Strautmann Verti-Mix 951-1651, Verti-Mix 1251-L, Verti-Mix 1501 D, Verti-Mix 951-L, Verti-Mix 3101 D Translation Of The Original Operating Instructions

Translation of the

Original Operating Instructions

Fodder mixing wagon

Verti-Mix 951-1651

Verti-Mix 951-L, 1251-L

Verti-Mix 1501 D-3101 D

65200921 0.000

05.16

Designation:

Fodder mixing wagon

Function:

Chopping, mixing, transport and discharge of all types of silage and normal

fodders used in keeping livestock

Model:

Verti-Mix

Verti-Mix L

Verti-Mix Double

Type:

951, 1251, 1451, 1651

951-L, 1251-L

1501 Double, 1801 Double, 2401 Double, 3101 Double

Serial number:

W09649000_0S38001-W09659000_0S38999

Trade name:

Fodder mixing wagon Verti-Mix

Fodder mixing wagon Verti-Mix L

Fodder mixing wagon Verti-Mix Double

Dipl.-Kfm. W. Strautmann

Managing Director

Dipl.-Wirt.-Ing. P. Strautmann

Managing Director

EU Declaration of Conformity

Manufacturer:

B. Strautmann & Söhne GmbH u. Co. KG

Bielefelder Str. 53

D-49196 Bad Laer

Legal person established within the EC and authorized to compile the technical documentation:

B. Strautmann & Söhne GmbH u. Co. KG

Bielefelder Str. 53

D-49196 Bad Laer

Description and identification of machine:

We hereby explicitly declare that the machine complies with all relevant provisions of the following

directives:

2006/42/EC:2006-05-17 EC machinery directive 2006/42/EC

2014/30/EU:2014-02-26 (Electromagnetic compatibility) Directive 2014/30/EU of the European

Parliament and the Council dated 26 February 2014 for harmonisation of

laws of the member states on the electromagnetic compatibility (revised

version)

Sources of the applied harmonized standards:

EN ISO 12100:2010 Safety of machinery - Basic concepts, general principles of design - Risk

assessment and risk reduction

EN ISO 13857:2008 Safety of machinery - Safety distances to prevent hazard areas from

EN ISO 4254-1:2013 Agricultural machinery - Safety - Part 1: General requirements

being reached by upper and lower limbs

EN 349:1993+A1:2008 Safety of machinery - Minimum distances to prevent limbs from being

crushed

EN ISO 4413:2010 Fluid power - General rules and safety requirements for hydraulic

systems and their components

EN 703:2004+A1:2009 Agricultural machinery - Silage loading, mixing and/or chopping and

Bad Laer, 04/01/2016

distributing machines - Safety

Identification data

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

3

Operating instructions, spare parts lists and brochures are also

available in the Strautmann information library on the internet:

www.strautmann-infothek.de

Identification data

Please enter the machine’s identification data here. They are registered on the type plate.

Manufacturer: B. Strautmann & Söhne GmbH u. Co. KG

Vehicle/Machine ID number: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Type:

Year of manufacture:

Manufacturer’s address

B. Strautmann & Söhne GmbH u. Co. KG

Bielefelder Straße 53

D-49196 Bad Laer

Phone: + 49 (0) 5424 802-0

Fax: + 49 (0) 5424 802-64

E-mail: info@strautmann.com

Spare parts order service

B. Strautmann & Söhne GmbH u. Co. KG

Bielefelder Straße 53

D-49196 Bad Laer

Phone: + 49 (0) 5424 802-30

Fax: + 49 (0) 5424 802-64

E-mail: parts@strautmann.com

Spare parts catalogue online: www.strautmann-elise.de

Please always refer to the vehicle/machine ID number of your machine when ordering spare parts.

Formal information about the operating instructions

Document number: 65200921 0.000

Date of compilation: 05.16

© Copyright B. Strautmann & Söhne GmbH u. Co. KG, 2016

All rights reserved.

Reproduction, even in excerpts, only allowed with the permission of B. Strautmann & Söhne GmbH u.

Co. KG.

Foreword

4

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Foreword

Dear customer,

You have decided in favour of a quality product from the large B. Strautmann & Söhne GmbH u. Co.

KG product range. We thank you for the confidence you have shown in us.

Upon receipt of the machine, please check for transport damage or missing parts! Check the delivered

machine for its completeness, including the ordered optional extras, by means of the delivery note.

Only immediate complaints will give reason to compensation!

Read and observe these operating instructions and any other included operating instructions for

individual machine components before the first start-up; in case of doubt, the details and information

contained in such sub-supplier documentation shall prevail! In particular observe the safety

instructions, thus being able to fully benefit from the advantages of your recently acquired machine.

Please make sure that all operators of the machine have read these operating instructions before

starting the machine.

The machines are available with various optional extras. Due to the individual equipment of your

machine, not all descriptions included in these operating instructions apply to your machine. Optional

extras are marked in these operating instructions and are available at extra cost.

In case of any inquiries or problems, please refer to these operating instructions or call us.

Regular service and maintenance and timely replacement of worn-out or damaged parts will result in a

longer service life of your machine.

