uPrint® and uPrint® Plus

uPrint

®

SE and uPrint® SE Plus

Service Manual

Part No. 209010-0001, Rev D

Notice

The information in this document is subject to change without notice.

STRATASYS, INC. MAKES NO WARRANTY OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Stratasys, Inc. shall

not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

© 2012 Stratasys Inc. All rights reserved. Stratasys, Dimension, uPrint, Catalyst, FDM,

Dimension BST, Dimension SST, WaveWash, and Ecoworks are registered trademarks of

Stratasys Inc. FDM Technology, Fused Deposition Modeling, ABSplus, Catalyst EX, and

Smart Supports are trademarks of Stratasys, Inc. All other trademarks are the property of

their respective owners, and Stratasys assumes no responsibility with regard to the selection,

performance, or use of these non-Stratasys products. Product specifications are subject to

change without notice. Printed in the USA.

Stratasys, Incorporated

7665 Commerce Way

Eden Prairie, MN 55344 USA

Telephone: (952) 937-3000

Fax: (952) 937-0070

www.stratasys.com

Publication Date: July 2012

ii

About This Guide

This service guide is designed to help you easily find the information you need to

successfully service Dimension BST and SST systems. This guide is arranged in chapters with

tabs for easy reference.

When viewing the electronic PDF version, you can easily hyperlink to specific headings or

chapters using the following methods:

• Use the Bookmarks window in the PDF application as hyperlinks.

• Click on the headings and page numbers in the Table of Contents to go to a specific page

or chapter.

• Click on italicized text, which are cross-references to figures, headings, and chapters.

The following conventions are used in this guide:

• When you see text in blue, it indicates that the text is a linked reference to a specific figure,

heading, or page number.

• When you see text in Bold, it indicates important information that needs to be empha-

sized.

• Text representing Interface Messages that appear on the display panel are presented in a

bold font.

iii

Table of Contents

Safety _______________________________________________________ 1-1

Hazard Classifications ________________________________________________________ 1-1

Product Safety Symbols_______________________________________________________ 1-1

Safety Devices_______________________________________ ________________________ 1-1

System Overview ____________________________________________ 2-1

What happens when...________________________________________________________ 2-2

Powering up _____________________________________________________________ 2-2

Powering Down __________________________________________________________ 2-3

Loading Material _________________________________________________________ 2-3

Building a Part____________________________________________________________ 2-3

Electronics Overview __________________________ _______________________________ 2-5

Single Board Computer ___________________________________________________ 2-6

Controller Board_______________________ ____ ___ ____ _______ ___ ___ ____ ___ ____ 2-7

Overview_____________________________________________________________ 2-7

Voltage Generation __________________________________________________ 2-7

Dual Port Memory Interface ___________________________________________ 2-7

X, Y, Z Axis Control ____________________________________________________ 2-7

Material Motor Control ________________________________________________ 2-7

Temperature Control__________________________________________________ 2-7

Liquefier Temperature Control _________________________________________ 2-8

Actuators, Switches & Optical Sensors__________________________________ 2-9

Safety Devices________________________________________________________ 2-9

Controller Board Layout __ ____ ___ ___ ____ ___ ____ ___ _______ ___ ____ ___ ____ 2-9

Reset Button_________________________________________________________ 2-10

Dip Switches___ ___ ____ ___ ____ ___ ___ ____ ___ ____ ___ ____ ___ ___ ____ ___ ___ 2-10

SW2_________________________________________________________________ 2-10

SW5_________________________________________________________________ 2-10

SW6_________________________________________________________________ 2-11

Memory_____________________________________________________________ 2-11

LEDs_________________________________________________________________ 2-11

Power Distribution Board (PDB) ___________________________________________ 2-12

Chamber Temperature Control_______________________________________ 2-13

Test Points and LED’s _________________________________________________ 2-13

I/O Card________________________________________________________________ 2-16

Head Board_______ ___ ____ ___ ____ ___ ___ ____ ___ ____ ___ ____ ___ ___ ____ ______ 2-17

Printer overview_______________________________________________________ ___ ___ 2-18

Finding more information _______ ____________________________________________ 2-23

iv

Software_____________________________________________________ 3-1

Software Architecture ________ ________________________________________________ 3-2

Operating System ________________________________________________________ 3-2

Display Driver_____________ _______ ___ ___ ____ ___ ____ ___ ____ ___ ___ ____ ___ ____ 3-2

Comm Server ____________________________________________________________ 3-2

System Manager _____________________________ ____ ___ _______ ___ ____ ___ ____ 3-3

Move Compiler __________________________________________________________ 3-3

Feeder___________________________________________________________________ 3-3

Event/Command Monitor_________________________________________________ 3-3

DataStatEX __________________________________________________________________ 3-4

CatalystEX___________________________________________________________________ 3-5

CatalystEX Overview _________________________________________________ ____ 3-5

Conventional Help File______________ ___ ____ ___ ____ _______ ___ ___ ____ ___ ____ 3-5

Dynamic Help______________________________________________ ___ _______ ____ 3-5

MaracaEX Help ______________________________________________________________ 3-6

Overview ________________________________________________________________ 3-6

Select a Modeler _________________________________________________________ 3-6

Modeler States ___________________________________________________________ 3-6

Modeler Setup ___________________________________________________________ 3-7

Configuration ____________________________________________________________ 3-7

Status____________________________________________________________________ 3-7

Printer Status__________________________________________________________ 3-7

Versions ______________________________________________________________ 3-8

Travel Limits___________________________________________________________ 3-8

Filament______________________________________________________________ 3-8

Door _________________________________________________________________ 3-8

Miscellaneous ________________________________________________________ 3-8

Setting the Serial Number______________________________________________ 3-9

Materials_________________________________________________________________ 3-9

Cartridge Information _________________________________________________ 3-9

Tip Offset_________________ ___ ____ ___ ___ ____ ___ ____ ___ ____ ______ ____ ___ ____ 3-9

Gantry___________________________________________________________________ 3-9

Gantry Hysteresis______________________________________________________ 3-9

Part Calibration______________________________________________________ 3-10

Temperatures ___________________________________________________________ 3-10

Temperature Setpoints _______________________________________________ 3-10

Outputs_________________________________________________________________ 3-10

Table ___________________________________________________________________ 3-10

Get Calibration _________________________________________________________ 3-11

Send Calibration ___________________________________________ ___ ____ ___ ___ 3-11

Get Config______________________________________________________________ 3-11

Test Parts________________________________________________________________ 3-11

Reset Password__________________________________________________________ 3-11

Connect________________________________________________________________ 3-12

Help ____________________________________________________________________ 3-12

v

Service Procedures __________________________________________ 4-1

Maintenance Preparation ___________________________________ _________________ 4-3

Read these warnings before performing service on printer!______________ 4-3

Required Tools list ____________ ________________________________________________ 4-4

Distributer/Reseller supplied Tools__________________________________________ 4-4

Supplied by Stratasys _____________________________________________________ 4-4

Pre-Maintenance Procedures_________________________________________________ 4-4

Exterior Components ___________________________________________ ___ ___________ 4-5

Top Panel ________________________________________________________________ 4-5

Side Panels_______________________________________________________________ 4-7

Display Panel_____________ ___ ____ ___ ___ ____ _______ ___ ____ ___ ___ ____ ___ ____ 4-9

Front Panel______________________________________________________________ 4-11

Door Solenoid ___________________________________________________________ 4-13

Door Sensor _____________________________________________________________ 4-14

Electronics Bay Components ________________________________________________ 4-15

Lower Electronics Bay Cover _____________________________________________ 4-15

Upper Electronics Bay Cover _____________________________________________ 4-17

Removing the Electronics Bay ____________________________________________ 4-19

Electronics Bay Cooling Fan______________________________________________ 4-21

Controller Board_______________________ ____ ___ ____ _______ ___ ___ ____ ___ ___ 4-23

