS 6644.

All air inlet and extract fans shall be fitted with automatic controls causing safety shut-down or

lockout of the boiler(s) in the event of the inlet or extract air flow failing.

4.0 GAS SUPPLY

4.1 An existing meter should be checked preferably by the Gas Supplier, to ensure the meter is

adequate to deal with the rate of gas required.

4.2 Pipework from the meter to the boiler must be of adequate size. Pipes of smaller size than the

boiler inlet gas connection should not be used. All gas pipework should be fitted and on completion of installation tested, in accordance with BS 6891 : IGE/UP/2 Gas Installation Pipework,

Boosters and Compressors on Industrial and Commercial Premises.

4.3 Gas supply connections is as follows:

Ascona APV 3 & PV 4 = 1/2" BSP

Ascona A3,A4,A5,A6&A7=1/2"BSP

Ascona A 8 & A 9 = 1" BSP.

4.4 A gas service cock must be fitted immediately adjacent to the boiler.

Table 5 refers to the ventilation requirements (direct to outside air) for the Ascona A7 – A9 boilers.

Table 3 refers to the ventilation requirements (to internal space) for the Ascona A3 – A6. Table 4

refers to ventilation direct to outside for the Ascona A3 – A6.

Loading...

Loading...