Page 1

INTEGRATION

GUIDE

TM

Solatop

INTEGRATION RECOMMENDATIONS

BEFORE YOU START

Carefully read this guide for the layout of the Solatop PV panels. If you do not have all the necessary information contact

Stratco for advice.

POTENTIAL APPLICATIONS

In principle, Solatop PV panels can be installed on any roof section with a minimum slope of 20º and facing North. The

panels can occupy entire roof surfaces or just a portion of the roof surface, meaning there are an almost unlimited

number of potential configurations.

As far as possible, roofs should not lie in the shadow of trees, neighbouring buildings or other objects, otherwise

performance will be correspondingly reduced. It may be necessary to plan for the use of dummy elements for optimum

aesthetic value.

Page 2

INTRODUCTION

This guide is intended for architects, builders and

experienced solar installers or individuals who have been

suitably trained and qualified.

Please read this layout guide thoroughly before

commencing the roof lay-out design. Double check

all dimensions, levels and locations when integrating

Solatop PV panels into the roof design.

It is recommended that the persons erecting the structure

have had some previous building experience because

some modifications to the existing house structure may

be required.

Stratco disclaims all liability for damages caused by

inadequate planning or faulty installation.

1.0 INTEGRATION INTO AN EXISTING ROOF & WIND LOAD CAPABILITIES

The architect, builder or council is to ensure the existing

or new house/structure is of suitable structural integrity

and complies with all relevant Australian Building codes

and standards.

Roof structure suitability is based on the Solatop PV

panels, Panel Mount Brackets, Mounting Batten, Panel

Support Bracket and Gutter Tray’s having a combined

2

mass of 25kg per 1m

The roof rafters are to have a maximum spacing of

1200mm and to be in sound condition to withstand the

systems mass and environmental loading.

.

The Solatop PV panel system has been engineered for

residential applications in accordance with AS4055-2006

Wind loads for housing.

The system can withstand loads from wind class, up to

and including, N4 and a maximum wind speed of 50m/s

(permissible). Refer to your local authorities for wind

classification in the specific installation site area.

For more information regarding the suitability of the

house structure to accommodate the Solatop PV panel

system, consult a structural engineer or a building

authority.

A water proofing membrane is required to be installed

between the Mounting Battens and Rafters. Sarking

membranes and sealing tapes, have to comply with local

requirements and building codes for fire resistance and

stability.

It is the builder’s responsibility to ensure that the

existing house roof structure is capable of withstanding

additional loads imposed by the Solatop PV system.

1.1 REQUIREMENTS FOR THE SUB-ROOF AND BATTEN CONSTRUCTION

The Solatop PV panel system requires ventilation between

the overlapped panels, whilst being as water tight as

possible.

A sarking membrane is recommended to be installed on

top of the rafters, making sure the sarking membrane

is lapped from the top, downwards and sealed with the

tape at the lapping joint, to resist water penetration.

The sarking membrane is to be installed across the roof

rafters, loose enough to allow air flow underneath the

Solatop PV panels, but without the possibility of pooling

water.

The sarking membrane will need to exit and attach into

the gutter, without any pooling area’s in front of the

fascia.

The Mounting Batten has been specifically designed

for the Solatop PV panel system. The Mounting Batten

spacing and placement is extremely important to the

finished array - battens must be planar and carefully

levelled if needed.