Single Board Computer (SBC) ____________________________________________ 4-26

Power Distribution I/O Card ______________________________________________ 4-29

Power Distribution Board (PDB) ___________________________________________ 4-31

Hard Drive ______________________________________________________________ 4-34

Line Filter________________________________________________________________ 4-40

Circuit Breaker __________________________________________________________ 4-42

AC Input________________________________________________________________ 4-44

Power Switch_________________________________ ___________________________ 4-46

24VDC Power Supply ____________________________________ ______ ____ ___ ___ 4-48

5/12VDC Power Supply ______________________________ ____ ______ ____ ___ ___ 4-51

120VDC Power Supply ___________________________________________________ 4-54

Head Components__________________________________________________________ 4-56

Head Cooling Fan__________________________________________ ___ _______ ___ 4-56

Toggle Head Assembly ________________ ____ ___ ____ ___ ____ ___ ___ ____ ___ ___ 4-58

Substrate Sensor_________________________________________________________ 4-64

Z Foam Level Assembly __________________________________________________ 4-67

Toggle Sensor ____________________________________ ___ ____ ___ ___ ____ ___ ___ 4-69

Toggle Bar ___________ ____ ___ ____ ___ ___ ____ ___ ____ ___ ____ ___ ___ ____ ___ ___ 4-71

Head Board_______ ___ ____ ___ ____ ___ ___ ____ ___ ____ ___ ____ ___ ___ ____ ______ 4-76

TC Amp board __________________________________________________________ 4-82

Umbilical Hose __________________________________________________________ 4-84

Material Tubes __________________________________________________________ 4-88

Umbilical Cable _________________________________________________________ 4-89

XY Table Components_______________________________________________________ 4-91

Y Home Sensor __________________________________________________________ 4-91

vi

Y EOT (End of Travel) Sensor ______________________________________________ 4-92

X Motor _________________________________________________________________ 4-93

Y Motor ________________________________________________________________ 4-100

Y Motor Belt ____________________________________________________________ 4-103

Y Drive Rod ____________________________________________________________ 4-110

XY Table _______________________________________________________________ 4-117

Z Stage Components ______________________________________________________ 4-137

Z Home Sensor _______________________________ ____ ___ ____ ___ ___ _______ __ 4-137

Z EOT (End of Travel) Sensor _____________________________________________ 4-138

Chamber Fans _________________________________________________________ 4-139

Chamber Heaters ______________________________________________________ 4-141

Thermal Fuses __________________________________________________________ 4-145

Chamber Thermocouple________________________________________________ 4-148

Z Motor _____________________ ____ ___ ___ ____ ___ ____ ___ ____ ______ ____ ___ __ 4-149

Z Stage _______ ____ ___ ____ ___ ____ ___ ___ ____ ___ _______ ____ ___ ___ ____ ___ __ 4-153

Calibrations & Adjustments ___________________________________ 5-1

Offset Calibrations ___________________________________________________________ 5-2

Adjusting Z Calibration and XY Tip Offset___________________________________ 5-2

Z Calibration ___ ___ ____ ___ ____ ___ ___ ____ ___ _______ ____ ___ ___ ____ ___ ____ 5-2

XY Tip Calibration___________________________________________ ______________ 5-5

Part Based Calibration____________________________________________________ 5-7

When to Perform Part Based calibration________________________________ 5-7

Tensioning the X & Y Drive Belts ______________________________________________ 5-37

Get/Send Calibration Files ___________________________________________________ 5-41

Get/Send calibration files ____________________________________________ 5-41

XY Table Leveling ________________________________________________________ ___ 5-43

Head Alignment Procedure__________________________________________________ 5-47

Troubleshooting______________________________________________ 6-1

User Troubleshooting _________________________________________________________ 6-2

Fault determination codes ________________________________________________ 6-3

Exporting printer configuration (.cfg) file ___________________________________ 6-4

Cycling power ___________________________________ ___ ____ ______ ____ ___ ____ 6-4

Diagnosing loss of extrusion ___________________________________________ ____ 6-4

Clogged tip______________________________________________________________ 6-5

Material Jam_____________________________________________________________ 6-6

Recovering from loss of extrusion __________________________________________ 6-8

Service Troubleshooting _____________________________________________________ 6-12

1.0 How to use this Guide ________________________________________________ 6-12

2.0 Code Errors __________________________________________________________ 6-13

Major Codes ____________ ____ ___ ___ ____ ___ ____ ___ ____ ___ ___ _______ ___ 6-13

Major Codes with Minor Codes _______________________________________ 6-14

Controller Abort Minor Errors (Code: 14, XX)____________________________ 6-14

Starting Up Failed Minor Errors (15.XX) _________________________________ 6-22

Controller Load Failed Minor Errors (17.XX) _____________________________ 6-22

Temperature Failed to Regulate Minor Errors (18.XX) ___________________ 6-23

vii

Controller Initialization Failed Minor Errors (19.XX)_______________________ 6-24

Door Unlatch Failed (20.XX)___________________________________________ 6-24

Controller Communications Failed Sub Errors (22.XX) _________ __________ 6-24

Universal Device Name Error (23.XX) __________________________________ 6-24

3.0 Non-Code Errors _____________________________________________________ 6-25

What happens during Power Up / Boot________________________________ 6-33

4.0 Connector Pinouts and Signals________________________________________ 6-40

Umbilical cable diagram_____________________________________________ 6-40

Umbilical cable pinouts ______________________________________________ 6-41

Upper harness _______________________________________________________ 6-42

Upper harness pinouts________________________________________________ 6-42

Lower harness ________ ___ ____ ______ ____ ___ ____ ___ ____ ___ ___ ____ ___ ___ 6-44

Lower harness pinouts_ ___ _______ ___ ____ ___ ____ ___ ____ ___ ___ ____ ___ ___ 6-45

Part Quality Troubleshooting ____________ _____________________________________ 6-46

Embedded support strands in model _____________________________________ 6-46

Brown streaks (burn marks)___________________________ ____ ___ _______ ___ ___ 6-47

Loss of Extrusion (LOE)________________________________ ____ ___ ___ ____ ___ ___ 6-48

Model embedded in to support__________________________________________ 6-49

Moisture in material______________________________________________________ 6-50

Open seams ____________________________________________________________ 6-51

Part curling______________________________________________________________ 6-52

Part fell over ____________________________________________________________ 6-53

Part shifting _____________________________________________________________ 6-54

Rough surface quality ___________________________________________________ 6-55

Rough quality all over____________________________________________________ 6-56

Model strands on parts___________________________________________________ 6-57

Witness marks ______________________ ___ ____ ___ ____ ___ ____ ___ ___ ____ ___ ___ 6-58

Wavy surface ___________________________________________________________ 6-59

Wavy parts______________________________________________________________ 6-60

Under fill ________________________________________________________________ 6-61

Material sagging on curved parts ________________________________________ 6-62

Fused layers_____________________________________________________________ 6-63

Z layers inconsistent_______ ___ ____ ___ ___ _______ ____ ___ ____ ___ ___ ____ ___ ___ 6-64

TeraTerm ___________________________________________________________________ 6-65

Using TeraTerm __________________________________________________________ 6-65

TeraTerm Commands____________________________________________________ 6-68

Preventive Maintenance _____________________________________ 7-1

Startup kit tools ______________________________________________________________ 7-2

Preventive Maintenance _____________________________________________________ 7-2

Daily_____________________________________________________________________ 7-2

500 Hour maintenance _____________________________________ ___ ____ ___ ____ 7-3

2000 Hour maintenance __________________________________________________ 7-9

Tip replacement and calibration_______________________________________ 7-9

viii

Illustrated Parts List ___________________________________________ 8-1

Front Door Area Components _________________________________________________ 8-2

Electronics Bay Components _________________________________________________ 8-3

Head Area Components _____________________________________________________ 8-5

XY Table Area Components __________________________________________________ 8 -8

Z Stage Area Components___________________________________________________ 8-10

Chamber Heater Area components__________________________________________ 8-11

Material Bay ________________________________________________________________ 8-12

Cables _____________________________________________________________________ 8-13

Checklists ___________________________________________________ 9-1

Hard Drive Installation Checklist_______________________________________________ 9-2

Toggle Head Assembly Installation Checklist __________________________________ 9-3

XY Table Assembly Installation Checklist ______________________________________ 9-4

Controller Board Checklist ____________________________________________________ 9-5

Required Tool List_____________________________________________________________ 9-6

Index_________________________________________________________ I-1

ix

Safety

Hazard Classifications

Please be aware of the following hazard classifications that are used throughout this guide.

