MULTISPAN GABLE

WITH GAZEBO END ATTACHED PATIO

STRATCO OUTBACK ASSEMBLY INSTRUCTIONS.

®

Your supplementary guide to building an

ATTACHED MULTISPAN GABLE VERANDAH or PATIO

WITH GAZEBO END

This set of instructions should be used in conjunction with the Stratco instruction brochure

‘ Your complete guide to building an Attached Outback

Verandah, Patio or Carport'.

Flat Verandahs Attached -

®

BEFORE YOU START

Carefully read these instructions, along with the Stratco Flat Verandahs Attached

Instructions. If you do not have all the necessary tools or information, contact Stratco

for advice. Before starting lay out all components and check them against the

delivery docket. The parts description identifies additional gable parts, and the

component layout diagram indicates their fastening position.

FINIAL

Provides decoration

at the apex of the

gable end frame.

PURLIN INTERSECTION

COVER

TEMPLATE

Fastened to hip

rafters to cover

purlins and

attach deck.

Used to mark the

purlin cover for

cutting around

purlins.

BEAM TO BEAM BRACKET

BEAM FILLER

Connects horizontal

beams.

Fills gap

between

intersecting

beams.

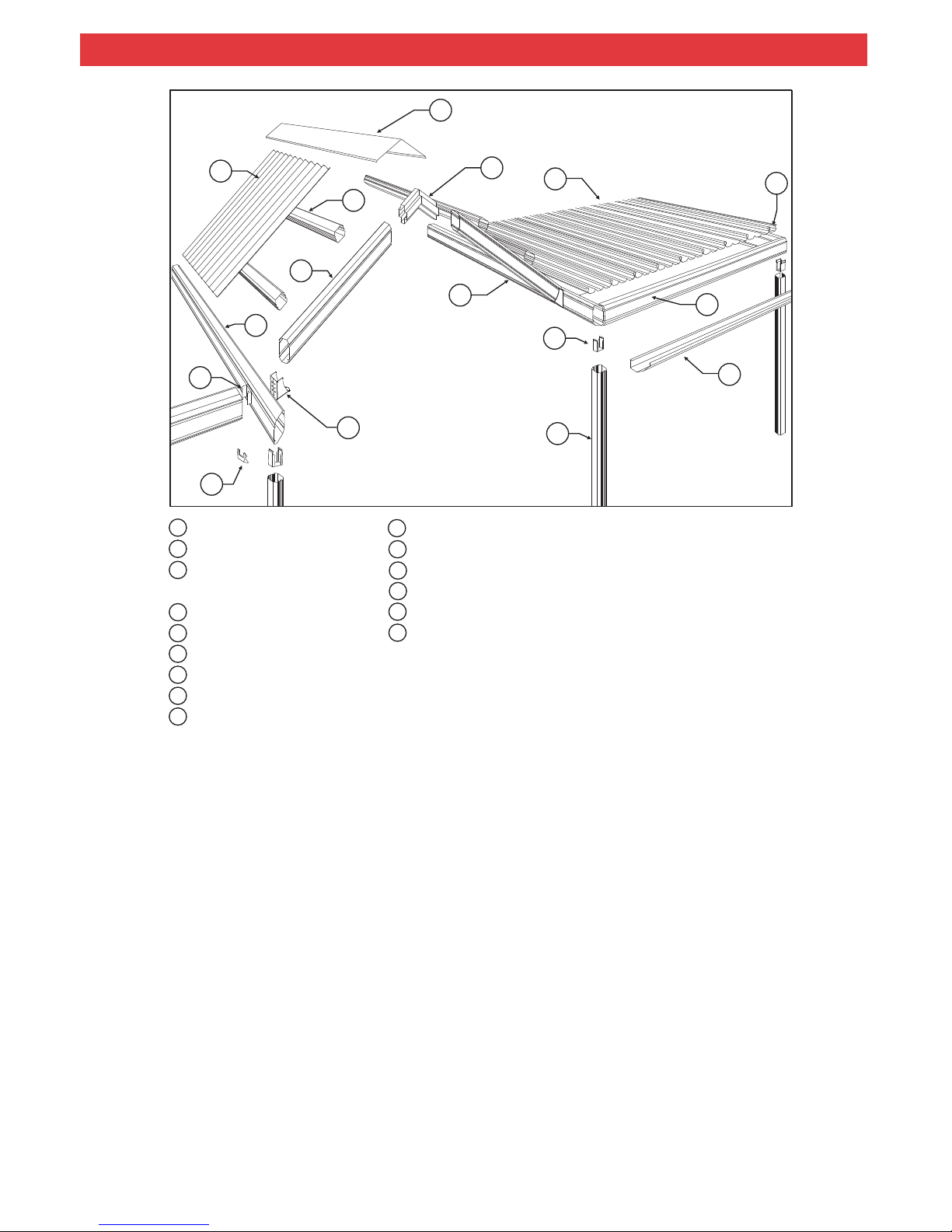

PARTS DESCRIPTION

1

BARGE CAP

The barge cap covers

the area where the

deck finishes at portal

frame.

SCREWS AND RIVETS

Fastener types vary depending

upon the connection, ensure

correct fixings are used.

14x95

12x20

10x16

RIVET

RIDGE KNUCKLE

Slots inside the gable rafters to

form connection at the ridge.

RIDGE CAP

This flashing covers the

roof sheets at the gable

ridge and the Gazebo End

hips.

22 or 30 END

RAFTER

BRACKET

Connects rafters to

header beam on an

infill gable.

ºº

END STRUT

The gable infill is

supported by the

end strut, which

consists of a section

of post.

22 or 30 END

STRUT PLATE

Secures the end

strut at the ridge.

ºº

PURLINS

Purlins provide support for

cladding.

RAFTERS

Gable Rafters

consist of pre-cut

120 Outback

beam.

®

SOAKER FLASHING

The soaker flashing

water proofs the rear

of the gable and

conceals the existing

house gutter.

PERIMETER

BRACKET

This bracket

fastens the

rafters to the

gazebo fascia

beam.

APEX BRACKET

This bracket fastens the hip

rafters to the apex of the gable

frame.

ANGLED INLINE

CONNECTORS

135°Angled Purlin

Connector.

67.5° Angled Inline

Connector.

BOLTS

Fastener types vary depending

upon the connection, ensure

correct fixings are used.

M10 HEX

HEAD BOLT

M12 HEX

HEAD BOLT

CUPHEAD

BOLT

RAFTER TO

VALLEY

BRACKET

This bracket

fastens the

rafter to the

valley beam.

SPACERS

Are used to prevent the

150 attachment beam

from crushing.

HEADER BEAM BRACKET

Connects end strut to header

beam on an infill gable.

HEADER FLASHINGS

Run along header beam to

neatly finish the base of

infill panels.

PANEL STRIPS

Decorative strips fixed to

infill panels.

INFILL PANEL

Cut to suit gable end

frames.

POST BRACKET

POST CAP

Connects post

to beam.

Fills gap between

post and beam.

7

8

9

10

6

5

4

3

2

1

Ridge Cap

Outback Deck

Purlin

Ridge Knuckle

Rafter

Valley Beam

Beam to Beam Bracket

®

®

Polycarbonate Sheet,

Outback Deck or CGI

Notched Beam Filler

15

14

13

12

11

Rafter to Valley Bracket

Post Bracket

Post

Front Fascia Beam

End Fascia Beam

Gutter

COMPONENT LAYOUT

1

4

7

10

3

2

6

8

12

11

5

13

7

15

14

9

1

GABLE FRAME

(GAZEBO END)

2

COMPONENT LAYOUT

7

8

9

10

6

5

4

3

2

1

Ridge Cap

Purlin

Purlin Intersection Cover

Ridge Knuckle

Hip Rafter

Gazebo Fascia Beam

135

Gazebo Apex Bracket

Polycarbonate Sheet,

Outback Deck or CGI

®

° Angled Purlin Connector

14

13

12

11

Rafter to Valley Bracket

Post Bracket

Post

67.5 Angled Inline Beam Connector

Perimeter Bracket

Hip Support Flashing

°

2

3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

GAZEBO END

15

15

ADDITIONAL MATERIALS

These materials are needed to complete the job, but are not

included in the basic kit price (they must be purchased as

extra items, and their quantities specified):

Rafter strengthening brackets and channels to suit 150

attachment beam for attaching gable to house.

M12 bolts and nuts for fixing strengthening brackets to the

rafter.

M12 bolts and nuts for fixing 150 attachment beam to

strengthening brackets.

Fascia Brackets for attaching gable on end to house.

M10 coach bolts and nuts for fixing fascia brackets to the

house rafter.

M8 masonary anchors for fixing Wall Brackets to masonary.

12x25 type 17 hex head screws for fixing Suspension

Brackets to timber.

10x16 hex head screws for fixing Suspension Brackets to

steel fascia.

