Page 1

OPERATOR'S MANUAL

MANUEL de L'UTILISATEUR

MANUAL del OPERADOR

Catalog No.

No de Cat.

Catálogo No.

6267-20

SPECIAL NOTE: New battery packs are not fully charged. Charge

your battery pack before using it for the first time and follow the

charging instructions in your charger manual.

NOTE SPÉCIALE : Les batteries neuves ne sont pas entièrement

chargées. Chargez la batterie avant de vous en servir la première fois

en suivant les instructions de recharge dans le manuel qui

accompagne cet outil.

NOTA ESPECIAL: Las baterías, cuando son nuevas, no están

totalmente cargadas. Cargue su batería antes de usarla por

primera vez y siga las instrucciones de carga que vienen en el

manual de la herramienta.

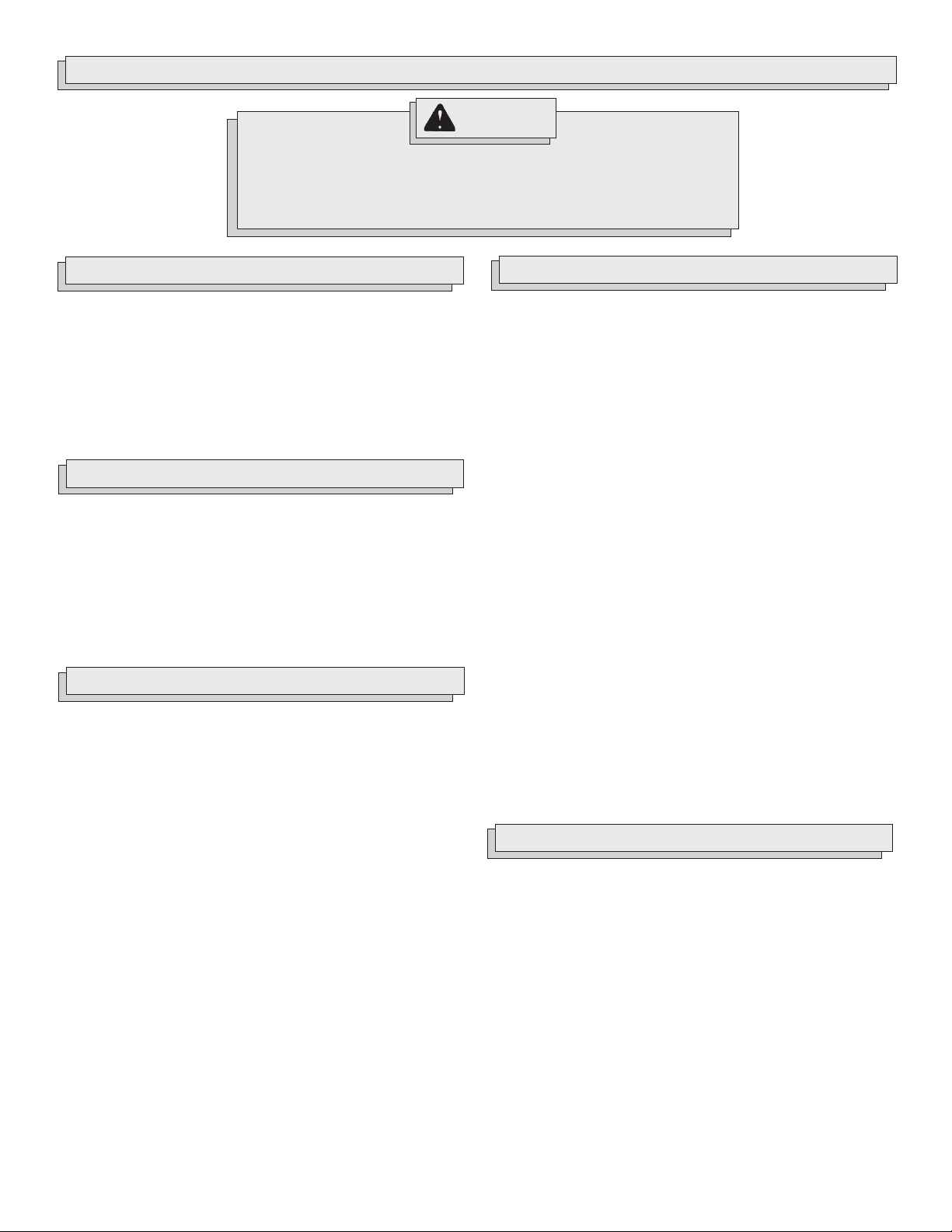

12 VOLT JIG SAW

SCUE SAUTUESE 12V

SIERRA CALADORS 12 VOLT

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND OPERATOR'S MANUAL.

AFIN DE RÉDUIRE LE RISQUE DE BLESSURES, L'UTILISATEUR DOIT LIRE ET BIEN COMPRENDRE LE

MANUEL DE L'UTILISATEUR.

PARA REDUCIR EL RIESGO DE LESIONES, EL USUARIO DEBE LEER Y ENTENDER EL MANUAL DEL

OPERADOR.

Page 2

GENERAL SAFETY RULES — FOR ALL BATTERY OPERATED TOOLS

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS.

Failure to follow all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

2. Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control. Protect others in the work area from debris such as chips and sparks. Provide

barriers or shields as needed.

ELECTRICAL SAFETY

4. Do not abuse the cord. Never use the cord to carry the tool. Keep

cord away from heat, oil, sharp edges, or moving parts. Replace

damaged cords immediately. Damaged cords may create a fire.

5. A battery operated tool with integral batteries or a separate battery pack must be recharged only with the specified charger for

the battery. A charger that may be suitable for one type of battery

may create a risk of fire when used with another battery.

6. Use battery operated tool only with specifically designated bat-

tery pack. Use of any other batteries may create a risk of fire.

PERSONAL SAFETY

7. Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or under the influence of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in serious personal injury.

8. Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in mov-

ing parts.

9. Avoid accidental starting. Be sure switch is in the locked or off

position before inserting battery pack. Carrying tools with your

finger on the switch or inserting the battery pack into a tool with the

switch on invites accidents.

10. Remove adjusting keys or wrenches before turning the tool on.

A wrench or a key that is left attached to a rotating part of the tool

may result in personal injury.

11. Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enable better control of the tool in unexpected situations.

12. Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be used for

appropriate conditions.

TOOL USE AND CARE

13. Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or against

your body is unstable and may lead to loss of control.

14. Do not force tool. Use the correct tool for your application. The

correct tool will do the job better and safer at the rate for which it is

designed.

15. Do not use tool if switch does not turn it on or off. A tool that

cannot be controlled with the switch is dangerous and must be repaired.

16. Disconnect battery pack from tool or place the switch in the

locked or off position before making any adjustments, changing

accessories, or storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

17. Store idle tools out of reach of children and other untrained per-

sons. Tools are dangerous in the hands of untrained users.

18. When battery pack is not in use, keep it away from other metal

objects like: paper clips, coins, keys, nails, screws, or other small

metal objects that can make a connection from one terminal to

another. Shorting the battery terminals together may cause sparks,

burns, or a fire.

19. Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edge are less likely to

bind and are easier to control.

20. Check for misalignment or binding of moving parts, breakage of

parts, and any other condition that may affect the tool’s operation. If damaged, have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools. Do not use a damaged

tool. Tag damaged tools “Do not use” until repaired.

21. Use only accessories that are recommended by the manufac-

turer for your model. Accessories that may be suitable for one tool

may create a risk of injury when used on another tool.

SERVICE

22. Tool service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified personnel may

result in a risk of injury.

23. When servicing a tool, use only identical replacement parts. Fol-

low instructions in the Maintenance section of this manual. Use

of unauthorized parts or failure to follow Maintenance Instructions may

create a risk of shock or injury.

page 2

Page 3

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates. These carry important information. If unreadable or missing, contact a MILWAUKEE service facility for a free

replacement.

2. WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to cause

cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filter out microscopic particles.

Symbology

SPM

1. Quik-Lok tension lever

2. Transparent blade cover

3. Blade

4. Shoe

5. Orbital action selector lever

6. Tilt angle scale

7. Hex key

8. Vacuum manifold

9. Battery pack

10. Release butttons

11. On/Off switch

Volts Direct Current

No Load Revolutions per

Minute

Properly Recycle Nickel

Cadmium Batteries

Underwriters

Laboratories, Inc.

FUNCTIONAL DESCRIPTION

1

Specifications

Catalog

No.

6267-20

Volts

DC

12

8

No Load

RPM

1700

10

911

2

3

4

5

7

6

DESCRIPTION

The MILWAUKEE 12 Volt Orbital Action Jig Saw can cut a wide variety of materials including metal, wood, and plastic. Cuts may be straight lines,

bevels curves or internal cut-outs. Notable features of these Jig Saws include:

• Rapid blades change without tools with the Quik-Lok® blade change system.

• Adjustable Orbital Action blade stroke cuts faster by pressing the blade against the work only during upstroke. This is particularly effective when

rough cutting thick wooden boards.

• Adjustable shoe can tilt up to 45° in either direction for bevel cuts.

• Built-in manifold for vacuum assisted dust collection (hose is optional).

• Transparent blade cover improves dust extraction.

• Vibration dampened mechanism permits quieter, smoother running.

page 3

Page 4

CHARGING AND USING BATTERY PACK

WARNING!

Charge only MILWAUKEE 12, 14.4 and 18 Volt

Power Plus battery packs in Power Plus

chargers. Other types of batteries may explode causing personal injury and damage.

Charge your battery pack before using your tool for the first time and

when your tool no longer performs with the power and torque needed for

the job. Full loading capacity of battery pack is only reached after

4 - 5 chargings. Never completely discharge the battery pack. Standard

charging time will vary according to the type of charger you use. The

charging time will also vary depending on the supply voltage and charge

needed. For example, if your battery pack does not require a full charge,

charging time will be less.

FOR SPECIFIC CHARGING INSTRUCTIONS, PLEASE READ THE

CHARGER INSTRUCTION SHEET SUPPLIED WITH YOUR CHARGER.

Battery packs are affected by temperature. Your battery pack will

perform best and have longest life if it is charged when the temperature

is between 60°-80°F (15°-27°C). Do not charge in temperatures below

40°F (5°C) or above 105°F (40°C). Under these conditions, capacity will

be reduced. See “Maintenance”.