Caution: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Warning: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Product Safety Symbols

The following symbol is located inside the system to warn you about high temperatures.

Note: Always read and adhere to safety statements, and be aware of the safety

symbol when you see it in the system.

Gloves: The gloves symbol indicates the presence of devices with high tempera-

tures. Always use extra care, and wear safety gloves, when working around

heated components.

ESD: Use standard electrostatic discharge (ESD) precautions

when working on or near electrical circuits.

Safety Devices

The following safety devices are incorporated into the system:

• Chamber T/C alarm – activated for a bad or missing thermocouple

• Liquefier T/C alarm – activated for a bad or missing thermocouple

• Power shut down signal from the PDB – activated if any thermal limit switches trip

• Thermal snap switch located on the Head Board.

• Main thermal fuse

uPrint/uPrint SE Service Manual 1-1

1-2

System Overview

What happens when...___________ _____________________________________ 2-2

Powering up ___________________ ___________________________________ 2-2

Powering Down ___________________________________________________ 2-3

Loading Material __________________________________________________ 2-3

Building a Part____________ ______ ____ ___ ____ ___ ____ ___ ___ ____ ___ ____ 2-3

Electronics Overview ____________ _____________________________________ 2-5

Single Board Computer ____________________________________________ 2-6

Controller Board___________________________________________________ 2-7

Overview______________________________________________________ 2-7

Voltage Generation ___________________________________________ 2-7

Dual Port Memory Interface ____________________________________ 2-7

X, Y, Z Axis Control _____________________________________________ 2-7

Material Motor Control _________________________________________ 2-7

Temperature Control___________________________________________ 2-7

Liquefier Temperature Control __________________________________ 2-8

Actuators, Switches & Optical Sensors___________________________ 2-9

Safety Devices_________________________________________________ 2-9

Controller Board Layout ________________________________________ 2-9

Reset Button___________________________ ___ ____ ___ ___ ____ ___ ___ 2-10

Dip Switches__________________________________________________ 2-10

SW2__________________________________________________________ 2-10

SW5__________________________________________________________ 2-10

SW6__________________________________________________________ 2-11

Memory ______________________________________________________ 2-11

LEDs__________________________________________________________ 2-11

Power Distribution Board (PDB) ____________________________________ 2-12

Chamber Temperature Control________________________________ 2-13

Test Points and LED’s __________________________________________ 2-13

I/O Card _________________________________________________________ 2-16

Head Board______________________________________________________ 2-17

Printer overview______________________________________ ___ ____________ 2-18

Finding more information ___________________________________________ 2-23

uPrint/uPrint SE Service Manual 2-1

What happens when...

Powering up

Once the unit is ready to build, the display will show Idle (no part in the queue) or Ready to

build

followed by the part name. Once a part is started the appropriate liquefier will begin to

heat. Once the liquefier and chamber reach the operating temperature (310C model, 300C

support, 77 Chamber) the system will begin to build a part.

2-2

Powering Down

When the Power Switch is turned off the unit begins a controlled shut down. The software

processes are stopped and the power to the liquefier and chamber heaters are turned off. The

Controller Board continues to monitor the temperature of the liquefier and the fans will

continue to run. During this time the display will show

continues to run to cool the liquefier down quickly to prevent backflow of material from the

liquefier. If the material is not cooled down during power down the system may experience a

loss of extrusion due to material build up at the liquefier. Once the liquefier temperature

drops below 102° C the SBC changes the display to

“Shutting down”. The head blower fan

“Shut down” and turns off.

Loading Material

When the load material button is pressed with carriers installed the SBC will ask the

Controller Board to unload the carriers requested by the operator. The most recent value for

material remaining is written to the cartridge EPROM. The material is run in reverse to

unload the liquefier. When filament is clear of the filament sensor the Controller Board tells

the SBC that the command is complete. The SBC sends

the carriers are unlatched, and the unit waits for you to respond.

“REMOVE CARRIER” to the display,

If there are no carriers in the printer when the material button is pushed, or if an unload has

just been completed, the SBC will ask the operator to

for a valid carrier EPROM. If there is no change to the EPROM status in 30 seconds, you are

asked if you want to RETRY. Once valid carriers are read, the unit begins the material load

sequence.

“INSERT CARRIER”. The unit will look

Building a Part

How to start building a part build is dependent upon whether or not a part is in the printer

queue:

1. If a part has not been sent to the printer for building (the build queue is empty):

2. The panel displays

A.

Wait for Part is blinking. Choose whether you want to start the build process from

a ‘remote’ location or from the display panel at the printer.

a. At Printer

work station. You start the build of the part from the printer.

B. Do not press the

C. From your CatalystEX work station, send a part to the printer.

D. The printer panel displays the name of the first model in the printer queue and

Start Model is blinking.

E. From the printer, press the

Idle and Queue Empty.

‘Start Model’ - You send a part to the printer from your CatalystEX

Wait for Part button

Start Model button to begin building the displayed part.

a. Remote

work station. The part automatically begins to build.

uPrint/uPrint SE Service Manual 2-3

‘Start Model’: - You send a part to the printer from your CatalystEX

F. From the printer, press the Wait for Part button.

Note: Make sure an empty modeling base is installed, then answer Yes to the prompt

Is Model Base Installed?

G.

Wait for Part is displayed in the upper window. Press Cancel if you wish to exit

the remote start mode.

H. From your CatalystEX work station, send a part to the printer. The printer will

automatically start to build the model.

3. If a part has been sent to the printer for build (there is at least one part in the build

queue), but is not building:

A. The panel displays

Ready to Build.

B. The name of the first model in the build queue is displayed.

C.

Start Model is blinking. Press the Start Model button to begin building the displayed

part.

Regardless of the method used to start building a part, the printer will perform the same

sequence of steps:

1. The printer drops (lowers) the substrate sensor.

2. System “touches down” six times which measures the height of the substrate.

3. SBC converts the model file (CMB) into the motion commands that the controller will

execute to build the model.

4. System completes substrate measurement.

5. Z stage moves to bottom of Z travel.

6. Head moves over the purge bucket and prepares to build purging the appropriate tip.

7. Once purge is complete, the printer will start to build the model.

During model construction, the printer will display the percentage of material remaining on

each spool. During building the keypad will allow you to pause the printer, or turn on the

chamber lights. The printer will stay in the Building State until the model is finished or the

printer pauses. If the printer pauses, it will enter a Pending Pause state until the current road

is finished. Once that road is complete, the head will move over the purge bucket, and the Z

stage will descend to the bottom of the envelope. In the Pause State the printer can be

resumed, material can be loaded and unloaded, the build can be canceled, and printer

maintenance may be performed.

2-4

PDB

Controller

Board

SBC

AC Input

+5 and +12

VDC Power

Supply

Support

heater +120

VDC power

supply

+24 VDC

power supply

1 20-240 V AC

in

120-240 VAC

I/O

Electronics Overview

Figure 2-1: Electronics Overview detail

uPrint/uPrint SE Service Manual 2-5

J2 power

input

IDE/SATA

Connector

P104

Connector

Display Panel

DB-9

Connector

RJ-45

Network

Connector

Single Board Computer

The single board computer (SBC) is the main processor in the system. See Figure 2-2.

showing the board layout.

The TCP/IP network interface connects directly to the RJ-45 connector on the SBC. The

network interface supports both 10baseT and 100baseT operation. The hardware

differentiates automatically. There are two LED’s at the RJ-45 connector. These show the

status of the network connection as follows:

• Green LED: Indicates there is a network connection present.

• Amber LED: Indicates there is a network communication.