Contents

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

5

Contents

1 User information 10

1.1 Purpose of document 10

1.2 Keeping of operating instructions 10

1.3 Location details in the operating instructions 10

1.4 Applied modes of specification 10

1.5 Applied terms 11

1.6 Activity-related safety instructions and important information 11

1.6.1 Activity-related safety instructions 11

1.6.2 Important information 12

2 Product description 13

2.1 General overview of machine 13

2.2 Safety and protective devices 14

2.3 Supply lines between tractor and mchine 16

2.4 Traffic-related equipment 16

2.5 Type plate 17

2.6 Technical data 18

2.6.1 Verti-Mix 18

2.6.1.1 Dimensions of wagon 20

2.6.1.2 Tyre pressure 22

2.6.2 Verti-Mix L 22

2.6.2.1 Dimensions of wagon 23

2.6.2.2 Tyre pressure 24

2.6.3 Verti-Mix Double 24

2.6.3.1 Dimensions of wagon 25

2.6.3.2 Tyre pressure 27

2.7 Required tractor equipment 28

2.8 Drawbar 30

3 Safety instructions 31

3.1 Correct use 31

3.2 Safety-conscious working 31

3.3 Organisational measures 32

3.3.1 User’s obligation 32

3.3.2 Operator’s obligation 32

3.3.3 Qualification of operator 33

3.4 Product safety 33

3.4.1 Hazardous areas and dangerous spots 33

3.4.2 Safety-conscious operation of machine 34

3.4.3 Safety and protective devices 34

3.4.4 Structural alterations 34

3.4.5 Spare and wearing parts, auxiliary materials 35

3.4.6 Warranty and liability 35

3.5 Basic safety instructions 35

3.5.1 General safety and accident prevention instructions 35

3.5.2 Hydraulic system 38

3.5.3 Electrical system 39

3.5.4 Propeller shaft operation 39

3.5.5 Hitched machines 40

3.5.6 Brake system 40

3.5.7 Axles 41

3.5.8 Tyres 42

3.5.9 Fodder mixing wagon 42

3.5.10 Service and maintenance of machine 43

3.6 Warning and instruction signs 43

Contents

6

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

3.6.1 Warning signs 44

3.6.2 Instruction signs 48

3.6.3 Placing of warning and instruction signs 49

3.7 Risks in case of non-observance of safety instructions and warning signs 52

4 Loading of machine 53

4.1 Verti-Mix 54

4.2 Verti-Mix L 54

4.3 Verti-Mix Double 55

5 Commissioning 56

5.1 Road traffic regulations 57

5.1.1 Road traffic regulations in Germany 57

5.2 Check tractor’s compatibility 58

5.2.1 Calculate actual values 58

5.2.2 Preconditions for the operation of tractors with rigid drawbar trailers 59

5.2.2.1 Combination options of coupling devices and drawgears 59

5.2.2.2 Calculate actual DC value for combination to be coupled 60

5.2.2.3 Calculate tractor’s admissible towing capacity 61

5.3 Secure tractor and machine against accidental starting and rolling 62

5.4 Drawbar 63

5.4.1 Adjust mounting height of drawbar 63

5.4.2 Couple drawbar 64

5.4.2.1 Bolt-type coupling 64

5.4.2.2 Tow-hook (hitch hook) and drawbar lug (hitch ring) 65

5.4.2.3 Draw pin (Piton-Fix) and drawbar lug (hitch ring) 65

5.4.2.4 Ball-type coupling and shell 65

5.4.3 Uncouple drawbar 66

5.4.3.1 Bolt-type coupling 66

5.4.3.2 Tow-hook (hitch hook) and drawbar lug (hitch ring) 67

5.4.3.3 Draw pin (Piton-Fix) and drawbar lug (hitch ring) 67

5.4.3.4 Ball-type coupling and shell 67

5.5 Propeller shaft 68

5.5.1 Adjust length of propeller shaft to tractor 69

5.5.2 Couple propeller shaft to the tractor 70

5.5.3 Uncouple propeller shaft from tractor 71

5.6 Supporting leg 71

5.6.1 Mechanical supporting leg 72

5.6.1.1 Lift mechanical supporting leg to transport position 72

5.6.1.2 Lower mechanical supporting leg to support position 72

5.6.2 Hydraulic supporting leg 73

5.6.2.1 Lift hydraulic supporting leg to transport position 73

5.6.2.2 Lower hydraulic supporting leg to support position 74

5.6.3 Fixed supporting leg with bottom hitch 74

5.7 Check machine for proper functioning 74

5.8 Hydraulic hose pipes 75

5.8.1 Connect hydraulic hose pipes 75

5.8.2 Disconnect hydraulic hose pipes 76

5.9 Brake system 76

5.9.1 Hydraulic service brake 77

5.9.1.1 Connect hydraulic brake system 78

5.9.1.2 Disconnect hydraulic brake system 79

5.9.2 Automatic reverse overrun brake system 79

5.9.2.1 Connect automatic reverse overrun brake system 80

5.9.2.2 Disconnect automatic reverse overrun brake system 80

5.9.3 Dual-line compressed-air brake system 81

5.9.3.1 Connect brake and feed line 82

5.9.3.2 Disconnect brake and feed line 83

5.9.3.3 Manoeuvre unhitched machine by means of a manoeuvring vehicle 84

5.9.4 Hydraulic service brake system 84

Contents

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

7

5.9.4.1 Connect hydraulic brake system 85

5.9.4.2 Disconnect hydraulic brake system 85

5.9.5 Parking brake 85

5.10 Hitch and unhitch machine 86

5.10.1 Hitch machine 86

5.10.2 Unhitch machine 88

5.11 Container attachment 88

5.12 Set conveyor speed 89

5.12.1 Manual setting of conveyor speed 89

5.12.2 Set conveyor speed via control set 90

5.12.3 Set control dial range of E-control set 90

5.13 Mount control set on the tractor 91

5.13.1 Mount holder with pocket for Bowden cable control set 91

5.13.2 Mount E-control set on the tractor 92

5.14 Battery for weighing device 92

5.15 Set deflector plate 93

6 Operation 95

6.1 Direct tractor connection 95

6.2 Bowden cable control set 95

6.2.1 Possible symbols and their meaning 96

6.3 E-control set 99

6.3.1 Functions and their symbols 99

7 Use of machine 105

7.1 Fill fodder mixing wagon 107

7.1.1 Recommended filling order 109

7.2 Mix fodder components 110

7.2.1 Counter-cutters 110

7.3 Fodder discharge 111

7.3.1 Eliminate blockages 112

7.4 Working with the straw blower 113

7.4.1 Eliminate blockages 114

7.5 Working with the litter spreading drum 115

7.6 Driving mechanism with switchgear 117

7.6.1 Change gear level by means of switchgear 118

8 Transport journeys 119

8.1 Secure protective devices for transport journeys 120

8.2 Stop-cock at side discharge conveyor or conveyor extension 121

9 Service and maintenance of machine 122

9.1 Enter the mixing container 123

9.2 Cleaning of machine 126

9.3 Lubrication of machine 126

9.3.1 Lubrication plan 127

9.4 Preservation/Longer downtimes 128

9.5 Check/Top up/Change gear lubricant oil 128

9.5.1 Quantities when filled and change intervals 128

9.5.2 Admissible gear lubricant oils 129

9.5.3 Mixer gearbox 129

9.5.3.1 Check oil level 129

9.5.3.2 Change oil 130

9.5.4 Switchgear 132

9.5.4.1 Check oil level 132

9.5.4.2 Change oil 133

9.5.5 Spur gear for driving mechanism with on-board hydraulic system without

switchgear 133

Contents

8

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

9.5.5.1 Check oil level 134

9.5.5.2 Change oil 134

9.6 On-board hydraulic system 134

9.6.1 Admissible hydraulic oils 135

9.6.2 Check oil level 135

9.6.3 Change oil 136

9.7 Replace shear bolts of shear bolt coupling 136

9.8 Auger position, Verti-Mix Double 137

9.9 Check / Adjust discharge door distance 137

9.10 Cutting knives of mixing auger(s) 138

9.10.1 Swivel / Replace cutting knives 139

9.10.2 Grind cutting knives 141

9.11 Crossover conveyor, discharge conveyor or conveyor extension 142

9.11.1 Check conveyor for visible defects 142

9.11.2 Adjust /Tighten conveyor 143

9.11.3 Clean driving rollers, carrying rollers and pulleys 143

9.12 C-conveyor 144

9.12.1 Check C-conveyor for visible defects 144

9.12.2 Tighten / Adjust C-conveyor 144

9.12.3 Clean C-conveyor 145

9.13 Replace Bowden cable of mechanical Bowden cable control unit 146

9.14 Replace remote control cable adapter 147

9.15 Hydraulic system 148

9.15.1 Depressurise hydraulic system 149

9.15.2 Hydraulic hose pipes 149

9.15.2.1 Marking and period of use of hydraulic hose pipes 149

9.15.2.2 Maintenance intervals 149

9.15.2.3 Inspection criteria for hydraulic hose pipes 150

9.15.2.4 Installation and removal of hydraulic hose pipes 150

9.16 Tyres 151

9.16.1 Check tyres 151

9.16.2 Change tyres 151

9.17 Brake system and chassis 152

9.17.1 Check/Clean in-line filters of compressed-air brake system 152

9.17.2 Check brake system for proper functioning. 153

9.17.3 Set compressed-air brake system 153

9.17.4 Drain compressed-air reservoir of compressed-air brake system 154

9.17.5 Set hydraulic brake system 155

9.17.6 Lubrication and maintenance plan – Chassis 155

9.17.7 Lubricate brake shaft bearing 157

9.17.8 Lubricate standard slack adjuster 158

9.17.9 Check clearance of wheel hub bearing 159

9.17.10 Check brake linings 159

9.18 Tightening torques 160

9.18.1 Tightening torques of wheel nuts 161

10 Remedy of malfunctions 162

10.1 Machine 162

10.2 Electrics 163

10.2.1 Emergency manual operation in case of failure of electrical system 163

10.3 Weighing device 164

11 Disassembly / Disposal 165

12 Circuit diagrams 166

12.1 Hydraulics 166

12.1.1 Without on-board hydraulic system 166

12.1.1.1 Bowden cable 166

12.1.1.2 E-control set and weighing and control set Multiscale 168

Contents

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

9

12.1.2 With on-board hydraulic system 170

12.1.2.1 Without straw blower 170

12.1.2.2 With straw blower 172

12.2 Electronic system 174

12.2.1 E-control set 174

12.2.1.1 3-function control set 174

12.2.1.2 4-function control set 176

12.2.1.3 7-function control set 178

12.2.1.4 7-function control set with straw blower 180

12.2.2 Weighing and control set Multiscale 182

12.3 Weighing device 185

12.4 Connection of lighting system 185

User information

10

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

1 User information

The chapter “User information“ provides information about how to use the operating instructions.

1.1 Purpose of document

These operating instructions:

describe the operation, service and maintenance of the machine,

provide important information about safety-conscious and efficient handling of the machine.

Please contact us for further inquiries.

1.2 Keeping of operating instructions

The operating instructions are part of the machine.

Therefore, always keep these operating instructions in the machine.

Hand these operating instructions over to the buyer when the machine is sold.

1.3 Location details in the operating instructions

Any directional data in these operating instructions refer to the direction of motion.

1.4 Applied modes of specification

Instructions and responses

Activities which have to be carried out in a predetermined order are specified as numbered

instructions. Always adhere to this order. In some cases, the response of the machine to the

respective instruction is marked by an arrow.

Example:

1. Instruction 1

→ Response of machine to instruction 1

2. Instruction 2

Lists

Lists without predetermined order are specified as lists with bullet points.

Example:

● Item 1

● Item 2

Position numbers in figures

Numbers in parentheses refer to position numbers in figures. The first number refers to the figure, the

second number to the position number in the figure.

Example: (Fig. 3/6) means figure 3, position 6.

Lines of position in figures

Starting from the position numbers, the lines of position refer to the respective components.

User information

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

11

A line without an arrow

head means:

the component can be seen in the figure,

A line with an arrow head

means:

the component cannot be seen in the figure (e.g.

hidden by protective device).

Term

The term means

third person/party

… all other persons apart from the operator.

risk

… the source of a possible injury or damage to health.

manufacturer

… B. Strautmann & Söhne GmbH u. Co. KG.

machine

… Fodder mixing wagon Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L,

Verti-Mix 1501 D-3101 D.

operating element

… the component of an operating element system which is directly

actuated by the operator, e. g. by pressing. An operating element may be

an adjusting lever, a key button, rotary switch, key etc.

DANGER

DANGER

marks a direct danger bearing a high risk, which will cause most

serious bodily injury (loss of limbs or long-term harm) or even

death if it is not prevented.

Non-observance of the safety instructions marked by “DANGER“

directly causes most serious bodily injury or even death.

References

An arrow head (►) in front of a sentence indicates a reference to further information elsewhere in the

operating instructions.

Example:

► Also observe the information in the chapter "Technical data", page 18.

1.5 Applied terms

1.6 Activity-related safety instructions and important information

Activity-related safety instructions and important information are included in the operating instructions.

Signal words and symbols help to identify activity-related safety instructions and important information

at a glance.

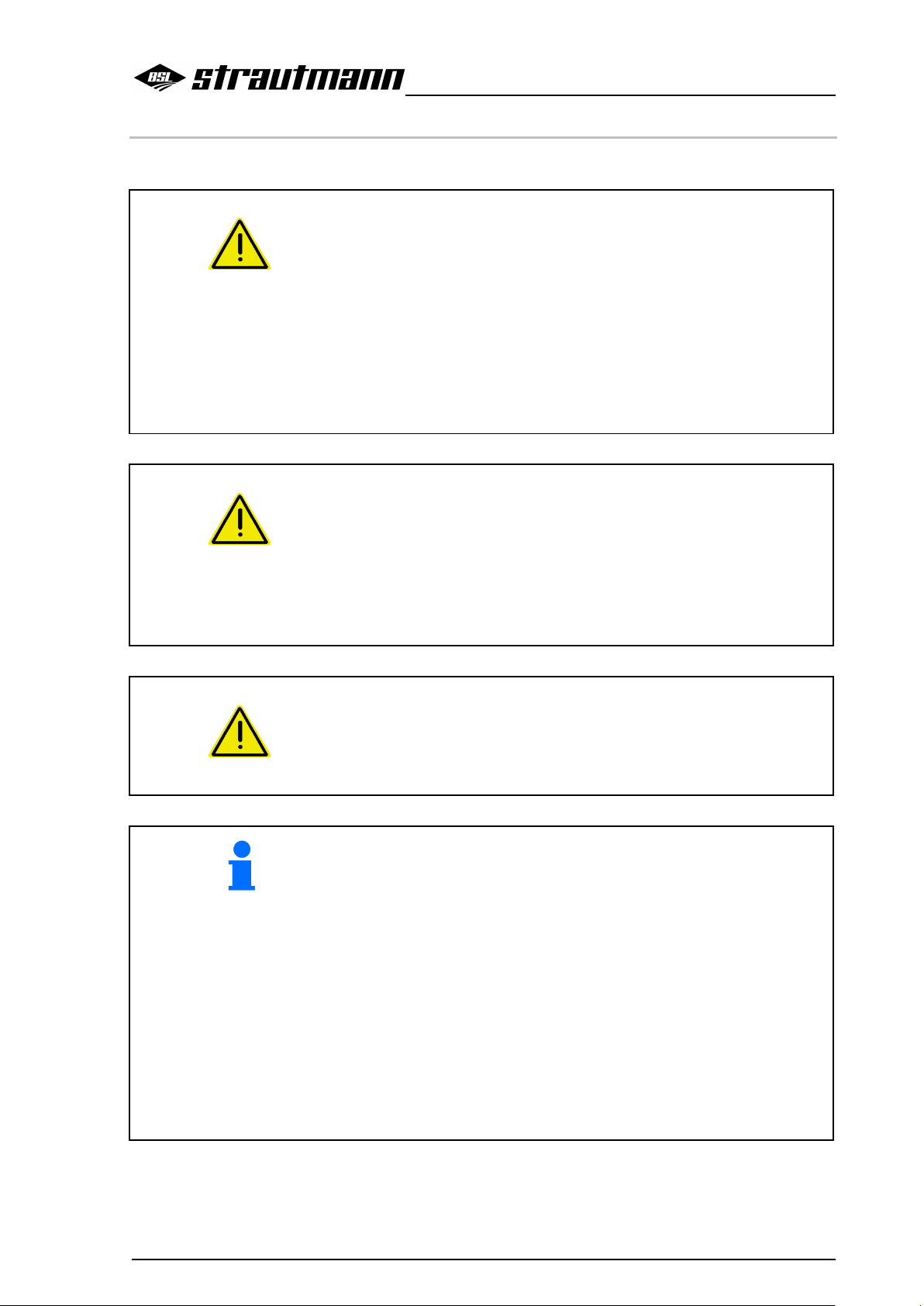

1.6.1 Activity-related safety instructions

Activity-related safety instructions:

warn about risks which may occur in a certain situation or in connection with a certain behaviour,

are directly mentioned in front of a hazardous activity in the individual chapters,

are marked by the triangular hazard symbol and a preceding signal word. The signal word refers

to the seriousness of the risk.