Cover flashings (measurements required).

Box gutter (measurements required).

These items are available at request:

Infill Panels

Panel Strips

Finial

Soaker Flashing in lieu of Header Flashing

Purlin Intersection Cap

OPTIONAL EXTRAS

1.0 INTRODUCTION

2.0 ATTACHING TO AN EXISTING

STRUCTURE

2.1 ATTACHING ON SIDE TO HOUSE

Please read these assembly instructions thoroughly before

commencing the construction. Double check all

dimensions, levels and bolting locations before cutting,

screwing or bolting structural members. It is recommended

that the persons erecting the structure have had some

previous building experience because some modifications

to the existing house structure are required.

The builder or council is to ensure the existing

house/structure is of a suitable structural integrity and

complies with all the relevant Australian Building codes and

standards. For more information regarding the suitability of

the house structure to accommodate the Stratco Attached

Multispan Gable, consult a structural engineer or a building

authority. It is the builders responsibility to ensure that the

existing house roof structure is strengthened correctly.

Refer to section 2.1 if attaching Multispan Gable on it’s side

to a house, section 2.2 if attaching on it’s end to a house or

refer to both sections if attaching the gable on it’s side and

end.

A Stratco Multispan attached on it’s side to a house is

attached to the existing eaves overhang at the fascia.

The first objective in the construction is to fix a structural

side beam along the fascia or wall, to which the Gable Unit

is attached.

Most existing houses have not been designed for the

attachment of portal framed gables to their side, therefore

additional strengthening of the house rafters must be

performed.

In order to strengthen the existing house rafters, the roof

tiles or roof sheets need to be lifted to expose the roof

frame. Steel rafter brackets and channels are then bolted

along the house rafters. Refer to section 2.1.1.

A 150 mm Outba beam is bolted to the strengthening

brackets at the fascia. Once the 150 attachment beam is

secured to the house, the Gable Unit can be erected and

fastened to the beam.

The first step is to determine the number of rafters which

need to be strengthened and their location relative to the

unit. You will have to lift some roof tiles or roof sheets to

discover the rafter positions and spacings. The number of

rafters which need to be strengthened is determined by the

builder.

: It is the builders responsibility to ensure the existing

rafters and fascia are adequately reinforced and

strengthened to accommodate any additional attached

structure. The reinforcing method must be approved by the

appropriate council or engineer.

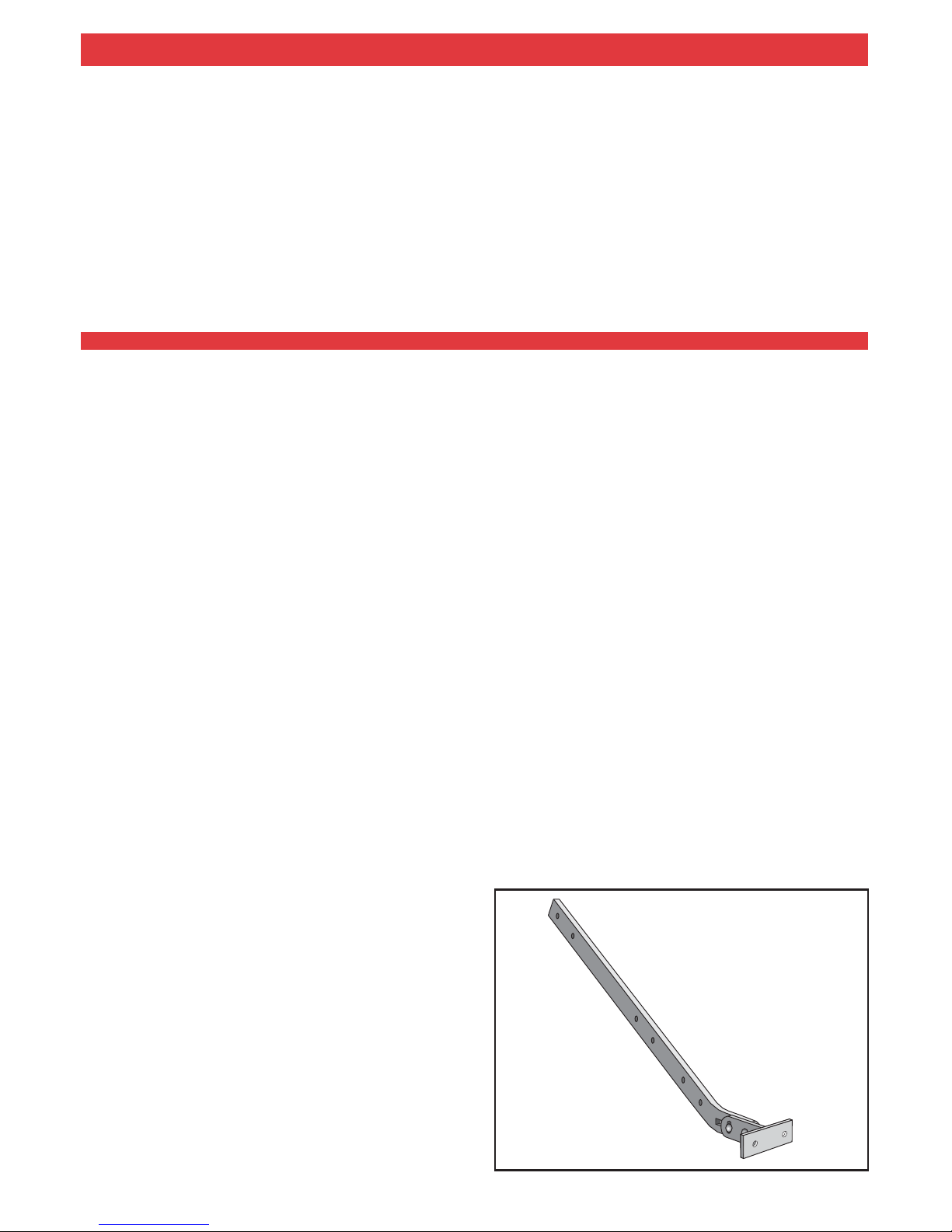

Use an adjustable rafter strengthening bracket and one

channel for eaves overhangs up to 450 mm. Use an

adjustable rafter strengthening bracket and two channels

for eaves overhangs over 450 mm and up to and including

600 mm, as shown in figure 4.

The adjustable rafter strengthening bracket is shown in

figure 3. Please note that this bracket may not be suitable

for applications where the front face of the house gutter is

higher than 120 mm. In these cases please contact Stratco

for alternative solutions.