The Hard Disk Drive (HDD) connects to the SBC with a standard IDE interface (ribbon cable)

or SATA cable. The HDD contains the Linux operating system and all the control software

needed to run the system (except the controller firmware). This is also where all the

downloaded models are stored in the queue.

The LCD Control Panel connects to the I/O Card. The signals then travel though the PDB

and on to the SBC. All user entered commands from the control panel buttons are routed

through the I/O and PDB and then on to the SBC.

The P104 connector on the top edge of the board is a bus level interface to the Controller

Board. This allows the SBC to read and write to the dual port ram on the Controller Board,

which forms the communication channel between the two boards.

Figure 2-2: Single Board Computer detail

2-6

Controller Board

Overview

The controller board provides all of the low level hardware control and sensing for the

system. The firmware runs on the controller CPU and is flash resident (rather than on the

HDD and SBC).

Voltage Generation

• +/-15 VDC is used for PMD DACs

• 10 VDC is used for DAC reference

• 3.3 VDC is used for controller board logic

Dual Port Memory Interface

The dual port memory located on the controller board provides the communication channel

with the single board computer (SBC) through the P104 connector. The SBC provides the

coordinates, velocities, and flow rate commands for modeling to the controller. The

controller board provides the status/error information about the hardware back to the SBC.

X, Y, Z Axis Control

The controller takes the flow rate information from the SBC and sends it to the PMD

processor. The PMD 2840 processor services the X and Y stepper motors and the model and

support head servo motors. The 3410 processor services the Z axis stepper motor. There is no

feedback from the stepper motors to the system (they are open-loop controlled).

Material Motor Control

The controller takes the flow rate information from the SBC and sends it to the PMD 2840

processors. The PMD uses this information along with the encoder signals from the material

motors to generate an output signal to drive the servo motors in the head assembly. Since the

encoders provide feedback the material motors have a closed-loop control. Their position

and rotation are precisely known at all times.

Temperature Control

The controller board reads the three thermocouple (T/C) inputs/signals - 2 for the head, 1

for the chamber.

uPrint/uPrint SE Service Manual 2-7

Liquefier Temperature Control

The liquefier T/C connects to the controller board through the power distribution board.

The T/C generates a variable low level current that depends on the temperature of the T/C.

This analog signal from the T/C is amplified by the head distribution. It is then sent down

the umbilical cable to the PDB, and then to the controller board. An A to D converter in the

ColdFire chip converts the analog signal to digital. In order to improve temperature

resolution, this signal is biased. The lowest reading possible is 109.5° C. The highest reading

is 330° C.

The liquefier temperature is maintained at: Model: 310° C, Support: 300° C

Temperature control is accomplished using “pulse wide modulation” See Figure 2-3.

Figure 2-3: Pulse Width Modulation (PWM)

Actual power to the liquefier heater is supplied by the PDB, which is controlled by the

controller board. The head heaters are turned off and on 1000 times a second (pulses). The

duration of the 120 VDC pulse determines the average power being supplied to keep the

liquefier at temperature. Temperatures can be read using a volt meter at test points TP5 for

model, and TP4 support on the PDB (10 mV per degree C).

2-8

Actuators, Switches & Optical Sensors

The input and output signals are passed through the PDB and then processed by the

controller board. The non-motor actuators on a uPrint system are 24 volt solenoids. The 24

volt power is supplied by the PDB which in turn is controlled by the controller board. The

following is a list of actuators:

• Door solenoid – locks the door to the modeling chamber.

• Carrier latches – holds carriers in the material bays.

• Material bay solenoids – engage the motor that feeds filament from carrier to the

liquefier during auto load.

The controller board reads and updates the remaining material information on the spool eprom. This is accomplished through a serial interface to the material bay encryption board.

The material encryption board in turn connects to the e-prom on the carrier/spool via two

pogo pins.

The controller board monitors these switches:

• Z limit switches – upper and lower

• X end of travel (EOT) switch

• Y end of travel (ETO) switch

The controller board monitors the following optical sensors:

• X home (BOT) sensor

• Y home (BOT) sensor

• Top of modeling base sensor

Safety Devices

The controller board monitors the following safety devices:

• Chamber T/C alarm – activated for a bad or missing T/C

• Liquefier T/C alarm – activated for a bad or missing T/C

• Head and chamber “snap” switches

• Two main thermal fuses

• Door open switch

• Door latch solenoid

Controller Board Layout

Figure 2-4. Shows the layout of the controller board connectors with labels indicating where

each of the functions described previously are connected. In addition to those functions, the

figure shows a reset button, a set of dip switches, and the LEDs (D1-D3 and D6-D13).

uPrint/uPrint SE Service Manual 2-9

Figure 2-4: Controller board connection detail

Reset Button

Located on the lower right side of the board, the reset button will do a hard reset of the

controller board. Before continuing with normal operation after resetting the board, system

power must be cycled before building. The reset button should only be used after using

TeraTerm.

Dip Switches

There are three dip switch banks (SW2, SW5, SW6) located on the top right side of the board.

Dip switches are factory set and should not be changed unless noted to be in another

position.

SW2

Number (in white) Description Default

16-24 Unused Off

SW5

Number (in white) Description Default

8-15 Unused Off

2-10

SW6

Number (in white) Description Default

0 Run built-in self test (BIST) Off

1 Load Firmware (turn on when using SNDBIN.EXE) Off

2 Disable door latching Off

3Unused Off

4 Don’t reset controller when in command is issued Off

5 Disable WatchDog timer Off

6 Enable use of dc commands Off

7Unused Off

Memory

There are three types of memory contained on the controller board.

• Dual Port RAM: The communication buffer between the controller board and the

single board computer. Events (from the controller), commands (from the SBC), and

motion control vertices (from the SBC) are passed through the P104 connector joining

the two boards.

• Flash Memory: Where the executable code resides.

Battery backup RAM; Where the controller board stores the following system parameters:

1. Results of last power-on self test (POST)

2. Results of certain built-in diagnostic tests, if used

3. Exception trace, which is a list of the most recent exception messages logged on the

controller board

4. State information, which stores printer state when it is powered off (includes things like

the type of gantry, whether material is loaded, the UDN, etc.).

LEDs

There are 11 LEDs located on the controller board. A grouping of three (D1-D3) are located

on the lower left side. The other group of eight (D6-D13) are located on the upper right side.

D1-D3 are lit when their associated voltage, as shown in table below, is present. The 3.3 VDC

supply is generated on the controller board, +5 and +12 VDC come from the PDB. One

function of the D6-D12 LEDs is that they turn on sequentially to show software download

progress. During normal operation, D13 will blink approximately once every two seconds to

indicate that the watchdog is monitoring the system and everything is operational.

LED Label Description

D1 +3.3 VDC Supply

D2 +5 VDC Supply

D3 +12 VDC Supply

D6-D12 Debug LEDs (software use only)

D13 Coldfire processor heartbeat

uPrint/uPrint SE Service Manual 2-11

Power Distribution Board (PDB)

Figure 2-5: PDB Detail

AJ1AC Power In

BJ2Power Switch/Thermostat

C J3 Chamber Heaters

D J22 Auxiliary 120VDC power supply

E J8 Z BOT, Z EOT, Chamber Fans, Frame ID, Filament detect sensor (not used)

FJ9Z motor

G J10 I/O board connection

H J11 I/O board connection

I J7 24VDC input

J Test points and LEDs (see detail in this section)

KJ45/12VDC input

L Voltage indicator LEDs (see detail in this section)

M J12 To material bay

N J16 To external UPS (optional)

O J18 LCD display from SBC

P J15 To controller board (ribbon cable)

Q J14 To controller board (ribbon cable)

R J13 To controller board (ribbon cable)

2-12

This board provides the power required to run the system. AC line voltage, +5 VDC, +12

VDC, and +24 VDC feed into the PDB. An additional +120 VDC input feeds into the PDB for

the support head heater.