Page 3

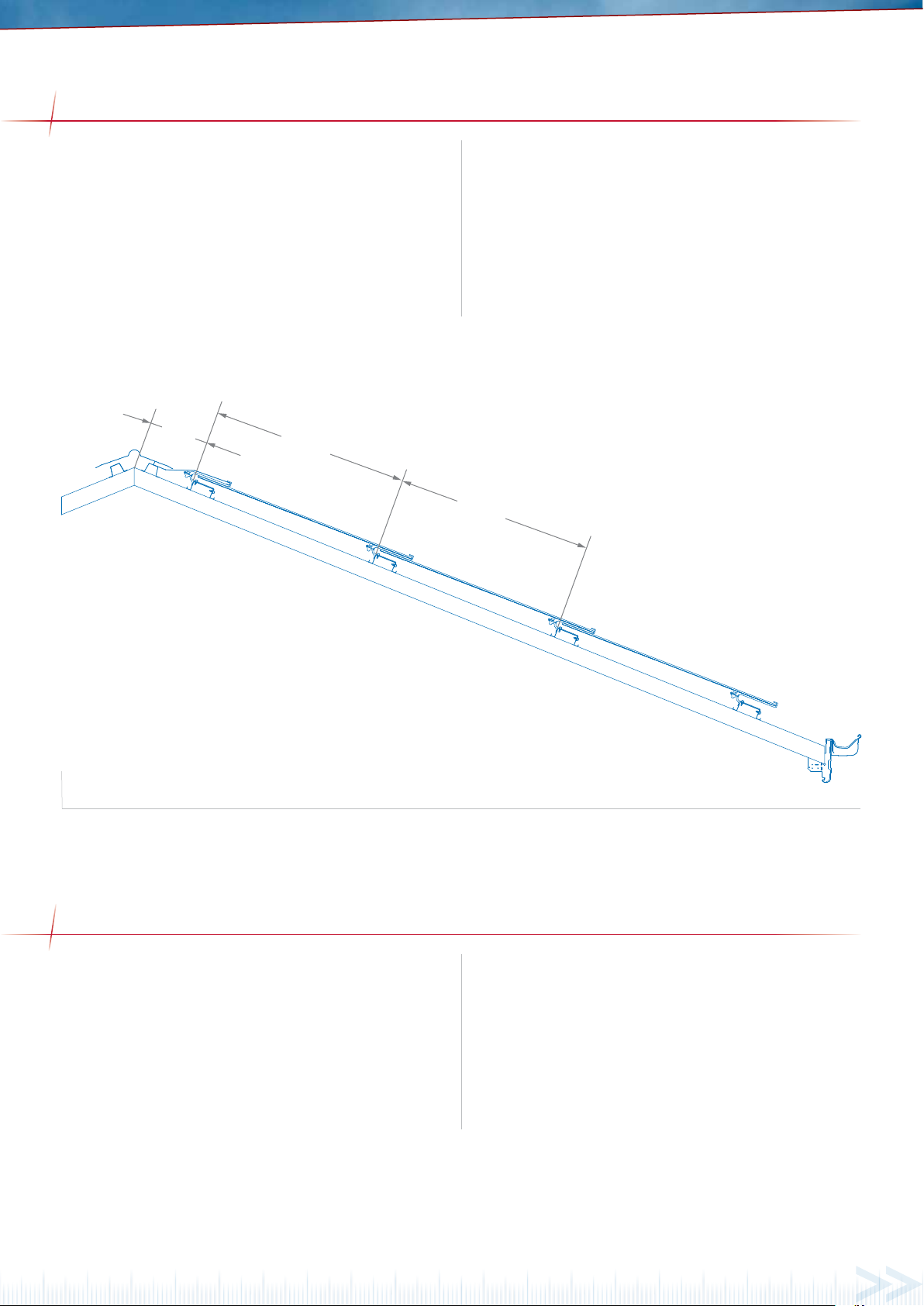

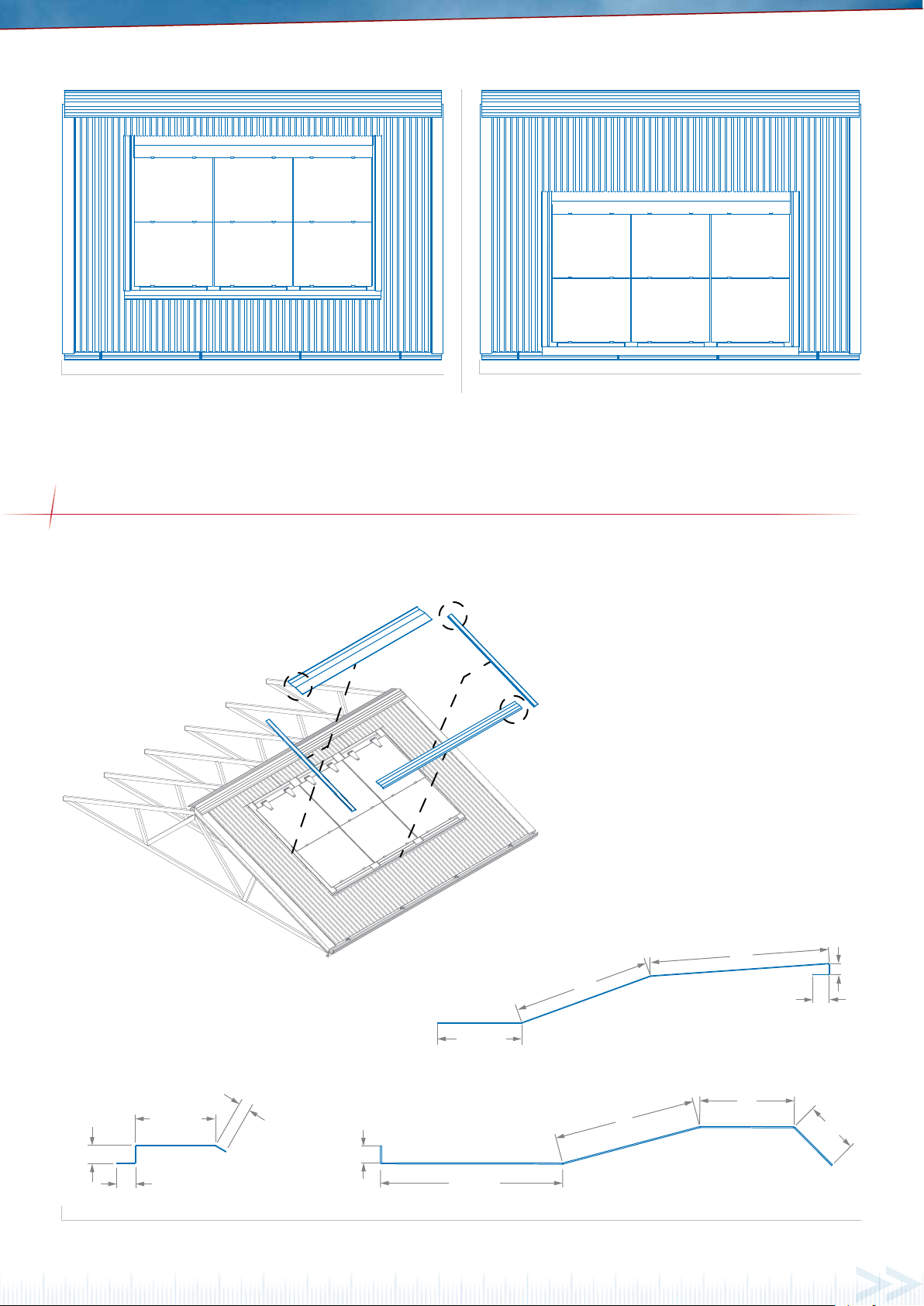

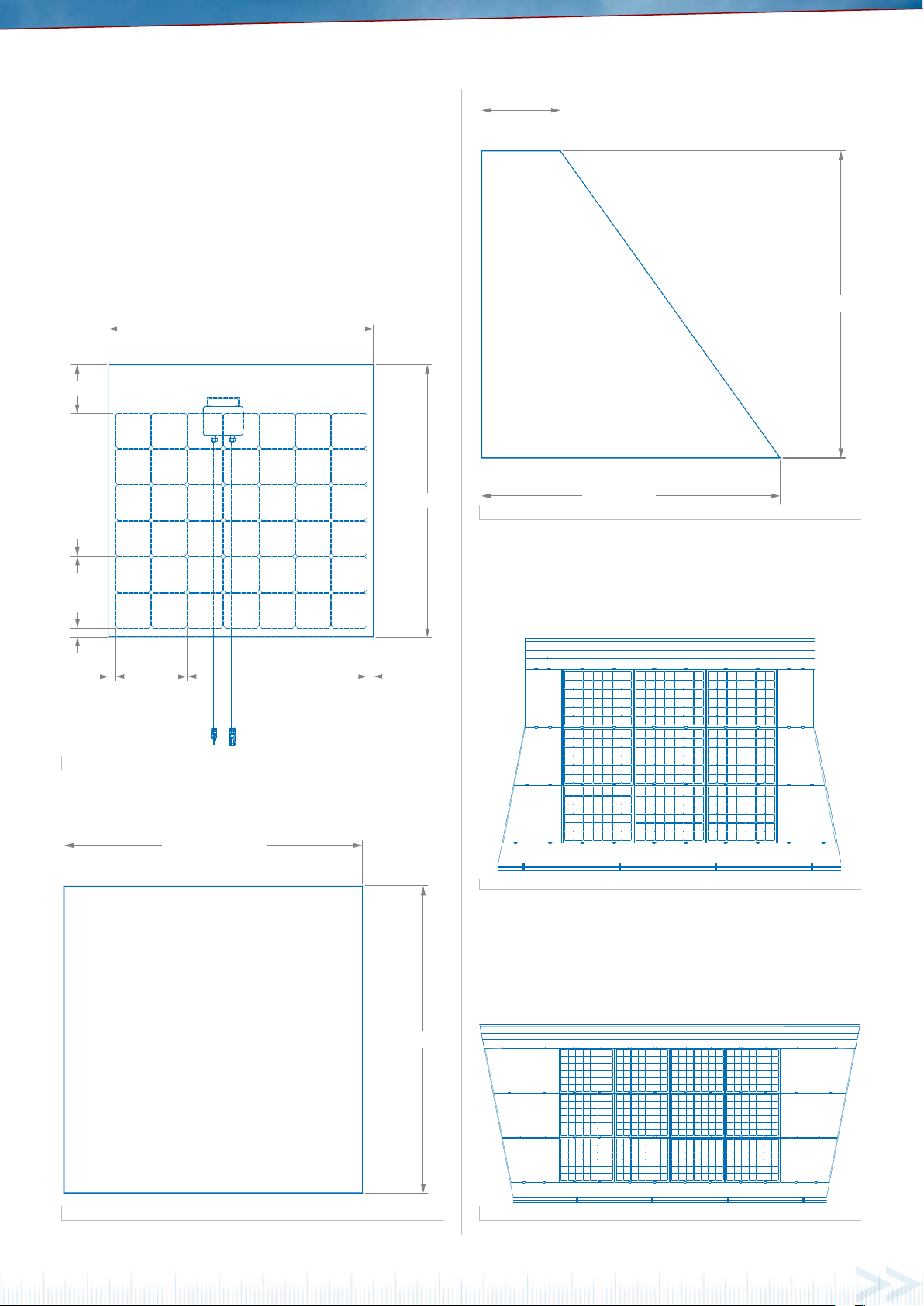

1.2 TOP MOUNTING BATTEN ARRANGEMENT

When the layout of the Solatop PV panel array starts from

the top of the roof, the first Mounting Batten is installed

270mm from the ridge centre point, as shown in Figure 1.

The batten needs to be parallel to the ridge line, which in

most cases will be the most visible aspect of the roof and

Solatop PV panel system.

270

832

The proceeding battens are then installed parallel to

the first batten, with a spacing distance of 832mm. The

battens are to be installed past the end panels and onto

the adjacent rafter.

832

1.3 BOTTOM MOUNTING BATTEN ARRANGEMENT

When the layout of the Solatop PV panel array starts

from the bottom of the roof, the first Mounting Batten

is installed as close as possible to the gutter, while

still allowing for sarking to exit into the gutter without

ponding, Figure 2.

The batten needs to be parallel to the fascia line, working

back up to the ridge line of the roof.

The proceeding battens are then installed parallel to

the first batten, with a spacing distance of 832mm. The

battens are to be installed past the end panels and onto

the adjacent rafter.

