Stratco CLICKFAST FASCIA AND GUTTER SYSTEM, CLICKFAST FASCIA, CLICKFAST GUTTER SYSTEM User Manual

The Clickfast Fascia and Gutter

System was originally designed

by Stratco and has proven to

be the most successful fascia

and gutter system in Australia

using a flat steel fascia.

It has been used successfully

by major builders for more than

20 years and remains the

industry leader. It is one of the

few products in Australia to receive the coveted

"classic" design award. In addition to design

excellence, this also guarantees a friendly, tried and

usable system for the Installer.

HOW TO USE THIS MANUAL

Before attempting to install the Clickfast Fascia and

Gutter system to a new home, you should read the

Clickfast Fascia and Gutter brochure and also this

installation manual completely. If further advice is

required, contact your nearest Stratco sales office.

185MM FLAT FASCIA

This fascia is a non structural component designed to cover the end of rafters, provide support for the gutter

and is suitable to support a 4.5mm or 6mm soffit lining placed horizontally, or a 4.5mm soffit raked up to 15˚.

STANDARD RAFTER BRACKET

This bracket supports the fascia and is nailed to the side of each rafter.

HIP RAFTER BRACKET

This bracket is bent at 45˚ and is used on hip rafters to provide a strong external corner.

EXTERNAL MITRE

These are fitted on the outside of the fascia for all 90˚ external corners. The ribs in the mitre continue the

smooth line of the fascia around external corners.

INTERNAL MITRE

After the fascia has been formed around an internal corner, this component is simply riveted to the underside

of the fascia.

JOINING SLEEVE

This component is fixed internally, joining two longer lengths of fascia together. It provides the ideal method of

joining two lengths.

BARGE RAFTER BRACKET

This is used to support the fascia when it is being used as a barge. The top of the bracket is recessed to allow

the barge gutter to sit neatly.

SUSPENSION CLIPS

These clips are a specially designed clip made of spring steel and are placed at approximately 1.2 metre

intervals along the fascia. It allows an adequate fall to be given to the gutter.

BARGE APEX COVER

This cover enables the apex of two joining barges to be joined neatly.

BARGE MOULD (specify left or right hand)

These are used to provide a neat corner where the fascia and barge meets. The ribs on the barge mould

allow a smooth flowing line to run along the fascia and continue neatly up the barge. They must be ordered as left

or right hand. The long face of the barge mould runs along the fascia.

BARGE GUTTER

This specially manufactured gutter fits over the top of the barge and is supported by timber outriggers. It

allows the small amount of water which falls between the last tile and the fascia to run to the gutter.

INTRODUCING THE CLICKFAST® FASCIA AND GUTTER SYSTEM

COMPONENTS OF THE CLICKFAST® FASCIA AND GUTTER SYSTEM

1: 185MM FLAT FASCIA

2: STANDARD RAFTER BRACKET

3: HIP RAFTER BRACKET 4: EXTERNAL MITRE

5: INTERNAL MITRE

9: BARGE APEX COVER 10: BARGE MOULD 11: BARGE GUTTER

6: JOINING SLEEVE 8: SUSPENSION CLIP

7: BARGE RAFTER BRACKET

1

2

3

4

5

6

7

8

9

10

11

EAVES & VERGE CONSTRUCTION

TILE ROOFS

BARGE GUTTER

FASCIA(AS BARGE)

TILE

OUTSIDE WALL

LINING

TRIMMER

RAFTER

TILE BATTENS

OUTRIGGER

FASCIA

To ensure that your barges perform as required, it is important that thought has been given to the correct

layout of roof framing for this area. Outriggers are generally required to support the weight of roofing

extending past the wall line. The following details show how these trimmers should be installed:

NOTE:

A roof purlin should

be placed

approximately

75mm from the top

of the fascia to

support the end of

the roofing sheet.

ARCHITECTS NOTE:

A 185mm fascia is generally suitable for the majority of standard house designs and

eaves & verge styles. In some cases variations in rafter depth and roof pitch will

require a fascia extension. This can simply be riveted to the top of the standard

fascia. Contact Stratco for details.

VERGE FRAMING

1

2

3

TRIMMER

TILE BATTENS

OUTRIGGER

1

1

2

3

3

2

3

3

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

SHEETMETAL ROOFS

MARKING OUT TOOLS

TOOLS YOU WILL NEED

INSTALLING FASCIA

Square, string line, adjustable

bevel square & spirit level.