AC line voltage comes into the PDB, See Figure 2-5. The voltage is routed through the solid

state relay to an auto switching circuit. The circuit is used to supply the chamber heater

voltage: 240 VAC in series, or 120 VAC in parallel. The solid state relay is controlled by the

controller board, and turns the heater on/off to regulate the chamber temperature. A second

solid state relay provides AC line voltage to the system. It is controlled by the controller

board and safely shuts down the system when the power down switch is turned off.

• The 5 VDC and 12 VDC are used by the controller board, single board computer, and

hard drive. The 12 VDC also powers the filament motors.

• The 24 VDC powers the stepper motors, solenoids, fans, and chamber lights.

• The 120 VDC circuit powers the model heater and a separate 120 VDC supply powers

the support heater.

There are two fuses on the power distribution board.

• Fuse F1 fuses the AC input to the +120 VDC supply.

• Fuse F2 fuses the +120 VDC output.

Chamber Temperature Control

The chamber thermocouple (T/C) connects via the I/O board to the PDB and is sent to the

controller board. The T/C generates a variable low level voltage that depends on the

temperature of the chamber. This analog signal from the chamber thermocouple is amplified

on the I/O board and sent to the PDB. From the amplifier, the signal goes to an A to D

converter in the ColdFire. The controller reads the chamber temperature and turns the

heaters on and off to maintain 77° C. The chamber fans run continuously when the system is

on. Temperatures can be read on the PDB using a volt meter at test points TP22 for model,

TP20 for support, and TP28 for the chamber NOTE: 10 mV = 1 degree C.

Test Points and LED’s

Test points and LED’s are very useful for troubleshooting the system. The test points and

LED’s are listed below with a brief description. See Figure 2-6. and Figure 2-7.

uPrint/uPrint SE Service Manual 2-13

Figure 2-6: Test points and LEDs detail

Component Test Pt Description

UPS TP29 Power fail signal from external UPS

+5V REF TP24 Head T/C service reference

Door Switch TP15 State of the door (open or closed)

On/Off Switch TP14 State of power down switch

Power Enable TP8 Enables power to circuitry (normally high)

Model Toggle TP17 Toggle travel complete

Chamber Thermocouple TP28 Voltage corresponds to chamber temperature (10 mV=° C)

Support Thermocouple TP20 Voltage corresponds to support temperature

Model Thermocouple TP22 Voltage corresponds to model temperature

HD Thermostat TP25 Chamber and head thermostat (snap switches)

Head TC Alarm TP26 High if head T/C not plugged in or open

Support Toggle TP16 Not used

Chamber TC Alarm TP27 High if chamber T/C not plugged in or open

X EOT TP18 X end of travel sensor (5 VDC), switches are wired normally closed (NC)

X Home TP19 X home sensor (5 VDC), switches are wired normally closed (NC)

Y EOT TP12 Y end of travel sensor (5 VDC), switches are wired normally closed (NC)

Y Home TP13 Y home sensor (5 VDC), switches are wired normally closed (NC)

Z EOT TP10 Z end of travel sensor (5 VDC), switches are wired normally closed (NC)

Z Home TP9 Z home sensor (5 VDC), switches are wired normally closed (NC)

Z Substrate TP23 Z substrate sensor (5 VDC)

(10 mV=° C)

(10 mV=° C)

(+5 VDC if both switches closed)

Normal = tp17 lo, tp19 hi

ch thermostat fault=tp17 lo, tp19 lo.

HD Type A TP21 Not used

HD Type B TP30 Not used

2-14

Figure 2-7: Voltage test points and LEDs detail

Component Test Pt Description

+ 5 VDC TP3 + 5VDC is present

+12 VDC TP4 + 12VDC is present

+12 VDC SW TP5 + 12VDC Switching is present

+24 VDC TP6 + 24VDC is present

+24 VDC SW TP7 + 24VDC Switching is present

uPrint/uPrint SE Service Manual 2-15

I/O Card

A J510 PDB Board connection

B J511 PDB Board connection

C J507 Chamber thermocouple

D J501 Y Motor

Figure 2-8: I/O card detail

E J502 X Motor

F J503 Y BOT and Y EOT sensors

G J504 Head blower fan, power on/off switch, left and right chamber lights, LCD display, door solenoid, door

switch.

H J505 Umbilical cable to: Model and support heaters, toggle sensor, X BOT and X EOT sensors

I J506 Umbilical cable to: Substrate detect sensor, head drive motor, chamber temperature alarm, model

thermocouple, support thermocouple, head temperature alarm

2-16

G

F

J

E

K

Rear view

Front view

D

A

B

C

I

H

Head Board

Figure 2-9: Head board layout

A J304 Z Sensor

B J302 Head Motor Power

C J303 Head Motor Ribbon Cable

D J301 Umbilical Cable

E J102 Support Heater

F U303 X Home Sensor

G J305 Toggle Sensor

H D1 Support 120VDC LED (120 VDC present if on)

I D2 Model 120VDC LED (120 VDC present if on)

J U304 X EOT Sensor

K J202 Model Heater

uPrint/uPrint SE Service Manual 2-17

Front view

2

3

4

5

1

6

Printer overview

uPrint SE and uPrint SE Plus build models from CAD STL files. The printer builds threedimensional parts by extruding a bead of ABS material through a computer-controlled

extrusion head, producing high quality parts that are ready to use immediately after

completion.

uPrint SE and uPrint SE Plus consist of two primary components — the 3D printer and

material bay. Catalyst

Windows Vista or Windows 7 platforms.

uPrint and uPrint SE build a maximum part size of 203 x 152 x 152 mm (8 x 6 x 6 in). uPrint

Plus and uPrint SE Plus build a maximum part size of 203 x 203 x 152 mm (8 x 8 x 6 in). Each

uPrint and uPrint Plus material carrier contains 492 cc (30 cu. in.) of usable material —

enough to build continuously for about 48 hours without reloading. Each uPrint SE and

uPrint SE Plus material carrier contains 688 cc (42 cu. in.) of usable material — enough to

build continuously for about 67 hours without reloading. You can add an optional second

material bay for extended build times.

®

EX is the preprocessing software that runs on Windows XP Pro,

Figure 2-10: Front and left side view of printer.

1 Display Panel 4 Optional Material Bay, Model Side

2 Material Bay, Support Side 5 Material Bay, Model Side

3 Optional Material Bay, Support Side 6 Power ON/OFF Switch

2-18

2

5

3

4

6

7

8

9

1

Figure 2-11: Interior chamber - front view

1Extrusion Head

2 Tip wipe assembly

3Purge bucket

4 Z stage platen

5 Modeling base retainers (x2)

6Modeling base

7 Z stage guide rods

8 Z stage lead screw

9 Extrusion Tips

uPrint/uPrint SE Service Manual 2-19

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Figure 2-12: Rear view of printer

1 Model Material Y Connector 9 Support Material Tube

2Model Material Tube 10 UPS Connection

3 AC Power Cord Connector 11 Material Bay Cable Connector

4 Circuit Breaker 12 RJ-45 Network Connector

5 Material Bay 13 Diagnostics Cable Connector

6 Optional Model Material Tube 14 Material Bay Communications Cable

7 Optional Material Bay 15 Optional Material Bay Communications Cable

8 Support Material Y Connector 16 Optional Support Material Tube

2-20

Note: To avoid damage to the printer from an uncontrolled power loss, installation of

a UPS (Uninterruptible Power Supply) is recommended.