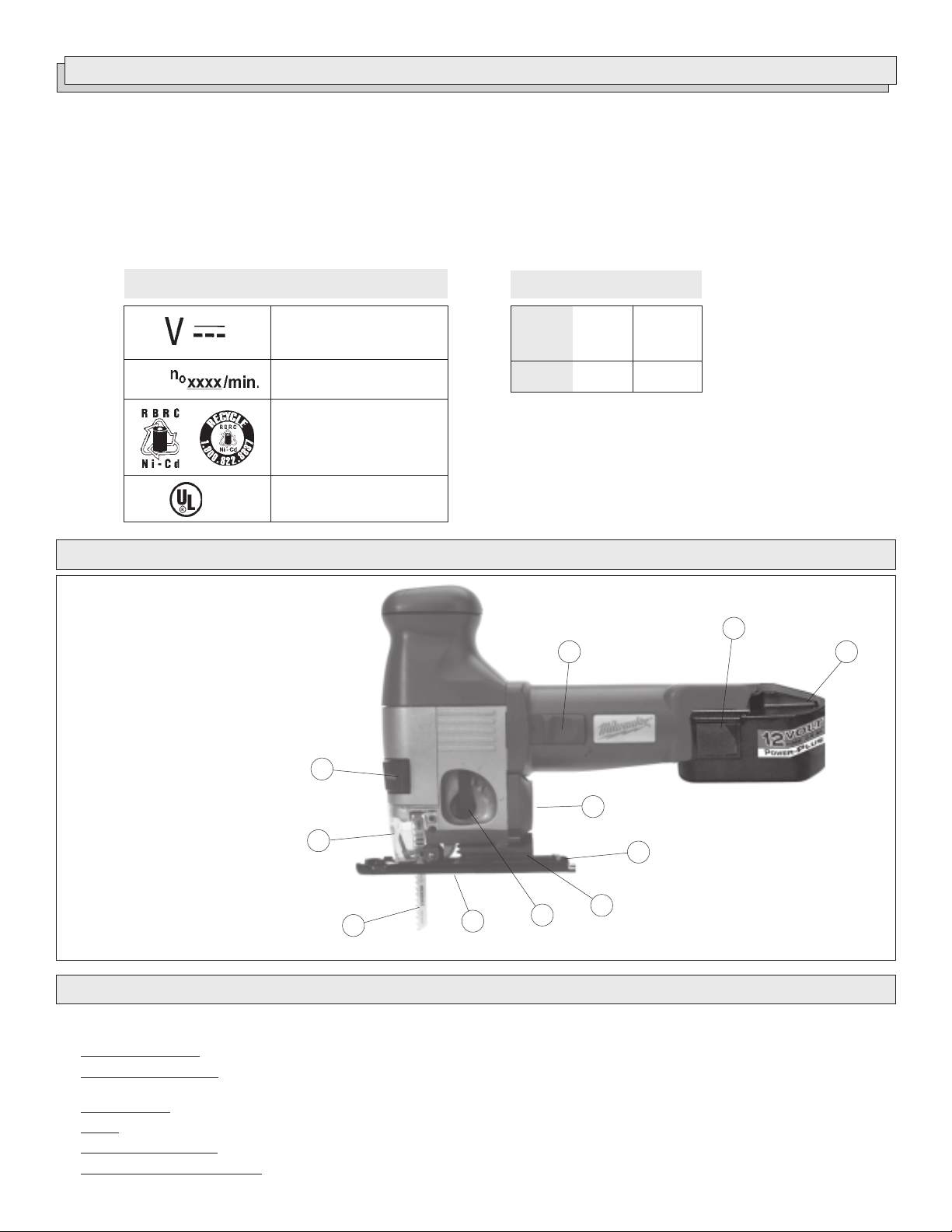

Removing Battery Pack from Tool (Fig. 1)

Push in the release buttons and remove the battery pack.

Fig. 1

Inserting Battery Pack into Tool (Fig. 2)

Insert the battery pack from the back by pressing in the release buttons

and sliding the battery pack into the body of the tool. Insert the battery

pack until clamp engages.

Fig. 2

TOOL ASSEMBLY

WARNING!

Always remove battery pack before changing or

removing accessories. Only use accessories specifically recommended for this tool. Others may

be hazardous.

Inserting the saw blade (Fig. 3)

1. Remove the battery pack from the tool before inserting or changing

blades.

2. This tool uses only T-Shank Jig Saw blades.

3. To install a blade, push the Quik-Lok tension lever as far as it will go

and hold in position.

4. Fit the saw blade into the slot in the support roller and push it firmly

into the plunger as far as it will go (Fig. 3). The lug of the saw blade

must be in the plunger.

Fig. 3

5. Release the Quik-Lok tension lever. The saw blade is automatically

held in place.

6. Check that the saw blade is held firmly; the slot in the plunger will be

at an angle to the saw blade.

NOTE: Only use the Quik-Lok tension lever when the tool is OFF.

page 4

Slot

Blade

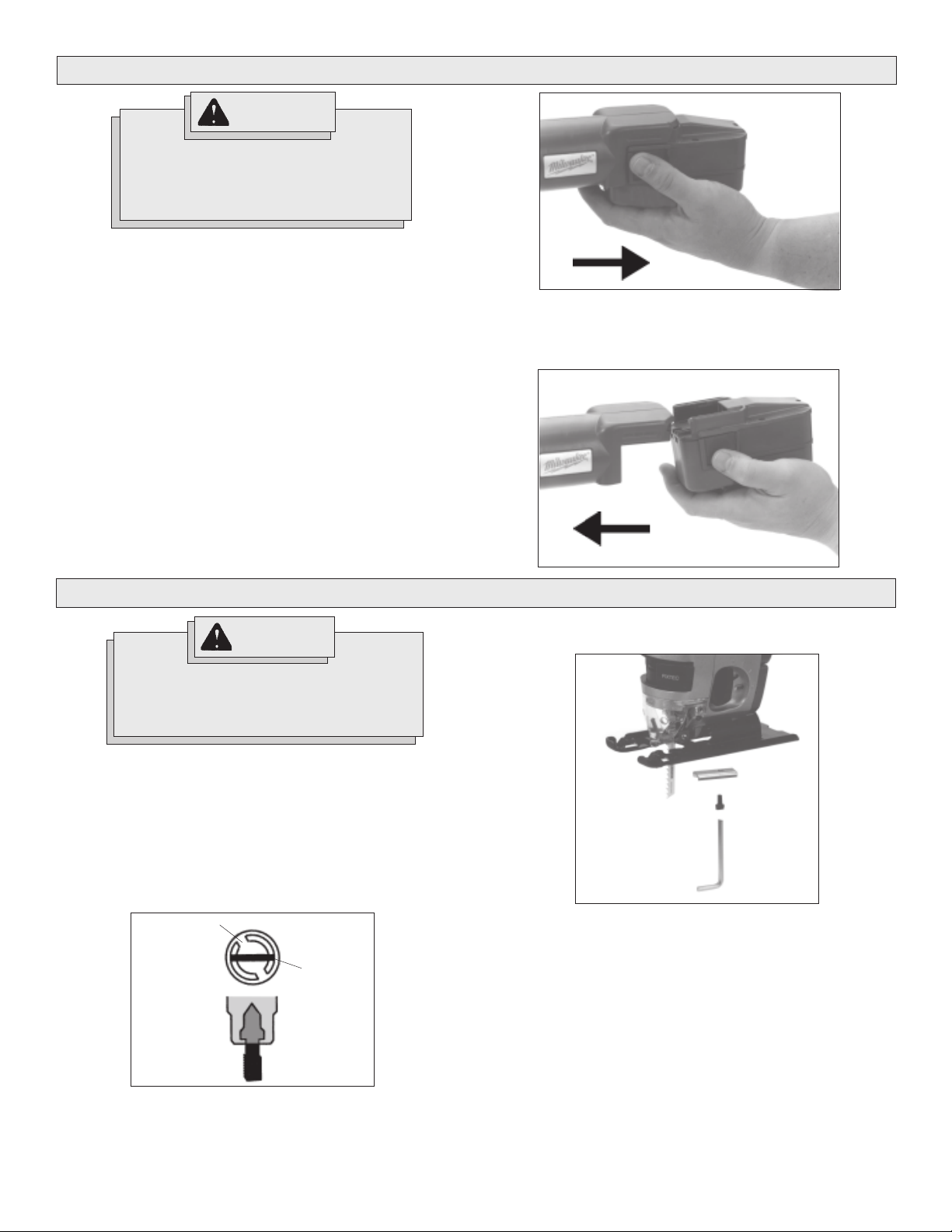

Adjusting the shoe (Fig. 4)

Fig. 4

The shoe may be tilted up to 45° in either direction and moved forward or

backward.

1. To set a tilt angle for angle cuts and bevels, loosen the screw hold-

ing the shoe, pull the base backward slightly until the retaining lugs

are no longer engaged. Tilt to the required preset angle (15°, 30°, or

45°) as read on the scale. Push back into the retaining lugs and

tighten the screw. If angles other than the presets are required, set

the desired angle and tighten the screw without engaging the retaining lugs.

NOTE: If very exact angles are needed it is recommended that a test

cut and subsequent adjustment be made.

2. To move the shoe back for plunge cuts or cuts in corners, loosen

the screw holding the shoe and pull the shoe completely back. The

screw will fit into a slot to hold the shoe at 0°.

Page 5

OPERATION

WARNING!

To reduce the risk of injury, wear safety goggles

or glasses with side shields.

Starting and stopping the tool

1. To start the tool, push the On/Off switch forward until “I” is visible.

2. To stop the tool, push the On/Off switch backwards until “0” is visible.

Adjusting the orbital action

The amount of orbital action may be adjusted with the selector lever. In

general, a large orbital action (III) should be used with soft materials and

a small orbital action (I) should be used with hard materials. When a

smooth cut is required, no orbit (0) should be used. Recommended orbit

settings for different material compositions are shown below. The optimum orbital action should be determined by the user for their specific

cutting requirements.

APPLICATIONS

Special Cutting Techniques

1. Straight cuts – To obtain a perfectly straight cut, clamp a strip of

wood as a guide along the workpiece or use the parallel guide (accessory).

2. Cutting at a bevel angle – Adjust the shoe to the correct angle (See

“Adjusting the Shoe”).

3. Cutting close to obstacles – Move the shoe backward to provide

greater clearance.

4. Cutting Sheet Metal – Sheet metal may vibrate when being cut. To

minimize this vibration, clamp the workpiece to a wood base.

Wood ................ III

Metal ................. 0

Plastic .............. I

Smooth Cut ...... 0

NOTE: Orbital action may be adjusted whether the tool is running or not.

General cutting

1. Set the stroke and orbital action according to the material to be cut.

2. Position the tool with the front part of the shoe on workpiece and turn

on tool.