CUTTING TOOLS

Hacksaw, snips.

FIXING TOOLS

Hammer, drill, silicone, rivet gun

pliers.

OTHER USEFUL ACCESSORIES

Ladder, scaffold.

MEASURING YOUR PROJECT

Draw your roof outline and measure each fascia

length required, marking it on your plan.

For lengths longer than 9 metres, allow a joining

point adjacent to one rafter and mark the adjusted

fascia lengths on your plan.

BEFORE YOU START

Ensure that all materials are on site and double check

that the materials delivered correspond with your

order and initial take-off. Ensure that all tools are on

hand and that you have completely read and

understood the Clickfast Fascia and Gutter

installation instructions.

If further advice is needed contact your nearest

Stratco Sales Office before commencing.

MARKING OUT

Check rafter foot and plumb cuts are correct.

Determine the eave height, by reference to the

plans and by the location of soffit supports. The

soffit should finish at the top of the window reveal,

unless otherwise specified and the distance from the

top of the top plate to the window reveal should be

recorded (measurement A). Generally, this

measurement should only be taken from the highest

windows (usually the WC, laundry or bathroom).

Check at least two windows to confirm the height.

Determine the distance from the back of the fascia

base (by using a rafter bracket) to the outside

face of the wall frame (measurement B). It is

important to use a spirit level to ensure that the

bracket is plumb in taking this measurement.

Measure barges by taking the actual roof length

from the top of the apex to the bottom of the

proposed fascia. Allow 300mm extra for laps and

angle cutting.

1

4

Deduct 60mm from measurement Aand 50mm

from measurement B to provide two mark out

points for setting out a bracket. The mark out points

determine the back of the bracket and the centre slot.

4

Using an adjustable bevel square, spirit level and

tape, mark the bracket location on the second

last rafter from each end of a fascia run. Nail a

bracket (commencing with the first nail in the

adjustment slot) to the inside of each rafter. Fully nail

off each bracket with three nails.

5

1

2

3

Place a nail into the

foot cut of the rafter

on the two brackets from

Step 5, on the

measurement B-50mm

line and run a taut string

line between them.

6

Using a bevel square,

mark the location for the

back of the bracket on

every second rafter. Repeat

this process around the

building.

NOTE: An alternative

method is to put the string

line on the inside of the

soffit groove on the bracket.

To mark out the remaining

brackets, use a loose

bracket and the bevel

square in conjunction with

the string line. Afinal check

is made using a spirit level

against the bracket.

7

Complete your order form by summarising all

fascia and barge lengths, counting internal and

external mitres, and listing the number of brackets

and other accessories required.

Phone or fax your order to your nearest Stratco

outlet, clearly specifying delivery details and the

fascia and gutter finishes required.

5

6

For internal corners not using butt joint method,

measure past the corner (approximately 1 metre,

and adjacent to a rafter) and mark the adjusted

lengths on your plan. If the butt joint method is used

lengths are measured to the actual corner.

3

2

INSTALLING ACCESSORIES

INSTALLING FASCIA AS BARGE

FASCIA INSTALLATION

Slide the fascia onto one of the two brackets fixed

(see 5 above).

▫ Clip the base of the fascia into the second bracket.

▫ Stretch the top of the fascia over the top of the

bracket. In some cases, fascia can be simply slid

over the second bracket.

At the centre point of the run, insert a bracket into

the fascia and then fix the bracket to the set up

point previously marked (Step 7 previous page) with

a nail in the centre slot only.

Check the fascia for straightness (by eye) by

looking along the base of the fascia (also check

with spirit level to base of fascia). When straight, fix

every second rafter to the set up lines marked, again

using the centre slot and now utilizing one of the

base holes. Ensure that the base of the fascia

stays straight.

1

MARKING OUT

On the barge rafter bracket, the centre slot is set

52 mm from the base of the outrigger and the

back of the bracket is set in 50 mm from its end.

FIXING BRACKETS

Fix only two brackets as previously described

using three nails on each side of gable.

INSTALLING

The first length of barge to be installed must first

have the lower end made to fit the fascia.

This is done by:

▫ Marking on the front of the

barge the roof pitch and then cut

off.

