Page 1

www.stratasys.com | c-support@stratasys.com

Finishing Touch™ Smoothing Station

User Guide

September 2012

Part No. 108912-0001, Rev C

Page 2

Liability Statement

The information in this document is subject to change without notice.

Stratasys, Inc. makes no warranty of any kind with regard to this material, including,

but not limited to, the implied warranties of merchantability and fitness for a

particular purpose. Stratasys, Inc. shall not be liable for errors contained herein or for

incidental or consequential damages in connection with the furnishing, performance,

or use of this material.

This document is protected by copyright. All rights reserved. Its use, disclosure, and

possession are restricted by an agreement with Stratasys per software copyright. No

part of this document may be photocopied, reproduced or translated into another

language without the prior written consent of Stratasys, Inc.

All drawings and information herein are the property of Stratasys Inc. All

unauthorized use and reproduction is prohibited.

Trademark Acknowledgments

Stratasys is a registered trademarks of Stratasys, Inc.

Finishing Touch and WaterWorks are trademarks and service marks of Stratasys Inc.

in the United States and other countries.

Windows NT, Windows 2000, and Windows XP are registered trademarks of

Microsoft Corporation.

Weld-On is a registered trademark of IPS Corporation.

Super Glue is a registered trademark of Super Glue Corporation.

Teflon is a registered trademark of DuPont.

MicroCare is a registered trademark of MicroCare Corporation.

All other product names are the property of their respective owners.

Notice

Information in this User Guide is subject to change without notice.

Stratasys Incorporated

7665 Commerce Way

Eden Prairie, MN 55344 USA

952.937.3000

Fax: 952.937.0070

www.stratasys.com

© Copyright 2012 Stratasys Inc. All rights reserved.

Printed in the United States of America

ii

Page 3

Safety

Revision Log

Finishing Touch Smoothing Station User Guide

Rev Date Description of Changes

A April 2010 First release of this document.

B May 2011 Added Supplemental Information chapter (Limited

Warranty Statement).

C September 2012 Updated Formatting.

The following basic safety tips are given to ensure safe installation,

operation, and maintenance of Stratasys equipment and are not to be

considered as comprehensive on matters of safety. The Finishing Touch

Smoothing Station is designed to be safe and reliable smoothing system.

Access to areas of the system are potentially dangerous.

Safe Environment

• Connect equipment to a grounded facility power source. Do not defeat

or bypass the ground lead.

• Know the location of equipment branch circuit interrupters or circuit

breakers and how to turn them on and off in case of emergency.

• Know the location of fire extinguishers and how to use them. Use only

ABC type extinguishers on electrical fires.

• Know local procedures for first aid and emergency assistance.

• Use adequate lighting at the equipment.

• Maintain the recommended range of temperature and humidity in

equipment area.

• Do not use this product in an environment containing volatile or

flammable compounds.

iii

Page 4

Safe Human Interface

• Use proper lifting techniques when moving or installing the

equipment.

Hazard Classifications

Be aware of the following hazard classification used in this user guide.

Warning: Indicates a potentially hazardous situation that may result in

death or serious injury.

Note: Always read and adhere to safety statements, and be aware of the

following safety signs located on the system.

Biohazard. The biohazard sign indicates that the material is hazardous to

the environment. Gloves and eye/face protection must be used around

this material.Use proper disposal practices in accordance with local

ordinances.

iv

Page 5

Table of Contents

Introduction ______________________________________________________ 1-1

Specifications ________________________________________________________ 1-2

Overview_____________________________________________________________ 1-3

Smoothing Fluid Reservoir __________________________________________ 1-4

Water Separator __________________________________________________ 1-4

Smoothing Chamber ______________________________________________ 1-5

Cold/Dry Chamber________________________________________________ 1-5

Front Panel _______________________________________________________ 1-5

Programmable Logic Controller (PLC) ______________________________ 1-5

Cooling/Heating System ___________________________________________ 1-6

Compressor ___________________________________________________ 1-7

Lower Primary Cooling Coils ____________________________________ 1-7

Upper Fin Coils_________________________________________________ 1-7

Exhaust Fan ___________________________________________________ 1-7

Heaters _______________________________________________________ 1-7

Foot Switch____________________________________________________ 1-7

Panel Controls ________________________________________________________ 1-8

On/Off Switch_____________________________________________________ 1-9

Start Button _______________________________________________________ 1-9

Stop Button _______________________________________________________ 1-9

Fluid Status Light___________________________________________________ 1-9

System Fault Light ________________________________________________ 1-10

System Status Light _______________________________________________ 1-10

Shut Down Status Light____________________________________________ 1-10

Safety ____________________________________________________________ 2-1

Safety ________________________________________________________________ 2-2

Drain and Vent Smoothing Station Prior to Service___________________ 2-2

Potential Health Effects ____________________________________________ 2-2

First Aid Measures _________________________________________________ 2-2

Inhalation _____________________________________________________ 2-2

Skin Contact __________________________________________________ 2-2

Eye Contact___________________________________________________ 2-2

Ingestion ______________________________________________________ 2-2

Environmental Safety__________________________________________________ 2-3

Spill Clean Up _____________________________________________________ 2-3

Handling and Storage _____________________________________________ 2-3

Handling ______________________________________________________ 2-3

Storage _______________________________________________________ 2-3

Waste Disposal ____________________________________________________ 2-4

Personal Protection ___________________________________________________ 2-4

Eye/Face Protection_______________________________________________ 2-4

Protective Clothing________________________________________________ 2-4

v

Page 6

Equipment Modification ___________________________________________ 2-4

Installation and Setup _____________________________________________ 3-1

Site Requirements _____________________________________________________ 3-2

Space Requirements ______________________________________________ 3-2

Environmental Requirements_______________________________________ 3-2

Electrical Requirements____________________________________________ 3-3

Compressed Air Requirements _____________________________________ 3-3

Exhaust Vent Requirements ________________________________________ 3-4

Consumables _____________________________________________________ 3-5

Smoothing Station Fluid ________________________________________ 3-5

Installing the System __________________________________________________ 3-6

Inspect Crate for Damage_________________________________________ 3-6

Required Tools and Equipment _____________________________________ 3-6

Forklift Truck Requirements _________________________________________ 3-6

Unpacking the System _____________________________________________ 3-7

Remove Shipping Crate________________________________________ 3-7

System Connections __________________________________________________ 3-8

Filling the Reservoir _______________________________________________ 3-10

Power On Process ________________________________________________ 3-11

Power Off Process ________________________________________________ 3-11

Prior to Smoothing Parts___________________________________________ 3-12

WaterWorks _________________________________________________________ 3-13

Support Material Removal ________________________________________ 3-13

Smoothing Operation ________________________________________________ 3-14

Masking _________________________________________________________ 3-15

Smoothing the Parts ______________________________________________ 3-15

Repeatability ____________________________________________________ 3-16

Post Finishing Tips _________________________________________________ 3-16

Post Finish Painting Tips ___________________________________________ 3-16

Recommended Burnishing Process ________________________________ 3-17

Effects of High Temperature_______________________________________ 3-17

Troubleshooting ___________________________________________________ 4-1

Troubleshooting_______________________________________________________ 4-2

Frequently Asked Questions ________________________________________ 4-2

System Will Not Start When the Cycle Start Button is Pressed ______ 4-2

Refrigeration Not Cooling or Does Not Have Inadequate Cooling 4-2

Excessive Frost or Ice on the Fin Coils ____________________________ 4-2

Smoothing Chamber Does Not Have Vapor or Vapor is Falling ___ 4-3

Troubleshooting Chart _____________________________________________ 4-4

Status Lights ___________________________________________________ 4-4

Ordering Supplies _____________________________________________________ 4-5

Smoothing Station Fluid ________________________________________ 4-5

Supplemental Information _________________________________________ 5-1

Stratasys Limited Warranty Statement __________________________________ 5-1

vi

Page 7

Chapter 1: Introduction

This chapter describes the Stratasys Finishing Touch Smoothing

Station and its component functions, and device specifications.

Specifications________________________________________________________ 1-2

Overview ____________________________________________________________ 1-3

Smoothing Fluid Reservoir __________________________________________ 1-4

Water Separator___________________________________________________ 1-4

Smoothing Chamber ______________________________________________ 1-5

Cold/Dry Chamber ________________________________________________ 1-5

Front Panel________________________________________________________ 1-5

Programmable Logic Controller (PLC) ______________________________ 1-5

Cooling/Heating System ___________________________________________ 1-6

Compressor ___________________________________________________ 1-7

Lower Primary Cooling Coils ____________________________________ 1-7

Upper Fin Coils _________________________________________________ 1-7

Exhaust Fan____________________________________________________ 1-7

Heaters________________________________________________________ 1-7

Foot Switch ____________________________________________________ 1-7

Panel Controls _______________________________________________________ 1-8

On/Off Switch _____________________________________________________ 1-9

Start Button _______________________________________________________ 1-9

Stop Button _______________________________________________________ 1-9

Fluid Status Light ___________________________________________________ 1-9

System Fault Light_________________________________________________ 1-10

System Status Light _______________________________________________ 1-10

Shut Down Status Light ____________________________________________ 1-10

Finishing Touch Smoothing Station User Guide 1-1

Page 8

Specifications

Area Specification

System Size 52.5 in. (133.35 cm) long X 46.0 in. (116.84 cm) high X 32 in.