3. Hold the machine firmly against the workpiece and guide it along the

desired cutting line. Do not feed into the work too hard, light pressure

on the saw blade will achieve the optimum cutting speed.

Fig. 5

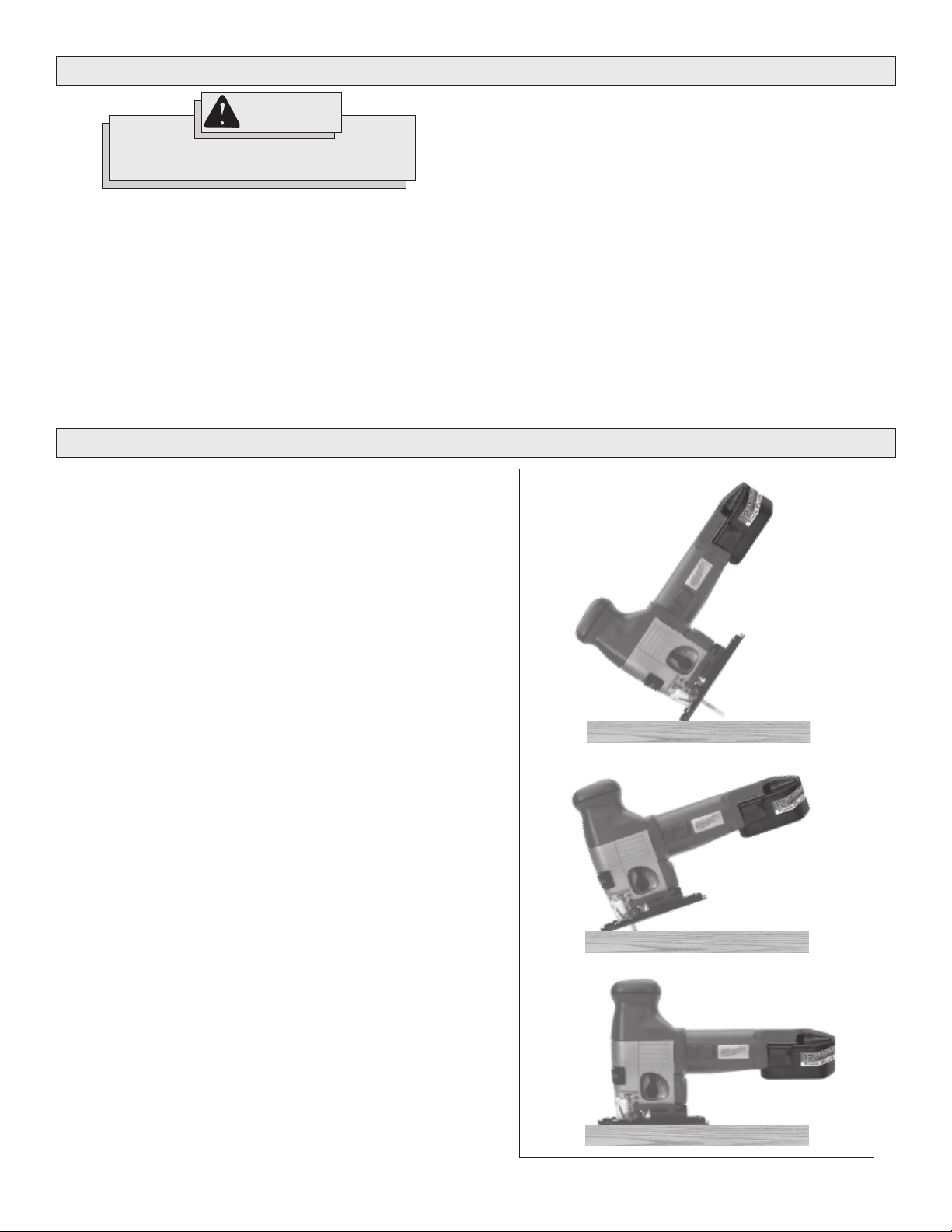

Plunge Cutting (Fig. 5)

The MILWAUKEE 12 Volt Jig Saw is well suited to making plunge cuts

into soft materials without a pre-drilled hole. Harder materials require a

starter hole with a diameter slightly wider than the blade.

1. To make a plunge cut, move the shoe all the way back.

2. Set the orbital action selector to 0.

3. Make sure nothing below the intended cut area will be damaged.

4. Without switching the tool on, place the front edge of the shoe solidly

on workpiece (a).

5. Align the blade with the intended cut line, keeping it above the

workpiece.

6. Using the front edge of the shoe as a pivot, turn the tool on and

gradually lower the blade into the workpiece (b).

7. When the shoe is firmly against the workpiece, begin the cut (c).

a

b

c

page 5

Page 6

MAINTENANCE

WARNING!

To reduce the risk of personal injury,

always unplug the charger and remove the

battery pack from the charger or tool

before performing any maintenance. Never

disassemble the tool, battery pack or

charger. Contact a MILWAUKEE service

facility for ALL repairs.

Maintaining Tool

Keep your tool, battery pack and charger in good repair by adopting a

regular maintenance program. After six months to one year, depending

on use, return the tool, battery pack and charger to a MILWAUKEE ser-

vice facility for:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning (gears, spindles,

bearings, housing, etc.)

• Electrical inspection (battery pack, charger, motor)

• Testing to assure proper mechanical and electrical operation

If the tool does not start or operate at full power with a fully charged

battery pack, clean the contacts on the battery pack. If the tool still does

not work properly, return the tool, charger and battery pack to a

MILWAUKEE service facility for repairs.

Maintaining Battery Pack

MILWAUKEE battery packs will operate for many years and/or hundreds

of cycles when they are maintained and used according to these instructions.

A battery pack that is stored for six months without being used will discharge itself. Batteries discharge at a rate of about 1% per day. Charge

the battery every six months even if it is unused to maximize battery life.

Do not tape the trigger in the “ON” position and leave the tool unattended

as this may discharge the battery to a point where it will no longer be able

to recharge. Use a MILWAUKEE battery pack only until it no longer performs with the power and torque needed for your application.

Store your battery pack in a cool, dry place. Do not store it where the

temperature may exceed 120°F (50°C) such as in a vehicle or metal building during the summer. High temperatures will overheat the battery pack,

reducing battery life. If it is stored for several months, the battery pack

will gradually lose its charge. One to three cycles of charging and discharging through normal use will restore the capacity of the battery pack.

During the life of the battery pack, the operating time between charges

becomes shorter. If the operating time becomes extremely short after a

proper charge, the usable life of the battery pack has been reached and

it should be replaced.

Cleaning

Clean dust and debris from charger and tool vents. Keep tool handles

clean, dry and free of oil or grease. Use only mild soap and a damp cloth

to clean the tool, battery pack and charger since certain cleaning agents

and solvents are harmful to plastics and other insulated parts. Some of

these include gasoline, turpentine, lacquer thinner, paint thinner, chlorinated cleaning solvents, ammonia and household detergents containing

ammonia. Never use flammable or combustible solvents around tools.

WARNING!

To reduce the risk of personal injury and

damage, never immerse your tool, battery

pack or charger in liquid or allow a liquid to

flow inside them.

page 6

WARNING!

To reduce the risk of explosion, never burn

a battery pack even if it is damaged, dead or

completely discharged.

RBRC Battery Recycling Seals

The RBRC™ Battery Recycling Seals (see "Symbology") on your tool battery packs indicate that MILWAUKEE has arranged for the recycling of that

battery pack with the Rechargeable Battery Recycling Corporation (RBRC).

At the end of your battery pack's useful life, return the battery pack to a

MILWAUKEE Branch Office/Service Center or the participating retailer nearest you. For more information, visit the RBRC web site at www.rbrc.org.

Disposing of Nickel-Cadmium Battery Packs

Nickel-Cadmium battery packs are recyclable. Under various state and

local laws, it may be illegal to dispose of this battery into the municipal

waste stream. Dispose of your battery pack according to federal, state

and local regulations.

Repairs

For repairs, return the tool, battery pack and charger to the nearest service center listed on the back cover of this operator's manual.

Battery Pack Warranty

Battery packs for cordless tools are warranted for one year from the date

of purchase.

WARRANTY

Every MILWAUKEE product is warranted to be free from defects in material and workmanship. MILWAUKEE will repair or replace any product which

examination proves to be defective in material or workmanship.

Limitations: This warranty does not cover: 1) repairs made or attempted

by other than MILWAUKEE or MILWAUKEE Authorized Service Station

personnel; 2) normal wear and tear; 3) abuse; 4) misuse; 5) improper

maintenance; 6) continued use after partial failure; 7) tools that have been

modified; or product used with an improper accessory.

Battery Packs are warranted for one (1) year from the date of purchase.

Should a problem develop, return the complete product to any

MILWAUKEE Factory Service Center or MILWAUKEE Authorized Service Station, freight prepaid and insured. If inspection shows the problem

is caused by a defect in material or workmanship, all repairs or a replacement will be made at no charge and the product will be returned, transportation prepaid. No other warranty, written or verbal, is authorized.

THE REPAIR AND REPLACEMENT REMEDIES DESCRIBED HEREIN

ARE EXCLUSIVE. IN NO EVENT SHALL MILWAUKEE BE LIABLE FOR

ANY INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES, INCLUDING LOSS OF PROFITS.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED WHETHER FOR MERCHANTABILITY OR FITNESS FOR

PARTICULAR USE OR PURPOSE.

This warranty gives you specific legal rights. You may also have other

rights that vary from state to state. In those states that do not allow the

exclusion of implied warranties or limitations of incidental or consequential damages, the above limitations or exclusions may not apply

to you.

Page 7

ACCESSORIES

WARNING!

Always remove battery pack before changing or

removing accessories. Only use accessories

specifically recommended for this tool. Others

may be hazardous.

For a complete listing of accessories refer to your MILWAUKEE Electric Tool catalog. To obtain a catalog, contact your local distributor or a service

center listed on the back cover of this operator’s manual.

12 Volt Power Plus Battery Packs

Fits MILWAUKEE Charger Cat. No. 48-59-0255.

1.3 Amp-Hours

Catalog No. 48-11-1960

2.4 Amp-Hours

Catalog No. 48-11-1970

Power Plus Chargers 120 Volt

For charging 12-18 Volt Power Plus Battery Packs.

1-Hour Vehicle Charger

Catalog No. 48-59-0186

Cat. No. 48-11-1960

1-Hour Universal Charger

Catalog No. 48-59-0255

Anti-Splintering Device

Catalog No. 48-08-0531

Vacuum Hose

Catalog No. 48-09-1040

The vacuum hose may be attached to the built in manifold to aid in removing sawdust from the cutting area. The transparent cover must be

attached for efficient vacuum action.