ck

®

Note

2.1.1 RAFTER STRENGTHENING

4

ADJUSTABLE RAFTER STRENGTHENING

BRACKET

3

4

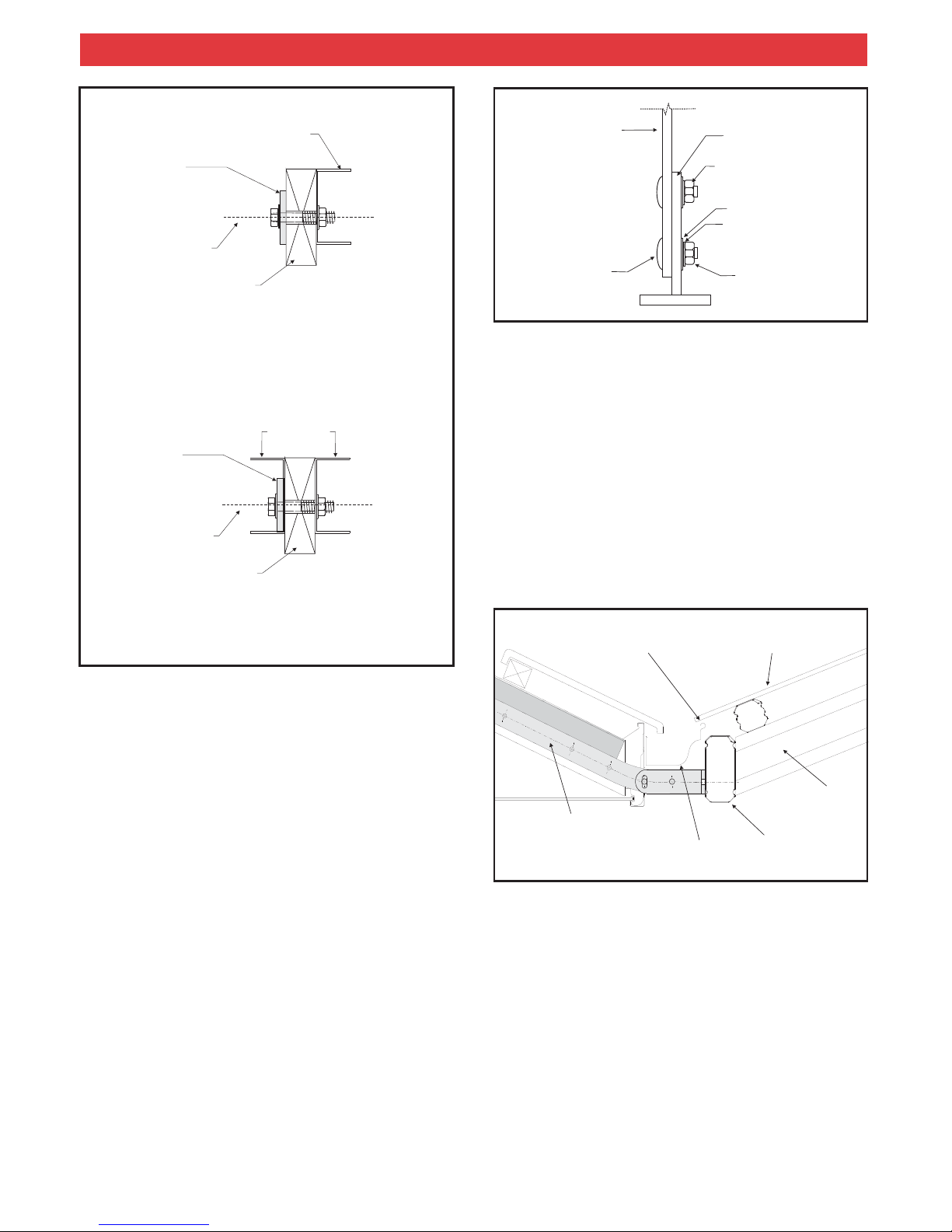

450mm EAVES OVERHANG

RAFTER

STRENGTHENING

BRACKET

M12 BOLT

TIMBER RAFTER

60x44x2.0 G450 GALVANISED

CHANNEL

600mm EAVES OVERHANG

RAFTER

STRENGTHENING

BRACKET

M12 BOLT

TIMBER RAFTER

60x44x2.0 G450 GALVANISED

CHANNEL

RAFTER

6

ENOUGH CLEARANCE FOR

ROOF SHEETS TO RUN INTO

THE HOUSE GUTTER

FIX BRACKET AS CLOSE

AS POSSIBLE TO THE BASE

OF THE GUTTER

RAFTER

STRENGTHENING

BRACKET

CGI, POLYCARBONATE

OR

OUTBACK ROOF SHEET

®

150 ATTACHMENT

BEAM

Fixing the 150 Attachment Beam in Place

After fixing all the brackets and channels, the 150

attachment beam is fixed in place.

Prop up the 150 attachment beam in position with the

double flange on top, the beam will need to be located at a

height on the bracket which allows clearance between the

gable roof sheets and the gutter. Fix to the end plates of the

rafter bracket using two M12 bolts, with the bolt head on the

150 attachment beam side. Insert spacers to prevent the

beam from crushing, and bolt in position, using nuts and

washers.

Do not over tighten bolts as this can lead to a visible

indentation due to the high gloss nature of the material.

Refer to Figure 8 for fixing spacers.

Note:

5

Fixing Rafter Strengthening Brackets and

Channels

The adjustable rafter strengthening bracket allows for an

adjustment of pitch in the range of 15 to 30 degrees. The

distance the bracket extends past the fascia is also

adjustable to allow for standard gutters or box gutters with a

width of up to 200mm.

In conjunction with rafter strengthening brackets, channels

are fixed to the side of the house rafter (Figure 4). The

bottom end of the channel will be located at the base of the

house rafter. Holes should be marked and pre-drilled in the

channels to suit the location of existing holes in the bracket.

The channel will extend beyond the bracket so additional

holes are to be drilled in the channel at approximately

500mm centres.

Initially the bracket T piece shall be fixed to the bracket arm

with two M12 cup head bolts (hand tighten only), a spring

washer is to be located between the standard M12 washer

and nut (Figure 5). Mark the position of the bracket on the

fascia and notch a rectangular hole in the fascia allowing

the bracket to be fed through thefrontof the fascia. The hole

may need to be enlarged slightly if the M12 cup head bolts

interfere with the fascia.

5

BRACKET ARM

T PIECE

TIGHTEN TO 35Nm

TORQUE

M12 WASHER

M12 SPRING WASHER

M12 NUT

M12x40 CUP HEAD

BOLT

Insert the bracket through the fascia and fix with the

channel(s) to the house rafter using M12 hex head bolts

through the existing holes in the bracket and further up the

channel(s) (Figure 7). Adjust the T piece so it is horizontal

and has the appropriate extension past the fascia to allow

for fixing of the attachment beam. T piece connection bolts

are to be tightened to a minimum 35Nm torque.

Fix the bracket as close to the baseofthe gutter as possible

(recommended distance 10mm from lowest end of gutter),

as shown in figure 6.

The 150 attachment beam is to be fixed to the end plate to

ensure the carport roof sheets drain into the existing house

gutter (Figure 6).

The 150 attachment beam becomes the base for the attachment of the Multispan gable unit. Figure 7 shows a unit attached at

the side.

7

CHANNEL EXTENSION

MULTISPAN GABLE ATTACHED AT THE SIDE

WEB OVERHANG

STUD WALL

TIMBER RAFTER

150 ATTACHMENT BEAM FIXED TO

RAFTER BRACKET WITH TWO

M12 BOLTS

GUTTER

150 ATTACHMENT BEAM

EAVES OVERHANG

BRICK WORK

RAFTER STRENGTHENING BRACKET

ATTACHED TO RAFTER WITH

6 (M12 HEX HEAD BOLTS)

RAFTER

EAVES PURLIN

FIXED TO

RAFTER USING

14 x 95 SCREWS

To insert spacers drill 11 mm holes through the 150

attachment beam. Then drill 16 mm holes on the outside

face only, ie, this time do not drill all the way through. This

will allow the spacer to slide in from the outside and stop at

the other side as shown in figure 8.

6

8

150 ATTACHMENT BEAM

SPACER

NUT

RAFTER

STRENGTHENING

BRACKET

M12 BOLT

DOUBLE FLANGE

ENLARGED HOLE

(16 MM THIS SIDE ONLY)

11 MM HOLE

WASHER

You would have ordered and received your custom made

flashings to cover the exposed brackets and holes through

fascia. Rivet flashings in place, figure 9 suggests a

simplified flashing. You may however use your imagination

and design a flashing that suits your individual taste.

Note: It is the builders responsibility to ensure the existing

rafters and fascia are adequately reinforced and

strengthened to accommodate any additional attached

structure. The reinforcing method must be approved by the

appropriate council or engineer.

If fixing a Multispan Gable on its end to a wall, two

alternatives are available. Purlins are fixed directly to the

wall using 68mm wall brackets andvalley beams using 150

beam to wall brackets. This option will not require a rear

gable frame and back channel is fixed to the wall to

accommodate sheets running along the wall. The other

alternative requires valley beams be fixed to the wall and a

rear gable frame installed for fixing purlins. The rear gable

frame will need to be slightly offset from the wall to allow the

appropriate bracket fixing.

If fixing a Multispan Gable on its end with suspension

brackets to a fascia (Figure 10), typically a soaker flashing

is used. In this case the gable rafter at the rear of the unit

2.2 ATTACHING ON END TO HOUSE

450

600

1800

1900

300

400

Eaves

Overhang

(mm)

Channel Extension

Beyond Birds Mouth

(mm)

Web Overhang

(mm)

Recommended Channel Extension

CHANNEL

WASHER

9

COVER FLASHING

(OPTIONAL)