(81.28 cm) deep.

System Size Crated 59.5 in. (151.13 cm) long X 58.5 in. (148.59 cm) high X 43in.

(109.22 cm) deep.

Weight 400 lbs. (181.44 kg) uncrated

~600 lbs. (~ 272.16 kg) crated

Electrical Rating 200-240 VAC 50/60Hz, 20 amp (dedicated circuit), single

phase

Compressed Air Requirements 5 SCFM @ 80 psi (minimum)

Regulatory Compliance CE

Noise Emission <60 dB

Operating Environment The smoothing station is for indoor use at temperatures from

60°F (15.6°C) to 85°F (29.4°C)

Humidity:<65% non-condensing

Maximum altitude of up to 10761 ft. (3280 m)

Compatible FDM Materials ABS-P400

ABS-M30

ABS-M30I

ABSplus

ABSI

Exhaust Requirement 4 in. (102 mm) to outside

1-2 Introduction

Page 9

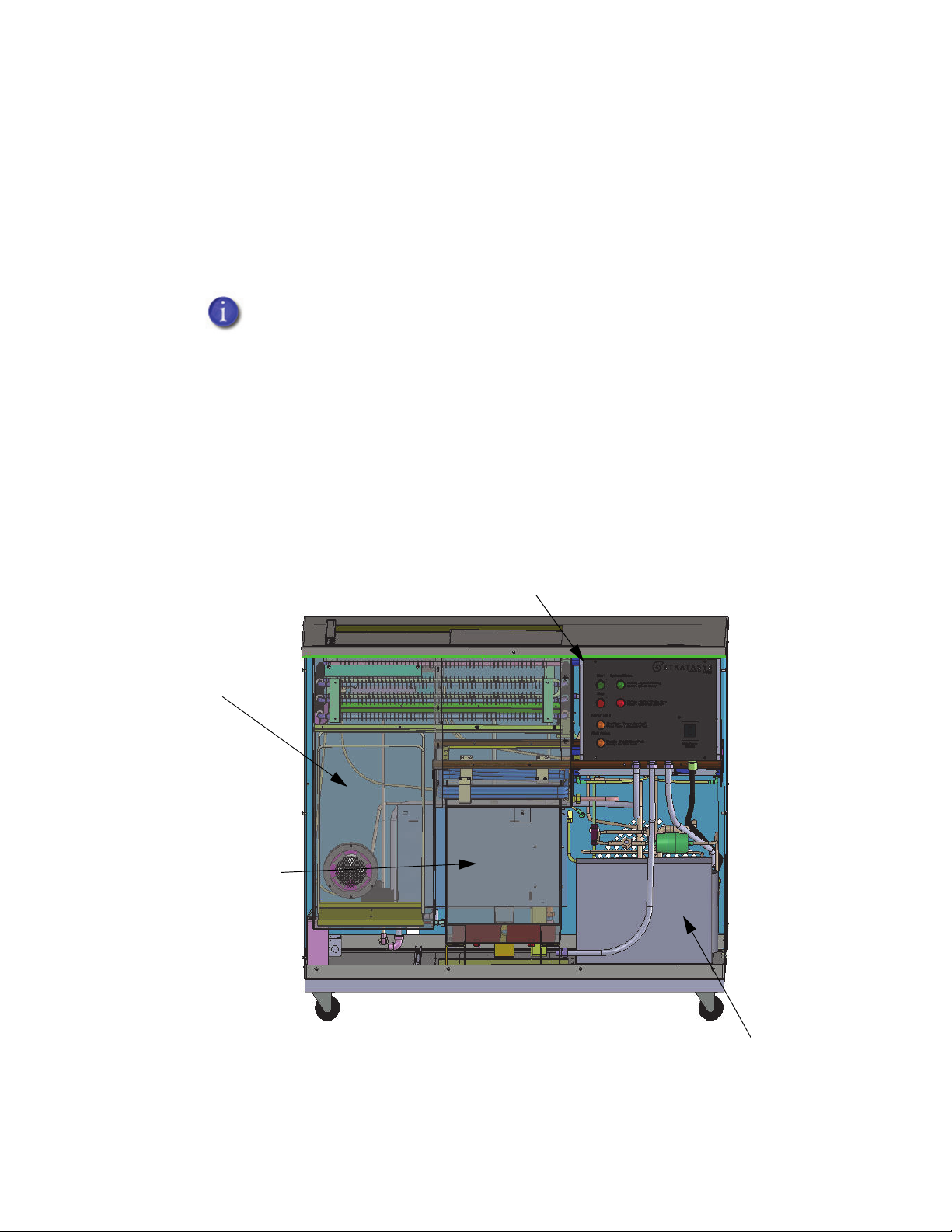

Cold/Dry Chamber

Cooling System

Smoothing Chamber

Front Panel

Programmable Logic

Controller (PLC)

(behind Front Panel)

Overview

The Stratasys Finishing Touch Smoothing Station is a proven method to

dramatically reduce, and in many cases eliminate the need for manual

post finishing. When used with a bead blaster burnishing station, FDM

ABS models can be finished to injection-molded quality in a short period

of time. See “Recommended Burnishing Process” on page3-17 for details.

Major components of the smoothing station includes the following:

• Smoothing Fluid Reservoir • Cooling/Heating System

• Water Separator • Front Panel

• Smoothing Chamber • Programmable Logic Controller (PLC)

When smoothing parts, it is important to remember that the better the

parts look before the smoothing process, the higher the quality of part

you will get after smoothing.

• Cold/Dry Chamber

Finishing Touch Smoothing Station User Guide 1-3

Figure 1-1: Major Components (Front View)

