Page 1

User Guide

D R A F T

2013

English

Objet1000 - Connex 2

3D Printer System

16 June

Page 2

2013

D R A F T

16 June

Page 3

Copyright

D R A F T

2013

Trademarks

Copyright © 2013 Stratasys Ltd. All rights reserved.

This documentation contains proprietary information of Stratasys Ltd. This information is supplied

solely to assist authorized users of Objet1000 Connex 2 3D printing systems. No part of this

document may be used for other purposes, and it may not be disclosed to other parties.

The specifications on which this document is based are subject to change without notice.

No part of this book may be reproduced in any form or by any means, nor stored in a database or

retrieval system, without prior permission in writing from Stratasys Ltd.

If this document is distributed as a PDF file, you may print it for internal use.

The following are registered trademarks of Stratasys Ltd.: Stratasys®, Objet®, FullCure®.

The following are trademarks of Stratasys Ltd.: Eden, Eden500V, Eden350V, Eden350, Eden330,

Eden260, Eden260V, Eden250, Connex, Connex500, Connex350, Objet30, Objet30 Pro, Objet30

OrthoDesk, Objet30 Scholar, Objet24, Alaris, Alaris30, PolyJet, PolyJet Matrix, CADMatrix, PolyLog,

Objet Studio, Job Manager, SHR, Clear, Durus, DurusWhite, MED610, MED690, ObjetGreen,

RoseClear, TangoBlack, TangoBlackPlus, TangoGray, TangoPlus, VeroBlue, VeroGray, VeroWhite,

VeroWhitePlus, VeroBlack.

Microsoft and Microsoft XP are trademarks of Microsoft Corporation.

All names of products and services cited in this book are trademarks or registered trademarks of their

respective companies.

FCC Compliance

The equipment referred to in this guide has been tested and found to comply with the limits for a

Class A device pursuant to part 15 of the FCC rules. These limits provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. Objet 3D

printing systems generate, use and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case

the user will be required to correct the interference at his own expense.

The 3D printer referred to in this guide contains a transmitter module, FCC ID YH6 XLRFID.

NOTE: Stratasys is not responsible for radio or TV interference caused by unauthorized modification

to this equipment. Such modification could void the users authority to operate the equipment.

Equipment Recycling

In the European Union, this symbol indicates that when the last user wishes to discard a product, it

must be sent to appropriate facilities for recovery and recycling. For information about proper

disposal, check your purchase contract, or contact the supplier of the equipment.

Limitation of Liability

The product, software or services are being provided on an as is and as available basis. Except as

may be stated specifically in your contract, Stratasys Ltd. expressly disclaims all warranties of any

kind, whether express or implied, including, but not limited to, any implied warranties of

merchantability, fitness for a particular purpose and non infringement.

You understand and agree that Stratasys Ltd. shall not be liable for any direct, indirect, incidental,

special, consequential or exemplary damages, including but not limited to, damages for loss of profits,

goodwill, use, data or other intangible losses (even if Stratasys has been advised of the possibility of

such damages), resulting from: (i) the use or the inability to use the product or software; (ii) the cost of

procurement of substitute goods and services resulting from any products, goods, data, software,

information or services purchased; (iii) unauthorized access to or alteration of your products, software

or data; (iv) statements or conduct of any third party; (v) any other matter relating to the product,

software, or services.

The text and drawings herein are for illustration and reference only. The specifications on which they

are based are subject to change. Stratasys Ltd. may, at any time and without notice, make changes to

this document. Stratasys Ltd., for itself and on behalf of its subsidiaries, assumes no liability for

technical or editorial errors or omissions made herein, and shall not be liable for incidental,

consequential, indirect, or special damages, including, without limitation, loss of use, loss or alteration

of data, delays, or lost profits or savings arising from the use of this document.

DOC-06800 Rev. A

16 June

Page 4

Patents

D R A F T

2013

This product is covered by one or more of the following U.S. patents:

5,386,500

6,259,962

6,569,373

6,658,314

6,850,334

7,183,335

7,209,797

7,225,045

7,364,686

7,369,915

7,479,510

7,500,846

7,604,768

7,628,857

7,658,976

7,725,209

Stratasys Ltd.

http://www.stratasys.com

DOC 06800

Revision Rev. A

June 2013

iv

16 June

Page 5

Contents

D R A F T

2013

1 About This Guide

Using This Guide ............................................................................................................................... 12

For More Information........................................................................................................................ 12

Terms Used in This Guide................................................................................................................ 13

2 Safety

Safety Features ................................................................................................................................... 22

Symbols and Warning Labels .......................................................................................................... 23

Safety Guidelines ............................................................................................................................... 24

Printer Installation .............................................................................................................................. 24

Printer Operation ................................................................................................................................ 24

UV Radiation ....................................................................................................................................... 24

Printer Maintenance ........................................................................................................................... 24

Model and Support Materials ........................................................................................................... 25

First Aid for Working with Printing Materials.............................................................................. 26

Contact with Skin................................................................................................................................ 26

Contact with Eyes ............................................................................................................................... 26

Ingestion ............................................................................................................................................... 26

Inhalation ............................................................................................................................................. 26

Waste Disposal ................................................................................................................................... 27

3 Introducing the Objet 3D Printing System

Welcome to Connex........................................................................................................................... 32

Work Configurations......................................................................................................................... 33

Source Files ......................................................................................................................................... 34

STL Files ............................................................................................................................................... 34

SLC Files ............................................................................................................................................... 34

Connex Workflows ............................................................................................................................ 35

Printing Materials .............................................................................................................................. 36

Storage .................................................................................................................................................. 36

Shelf Life............................................................................................................................................... 36

Exposure to Light................................................................................................................................ 36

Safety Considerations......................................................................................................................... 36

Disposal ................................................................................................................................................ 37

Work Environment ............................................................................................................................ 37

Preparing Files for Use with Objet 3D Printing Systems ............................................................. 38

Converting CAD Files to STL Format.............................................................................................. 38

Converting Files to SLC Format ....................................................................................................... 38

Objet Studio Software ....................................................................................................................... 39

4 Installing Objet Software

How to Install Software for the Objet 3D Printing System.......................................................... 42

How to Uninstall Objet Studio......................................................................................................... 45

DOC-06800 Rev. A

16 June

Page 6

Objet1000 - Connex 2 User Guide

D R A F T

2013

5 Using Objet Studio

Launching Objet Studio .................................................................................................................... 53

Windows® 7 Security Warning......................................................................................................... 53

Objet Studio Interface ......................................................................................................................... 54