User information

12

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

WARNING

WARNING

marks a possible danger bearing a moderate risk, which might

cause most serious bodily injury or even death if it is not

prevented.

Non-observance of the safety instructions marked by

“WARNING“ may cause most serious bodily injury or even

death.

CAUTION

CAUTION

marks a possible danger bearing a low risk, which might cause

light or moderate bodily injury or material damage if it is not

prevented.

Non-observance of the safety instructions marked by

"CAUTION" may cause light or moderate bodily injury or

material damage.

IMPORTANT

marks an obligation to behave in a particular manner or to act in

a certain way, in order to use the machine properly.

Non-observance of these instructions may cause malfunctions

of the machine or in its vicinity.

INFORMATION

marks user hints and particularly useful information.

This information will help you to use all functions of your

machine in the best possible way.

1.6.2 Important information

Important information:

provides details for proper use of the machine,

provides user hints for optimum use of the machine,

is marked by the following symbols.

Product description

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

13

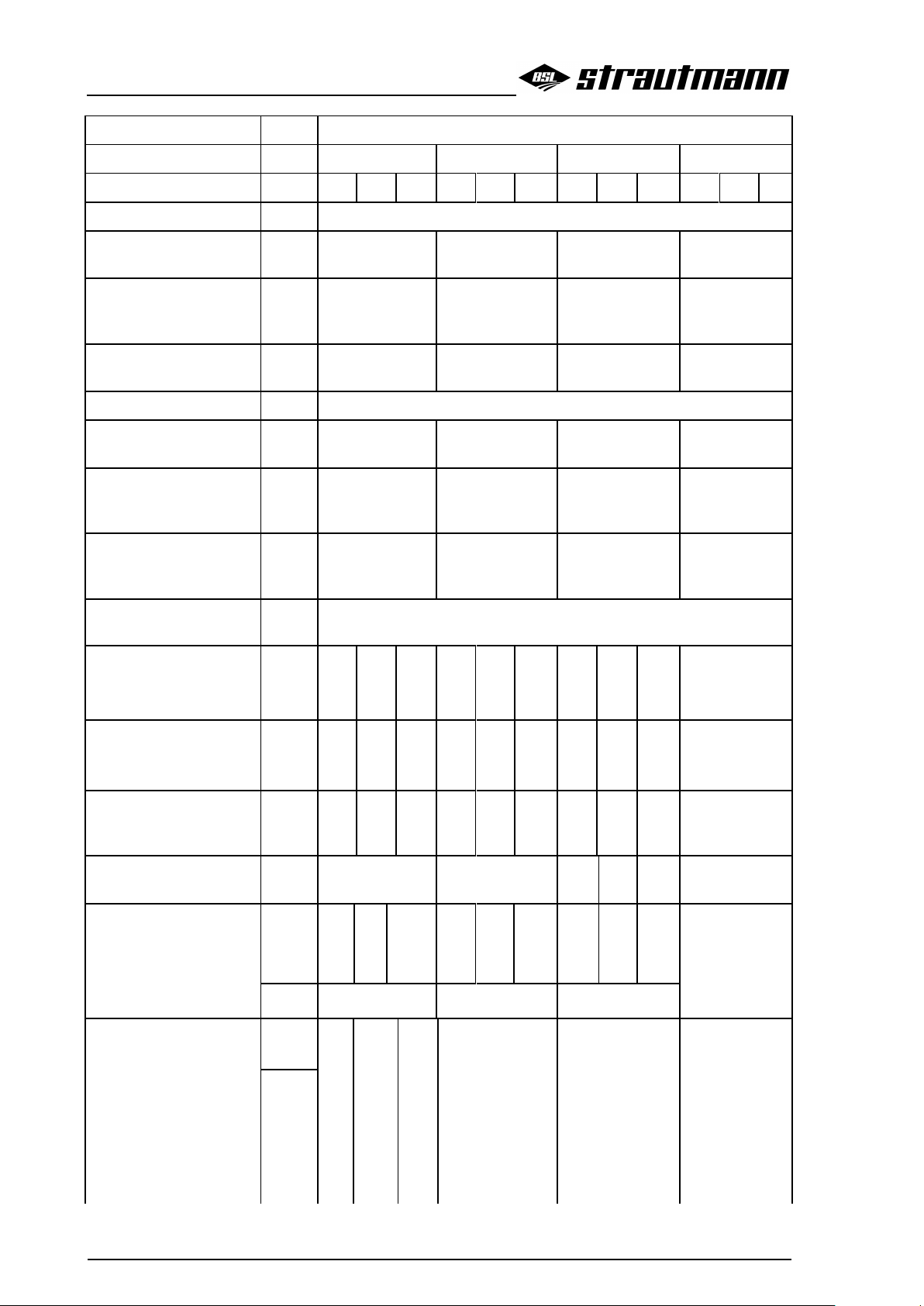

Fig. 1

(1) Drawbar

(2) Propeller shaft

(3) Propeller shaft holder

(4) Ladder, platform

(5) Supporting leg

(6) Counter-cutter

(7) Mixing container

(8) Parking brake

(9) Angular gear for mixing auger drive

(10) Shear bolt locking mechanism

(11) Braking axle

(12) Wheels

(13) Crossover conveyor *

(14) Protective device for crossover conveyor

(15) Hose holder for supply lines

(16) Control terminal of weighing device *

(17) Swivelling holder for control terminal of

weighing device

(18) Electro-hydraulic control block *

(19) Control set of electro-hydraulic E-control *

(20) Rear-view camera *

(21) Work light *

* Optional extra

2 Product description

Please read this chapter in the immediate vicinity of the machine if possible, thus acquainting yourself

with the machine in the best possible way.

The machines are available with various optional extras. Due to the individual equipment of your

machine, not all descriptions included in these operating instructions apply to your machine. Optional

extras are marked in these operating instructions and are available at extra cost.

2.1 General overview of machine

Product description

14

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Fig. 2

(1) Opening scale for dosage gate

(2) Pointer for opening width of dosage gate

(3) Chocks

(4) Compensating reservoir for gear lubricant

oil of angular gears

(5) Hydraulic or mechanical counter-cutter *

(6) Crossover conveyor *

(7) Protective device for crossover conveyor

(8) Spur gear for driving mechanism with on-

board hydraulic system *

(9) Inspection window *

(10) Feed funnel for mineral feed *

(11) Mixing auger(s), where applicable with

magnetic system *

WARNING

Risk to people of being crushed, drawn in and becoming entangled due to

unprotected powered driving elements during machine operation!

Start the machine only with the protective devices completely mounted.

It is not allowed to open protective devices:

when the machine is powered,

as long as the tractor engine is running with the propeller shaft coupled/the

hydraulic system connected,

if the ignition key is in the tractor and the tractor engine can be accidentally

started with the propeller shaft coupled/the hydraulic system connected,

if tractor and machine have not been secured against accidental rolling by

means of their respective parking brake and/or the chocks.

Close open protective devices before powering the machine.