Page 10

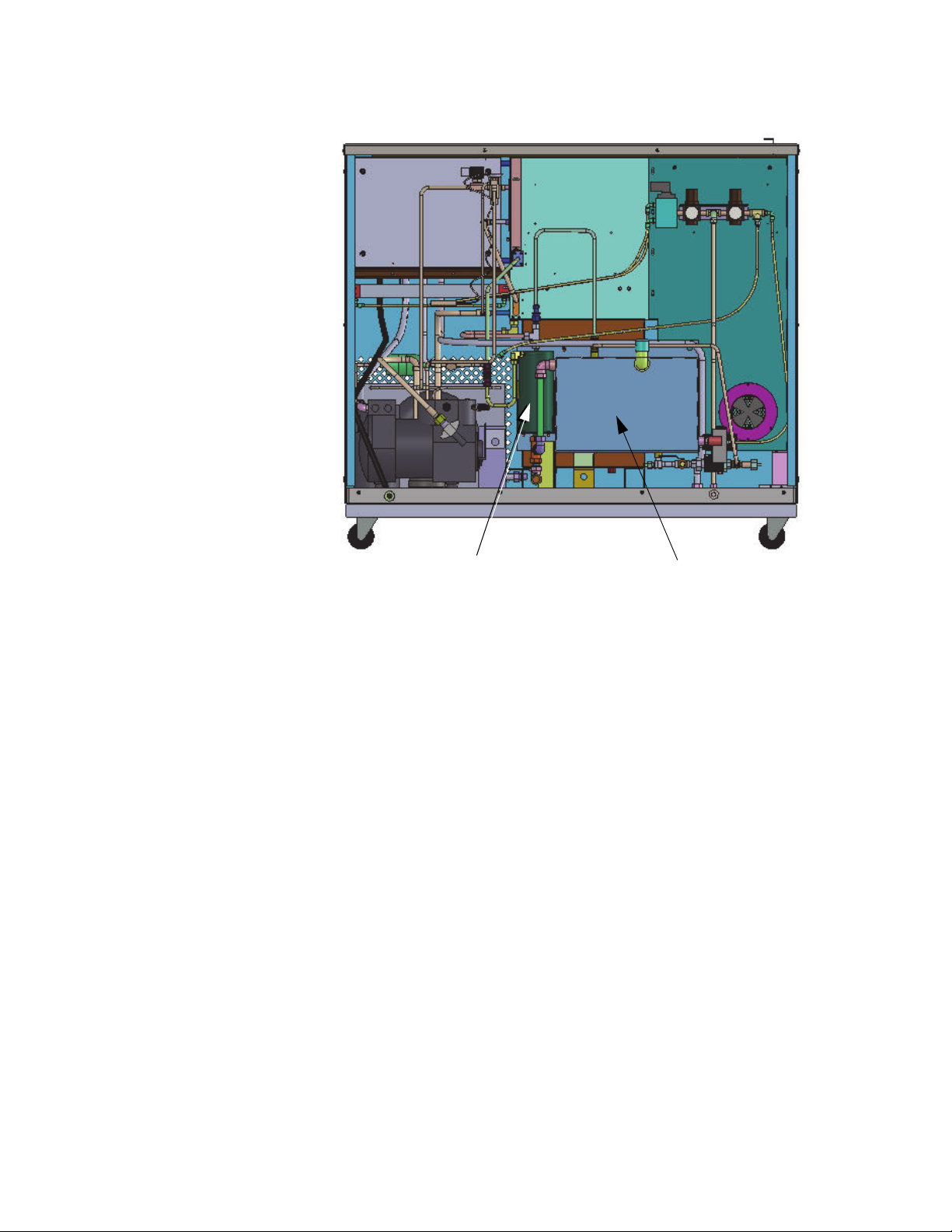

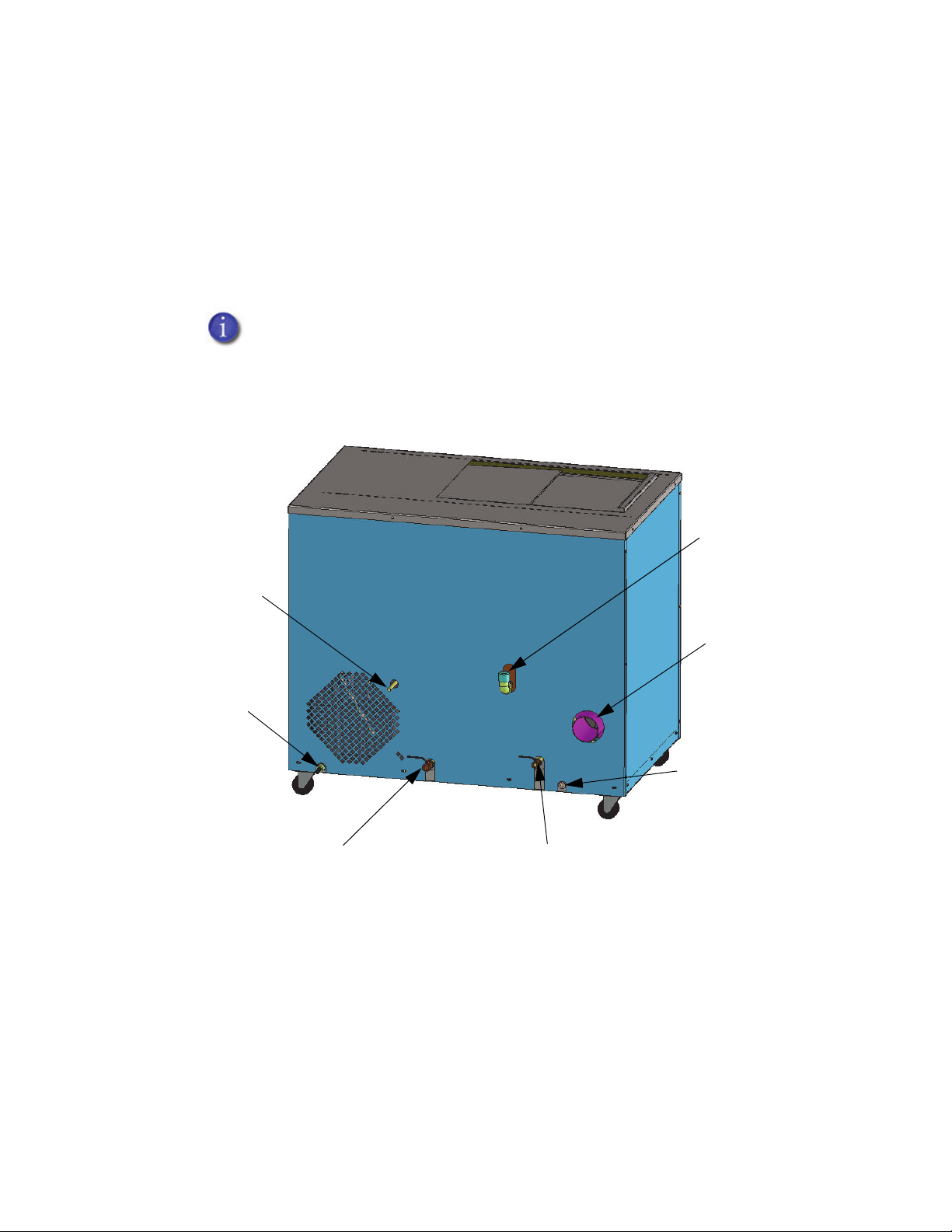

Smoothing Fluid Reservoir

Water Separator

Figure 1-2: Major Components (Back View)

Smoothing Fluid Reservoir

Located in the back of the system, the smoothing fluid reservoir is a

7-gallon container that holds the smoothing solution. There is a low level

float inside the tank that indicates when it is time to add solution.

Water Separator

Located next to the smoothing fluid reservoir, the water separator

removes water from the smoothing solution. This occurs as the solution

enters the separator after being cycled through the smoothing chamber.

The separator works on the principle that the smoothing solution is

heavier than water and that the two will not mix with each other. The

lighter water floats on top of the solution and is siphoned off through the

P-trap over flow tube and into an external collection container. Follow

local guidelines and regulations concerning safety and disposal of

drained water.

1-4 Introduction

Page 11

Smoothing Chamber

The smoothing chamber is located under the smoothing lid and is where

parts are smoothed. The smoothing solution is heated from the bottom of

the chamber. Once hot, the vapor from the solution fills the chamber until

it is collected by the cooling coils at the top of the chamber. The collected

fluid is then recycled back into the separator and then into the smoothing

fluid reservoir.

Cold/Dry Chamber

The cold/dry camber is located next to the smoothing chamber. This

chamber provides hanging racks for parts that are drying or are cooling.

The manual sliding lid should be drawn closed across both the cold/dry

chamber and the smoothing chamber when not actively smoothing parts.

Keep this lid closed for safety and for cooling parts.

Front Panel

The front panel of the system contains all of the operator interface

switches and indicator lights. Located behind the panel is the main

electrical box.

Programmable Logic Controller (PLC)

Located in the main electrical box, the PLC controls the entire operation of

the system.