Figure 1

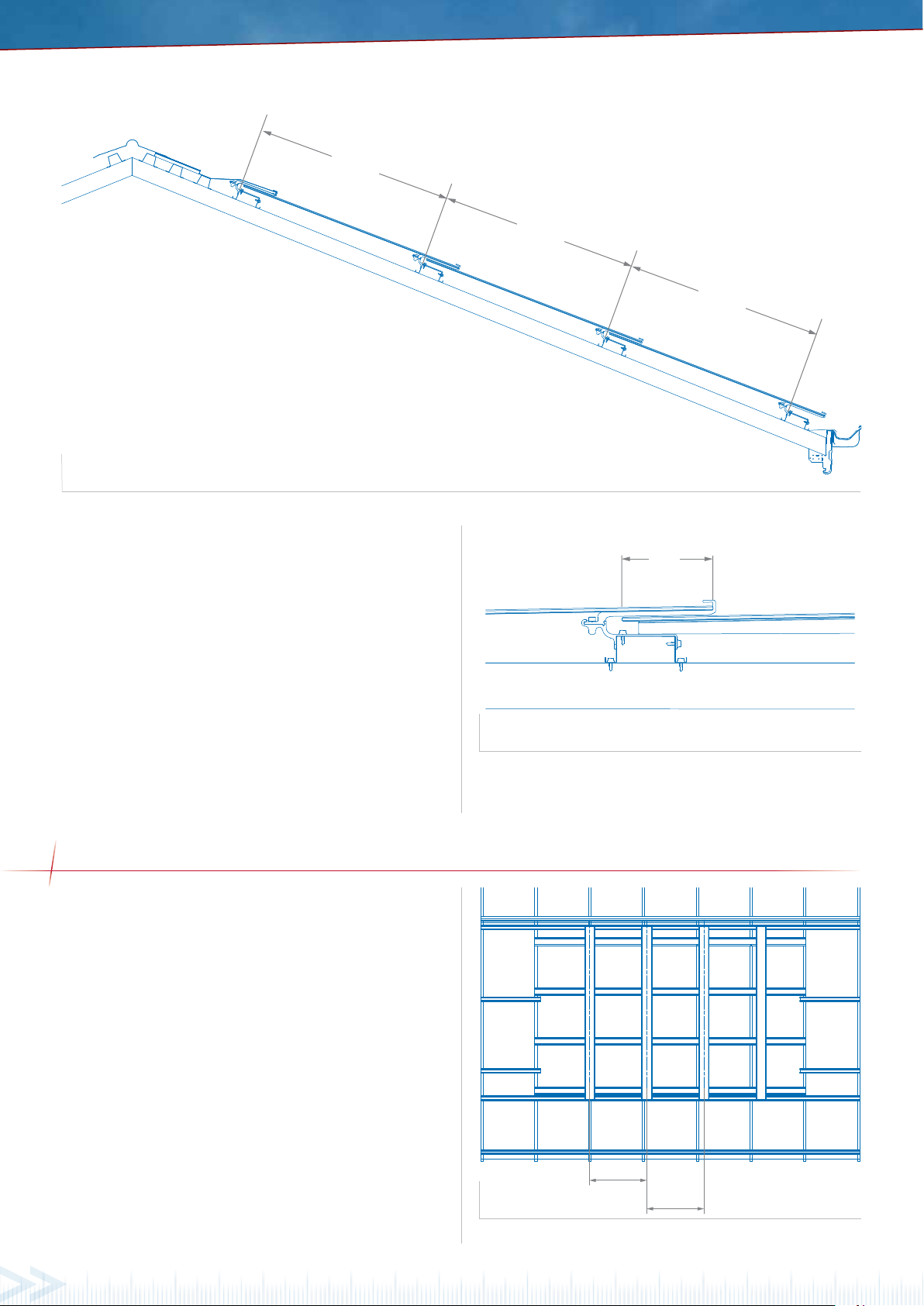

Page 4

140

832

IMPORTANT

As the Mounting Brackets are attached to the Mounting

Battens a standard overlapping distance is created

between the Solatop PV panels. This overlap needs to

be maintained throughout the array of panels, refer to

Figure 3.

832

832

Figure 2

The overlap distance will remain the same regardless of

a bottom or top arrangement.

The top Mounting Batten requires a row of Mounting

Brackets to allow a top flashing to be secured and overlap

the top Solatop PV panels.

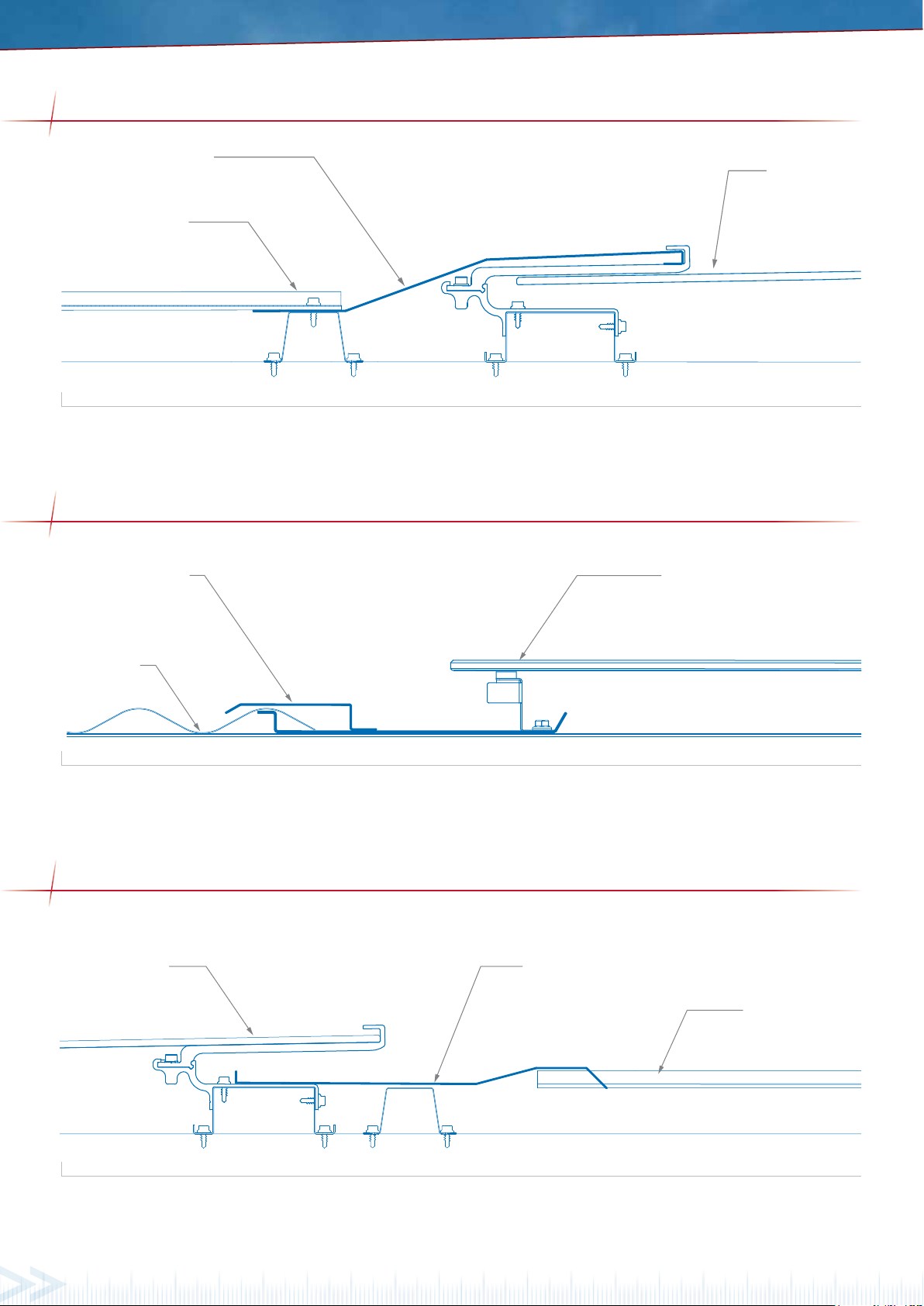

1.4 GUTTER TRAY ARRANGEMENT

The Outer and Inner Gutter Trays are to be installed with

a centre pitch of 958mm as shown in Figure 4.