RIVET

RIVET

STRENGTHENING

BRACKET

FASCIA

150 ATTACHMENT

BEAM

HOUSE

GUTTER

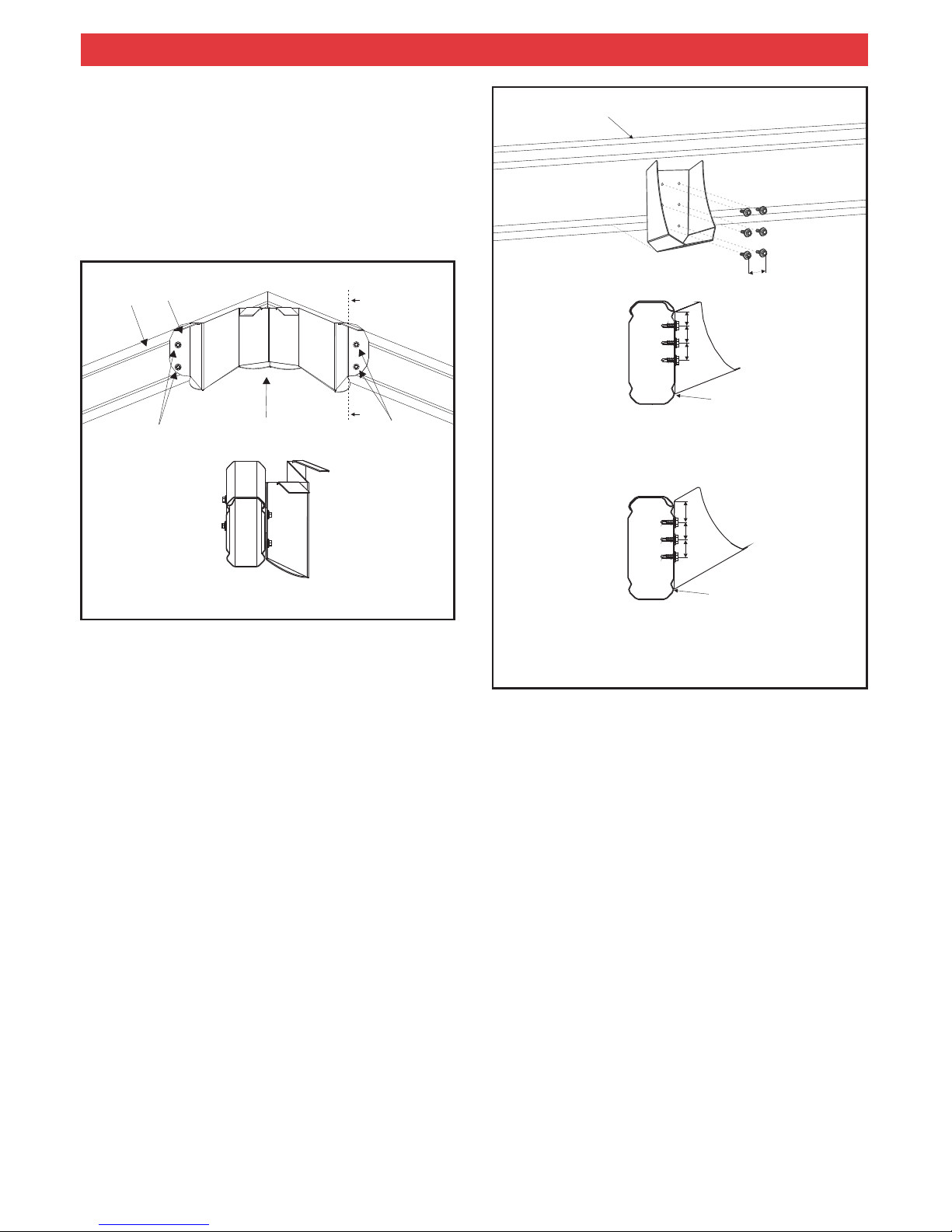

Measure the distance between rafter ends, O, to check

valley beam spacing (Figure 13).

13

GABLE OPENING (O)

12

2 (12 X 20 HEX HEAD SELF

DRILLING SCREWS) EACH

SIDE OF BOTH RAFTERS

2 (12 X 20 HEX HEAD SELF

DRILLING SCREWS) THROUGH

TOP OF BOTH RAFTERS

11

OPEN GABLE RAFTER

INFILL GABLE RAFTER

7

Insert ridge knuckle into the pre-cut rafters and screw

together using two 12x20 hex head self drilling screws both

sides of each rafter and two 12x20 hex head self drilling

screws through the top (double flange side) of each rafter.

Pilot holes indicate screw locations as shown in figure 12.

Make sure that the two ends are flush at the connection,

leaving no gaps.

10

120 GABLE RAFTER

INFILL PANEL

GUTTER

SOFFIT LINING

SUSPENSION

BRACKET

VALLEY BEAM

BACK CHANNEL

STEEL FASCIA BRACKET

(ATTACHED TO RAFTER

AND BACK CHANNEL)

3.0 GABLE FRAME ASSEMBLY

IMPORTANT:

Note:

Ensure that the double flange portion is at

the top when installing all beams and rafters.

The rafters are supplied pre-cut and drilled at the

ridge as shown in figure 11.

is to be 153mm from the house fascia in order to

accommodate a standard soaker flashing (refer Figures 24

and 25).

If your house gutter is wider than 150mm a custom

made soaker flashing will need to be ordered and the rafter

set back adjusted to suit.

If fixing a Multispan Gable on its end to an attachment

beam, elevated to the existing house gutter height, the

attachment beam is to be as close as possible (within 5mm)

to the outside face of the gutter (Figure 26). The 150

attachment beam is fixed to rafter strengthening brackets

as detailed in section 2.1.1.

It is the builders responsibility to ensure the existing

rafters and fascia are adequately reinforced and

strengthened to accommodate any additional attached

structure. The reinforcing method must be approved by the

appropriate council or engineer.

Note:

Note:

2.2.1 FASCIASTRENGTHENING

Steel fascia brackets are generally fastened at 1200mm

centres to fascia and rafters (Figure 10). It is the builders

responsibility to determine the adequacy of the fascia and

rafters and the frequency of brackets for each individual

situation.

SOAKER FLASHING

8

A Gazebo Apex Flashing is secured with rivets behind the

apex bracket and will cover gaps created by purlin

intersection covers (Section 9.3).

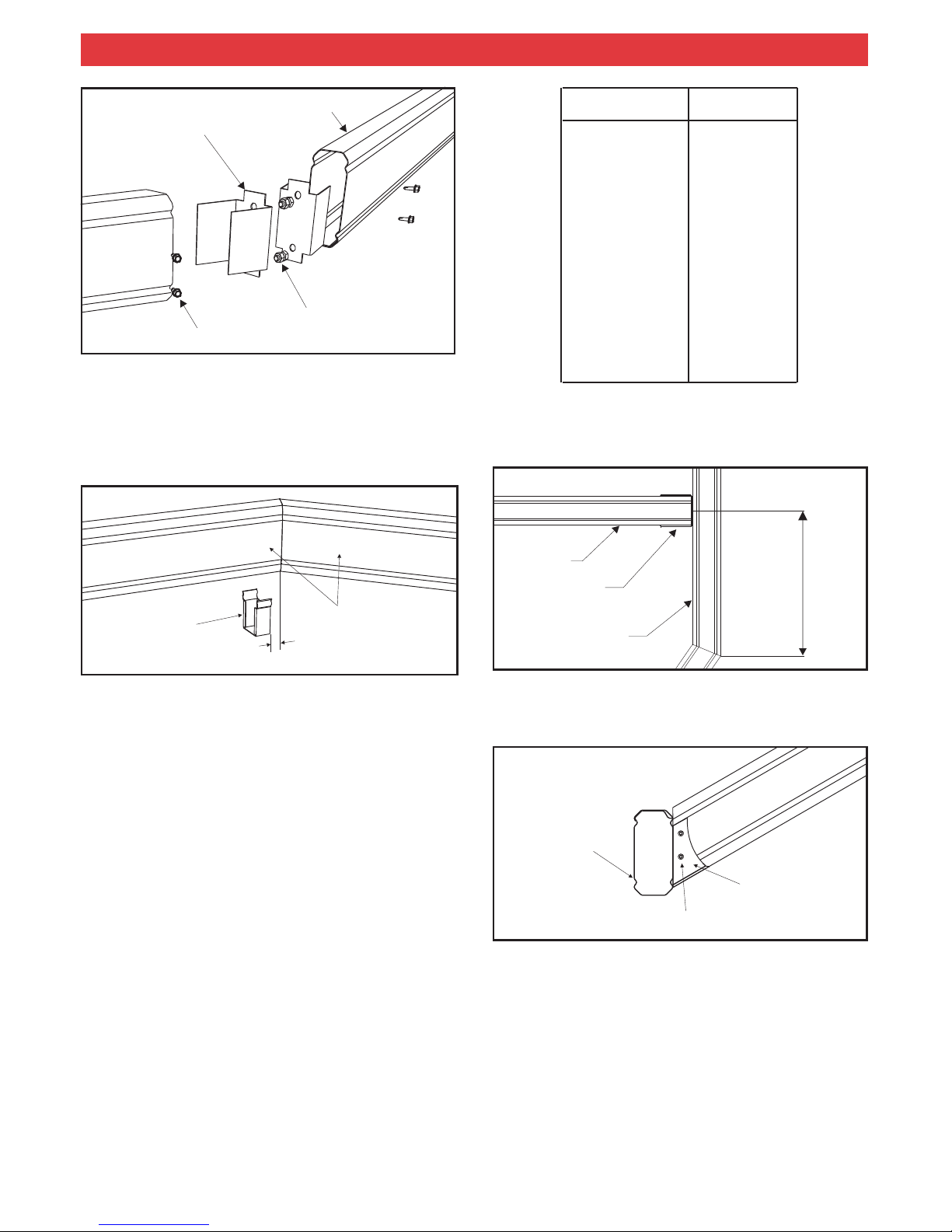

For side attached units fix the rafter to valley bracket to the

valley beam (150 attachment beam will be considered a

valley beam) at the correct rafter positions (refer Section 6)

using six 12x20 hex head screws per bracket through the

pre-drilled holes (Figure 15). Pleasenote the bottom face of

the bracket lines up with the bottom edge of the lower

groove in the valley beam for 150 beams (Figure 15). Check

positions before drilling.