Figure 1-3: Programmable Logic Controller

Finishing Touch Smoothing Station User Guide 1-5

Page 12

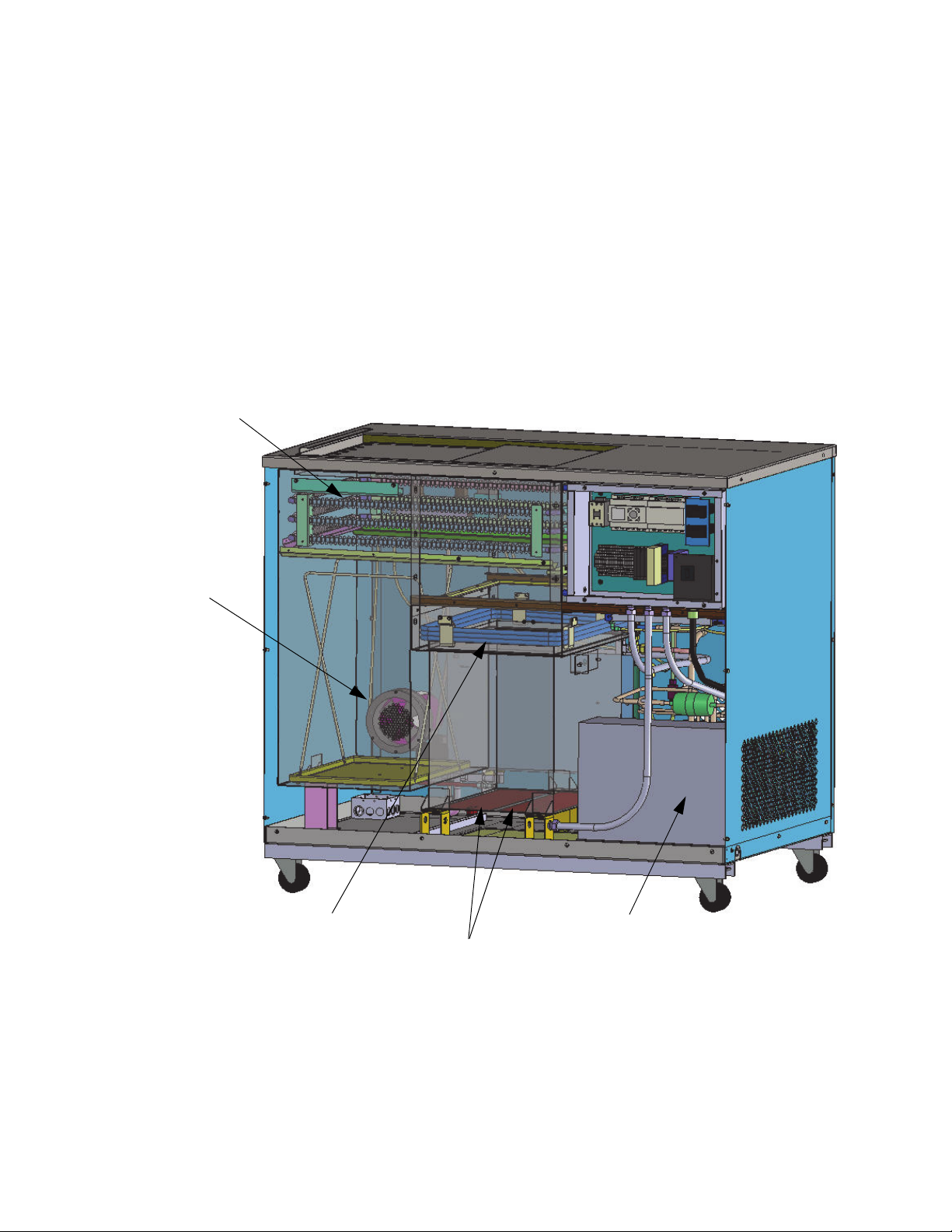

Compressor

Lower Primary Cooling Coils

Upper Fin Coils

Exhaust Fan

Heaters

Cooling/Heating System

The cooling/heating system is comprised of the following components:

• Compressor

• Lower Primary Cooling Coils

• Upper Fin Coils

• Exhaust Fan

• Heaters

Figure 1-4: Cooling/Heating System Components

1-6 Introduction

Page 13

Compressor

A ¾ horse semi-hermetic compressor cools the system. The vents on the

panels of the smoothing station must be kept free of obstructions to allow

for free air movement through the compressor.

Lower Primary Cooling Coils

These coils are located beneath the air driven smoothing chamber lid.

They create a cold air blanket over the top of the smoothing chamber. This

cold air blanket keeps the smoothing solution vapor contained within the

smoothing chamber. They also are the collection point for the smoothing

vapor as it is cooled as it changes back into a liquid for recycling back into

the smoothing fluid reservoir.

Upper Fin Coils

Located over both the smoothing chamber and the cool/dry chamber

these coils cool the surfaces of the parts prior to exposing them to the

vapor in the smoothing chamber. They also collect any smoothing

solution vapor that is out gassed during the drying process.

Exhaust Fan

Heaters

Foot Switch

Located at the bottom of the cool/dry chamber, the exhaust fan removes

any out gassed vapors collected in the chamber. The exhaust must be

directed to an unobstructed area that is located outside of the building.

The process works on the principle that the smoothing solution vapor is

approximately 4 times heavier than air. This causes the vapor to sink to

the bottom of the chamber.

The smoothing station has two temperature controlled silicon pad heaters

located on the bottom of the system. The temperature of the heaters are

factory set and should not be adjusted except by qualified service

personnel.

The foot switch, located on the floor, activates an air driven linear actuator

to open the lid covering the smoothing chamber. When the foot switch is

pressed, the PCL resets the over all timer on the system. If the switch is not

pressed within a four hour period, the system assumes that no activity has

taken place and goes into a shutdown mode.

Finishing Touch Smoothing Station User Guide 1-7

Page 14

On/Off

System Status Light

Start

Stop

System Fault

Fluid Status

Switch

Shut Down

Status Light

Button

Button

Light

Light

Panel Controls

The front panel controls of the smoothing station includes the following:

• On/Off Switch

• Start Button

• Stop Button

• Fluid Status Light

• System Fault Light

• System Status Light

• Shut Down Status Light

Figure 1-5: Front Panel Control Components

1-8 Introduction

Page 15

On/Off Switch

The main power breaker on/off switch activates power to the system.

Start Button

Pressing the momentary start switch activates the smoothing station

operation cycle. Once pressed, an internal timer automatically causes the

system to shutdown if the foot switch for the air activated smoothing lid

has not been pressed within a four hour time period.

Stop Button

The momentary stop button initiates the cycle shutdown procedure. The

smoothing station operation cycle can be restarted by pressing the start

button.

Once the stop button is pressed (or a four hour time period has elapsed

without the lid over the smoothing chamber being opened) the red

indicator light will begin flashing indicating that the system is in a

shutdown mode. When the shutdown cycle is complete, the red shutdown

light will remain in a steady on state. This indicates that the system has

shutdown.

Fluid Status Light

When this amber fluid status light is rapidly flashing, there is not enough

fluid is flowing into the vapor chamber. This condition also may indicate

that the fluid valve is not closing properly.

When the amber fluid status light is on steady, there is low fluid in the

storage container. Adding solution to the smoothing reservoir will cause

the light to turn off.

Finishing Touch Smoothing Station User Guide 1-9

Page 16

System Fault Light

The system fault light will illuminate indicating there is a fault in the

system. Refer to the “Troubleshooting Chart” on page4-4 for details.

System Status Light

When the system is ready to begin smoothing parts, the green system

status light will be illuminated. When the stop button is pressed, the light

will turn off.

Shut Down Status Light

Once the stop button is pressed (or four hours have elapsed without the

lid over the smoothing chamber being opened), the red shut down light

will begin flashing. The flashing indicates that the system is shutting

down. When the shutdown cycle is complete, the light will remain steady

on indicating that the system shutdown is complete.

1-10 Introduction

Page 17

Chapter 2: Safety

This chapter describes the Stratasys Finishing Touch Smoothing

Station general safety information along with environmental safety

and personal protection concerns.

Safety _______________________________________________________________ 2-2

Drain and Vent Smoothing Station Prior to Service ___________________ 2-2

Potential Health Effects ____________________________________________ 2-2

First Aid Measures__________________________________________________ 2-2

Inhalation _____________________________________________________ 2-2

Skin Contact___________________________________________________ 2-2

Eye Contact ___________________________________________________ 2-2

Ingestion ______________________________________________________ 2-2

Environmental Safety _________________________________________________ 2-3

Spill Clean Up _____________________________________________________ 2-3

Handling and Storage _____________________________________________ 2-3

Handling ______________________________________________________ 2-3

Storage _______________________________________________________ 2-3

Waste Disposal ____________________________________________________ 2-4

Personal Protection___________________________________________________ 2-4

Eye/Face Protection _______________________________________________ 2-4

Protective Clothing ________________________________________________ 2-4

Equipment Modification ___________________________________________ 2-4

Finishing Touch Smoothing Station User Guide 2-1

Page 18

Safety

Drain and Vent Smoothing Station Prior to Service

Under no circumstances should any smoothing solution be poured

on the ground or down a sewer drain. Always follow local guidelines

and regulations concerning the disposal of smoothing solution.

Allow the smoothing solution to cool before draining. Make sure that all

solution is drained from the smoothing chamber and the chamber is well

ventilated prior to performing any work in the chamber. This includes

cleaning the chamber.

Potential Health Effects

Read and understand the Material Safety Data Sheet (MSDS)

associated with the smoothing solution.

• Avoid inhaling vapors because dizziness and weakness can occur.

• Skin contact may cause severe irritation with burning, redness,

swelling, pain or rash.

• Eye contact may cause severe eye irritation with tearing, pain or

blurred vision.

• Do not ingestion any solutions associated with the smoothing station.

First Aid Measures

Inhalation

If inhaled, move to fresh air. If not breathing, give artificial respiration. If

breathing is difficult, give oxygen. Call a physician.

Skin Contact

Flush skin with water after contact. Wash contaminated clothing before

reuse.

Eye Contact

In case of contact, immediately flush eyes with plenty of water for at least

15 minutes. Call a physician.

Ingestion

If swallowed, do not induce vomiting. Immediately give two glasses of

water. Never give anything by mouth to an unconscious person. Call a

physician.

2-2 Safety

Page 19

Environmental Safety

Under no circumstances should any smoothing solution be poured

on the ground or down a sewer drain. Always follow local guidelines

and regulations concerning the disposal of smoothing solution.

Spill Clean Up

• Immediately evacuate the area and provide maximum ventilation,

especially in low places where heavy vapors might collect.

• Only personnel equipped with proper equipment should be permitted

in the area.

• Soak up with sawdust, sand, oil dry or other absorbent material.