The first outer gutter tray needs to be positioned

perpendicular to the battens, leaving enough space

above the top row of panels, to make sure that a flashing

suitably overlaps the gutter tray.

The bottom of the gutter tray will either empty into the

roofs gutter or onto a transition flashing between the

roof cladding and the gutter tray.

Figure 3

958

958

Figure 4

Page 5

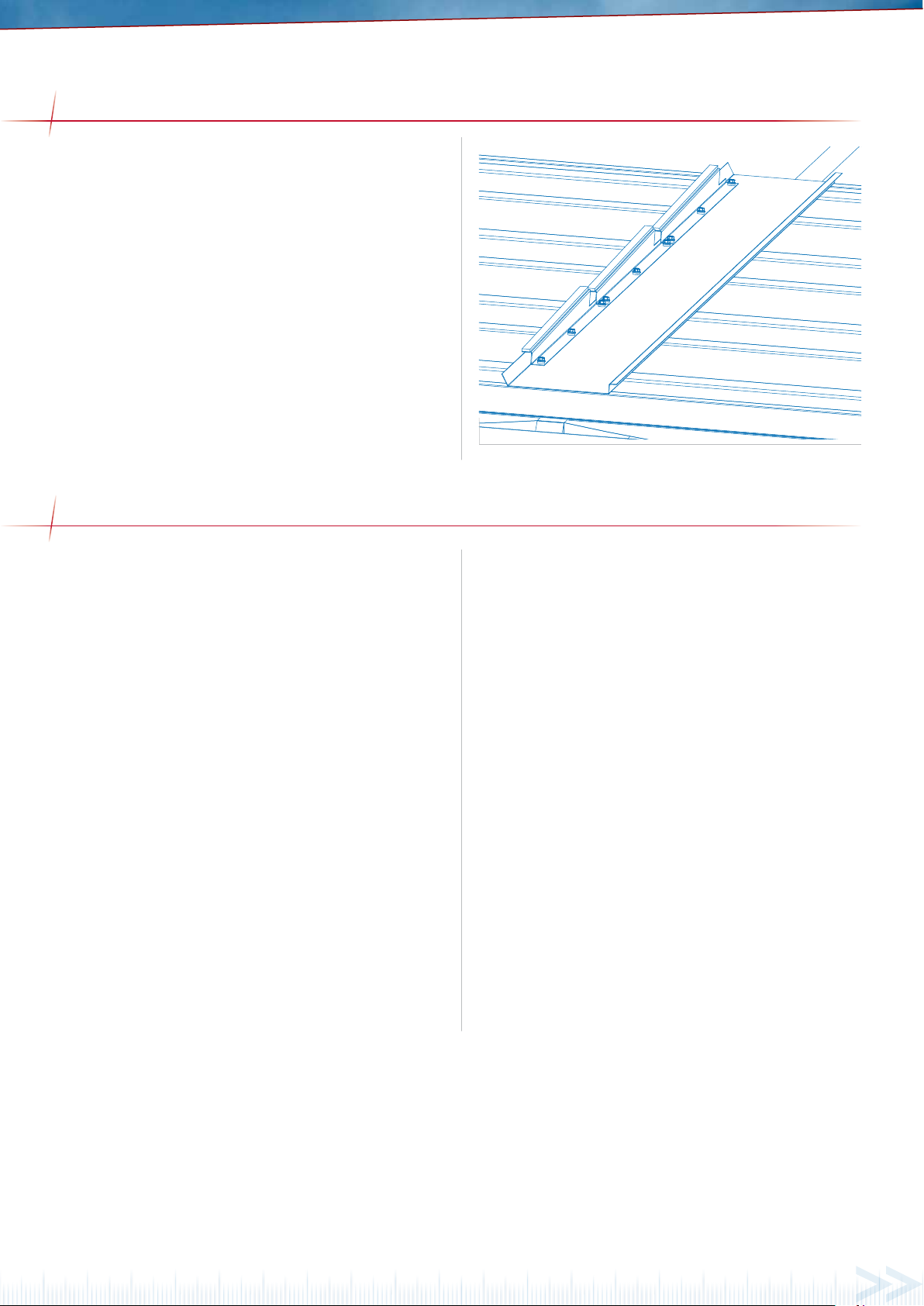

1.5 PANEL SUPPORT BRACKETS

The first Panel Support Bracket is to be positioned by

locating the narrow end of the bracket, 16mm past the

edge of the Mount Batten. The Panel Support Brackets

are supplied in a left and right hand configuration.

Figure 5 shows the correct orientation of the bottom

fold which mounts to the Gutter Tray. The Panel Support

Brackets should be mounted as close to the Gutter tray

edge as possible.

2.0 FLASHING RECOMMENDATIONS

Figure 5

Each roofing project has its own particular physical

constraints. Following the design procedures detailed

within this guide will ensure a successful integration of

PV panels with the roof line.

Solatop PV panels can be integrated with the roof

cladding at the top, middle or bottom of a roof section.

They can also be used during the design of new structures

to replace roof cladding as part of the standard build

process.

Solatop PV panels can be incorporated across an entire

roof section. It is necessary to work out the area of roof

available to determine the layout of the Solatop PV panels

and if glass infill panels are required.

The Solatop PV panels and glass infill panels must adhere

to all structural elements of the existing roof including

the strength, watertightness and drainage.

Choosing a system that best suits your design needs is

dependant on the unshaded roof area available.

In Australia fixed Solatop PV panels should be North

facing at a minimum pitch of 20° for optimum electricity

production.

It is the responsibility of the designer/builder to

determine how many solar panels will physically fit in the

chosen roof space. Solatop PV panels can be integrated to

existing roofs, interspersed with standard roof cladding.

DESIGN RULES

Solatop PV panels perform at optimum capacity when

placed in direct sunlight. When designing the new

structure, or installing panels in an existing building,

position the Solatop PV panel array on a North facing

roof section to ensure efficiency year round.

When designing a new building ensure the roof area is

not shaded by trees or other buildings. Shading effects

the potential power production of your solar system.