If any intermediate columns are required, measure the

valley beam marking where they meet. Fasten post

brackets as explained in ‘Outback Flat Attached

Verandahs, Patios & Carports’ under “FRONT FASCIA

BEAM”.

Support the second valley beam at the spacing determined

in part 3.0 on adjustable construction props.

4.0 VALLEYBEAMASSEMBLY

4.1 SIDE ATTACHED

3.1 APEX BRACKET

The Gazebo Apex bracket is to be fixed to the front face of

the front gable frame at the apex. The bracket is to be

located so the bottom edge of the apex bracket is in-line

with the top edge of the bottom chamfer of the gable frame

rafters. The apex bracket is to be located centrally at the

apex and fixed through the pre-drilled holes using 12x20

hex head screws (Figure 14).

14

APEX BRACKET

RAFTER

12x20 HEX HEAD

SCREWS

12x20 HEX HEAD

SCREWS

SIDE FIXING

TAB

A

A

SECTION A-A

4.2 END ATTACHED

For units attached on the end to a wall, wall brackets are

positioned at either side of the gable opening at the spacing

determined in part 3.0. The first bracket is fastened to the

wall with two M8x65mm masonry anchors.The curved legs

of the bracket are located at the top and the highest point of

the wall bracket will be 15mm below the top of the beam

(Figure 16).

Pivot the first valley beam (double flange on top) up into the

wall bracket so the curved legs locate against the top flute of

the beam. The valley beam is fastened to the wall bracket

with 10x16 hex head screws in the pre-drilled holes while

the opposite end is supported on adjustable construction

props.

40

150 VALLEY

BEAM

150 VALLEY BEAM WITH 30°

RAFTER TO VALLEY BRACKET

30

25

150 VALLEY BEAM WITH 22°

RAFTER TO VALLEY BRACKET

20

25

BRACKET POSITION INLINE WITH

THE BOTTOM EDGE OF THE

LOWER GROOVE

15

BRACKET POSITION INLINE WITH

THE BOTTOM EDGE OF THE

LOWER GROOVE

25

25

9

For units attached on the end to a fascia, suspension

brackets are positioned ateither side of the gable opening

at the spacing determined in section 3.0 (Figure 13). The

top tab of the suspension bracket must be located

between the fascia and back channel. A minimum of two

10x16 hex head screws are fixed through back channel,

suspension bracket and steel fascia while two 12x25 type

17 screws are used to fix through back channel,

suspension bracket and timber (Figure 17).

If back channel is not present, (ie, no adjacent flat

roof) locate washer plate behind steel fascia at

suspension bracket. Fix through bracket, fascia and plate.

The first valley beam is fastened into the suspension

bracket with 10x16 hex head screws through the dimples

while the opposite end is supported on adjustable

construction props.

Note:

16

WALL

BRACKET

TWO 10x16

HEX HEAD SELF

DRILLING SCREWS

EITHER SIDE

TWO M8x65 MASONARY ANCHORS

or

TWO 6mm DIAMETER SCREWBOLTS

WITH A MINIMUM EMBEDMENT OF 45mm

MINIMUM EDGE DISTANCE OF BOLTS &

SCREWS IS (10 x dia)

15mm

17

OUTBACK

DECK

®

1.0mm STEPPED

BACK CHANNEL

VALLEY EAMB

SUSPENSION

BRACKET

10x16 HEX HEAD SCREWS TO STEEL

12x25 TYPE 17 SCREWS TO TIMBER

For units attached on the end to an attachment beam

(Figure 26), beam to beam brackets are positioned at either

side of the gable opening at the spacing determined in

section 3.0 (Figure 13).

18

TWO 10x16 HEX

HEAD SELF DRILLING

SCREWS EITHER SIDE

BEAM TO

BEAM BRACKET

BEAM FILLER

ATTACHMENT

(HEADER) BEAM

TWO 10x16 HEX HEAD

SELF DRILLING SCREWS

If any intermediate columns are required measure the

valley beam marking where they meet. Fasten post

brackets as explained in the installation guide ‘Outback Flat

Attached Verandahs, Patios & Carports’ under “FRONT

FASCIABEAM”. This can be done before valley beams are

fixed in place.

Support the second valley beam on adjustable construction

props but do not fix to the wall, fascia or attachment beam

until the front gable frame has been attached.

Fix the rafter to valley brackets to the valley beam at the

correct rafter positions (refer Section 6). Fixing details as

indicated in section 4.1.

Attach the in-line connector brackets back to back using

M10 bolts and nuts in the holes provided (Figure 19).

Ensure the constructed bracket makes the required

internal angle of 135 degrees.

Slide the in-line connector into the valley beam and fix

using two 12x20 hex head screws to the outside face of the

beam only. Fix one of the three Gazebo Fascia Beams to

the protruding half of the in-line connector using two 12x20

hex head screws to the outside face of the beam ensuring

both beams are flush with one another. Support the first

gazebo fascia beam on an adjustable construction prop.

Repeat the above process on the centre gazebo fascia

beam. Fix the remaining in-line connectors to the free ends

of the fascia and valley beams. The final gazebo fascia

beam is now be fixed in place.

5.0 GAZEBO FASCIA BEAMS .

Fix beam to beam brackets to the attachment beam

(header beam) with two 10x16 hex head screws so they

clamp the beam filler to the beam (Figure 18).

The first valley beam is fastened over the beam to beam

bracket with two 10x16 hex head screws either side while

the opposite end is supported on adjustable construction

props.

19

INLINE CONNECTOR

12x20 HEX HEAD SCREW

M10 BOLT

GAZEBO FASCIA BEAMS

20

POST BRACKET

GAZEBO FASCIA

BEAMS

With all the gazebo fascia beams secured, post brackets

are to be fastened approximately 60mm from the fascia

beam joins (Figure 20), allowing for perimeter brackets and

post caps. Refer to, ‘Your complete guide to building an

attached verandah, patio or carport’ under “FRONT

FASCIABEAM” forpost bracket fixing details.

6.0 GABLE FRAME CONNECTION

Note: Be aware that gable frames are always 120 beams

and valley beams are always 150 beams for Multispan units

with a gazebo end.

The front gable frame will need to be set back from the front

of the valley beams to accommodate the gazebo end. Refer

to Figure 21 and Table1 for set back distance.

The rafter to valley brackets will have been attached to the

valley beams using six 12x20 hex head screws (Figure 15,

Section 4) at the location determined from Table 1 (Figure

21).

6.1 GABLE FRAMES

(Figure 1)

150

VALLEY BEAM

120 RAFTER

RAFTER TO VALLEY

BRACKET

22

Fix the gable rafters into the rafter to valley brackets with

two 12x 20 hex head screws either side (Figure 22).

VALLEY BEAM

21

RAFTER

A (SET BACK)

RAFTER TO VALLEY

BRACKET

Table 1

Interpolation may be used to determine values

between those shown.

All lengths in millimetres (mm).

OPENING, O

A(Set Back)

1200

1500

1800

2100

2400

2700

3000

3300

3600

3900

4200

4500

4800

5100

5400

5700

6000

6300

6600

1022

1084

1147

1209

1333

1395

277

339

401

463

525

587

649

712

774

836

898

960

1271

TWO 12x20 HEX HEAD

SCREWS EITHER SIDE

If attached on the end, attach the second valley beam into

the wall or suspension bracket.

If the unit includes rear infill a rear header beam is

required and must be installed before fixing the second

valley beam in position, refer section 6.2.

Intermediate frames should be spaced evenly and fixed into

rafter to valley brackets as previously described.

A rear gable frame without a header beam is fixed as per an

intermediate frame.

Note:

10

60mm

6.2. REAR INFILL

A rear header beam will be required if the unit includes infill

to the rear gable frame. For units attached at the rear with

suspension brackets, the rear header is fixed between

valley beams using beam to beam brackets. If fixed at the

rear to an attachment beam (Figure 26), the attachment

beam becomes the header (valley beams are fixed to the

header beam) and if attached on the side the rear header is

fixed to the attachment beam with beam to beam brackets.

Attach end rafter brackets to the rear header beam at

spacing, O, as determined in section 3 using six 10x16

hex head self drilling screws (Figure 23).

Fasten the rafters that form the end gable frame over the

end rafter brackets with a minimum of two 10x16 hex

head screws either side (Figure 23).

Refer section 14 for details of fixing infill panels to gable

frames.

6.2.1 SOAKER FLASHING

In the case of a rear infill panel, a soaker flashing is used to

conceal the existing house gutter, waterproof the rear end

of the gable and neatly finish the base of the infill panel

(Figure 24).