• After all visible traces, including vapors, have been removed,

thoroughly wet vacuum the area.

• Do not flush solution into a sewer.

• If area of the spill is porous, remove as much contaminated earth and

gravel, etc. as necessary and place in closed containers for disposal.

• Consult the MSDS in case of an accidental spill and then proceed with

clean up accordingly.

Handling and Storage

Always follow directions printed on the outside of the container.

Handling

Do not inhale vapors emitted from the container. Avoid contact with eyes,

skin or clothing. Wash thoroughly after handling. Keep container tightly

closed.

Storage

Store solution in a clean and dry area. Do not allow stored product to

exceed 125° F (52° C) in temperature to prevent leakage or potential

rupture of container from pressure and expansion. Protect from freezing

temperatures. If the solvent is stored below 14° F (-10° C), mix prior to use.

Refer to the MSDS for specific details.

Finishing Touch Smoothing Station User Guide 2-3

Page 20

Waste Disposal

Under no circumstances should any smoothing solution be poured

on the ground or down a sewer drain. Always follow local guidelines

and regulations concerning the disposal of smoothing solution.

Treatment, storage, transportation, and disposal must be in accordance

with applicable Federal, State/Provincial, and local regulations.

Personal Protection

Use only with adequate ventilation. Vapors are heavier than air, posing a

hazard of asphyxia if they are trapped in enclosed or low places.

Eye/Face Protection

Wear safety glasses. Where splash potential exists, wear chemical splash

goggles.

Protective Clothing

Wear appropriate protective clothing and gloves to avoid potential skin

contact.

Equipment Modification

Protection provided by the equipment may be impaired if not used in the

manner specified in the instructions.

2-4 Safety

Page 21

Chapter 3: Installation and Setup

This chapter describes installation and setup procedures for the

Stratasys Finishing Touch Smoothing Station.

Site Requirements ____________________________________________________ 3-2

Space Requirements ______________________________________________ 3-2

Environmental Requirements _______________________________________ 3-2

Electrical Requirements ____________________________________________ 3-3

Compressed Air Requirements _____________________________________ 3-3

Exhaust Vent Requirements ________________________________________ 3-4

Consumables _____________________________________________________ 3-5

Smoothing Station Fluid ________________________________________ 3-5

Installing the System__________________________________________________ 3-6

Inspect Crate for Damage _________________________________________ 3-6

Required Tools and Equipment _____________________________________ 3-6

Forklift Truck Requirements _________________________________________ 3-6

Unpacking the System _____________________________________________ 3-7

Remove Shipping Crate ________________________________________ 3-7

System Connections _________________________________________________ 3-8

Filling the Reservoir _______________________________________________ 3-10

Power On Process ________________________________________________ 3-11

Power Off Process ________________________________________________ 3-11

Prior to Smoothing Parts ___________________________________________ 3-12

WaterWorks _________________________________________________________ 3-13

Support Material Removal ________________________________________ 3-13

Smoothing Operation _______________________________________________ 3-14

Masking__________________________________________________________ 3-15

Smoothing the Parts ______________________________________________ 3-15

Repeatability_____________________________________________________ 3-16

Post Finishing Tips _________________________________________________ 3-16

Post Finish Painting Tips ____________________________________________ 3-16

Recommended Burnishing Process ________________________________ 3-17

Effects of High Temperature _______________________________________ 3-17

Finishing Touch Smoothing Station User Guide 3-1

Page 22

Smoothing Station

(Top View)

Exhaust Vent

36 in. (91.44 cm) Clearance in

front of the Smoothing Station

24 in. (60.96 cm)

Clearance at the

back and on the sides

of the Smoothing Station

Site Requirements

Space Requirements

Allow 24 in. (60.96 cm) of clearance in the back of the system as well as on

both the left and right-hand sides. Allow 36 in. (91.44 cm) in the front. The

minimum ceiling height is 96 in. (243.84 cm) and the floor must be hard

and level.

The room must be well ventilated and allow for free flow of air exchange.

The exhaust air flow must not create a negative pressure. The system may

not establish a proper exhaust if a negative pressure condition exists.

Figure 1: System Space Requirements

Environmental Requirements

• The smoothing station is intended for indoor use only.

• Operating temperature: 60°F (15.6°C) to 85°F (26.7°C)

• Humidity: <65% non-condensing

3-2 Installation and Setup

Page 23

Electrical Requirements

The facility power is required to meet the following power quality and

nominal voltage requirements:

• 200-240 VAC

• 50/60 Hz

• Single phase

• 20 Amp (dedicated circuit)

Operation of the system outside this range is not recommended and may

degrade of the performance of the system.

A power plug is not supplied at the end of the power cord. Check

with local electrical ordinances for the size and plug configuration for

a 20 amp dedicated electrical circuit outlet.

Compressed Air Requirements

The system has an onboard pressure regulator and an onboard particle

filtration, water, and oil separation.

• Supply pressure at the system must be at least 5 SCFM at 80 psi

(minimum)

• Non-lubricated

• Non-condensing

• For serviceability, there should be at least one quick disconnect

installed so the system can be easily disconnected from the air supply.

• A flexible air hose should be used to allow for movement of the

machine.

The system is equipped with a threaded female fitting (dimensional ¼

NPT standard) for a compressed air connection. The user must supply the

necessary connections between the fitting and the customer’s compressed

air supply.

Finishing Touch Smoothing Station User Guide 3-3

Page 24

Outside Exhaust

Vent

Flexible Exhaust Hose

50 ft.

(15.24 m)

Max

Exhaust Vent Requirements

The system requires the installation of a 4-inch (101.5 mm) exhaust vent

(with screen) to the outside of the building.

• The exhaust vent should be properly located so the exhaust fumes will

not be directed back into the building. Keep the exhaust vent at least 6

ft. (

1.8 m) away from windows or near air intakes.

• The pipe from the vent should extend into the room at a minimum of

2-inches (50 mm) so a flexible exhaust hose can be attached later

(shipped with the system).

• The room must allow for free flow of air exchange so exhaust air from

the system does not create a negative pressure. The exhaust system

may not perform properly if a negative pressure exists.

A maximum of 50 ft. (15.24 m) of rigid smooth walled hose is allowed

between the system exhaust hose and the exhaust vent. Keep 90°

bends to a minimum to ensure adequate air flow at exit. Do not

exceed more than 270° worth of bends.

Figure 2: Flexible Exhaust Hose

3-4 Installation and Setup

Page 25

Consumables

Smoothing Station Fluid

It is recommended that a minimum of two 5-gallon containers of

Smoothing Station Fluid be available at the time of installation.

Product name: SSF - Microcare SSF, Smoothing Station Fluid (part number

MCC-SSF0IP) can be ordered from the following company:

www.SmoothingFluids.com

MicroCare Corp.

595 John Downey Drive

New Britain, CT 06051

United States of America

Phone: 860.827.0626 or 800.638.0125

techsupport@microcare.com

MicroCare Europe bvba

Erasmuslaan 10

B-1804 Cargovil (Zemst) Belgium

Phone: 00 +32 2 251 95 05

techsupport@microcare.com

Randall Oliveiro, Marketing Director

Uniwes Technology (S) Pte Ltd

102E Pasir Panjang Road #03-01/02

Citilink Warehouse Complex

Singapore, 118529

randall_oliveiro@uniwes.com.sg

Phone: 011-65-6275-8183

Finishing Touch Smoothing Station User Guide 3-5

Page 26

46.0 in.

(116.84 cm)

Installing the System

Inspect Crate for Damage

Before opening the shipping crate, inspect the crate for signs of exterior

damage.

Report evidence of excessive damage to Stratasys and the shipping

company.

Required Tools and Equipment

• Basic hand tools (powered screwdriver or drill with phillips bit).

• Forklift truck of sufficient size to raise the system from the shipping

skid.

Forklift Truck Requirements

The smoothing station is heavy and requires a forklift truck with the

following minimum capabilities:

• Ability to lift a crated system of 600 lbs. (272.16 kg).

• The forks on the forklift truck must be at least 46.0 inches (116.84 cm)

long to fit under the of the skid of the crated system.

Figure 3: Forklift Length

3-6 Installation and Setup

Page 27

To p

Runner Boards

Back

Base Shipping Board

2X

Unpacking the System

Remove Shipping Crate

Caution: Wear safety glasses when removing the system from the

shipping crate

Figure 4: Unpacking the System

Screws that are to be removed are highlighted with red paint.

1. Unscrew and remove the back and top of the shipping crate.

2. Unscrew and remove the two runner boards from the top of the crate.

3. Unscrew and remove the base shipping board that holds the system in

the crate

4. Use a forklift truck to lift the system from the shipping skid.

5. Carefully remove the plastic wrap from the system.

Caution: Use care when removing the plastic wrap to avoid

scratching the system surfaces.