Page 6

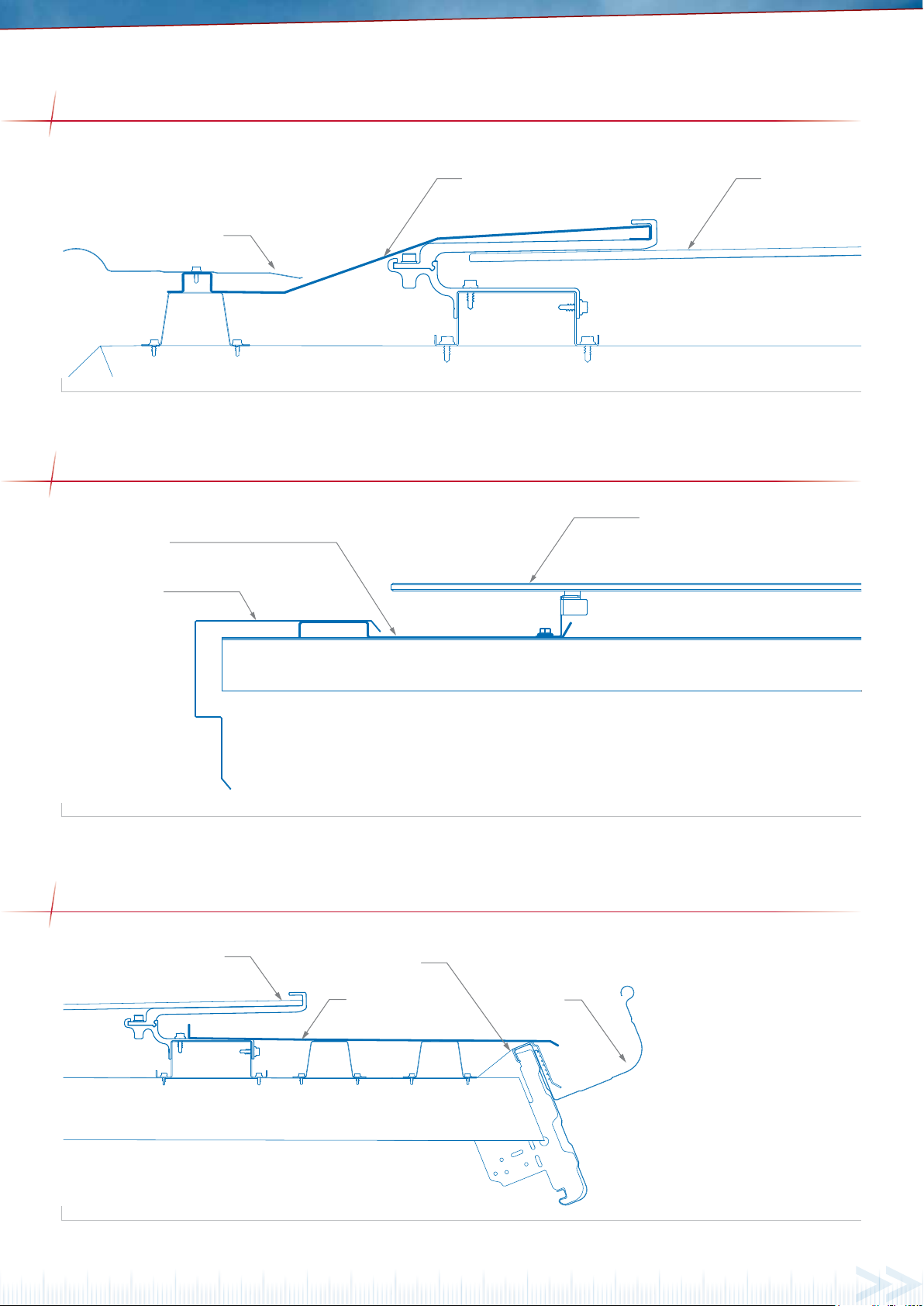

2.1 PARTIAL INTEGRATION WITH STEEL SHEET ROOFING

PANEL LAYOUT

Solatop PV panels can be placed at the top of a steel

sheet roof. A top row of mount brackets need to be used

to secure and locate the top flashing over the Solatop PV

panels.

Flashings are secured down through the sheet metal

roofing and into the battens.

Solatop PV panels can be placed in the middle of a steel

sheet roof. Sheeting will run under the ridge cap and over

the top flashing giving a neat finish to the roof line.

Solatop PV panels can be placed at the bottom of a steel

sheet roof. The bottom flashing will be turned down into

the gutter aiding water flow.

Figure 6

Top Mounted Solatop Array

Page 7

Middle Mounted Solatop Array

Bottom Mounted Solatop Array

FLASHING RECOMMENDATIONS

Integrating Solatop PV panels into steel sheet roofing will require the use of 4 seperate flashings; top, sides and bottom.

Typical flashing sizes are shown in Figure 7, and should be adjusted accordingly for each roof design.

B

A

C

B)

15

15

Variable

10

C)

15

A)