The rear gable frame and header beam are positioned 153

mm from the house fascia in order to accommodate the

standard soaker flashing which is optional with the

Outback unit (Figure 25). The frame is fixed on the rear

header over end rafter brackets (Figure 23).

Fix the standard soaker flashing into position on top of the

back channel and underneath the gutter. Infill panels must

be fixed with split tail soft pull rivets at 500mm centres a

minimum of 20 mm above the pan of the soaker flashing.

This will reduce the possibility of moisture being absorbed

into the sheet.

Refer section 14 for details of fixing infill panels to gable

frames.

®

25

120 GABLE RAFTER

INFILL PANNEL

GUTTER

SOFFIT LINING

SUSPENSION

BRACKET

20mm GAP

VALLEY BEAM

BACK CHANNEL

153MM

SPLIT TAIL SOFT

PULL RIVETS

24

SOAKER

FLASHING

SOAKER FLASHING

Note:

1. If your house gutter is wider than 150 mm a custom made

soaker flashing will need to be ordered to the required

dimensions. The rafter setback will need to be adjusted to

suit.

2. Do not form stop ends at either end of the soaker flashing.

3. Soaker flashing is not to come in contact with the base of

the house gutter.

6.2.2 HEADER FLASHING

When a gable is fixed at the rear to an attachment beam,

elevated to the existing house gutter height, typically a

header flashing is used in conjunction with the rear infill. In

this case, the rear attachment beam is considered a

header,and along with the reargable frame is fixed as close

as possible (within 5mm) to the existing gutter in order to

accommodate the header flashing.The gable frameis fixed

on the rear header over end rafter brackets (Figure 23).

Fix the header flashing into position over the existing gutter

lip with rivets. Infill panels are located behind the header

flashing and fixed with split tail soft pull rivets at 500mm

centres (Figure 26).

Refer section 14 for details of fixing infill panels to gable

frames.

11

23

END RAFTER

BRACKET

HEADER BEAM

RAFTER

ATTACH RAFTER TO

BRACKET USING A MINIMUM

OF TWO 10x16 HEX HEAD

SELF DRILLING SCREWS

EACH SIDE

ATTACH END RAFTER

BRACKET USING A MINIMUM

OF SIX 10x16 HEX HEAD

SELF DRILLING SCREWS

26

STRENGTHENING

BRACKET

FASCIA

150 ATTACHMENT

BEAM

HOUSE

GUTTER

INFILL PANEL

HEADER FLASHING

SPLIT TAIL

SOFT PULL RIVET

27

PERIMETER BRACKET

12x20 HEX HEAD

SCREWS

GAZEBO FASCIA

BEAMS

7.0 PERIMETER BRACKETS

Perimeter brackets are to be located at the internal join of

the gazebo fascia beams so the bottom face of the bracket

is in-line with the bottom of the lower groove in the beams

(Figure 27). Brackets are to be fastened to the gazebo

fascia beams using four 12x20 hex head screws through

the pre-drilled holes.

12

8.0 GAZEBO HIP RAFTERS

Having all the Perimeter Brackets in place will allow rafters

to be located. The two shorter rafters are to be positioned

closest to the end gable frame on either side. It is important

that rafters are firstly fixed at the apex, position rafters over

the apex bracket tabs so the cut face of the rafter is flush

with the face of the bracket.

Two 12x20 hex head screws are used to fix the rafter to the

tab with the first screw being located 20mm from the front

face of the bracket and the second 20mm from the first

screw (Figure 28). This process is repeated for the two

internal gazebo hip rafters.

HIP RAFTERS

12x20 HEX HEAD SCREWS

GAZEBO APEX

BRACKET

INTERNAL HIP

RAFTER

GAZEBO APEX

BRACKET

20

20

28

With all gazebo rafters fixed at the apex they can be

fastened to the perimeter brackets. Fix rafters through the

base of the perimeter brackets using two 12x20 hex head

screws at a minimum spacing of 30mm. As a small

tolerance is allowed for at this bracket it is important that the

screws are located at least 20mm from the bracket edge

and the bottom edge of the rafter (Figure 29).

9.0 PURLINS

9.1 CUTTING PURLINS

The location of all the purlins must be known before any

purlins are to be cut.The top purlin is positioned amaximum

of 100mm from the gable ridge (Figure 30) and ends at the

front edge of the gable frame on either side. The end of this

purlin is cut straight to be left flush with the top of the rafter

chamfer (Figure 31).

The lowest purlin shall be amaximum 50mm from the valley

beam (Figure 30) and any intermediate purlins are spaced

evenly on rafters, ensuring maximum recommended deck

end spans are not exceeded. Both the lowest purlin and

intermediate purlin/s will follow the shape of the gazebo end

and therefore purlins will need to bemitred at 67.5 to length

to suit this shape. The highest edge of the gazebo end

purlins will end at the centre of the top face of gazebo hip

rafters. Refer to Figure 31 for further details.

It is recommended the three lowest purlins around

the front of the gable end are set as low as possible on the

hip rafters to eliminate any gap between purlins and gazebo

fascia beams. It is not critical that the level of the lowest

purlins exactly match the purlins adjacent to the valley

beams.

°

Note:

HIP

RAFTER

PERIMETER BEAM

BRACKET

GAZEBO FASCIA

BEAM

12x20 HEX HEAD

SCREWS

>20

>30

>20

29

31

CENTRE LINE

HIP RAFTER

PURLINS

67.5° MITRE

STRAIGHT

CUT

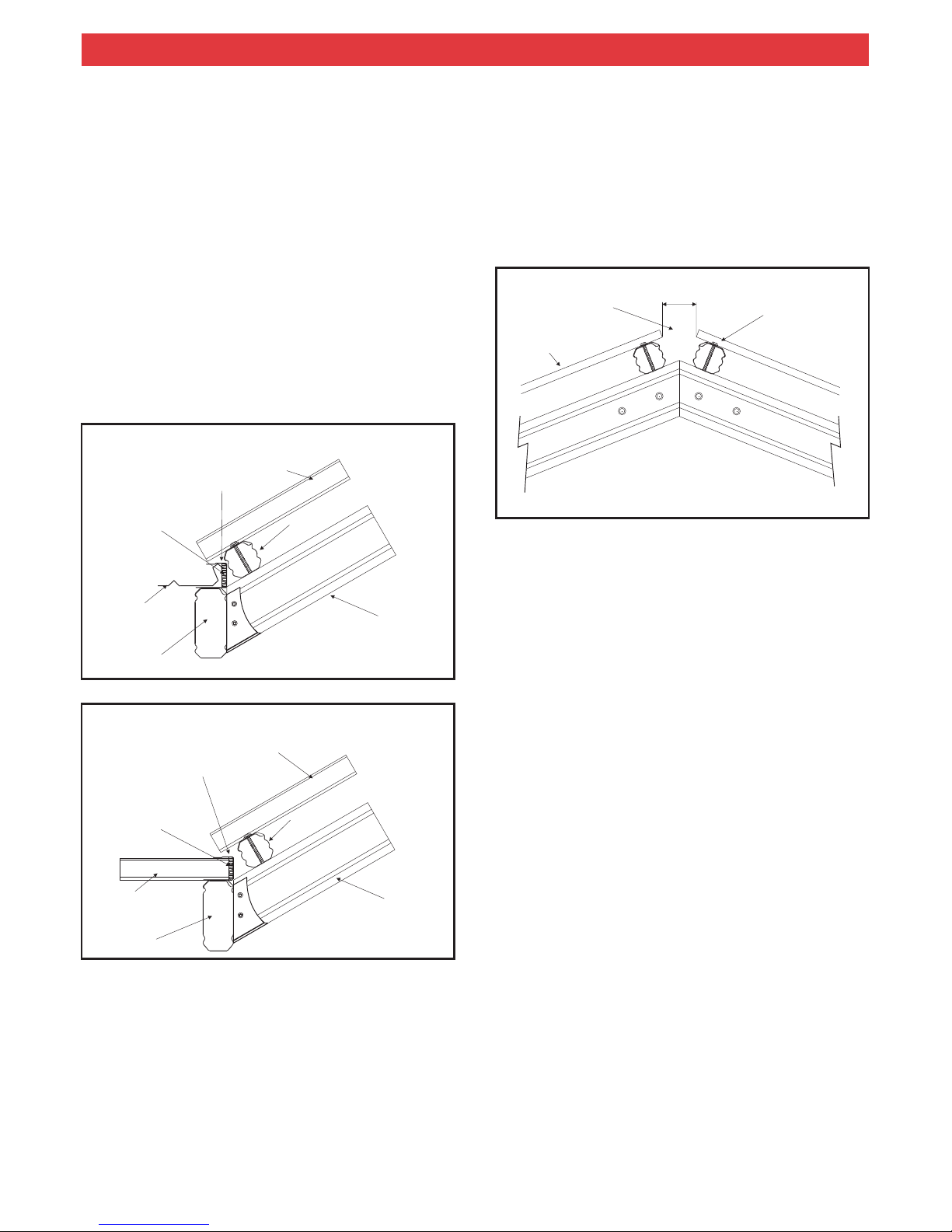

9.2 ATTACHING PURLINS

Where purlins are continuous over rafters they are fixed in

position using 14x95 hex head self drilling screws. If it is

necessary for purlins to be broken over standard gable

frames (ie, purlins continue inthe same directionpast a join)

a 68mm in-line purlin connector is used.