* Optional extra

2.2 Safety and protective devices

Product description

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

15

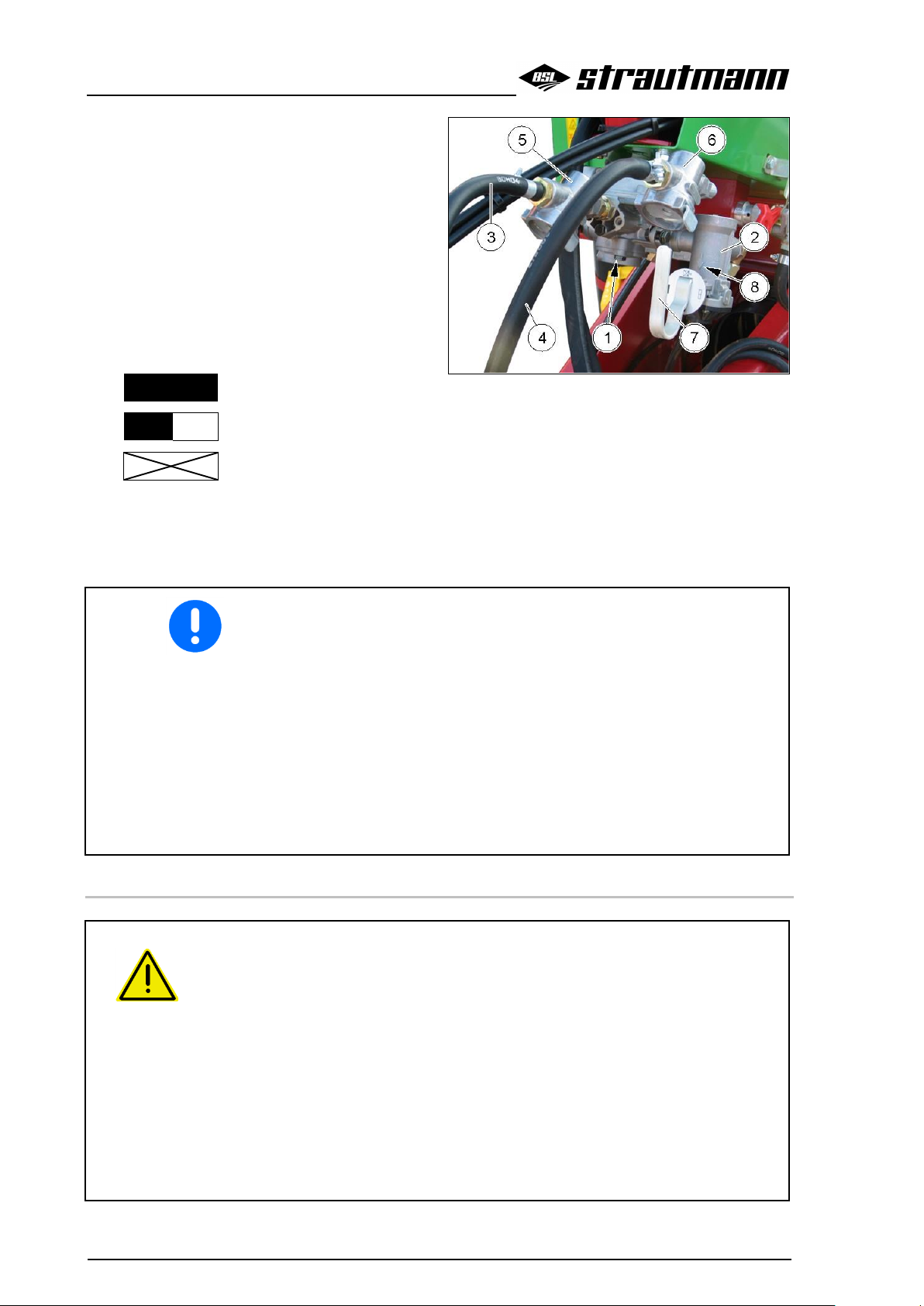

Fig. 3

(1) Propeller shaft holder

(2) Protective devices of propeller shaft

(3) Protective sleeve for drive shaft

(4) Hose holder for supply lines

(5) Ladder, platform

(6) Protective device for crossover conveyor at

the left-hand and right-hand front

(7) Protective device for side discharge at the

front (close-fitting, swivelling protective

cover), for protection against accidental

contact with the powered mixing auger

(8) Chocks

Fig. 4

Product description

16

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

(1) Hydraulic connector "Flow line" red

(2) Hydraulic connector "Return line" blue

(3) Hydraulic connector for hydraulic service

brake

(4) Power supply for control system, 3-pole

(5) Lighting connector, 7-pole

(6) Compressed-air brake, feed line red

(only available with optional extra

equipment)

(7) Compressed-air brake, brake line yellow

(only available with optional extra

equipment)

(8) Hydraulic connector for hydraulic brake with

hydraulic clutch according to ISO 5676

(only with available optional extra

equipment, not allowed in Germany)

Fig. 5

Properly fix and check the traffic-related equipment for proper

functioning before travelling on public roads and paths.

Depending on the machine’s equipment, it is fitted with:

a lighting and identification system according to the national road traffic regulations,

a brake system, for details please refer to the chapter "Brake system", page 76.

Fig. 6

2.3 Supply lines between tractor and mchine

2.4 Traffic-related equipment

Product description

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

17

(1) Speed sign

(2) Multi-function light with triangular reflector

(3) License plate

(4) Side reflectors

(5) Chocks

The complete marking is treated as a document and must not be

altered or made unrecognizable.

(1) Type plate with CE symbol

(2) Vehicle identification number (machine ID

number) (embossed into the frame)

Fig. 7

Information on the type plate:

(1) Manufacturer

(2) CE symbol

(3) Vehicle/Machine ID number

(4) Type

(5) Empty weight [kg]

(6) Gross vehicle weight rating [kg]

(7) Admissible tongue load/front axle load [kg]

(8) Admissible rear axle load [kg]

(9) Approval number

(10) Year of manufacture

(11) Rated speed [min-1]

(12) Admissible hydraulic pressure [bar]

(13) Maximum admissible speed [km/h]

Fig. 8

2.5 Type plate

Product description

18

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

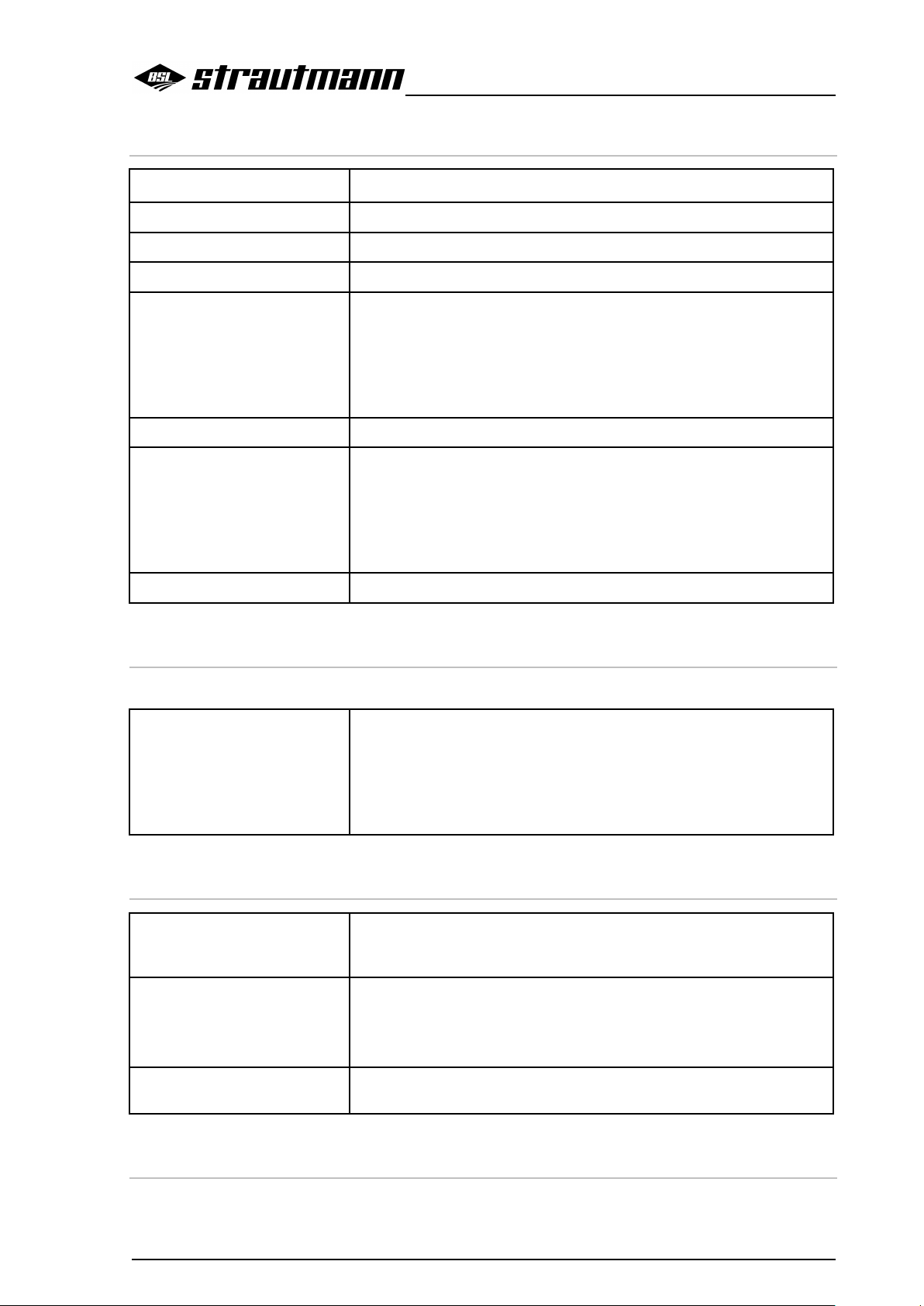

Type

Verti-Mix

Unit

951

1251

1451

1651

Usable mixing capacity*

(Loading capacity)

m3

7.5

8.5

9.5

10.0

11.5

12.5

13.5

15.0

--

13.5

15.0

16.5

Extension height

m

--

0.18

0.36

--

0.18

0.36

--

0.18

--

--

0.18

0.36

Gross vehicle weight rating

when equipped with:

Hydraulic service brake

kg

7000

9000

11400

11400

Overrun brake

kg

7000

8000

--

--

Dual-line service brake

system

kg

7000

9000

11400

11400

Admissible axle load when

equipped with:

Hydraulic service brake

kg

6000

7800

10000

10000

Overrun brake

kg

6000

7000

--

--

Dual-line service brake

system

kg

6000

7800

10000

10000

Admissible tongue load

Hydraulic service brake/

Dual-line service brake

system

kg

1000

1200

1400

1400

Overrun brake

kg

1000

1000

--

--

Empty weight (approx.):

with crossover conveyor

kg

3260

3860

4840

4900

Minimum power required:

without switchgear, 26

min-1

kW

26

28

31

37

38

41

53

58

--

--

--

--

with switchgear, 14.4 / 26

min-1

kW

19

21

22

26

28

29

33

36

--

--

--

--

without switchgear, 30

min-1

kW

32

35

37

49

51

54

63

69

--

65

71

78

with switchgear, 16.7 / 30

min-1

kW

23

25

27

35

37

41

45

49

--

40

44

48

without switchgear, 23

min-1

kW

--

--

--

--

--

--

--

--

--

54

59

65

with switchgear, 12.8 / 23

min-1

kW

--

--

--

--

--

--

--

--

--

33

36

40

Maximum operating pressure

bar

210

Oil flow rate

l/min

25 – 45

Power supply weighing device /

volt

12 VDC

2.6 Technical data

2.6.1 Verti-Mix

Product description

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

19

Type

Verti-Mix

Unit

951

1251

1451

1651

Usable mixing capacity*

(Loading capacity)

m3

7.5

8.5

9.5

10.0

11.5

12.5

13.5

15.0

--

13.5

15.0

16.5

Extension height

m

--

0.18

0.36

--

0.18

0.36

--

0.18

--

--

0.18

0.36

lighting system / electrohydraulic control set

P.t.o. speed

min-1

540

Sound pressure level

dB(A)

≤84

* Actually usable mixing capacity, mixing augers having been deducted from the

capacity

Tab. 1

Figures, technical data and weights may change due to technical development and are not binding for

delivery.