Ribbon Commands..............................................................................................................................56

Objet Studio Commands Menu .........................................................................................................58

Model Tree Pane .................................................................................................................................. 58

Preparing Models for Production.................................................................................................... 59

OBJDF Files: Overview ....................................................................................................................... 59

Model Files ........................................................................................................................................... 59

Placing Objects on the Build Tray ...................................................................................................510

Opening Objet Tray Files..................................................................................................................514

Quick Access Model Commands ....................................................................................................516

Copying and Pasting Objects........................................................................................................... 517

Selecting Objects ................................................................................................................................518

Splitting Objects into Components ................................................................................................. 518

Model Material Settings ...................................................................................................................520

Changing the Model Material..........................................................................................................521

Digital Materials ................................................................................................................................ 521

Assigning a Model Material to Objects .......................................................................................... 522

Surface Finish..................................................................................................................................... 523

Coating Objects .................................................................................................................................. 523

Assigning Properties to Hidden Objects........................................................................................ 525

Positioning Objects on the Build Tray .......................................................................................... 526

Automatic Orientation......................................................................................................................526

Automatic Placement........................................................................................................................ 527

Manual Positioning ...........................................................................................................................528

Model Orientation............................................................................................................................ 529

Manipulating Objects on the Build Tray ...................................................................................... 530

Positioning Objects on the Z Axis...................................................................................................530

Valid Object Placement.....................................................................................................................531

Using a Grid to Position Objects ..................................................................................................... 532

Measurement Units........................................................................................................................... 533

Setting Model Dimensions ............................................................................................................... 534

Repositioning Objects ....................................................................................................................... 534

Changing an Objects Orientation................................................................................................... 536

Grouping and Ungrouping Objects ................................................................................................537

Freezing Model Orientation............................................................................................................. 538

Display Options................................................................................................................................ 539

Viewing Objects .................................................................................................................................539

Screen Layout .....................................................................................................................................541

Tray Perspective ................................................................................................................................542

Setting Object Colors.........................................................................................................................543

Loading Large Files ...........................................................................................................................544

Large File Manipulation ...................................................................................................................544

Zoom Options ....................................................................................................................................546

Handling Completed Trays............................................................................................................ 547

Tray Validation ..................................................................................................................................547

Production Estimates ........................................................................................................................548

Printing Modes ..................................................................................................................................548

E mailing Objet Digital Files............................................................................................................ 549

Printing the Tray File ........................................................................................................................550

vi

16 June

Page 7

User Guide

D R A F T

2013

Applying Additional Objet Studio Features................................................................................ 554

Dividing Objects................................................................................................................................ 554

Choosing the Support Strength ...................................................................................................... 555

Hollow Filling Models with Support Material ..................................................................... 556

Displaying the Cross Section of Objects ........................................................................................ 557

Saving the Screen Display as an Image File.................................................................................. 558

Exporting and Importing Objet Build Trays................................................................................. 559

Customizing Objet Studio .............................................................................................................. 560

Creating a Quick Access Toolbar.................................................................................................... 560

Hiding the Ribbon ............................................................................................................................ 561

Display Colors ................................................................................................................................... 562

Keyboard Shortcuts .......................................................................................................................... 563

Setting User Preferences .................................................................................................................. 564

Professional Mode Features ........................................................................................................... 565

Default Settings ................................................................................................................................. 566

Open GL Driver Configuration ...................................................................................................... 567

Getting Additional Objet Studio Assistance ................................................................................ 569

Objet Studio Version, Material Module and Licensed Features ............................................... 569

Monitoring and Managing Print Jobs ........................................................................................... 572

Job Manager Screen .......................................................................................................................... 572

Setting the Printer Connection ........................................................................................................ 574

Off line Mode .................................................................................................................................... 575

Setting the Remote Printer Connection (Client Mode)................................................................ 576

Job Manager Commands ................................................................................................................. 576

Configuring User Alerts................................................................................................................... 579

Printing the Tray ............................................................................................................................... 580

Additional Server Features.............................................................................................................. 580

6 Operating & Maintaining the Objet1000 Connex 2 3D Printer

Starting the Objet1000 Printer .......................................................................................................... 62

Loading Model and Support Cartridges ........................................................................................ 64

Producing Models.............................................................................................................................. 65

Printer Interface Color Key................................................................................................................ 67

Printing Indicators .............................................................................................................................. 68

Resuming Production After Printing has Stopped ....................................................................... 69

Changing the Model Material ........................................................................................................ 611

Advanced Settings ............................................................................................................................ 614

Keeping the Printer in Idle Mode.................................................................................................. 616

Shutting Down the Printer ............................................................................................................. 617

Maintaining the Printer................................................................................................................... 619

Routine Maintenance Schedule....................................................................................................... 619

Cleaning the Print Heads................................................................................................................. 620

Pattern Test ........................................................................................................................................ 623

Improving Print Quality .................................................................................................................. 624

Cleaning and Replacing the Wiper ................................................................................................ 624

Cleaning the Roller Waste Collector and Inspecting the Roller Scraper .................................. 627

Replacing the Roller Scraper ........................................................................................................... 629

Aligning the Print Heads ................................................................................................................. 632

Replacing Print Heads...................................................................................................................... 636

Testing and Calibrating the UV Lamps ......................................................................................... 636

Calibrating the Load Cells ............................................................................................................... 640

Replacing the UV Lamps ................................................................................................................. 642

Built in Tests ...................................................................................................................................... 647

Replacing the Waste Container....................................................................................................... 653

.Cleaning the Exterior Panels .......................................................................................................... 653

DOC-06800 Rev. A

16 June

vii

Page 8

Objet1000 - Connex 2 User Guide

D R A F T

2013

viii

16 June

Page 9

About This Guide

D R A F T

2013

Using This Guide................................................................................. 2

For More Information......................................................................... 2

Terms Used in This Guide.................................................................. 3

DOC-06800 Rev. A

16 June

1–1

Page 10

About This Guide

D R A F T

2013

Using This Guide

This user guide provides instructions for installing, operating and

maintaining Objet 3D printing systems. It explains how to use features, and

provides practical examples to guide you as you use the system.

The text and figures in this guide are based on the 3 D printer, printer

software version 100.2.0 and Objet Studio software version 9.2.

This guide assumes that:

all the hardware, software, and network components of your Objet

system are installed, configured, and operating correctly.

the operator has a working knowledge of the Windows®PC platform.

For More Information

Visit http://www.stratasys.com/ for more details about Objet printer

technology, products and consumables, and for service and support

contacts.