By drilling pilot holes and screwing through the top of

the purlin before lifting it into position, the process of

screwing into the rafters is made easier. Pilot holes should

also be drilled through rafters at the fixing location.

In the case of purlin joins which occur over a gazebo hip

rafter an angled purlin connector will be required. Fix purlins

together using 12x20 hex head screws. A 14x95 hex head

self drilling screw is fastened through the connector to hold

purlins to the rafter (Figure 32). A gap will be noticed at the

lower edge of the purlin join but this will not be seen after

installation of the purlin intersection cover.

If purlins do not align (ie, lowest gazebo end purlins and

lowest gable purlins) they may be screwed directly into hip

rafters.

Note:

30

MAX 100 mm

50 mm

PURLIN

120 RAFTER

VALLEY

BEAM

RIDGE

(MAX)

13

PURLINS

14

Note: Purlin Intersection Caps are available as an optional

extra and can be used to fill the small gap between the purlin

and the template cut out. Caps are riveted to the side of the

purlin cover.

With the exception of Gazebo Ends with Outback

®

deck, hip

support flashings ( Figure 2) are secured directly over purlin

intersection covers to hide roof sheeting cuts. Fix the

flashing to purlins at each purlin junction using a single rivet

either side of the flashing.

Mitre hip support flashings at the apex for a neat finish.

Connect the gutter to the flat roof Outbacks as described in

Assemble the remaining framework of the verandah as per

the installation guide ‘Outback Flat Attached Verandahs,

Patios & Carports’.

Fix the posts, as describedin the instructionbrochure under

"COLUMNS AND FOOTINGS” or "ALTERNATIVE

FOOTING".

Note: All adjustable construction props are to be left in

position until decking is attached and concrete is set.

‘Outback Flat Attached Verandahs, Patios & Carports’.

Gutters will need to be mitred at the point the flat roof unit

meets the gable and around the front of the gazebo end.All

gutter joins are to be waterproofed with silicon.

Where there is no flat roofadjacent to the gable, thegutter is

attached with gutter straps and flat connecting strips which

are fixed to the valley beam. Cut the strip into sections and

rivet at 1000 mm intervals to the valley beam. Fix the gutter

to the strip with rivets as shownin figure 34.Once decking is

attached (Section 12.0) the gutter is secured to the roof

sheeting using gutter straps at maximum 1200mm

intervals. Gutter straps may need to be bent slightly so they

can be rivetted to the roof sheets. Waterproof rivets with

silicone.

The above method is also used to fix gutter around the front

of the gazebo perimeter beams.

®

10.0 REMAINING FRAME ASSEMBLY

11.0GUTTERING

33

14x95 HEX HEAD

SCREW

12x20 HEX HEAD

SCREWS

PURLIN

INTERSECTION

COVER

TEMPLATE

CUT OUT

PURLINS

HIP RAFTER

CONNECTION DETAIL

RIVET

STEEL STRIP RIVETTED AT

1000mm INTERVALS TO

VALLEY BEAM AND GUTTER

34

150 VALLEY

BEAM

GUTTER

120 RAFTER

32

RAFTER

PURLIN

PURLIN

PURLIN

CONNECTION

12x20 HEX HEAD

SCREWS

12x20 HEX HEAD

SCREWS

14x95 HEX HEAD

SCREWS

9.3 PURLIN INTERSECTION COVER

The purlin intersection covers are used to cover any gaps at

purlin joins and also to attach decking. The location of

purlins are to be marked along each side of the purlin

intersection cover and the cover is then cut with tin snips to

allow a tight fit over purlins. The template provided will allow

the cut shape to be marked on the cover at the location of

each purlin.

The purlin intersection cover is now riveted on either side to

the chamfer of the rafter, rivets are to be located a maximum

of 50mm from purlins on both the higher and lower sides

and at spacings of no more than 300mm (Figure 33)

Each cover should be mitred at the apex to finish flush with

the gazebo apex flashing.

.

UNIVERSAL

DECK STRAP

15

35

OUTBACK DECK RUNNING

PARALLEL TO 150 VALLEY BEAM

®

150 VALLEY BEAM

OUTBACK

DECK

®

BITUMEN IMPREGNATED

FOAM INSERT

BACK CHANNEL

(UPSIDE DOWN)

ROOFING

120 RAFTER

68 PURLIN

36

OUTBACK DECK RUNNING

PERPENDICULAR TO 150 VALLEY BEAM

®

150 VALLEY BEAM

OUTBACK

DECK

®

BITUMEN

IMPREGNATED

FOAM

BACK CHANNEL

(UPSIDE DOWN)

ROOFING

120 RAFTER

68 PURLIN

12.2 MULTISPAN GABLE

When attaching the decking to the gable, start from the rear

(non gazebo end) on one side of the gable, aligning the

sheets so as to avoid the purlin fixing screws.

If the deck of the flat roof section runs perpendicular to the

valley beams, align the ribs of the gable decking up with the

flat roof section. Fix the decking so thatit is level with the top

of the flat deck, and so there is a maximum 100 mm gap at

the ridge (Figure 37).

37

POLYCARBONATE

OR CGI

ROOF SHEET

NO BACK

CHANNEL

REQUIRED

PURLIN

FIXING SCREW

MAX

100 MM

12.3 GAZEBO END

At the point when less than one full sheet is required to pass

the centreline of the front gable frame on one side, the

Gazebo End decking will need to be cut to suit. Refer to

figure 39 for cutting order and laying direction.

Continue laying deck past the end gable frame (Section 1,

Figure 39) and cut the sheeting along the centreline of the

purlin intersection cover. The offcuts from this section are

used in section 2 but deck is layed in the opposite direction

as shown by the arrow in figure 39. When all offcuts are

utilised begin with new sheeting.

This process is continued around the front of the Gazebo

End and back down the side of the Multispan Gable (i.e.

Offcuts from section 2 are used in section 3 with deck being

layed in the direction shown in figure 39, offcuts from

section 3 are used in section 4 and so on).

The centreline of the purlin intersection covers are

used to mark the sheets for cutting. Sheets are to be taken

down from the framework to be cut. It is recommended

sheeting is supported in a horizontal plane off the ground at

a comfortable height for cutting.

All sheeting which ends at the apex is to be cut to a point so

it meets directly above the centre of the end gable frame.

Gazebo end decking will need to overhang the last purlin

and gazebo fascia beams allowing water to flow directly

into the gutter (Figure 34). It may be necessary to notch the

top of the backchannel on the valley beams to avoid

interference with roof sheets at the first gazebo corner.

The edge of roof sheeting, running along hips, is to be fixed

through the hip support flashing and into the purlin

intersection cover.

Note:

12.0 ATTACH DECKING

12.1 FLAT ROOF

Attach the decking to the flat roof verandah first as laid out

under "THE DECKING" (‘Outback Flat Attached

Verandahs, Patios & Carports’), starting from the valley

beam and working away, on both sides.

The back channel is attached upside down (the shorter leg

on top) along valley beams to assist the fixing of decking.

(Figures 35 and 36). The channel extends to the end of the

valley beams.

Figure 35 shows the back channel and Outback deck

running parallel fixed to a 150 valley beam. Figure 36

shows the back channel and Outback deck running

perpendicular to a 150 valley beam.