Shoe Cover

Catalog No. 48-08-0533

Combination Rip and Circle Guide

Catalog No. 49-22-4250

Cat. No. 48-59-0186

Cat. No. 48-59-0255

page 7

Page 8

RÈGLES DE SÉCURITÉ GÉNÉRALES POUR TOUS LES OUTILS À BATTERIE

AVERTISSEMENT!

VOUS DEVEZ LIRE ET COMPRENDRE TOUTES LES INSTRUCTIONS.

Le non-respect, même partiel, des instructions ci-après entraîne un risque de choc

électrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

AIRE DE TRAVAIL

1. Veillez à ce que l'aire de travail soit propre et bien éclairée. Le

désordre et le manque de lumière favorisent les accidents.

2. N'utilisez pas d'outils électriques dans une atmosphère explo-

sive, par exemple en présence de liquides, de gaz ou de

poussières inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les poussières ou les vapeurs.

3. Tenez à distance les curieux, les enfants et les visiteurs pendant

que vous travaillez avec un outil électrique. Ils pourraient vous

distraire et vous faire faire une fausse manoeuvre. Installez des

barrières ou des écrans protecteurs si nécessaires.

SÉCURITÉ ÉLECTRIQUE

4. Ne maltraitez pas le cordon. Ne transportez pas l'outil par son

cordon. N'exposez pas le cordon à la chaleur, à des huiles, à

des arêtes vives ou à des pièces en mouvement. Remplacez

immédiatement un cordon endommagé. Un cordon endommagé

peut constituer un risque d'incendie.

5. Un outil à bloc-batterie amovible ou à batterie intégrée ne doit

être rechargé qu'avec le chargeur prévu pour la batterie. Un

chargeur qui convient à tel type de batterie peut présenter un risque

d'incendie avec tel autre type de batterie.

6. N'utilisez un outil qu'avec un bloc-batterie conçu spécifiquement

pour lui. L'emploi d'un autre bloc-batterie peut créer un risque

d'incendie.

SÉCURITÉ DES PERSONNES

7. Restez alerte, concentrez-vous sur votre travail et faites preuve

de jugement. N'utilisez pas un outil électrique si vous êtes fatigué

ou sous l'influence de drogues, d'alcool ou de médicaments. Un

instant d'inattention suffit pour entraîner des blessures graves.

8. Habillez-vous convenablement. Ne portez ni vêtements flottants

ni bijoux. Confinez les cheveux longs. N'approchez jamais les

cheveux, les vêtements ou les gants des pièces en mouvement.

Des vêtements flottants, des bijoux ou des cheveux longs risquent

d'être happés par des pièces en mouvement.

9. Méfiez-vous d'un démarrage accidentel. Avant d'insérer un

bloc-batterie, assurez-vous que l'interrupteur de l'outil est sur

ARRÊT. Le fait de transporter un outil avec le doigt sur la détente ou

d'insérer un bloc-batterie alors que l'interrupteur est en position

MARCHE peut mener tout droit à un accident.

10. Enlevez les clés de réglage ou de serrage avant de démarrer

l'outil. Une clé laissée dans une pièce tournante de l'outil peut

provoquer des blessures.

11. Ne vous penchez pas trop en avant. Maintenez un bon appui et

restez en équilibre en tout temps. Un bonne stabilité vous permet

de mieux réagir à une situation inattendue.

12. Utilisez des accessoires de sécurité. Portez toujours des lunettes

ou une visière. Selon les conditions, portez aussi un masque

antipoussière, des bottes de sécurité antidérapantes, un casque

protecteur et/ou un appareil antibruit.

13. Immobilisez le matériau sur une surface stable au moyen

debrides ou de toute autre façon adéquate. Le fait de tenir la pièce

avec la main ou contre votre corps offre une stabilité insuffisante et

peut amener un dérapage de l'outil.

UTILISATION ET ENTRETIEN DES OUTILS

14. Ne forcez pas l'outil. Utilisez l'outil approprié à la tâche. L'outil

correct fonctionne mieux et de façon plus sécuritaire. Respectez aussi

la vitesse de travail qui lui est propre.

15. N'utilisez pas un outil si son interrupteur est bloqué. Un outil que

vous ne pouvez pas commander par son interrupteur est dangereux

et doit être réparé.

16. Retirez le bloc-batterie ou mettez l'interrupteur sur ARRÊT ou

en position verrouillée avant d'effectuer un réglage, de changer

d'accessoire ou de ranger l'outil. De telles mesures préventives

réduisent le risque de démarrage accidentel de l'outil.

17. Rangez les outils hors de la portée des enfants et d'autres

personnes inexpérimentées. Les outils sont dangereux dans les

mains d'utilisateurs novices.

18. Lorsque le bloc-batterie n'est pas en service, tenez-le à l'écart

d'autres objets métalliques (trombones, pièces de monnaie, clés,

clous, vis, etc.) susceptibles d'établir un contact électrique entre les deux bornes. La mise en court-circuit des bornes de la batterie

peut produire des étincelles et constitue un risque de brûlures ou

d'incendie.

19. Prenez soin de bien entretenir les outils. Les outils de coupe

doivent être toujours bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger.

20. Soyez attentif à tout désalignement ou coincement des pièces

en mouvement, à tout bris ou à toute autre condition préjudiciable

au bon fonctionnement de l'outil. Si vous constatez qu'un outil

est endommagé, faites-le réparer avant de vous en servir. De

nombreux accidents sont causés par des outils en mauvais état. Fixezy une étiquette marquée « Hors d'usage » jusqu'à ce qu'il soit réparé.

21. N'utilisez que des accessoires que le fabricant recommande pour

votre modèle d'outil. Certains accessoires peuvent convenir à un

outil, mais être dangereux avec un autre.

RÉPARATION

22. La réparation des outils électriques doit être confiée à un

réparateur qualifié. L'entretien ou la réparation d'un outil électrique

par un amateur peut avoir des conséquences graves.

23. Pour la réparation d'un outil, n'employez que des pièces de

rechange d'origine. Suivez les directives données à la section «

Réparation » de ce manuel. L'emploi de pièces non autorisées ou

le non-respect des instructions d'entretien peut créer un risque de

choc électrique ou de blessures.

page 8

Page 9

RÈGLES DE SÉCURITÉ PARTICULIÈRE

1. Entretenez les étiquettes et marques du fabricant. Les indications qu'elles contiennent sont précieuses. Si elles deviennent illisibles ou se

détachent, faites-les remplacer gratuitement à un centre de service MILWAUKEE accrédité.

2. AVERTISSEMENT! La poussière dégagée par perçage, sciage et autres travaux de construction contient des substances chimiques reconnues

comme pouvant causer le cancer, des malformations congénitales ou d’autres troubles de reproduction. Voici quelques exemples de telles substances :

• Le plomb contenu dans la peinture au plomb.

• Le silice cristallin contenu dans la brique, le béton et divers produits de maçonnerie.

• L’arsenic et le chrome servant au traitement chimique du bois.

Les risques associés à l’exposition à ces substances varient, dépendant de la fréquence des travaux. Afin de minimiser l’exposition à ces sub-

stances chimiques, assurez-vous de travailler dans un endroit bien aéré et d’utiliser de l’equipement de sécurité tel un masque antipoussière

spécifiquement conçu pour la filtration de particules microscopiques.

Pictographie

Tension CD seul.

SPM

1. Levier de tension Quik-Lok

2. Chape de lame transparante

3. Lame

4. Semelle

5. Réglage du mouvement orbital

6. Échelle d'inclinaison de semelle

7. Clé hex

8. Collecteur de sciure

9. Batterie

10. Boutons dégagement

11. Interrupteur On/Off

Tours-minute á vide

Disposez correctement des

batteries au nickelcadmium

Underwriters

Laboratories, Inc.

DESCRIPTION FONCTIONNELLE

1

2

Spécifications

No de

Cat.

6267-20

Volts

CD

12

8

Tr/min.

à vide

1 700

10

911

7

3

4

5

6

DESCRIPTION

La MILWAUKEE scie sauteuse 12V à mouvement orbital peut couper une grande variété de matériaux y compris les bois, métaux et plastiques. Les

coupes peuvent être droites, en biseau ou en découpage. Les caractéristiques remarquables de cette scie sauteuse comprennent:

• Changement de lame rapide sans l'aide d'outils, grâce au système de changement de lame Quik- Lok®.

• Le mouvement orbital réglable de la lame assure une coupe plus rapide car la lame mord dans le matériau en remontant seulement. Cette

technique est particulièrement utile pour dégrossir les planches de bois.

• Semelle inclinable à 45° de duex côtés pour les coupes en biseau.

• Collecteur intégré pour l'installation d'un aspirateur de poussière (Boyau facultatif).

• Chape de lame transparente facilitant l'evacuation de sciure.

• Mécanisme antivibration assurant un roulement plus doux et plus silencieux.

page 9

Page 10

RECHARGE ET USAGE DE LA BATTERIE

AVERTISSEMENT!

Seules les batteries MILWAUKEE Power Plus de

12V. 14,4V et 18V doivent être rechargées avec le

chargeur de batterie Power Plus. D’autres types

de batteries pourraient exploser et causer des

dommages et des blessures corporelles.

Rechargez la batterie avant de vous servir de l’outil la première fois, ou

lorsque l’outil n’offre plus la puissance et le couple nécessaire au travail

à accomplir. Ne laissez jamais la batterie s’épuiser complètement. Les

batteries neuves n’atteignent leur puissance maximale qu’après 4 ou 5

cycles de recharge-décharge. La durée normale de recharge est variable

selon le type de chargeur utilisé. Elle peut aussi varier selon le voltage à

la source et la recharge nécessaire. Par exemple, si la batterie n’a pas

besoin d’une recharge complète, la durée de recharge sera moindre.

VEUILLEZ CONSULTER LA FEUILLE D'INSTRUCTIONS QUI

ACCOMPAGNE LE CHARGEUR POUR CONNAÎTRE EN DÉTAIL LA

TECHNIQUE DE RECHARGE.

Les batteries sont affectées par la température. La vôtre aura un meilleur

rendement et durera plus longtemps si la recharge est effectuée à une

température se situant entre 15°-27°C (60°F à 80°F). Ne procédez pas à

une recharge lorsque la température est inférieure à 5°C (40°F) ou

supérieure à 40°C (105°F), car à ces températures, la recharge sera moins

efficace. Voir « Maintenance ».