For other documents that relate to Objet1000 Connex 2 3 D printing

systems, and for this document in other languages, contact your regional

Stratasys Customer Support office.

If you have any questions about the information presented in this

document, or if you have any comments or suggestions for future editions,

please send a message to c support@stratasys.com.

1–2

16 June

DOC-06800 Rev. A

Page 11

Objet1000 - Connex 2 User Guide

D R A F T

2013

Terms Used in This Guide

build tray In Objet Studio: The surface displayed on the screen that

represents the actual build tray in the printer.

In the printer: The surface upon which models are produced.

cleaning fluid Cleanser for flushing material feed tubes and the printing

block, used to completely remove Model and Support

material from the system before loading another type of

material in the printer and before long term shutdown. The

cleaning fluid is supplied in material cartridges.

client/user workstation The workstation on which Objet software is installed, used

for preparing build trays for production on Objet printers.

(There is no limit to the number of client workstations in the

local network.)

Objet printer The Objet 3D printer referred to in this guide.

Printer computer The computer inside the Objet printer that operates it. (This is

sometimes referred to as the embedded computer.)

Printer interface The GUI (graphical user interface) used for controlling the

Objet printer.

Printer software Software running on the computer inside the Objet printer,

that controls all printer operations.

Digital Material Combinations of model materials fabricated in the printer

from the two basic model materials installed.

Digital Material Mode The printer mode used to print a job using two different

model materials. (This mode can also be used to eliminate the

need for performing the Material Replacement procedure

when printing with a single model material.)

host/server workstation The workstation that interfaces directly with the Objet printer

and is typically positioned next to it.

Job Manager The part of Objet Studio software that manages production

jobs before they are sent to the Objet printer.

mixed part Models whose parts are printed using more than one model

material.

mixed tray A build tray containing objects, each of which is designed to

be printed using a different model material.

Model material Material used for building models.

Objet Studio The software with which users prepare jobs for producing

models.

OBJDF (Objet Digital Format) The extension of a file that contains information about the

geometry of an object and the materials required to print it.

objdf files are created in Objet Studio.

DOC-06800 Rev. A

16 June

1–3

Page 12

About This Guide

D R A F T

2013

OBJTF (Objet Tray Format) The extension of a file that contains all of the information

needed for a model printing job on Objet 3D printers. An objtf

file is used to send a print job to an Objet 3D printer.

OBJZF (Objet Z Format) The extension of a compressed wrapper file containing all

of the files used in an Objet Studio build tray. Using objzf files,

a printing job can be saved as a single file, for convenient

storage and transfer.

PolyJet Matrix The technology of printing models by jetting multiple

materials simultaneously from the print heads. This

technology enables Objet1000 Connex 2 printers to print in

Digital Material mode.

resin The base substance from which photopolymer printing

materials are made for use in Objet printers. In Objet Studio

and printer application screens, resin refers to cartridges of

model and support materials.

SLC A file type used with Objet software. (These files are bitmaps

of individual slices of the object. For more information, see

page 3 4.)

STL A file type used with Objet software. (For more information,

see page 3 4.)

Support material Material used for supporting the structure of models during

production.

1–4

16 June

DOC-06800 Rev. A

Page 13

Safety

D R A F T

2013

Safety Features ............................................................................................. 2

Symbols and Warning Labels .................................................................... 3

Safety Guidelines......................................................................................... 4

Printer Installation ......................................................................................... 4

Printer Operation ........................................................................................... 4

UV Radiation .................................................................................................. 4

Printer Maintenance ...................................................................................... 4

Model and Support Materials ...................................................................... 5

First Aid for Working with Printing Materials ....................................... 6

Waste Disposal............................................................................................. 7

DOC-06800 Rev. A

16 June

2–1

Page 14

Safety

D R A F T

2013

Safety Features

Objet 3D printers are designed to comply with CE and FCC standards.

They are equipped with the following safety features:

Interlock Switch The power supplied to the UV lamp and the

motion motors is turned off when the doors are

opened.

WARNING: Do not defeat (override) the

interlock switch. Doing so could result in

serious personal injury. If the interlock switch

does not function correctly, do not use the

printer, and contact your service provider.

Safety Lock The doors are locked while the printer is

UV Screening The transparent section of the doors blocks

Circuit Breaker The power to the printer is turned off in case of

working. The lock is released when the printer

reverts to pause or stop mode.

WARNING: Do not defeat (override) the

safety lock. Doing so could result in serious

personal injury.

If the safety lock does not function correctly, do

not use the printer, and contact your service

provider.

harmful UV radiation, allowing the operator to

view the model as it is being made.

electrical overcurrent.

Note: The circuit breaker is only accessible to

service personnel.

Grounded Chassis The chassis of the printer is grounded, to

prevent electrical shock.

Note: The power outlet must be properly

grounded, in accordance with the local

electric code, to provide this protection.

Emergency Stop Emergency stop switches are located on the

front and back of the printer.

Important: Pushing the emergency stop

switch disconnects power to motors only.

It does not disconnect the power supply to

the printer; printer circuits remain on.

2–2

Figure 2-1: Objet1000—front view

Figure 2-2: Emergency Stop Switch—Push to stop motors, turn to release

DOC-06800 Rev. A

16 June

Page 15

If the Objet 3D printing system is not used as specified in this guide, the

D R A F T

2013

safety features may not provide adequate protection.

Symbols and Warning Labels

This following table lists the warning labels located on or in Objet printers.

Objet1000 - Connex 2 User Guide

Warning

Symbol

Meaning Location Comments

Hazard

(general)

Hot surface On the print head

High voltage Near .

Ultraviolet

radiation

On the name plate

on the back of the

printer.

block.

Near the power

supply enclosures.

Read the instructions

in this document

before operating the

printer.

Risk of burns. Do not

touch this surface

after printing.

Risk of electric shock.

Risk of injury from

ultraviolet radiation.

DOC-06800 Rev. A

Moving parts Risk of injury from

moving parts.

2–3

16 June

Page 16

Safety

D R A F T

2013

Safety Guidelines

The following general guidelines, together with the instructions provided

throughout this user guide, ensure user safety while operating and

maintaining the Objet system. If the system is not operated as specified,

the user s safety may be compromised!

Printer

Installation

Printer

Operation

Installation and removal of the printer should only be done by qualified

service personnel.

Connect the printer to the electric outlet using a power cord that is

safety certified.

The electric outlet should be easily accessible, near the printer.