The sound pressure level mainly depends on the tractor used.

Product description

20

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Fig. 9

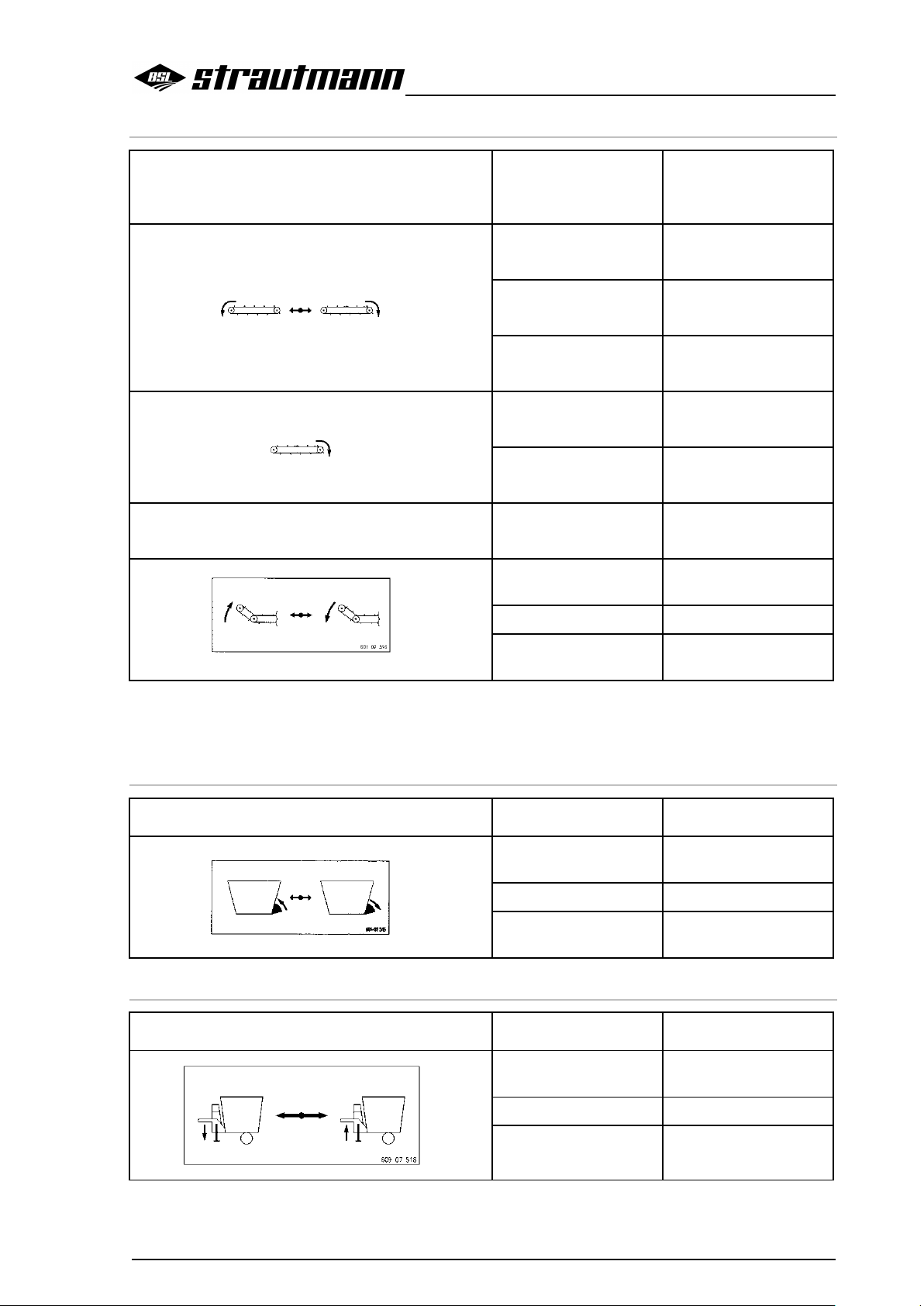

2.6.1.1 Dimensions of wagon

Product description

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

21

Type

Verti-Mix

Unit

951

1251

1451

1651

Extension height

- 0.18

0.36

-

0.18

0.36

-

0.18 - -

0.18

0.36

Length:

A = with front crossover

conveyor

m

5.30

5.50

5.75

5.75

B = with rear crossover

conveyor*

m

4.90

5.04

5.17

5.17

C = with side discharge /

without crossover conveyor

m

4.65

4.87

5.10

5.10

Width:

D = with crossover conveyor

m

2.16

2.28

2.42

2.42

E = with right-hand or left-

hand side discharge

m

2.26

2.38

2.52

2.52

E = with side discharge on

both sides

m

2.36

2.48

2.62

2.62

Height incl. tyres:

F = with 10.0/75-15.3 (18 PR)

m

2.31

2.49

2.67

--

--

--

F = with 30 x 11.5 -14.5

m

2.30

2.48

2.66

2.59

2.77

2.95

--

--

F = with 250/70-15.5 (18 PR)

Reduction of load capacity:

m

2.32

2.5

2.68

2.61

2.79

--

--

--

kg

--

8500

F = with 400/60-15.5 (14 PR)

m

2.43

2.61

2.79

--

--

--

F = with 400/60-15.5 (18 PR)

Reduction of load capacity:

m

--

2.72

2.9

3.08

3.05

--

--

3.05

--

--

kg 9660

9660

F = with 8.15-15 (14 PR)

double

m

--

2.58

2.76

--

2.94

3.12

--

2.94

3.12

3.30

F = with 19.0/45 - 17

Reduction of load capacity:

m

--

2.72

2.90

--

--

--

kg

8320

--

F = with 215/75R17.5 (133)

double

m

--

--

2.97

3.15

-

2.97

3.15

3.33

F = with 435/50 R 19.5,

retreated

m

--

2.8

2.98

3.16

3.14

3.32

-

3.14

3.32

3.50

G = Track

m

1.51

1.63

1.74

1.74

H = Outside wheel width incl.

standard tyres:

m

1.78

(10.0/75-

15.3)

2.04

(400/60-15.5)

2.23

(8.15-15)

2.23

(8.15-15)

J = Container length

m

3.03

3.33

3.67

3.67

Discharge height

m

0.75

0.87

0.74

0.74

* + 0.13 m with lighting

Tab. 2

Figures, technical data and weights may change due to technical development and are not binding for

delivery.

Product description

22

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Type

Verti-Mix

Tyres

Unit

951

1251

1451

1651

10.0/75-15.3 (18 PR)

bar

7.0

--

--

--

30 x 11.5 – 14.5

bar

8.0

8.0

--

--

250/70-15 (18 PR)

bar

9.5

9.5

--

--

400/60-15.5 (14 PR)

bar

5.0

--

--

--

400/60-15.5 (18 PR)

bar

--

6.0

6.0

6.0

8.15-15 (14 PR) double

bar

--

9.0

9.0

9.0

19.0/45-17

bar

--

4.0

--

--

215/75R17.5 (133) double

bar

--

--

9.5

9.5

435/50 R 19.5

bar

--

9.0

9.0

9.0

Tab. 3

Type Verti-Mix L

Unit

951-L

1251-L

Usable mixing capacity* (Loading capacity)

m3

7.5

8.5

9.5

10.0

11.0

12.5

Extension height

m

--

0.18

0.36

--

0.18

0.36

Gross vehicle weight rating when equipped with:

Hydraulic service brake

kg

7760

8700

Admissible axle load when equipped with:

Hydraulic service brake

kg

5260

6200

Admissible tongue load

kg

2500

2500

Empty weight (approx.):

kg

with side discharge on both sides

kg

3250

3820

Minimum power required:

without switchgear, 26 min-1

kW

26

28

31

37

38

41

with switchgear, 14.4 / 26 min-1

kW

19

21

22

26

28

29

without switchgear, 30 min-1

kW

32

35

37

49

51

54

with switchgear, 20 / 30 min-1

kW

23

25

27

35

37

41

Maximum operating pressure

bar

210

Oil flow rate

l/min

25 – 45

Power supply weighing device / lighting system / electrohydraulic control set

volt

12 VDC

P.t.o. speed

min-1

540

Sound pressure level

dB(A)

≤84

* Actually usable mixing capacity, mixing augers having been deducted from the capacity

Tab. 4

2.6.1.2 Tyre pressure

2.6.2 Verti-Mix L

Product description

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

23

Fig. 10

Type

Verti-Mix L

Unit

951-L

1251-L

Extension height

m

-

0.18

0.36

-

0.18

0.36

Length:

A = with side discharge

m

4.85

4.85

Width:

B = with right-hand or left-hand side

discharge

m

2.26

2.38

B = with side discharge on both sides

m

2.36

2.48

Height incl. tyres*:

C = with 250/70-15.5 (18 PR)

m

2.10

2.28

2.46

2.39

2.57

2.75

C = with 400/60-15.5 (18 PR)

m

2.16

2.34

2.52

2.45

2.63

2.81

C = with 30 x 11.5-14.5

m

2.10

2.28

2.46

2.39

2.57

2.75

D = Track

m

1.65

1.65

E = Outside wheel width incl. standard tyres:

m

1.90

1.90

F = Container length

m

3.03

3.33

Discharge height*

m

0.54

0.54

*a change in height of + 6 cm (high version) or - 6 cm (low version) can be achieved via a change of

the axle position. In the factory setting, the axle is mounted in middle position (dimensions as

described above).

Tab. 5

Figures, technical data and weights may change due to technical development and are not binding for

delivery.

The sound pressure level mainly depends on the tractor used.

2.6.2.1 Dimensions of wagon

Figures, technical data and weights may change due to technical development and are not binding for

delivery.