Variable

Variable

123

66

161

10

15

44

25

Figure 7

Page 8

TOP FLASHING DETAIL

Top Flashing A

Sheet Metal

Roofing

SIDE FLASHING DETAIL

Side Flashing B

Solatop PV

Panel

Steel Sheet Roof Integration: Flashing A

Solatop PV Panel

Sheet Metal

Roofing

BOTTOM FLASHING DETAIL

Panel

Steel Sheet Roof Integration: Flashing B

Bottom Flashing CSolatop PV

Sheet Metal

Roofing

Steel Sheet Roof Integration: Flashing C

Page 9

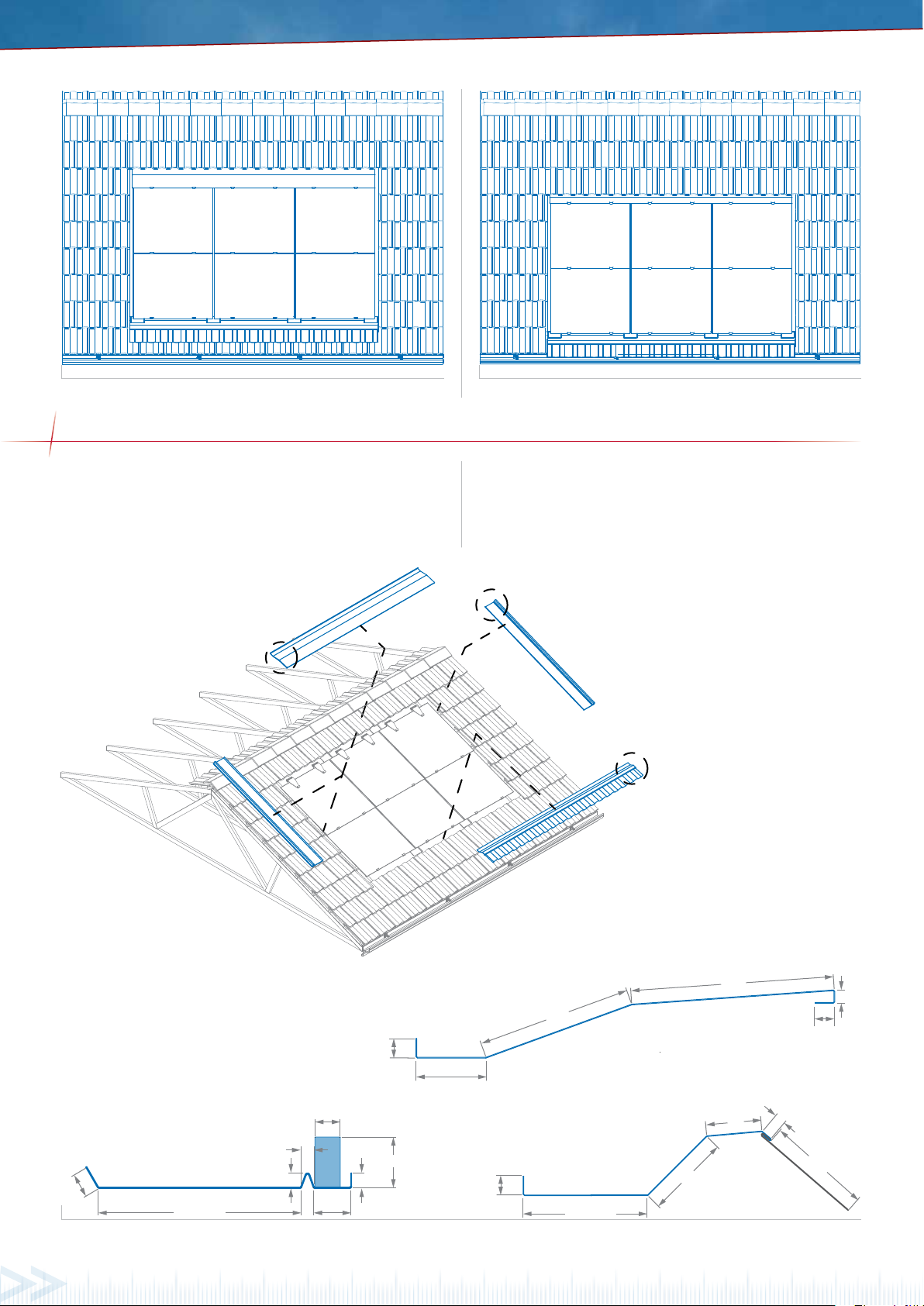

2.2 PARTIAL INTEGRATION WITH TILED ROOFING

PANEL LAYOUT

Solatop PV panels can be placed at the top of a tiled

roof. A minimum one row of tiles need to be above the

Solatop PV panels, allowing for grouting and securing of

the ridge cap.

Solatop PV panels can be placed in the middle of a tiled

roof. Tiles sit under the ridge tiles and over the top

flashing, allowing water to fall toward the gutters.

Solatop PV panels can be placed at the bottom of a tiled

roof. The bottom flexible flashing will be turned down

into the gutter aiding water flow.

The bottom flashing comprises a folded metal sheet and

a flexible lead free flashing which forms a water tight

bond when adhered to the roof tiles.

Figure 8

Top Mounted Solatop Array

Page 10

Variable

Middle Mounted Solatop Array Bottom Mounted Solatop Array

FLASHING RECOMMENDATIONS

Integrating the Solatop PV panels into tiled roofing will

require the use of 4 seperate flashings; top, sides and

bottom. Typical flashing sizes are shown in Figure 9, and

should be adjusted accordingly for each roof design.

A

The foam insert in side flashings B and D needs to be cut

on site to match the tile profile. The foam insert prevents

water flowing back under the tiles. Flexible flashing C

needs to be formed according to the tile profile.

B

C

B)

19

Variable

12

10

20

12

A)

15

40

Variable

C)