Retrait de la batterie de l’outil (Fig. 1)

Appuyez sur les boutons de dégagement et retirez la batterie.

Fig. 1

Introduction de la batterie dans l’outil (Fig. 2)

Introduisez la batterie par l’arrière en appuyant sur les boutons de

dégagement et en la glissant dans le corps de l’outil pour qu’elle

s’enclenche.

Fig. 2

MONTAGE DE L'OUTIL

AVERTISSEMENT!

Il faut toujours verrouiller la détente de l’outil

avant de changer ou d’enlever les accessoires.

L’emploi d’accessoires autres que ceux qui sont

expressément recommandés pour cet outil peut

comporter des risques.

Insertion de la lame de scie (Fig. 3)

1. Débranchez l’outil avant d’y insérer la lame ou de la remplacer.

2. Cet outil n’emploie que des lames de scie sauteuse à tenon en T.

3. Pour installer une lame, poussez le levier de tension Quik-Lok aussi

loin que possible et maintenez-le en place.

4. Insérez la lame dans la rainure du galet d’appui et poussez-la

fermement dans le piston aussi loin que possible (Fig. 3). Le talon de

la lame doit être inséré dans le piston.

Fig. 3

5. Relâchez le levier de tension Quik-Lok et la lame sera maintenue en

place automatiquement.

6. Assurez-vous que la lame soit bien fixée. La rainure dans le piston

devra être à angle droit de la lame.

NOTE: Avant d’utiliser le lever de tension Quik-Lok, placez l’interrupteur

à la position OFF.

page 10

Rainure

Lame

Réglage de la semelle (Fig. 4)

Fig. 4

La semelle peut être inclinée jusqu’à 45° d’un côté comme de l’autre.

Elle peut aussi être poussée vers l’avant ou l’arrière.

1. Choix de l’inclinaison pour les coupes à angle et les biseaux,

desserrez la vis de blocage de la semelle, poussez la base légèrement

vers l’arrière jusqu’à ce que les crans se dégagent. Inclinez la semelle

à l’angle de réglage choisi de 15°, 30° ou 45° indiqué à l’échelle.

Replacez la base dans ses crans et serrez la vis de blocage. Si des

angles différents de ceux qui figurent à l’échelle sont requis, inclinez

la semelle à l’angle requis et serrez la vis de blocage sans replacer

la base dans ses crans.

NOTE: Si un angle très précis est requis, il est recommandé

d’effectuer une coupe d’essai et de revoir le réglage, si nécessaire.

2. Déplacement de la semelle vers l’arrière les coupes en plongée

ou en coin, desserrez la vis de blocage de la semelle et poussez la

semelle complètement vers l’arrière. La vis pourra alors s’engager

dans une rainure pour maintenir la semelle à la postion 0°.

Page 11

MANIEMENT

AVERTISSEMENT!

Pour minimiser les risques de blessures,

portez des lunettes à coques latérales.

Démarrage et arrêt de l’outil

1. Pour mettre l’outil en marche, poussez l’interrupteur « ON/OFF » en

avant pour que la lettre I apparaisse.

2. Pour arrêter l’outil, poussez l’interrupteur « ON/OFF » vers l’arrière

pour que la lettre O apparaisse.

Réglage du mouvement orbital

L’ampleur du mouvement orbital peut être réglée à l’aide du levier sélecteur.

En général, un mouvement orbital ample (III) est recommandé pour les

matériaux mous, tandis qu’un mouvement orbital restreint (I) convient

aux matériaux durs. Si une coupe lisse est requise, il faut employei'le

réglage (0) à mouvement orbital restreint. Les réglages du mouvement

orbital recommandables pour divers matériaux sont présentés ci-dessous.

Le mouvement orbital idéal devrait être déterminé par l’usager selon les

tâches spécifiques.

APPLICATIONS

Techniques de coupe spéciales

1. Coupes rectilignes – Pour réussir des coupes parfaitement droites,

fixez une languette de bois sur le matériau pour vous en servir comme

guide ou utilisez un guide-coupe parallèle (en accessoire).

2. Coupe en biseau – Ajustez la semelle à l’angle voulu (Voir “Réglage

de la semelle”).

3. Coupe près des obstacles – Poussez la semelle vers l’arrière afin

d’augmenter la maniabilité de la lame.

4. Coupe de tôle – Le métal en feuille peut vibrer durant la coupe. Pour

minimiser la vibration, fixez la feuille de tôle sur une base en bois.

Bois ........................ III

Métal ....................... 0

Plastique ................ I

Coupe lisse ............ 0

NOTE: Le mouvement orbital peut être réglé même si l’outil est en marche.

Coupe généralités

1. Réglez la fréquence des cycles et le mouvement orbital selon le

matériau à couper.

2. Placez la partie avant de la semelle sur le matériau et mettez l’outil

en marche.

3. Tenez l’outil fermement sur le matériau et guidez-le sur la ligne de

coupe. Ne forcez pas trop l’outil dans le matériau, une pression légère

sur la lame assurera la vitesse de coupe optimale.

Fig. 5

Coupe en plongée (Fig. 5)

Les scies sauteuses MILWAUKEE 12V sont idéales pour faire des coupes

en plongée dans les matériaux mous, sans qu’il soit nécessaire de percer

un trou-guide. Cependant, pour les matériaux durs, il est nécessaire de

percer un trou-guide d’un diamètre légèrement supérieur à la largeur de

la lame.

1. Pour réussir une coupe en plongée, poussez la semelle de la scie

complètement vers l’arrière.

2. Réglez le mouvement orbital à la position 0.

3. Assurez-vous que rien ne pourra être endommagé par la lame sous

la surface du matériau.

4. Avant de mettre l’outil en marche, posez fermement le bord avant de

la semelle de la scie sur le matériau (a).

5. Alignez la lame sur la ligne de coupe mais maintenez-la au-dessus

du matériau.

6. En vous servant du bord avant de la semelle comme appui, pressez

sur la détente et abaissez graduellement la lame dans le matériau

(b).

7. Lorsque la semelle sera rendue fermement à plat sur le matériau,

continuez la coupe de façon normale (c).

a

b

c

page 11

Page 12

MAINTENANCE

AVERTISSEMENT!

Pour minimiser les risques de blessures

corporelles, débranchez le chargeur et retirez la

batterie du chargeur ou de l’outil avant d’y

effectuer des travaux d’entretien. Ne démontez

jamais l’outil, la batterie ou le chargeur. Pour

toute réparation, consultez un centre de service

MILWAUKEE accrédité.

Entretien de l’outil

Gardez l’outil, la batterie et le chargeur en bon état en adoptant un

programme d’entretien ponctuel. Après une période de six mois à un an,

selon l’utilisation, renvoyez l’outil, la batterie et le chargeur à un centre de

service MILWAUKEE accrédité pour les services suivants:

• Lubrification

• Inspection et remplacement des balais

• Inspection et nettoyage de la mécanique (engrenages, pivots,

coussinets, boîtier etc.)

• Inspection électrique (batterie, chargeur, moteur)

• Vérification du fonctionnement électromécanique

Si l’outil ne démarre pas ou ne fonctionne pas à pleine puissance alors

qu’il est branché sur une batterie complètement chargée, nettoyez les

points de contact entre la batterie et l’outil. Si l’outil ne fonctionne toujours

pas correctement, renvoyez l’outil, le chargeur et la batterie à un centre

de service MILWAUKEE accrédité, afin qu’on en effectue la réparation.

Entretien de la batterie

Les batteries MILWAUKEE sont conçues pour durer plusieurs années et/

ou des milliers de cycles lorsqu’elles sont bien entretenues et utilisées

selon les instructions de ce manuel.

Une batterie qui est rangée durant six mois perdra sa charge si elle n’est

pas utilisée. Les batteries se déchargent selon un taux d’environ 1% par

jour. Rechargez la batterie tous les six mois, même si elle n’est pas utilisée,

cela prolongera sa durée. Ne maintenez pas la détente d’interrupteur à la

positon « ON » à l’aide d’un ruban adhésif et ne laissez pas l’outil sans

surveillance car cela pourrait décharger la batterie0 à un point tel

qu’il deviendra impossible de la recharger. Employez une batterie

MILWAUKEE aussi longtemps qu’elle fournira la puissance requise.

Rangez la batterie dans un endroit frais et sec. Ne la rangez pas dans un

endroit où la température pourrait excéder 50°C (120°F),dans un véhicule

ou une structure d’acier, l’été par exemple. Les températures élevées

provoquent la surchauffe de la batterie et en réduisent la durée. Si la

batterie est rangée pour une période de plusieurs mois, elle perdra

graduellement sa charge. Cependant, après plusieurs cycles de recharge

et de décharge en période d’utilisation normale, elle retrouvera sa charge

initiale. Avec le temps, les intervalles entre les recharges de la batterie

deviendront de plus en plus courts. Lorsque ces intervalles, devenus trop

courts, rendront l’outil inutilisable, il faudra remplacer la batterie.

Nettoyage

Débarrassez les évents du chargeur et de l’outil des débris et de la

poussière. Gardez les poignées de l’outil propres, à sec et exemptes

d’huile ou de graisse. Le nettoyage de l’outil, du chargeur et de la batterie

doit se faire avec un linge humide et un savon doux. Certains nettoyants

tels l’essence, la térébenthine, les diluants à laque ou à peinture, les

solvants chlorés, l’ammoniaque et les détergents d’usage domestique

qui en contiennent pourraient détériorer le plastique et l’isolation des

pièces. Ne laissez jamais de solvants inflammables ou combustibles

auprès de l’outil.

AVERTISSEMENT!

Pour minimiser les risques de blessures ou de

dommages à l'outil, n'immergez jamais l'outil,

la batterie ou le chargeur et ne laissez pas de

liquide s'y infiltrer.

AVERTISSEMENT!

Pour minimiser les risques d’explosion ne

faites jamais brûler une batterie, même si elle

est avariée, âgée ou complètement épuisée.

Sceaux de recyclage pour pile RBRC

Les sceaux de recyclage pour piles RBRC™ (voir la « Pictographie »)

sur la pile de votre outil, indiquent que MILWAUKEE a pris des dispositions avec Rechargeable Battery Recycling Corporation (RBRC) pour le

recyclage de ce bloc de piles. Lorsque la vie utile de ce bloc de pile est

épuisée, retournez-le à une succursale ou à un centre de service

MILWAUKEE, ou au détaillant participant le plus près de chez vous. Pour

obtenir plus d’informations, visitez le site Web RBRC au www.rbrc.org.