Support material carrier

Model material carrier

Modeling base

Figure 2-13: Material carriers

Figure 2-14: Modeling base

Caution: DO NOT reuse modeling bases. If a modeling base is reused, calibration

errors, poor part quality, and loss of extrusion may occur. Additional modeling

bases are available from your reseller.

uPrint/uPrint SE Service Manual 2-21

Figure 2-15: Startup Kit contents

1Gloves

2 Power cord (Euro)

3Power cord (US)

4 Crossover cable (orange)

5 Network cable (blue)

6 Tip replacement kit (A. Support tip B. Model tip C. 8 Tip shields D. 4 Tip wipe assemblies)

7 10x magnifier loupe

8Wire brush

9Cutters

10 1/8 inch T-Handle wrench (red)

11 7/64 inch T-Handle wrench (yellow)

12 Needle nose pliers

13 Model material spool

14 Support material spool

15 CatalystEX CD

16 System Software CD

17 User Guide CD

2-22

Finding more information

CatalystEX Online Help

Simple operating

instructions for

CatalystEX are

available in

CatalystEX

Dynamic Help. You

can also see

CatalystEX Help

from the menu bar -

Help>Contents

World Wide Web

Additional information is available at:

http://www.uprint3dprinting.com

uPrint/uPrint SE Service Manual 2-23

2-24

Software

Software Architecture ________________________________________________ 3-2

Operating System _________________________________________________ 3-2

Display Driver ______________________________________________________ 3-2

Comm Server _____________________________________________________ 3-2

System Manager __________________________________________________ 3-3

Move Compiler____________________________ ___ ____ ___ ___ _______ ____ 3-3

Feeder____________________________________________________________ 3-3

Event/Command Monitor__________________________________________ 3-3

DataStatEX___________________________________________________________ 3-4

CatalystEX___________________________________________________________ 3-5

CatalystEX Overview_______________________________________________ 3-5

Conventional Help File_____________________________________________ 3-5

Dynamic Help_____________________________________________________ 3-5

MaracaEX Help ________________________ ______________________________ 3-6

Overview _________________________________________________________ 3-6

Select a Modeler __________________________________________________ 3-6

Modeler States ____________________________________________________ 3-6

Modeler Setup ____________________________________________________ 3-7

Configuration _____________________________________________________ 3-7

Status_____________________________________________________________ 3-7

Materials__________________________________________________________ 3-9

Tip Offset__________________________________________________________ 3-9

Gantry____________________________________________________________ 3-9

Temperatures ____________________________________________________ 3-10

Outputs__________________________________________________________ 3-10

Table ____________________________________________________________ 3-10

Get Calibration___________________________________________________ 3-11

Send Calibration _________________________________________________ 3-11

Get Config_______________________________________________________ 3-11

Test Parts_________________________________________________________ 3-11

Reset Password____________________________ ___ ____ ___ ___ ____ ___ ___ 3-11

Connect_________________________________________________________ 3-12

Help _____________________________________________________________ 3-12

uPrint/uPrint SE Service Manual 3-1

Software Architecture

Figure 3-16. shows the major software components that control the system. The software that

runs on the Controller Board is EPROM based. The software that runs on the single board

computer is stored on the HDD and loaded during power up. Like all PC compatible

computers, the SBC runs a brief self-test on power up and then loads the operating system

followed by the system’s application components.

Figure 3-16: Software Architecture Diagram

Operating System

The system’s software currently runs on RedHat Linux. The OS is multi tasking allowing the

software components to run fairly independently. The OS also provides support for the

TCP/IP network interface and the HDD.

Display Driver

This software interacts with the operator display panel on the front of the system. This

software processes all button pushes. The driver also formats the information going to the

four line display and the context sensitive button labels.

Comm Server

The comm server software on the system is the other half of the download software that is

part of the Catalyst workstation software. Parts to be built (.cmb files) are received by the

comm server and saved on the data partition of the HDD. Queue management of the parts to

be built is also part of the comm server. Lastly the comm server provides Catalyst the system

status information that is displayed on workstation.

3-2

System Manager

The system manager software provides the overall control and decision making functions

that are used by the system during all operations. User requests are received from the

Display Driver (in response to button pushes). The requests are processed and commands

sent to the Controller Board to activate the appropriate hardware.

Move Compiler

When “start part” is requested the system manager activates the move compiler. The move

compiler retrieves the cmb file from the top of the queue. The cmb defines the tool path for

the part on a layer by layer basis. The move compiler calculates the proper extrusion rate for

the road thus combining tool path and extrusion. The resulting motion control is saved in a

PCB file.

Feeder

This driver takes the output of the move compiler and feeds the motion control information

to the Controller Board on demand. The feeder will typically start before the move compiler

has finished the calculations for the part. This eliminates waiting for all calculation to be

complete. As the Controller Board executes the motion control commands they are removed

from dual port memory. The feeder adds new commands as space becomes available.

Event/Command Monitor

This software handles all non-motion control interactions between the SBC and the

Controller Board. Events are printer status information being sent to the SBC. Commands

come from the SBC telling the Controller Board to do something such as find home.

uPrint/uPrint SE Service Manual 3-3

DataStatEX

DataStatEX is a “condensed” version of MaracaEX. It was developed to:

• Aid in troubleshooting system problems by allowing the customer to view and report

specific system information.

• Allow the customer to adjust Z Tip to Tip (difference in tip heights)

• Replacement toggle heads will be shipped with a factory Z Tip to Tip value. One the

head is installed the customer must enter this value using DataStatEX. Service

providers may also use MaracaEX to enter this value.

Using DataStatEX allows you to:

• Select a modeler.

• Add or delete a modeler.

• View a detailed system status window. The window includes important output

“state” information. This information will aid in troubleshooting system problems

without being on-site.

• View detailed material information.

• Adjust Z Tip to Tip.

• Reset the administrator password to null.

DataStatEX is located as a separate program on all system CD’s. DataStatEX will NOT install

on the workstation when performing a backend download. DataStatEX is used primarily for

diagnosing system problems. Generally the customer does not need to access DataStatEX.

For this reason, the customer should only use DataStatEX when requested by a trained

service representative.

Parts and Tools Required

• System CD

• Workstation

Procedure

1. Insert the system CD into workstation.

2. Select the CD drive and open the DataStatEX folder.

3. Select setup.exe.

4. Follow the install steps displayed to load the program on the workstation.

5. Open DataStatEX from Start – Programs pull down.

6. Select the “+” button and enter the system name, type and IP address. Do not enter

leading 0’s in the IP address.

7. Select the green arrow to close the window.

8. Select the “connect to modeler” (two blue arrows) button to establish communications to

the system.

9. Information is now shown in the Current Modeler and State windows of DataStatEX.

10. From this point the customer can open any of the button options.

3-4

CatalystEX

CatalystEX Overview

CatalystEX is an intuitive, user-friendly application designed to interface with Dimension 3D

printers. It allows you to quickly and easily open a 3D drawing of a part, prepare the

drawing for print, and send the print command to create the part.

CatalystEX provides 'Help' information in two ways - through a Conventional Help file and

through a Dynamic Help system.

Conventional Help File

The entire Help file is accessible through the Menu Bar (Help>Contents). This will open

CatalystEX Help in a separate window containing standard Help tools - TOC, Search, Index,

and personally selected Favorites.

Dynamic Help

Dynamic Help is available from within the CatalystEX application window. The right side of

the application window is dedicated to Dynamic Help.

uPrint/uPrint SE Service Manual 3-5

MaracaEX Help

Overview

MaracaEX is a program used for machine configuration and troubleshooting. It is intended

for use by trained service personnel only.

Caution: It is possible, using this program, to damage the controller software and

make the machine non-functional.

Using MaracaEX you can select a modeler to work with, modify machine-specific

configuration parameters, download new calibration file data, download new test parts, and

test the machine's operation.

• Select a Modeler

• Modeler States

• Modeler Setup

• MaracaEX Configuration

• Show Machine Status

• Materials

• Tip Offset and Liquefier Calibration

• Gantry

• Temperatures

• Outputs

• Table Calibration

• Get Calibration

• Send Calibration

• Get Configuration

• Test Parts

• Reset Password

• Connect

Select a Modeler

From the Current Modeler drop down list select a modeler to connect to with MaracaEX. To

add modelers to the list, use the plus button at the bottom of the window.

Modeler States

These three fields provide the current information for the state of the machine:

State

Internal State

Home State

3-6

The current machine state as reported to CatalystEX status.

The current internal software state (e.g. sttIdle)

The previous internal state in any state that cares about that state.

Modeler Setup

In order to use MaracaEX on a network modeler, you must first create a modeler definition.

You can create modeler definitions by clicking the + button in the main window.

A modeler definition is made complete by specifying the following:

• Modeler name (You can use any descriptive name for the modeler.)