Product description

24

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Type Verti-Mix L

Tyres

Unit

951-L

1251-L

250/70-15 (18 PR)

bar

9.5

9.5

400/60-15.5 (18 PR)

bar

6.0

6.0

30 x 11.5-14.5

bar

8.0

8.0

Tab. 6

Type

Verti-Mix Double

Unit

1501 D

1801 D

2401 D

3101 D

Usable mixing capacity* (Loading

capacity)

m3

12

13.5

15

14

16

18

19

21

24

25

28

31

Extension height

m

-

0.18

0.36

-

0.18

0.36

-

0.18

0.36

-

0.18

0.36

Gross vehicle weight rating when

equipped with:

Single axle

kg

11800

11800

11800

--

Tandem axle

kg

--

12800

17800

18000

Admissible axle load when

equipped with:

Single axle

kg

10000

10000

10000

--

Tandem axle

kg

--

11000

16000

16000

Admissible tongue load

kg

1800

1800

1800

2000

Empty weight with crossover

conveyor (approx.):

Single axle

kg

5550

6150

7350

--

Tandem axle

kg

--

6550

7800

9675

Minimum power required:

without switchgear, 26 min-1

kW

62

68

75

66

73

80 - - - - - -

without switchgear, 30 min-1

kW

73

80

88

84

91

98 - - - - - -

with switchgear, 14.4 / 26

min-1

kW

38

42

46

40

45

49

60

64

67 - -

-

with switchgear, 16.7 / 30

min-1

kW

45

49

54

52

56

60

73

78

82

87

92

98

with switchgear, 12.8 / 23

min-1

kW

- - - - - - - - -

74

78

82

Maximum operating pressure

bar

210

Oil flow rate

l/min

25 - 45

Power supply weighing device /

lighting system / electro-hydraulic

control set

volt

12 VDC

2.6.2.2 Tyre pressure

2.6.3 Verti-Mix Double

Product description

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

25

Type

Verti-Mix Double

Unit

1501 D

1801 D

2401 D

3101 D

P.t.o. speed

min-1

540

Sound pressure level

dB(A)

≤85

* Actually usable mixing capacity, mixing augers having been deducted from the capacity

Tab. 7

Fig. 11

Figures, technical data and weights may change due to technical development and are not binding for

delivery.

The sound pressure level mainly depends on the tractor used.

2.6.3.1 Dimensions of wagon

Product description

26

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Type

Verti-Mix Double

Unit

1501 D

1801 D

2401 D

3101 D

Extension height

m

-

0.18

0.36

-

0.18

0.36

-

0.18

0.36

-

0.18

0.36

Length:

A = with front

crossover conveyor

m

7.01

7.40

7.76

8.13

B = with rear

crossover

conveyor*

m

6.61

6.98

7.27

7.55

C = without

crossover conveyor

m

6.34

6.71

7.06

7.44

Width:

D = with crossover

conveyor

m

1.96

2.16

2.28

2.42

E = with right-hand

or left-hand side

discharge

m

2.06

2.26

2.38

2.52

E = with side

discharge on both

sides

m

2.16

2.36

2.48

2.62

Height incl. tyres (single

axle):

F = with 8.15- 15

(14 PR) double

Middle axle position

m

m

2.30

2.28

2.48

2.46

2.66

2.64

2.34

--

2.52

--

2.70

--

2.62

--

2.80

--

2.98

--

--

--

F = with 215/75-

17.5 double

Middle axle position

m

m

2.36

2.35

2.54

2.53

2.72

2.71

2.37

--

2.55

--

2.73

--

2.66

--

2.84

--

3.02

--

--

--

F = with

235/75R17.5

double

m

--

--

2.66

2.84

3.02

--

F = with

455/45R22.5

m

--

--

2.85

3.03

3.21

F = with

435/50R19.5

Middle axle position

Reduction of load

capacity:

m

m

2.51

2.49

2.69

2.67

2.87

2.85

2.52

--

2.70

--

2.88

--

2.80

2.98

--

3.16

-kg

--

--

12100

F = with 400/60-

15.5

Middle axle position

Reduction of load

capacity:

m

m

2.43

2.38

2.61

2.56

2.79

2.74

--

--

kg

Product description

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

27

Type

Verti-Mix Double

Unit

1501 D

1801 D

2401 D

3101 D

Extension height

m

-

0.18

0.36

-

0.18

0.36

-

0.18

0.36

-

0.18

0.36

Height incl. tyres

(Tandem axle):

F = with 10.0/75-

15.3

m

2.38

2.56

2.74

F = with 400/60-

15.5

Increase of load

capacity:

m

2.51

2.69

2.87

2.8

2.98

3.16

kg

12800

17800

--

F = with

435/50R19.5, track

1930

m

--

--

2.87

3.05

3.23

3.21

3.39

3.57

Increase of load

capacity:

kg

--

--

17800

--

F = with 435/50R19.5,

track 1720

m

--

2.56

2.74

2.92

2.84

3.02

3.20

3.21

3.39

3.57

Increase of load

capacity:

kg

--

12800

17800

--

G = Track

m

1.52

1.52

1.74

1.94

H = Outside wheel width

incl. standard tyres:

m

2.03

2.03

2.03

J = Container length

m

4.84

5.17

5.59

6.07

Discharge height with

crossover conveyor

m

0.79

0.81

0.81

1.03

* + 0.13 m with lighting

Tab. 8

Type

Verti-Mix Double

Tyres

Unit

1501 D

1801 D

2401 D

3101 D

Single axle

8.15-15 (14 PR) double

bar

9.0

9.0

9.0

--

215/75R17.5 (133) double

bar

9.5

9.5

9.5

--

235/75R17.5 double

bar

--

--

9.5

--

435/50 R 19.5

bar

9.0

--

--

--

400/60-15.5 (18 PR)

bar

6.0

--

--

--

455/45R22.5

bar

--

--

9.0

--

Figures, technical data and weights may change due to technical development and are not binding for

delivery.

2.6.3.2 Tyre pressure

Product description

28

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Type

Verti-Mix Double

Tyres

Unit

1501 D

1801 D

2401 D

3101 D

Tandem axle

10.0/75-15.3 (18 PR)

bar

--

7.0

--

--

400/60-15.5 (18 PR)

bar

--

6.0

6.0

--

435/50 R 19.5

bar

--

--

9.0

9.0

Tab. 9

Battery voltage:

12 V (volt)

Socket for lighting:

7-pole

Socket for control set:

3-pole (DIN 9680). The feed line of the 3-pole socket should

have a minimum cable cross section of 4 mm².

Check the compatibility of the hydraulic oils before connecting

the machine to the hydraulic system of your tractor. For details

about checking the compatibility of the hydraulic oils, contact

your agricultural machinery dealer if necessary.

Do not mix mineral oils with bio oils.

Maximum operating pressure:

210 bar

Delivery rate of hydraulic pump

min. 25 l/min and max. 45 l/min at 180 bar

Hydraulic oil of machine:

ATF Hydraulic oil

Depending on their function, the hydraulic components can be

connected to:

a double-acting control device,

a single-acting control device and a depressurised return line

leading directly into the hydraulic oil tank of the tractor.

Given a free choice, we recommend a single-acting control device

and a depressurised return line. The hydraulic oil flows back into the

hydraulic oil tank of the tractor through the free return line with a low

back pressure. Thus, a free return line reduces heating-up of the

hydraulic oil.

2.7 Required tractor equipment

The employed tractor must meet the following requirements, in order to ensure correct use of the

machine:

Tractor engine output

For the necessary power required, please refer to chapter "Technical data", page 18.

Electrical system

Hydraulics

Product description

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

29

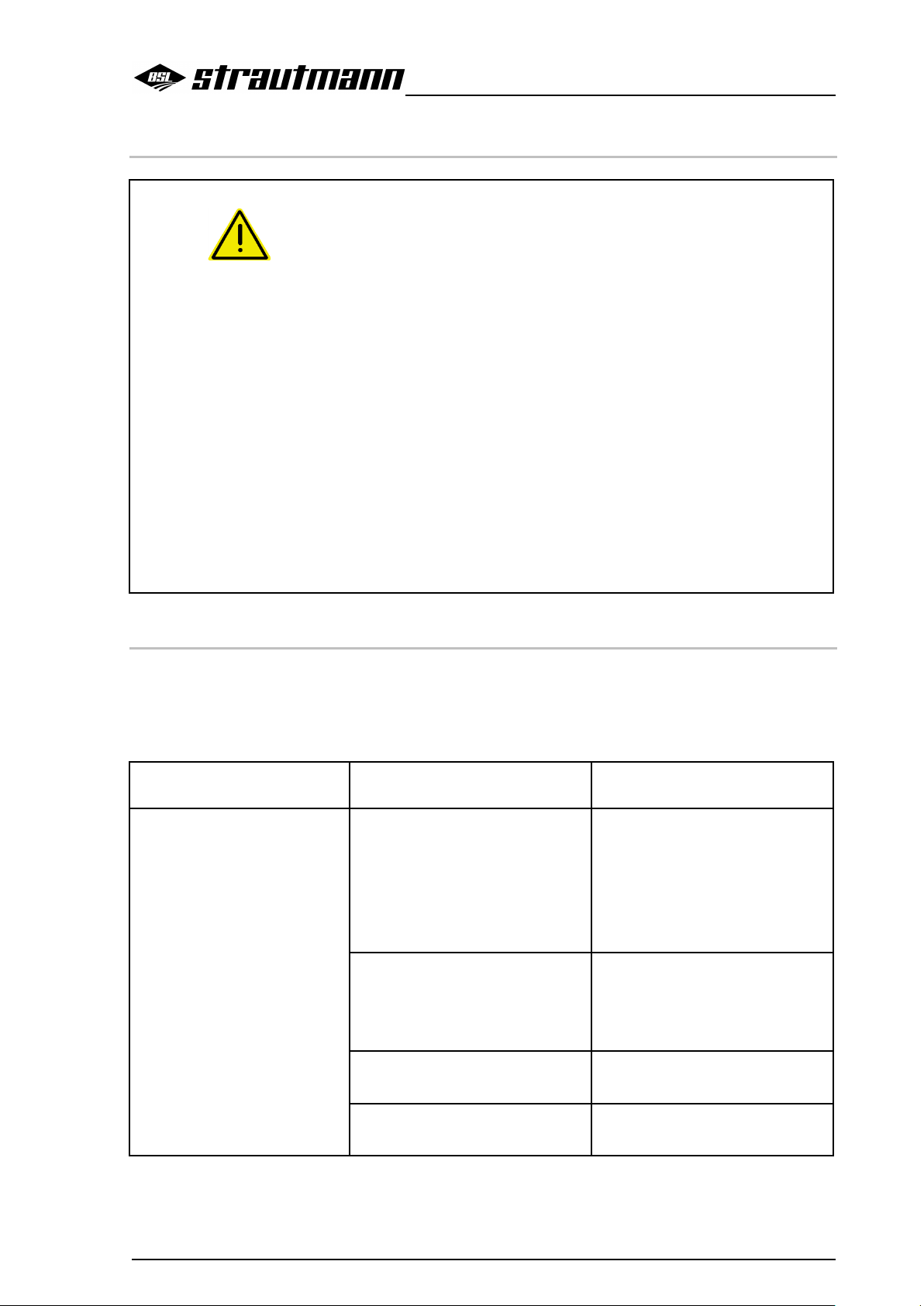

Hydraulic component:

Required control devices on the tractor:

Discharge door:

1 double-acting control device

Hydraulic supporting leg:

1 double-acting control device

Hydraulic counter-cutters:

1 double-acting control device

Hydraulic motor for

crossover conveyor:

Optional:

1 double-acting control device or

1 single-acting control device and

1 pressure-less return line (max. back pressure in return line

5 bar)

Side discharge conveyor:

1 double-acting control device (extend and retract)

Hydraulic motor for side

discharge conveyor:

Optional:

1 double-acting control device or

1 single-acting control device and

1 pressure-less return line (max. back pressure in return line

5 bar)

Conveyor extension:

1 double-acting control device (extend and retract)

Tab. 10

Required control devices on

the tractor:

Optional:

1 double-acting control device or

1 single-acting control device and

1 pressure-less return line (max. back pressure in return line

5 bar)

Tab. 11

Hydraulic service brake up to 6

km/h (not licensed for public

road traffic):

1 single-acting control device

Dual-line service brake system:

Dual-line compressed-air brake system including:

1 hose coupling (red) for the feed line

1 hose coupling (yellow) for the brake line

Hydraulic service brake (only

available for export):

1 hydraulic clutch according to ISO 5676 (100 bar)

Tab. 12

The used tractor must be equipped with mirrors such that the hazardous areas on both sides of the

machine are clearly visible from the tractor's seat.