Disposition des batteries au nickel-cadmium

Les batteries au nickel-cadmium doivent être traitées comme les déchets

dangereux. On doit en disposer conformément aux règlements fédéraux,

provinciaux et locaux.

Réparations

Pour les réparations, retournez outil, batterie et chargeur au centre-service MILWAUKEE le plus près selon la liste apparaissant à la dernière

page de ce manuel.

Garantie des batteries

Les batteries pour outils sans cordon sont garanties pour un an à compter

de la date d’achat.

GARANTIE

Chaque produit MILWAUKEE porte la garantie d’être exempt de défauts

de matériaux ou de fabrication. MILWAUKEE réparera ou remplacera

tout produit porteur de défauts de matériaux ou de fabrication.

Limites : La présente garantie ne s’applique pas dans les cas suivants :

(1) Des réparations ont été effectuées ou tentées par d’autres personnes

que des techniciens mandatés par MILWAUKEE ou ses centres de service accrédités. (2) Les réparations sont rendues nécessaires par l’usure

normale de l’outil. (3) L’outil a été employé abusivement. (4) L’outil a

servi à un usage anormal. (5) L’outil a reçu un entretien inadéquat.

(6) L’outil a été utilisé après une défaillance partielle. (7) L’outil a été

modifié ou employé avec un accessoire incompatible.

Les batteries sont garanties pour un (1) an à compter de la date d’achat.

S’il survient un trouble, retournez l’outil au complet port payé à une succursale

de service MILWAUKEE ou un centre de service MILWAUKEE accrédité. Si

l’examen de l’outil démontre que le trouble est dû à un défaut de fabrication

ou de matériaux, les réparations seront effectuées gratuitement et l’outil vous

sera retourné aux frais de MILWAUKEE. Nulle autre forme de garantie, écrite

ou verbale, n’est autorisée.

LES RÉPARATIONS OU REMPLACEMENTS DÉCRITS CI-DESSUS

SONT EXCLUSIFS. MILWAUKEE NE SAURAIT, EN AUCUN CAS, ÊTRE

TENUE RESPONSABLE DES DOMMAGES INCIDENTS, SPÉCIAUX OU

CONSÉCUTIFS, Y COMPRIS LA PERTE DE REVENUS.

LA PRÉSENTE GARANTIE ANNULE ET REMPLACE TOUTE AUTRE

GARANTIE, EXPRESSE OU IMPLICITE, DE QUALITÉ MARCHANDE

OU D?APTITUDE À UN USAGE OU À UN BUT PARTICULIER.

La présente garantie vous confère des droits juridiques spécifiques.

Vous pouvez avoir d’autres droits variant d’un état à l’autre. Dans

ces états qui ne permettent pas l’exclusion de garanties implicites

ou de limites de dommages incidents ou consécutifs, il se peut que

les exclusions ou limites de la présente garantie ne soient pas

applicables.

page 12

Page 13

ACCESSOIRES

AVERTISSEMENT!

Il faut toujours retirer la batterie et verrouiller la

détente de l’outil avant de changer ou d’enlever

les accessoires. L’emploi d’accessoires autres

que ceux qui sont expressément recommandés

pour cet outil peut comporter des risques.

Consultez la liste complète des accessoires dans le catalogue d’outils électriques MILWAUKEE. Pour vous procurer le catalogue

MILWAUKEE, adressez-vous à votre distributeur local ou à un centre-service MILWAUKEE accrédité. Reportez-vous à la dernière page de ce manuel

pour connaître l’adresse du centre-service le plus près.

Batterie Power Plus 12V

Convient aux chargeurs MILWAUKEE No de catalogue 48-59-0255.

1,3 Amp - Heure

No de catalogue 48-11-1960

2,4 Amp - Heure

No de catalogue 48-11-1970

Chargeur Power Plus 120V

Pour la recharge des batteries Power Plus de 12, 14,4 et 18 V.

Chargeur-automobile 1 heure

No de catalogue 48-59-0186

Chargeur universel 1 heure

No de catalogue 48-59-0255

Dispositif anti-éclats

No de Cat. 48-08-0531

Boyau aspirateur

No de Cat. 48-09-1040

Le boyau aspirateur peut etre raccordé au collecteur de sciure pour

favcoriser l'eevacuation de la scuire de la ligne de coupe. La chape

transparente doit etre installée pour assurer une bonne succion.

Semelle de chape

No De Cat. 48-08-0533

Cat. No. 48-11-1960

Cat. No. 48-59-0186

Guide-coupe parallèle ou circulaire

No de Cat. 49-22-4250

Cat. No. 48-59-0255

page 13

Page 14

INSTRUCCIONES GENERALES DE SEGURIDAD - PARA LAS HERRAMIENTAS A BATERIAS

¡ADVERTENCIA!

LEA Y ENTIENDA TODAS LAS INSTRUCCIONES.

Se debe seguir todas las instrucciones a continuación para evitar una

descarga eléctrica, incendio y/o lesiones graves.

GUARDE ESTAS INSTRUCCIONES

AREA DE TRABAJO

1. Mantenga el área de trabajo limpia e iluminada. Las mesas de

trabajo desordenadas y las áreas con poca iluminación propician los

accidentes.

2. No opere las herramientas con motor en ambientes explosivos,

tales como los ambientes con líquidos, gases o polvo

inflamables. Las herramientas con motor producen chispas que

pueden inflamar el polvo o los gases.

3. Mantenga a las personas alejadas mientras esté utilizando una

herramienta con motor. Las distracciones pueden causar la pérdida

del control de la herramienta. Proteja a las demás personas en el

área de trabajo contra escombros, tales como astillas y chispas.

Instale barreras si se necesitan.

SEGURIDAD ELECTRICA

4. No utilice los cordones de manera inadecuada. Nunca transporte

la herramienta por el cordón. Mantenga el cordón alejado del

calor, aceite, bordes afilados o partes en movimiento. Sustituya

los cordones dañados inmediatemente. Los cordones dañados

pueden causar un incendio.

5. Una herramienta con baterías incorporadas o con una batería

separada debe ser recargada solamente con el cargador

específico para este tipo de batería. Un cargador que es apropiado

para un tipo de batería puede producir riesgo de incendio si se usa

con otra batería.

6. Use la herramienta a batería solamente con la batería

especificamente designada para ella. El uso de cualquier otro tipo

de batería puede producir riesgo de incendio.

SEGURIDAD PERSONAL

7. Ponga mucha atención, fíjese en lo que hace y use su sentido

común al operar una herramienta con motor. No use la

herramienta cuando esté cansado o bajo la influencia del alcohol, drogas o medicamentos. Descuidarse por sólo un momento

cuando se esté utilizando la herramienta, puede resultar en lesiones

graves.

8. Vístase apropiadamente. No lleve ropa o joyas sueltas. Mantenga

el pelo largo recogido. Mantenga el cabello, la ropa y los guantes

alejados de las partes movibles. Las ropas sueltas, las joyas, o el

cabello largo pueden engancharse en las partes movibles.

9. Evite el encendido accidental de la herramienta. Asegúrese que

el gatillo esté bloqueado o apagado antes de insertar la batería.

Llevar la herramienta con el dedo sobre el gatillo o insertar la batería

en una herramienta con el gatillo encendido, aumenta el riesgo de

accidentes.

10. Saque las llaves antes de encender la herramienta. Una llave

sujeta a una parte en movimiento puede causar lesiones.

11. No se aleje demasiado del material de trabajo. Siempre mantenga

el equilibrio. El equilibrio correcto permite el mejor control de la

herramienta durante situaciones inesperadas.

12. Utilice el equipo de seguridad. Siempre utilice la protección para

los ojos. Se debe usar una máscara contra el polvo, zapatos de

seguridad antidelizantes, casco y protector para los oidos, cuando

las condiciones así lo requieran.

EL USO Y MANTENIMIENTO DE LA HERRAMIENTA

13. Utilice abrazaderas u otra manera práctica para sujetar y apoyar

el material en una plataforma estable. Tener el material en la mano

o contra el cuerpo es inestable y puede causar la pérdida del control.

14. No fuerce la herramienta. Utilice la herramienta apropiada para

la aplicación. La herramienta realizará el trabajo de manera más

eficaz y segura, si la opera a la velocidad apropiada.

15. Si el gatillo no enciende o apaga la herramienta, no utilice la

herramienta. Una herramienta que no se puede controlar con el

gatillo es peligrosa y debe ser reparada.

16. Desconecte la batería de la herramienta o coloque el gatillo en

la posición de bloqueo o apagado antes de realizar un ajuste,

cambiar accesorios o almacenar la herramienta. Tales medidas

preventivas de seguridad reducen el riesgo de encender la

herramienta accidentalmente.

17. Almacene las herramientas que no se estén usando fuera del

alcance de los niños y de personas que no estén capacitadas.

Es peligroso permitir a los usuarios utilizar las herramientas, si no

están capacitados previamente.

18. Cuando la herramienta no esté en uso, manténgala alejada de

otros objetos metálicos tales como clips, moneda, llaves, clavos,

tornillos u otro objetos pequeños metálicos que pueden realizar

una conexión desde una terminal a otro. Hacer un cortocircuito

de las terminales de la batería, puede producir chispas, quemaduras

o un incendio.

19. Mantenga las herramientas en buenas condiciones. Las

herramientas cortadoras deben mantenerse afiladas y limpias.

Esto reduce el riesgo de que la herramienta se atasque y facilita el

control de la misma.

20. Verique que las partes en movimiento estén alineadas y no estén

atascadas. También debe verificarse que las partes no estén

rotas o tengan cualquier otra condición que pueda afectar el

funcionamiento de la herramienta. Si está dañada, se debe

reparar la herramienta antes de utilizarla. Muchos accidentes se

deben al mantenimiento incorrecto de la herramienta. No utilice una

herramienta dañada. Colóquele una etiqueta que diga “No Debe

Usarse” hasta que sea reparada.

21. Utilice solamente los accesorios recomendados por el fabricante

para ese modelo. Los accesorios que son apropiados para una

herramienta pueden aumentar el riesgo de lesiones cuando se usan

con otra herramienta.

SERVICIO

22. El servicio de mantenimiento debe ser realizado solamente por

personal técnico debidamente capacitado. El servicio o

mantenimiento realizado por personal no calificado puede aumentar

el riesgo de lesiones.

23. Cuando realice el servicio de mantenimiento, utilice solamente

repuestos idénticos. Siga las instrucciones en la sección de

mantenimiento de este manual. El uso de partes no autorizadas o

el incumplimiento de las instrucciones de mantenimiento puede

aumentar el riesgo de descarga eléctrica o lesiones.

page 14

Page 15

REGLAS ESPECIFICAS DE SEGURIDAD - LLAVE DE IMPACTO

1. Guarde las etiquetas y placas de especificaciones. Estas tienen información importante. Si son ilegibles o si no se pueden encontrar, póngase

en contacto con un centro de servicio de MILWAUKEE para una refacción gratis.