6. Inspect the system exterior for dents and scratches. Immediately

report any damage to Stratasys and the shipping company.

Finishing Touch Smoothing Station User Guide 3-7

Page 28

Storage Tank Drain

Water Separator Drain

Exhaust Port

Fill Tube

Power Cord

Water

Overflow

Compressed Air

System Connections

Perform the following steps to connect the smoothing station:

1. Position the smoothing station in the desired location. Make sure there

is adequate room in the back and on the sides of the smoothing

station. The air vents can not be blocked and must allow for free

airflow.

Use Teflon tape on all fittings for an airtight seal.

2. Attach a compressed air fitting (customer supplied) to the compressed

air fitting on the back of the system. Connect the air supply to the

fitting.

Figure 5: Smoothing Station Connections

3. Locate and verify that both the storage tank drain and the water

separator drain valves are closed.

4. Connect one end of the flexible 4-inch (10.16 cm) exhaust hose to the

exhaust port on the back of the system. Connect the other end of the

hose to the outside exhaust vent.

3-8 Installation and Setup

Page 29

5. Locate the plastic carboy container and plastic tube in the accessory

kit. Fill the carboy container with 1 inch (2.54 cm) of water and place

behind the system. Place one end of the tube over the end of the water

overflow drain and insert the other end of the tube into the carboy

container. Make sure the hose is touching the bottom of the container.

6. Connect the power cord to the electrical supply.

7. Refer to the Finishing Touch Smoothing Station User Guide CD

located in the accessory kit for instructions on how to smooth parts.

Finishing Touch Smoothing Station User Guide 3-9

Page 30

Filling the Reservoir

Only transfer smoothing solution from the bulk container to the

smoothing fluid reservoir in a well-ventilated area.

Always wear safety goggles and observe proper safety procedures

when transferring smoothing solution. Read and understand the

MSDS associated with smoothing solution.

Perform the following steps when filling the fluid reservoir with

smoothing solution:

1. Locate the bung wrench, faucet, plastic pail and funnel in the

accessory kit.

2. Remove the fill cap on the fill tube on the smoothing station.

3. Insert the funnel into the fill tube.

4. Remove the finishing solution from its shipping container.

5. Using a small pliers remove the safety cover over the 2-inch (5.08 cm)

bung opening.

6. Assembly the faucet provided in the accessory kit by screwing

together.

7. Use the bung wrench to remove the 2-inch (5.08 cm) bung cap from

the storage can.

8. Screw the faucet into the opening.

9. Place the storage container at an elevation above the bucket.

10. Rotate the container so that the faucet is pointing down toward the

bucket.

11. Open the faucet and fill the bucket ¾ full. Shut off the faucet.

12. Pour the contents of the bucket into the funnel use caution not to over

flow the funnel.

13. Repeat steps 10 and 11 until the storage container is empty, or the

smoothing station storage tank is full.

14. Replace the cap on fill tube of the smoothing station.

15. Remove the faucet from the storage container.

16. Replace the 2-inch (5.08 cm) bung cap on the container to retain the

remaining solvent, or dispose of the container according to local

regulations.

3-10 Installation and Setup

Page 31

Power On Process

1. Turn the On/Off switch on to start the smoothing station.

2. The following action will start when the Cycle Start button is pressed:

• The refrigeration compressor will start.

• The cooling fan will turn on for 2-minutes and then will cycle

automatically.

• The air activated ball valve will open and start metering

smoothing solution to the smoothing chamber.

• After the solution is metered in the chamber, the heaters will turn

on.

• The green Ready light will illuminate and flash during warm-up

(approximately 5 minutes).

3. The smoothing station will warm up in approximately 10 minute.

The entire system is controlled by an over all timer. The timer will

begin the shutdown sequence if the air driven door over the

smoothing chamber is not opened at a minimum of every four hours.

Power Off Process

After all the parts are finished, press the stop button. The system will

begin the shutdown process. This process includes:

• The red light begins to flash indicating that the system has begun the

power down process.

• The ball valve controlling the amount of smoothing solution in the

chamber is clamped shut so that no more solution is allowed in the

chamber.

• The system will continue to heat the solution until it is has all

evaporated and distilled on the cooling coils and been recycled back

into the smoothing solution container.

• The heaters shut off.

• The refrigeration compressor shuts off.

• The red light stops flashing and stays on steady to indicate that the

shutdown is complete (approximately 1 hour in duration).

Finishing Touch Smoothing Station User Guide 3-11

Page 32

Prior to Smoothing Parts

The process for smoothing parts begins first with the building of the part.

The better the file preparation, orientation, system set up ,and tip

condition, the better the part will look after being processed by smoothing

station.

In general, the better the part at the start, the higher the quality at the end

of the smoothing process.

3-12 Installation and Setup

Page 33

WaterWorks

Support Material Removal

Use the following information when removing support material from

parts using WaterWorks™:

• Replace WaterWorks solution that has a low pH or is discolored and

full of support material. Low solution pH will increase the amount of

time necessary to remove support material. Parts can also become

stained from using dirty solution.

• Parts must be rinsed free of any WaterWorks solution. If there is any

dried on WaterWorks solution left on the part, the surface may blister

when exposed to the smoothing solution. Make sure that the rinse

water is clean and changed frequently. Agitation of the parts in the

rinse water will help remove any WaterWorks solution.

• Sparsely filled built parts can fill with WaterWorks solution during the

support removal process. All cavities must be free of WaterWorks

solution and completely dry. Pre filling the parts with clean water

prior to putting them in the WaterWorks tanks can help to avoid

absorbing WaterWorks solution into the parts. When possible, avoid

using sparse filled parts in the surface smoothing process.

• Completely dry parts prior to using the smoothing station. After the

parts are dry, inspect the surfaces that faced down during the drying

process. If there is evidence of a powdery residue from the

WaterWorks solution, rinse and dry the parts again before using the

smoothing station.

Finishing Touch Smoothing Station User Guide 3-13

Page 34

Smoothing Operation

The following information should be use to inspect parts prior to

smoothing:

• Inspect the part for build flaws, imbedded supports, or missing

geometry.

• Using your judgement lightly sand areas that could use some work

prior to utilizing the surface smoothing process. This may include

over sized seams, errant geometry blips etc. Do not spend a lot of time

pre-sanding.

• Do not use any type of cyanoacrylate glues (Super Glue) or epoxies on

parts prior to surface smoothing. The smoothing solution will dissolve

the glue. If a part needs repair prior to smoothing use a solvent

bonding process with solvents such as Weld-On®.

• Look for the best orientation to suspend the part. The parts should be

suspended so that it does not collect the smoothing solution while

being exposed. When solution is collected on or in a part, it is referred

to as “cupping”. This can cause damage to the part.

• Suspending the part once the orientation is determined. Look for a

suspension place on the part. Holes or cavities work well. If the part

does not have an obvious place to suspend if from, try one of the

following methods:

• Drill a small hole in the part so that the end of the suspension

hanger can be inserted into the hole. After the process is done, a

light sanding of the area with a small amount of glue will hide the

hole.

• Drill a 0.040-inch (0.102 cm) hole in or through the part. If possible

drill in a non-critical surface. Suspend the part from the hole. After

the process is done, drill the hole to 0.070-inch (0.178 cm) and

using a solvent bonding agent, insert a small piece of the same

color filament into the hole. Sand the filament smooth to the

surface.

It is advantageous to rotate some parts to different hanging points for

each exposure. If this is desired, plan ahead and locate the

appropriate number of hanging points.

3-14 Installation and Setup

Page 35

Masking

If desired, small holes and other features can be masked so the smoothing

solution does not effect them. This can be accomplished by applying a

water based masking material (modeling clay). This water-soluble

material can be pressed into any hole or over a feature and then removed

after the smoothing process.

Smoothing the Parts

The following information is important when smoothing parts in the

smoothing station:

• Suspend the part(s) in the cool/dry chamber of the smoothing station.

Allow the surface of the part to cool. This usually takes 10 to 15

minutes. The cooler the surface of the part, the better the reaction of

the smoothing solution is on the part.

• After cooling the part, open the smoothing chamber sliding door by

pressing on the foot switch. Use a slow deliberate decent, suspend the

part in the smoothing chamber so that the part is below the cooling

coils making sure not to touch the bottom or sides. Allow the part to

be exposed for 20 to 30 seconds. You should notice that the smoothing

solution collects on the part and begins to drip off. Once the dripping

has slowed or stopped, the smoothing process is complete. Lift the

part above the lower cooling coils and allow any remaining solution to

drip back into the smoothing chamber. Place the part back into the

cool/dry chamber. Release the foot switch, closing the smoothing

chamber lid, and then slide the top lid closed. Allow the part to cool/

dry for 10 to 15 minutes.