• Modeler type

• Modeler IP address

You can delete a modeler definition by selecting the - button in the main window and then

choosing the modeler to delete from the current list of modelers.

Configuration

Clicking the properties icon, “Set up the display parameters”, in the main window will bring

up a dialog to select Metric or English units of measure. Click the green arrow to close the

window after making your selection. MaracaEX will now display numerical values in the

units you chose.

Status

MaracaEX machine status provides the ability to set the machines serial number and detailed

information about the current mechanical state of the machine.

• Position and Temperatures

• Versions

• Travel Limits

• Filament

• Door

• Setting the Serial Number

Printer St atus

Current Position

XYZ Scale/Inch

Current / Total Layers

Current Curve

Head Temp

Head PWM

Support Temp

Support PWM

Chamber Temp

The current X, Y and Z position in inches.

Scale factors in microsteps per inch.

The current build layer and the total number of layers in the model.

The current curve number of the model.

The model liquefier temperature and its set point in C.

Not used.

The support liquefier temperature and its set point in C (SST only).

Not used.

The actual chamber temperature and its set point in C.

uPrint/uPrint SE Service Manual 3-7

Versions

Product Version

Build Version

Firmware Version

PLD Version

Product serial number

The current version number for the complete software rel ease.

The build number for current SBC software.

The current version for the 186/Controller software.

The current version of the programmable logic devices on the 186 or Controller boards.

The serial number of the complete system.

Travel Limits

If the box is checked the switch is tripped.

Note: Only updates when system is looking for the input. Manually blocking the

sensor will not update this field.

X home

X Limit

Y Home

Y Limit

Z Home

Z Limit

Z Jam

Z Foam

The X axis home limit switch state.

The X axis end of travel limit switch state.

The Y axis home limit switch state.

The Y axis end of travel limit switch state.

The Z axis home limit switch state.

The Z axis end of travel limit switch state.

The Z jam encoder switch state.

The Z top of foam switch state.

Filament

Model Latched

Model in Head

Support Latched

Support in Head

Door

Door Latched

Door Open

Miscellaneous

Lights On

Chamber Heater

The model material cartridge latch state.

The state of the modeling material in the machine.

True = material moved out of cartridge.

False = material not moved out of cartridge.

The support material cartridge latch state.

The state of the support material in the machine.

True = material moved out of the cartridge.

False = material not moved out of the cartridge

The state of the door latch solenoid.

The state of the door switch.

State of the chamber light.

State of the chamber heater.

3-8

Setting the Serial Number

To set the system serial number enter the serial number in the “Product Serial Number” field

and click on the green check mark. The serial number displayed in this field is the current

serial number of the product.

Materials

Every cartridge has a SmartSpool EEPROM attached that tracks information about the

filament remaining on the cartridge, and shelf life information. The following information is

provided for each cartridge. The top cartridge is the Model material cartridge, and the

bottom cartridge is the Support material cartridge.

Cartridge Information

Serial Number

Material Type

Manufacturing Lot

Manufacturing Date

Use Date

Initial Quantity

Current Quantity

This is a unique number assigned to each cartridge.

This is the type of material on the cartridge. For example:

P400 - is a standard modeling material

P400R - is a standard release material.

P400SR - is a standard soluble release material.

This is a lot code used by Stratasys to control the manufacturing process.

This is the date that the cartridge was manufactured.

This is the date that the cartridge was first inserted in a machine.

This is the amount of material that was on the cartridge initially.

This is the amount of material currently on the cartridge.

Tip Offset

The tip offset control dialog allows you to adjust the tip offset values.

Tip Offset X,Y

Z Tip to Base

Z Tip to Tip

XY distance from model tip to support tip.

Depth of tip into modeling base.

Z distance from model tip to support tip with desired offset.

Gantry

The gantry controls the adjustment for the XY gantry. These values are set in the factory and

do not need to be adjusted unless the XY gantry is adjusted or replaced.

Gantry Hysteresis

Y Lash

X Adjust

uPrint/uPrint SE Service Manual 3-9

Mechanical lash is the tendency of the gantry to remain stationary after a change in direction until the

mechanical slop in the system is taken up by the move.

X Axis adjustment provides a method of removing additional linear part error that is present in the XY

Gantry after assembly.

Part Calibration

Left

Right

Front

Back

Left Front

Left Rear

Measured on left side of modeling base, front to back.

Measured on right side of modeling base, front to back.

Measured on front side of modeling base, left to right.

Measured on back side of modeling base, left to right.

Measured from front left corner to rear right corner.

Measured from front right corner to rear left corner.

Temperatures

The temperature control dialog allows you to adjust the set points for the head and chamber

temperatures, for both modeling and at standby.

Temperature Setpoints

Item Build Setpoint Standby Setpoint

Model 300 102.5

Support 300 102.5

Chamber 75 75

Outputs

The outputs dialog contains toggle buttons to control solenoids and motors that can not be

directly controlled on the Control Panel Display.

Model Latch

Motor Enabled

Motor Running

Support Latched

Motor Enabled

Motor Running

Door Latch

Lights On

The check box shows the state of the model (top) cartridge latch, and the toggle bu tt o n

changes that state.

The check button shows the state of the model (top) feed motor solenoid, and the toggle but-

ton changes that state.

The check box shows the state of the model (top) filament feed motor, and the toggle button

changes that state.

The check box shows the state of the support (bottom) cartridge latch, and the toggle button

changes that state.

The check box shows the state of the support (bottom) feed motor solenoid, and the toggle

button changes that state.

The check box shows that state of the support (bottom) filament feed motor, and the toggle

button changes that state.

This check box shows the state of the door latch solenoid, and the toggle button changes that

state.

This check box shows the state of the chamber lights, and the toggle button changes that

state.

Table

Table calibration consists of downloading the correct XY table calibration file to the machine

to properly adjust for table-to-table tolerance issues. The Table dialog allows you to browse

for and select the calibration file for the currently installed XY table and to download it to the

machine.

3-10

Get Calibration

The Get Calibration button allows a single calibration file to be retrieved from any machine

with a build number greater than or equal to 1132. This calibration file will also be on the

system calibration floppy disk/CD that ships in the electronics pan for systems with a build

number greater than or equal to 1132. This file contains all the factory calibration

information, including, but not limited to: Tip Offset, Tip Depth, Y Lash, X Correction, and

the table calibration DAT file.

When the button is pressed, a file selection dialog is presented allowing the assignment of a

file name and the selection of a storage location. This file should be updated any time

maintenance is performed that affects the factory calibration.

Send Calibration

The Send Calibration button allows you to send the complete set of factory calibrations to the

machine as a single file. This includes but is not limited to: Tip Offset, Tip Depth, YLash, X

Correction, and the gantry DAT file. This file is stored on the system calibration floppy disk/

CD if the system shipped with Controller software build 1132 or higher installed. A

calibration file can be retrieved from the modeler using Get Calibration from any system

with a build number of 1132 or higher.

When this button is pressed a dialog box appears that allows you to browse for and select the

calibration file to send to the machine.

Get Config

When the Get Config button is pressed a file selection dialog is presented allowing the

assignment of a file name and the selection of a storage location.

Test Parts

Test Parts consists of downloading sample and test part files to the machine. These file must

be in the .cmb.gz format produced by CatalystEX.

The Test Part dialog allows you to browse for and select the sample or test file and to

download it to the machine. The Test Parts are not preserved during a software upgrade. To

remove unwanted test parts, upgrade the software to the current level and only the factory

test parts will remain on the system.

Reset Password

This button resets the administrator password to null. This turns off password control of the

queue. This is used for clearing a forgotten password.

uPrint/uPrint SE Service Manual 3-11

Connect

If the system is not available over the network, when MaracaEX first loads, MaracaEX will

only try to connect one time. This allows you to interact with MaracaEX when it is not

connected to a machine. The Connect button allows you to request additional connection

attempts.

Help

Click the question mark to display the Help files.