2. ¡ADVERTENCIA! Algunas partículas de polvo resultantes del lijado mecánico, aserrado, esmerilado, taladrado y otras actividades relacionadas a

la construcción, contienen sustancias químicas que se saben ocasionan cáncer, defectos congénitos u otros daños al aparato reproductivo.

A continuación se citan algunos ejemplos de tales sustancias químicas:

• plomo proveniente de pinturas con base de plomo

• sílice cristalino proveniente de ladrillos, cemento y otros productos de albañilería y

• arsénico y cromo provenientes de madera químicamente tratada.

El riesgo que usted sufre debido a la exposición varía dependiendo de la frecuencia con la que usted realiza estas tareas. Para reducir la

exposición a estas sustancias químicas: trabaje en un área bien ventilada, y utilice equipo de seguridad aprobado como, por ejemplo, máscaras

contra el polvo que hayan sido específicamente diseñadas para filtrar partículas microscópicas.

Simbología

Volts corriente directa

SPM

1. Palanca tensora Quik-Lok

2. Cubierta transparente

3. Sequeta

4. Zapata

5. Acción orbital palanca selectora

6. Selector de carrera pendular

7. Llave hexagonal

8. Canal de aspiración

9. Batería

10. Seguro de botón

11. Interruptor de encendido/apagado

Revoluciones por minuto

sin carga

Baterías de níquel cadmio

correctamente recicladas

Underwriters

Laboratories, Inc.

Especificaciones

Cat.

No.

6267-20

Volts

cd

12

rpm

1 700

DESCRIPCIÓN FUNCIONAL

10

911

1

8

2

7

3

4

5

6

DESCRIPIÓN

La MILWAUKEE Sierra Caladora con accoión orbital de 12 volt de peude cortar una gran variedad de materiales incluyendo metal, madera y plásticos.

Los cortes pueden ser en linea recta, calados, curvos o resaques interiores. Algunas características notables de esta sierra caladora son:

• Con el sistema Quik-Lok®, las seguetas se cambian rápidamente sin necesidad de usar herramientas.

• La Acción Orbital Ajustable de la carrera de la segueta permite cortar mas rápidamente al presionar la segueta contra el material cortar, únicamente

cuando la segueta va hacia arriba en su carrera. Esto es particularmente efectivo cuando se trozan tramos de madera gruesos.

• La zapata ajustable puede moverse hasta 45° en cualquier dirección para cortes en ángulo.

• Conector interconstruído para una manguera de aspiradora, con el objeto de asistirse en la recolección del polvo o aserrín (la manguera es

opcional).

• La cubierta transparente de la segueta mejore la extracción del polvo.

• Su mecanismo anti-vibratorio permite una operación mas suave y silenciosa.

page 15

Page 16

USO Y CARGA DE LA BATERIA

¡ADVERTENCIA!

Cargue solamente las baterías

MILWAUKEE de Power Plus de 12 V, 14,4 V

y 18 V en cargadores de Power Plus.

Otros tipos de baterías pueden explotar y

causar lesiones personales y daños.

Cargue su batería antes de usar su herramienta por primera vez o cuando

la misma no opera ya con el poder y torque necesarios para la aplicación.

La capacidad total de carga de batería es alcanzada sólo después de 45 cargas. Nunca permita que la batería se descargue por completo. El

tiempo estándar de cargado variará dependiendo del tipo de cargador

que utilice. El tiempo estándar de cargado variará dependiendo del voltaje

en el tomacorriente y de la carga que necesita la batería. Por ejemplo, si

su batería no requiere una carga completa, el tiempo para cargarla será

menor.

PARA CONOCER LAS INSTRUCCIONES ESPECIFICAS DE CARGADO,

POR FAVOR LEA LA HOJA DE INSTRUCCIONES QUE VIENE CON SU

CARGADOR.

Las baterías pueden ser afectadas por la temperatura. Su batería se

desempeñará mejor y tendrá una vida útil más larga si se carga en

ambientes con temperaturas entre 15°C - 27°C (60°F à 80°F). No la

cargue en ambientes con temperaturas por debajo de 5°C (40°F) o por

encima de 40°C (105°F). Si lo hace en estas condiciones, reducirá la

capacidad de la batería. Vea “Mantenimiento”.

Como se quita la batería de la herramienta (Fig. 1)

Presione el botón de liberación y saque la batería.

Fig. 1

Cómo se retira la batería de la herramienta (Fig. 2)

Coloque la batería desde la parte posterior, presionando el botón

de liberación y deslizando la batería en el cuerpo de la herramienta.

Coloque la batería hasta que la grapa se accione.

Fig. 2

ENSAMBLAJE DE LA HERRAMIENTA

¡ADVERTENCIA!

Cuando use herramientas eléctricas es necesario siempre

seguir ciertas precauciones básicas de seguridad con el objeto de

reducir el riesgo de descargas eléctricas o lesiones al operario.

Colocación de la segueta (Fig. 3)

1. Desconecte la herramienta antes de insertar o cambiar la segueta.

2. Esta herramienta usa sólo seguetas con zanco tipo “bayoneta”.

3. Para instalar la segueta, empuje la palanca tensora Quik-Lok tanto

como pueda y sosténgala en posición.

4. Coloque la segueta dentro de la canal en el rodillo de soporte y

empújela firmemente dentro del sujetador tanto como sea posible

(Fig. 3). La entrada de la segueta debe quedar en el sujetador.

Muesca

Fig. 3

Segueta

5. Libere la palanca tensora Quik-Lok y la segueta quedará

automáticamente sujeta.

6. Verifique que la segueta esté sujeta firmemente; la muesca en el

sujetador estará en un ángulo con relación a la segueta.

NOTA: Accione la palanca tensora Quik-Lok solamente cuando la

herramienta esté apagacfa.

page 16

Ajustando la zapata (Fig. 4)

Fig. 4

La zapata puede girarse hasta 45° en ambas direcciones y además puede

moverse hacia adelante o atrás.

1. Al fijar la zapata para realizar cortes en ángulo, afloje el tornillo que

sostiene la zapata, jale ligeramente la base hacia adelante, hasta

que las muescas de retención ya no actuen. Coloque la zapata en el

ángulo prefijado deseado (15°, 30° o 45°) como lo marca la

graduación. Empuje hacia atrás, hacia las muescas de retención

para que actuen, y apriete el tornillo. Si se desean ángulos diferentes

a los prefijados, coloque dicho ángulo y apriete el tornillo sin que

actuen las muescas de retención.

NOTA: Si se requieren ángulos muy exactos, se recomienda hacer

cortes de prueba y hacer los ajustes necesarios.

2. Para mover la zapata hacia atrás para cortes inieriores, resaques o

cortes en las esquinas, afloje el tornillo que sujeta la zapata y corra

la zapata hasta atrás. El tornillo entrará en una muesca y mantendrá

la zapata a 0°.

Page 17

OPERACION

¡ADVERTENCIA!

Para reducir el riesgo de lesiones, use

siempre lentes de seguridad o anteojos con

protectores laterales.

Encendido y apagado de la herramienta

1. Para encender la herramienta, empuje el interruptor encendido/

apagado hacia adelante hasta que “I” esté visible.

2. Para detener la herramienta, empuje el interruptor encendido/

apagado hacia atras hasta que “0” esté visible.

Ajustando la acción orbital

La cantidad de acción orbital puede ser ajustada con la palanca selectora.

En general, una acción orbital muy grande (III) debe usarse en materiales

suaves y una acción orbital pequeña (I) debe usarse con materiales duros.

Cuando se requiera de un corte suave, no deben usarse órbitas (0). A

continuación se ilustran diferentes acciones, orbitales con base en

diferentes composiciones del material a cortar. La acción orbital óptima

debe ser determinada por el usuario con base en los requerimientos

especiales del corte.

APPLICACIONES

Técnicas especiales de corte

1. Cortes rectos – Para obtener un corte perfectamente recto, fije un

tramo de madera como guía, a todo lo largo de material a cortar o

use la guía paralela (accesorio).

2. Cortes en ángulo – Ajuste la zapata al ángulo correcto (Ver

“Ajustando la zapata”).

3. Cortes cerca de obstáculos – Mueva la zapata hacia atrás para

tener mayor área de libramiento de corte.

4. Cortando hojas de metal – Las hojas de metal pueden vibrar a la

hora de realizar el corte. Para minimizar estas vibraciones, sujete

con pinzas, la hoja de metal a una base de madera.

Madera ................ III

Metal .................... 0

Plástico ................I

Corte suave ......... 0

NOTA: La acción orbital puede ser ajustada con la herramienta en

operación o detenida.

Cortando general

1. Seleccione las carreras y la acción orbital, tomando en cuenta el

material que se va a cortar.

2. Coloque la herramienta con la parte frontal de la zapata sobre el

material y accione el interruptor.

3. Sujete firmemente la herramienta contra el material y guíela a través

de la linea de corte deseada. No la “alimente” muy fuertemente contra el material, una ligera presión en la segueta hará que se logre la

velocidad óptima de corte.

Fig. 5

Cortes interiores o resaques (Fig. 5)

Las sierra caladoras MILWAUKEE de 12 volt están bien adaptadas para

realizar cortes inclinación en materiales suaves sin un agujero preperforado. Los materiales más duros requieren de esta perforación guía

con un diámetro ligeramente mayor que el ancho de la segueta.

1. Para realizar un corte interior, corra la zapata totalmente hacia atrás.

2. Coloque en 0, el selector de acción orbital.

3. Asegúrese que no haya nada que se pueda dañar debajo de la

superficie de corte.

4. Antes de accionar el interruptor, coloque firmemente la parte frontal

de Ia zapata sobre el material a cortar (a).

5. Alinee la segueta con la linea de corte por realizar.

6. Usando la parte frontal de la zapata como pivote, accione la

herramienta y baje gradualmente la segueta contra el material a cortar

(b).

7. Una vez que la zapata esté apoyada firmemente contra la superficie

del material, realice el corte en forma normal (c).

a

b

c

page 17

Page 18

MANTENIMIENTO

¡ADVERTENCIA!

Para reducir el riesgo de una lesión, desconecte

siempre la herramienta antes de darle cualquier

mantenimiento. Nunca desarme la herramienta

ni trate de hacer modificaciones en el sistema

eléctrico de la misma. Acuda siempre a un

Centro de Servicio MILWAUKEE para TODAS las

reparaciones.