Do not lower or raise the part out of the smoothing chamber

rapidly. This will disturb the cold air blanket and allow smoothing

vapor to escape and be exhausted to the outside.

Do not lift the part above the top of the smoothing chamber. This

will allow solution fumes into the room.

• Repeated exposures of thin walled parts can cause warping or other

distortion. If the part has been exposed multiple times it is better to

allow it to dry over night and then inspect for additional exposure

needs.

• Once the part is smoothed leave the part in the cool dry rack

overnight. The parts will be dry to the touch in minutes, but it takes

several hours to fully cure.

Finishing Touch Smoothing Station User Guide 3-15

Page 36

Repeatability

The smoothing station has repeatable smoothing performance from part

to part. Once the process has been established and constantly repeated, all

parts will exhibit the same conformity.

Post Finishing Tips

• Inspect the part and if necessary, light sanding can be done on the

part. Sanding and smoothing can be done several times to obtain the

desired finish. Over smoothing and over sanding should be avoided.

• Cyanoacrylate (Super Glue®) glues can be used to join or repair

defects in parts.

• Thin walled parts should not exceed two smoothing cycles to avoid

warping the part.

• Place the part in the bead blaster (using recommended beads) and

using a sweeping motion 3 to 4 inches (7.62 cm to 10.16 cm) from the

part, burnish the entire part giving it a satin luster finish.

• Remove any masking by either picking it off, or placing the part in

luke warm water to dissolve it.

Post Finish Painting Tips

• Bead blasting is not required for parts that are going to be painted,

investment cast, or electroplated.

• Apply a coat of sand-able primer suitable for plastic to the part.

• The finish with colored ABS will diminish when burnishing. Spray

with a flat acrylic to bring back the color after burnishing.

• If necessary, apply smoothing putties (such as white putty from

Squadron products) to small areas. Allow the putty to dry so it can be

sanded to create a smooth finish.

• Wet sand primer to desired finish if required.

• Finish with a good quality spray paint suitable for use over plastic.

3-16 Installation and Setup

Page 37

Recommended Burnishing Process

Burnishing gives your parts an even smoother appearance and a matte

finish. Although this step is optional, it is recommended when a near

injection molded look is desired.

To prep your part for burnishing, first smooth your part using the

Smoothing Station, then lightly sand it. Smooth and sand your part again,

then smooth it a third time.

For burnishing, sand blasters (sometimes called bead blasters) are

available at tool supply stores. Choose one with the following

specifications:

• No > 30 psi or 2.068 bar at the spray nozzle

• Envelope size 1016 x 509 x 508 mm (40 x 22 x 20 in)

Stratasys recommends POLYHARD Type III bead media for burnishing

inside the sand blaster. Specify 20/30 bead screen size (0.841-0.595 mm or

0.0331- 0.0234 inches).

Order online at www.ustechnology.com/stratasys.

Effects of High Temperature

Parts that have been processed through the smoothing station should not

be subjected to high temperatures. This will cause the surface of the part

to expand more rapidly than the core of the part and blisters will result.

Finishing Touch Smoothing Station User Guide 3-17

Page 38

3-18 Installation and Setup

Page 39

Chapter 4: Troubleshooting

This chapter provides troubleshooting information for the

Stratasys Finishing Touch Smoothing Station.

Troubleshooting ______________________________________________________ 4-2

Frequently Asked Questions________________________________________ 4-2

System Will Not Start When the Cycle Start Button is Pressed ______ 4-2

Refrigeration Not Cooling or Does Not Have Inadequate Cooling 4-2

Excessive Frost or Ice on the Fin Coils ___________________________ 4-2

Smoothing Chamber Does Not Have Vapor or Vapor is Falling ___ 4-3

Troubleshooting Chart _____________________________________________ 4-4

Status Lights ___________________________________________________ 4-4

Ordering Supplies_____________________________________________________ 4-5

Smoothing Station Fluid ________________________________________ 4-5

Finishing Touch Smoothing Station User Guide 4-1

Page 40

Troubleshooting

Internal components of the smoothing station are powered by high

voltage. Improper servicing can cause electric shock. Only qualified

service personnel should service the smoothing station.

Frequently Asked Questions

System Will Not Start When the Cycle Start Button is Pressed

• Turn on the main power switch.

• Cycle start switch was pressed too quickly. The smoothing station will

not start until the PCL has come up. This takes a few seconds. Press

the button again.

• System not connected to a power source, or the power source breaker

is tripped.

• System circuit breaker is tripped.

Refrigeration Not Cooling or Does Not Have Inadequate Cooling

• The system is low on refrigerant. There is potentially a leak in the

refrigeration system. Contact your service representative. Only

qualified refrigeration personnel can inspect or repair the refrigeration

system, and replenish the coolant. Make sure that the coolant put into

the system matches the type indicated on the compressor.

Excessive Frost or Ice on the Fin Coils

• Excessive frost or ice on the coils can cause an insulation effect on the

coils. This can raise the temperature of the cold air blanket.

• Excessive frosting of the coils is defined by the finned coils being

frosted to the point of not being able to see the fins.

• Frost and ice on the coils are caused by humidity (Water) in the air.

Excessive humidity may not be able to be controlled by the

refrigeration defrost. If this is the case the system needs to be moved

to an area with less humidity (air-conditioned).

4-2 Troubleshooting

Page 41

Smoothing Chamber Does Not Have Vapor or Vapor is Falling

• Make sure the system is allowed to recover and stabilize the fluids

before preceding.

• The system in a shutdown mode. Check to see if the red light is

flashing or on steady.

• This system not heating properly. Internal heaters are high voltage.

Only qualified service personnel should attempt to service or replace

these heaters.

• Smoothing solution is contaminated with too much water. Excessive

moisture on the coils can cause the water separator to over flow into

the fluid storage container. If this happens repeatability water can

build up to the point that there is very little solvent in the system. In

this case drain the fluid storage tank and the water separator.

Replenish the tank with new solvent. Dispose of the drained water

properly according to local regulations.

Finishing Touch Smoothing Station User Guide 4-3

Page 42

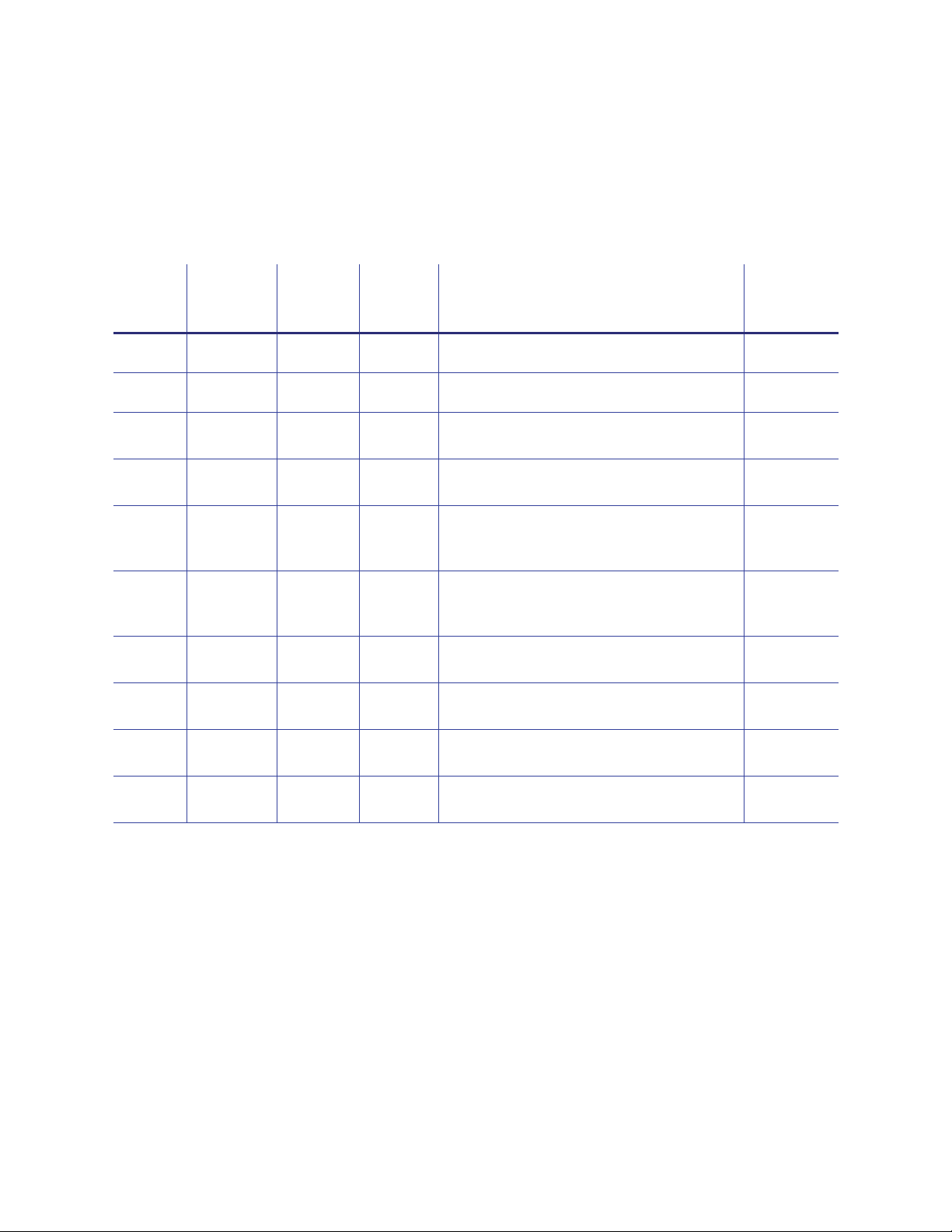

Troubleshooting Chart

Use the troubleshooting charts below to diagnose errors in the smoothing

station.