▫ On the cut edge, mark down

185 mm, and then draw a line at

90˚ from the base to intersect this

point, then cut this off.

▫ On the cut edge, mark a line at

90˚ at the intersection of the two

previous steps. This line will go to

the base of the fascia.

▫ Cut along the line marked in the

previous step. Also cut excess

metal from below soffit groove

(trim this groove to length if

needed). Push upwards and rivet.

Attach barge as previously described for fascia.

Attach barge mould as per external mitre (remember that the long leg of the barge mould fits on the

fascia. Both left hand and right hand barge moulds are available).

Install remaining barge rafter brackets.

1

1

1

2

3

4

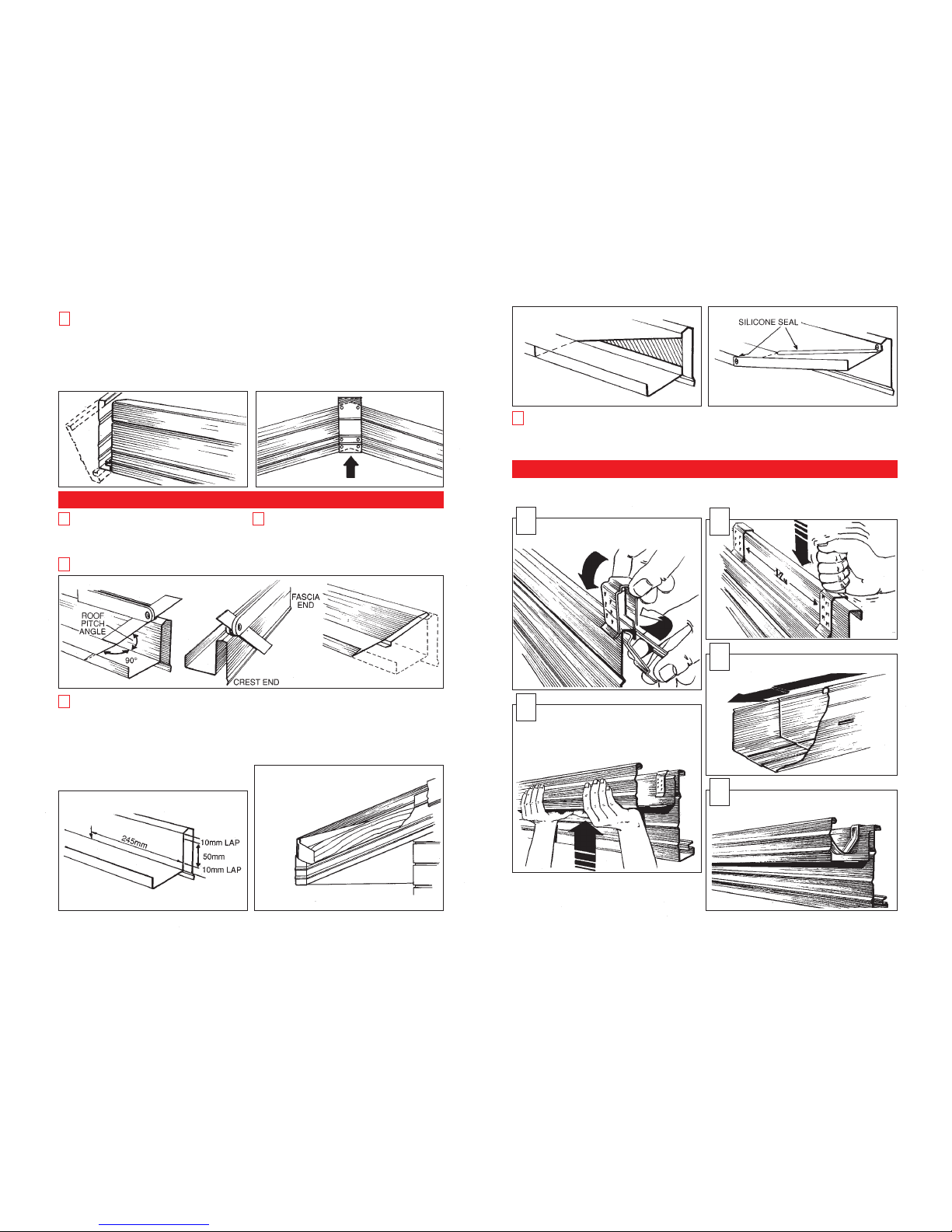

JOINING SLEEVES

Where a joining sleeve is required, do not fully

nail standard rafter brackets for at least two

rafters adjacent to the join.