Never connect the power plug to an outlet that does not have a ground

(earth) wire, and never disconnect the ground. Doing so might expose

the operator to serious danger from electric shock.

Leave a minimum of centimeters between ventilation openings and

walls or other objects.

The printer should only be operated by persons trained by a Stratasys

customer support representative.

All personnel operating or maintaining the printer should know the

location of first aid and emergency equipment and how to use it. Never

block access to this equipment!

Keep fingers and other body parts clear of the printer cover when

closing it.

Never attempt to open the main cover of the printer while it is working!

Never override the interlock safety switch!

If the interlock safety switch ever fails, do not use the printer.

Several parts of the printer remain extremely hot even after it has

stopped operating. Avoid touching the UV lamps and the print block.

UV Radiation

Printer

Maintenance

2–4

The UV lamps used in the printer emit dangerous radiation.

If the UV lamps remain on when the printer cover is open, do not stare

directly at the UV light. Shut down the printer and call your Stratasys

service provider.

Service operations should be performed only by qualified personnel

who have been instructed in relevant safety precautions.

Notify co workers and those who have access to the Objet system

before beginning non routine and hazardous work.

Report any potential dangers and safety-related accidents to your safety

officer or to other appropriate authorities.

DOC-06800 Rev. A

16 June

Page 17

Objet1000 - Connex 2 User Guide

D R A F T

2013

Model and

Support

Materials

Model and support materials are made of chemical substances. Although

precautions must be taken when handling these materials directly, all

model and support materials used by the Objet system are handled in

sealed cartridges. Normally, operators of the printer should never be

directly exposed to hazardous materials. In the unlikely event of a leak or

spill, follow the instructions that are included with the printing material

cartridge used.

Store cartridges of model and support materials indoors, in a dry area

with adequate ventilation, between 16 27 degrees Celsius (60 81

degrees Fahrenheit). Never expose them to flames, heat, sparks, or

direct sunlight.

Keep model and support materials away from areas where food and

drink are stored, prepared and consumed.

Uncured printing material is considered a hazardous substance,

requiring certain precautions when directly handling it. To prevent skin

irritation, wear neoprene or nitrile gloves. If there is any chance that

model and support materials might splash into the eyes, wear safety

goggles. Prolonged direct contact with printing materials can cause an

allergic reaction.

When handling UV cured models that may not be completely cured on

the surface, common latex gloves are adequate.

To prevent respiratory irritation, ventilate areas where model and

support materials are used. The ventilation system should totally

replace the air at least 20 times per hour.

Clean up model material and support material spills with disposable

towels or other absorbent, non reusable material, such as sawdust or

activated charcoal. Rinse the spill area with denatured or isopropyl

alcohol (IPA), followed by soap and water. Dispose of the absorbent

material in accordance with local regulations.

Do not wash contaminated clothing at home; clothing should be

professionally laundered.

Dispose of contaminated shoes, belts and other leather items in

accordance with any applicable regulations. Absorbed printing

material may re expose the user when these items are worn.

DOC-06800 Rev. A

16 June

2–5

Page 18

Safety

D R A F T

2013

First Aid for Working with Printing Materials

In general, try to avoid direct contact with uncured printing material. If

skin or eyes come into contact with it, wash the area immediately and

thoroughly with water, and follow these first aid instructions.

The Material Safety Data Sheet (MSDS) that accompanies printing

materials contains important safety information. Keep this in an accessible

place where these materials are used and stored.

Contact with

Skin

Contact with

Eyes

If uncured printing material comes in contact with skin, wash the affected

area immediately and thoroughly with soap and cool water, then remove

contaminated clothing. Pay particular attention to flushing the hair, ears,

nose and other parts of the body that are not easily cleaned.

Use cool water to prevent skin pores from opening, so that the liquid

material does not easily penetrate the skin.

Do not use solvents to clean skin.

If large areas of skin have been exposed, or if prolonged contact results

in blisters, seek medical attention. In any case, if irritation persists, seek

medical attention.

Avoid the accidental transfer of printing material from the hands to

other areas of the body, especially to the eyes.

If protective cream was used, do not reapply it until the skin has been

completely cleansed.

If uncured printing material comes in contact with the eyes, flush

immediately with large amounts of water for 15 minutes and seek medical

attention.

Avoid sunlight, fluorescent light, and other sources of ultraviolet

radiation.

The wearing of contact lenses when handling liquid printing materials is

not recommended. If the liquid splashes into the eyes when contact lenses

are worn, immediately remove the lenses and flush the eyes with water.

Clean and disinfect the contaminated lenses.

Do not wear contact lenses until eye irritation disappears.

Ingestion

Inhalation

2–6

If printing material is swallowed, refer to the instructions included with the

cartridge. Seek medical attention immediately.

Vapors from printing materials can be irritating to the respiratory system.

If respiratory irritation occurs, expose the victim to fresh air immediately.

If the victim has stopped breathing, perform artificial respiration or

cardiopulmonary resuscitation.

Seek medical attention immediately.

Keep the patient warm but not hot.

Never feed anything by mouth to an unconscious person.

Oxygen should be administered by authorized personnel only.

DOC-06800 Rev. A

16 June

Page 19

Waste Disposal

D R A F T

2013

Objet1000 - Connex 2 User Guide

Fully cured printed models can be disposed of as ordinary office trash.

However, special care is required when handling printer waste.

When removing the waste container from the Objet printer, wear

neoprene or nitrile gloves.

To prevent liquid waste from splashing into the eyes, wear safety

goggles.

Liquid waste from the Objet printer is classified as hazardous industrial

waste. Therefore, printing material waste must be packaged and

disposed of in a manner that prevents human contact with it and

contamination of water sources.

Empty model material and support material cartridges contain residue

of their contents. Some leakage of this residue may occur through the

broken cartridge seal. Therefore, handle and store empty cartridges

with care.

Do not attempt to reuse empty cartridges, and do not puncture them.

Dispose of used cartridges and waste containers in accordance with

local regulations.

Discard contaminated clothing, shoes, empty containers, etc., in

accordance with any applicable regulations.