®

®

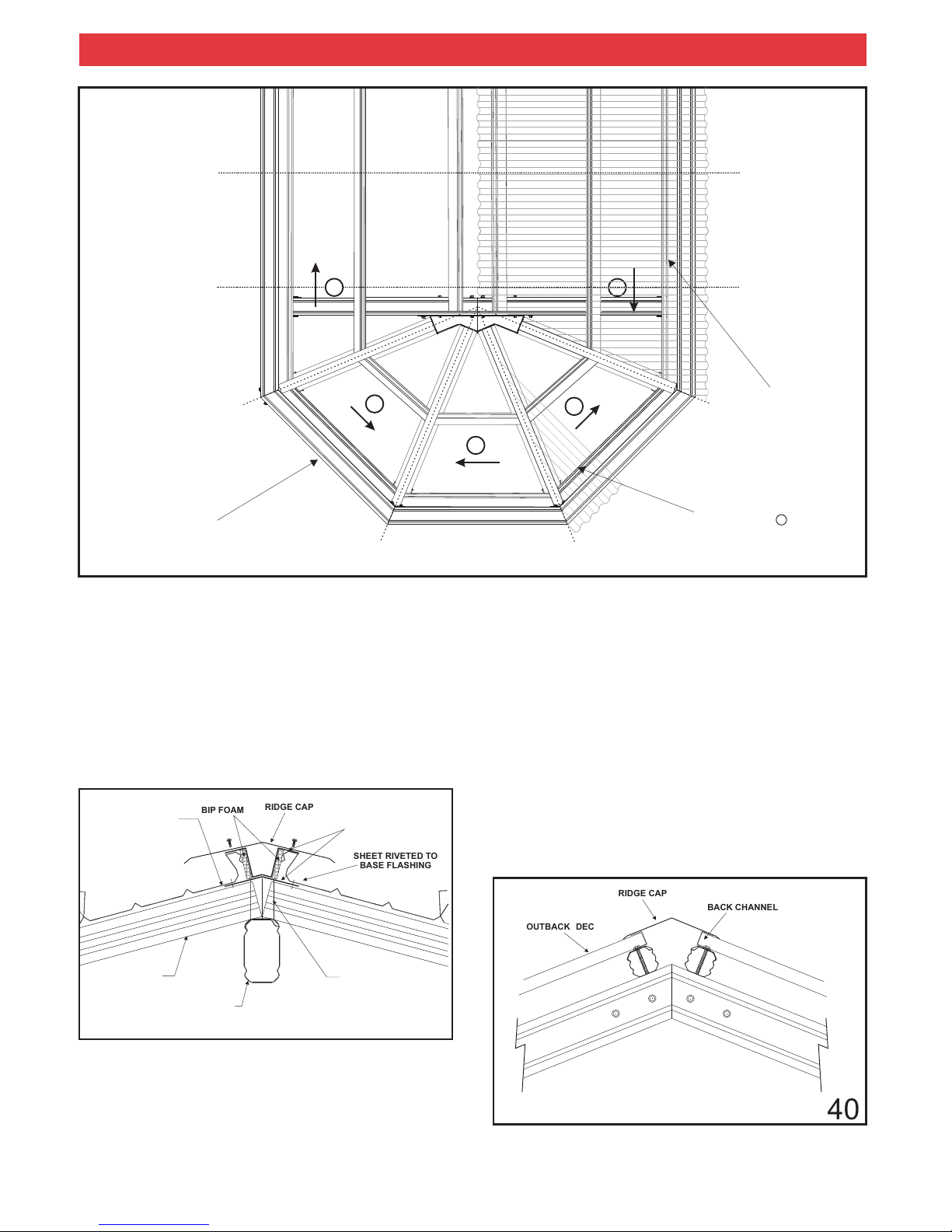

When using polycarbonate or corrugated roofing no back

channel is required at the ridge. When Outback deck is

used, back channel is required at the ridge, and is supplied

with the unit (Figure 40).

Two piece back channel is required at the ridge. When

Outback deck is used, back channel is required at the

ridge, and is supplied with the unit (Figure 40).

®

®

16

39

12.3.1 OUTBACK DECK

®

For Outback deck a special two piece backchannel will be

required and is to be located along the purlin cover before

the decking is fastened in place (Figure 38). The flashings

are screwed to the purlin cover using 12x20 hex head

screws at 500mm centres on alternating sides of the

shallow ridge. Outback deck is riveted to the base flashing

at 250mm centres

®

®

.

For Outback deck slide back channel over the ridge end of

the deck and rivet into place. Position the ridge cap over the

two back channels and screw or rivet into the channel

(Figure 40).

For polycarbonate and corrugated roofing screw or rivet

(depending on ridge cap style) the ridge cap directly onto

the top of the deck. Waterproof rivets with silicone.

Do not rivet to polycarbonate decking, screw only.

®

Note:

13.0 RIDGE CAPPING

13.1 MAIN RIDGE

3

2

1

DECKING

GAZEBO END

4

5

OFFCUT FROM SECTION 1

TWO PIECE BACK

CHANNEL

OUTBACK DECK

®

38

PURLIN

HIP RAFTER

PURLIN COVER

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

aaaa

BIP FOAM

SHEET RIVETED TO

BASE FLASHING

RIDGE CAP

40

BACK CHANNEL

RIDGE CAP

OUTBACK DECK

®

17

14.1 HEADER BEAM WITHGUTTER

Attach the header flashing to the rear gutter lip with rivets.

Infill panels are fixed through the top groove of rafters and

the end strut with 8x35mm self embedding teks at 500mm

centres in non-cyclonic areas and 250mm centres in

cyclonic areas. Panels are fixed at the base through the

header flashing with split tail soft pull rivets at 500mm

centres (Figure 43).

INFILL PANEL

43

GUTTER

HEADER FLASHING

SPLIT TAIL SOFT

PULL RIVETS

HEADER BEAM

14.0 INFILL PANELS

Two styles of header flashings are available to neatly finish

the base of infill panels, one is used on header beams with

gutter and the other for headers without gutter. Gable infill

panels are to be cutin triangular shapesto fit theend frame.

Panels can be painted to the desired colour before

installing.

End struts are fixed mid-span of the header to a header

beam bracket at the base and an end strut plate at the ridge

(Figure 42).

HEADER BEAM

INFILL PANEL

44

8x35mm SELF

EMBEDDING TEK

10x16 HEX HEAD SELF

DRILLING SCREWS

HEADER FLASHING

15.0 ATTACHING BARGE CAPPING

If barge capping is required at the opposite end to the

gazebo, attach the barge cap by screwing the lower lip to

the rafter and screw the top sectionto the purlin throughthe

deck, as shown in figure 45. Mitre the barge at the apex of

the gable for a neat finish. Run the barge cap along the

gable section to where it meets the flat verandah deck and

finish neatly.

If infill panels have been installed, the lower lip of the barge

capping should cover the panel screws to give a neat finish.

14.2 HEADER BEAM WITHOUTGUTTER

Infill panels are fixed through the top groove of rafters and

the lower groove of the header beam with 8x35mm self

embedding teks. Fix at 500mm centres in non-cyclonic

areas and 250mm centres in cyclonic areas. Panels are

fixed to the end strut at the same spacings. Attach the

header flashing to the underside of the header beam with

10x16 hex head screws to neatly finish the base of the infill

panels (Figure 44).

42

FIX TO FRONT OF RIDGE

WITH 2 12x20 HEX HEAD

SELF DRILLING SCREWS

FIX TO STRUT WITH

2 10x16 HEX HEAD SELF

DRILLING SCREWS

FIX STRUT TO BRACKET

WITH 2 10x16 HEX HEAD

SELF DRILLING SCREWS

EITHER SIDE

FIX BRACKET TO HEADER

WITH 2 10x16 HEX HEAD

SELF DRILLING SCREWS

13.2 GAZEBO END CAPPING

Ridge cap is also used over all gazebo end rafters to

conceal the line in the deck.

For Outback deck a special

back channel is required andshould have been installedas

described in section 12.3.1. The ridge cap is positioned

over the channels and screwed in place through the

channels (Figure 38). For Polycarbonate and corrugated

decking the cap is screwed directly to the top of the deck.

Ridge capping will need to be cut to meet a point at the

apex as detailed in figure 41. Allow an approximate 20mm

overlap at the ridge. The capping isto be fully siliconsealed

at the apex for waterproofing.

®

41

20mm OVERLAP

FRONT GABLE FRAME

RIDGE CAPPING

18

16.0 HELPFUL TIPS

Leave plastic coating on members until they are about to

be fastened to the structure. This will help prevent

scratching of the coloured finish.

Sweep the roof and clean gutters after the completion of

work. Ensure any swarf and rivet stubs are removed as

they can cause unsightly rust stains.

Do not allow soil to remain in permanent contact with the

columns, as corrosion will result in the base of the

column. Refer to the “Selection, Use and Maintenance of

Stratco Steel Products” brochure for complete details of

the maintenance requirements.

Double check all measurements and drilling locations

before proceeding.

Regularly check framework for squareness and vertical

alignment to make sure it hasn't moved during

construction.

Purlin Overhang

BARGE CAP

RIVET

RAFTER

ROOFING

14 x 95 HEX HEAD

SELF DRILLING SCREWS

PURLIN

No Purlin Overhang

BARGE CAP

12x35mm ROOFING

SCREWS

END OF

PURLIN INLINE WITH

RAFTER CHAMFER

RAFTER

ROOFING

14 x 95 HEX HEAD

SELF DRILLING SCREWS

PURLIN

ATTACH THROUGH

DECK AND PURLIN

ATTACH THROUGH

DECK AND PURLIN

45

Loading...

Loading...