Operation via direct tractor connection

Operation via Bowden cable or electro-hydraulic E-control

Optional extra

Brake system

Mirrors

Product description

30

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

The machine is equipped with a vertically adjustable drawbar for:

Top linkage with flanged drawbar lug 40 mm according to DIN 74054-1/2 / ISO 8755,

Top linkage with drawbar lug 40 mm according to DIN 74054-1/2 / ISO 8755 with automatic

reverse system (25 km/h) (only Verti-Mix 951, 1251),

Top linkage with flanged and cranked drawbar lug 40 mm

Top linkage with coupling head type 80

Bottom linkage with coupling head type 80

Bottom linkage with flanged drawbar lug type 3394 and fixed supporting leg,

Bottom linkage with flanged drawbar lug 50 mm according to DIN 74053-1 / ISO 1102.

The drawbar (1) can be screwed on within the

adjusting range of the positioning holes (2) at

different levels compared to the chassis (3)

(Fig. 12).

This allows optimum adjustment of the drawbar

lug (4) to the respective height of the coupling

device of the different tractors.

The drawbar lug (4) is coupled by means of an

appropriate bolt-type coupling.

Fig. 12

2.8 Drawbar

► See also chapter "Adjust mounting height of drawbar ", page 63!

Safety instructions

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

31

Observe all safety instructions included in these operating

instructions!

Most accidents are caused by non-observance of simplest safety

rules.

By observing all safety instructions included in these operating

instructions, you help to prevent accidents.

The fodder mixing wagons of the Verti-Mix series:

are designed for chopping, homogeneous mixing, transport and discharge all types of silage and

normal fodders used in keeping livestock if the dry substance content of the total mixture is more

than 30 % at any time of the mixing process,

must not be charged otherwise than by means of:

a tractor equipped with a front loader,

a yard or wheeled loader,

a telescopic loader,

the provided feeding aids such as mineral feed funnel, etc.

directly from the pipe or conveying device for concentrated feed, mineral feed etc.

3 Safety instructions

This chapter contains important information for the user and the operator on how to operate the

machine in a safety-conscious and trouble-free way.

3.1 Correct use

The following is also part of the correct use:

the observance of all instructions contained herein,

the observance of the specified service and maintenance work on the machine,

the exclusive use of original spare parts.

Any use beyond this is prohibited and will be regarded as incorrect.

For any damage resulting from incorrect use:

the user will be solely responsible,

the manufacturer will not assume any liability.

3.2 Safety-conscious working

The machine complies with the safety-related requirements and state of the art. When using the

machine, risks and impairments might yet arise:

● for life and limb of the operator or third parties,

● for the machine itself,

● to other material assets.

For the safety-conscious operation of the machine, please observe:

● these operating instructions, in particular:

Safety instructions

32

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

WARNING

Risk of being crushed, cut, becoming entangled, being drawn in

or risk of impact if the tractor and the machine are not in

adequate roadworthy and reliable condition!

Check tractor and machine for their road and operational safety

before each startup.

The operating instructions:

must always be kept at the machine's place of operation,

must always be easily accessible for operating and maintenance

staff.

● the basic safety instructions, the activity-related safety instructions and the instructions

what to do,

● the instructions regarding correct use.

● the warning signs on the machine,

● the general national occupational safety, accident prevention and environmental protection

rules,

● the national road traffic regulations when carrying out transport journeys.

Only operate the machine in perfect safety-related condition.

3.3 Organisational measures

3.3.1 User’s obligation

The user is obliged:

to observe the general national occupational safety, accident prevention and environmental

protection rules,

to exclusively have staff operating the machine who:

know the basic occupational safety and accident prevention regulations,

have been instructed how to operate the machine,

have read and understood these operating instructions.

to keep all warning signs attached to the machine in legible condition,

to replace any damaged warning signs,

to provide the necessary personal protective equipment such as protective goggles, work gloves

according to DIN EN 388, safety footwear, protective clothing, skin protectant, etc.

3.3.2 Operator’s obligation

Any members of staff charged to operate the machine are obliged:

to acquaint themselves with the machine before starting operation,

to acquaint themselves with the following regulations and to observe them during work:

the general national occupational safety, accident prevention and environmental protection

rules,

the chapter "Basic safety instructions“, page 35,

the chapter „Warning and instruction signs“, page 43, and the warning signs when operating

the machine,

Safety instructions

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

33

Only trained and instructed staff is allowed to operate the machine.

The user must clearly define the responsibilities of the members of

staff for operation, service and maintenance.

A person to be trained must be supervised when operating the

machine.

The operator is only allowed to carry out such work as specified in

these operating instructions which is not marked as "Shop work".

Only authorised workshops are allowed to carry out work on the

machine which requires special expert knowledge. Authorised

workshops have qualified staff and adequate means (tools, lifting and

supporting equipment) at their disposal to carry out this work properly.

This applies to any work:

which is not mentioned in these operating instructions,

which is marked as "Shop work" in these operating instructions.

People are not allowed in the hazardous area:

if the tractor engine is running with the propeller shaft coupled/

the hydraulic/electronic system connected,

if tractor and machine are not secured against accidental

starting and rolling.

Only if no people are within the hazardous area of the machine, is the

operator allowed to:

move the machine,

set movable machine parts from transport to working position

and from working to transport position,

power working tools.

the chapters of these operating instructions which are important for the tasks assigned to

them.

If the operator notices that a device is not in a sound safety-related condition, the operator shall be

obliged to immediately eliminate this defect. If this is not part of the operator’s scope of tasks or he/she

lacks adequate expert knowledge, the operator shall be obliged to report this defect to his/her superior

or to the user.

3.3.3 Qualification of operator

3.4 Product safety

3.4.1 Hazardous areas and dangerous spots

The hazardous area is the area within and/or in the vicinity of a machine, in which the safety or health

of people might be impaired.

Within the hazardous area, risks occur at dangerous spots which cannot be completely eliminated due

to the operational safety of the machine. The risks exist permanently or may occur unexpectedly.

Dangerous spots are marked by warning signs attached to the machine, which warn about existing

residual risks.

Safety instructions

34

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Dangerous spots exist:

within the drawbar area between tractor and machine,

within the area of the powered propeller shaft,

within the area of the discharge openings,

within the area of the powered discharge conveyor, crossover conveyor or conveyor extension,

in the mixing container with the machine powered or not powered,

around the discharge pipe and in ejection direction in case of machines equipped with straw

blower.

In these operating instructions, activity-related safety instructions mark the existing residual risks.

Risks may arise:

due to work-related movements of the machine and its working tools,

due to substances or foreign objects blown out of the machine,

due to accidental lowering of the lifted machine/of lifted machine parts,

due to accidental starting and rolling of the machine / of tractor and machine.

3.4.2 Safety-conscious operation of machine

The machine is only allowed to be operated from the driver’s seat of the tractor, provided that no

people are within the machine’s hazardous area. Observe the information in the chapter "Hazardous

areas and dangerous spots", page 33.

3.4.3 Safety and protective devices

Only operate the machine when all safety and protective devices are properly fixed and in fully

operable condition.

Defective or removed safety and protective devices might cause dangerous situations.

Check all safety and protective devices for visible damage and functional ability before starting

the machine.

3.4.4 Structural alterations

Vehicles provided with an official operating license or vehicle-linked devices and equipment

provided with an official operating license or a road traffic license according to the road traffic

regulations must be in the condition specified by that license.

You are only allowed to carry out structural alterations, extensions or modifications on the

machine with the prior written consent of the manufacturer.

In case of non-authorized structural alterations, extensions or modifications:

the declaration of conformity and the CE symbol of the machine will become invalid,

the operating license according to national and international regulations will become invalid.

Exclusively use original parts or modification and accessory parts approved by the manufacturer

such that:

the declaration of conformity and the CE symbol of the machine will remain unaffected,

the operating license according to national and international regulations will remain

unaffected,

perfect functioning of the machine will be ensured.

The manufacturer will not assume any liability for damage resulting from:

Safety instructions

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

35

unauthorized alterations of the machine,

non-approved modification and accessory parts,

welding and drilling work on load-bearing parts of the machine.

3.4.5 Spare and wearing parts, auxiliary materials

Immediately replace machine parts which are not in perfect condition.

Exclusively use original parts of the manufacturer or parts approved by the manufacturer such that the

operating license according to national and international regulations will remain unaffected. If spare

and wearing parts produced by third-party manufacturers are used, their stress-related and safetyconscious design and production will not be ensured.

The manufacturer will not assume any liability for damage resulting from the use of non-approved

spare and wearing parts or auxiliary materials.

3.4.6 Warranty and liability

As a basic principle, our "General Sales Terms and Delivery Conditions" shall apply. They have been

handed over to the user upon conclusion of contract at the latest.