Rivet the joining sleeve to one length of fascia

as shown.

1

2

Slide the second piece of fascia over the joining

sleeve and rivet.

Check that the fascia is straight by sighting

along the base of the fascia and nail the

remaining brackets.

3

4

EXTERNAL MITRES

Slide the external mitre over the adjoining fascia

and check that the fascia has not been pulled out

of line and that the corner remains square.

Rivet the external mitre at the 'dimples' embossed

in the mitre. Recheck for square and alignment.

1

2

2

3

INTERNAL MITRES

Measure the fascia from the inside of the nearest

external corner or joining sleeve to the proposed

position of the internal mitre.

Cut the top lip of the fascia and the base with a

hacksaw and bend to 90˚.

Fix the fascia to the brackets on the long run in

the same manner as previously described.

Ensuring that the internal corner remains at 90˚,

fix the rafter brackets to the short run of fascia.

Attach the internal corner with rivets as shown.

Note that the alternate butt joint method still

requires an internal corner mitre.

1

2

3

5

4

Finish nailing all marked brackets and then all

brackets not previously installed.

Install hip rafter brackets remembering to fold the

top tag over the rafter and nail.

4

5

52mm

PREPARING AND INSTALLING BARGE GUTTER

CLICKFAST®GUTTER INSTALLATION

Cut barge vertically at apex. The second length of

barge to be put up is done in a reverse manner.

This is done by:

▫ Cut barge vertically to suit apex on the ground.

▫ Install barge as per previous length.

▫ Mark length against fascia.

▫ Remove the second piece of barge.

▫ Modify end to suit fascia as per previous length.

▫ Re-install barge.

▫ Attach barge mould as per previous.

▫ Install remaining barge rafter brackets.

▫ Install barge apex cover by pushing up from

bottom, rivet to barge and trim excess.

5

On the apex end of your barge gutter, set an

adjustable bevel to the roof pitch, mark a line up

the front of the barge gutter, continue the line over

the crest of the gutter, across the pan and up the

short side, again using the roof pitch.

Cut along the lines to remove the excess

material.

1

2

Repeat the above process, drawing a second line

10mm from the cutting line, this allows a lap to

join the two lengths together at the apex later.

(This length has a joining line marked on it).

3

Measure the barge from the apex cut to the

outside edge of the fascia.

NOTE: Where your barge gutter reaches the eaves

gutter, the barge gutter is below the level of the back

of the eaves gutter. To rectify this simply follow these

steps.

▫ From the base of the barge gutter, allow a 10mm

lap then mark a second line 50mm above the first

(note: make sure to leave at least 10mm from the top

edge to join together).

To maintain a downward water flow to the gutter:

▫ Mark and cut as shown in the drawing.

▫ Fold the base up and rivet and silicone joints.

Please note that the vertical edge may need to be

trimmed to suit tiles.

▫ Repeat for remaining lengths.

4

Install the first length of barge gutter (that has

no allowance for joining at the apex) ensuring it

sits parallel to the barge.

▫ Rivet the barge gutter to the barge at

approximately 900mm centres just above the rib.

NOTE: Most gutter profiles produced by other manufacturers cannot be used in conjunction with the Stratco

suspension clip.

▫ Install the second length of barge gutter and at the

apex, where the two lengths meet, bend the laps

down to meet the first length of barge gutter, rivet

and seal.

5

In the middle of a run of gutter and fascia,

two suspension clips are installed onto the

fascia, approximately 1200mm apart.

1

NOTE: When joining gutter lengths, always

make sure that the water flow runs down

the lap.

4

Internal gutter straps are rolled into the front

bead and then bent over the back of the

fascia. These are also placed at approximately

1200mm spacing.

5

The gutter is lifted until the suspension clip

engages the back of the gutter to hold it in

position.

Falling the gutter to the water outlets is achieved

by “clicking” the gutter up to the top tooth at the

point furthest away and to the second lowest tooth

near the water outlet.

3

2

Loading...

Loading...