DOC-06800 Rev. A

16 June

2–7

Page 20

Safety

D R A F T

2013

2–8

16 June

DOC-06800 Rev. A

Page 21

Introducing the

D R A F T

2013

Objet 3D Printing System

Work Configurations .......................................................................... 3

Source Files........................................................................................... 4

STL Files ................................................................................................. 4

SLC Files ................................................................................................. 4

Connex Workflows.............................................................................. 5

Printing Materials................................................................................ 6

Storage .................................................................................................... 6

Shelf Life ................................................................................................. 6

Exposure to Light .................................................................................. 6

Safety Considerations........................................................................... 6

Disposal .................................................................................................. 7

Work Environment.............................................................................. 7

Preparing Files for Use with Objet 3D Printing Systems .............. 8

Converting CAD Files to STL Format ................................................ 8

Converting Files to SLC Format.......................................................... 8

Objet Studio Software ......................................................................... 9

DOC-06800 Rev. A

16 June

3–1

Page 22

Introducing the Objet 3D Printing System

D R A F T

2013

Welcome to Connex

The advanced capabilities of the Objet 3 D printing system are made

possible by PolyJet Matrix technology, specially developed by Objet for

printing models simultaneously with different model materials. For the

first time, you can achieve the following results when printing 3 D models:

You can prepare models for printing with designated model materials

•

and then print themusing two basic model materials loaded in the

printer, or combinations of these materials (digital materials).

Parts of the same model can be madesimultaneouslyfrom different

•

materials.

Models made from digital materials can have unique physical

•

properties, depending on the materials used.

You can print objects that have a coating made from a different

•

material than the main part of the object.

In addition, because Objet printers can be loaded with two different

materials, and can print simultaneously with combinations of them, you

can streamline and economize the process of producing models:

You can print models made from different (single) materials on the

•

same build tray (mixed tray), in the same print job. This eliminates

the time consuming need and expense of loading another material,

flushing the system, and sending a separate job to be printed.

You can quickly alternate printing jobs with either of the model

•

materials loadedor with material combinationsagain, without the

need and expense of replacing materials.

The Objet system also enables you to split models into component parts

(shells) so you can isolate, manipulate and print parts of a model.

However, you have ultimate control when separating models into shells by

preparing stl files with your CAD software. Then, with Objet software, you

can assign model materials and other characteristics to the shells.

3–2

Figure 3-1: The 3D Printer

DOC-06800 Rev. A

16 June

Page 23

Work Configurations

D R A F T

2013

The Objet 3D printing system can be set up as a single station system or as

a multi station system. When connected to a local computer network, the

system can serve multiple users. In such configurations, each user

workstation (client) prepares files with Objet Studio software for

production. A server (host), typically next to the 3D printer, acts as a job

manager that sends production jobs to the printer for production.

Figure 3 2 shows the printer set up in a multi client configuration.

Objet1000 - Connex 2 User Guide

Client

workstations

Printer

Figure 3-2: Multi-client network configuration

When installing the Objet software, you choose whether to install it as a

client station or as a master station (server or standalone station).

The Objet software arranges the jobs it receives according to their priorities,

model material type, and other factors. In multi workstation

configurations, the operator of the servertypically the production

administratorhas total control over the jobs sent to the 3D printer, and

can prioritize and delete jobs, review job history and reprint a job, and so

on.

DOC-06800 Rev. A

16 June

3–3

Page 24

Introducing the Objet 3D Printing System

D R A F T

2013

Source Files

Objet 3D printing systems produce three dimensional models designed

with most 3D CAD tools and with other job specific 3D applications. Objet

systems accept:

STL Files

•

SLC Files

•

Objet systems feature the capability of producing both types of model files

simultaneously.

STL Files

SLC Files

STL is short for Standard Triangulation Language. This language views any

object as a collection of surfaces, and describes each surface of the object as

a collection of triangles.

For example, a square can be described as two triangles; a cube (six

squares) as 12 triangles. Curved surfaces need more triangles to describe

them. The higher the tolerance (for smooth surfaces), the more triangles are

needed. The result is that high quality object descriptions mean very heavy

files.

Most CAD software can export STL files. The Objet system utilizes these

files for building models (rapid prototyping), and also for directly making

molds for mass producing items.

STL files can be ASCII (text) files or binary files. The content of the ASCII

file begins with solid and ends with end solid (both lower case).

Between these keywords is a list of the triangles that describes the faces of

the solid model. Each triangle defines a single normal vector directed away

from the solids surface, followed by its X Y Z coordinates. These are

expressed as Cartesian coordinates and are floating point values. The

coordinates of all triangles should be positive and should fall within the

volume of the model.

SLC is short for Stereo Lithography Contour. SLC files describe two

dimensional contours of the three dimensional models. These contour lines

are polylines.

SLC files are ASCII (text) files that save models as a series of slices. This

means that models based on SLC files cannot be orientated; only their scale

(size) and position on the build tray can be controlled. For this reason, the

models orientation must be suitable for production before it is saved as an

SLC file. Because of the nature of SLC files, the appearance of models in

Objet Studio may be different than the solid object images displayed from

STL files.

3–4

16 June

DOC-06800 Rev. A

Page 25

Connex Workflows

D R A F T

2013

With Objet Connex 3 D printing systems, you have great flexibility in

preparing model files and printing them. Below are the major workflows

that have been made possible by PolyJet Matrix technology on Connex

systems. You can find detailed instructions for implementing the listed

tasks in chapter 5 (Using Objet Studio).

Stage Workflow A Workflow B Workflow C

CAD program

•

•

Design a 3 D object.

Save as a single stl

file.

Objet1000 - Connex 2 User Guide

Design a 3 D object.

•

Save the object as an

•

assembly of stl files.

Objet Studio

Objet Printer

WaterJet

Open (Insert) the stl

•

file.

Separate the object

•

into its components

(shells).

Assign materials to

•

the components.

Save the object as an objdf file (optional).

•

Save the build tray. / Send the build to the printer.

•

Open (Insert) the stl

•

files as an assembly.

Assign materials to

•

the assemblys

components.

Models are produced in the printer.

Remove the support material from the models.

•

Open (Import) an

•

objdf file. (objdf files

contain model

material

information.)

Finished model

DOC-06800 Rev. A

Finished model.

workflows, from design to finished models

Objet

16 June

3–5

Page 26

Introducing the Objet 3D Printing System

D R A F T

2013

Printing Materials

Objet printers produce models by jetting thin layers of printing materials

on the build tray, until the complete model is formed. Two types of material

are used in this process:

Model materialwhich makes up the finished model

•

Support materialwhich fills gaps and spaces in the model during

•

printing, and is removed after printing

Storage

Shelf Life

Materials used for printing models with Objet printers are made of resins,

which are composed of reactive monomers and oligomers. Although

printing materials are supplied in sealed, UV proof cartridges, care must be

taken when storing and handling them. Follow these guidelines to protect

operators and the environment, and to ensure optimum results.