Status Lights

System

Status

(Green)

Flashing System is warning up.

Steady System is in ready to smooth parts.

Steady Low fluid in storage container.

Rapid

Rapid

Rapid

Flashing

Shut Down

Status

(Red)

Flashing System is shutting down. This is normal

Steady Shutdown of system is complete. This is

Flashing

Slow

System

Fault

(Amber)

Slow

Flashing

Flashing

Fluid

Status

(Amber) Error Condition

operation.

normal operation.

Replenish the fluid for normal

operation.

Fluid fault - Not enough fluid flow into

Flashing

High temperature condition (HTC). The

Unsafe vapor condition (SVC). Vapor

the vapor chamber, or the fluid valve is

not closing.

thermocouple from controller too hot.

level are too high in the system.

Restart

Method

Press Start

button

Press Start

button

Press Start

button

Cycle

breaker

Cycle

breaker

Rapid

Flashing

Rapid

Flashing

4-4 Troubleshooting

Rapid

Rapid

Flashing

Flashing

Refrigeration high pressure switch

open.

Refrigeration low pressure switch open. Cycle

Cycle

breaker

breaker

Page 43

Ordering Supplies

• USE ONLY MicroCare SSF as the smoothing station fluid. This

product can be ordered from your local MicroCare distributor. Use of

any other solution will void the warranty and is used at the user’s own

risk.

• Order two pails for the initial install of the system, and then usually

one pail at a time after that.

• The solution will last quite a while in the smoothing station, but the

amount of use and parts smoothed will determine actual usage.

• Read and under stand the MSDS information for the product. Follow

precautions as described in the MSDS.

Smoothing Station Fluid

Product name: SSF - Microcare SSF, Smoothing Station Fluid (part number

MCC-SSF0IP) can be ordered from the following company:

www.SmoothingFluids.com

MicroCare Corp.

595 John Downey Drive

New Britain, CT 06051

United States of America

Phone: 860.827.0626 or 800.638.0125

techsupport@microcare.com

MicroCare Europe bvba

Erasmuslaan 10

B-1804 Cargovil (Zemst) Belgium

Phone: 00 +32 2 251 95 05

techsupport@microcare.com

Randall Oliveiro, Marketing Director

Uniwes Technology (S) Pte Ltd

102E Pasir Panjang Road #03-01/02

Citilink Warehouse Complex

Singapore, 118529

randall_oliveiro@uniwes.com.sg

Phone: 011-65-6275-8183

Finishing Touch Smoothing Station User Guide 4-5

Page 44

4-6 Troubleshooting

Page 45

Chapter 5: Supplemental Information

This chapter contains the Stratasys Finishing Touch Smoothing

Station Limited Warranty Statement.

Stratasys Limited Warranty Statement

Stratasys Limited Warranty and Limitation of Liability

Stratasys, Inc. ("Stratasys") warrants its FINISHING TOUCHTM SMOOTHING STATION systems and

associated peripheral devices and replacement parts (collectively, the "Product") purchased from Stratasys

or an Authorized Stratasys Reseller to be free from defects in material and workmanship according to the

terms and conditions stated below:

Warranties extend only to the original purchaser of the Product. The warranty on the original Product, as

delivered, extends for one year starting on the date of delivery. Your sole remedy as purchaser under this

Limited Warranty shall be repair or replacement as provided herein.

To preserve your warranty rights, all FINISHING TOUCH SMOOTHING STATION Products must be installed

in accordance with the then-current User Guide available at www.stratasys.com. During the Limited

Warranty period, Stratasys or its designated representative will, at their option, repair or replace a defective

Product as set forth below. Service Parts and replacement Products will be furnished on an exchange basis,

and will be either new or refurbished. All replaced parts or replaced Products become the property of

Stratasys, and you will be invoiced for replacement parts if defective parts are not returned as directed by

Stratasys under this Limited Warranty.

Stratasys will bear the cost of returned parts, as well as for shipping new or rebuilt replacement parts to you,

provided that you report the warranty claim within the Limited Warranty period and obtain return instructions

from Stratasys prior to return. Replacement parts independently carry a 90-day warranty from date of

shipment from Stratasys or designated representative location. Consumable parts are not covered by this

Limited Warranty. Warranty services may be provided by Stratasys, an Authorized Reseller, or a third party

service provider designated by Stratasys.

No coverage or benefits under this Limited Warranty will exist if any of the following conditions apply:

(a) The FINISHING TOUCH SMOOTHING STATION Product has been subjected to abnormal use,

improper or inadequate maintenance, unauthorized modifications, unauthorized repair, misuse, abuse,

exposure to moisture, flooding, fire, electrical problems associated with incoming power, or other acts which

are not the fault of Stratasys, Inc.

(b) Stratasys' Customer Service Department was not notified of the defect or malfunction of the

FINISHING TOUCH SMOOTHING STATION system prior to expiration of the one-year warranty period.

Finishing Touch Smoothing Station User Guide 5-1

Page 46

(c) Parts or consumables were installed and used that were not certified or approved by Stratasys.

Stratasys approves only the solution sold under the name SSF-Microcare SSF as the smoothing station fluid to

be used in the FINISHING TOUCH SMOOTHING STATION Product. Use of any other solution will void the

warranty and is used at the user’s own risk.

Stratasys will not be liable under any circumstances for Product replacement or associated labor, part

replacement, loss of use, loss of profits, or for any other indirect, incidental, collateral, exemplary, punitive,

consequential or special damages, losses or injuries arising out of the use of any solvent not approved by

Stratasys as the fluid in the FINISHING TOUCH SMOOTHING STATION Product. Stratasys reserves the

right to refuse to furnish service or to warranty replacement parts on a FINISHING TOUCH SMOOTHING

STATION Product in which an unauthorized solvent was used.

Stratasys will also not be liable under any circumstances for Product replacement or associated labor, loss of

use, loss of profits, or for any other indirect, incidental, collateral, exemplary, punitive, consequential or

special damages, or losses arising out of the purchase of the FINISHING TOUCH SMOOTHING STATION

Products and/or out of this limited warranty, even if Stratasys or its designated representative have been

advised of the possibility of such damages or claims. To the extent such claims are not excludable as

adjudged by a court of competent jurisdiction; you agree to accept as sole and exclusive remedy, a

payment equal to the original purchase price for the product adjudged to be defective.

SOME COUNTRIES, REGIONS, STATES OR PROVINCES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF REMEDIES OR OF INCIDENTAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES, OR THE

APPLICABLE TIME PERIODS, SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU.

EXCEPT TO THE EXTENT LAWFULLY PERMITTED, THIS LIMITED WARRANTY DOES NOT EXCLUDE,

RESTRICT OR MODIFY, AND IS IN ADDITION TO THE STATUTORY RIGHTS APPLICABLE TO THE SALE OF

THIS PRODUCT TO YOU.

This warranty gives you specific legal rights and you might also have other rights that vary from country/

region to country/region, state to state, or province to province.

EXCEPT FOR THIS LIMITED WARRANTY, AND TO THE FULLEST EXTENT ALLOWED BY LAW, NEITHER

STRATASYS NOR ANY AUTHORIZED RESELLER MAKES ANY OTHER WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. STRATASYS DOES NOT OFFER, ASSUME OR AUTHORIZE THE OFFER OR

ASSUMPTION OF LIABILITY FOR IT OR FOR ANY OTHER WARRANTY, EITHER EXPRESS OR IMPLIED BY

ANY AUTHORIZED RESELLER OR OTHER INDEPENDENT THIRD PARTY.

5-2 Supplemental Information

Loading...

Loading...