3-12

Service Procedures

Maintenance Preparation ____________________________________________ 4-3

Required Tools list ____________________________________________________ 4-4

Distributer/Reseller supplied Tools ______________ ____ ___ _______ ___ ____ 4-4

Supplied by Stratasys ______________________________________________ 4-4

Pre-Maintenance Procedures_________________________________________ 4-4

Exterior Components _________________________________________________ 4-5

Top Panel __ ___ ____ ___ ____ ___ ___ ____ ___ ____ ___ _______ ___ ____ ___ ____ 4-5

Side Panels________________________________ ___ ____ ___ ___ ____ ___ ____ 4-7

Display Panel______________________________________________________ 4-9

Front Panel_______________________________________________________ 4-11

Door Solenoid ____________________________________________________ 4-13

Door Sensor ______________________________________________________ 4-14

Electronics Bay Components ________________________________________ 4-15

Lower Electronics Bay Cover ______________________________________ 4-15

Upper Electronics Bay Cover ______________________________________ 4-17

Removing the Electronics Bay _____________________________________ 4-19

Electronics Bay Cooling Fan_______________________________________ 4-21

Controller Board__________________________________________________ 4-23

Single Board Computer (SBC) ___________________________ __________ 4-26

Power Distribution I/O Card _______________________________________ 4-29

Power Distribution Board (PDB) ____________________________________ 4-31

Hard Drive _______________________________________________________ 4-34

Line Filter_________________________________________________________ 4-40

Circuit Breaker ___________________________________________________ 4-42

AC Input __________ ___ ____ ___ ___ ____ ___ ____ ___ ____ ___ ___ ____ ___ ___ 4-44

Power Switch_____________________________________________________ 4-46

24VDC Power Supply _____________________________________________ 4-48

5/12VDC Power Supply ___________________________________________ 4-51

120VDC Power Supply ____________________________________________ 4-54

Head Components__________________________________________________ 4-56

Head Cooling Fan________________________________________________ 4-5 6

Toggle Head Assembly ___________________________________________ 4-58

Substrate Sensor__________________________________________________ 4-64

Z Foam Level Assembly ___________________________________________ 4-67

uPrint/uPrint SE Service Manual 4-1

Toggle Sensor __________________________________________ ____ ___ ___ 4-69

Toggle Bar _______________ ___ ___ ____ _______ ___ ____ ___ ___ ____ ___ ___ 4-71

Head Board________________________ ___ ____ ___ ____ ___ _______ ___ ___ 4-76

TC Amp board ___________________________________________________ 4-82

Umbilical Hose ___________________________________________________ 4-84

Material Tubes ___________________________________________________ 4-88

Umbilical Cable__________________________________________________ 4-89

XY Table Components ___ ____________________________________________ 4-91

Y Home Sensor ___________________________________________________ 4-91

Y EOT (End of Travel) Sensor_______________________________________ 4-92

X Motor__________________________________________________________ 4-93

Y Motor_________________________________________________________ 4-100

Y Motor Belt_____________________________________________________ 4-103

Y Drive Rod _____________________________________________________ 4-110

XY Table ________________________________________________________ 4-117

Z Stage Components_______________________________________________ 4-137

Z Home Sensor _____________________________________________ ___ __ 4-137

Z EOT (End of Travel) Sensor ______________________________________ 4-138

Chamber Fans __________________________________________________ 4-139

Chamber Heaters _______________________________________________ 4-141

Thermal Fuses ___________________________________________________ 4-145

Chamber Thermocouple ________________________________________ 4-148

Z Motor ____________________________ ___ ____ ___ ____ ___ ___ ____ ___ __ 4-149

Z Stage ______________ ____ ___ ___ ____ ___ ____ ___ ____ ___ ___ _______ __ 4-153

4-2

Maintenance Preparation

Read these warnings before performing service on printer!

Warning: Make sure the power is disconnected when performing any of the

disassembly or assembly instructions in this chapter. Failure to do so can cause

severe personal injury or damage to the electronics.

Warning: Servicing instructions outlined in this chapter are intended for use by

qualified personnel only. Failure to follow these guidelines can cause severe

injury.

Warning: The Power Switch does NOT remove power from the printer. The

Breaker Switch located on the rear of the printer MUST be off before service is

performed on the printer. It is recommended that the AC power cord be

disconnected before performing maintenance outlined in this chapter.

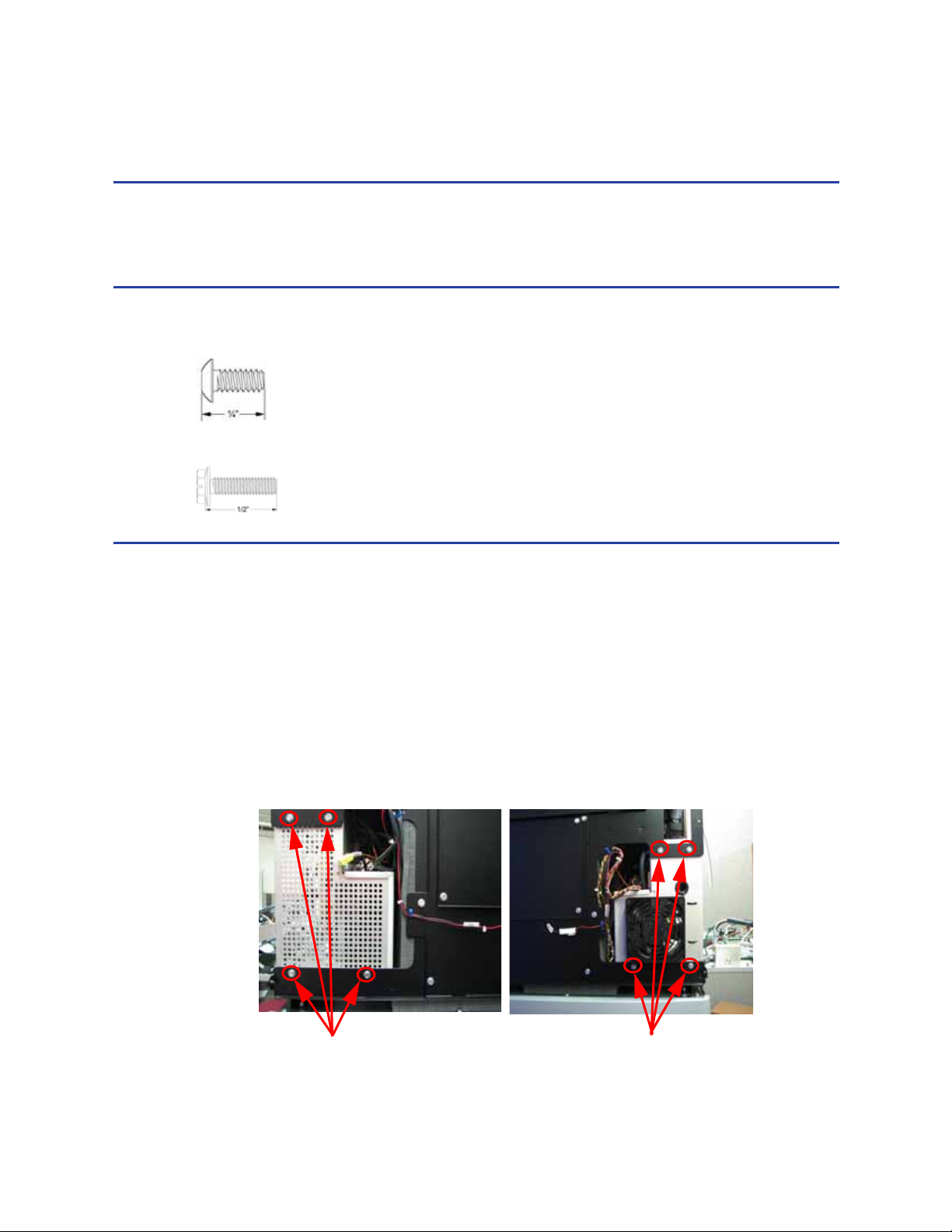

Warning: Use extreme caution when the door solenoid is disabled. Axes may