To ensure product stability, do not allow these materials to come into

•

contact with metal. Plastics made from monomer soluble substances

(such as polystyrene or polyvinyl chloride) are not suitable for storing

Objet printing materials.

When not in use, keep material cartridges tightly sealed to prevent

•

contamination, the effects of exposure to UV radiation, and accidental

spillage.

Store material cartridges indoors, in a dry area with adequate

•

ventilation, between 1627 degrees Celsius (6081 degrees Fahrenheit).

If exposed to heat or flames, cartridges may burst or ignite.

Signs of premature polymerization in material cartridges may include

•

bulging, leaking, the emission of heat, and unusual odor. Exposure to

heat can cause resin to gel in the cartridge.

Make sure that material cartridges are stored in accordance with all

•

local regulations and other applicable requirements.

Materials used for producing models have a limited shelf life. The expiry

date on the label is valid when properly stored in an undamaged,

unopened cartridge. Always rotate your stock, so that the cartridge with

the earliest date is used first.

Exposure to

Light

Safety

Considerations

3–6

If printing materials are not in their sealed cartridges, make sure to shield

them from sunlight and other sources of UV radiation, such as fluorescent

and mercury vapor lights. Exposure to UV radiation causes an increase in

viscosity and, eventually, solidification.

Before being cured, resins are hazardous materials. To prevent possible

health hazards, follow these precautions regarding printing materials:

Do not expose to flames, heat or sparks.

•

Prevent contact with skin and eyes.

•

Ventilate areas where they are handled.

•

Keep them separate from food and drink.

•

Cured plastic parts, however, are safe. They can be handled and stored

without precautions.

You can find more safety information about resins in “Safety Guidelines” on

page 2-4, and “First Aid for Working with Printing Materials” on page 2-6.

16 June

DOC-06800 Rev. A

Page 27

Objet1000 - Connex 2 User Guide

D R A F T

2013

Disposal

Dispose of cartridges of Objet model and support material in accordance

with all applicable laws and regulations. If necessary, the cartridges can be

disassembled for recycling.

Work Environment

Extreme heat and humidity conditions can adversely affect the operation of

the Objet 3D printer. Therefore, it is recommended that you use ventilation

or air conditioning systems, if necessary, to keep the work area within the

following ranges:

18 25 C (64 77 F)

•

30%70% relative humidity

•

DOC-06800 Rev. A

16 June

3–7

Page 28

Introducing the Objet 3D Printing System

D R A F T

2013

Preparing Files for Use with Objet 3D Printing Systems

Before using files with Objet 3D printing systems, you must convert them

in your CAD program to either stl files or slc files. (For an explanation of

these file formats, see Source Files on page 3 4.)

After converting the model files, it is recommended that you check them for

defects in an STL repair application (such as Magics, by Materialise®)

before opening them in Objet Studio and producing the model.

Converting

CAD Files to

STL Format

This procedure may vary slightly, depending on the CAD software used,

but the following instructions generally apply.

To convert a file to STL format (in a CAD program):

1. From the

2. In the Save As dialog box, open the Save As Type pull down menu and

select

3. Click

Total Qualityapproximately 0.01 mm (deviation tolerance /

•

linear dimension tolerance)

Detail Qualityapproximately 5° (angle tolerance)

•

Note: Lowering these values produces more accurate models, but

results in larger files and longer loading and processing times. For this

reason, it is generally not recommended that you use lower values.

4. In the file format option, choose binary or ASCII. (Both binary and

ASCII formats can be used in Objet Studio. However, binary files are

smaller, so this option is recommended.)

5. ClickOKor

For more information, search for “CAD to STL” on objet.com.

File

*.STL

Options

menu, select

.

and set the following parameters:

.

Save

Save As

.

Converting

Files to SLC

Format

3–8

When converting files to SLC format, it is recommended that you set a layer

thickness of 15 microns (0.015 mm). Since SLC files cannot be orientated in

Objet Studio, it is important that models are properly orientated before

being saved as SLC files. Considerations for suitable model orientation are

explained in Model Orientation on page 5 29.

DOC-06800 Rev. A

16 June

Page 29

Objet Studio Software

D R A F T

2013

Objet Studio software for the Objet 3D printing system consists of two main

screens:

Tray Settings / Model Settings

•

Job Manager

•

Tray Settings / Model Settings

In the Tray Settings and Model Settings screens, you prepare source files for

production in Objet 3 D printers. Objet Studio offers you a wide variety of

file preparation options, but always consists of the following basic

procedure:

1. Inserting one or more objects on the build tray

2. Positioning the object(s) on the tray

3. Configuring object and tray parameters

4. Saving the tray configuration as an objtf (Objet Tray Format) file

5. Sending the objtf file to the Objet 3D printer for production

Using Objet Studio to perform these tasks is described in detail in chapter 5,

Using Objet Studio.

Objet1000 - Connex 2 User Guide

Job Manager

The Job Manager screen is different for client workstations and for the

computer connected directly to the Objet 3D printer.

In Objet Studio installed on the directly connected computer (server),

•

the Job Manager screen displays the queue and status for all jobs sent to

the 3D printer by the server itself and by all client computers on the

network. All jobs displayed can be edited and manipulated.

In Objet Studio installed on client computers, the Job Manager screen

•

displays the queue and status only for jobs sent to a 3D printer server

from that computer. Only these jobs can be edited and manipulated

from the client computer.

Client computers can be connected, via the local network, to different Objet

3D printers, but only to one at a time. The Job Manager screen displays the

status of the 3D printer to which the client is currently connected.

DOC-06800 Rev. A

16 June

3–9

Page 30

Introducing the Objet 3D Printing System

D R A F T

2013

3–10

16 June

DOC-06800 Rev. A

Page 31

Installing Objet Software

D R A F T

2013

How to Install Software for the Objet 3D Printing System ........... 2

DOC-06800 Rev. A

16 June

4–1

Page 32

Installing Objet Software

D R A F T

2013

How to Install Software for the Objet 3D Printing System

The Objet Studio setup wizard guides you when installing the Objet

software. During installation, you must choose to install either the server

(host) application or the client application.

To install Objet software:

1. Insert the Objet Studio CD into the disk drive.

2. Right click the

Start

button and select

for displaying files on the computer).

3. Open the CD drive folder and select

4. If you are installing an Objet Studio upgrade, make sure that your

printer is compatible with it by checking the list displayed.

Explore

Setup

(or use any other method

.