Any warranty and liability claims in case of personal injury and material damage will be excluded if

they are due to one or several of the following reasons:

improper use of the machine,

improper assembly, commissioning, operation and maintenance of the machine,

operation of the machine, the safety devices being defective or the safety and protective devices

having not been properly installed or being not serviceable,

non-observance of the instructions included in the operating instructions referring to

commissioning, operation and maintenance,

unauthorized structural alterations on the machine,

insufficient inspection of machine parts which are subject to wear,

improperly effected repairs,

disasters due to foreign objects and force majeure.

3.5 Basic safety instructions

► See also chapter "Secure tractor and machine against accidental starting and rolling", page 62!

► See also chapter "Enter the mixing container ", page 123!

Basic safety instructions:

shall, as a basic principle, apply to the safe operation of the machine,

are summarized in the subsections below.

3.5.1 General safety and accident prevention instructions

Observe the general national safety and accident prevention regulations in addition to the safety

instructions included in this chapter!

Observe the warning and instruction signs attached to the machine. They provide important

information for the safe and trouble-free operation of the machine!

Observe the activity-related safety instructions included in the other chapters in addition to the

basic safety instructions included in this chapter!

Safety instructions

36

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Wear your personal protective equipment when carrying out work on the machine!

Make sure that people leave the immediate vicinity of the machine before moving or starting the

machine! Particularly be aware of children!

Never carry passengers, animals or objects on the machine! Carrying passengers and transport

of animals or objects are not allowed on the machine!

Adapt your driving such that you have always safe control over the tractor with the

attached/hitched machine!

Consider your personal abilities as well as the road, traffic, visibility and weather conditions, the

driving characteristics of the tractor and the influences exerted by the attached/hitched machine.

The following measures are imperative before carrying out any work on the machine such as

adjusting work or trouble-shooting:

secure the machine against rolling with the machine not hitched to the tractor,

turn the tractor engine off and secure tractor and machine against accidental starting and

rolling with the machine hitched to the tractor,

secure lifted machine parts/the lifted machine against accidental lowering.

Hitching and unhitching of machine

Only use appropriate tractors to hitch and transport the machine!

Properly hitch the machine to the specified devices!

Be sure not to exceed the following values when hitching the machine to the front and/or rear of a

tractor:

the gross vehicle weight rating of the tractor,

the admissible axle loads of the tractor,

the admissible tongue load at the tractor's coupling spot,

the admissible towing capacity of the coupling device,

the admissible load capacities of the tractor tyres,

the tractor's front axle load must never fall below 20 % of the tractor's empty weight!

The tractor must reach the deceleration specified by the tractor's manufacturer even with

the machine attached / hitched up.

Secure tractor and machine against rolling before hitching or unhitching the machine!

People are not allowed between tractor and machine, while the tractor is approaching the

machine!

Present helpers are only allowed to act as a guide next to the vehicles and to enter the space

between the vehicles after the vehicles have completely stopped.

Put the support device into support position when hitching and unhitching the machine (stability)!

Risk of crushing and shearing when actuating support devices!

Hitching and unhitching the machine to or from the tractor requires particular care! Crushing and

shearing zones exist within the area of the coupling spots between tractor and machine!

Check the connected supply lines. Connected supply lines:

must easily give way to any movements during cornering without any stress, buckling or

must not chafe against external components!

Always park the unhitched machine in a stable position! Pay attention to the ground condition.

Beware of soft surfaces.

chafing,

Safety instructions

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

37

Use of machine

Acquaint yourself with all mechanisms and operating elements of the machine and their functions

before starting work! During operation it will be too late.

Wear close-fitting clothing! Loose-fitting clothing increases the risk of becoming entangled in or

wound up at drive shafts!

Start the machine only if all protective devices have been installed and are in protective position!

Observe the maximum load capacity of the attached/hitched machine and the admissible axle

and tongue loads of the tractor! Run the machine with the cargo space being only partly filled if

necessary.

People are not allowed:

within the operating/hazardous area of the machine,

within the discharge area of the machine,

within the turning and swivelling range of movable machine parts,

beneath lifted and unsecured movable machine parts!

You are only allowed to operate powered machine parts if there are no people within the

machine’s hazardous area!

Secure the tractor against accidental starting and rolling before leaving it!

Safely support folded-up covers before standing underneath them!

Transport of machine

Observe the respective national road traffic regulations when carrying out transport journeys on

public roads!

Before carrying out transport journeys, check:

the supply lines for proper connection,

the lighting system for damage, proper functioning and cleanliness,

the brake and hydraulic system for visible defects,

whether the parking brake has been completely released,

the brake system for proper functioning,

whether the required transport equipment, such as lighting, warning and protective devices,

has been properly mounted on the machine!

Always ensure sufficient steerability and braking ability of the tractor!

Machines attached/hitched to a tractor and front or tail weights influence the driving

characteristics as well as the steerability and the braking ability of the tractor.

Use front weights if necessary!

The tractor's front axle load must never fall below 20 % of the tractor's empty weight, in order to

ensure sufficient steerability.

Always properly fix front weights to the fixing points provided for this purpose!

Observe the maximum loading capacity of the attached/hitched machine and the admissible axle

and tongue loads of the tractor!

Check the braking effect before starting the journey! The tractor must produce the required

deceleration for the combination of tractor and attached/hitched machine!

Observe the broad overhang and the flywheel mass of the machine when cornering with

attached/hitched machine!

Safety instructions

38

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Avoid sudden changes of direction, in particular when travelling uphill and downhill and when

traversing hills!

Set all movable machine parts to transport position and secure them before carrying out transport

journeys! Use the transport locks provided for this purpose!

Before transport journeys, check whether the required transport equipment, such as lighting,

warning and protective devices, has been properly mounted on the machine!

Adapt your travelling speed to the conditio ns prevailing at the time!

Adapt your travelling speed to the conditions prevailing at the time!

Shift down to a lower gear before travelling uphill!

Switch the single-wheel brake system off (lock pedals) before carrying out transport journeys!

3.5.2 Hydraulic system

Only an authorised workshop is allowed to carry out work on the hydraulic system!

Make sure that the hydraulic system on the tractor and on the machine has been depressurized

when connecting the hydraulic hose pipes!

Ensure to properly connect the hydraulic hose pipes!

● Do not block any operating elements, which serve to directly initiate hydraulic or electrical

movements of components, e.g. folding, swivelling and sliding operations!

The respective movement must automatically stop as soon as the respective operating element

is released.

This shall not apply to:

● continuous movements of devices,

● automatically controlled movements of devices,

● movements of devices which, for functional reasons, require an open-centre or pressing

position.

Before carrying out any work on the hydraulic system:

secure lifted movable machine parts against accidental lowering,

depressurize the hydraulic system,

turn the tractor engine off,

pull the ignition key out,

apply the parking brake.

Have hydraulic hose pipes checked for their operational safety by an expert at least once a year!

Hydraulic hose pipes must be replaced in case of visible defects, damage and ageing! Only use

original hydraulic hose pipes!

The period of use of the hydraulic hose pipes should not exceed six years (including a maximum

possible shelf life of two years).

Never try to block leaking hydraulic hose pipes with your hand or fingers! Immediately contact an

authorized workshop if a leak is suspected.

Hydraulic oil squirting out under high pressure may enter the skin and the body and cause

serious injuries.

If injuries caused by hydraulic oil occur, immediately contact the medical services. Risk of

infection!

Never try to detect leakage points with your bare hands. Risk of serious infection! Use

appropriate means when trying to locate leakage points (cleaning sprays, special leak detector

spray)!

Safety instructions

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

39

3.5.3 Electrical system

Before carrying out any work on the electrical system, disconnect the minus pole of the battery!

Always cover the plus pole of the battery as required. Risk of explosion in case of accidental

ground!

Only use the specified fuses. When using bigger fuses, the electrical system may be destroyed.

Risk of fire!

Ensure correct order when connecting and disconnecting the battery:

connection: first connect the plus pole, then the minus pole,

disconnection: first disconnect the minus pole, then the plus pole!

Avoid sparking and open fire in the vicinity of the battery! Risk of explosion!

● The machine can be equipped with electronic components and parts, the functioning of which

may be affected by electromagnetic emissions of other devices. Such interferences may be a

risk to people if the following safety instructions are not observed:

● In case of a retrofitting of electrical devices or components into the machine and their

connection to the on-board electrical system, the user must check on his own

responsibility whether the retrofitted parts interfere with the vehicle electronics or other

components.

● Ensure that the retrofitted electrical and electronic components comply with the EMC

Never fit the machine with additional work lights without authorisation! The manufacturer will not

assume any liability or warranty for subsequent damage on the electrical system.

directive as amended from time to time and bear the CE symbol!

3.5.4 Propeller shaft operation

The included operating instructions of the propeller shaft manufacturer shall apply!

Only use the propeller shafts specified by the manufacturer and equipped with the proper

protective devices!

Always transport the propeller shaft in horizontal position, in order to avoid injuries due to the

propeller shaft halves falling apart!

Check the propeller shaft:

protective tube and protective cone of the propeller shaft must be undamaged,

a protective cover must be mounted to the tractor's and to the machine's p.t.o. shaft! The

Working with the protective devices being damaged is not allowed!

Mounting and dismounting of the propeller shaft is only allowed:

Always ensure proper mounting and securing of the propeller shaft!

Secure the propeller shaft guard against rotation by installing the chain/s!

Always mount the wide-angle joint at the pivot point between tractor and machine when using a

In case of propeller shafts equipped with overload or overrunning clutch, this clutch must always

protective covers must be in proper condition!

with the p.t.o. shaft switched off,

with the tractor engine turned off,

with the ignition key pulled out,

with the parking brake applied!

wide-angle propeller shaft!

be mounted at the machine!

Safety instructions

40

Verti-Mix 951-1651, Verti-Mix 951-L, 1251-L, Verti-Mix 1501 D-3101 D 05.16

Before switching the propeller shaft on, check whether the selected speed and the sense of

rotation of the tractor's p.t.o. shaft have been adjusted to the admissible drive speed and the

sense of rotation of the machine!

Make sure that people leave the hazardous area of the machine before switching the p.t.o. shaft

on!

Do not use the coupled propeller shaft as a step!

Never switch the propeller shaft on with the tractor engine turned off!

Observe the admissible angular misalignment and the travel of the propeller shaft when

cornering!

Observe the transport and working position of the specified tubular covers of the propeller shafts!

People are not allowed within the range of the rotating propeller shaft when work with the

propeller shaft is being carried out!

Always switch the propeller shaft off if the angular misalignments occurring are too large or when

it is not required!

Risk of injury due to the flywheel mass of the machine parts continuing to rotate for a short time

after the propeller shaft has been switched off!