Mantenimiento de la herramienta

Adopte un programa regular de mantenimiento y mantenga su

herramienta, batería y cargador en buenas condiciones. Después de 6

meses a un año, dependiendo del uso dado, envíe su herramienta, batería y

cargador al Centro de Servicio MILWAUKEE más cercano para que le hagan:

• Lubricación

• Inspección y cambio de carbones

• Inspección mecánica y limpieza (engranes, flechas, baleros,

carcaza, etc.)

• Inspección eléctrica (batería, cargador, motor)

• Prueba para asegurar una adecuada operación mecánica

y eléctrica

Si la herramienta no arranca u opera a toda su potencia con una batería

completamente cargada, limpie los contactos de la batería. Si aún así la

herramienta no trabaja correctamente, regrésela, junto con el cargador y

la batería, a un centro de servicio MILWAUKEE para que sea reparada.

Mantenimiento de las baterías

Las baterías MILWAUKEE operarán por muchos años y / o cientos de

ciclos, cuando son usadas y mantenidas de acuerdo a las instrucciones.

Una batería que esté guardada, sin usarse, por espacio de seis meses,

se descargará. La baterías se descargan a razón de 1% por día. Con el

objeto de maximizar la vida de la batería, cárguela cada seis meses aun

si no la usa. No trabe el interruptor en la posición “ON” y deje la herramienta

desatendida ya que se podría descargar la batería a un grado tal que no

podría volver a cargarse nuevamente. Use una batería MILWAUKEE hasta

que ya no trabaje con la potencia y el torque necesarios para la aplicación

requerida.

Almacene su batería en un lugar seco y fresco. No la almacene donde

las temperaturas puedan exceder 50°C (120°F), tales como dentro de un

vehículo o un edificio metálico durante el verano. Las altas temperaturas

sobrecalentarán la batería, reduciendo la vida útil de la misma. Si se

guarda por varios meses, la batería perderá su carga en forma gradual.

Se llevará entre uno y tres ciclos de carga y descarga con un uso normal,

para que se restablezca la capacidad total de la batería. Durante la vida

útil de la batería, el tiempo operativo de la misma se va reduciendo. Si

este tiempo operativo se vuelve demasiado corto luego de una carga

adecuada, significa que la vida útil de la batería ha finalizado y deberá

cambiarse por una nueva.

Limpieza

Limpie el polvo y suciedad de las ventilas del cargador y la herramienta.

Mantenga los mangos y empuñaduras limpios, secos y libres de aceite o

grasa. Use sólo jabón neutro y un trapo húmedo para limpiar la

herramienta, batería y el cargador, ya que algunas substancias y solventes

limpiadores son dañinos a los plásticos y partes aislantes. Algunos de

estos incluyen: gasolina, turpentina, diluyente para lacas, diluyente para

pinturas, solventes para limpieza con cloro, amoníaco y detergentes

caseros que tengan amonia. Nunca use solventes inflamables o combustibles cerca de una herramienta.

¡ADVERTENCIA!

Para reducir el riesgo de una lesión, descarga

eléctrica o daño a la herramienta, batería o

cargador, nunca los sumerja en líquidos ni

permita que estos fluyan dentro de los mismos.

page 18

¡ADVERTENCIA!

Para reducir el riesgo de una explosión, no

queme nunca una batería, aun si está

dañada, “muerta” o completamente

descargada.

Sellos de Reciclaje de Baterías RBRC

Los Sellos de Reciclaje de Baterías RBRC™ (véase “Simbología”) en las

baterías de su herramienta indican que MILWAUKEE ha hecho los arreglos

pertinentes para reciclar dichas baterías con la Rechargeable Battery

Recycling Corporation (Corporación de Reciclaje de Baterías Recargables,

o RBRC por sus siglas en inglés). Al final de la vida útil de las baterías,

devuelva éstas a la Oficina Principal/Centro de Servicio de MILWAUKEE

o el distribuidor autorizado más cercano a usted. Si desea mayor

información, visite el sitio web de RBCR en www.rbrc.org.

Cómo desechar las baterías de níquel-cadmio

Las baterías de níquel-cadmio son reciclables. Bajo ciertas leyes estatales

y locales, puede ser ilegal desechar las baterías en el drenaje municipal.

Deshágase de ellas de acuerdo a regulaciones federales, estatales o

locales.

Reparaciones

Si su herramienta, batería o cargador están dañados, envíelos al centro

de servicio más cercano de los listados en la cubierta posterior de este

manual del operario.

Garantía de la batería

Las baterías para herramientas inalámbricas están garantizadas por un

año a partir de la fecha de compra.

GARANTIA

Se garantiza que todos los productos MILWAUKEE están libres de fallas

en el material y la mano de obra. MILWAUKEE reparará o reemplazará

cualquier producto que, luego de una revisión, se encuentre está

defectuoso ya sea en el material o en la mano de obra.

Límites: Esta garantía no cubre: 1) reparaciones o intentos realizados

por personas ajenas a MILWAUKEE o al Taller Autorizado de Servicio

MILWAUKEE; 2) uso y desgaste normal; 3) abuso; 4) mal uso;

5) mantenimiento inadecuado; 6) uso continuo luego de presentar fallas

parciales; 7) herramientas que han sido modificadas; o productos

utilizados con un accesorio inadecuado.

Las baterías están garantizadas por un (1) año a partir de la fecha de

compra.

En caso de que se presente un problema, favor de regresar el producto

completo a cualquier Centro de Servicio de Fábrica MILWAUKEE o Taller

Autorizado de Servicio MILWAUKEE, con flete pagado y asegurado. Si

se encontrase que el problema es causado por fallas en el material o la

mano de obra, se reparará o reemplazará el producto sin cargo y se le

regresará (con flete pagado) a su propietario. No se reconoce ninguna

otra garantía ni verbal ni escrita.

NO EXISTE NINGUNA OTRA POSIBILIDAD DE REPARACION Y

REEMPLAZO QUE LA DESCRITA EN LA PRESENTE GARANTIA. EN

NINGUN CASO MILWAUKEE SERA CONSIDERADA RESPONSABLE

POR DAÑOS INCIDENTALES, ESPECIALES O CONSECUENTES,

INCLUYENDO LA PERDIDA DE GANANCIAS.

ESTA GARANTIA SE CONFIERE EN LUGAR DE TODA OTRA

GARANTIA, EXPRESA O IMPLICITA DE COMERCIALIZACION O DE

IDONEIDAD PARA UN USO O PROPOSITO EN PARTICULAR.

Esta garantía le otorga derechos legales específicos. Podría tener

además otros derechos que varían de estado a estado. En aquellos

estados que no permiten la exclusión de garantías implícitas o límites

por daños incidentales o consecuentes, los límites o las exclusiones

anteriores podrían no aplicar en su caso.

Page 19

ACCESORIOS

¡ADVERTENCIA!

Siempre retire la batería antes de cambiar

o retirar accesorios. Utilice únicamente

accesorios específicamente recomendados

para esta herramienta. El de uso accesorios

no recomendados podría resultar peligroso.

Para una lista completa de accesorios, consulte el catálogo de Herramientas eléctricas MILWAUKEE (Milwaukee Electric Tool). A fin de obtener un

catálogo, sírvase ponerse en contacto con su distribuidor o centro de servicio local. Para saber la dirección de la localidad más cercana, consulte el

reverso de este manual del operario.

Batería de Power Plus de 12 V

Puede usarse con los cargadores de MILWAUKEE

Cat. No. 48-59-0255.

1,3 Amps – Horas

Cat. No. 48-11-1960

2,4 Amps – Horas

Cat. No. 48-11-1970

Cargador de Power Plus de 120 V

Para cargar baterías de hasta 12-18 V de Power Plus.

Cat. No. 48-11-1960

Cargador de Vehículos de 1 Hora

Cat. No. 48-59-0186

Cargador Universal de 1 Hora

Cat. No. 48-59-0255

Aditamento anti roturas o astillados

Catálogo No. 48-08-0531

Manguera para aspiradora

Catálogo No. 48-09-1040

La manguera para aspirador puede ser conectada a la entrada

interconstuida, con el objeto de ayudar a retirar del área de

corte, el serrín o polvo. La cubierta transparante debe ser

colocada con el objeto de logara una acción eficiente de

aspirado.

Zapata cubierta

Catálogo No. 48-08-0533

Guía para coirtes paralelos y circulares

Catálogo No. 49-22-42509-22-4245

Cat. No. 48-59-0186

Cat. No. 48-59-0255

page 19

Page 20

UNITED STATES

CANADA

MILWAUKEE Service

To locate the factory SERVICE CENTER or

authorized service station nearest you, call

1-800-414-6527

TOLL FREE • NATIONWIDE

Monday-Friday • 8:00 AM - 4:30 PM • Local Time

In addition, there is a worldwide network of

distributors ready to assist you. Check your

“Yellow Pages” under “Tools-Electric” for the names

of those nearest you.

For further information on factory SERVICE CENTER

or authorized service station locations,

visit our website at:

www.mil-electric-tool.com

Service MILWAUKEE

Milwaukee Electric Tool (Canada) Ltd

755 Progress Avenue

Scarborough, Ontario M1H 2W7

Tel. (416) 439-4181

Fax: (416) 439-6210

En outre le réseau de distributeurs est à la disposition de la

clientèle d’un océan à l’autre. Consultez les pages jaunes de

l’annuaire téléphonique pour l’adresse du centre le plus près

de chez vous.

In addition, there is a worldwide network of distributors ready

to assist you. Check your “Yellow Pages”under “Tools-Electric” for the names of those nearest you.

Corporate Product Service Support -

Warranty and Technical Information

Brookfield, Wisconsin USA

1-800-729-3878

MEXICO

Servicios de MILWAUKEE

Milwaukee Electric Tool

División de : Atlas Copco Mexicana S.A. de C.V.

Blvd. Abraham Lincoln no. 13

Colonia Los Reyes Zona Industrial

Tlalnepantla, Edo. México C.P. 54073

Tels. 5565-1414 5565-4720

Fax: 5565-0925

Además se cuenta con una red nacional de distribuidores

listos para apoyarlo. Vea en las “Páginas Amarillas” sección

“Herramientas Eléctricas”.

MILWAUKEE ELECTRIC TOOL CORPORATION

A Company within the Atlas Copco Group

13135 West Lisbon Road • Brookfield, Wisconsin, U.S.A. 53005

58-14-3850d5 04/03 Printed in U.S.A.

Loading...

Loading...