Figure 4-3: Objet Studio compatibility check

5. To install Objet Studio, you must agree to the license agreement. After

reading its terms, click

If you click

Figure 4-1:Objet Studio installation wizard—Welcome screen

6. Click

Yes

, the following screen should appear.

Next

to begin installation.

to continue, orNoto close the wizard.

Yes

4–2

16 June

DOC-06800 Rev. A

Page 33

Objet1000 - Connex 2 User Guide

D R A F T

2013

7. In the Select Features screen, select the required installation option.

Objet Studio for a server computer

Select

if you are installing Objet Studio on a server (host) computer

...

the computer directly connected to an Objet printer.

if you are installing Objet Studio on a standalone (off line)

computer.

Objet Studio for client workstations

Select

if you are installing Objet

Studio on a client workstationa remote computer that prepares

print jobs and then sends them to a server computer.

Figure 4-2: Objet Studio configuration selection

8. In the Select Installation Folder screen, verify the destination folder and

click

Next

.

It is recommended that you do not change the default destination folder.

Click

Disk Space

to check the space in the destination folder.

DOC-06800 Rev. A

Figure 4-3: Objet Studio installation-folder selection

9. In the Confirm Installation screen, click

16 June

to begin installation.

Next

4–3

Page 34

Installing Objet Software

D R A F T

2013

Installation begins and a progress bar appears, showing the progress of

the installation process.

Figure 4-4: Installation progress bar

When the Objet program installation is complete, the final InstallShield

Wizard screen appears.

4–4

Figure 4-5: Final installation screen

10. Restart the computer to complete the software installation.

Note: Make sure to remove the CD from the disk drive before restarting the

computer.

The installation process ends when the appropriate icon(s) appear on the

computer desktop:

Objet Studio

Stop Job Manager (for servers and standalone stations)

16 June

DOC-06800 Rev. A

Page 35

How to Uninstall Objet Studio

D R A F T

2013

If there is ever a need to uninstall the Objet Studio software, do not attempt

to do so from the Windows Control Panel. (This does not completely

remove all software components.) Instead

From the Start menu, select

Studio.

Objet1000 - Connex 2 User Guide

All Programs > Objet Studio > Uninstall Objet

DOC-06800 Rev. A

16 June

4–5

Page 36

Installing Objet Software

D R A F T

2013

4–6

16 June

DOC-06800 Rev. A

Page 37

Using Objet Studio

D R A F T

2013

Launching Objet Studio...................................................................... 3

Windows® 7 Security Warning........................................................... 3

Objet Studio Interface ........................................................................... 4

Ribbon Commands ............................................................................... 6

Objet Studio Commands Menu .......................................................... 8

Model Tree Pane.................................................................................... 8

Preparing Models for Production ..................................................... 9

OBJDF Files: Overview......................................................................... 9

Model Files............................................................................................. 9

Placing Objects on the Build Tray..................................................... 10

Opening Objet Tray Files ................................................................... 14

Quick Access Model Commands...................................................... 16

Copying and Pasting Objects ............................................................ 17

Selecting Objects.................................................................................. 18

Splitting Objects into Components ................................................... 18

Model Material Settings ..................................................................... 20

Changing the Model Material ........................................................... 21

Digital Materials .................................................................................. 21

Assigning a Model Material to Objects............................................ 22

Surface Finish....................................................................................... 23

Coating Objects.................................................................................... 23

Assigning Properties to Hidden Objects ......................................... 25

Positioning Objects on the Build Tray............................................ 26

Automatic Orientation ....................................................................... 26

Automatic Placement ......................................................................... 27

Manual Positioning ............................................................................. 28

Model Orientation............................................................................. 29

Manipulating Objects on the Build Tray........................................ 30

Positioning Objects on the Z Axis .................................................... 30

Valid Object Placement....................................................................... 31

Using a Grid to Position Objects ....................................................... 32

Measurement Units............................................................................. 33

Setting Model Dimensions................................................................. 34

Repositioning Objects......................................................................... 34

Changing an Objects Orientation..................................................... 36

Grouping and Ungrouping Objects.................................................. 37

Freezing Model Orientation .............................................................. 38

DOC-06800 Rev. A

16 June

5–1

Page 38

Display Options................................................................................. 39

D R A F T

2013

Viewing Objects................................................................................... 39

Screen Layout ...................................................................................... 41

Tray Perspective .................................................................................. 42

Setting Object Colors .......................................................................... 43

Loading Large Files ............................................................................ 44

Large File Manipulation ..................................................................... 44

Zoom Options ...................................................................................... 46

Handling Completed Trays ............................................................. 47

Tray Validation .................................................................................... 47

Production Estimates.......................................................................... 48

Printing Modes .................................................................................... 48

E mailing Objet Digital Files ............................................................. 49

Printing the Tray File .......................................................................... 50

Applying Additional Objet Studio Features ................................. 54

Dividing Objects.................................................................................. 54

Choosing the Support Strength......................................................... 55

Hollow Filling Models with Support Material ....................... 56

Displaying the Cross Section of Objects .......................................... 57

Saving the Screen Display as an Image File .................................... 58

Exporting and Importing Objet Build Trays ................................... 59

Customizing Objet Studio................................................................ 60

Creating a Quick Access Toolbar...................................................... 60

Hiding the Ribbon............................................................................... 61

Display Colors ..................................................................................... 62

Keyboard Shortcuts ............................................................................ 63

Setting User Preferences..................................................................... 64

Professional Mode Features............................................................. 65

Default Settings ................................................................................... 66

Open GL Driver Configuration......................................................... 67

Getting Additional Objet Studio Assistance ................................. 69

Objet Studio Version, Material Module and Licensed Features. 69

Monitoring and Managing Print Jobs ............................................ 72

Job Manager Screen ............................................................................ 72

Setting the Printer Connection .......................................................... 74

Off line Mode....................................................................................... 75

Setting the Remote Printer Connection (Client Mode).................. 76

Job Manager Commands ................................................................... 76

Configuring User Alerts ..................................................................... 79

Printing the Tray.................................................................................. 80

Additional Server Features ................................................................ 80

5–2

16 June

DOC-06800 Rev. A

Page 39

Launching Objet Studio

D R A F T

2013

After you install Objet Studio, a launch icon appears on the

Windows desktop. Open the application by double clicking this icon, or by

selecting Objet Studio from the

Start

Objet1000 - Connex 2 User Guide

menu.

Windows® 7

Security

Warning

Depending on the User Account Control settings in Windows®7, you may

see the following warning when opening Objet Studio.