15

123

66

161

45

10

15

10

120

Figure 9

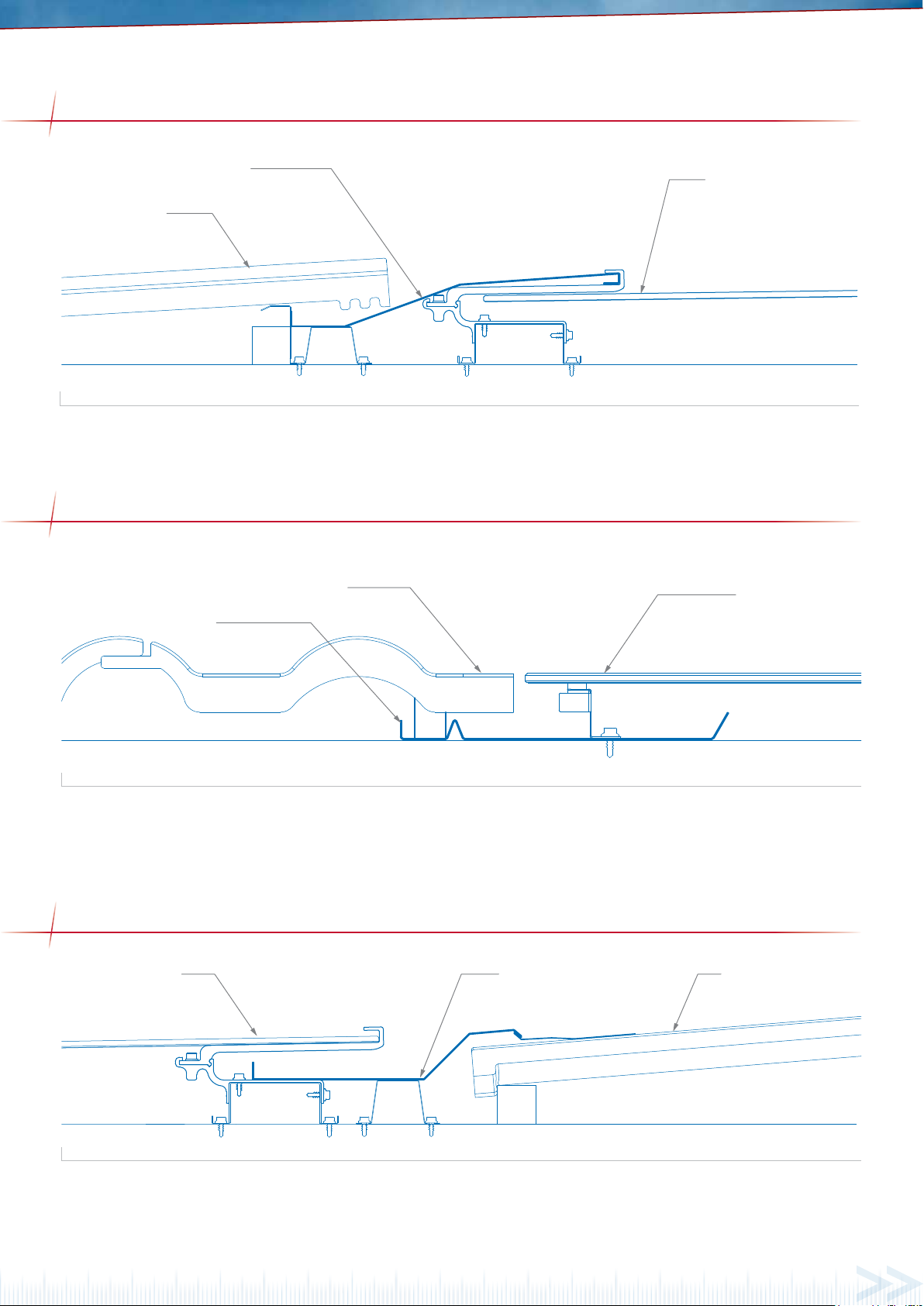

Page 11

TOP FLASHING DETAIL

Top Flashing A

Tiled Roofing

SIDE FLASHING DETAIL

Tiled Roofing

Solatop PV Panel

Tiled Roof Integration: Flashing A

Solatop PV Panel

Side Flashing B

BOTTOM FLASHING DETAIL

Panel

Tiled Roof Integration: Flashing B

Bottom Flashing CSolatop PV

Tiled Roofing

Tiled Roof Integration: Flashing C

Page 12

2.3 FULL INTEGRATION WITH ROOFING

PANEL LAYOUT

Solatop PV panels can be used as a substitute for

traditional roof sheeting. Full roof integration requires

the architect/builder to measure the available roof space

to confirm the number of Solatop PV panels and glass

infill panels to be used.

Dimensions of the Solatop PV panels and glass infill

panels need to be considered when designing the lay-out.

Solatop PV panels have fixed dimensions: 943mm x

970mm (Figure 11).

Glass infill panels have dimensions: 943mm x 970mm

Maximum (Figure 12), and 50mm x 300mm x 970mm

Minimum (Figure 13).

BRACKETS

Both the Solatop PV panels and glass infill panels are

supported by the Mounting Brackets. The Mounting

Brackets are secured to the Mount Battens and the

glass infill panels are mounted using the same process

as for the Solatop PV panels. Refer to the Solatop BIPV

Installation guide for panel mounting process.

Figure 10

Full Roof Solatop Array

The top row of panels, whether they are glass infill or

Solatop PV panels will require a row of Mount Brackets

above the panel to allow a top flashing to be secured

over the top.

Page 13

943 x 2 max.

300 min.

970

Glass infill panels require two brackets at the base and

a minimum one bracket at the top to ensure secure

attachment to the roof. Solatop PV panels require two

brackets at the base and two brackets at the top.

FULL ROOF INTEGRATION LAYOUTS

Layout of the roof will need to be carefully considered by

the architect/builder to maximise the number of Solatop

PV panels in the array.

943

172

50 min.

970

3

33

25 3

943 x 2 max.

300 min.

970

25

Figure 11

300 min.

Figure 13: Minimum Dimensions

Gambrel Roof Example Layout

970

Figure 12: Maximum Dimensions

Double Valley Example Layout

Page 14

Double Ridge Roof Example Layout

Trapeziod Roof Example Layout

FLASHING RECOMMENDATIONS

Integrating the Solatop PV panels across the whole roof will require the use of 4 seperate flashings; top, sides and

bottom. Typical flashing sizes are shown in Figure 14, and should be adjusted accordingly for each roof design. A

custom made valley gutter will need to be ordered for the ridge of the roof section.

B

A

13

B)

Variable

52

16

15

A)

C)

15

21

21

C

161

10

123

15

Variable

10

Variable

Figure 14

Page 15

TOP FLASHING DETAIL

Solatop PV Panel

Ridge Cap

SIDE FLASHING DETAIL

Side Flashing B

Top Flashing A

Full Roof Integration: Flashing A

Solatop PV Panel

Barge Capping

BOTTOM FLASHING DETAIL

Solatop PV Panel

Anti Ponding Flashing

Bottom

Flashing C

Full Roof Integration: Flashing B

Gutter

Full Roof Integration: Flashing C

Page 16

CONTACT

1300 165 165

3.0 LAYOUT PLANNING

BROCSIG

© Copyright February 2012

All brands and logos/images accompanied by ® or ™ are

trade marks of Stratco (Australia) Pty Limited.

www.stratco.com.au

Loading...

Loading...