Figure 5-1: Security Warning

If you click

Yes

, Objet Studio opens. However, this warning message will

appear each time you open the program, unless you change the User

Account Control settings.

To prevent the warning message from appearing again:

1. Click the link at the bottom of the security warning dialog box (

when these notifications appear

).

Change

2. In the User Account Control Settings screen, move the slider to Never

notify.

DOC-06800 Rev. A

Figure 5-2: Changing the User Account Control settings

3. ClickOK.

5–3

16 June

Page 40

Using Objet Studio

D R A F T

2013

Objet Studio

Interface

4. In the following dialog box, click

Figure 5-3: Confirming the change in the User Account Control settings

Yes

.

When Objet Studio opens, the Tray Settings screen appears, showing an

empty build tray.

Objet Studio

Commands

menu

Quick Access

toolbar

Model Tree

pane

Help

Standard

toolbar

Active

ribbon

Job

Manager

tab

Figure 5-4: Objet Studio opening screen

The Objet Studio interface consists of two main screens:

Tray Settingsfor arranging models and preparing them for printing.

•

This screen is described below.

Job Managerfor monitoring and managing print jobs.

•

This screen is described in Monitoring and Managing Print Jobs on

page 72.

Each screen is controlled by menus and icons on its own ribbon. An

additional ribbon, Model Settings, displays controls for configuring and

manipulating selected models.

Objet Studio anticipates your workflow by displaying and enabling the

options relevant to your current task. For example, when you first open

Objet Studio, the Model Settings ribbon is disabled until you place a model

on the build tray. Similarly, menu options available from the Standard

Toolbar menus are enabled or disabled to match the current workflow.

5–4

16 June

DOC-06800 Rev. A

Page 41

Objet1000 - Connex 2 User Guide

D R A F T

2013

The ribbon, colors used, and several other interface features can be

customized. How to change the appearance of the interface is explained in

Customizing Objet Studio on page 60.

Instructions for using the commands for preparing models for production

and sending jobs to the printer, appear later in this chapter.

Figure 5-5: Tray Settings ribbon

Figure 5-6: Model Settings ribbon

DOC-06800 Rev. A

16 June

5–5

Page 42

Using Objet Studio

D R A F T

2013

Ribbon

Commands

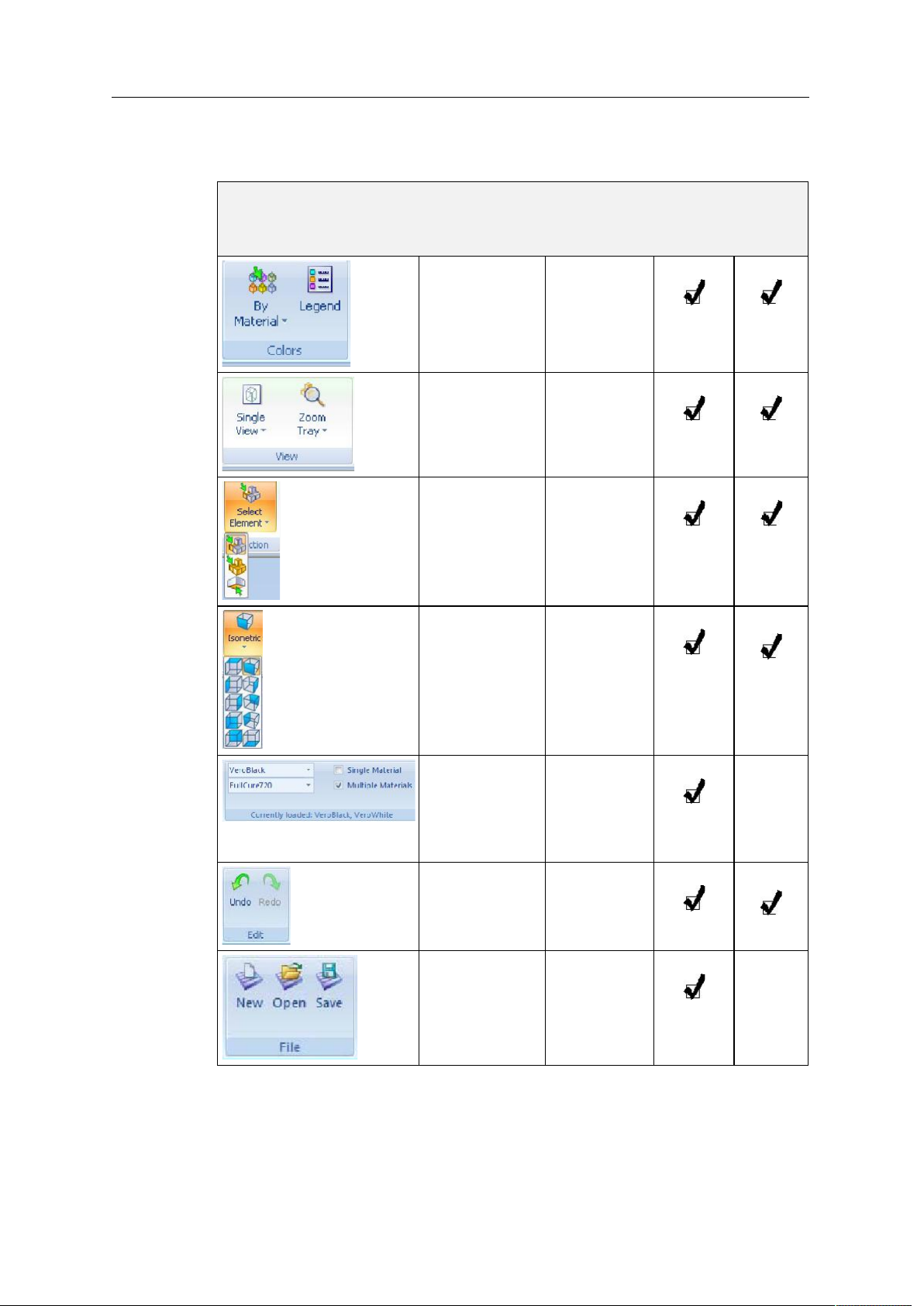

The following table lists the Tray Settings and Model Settings ribbon

command groups, and shows when they are enabled, and where they

appear.

Group Purpose When

enabled

Setting display

colors.

Selecting

perspective and

zoom level.

Choose to select

a plane,

elements, or

element groups

(assemblies).

Always.

Models are on

the build tray.

Models are on

the build tray.

Tray

Settings

Ribbon

Model

Settings

Ribbon

Change the

perspective of

the active pane.

Assigning model

material(s).

Undoing or