Page 1

Part No. 401691-0001_REV_D

F123 Series

Shared Office 3D Printers

USER GUIDE

Page 2

LIABILITY STATEMENT

The information in this document is subject to change without notice. Stratasys, Inc. shall

not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material. Stratasys, Inc. makes

no warranty of any kind with regard to this material, including, but not limited to, the implied

warranties of merchantability and fitness for a particular purpose. It is the responsibility of

the system owner/material buyer to determine that the Stratasys material is safe, lawful,

and technically suitable for the intended application as well as identify the proper disposal

(or recycling) method consistent with local environmental regulations. Except as provided in

Stratasys' standard conditions of sale, Stratasys shall not be responsible for any loss

resulting from any use of its products described herein.

COPYRIGHT STATEMENT

This document is protected by copyright. All rights reserved. Its use, disclosure, and possession are

restricted by an agreement with Stratasys per software copyright. No part of this document may be

photocopied, reproduced or translated into another language without the prior written consent of Stratasys,

Inc.

All drawings and information herein are the property of Stratasys Inc. All unauthorized use and reproduction

is prohibited.

TRADEMARK ACKNOWLEDGMENTS

Stratasys, F123 Series, F170, F270, F370, GrabCAD, Insight and FDM are trademarks of Stratasys Ltd.

and/or subsidiaries or affiliates and may be registered in certain jurisdictions. All other product names and

trademarks are the property of their respective owners.

ii

Page 3

ABOUT THE F123 SERIES PRINTERS

The Stratasys F123 Series 3D printers incorporate the latest in innovative technology to

provide you with precise prototypes from a CAD design. Stratasys’ Fused Deposition

Modeling (FDM) technology provides prototype parts, including internal features, that can

be used to field-test form, fit, and function. Direct Digital Manufacturing (DDM) allows for the

creation of customized end-use parts straight from 3D CAD data. The F123 Series printers

feature a servo/belt driven XY gantry with multiple modeling material capability.

COMPONENTS

• The F123 Series Printer

• Material Package(s)

• Welcome Kit (containing documentation on how to download your user guide and common tools for

maintaining the printer)

• GrabCAD Print Software Package

• A Computer Workstation (not sold by Stratasys)

F170 HIGHLIGHTS

• Envelope Size: 10 x 10 x 10 inch (254 x 254 x 254 mm)

• Material Bays: 1 model, 1 support

• Touchscreen Graphical User Interface

• Wi-Fi capabilities

• Three USB ports (2 in front, 1 in back)

• Camera for remote monitoring

F270 HIGHLIGHTS

• Envelope Size: 12 x 10 x 12 inch (308 x 254 x 308 mm)

• Material Bays: 2 model, 2 support

• Touchscreen Graphical User Interface

• Auto changeover capabilities

• Wi-Fi capabilities

• Three USB ports (2 in front, 1 in back)

• Camera for remote monitoring

F370 HIGHLIGHTS

• Envelope Size: 14 x 10 x 14 inch (356 x 254 x 356 mm)

• Material Bays: 2 model, 2 support

• Insight Software Package

• Touchscreen Graphical User Interface

• Auto changeover capabilities

• Wi-Fi capabilities

• Three USB ports (2 in front, 1 in back)

• Camera for remote monitoring

iii

Page 4

ABOUT THIS GUIDE

This guide is your introduction to building prototypes and end-use parts using a Stratasys

3D production, rapid prototype system. It is designed as a learning and reference tool that

explains system operation in an easy to understand, step-by-step, process.

HOW TO USE THIS GUIDE

This guide is divided into easy-to-follow chapters. You can read this guide chapter by

chapter or use the Table of Contents when you need to quickly find specific information.

Keeping this guide close to your printer will efficiently allow you to troubleshoot and

maintain the printer.

CONVENTIONS USED IN THIS GUIDE

The following conventions are used in this guide:

• When you see text in this font, it indicates a button being pressed via the User Interface touchscreen.

For example, press the Queue

• When you see text in blue, it indicates that the text is a linked reference to a specific figure, table,

heading, or page number.

• Standard bold text is used to emphasize items within instructional sequences or indicate a

navigational path you must follow to locate/start a software application, open or save a file on your

workstation PC, or perform an operation when working with GrabCAD Print. The > character is used

to separate items within a navigational path. For example, navigate to File > Open from the Main

Menu.

button within the Navigation Menu.

REVISION LOG

0.

Revision Date Description of Changes

A January 2017 First release of this document

B February 2017 Updated manual tip calibration procedure

C April 2017 Updated Troubleshooting chapter, Warnings and Errors

D December 2017 Updated User Interface, troubleshooting, and procedures

iv

Page 5

TABLE OF CONTENTS

1 SERVICE AND SUPPORT ................................................................... 1

SERVICE.................................................................................................................................... 1

SOFTWARE SUPPORT............................................................................................................. 1

SAFETY INSTRUCTIONS ......................................................................................................... 2

Hazard Types .................................................................................................................................................... 2

Product Safety Signs ......................................................................................................................................... 2

Product Safety Label Locations......................................................................................................................... 3

Potential Safety Hazard Areas........................................................................................................................... 5

Door Locks......................................................................................................................................................... 6

General Safety Practices................................................................................................................................... 6

Environmental Requirements ............................................................................................................................ 6

2 PRINTER SETUP .................................................................................7

GENERAL INFORMATION ........................................................................................................ 7

Welcome Kit Contents ....................................................................................................................................... 7

BASIC SETUP.......................................................................................................................... 11

Stabilizing the Printer....................................................................................................................................... 11

Identifying Your Printer .................................................................................................................................... 12

Making the Network Connection...................................................................................................................... 13

Connecting the Power Cable........................................................................................................................... 13

Configuring the Network .................................................................................................................................. 14

Installing GrabCAD Print.................................................................................................................................. 19

Connecting to the F123 Series Printer............................................................................................................. 19

Setting the Printer’s Date and Time................................................................................................................. 19

Updating the Controller software Version........................................................................................................ 19

Adjusting the Tip Wipe Height ......................................................................................................................... 19

3 SYSTEM COMPONENTS ..................................................................20

PRINTER OVERVIEW ............................................................................................................. 20

Access Doors and Panels................................................................................................................................ 20

Interface Panel................................................................................................................................................. 22

OVEN COMPONENTS ............................................................................................................ 23

v

Page 6

Oven Door ....................................................................................................................................................... 23

Oven Light ....................................................................................................................................................... 25

Platen .............................................................................................................................................................. 26

Tip Wipe Assemblies ....................................................................................................................................... 27

Purge Chute .................................................................................................................................................... 28

MATERIAL BAY DRAWER COMPONENTS ........................................................................... 29

Material Bays................................................................................................................................................... 29

Material Drive Controller.................................................................................................................................. 30

Storage Drawer ............................................................................................................................................... 31

GANTRY .................................................................................................................................. 32

Print Heads...................................................................................................................................................... 33

MODELING MATERIALS......................................................................................................... 34

Materials Used ................................................................................................................................................ 34

Material Spool Memory Chip ........................................................................................................................... 35

Tips and Slice Height....................................................................................................................................... 36

SOFTWARE............................................................................................................................. 37

Controller Software.......................................................................................................................................... 37

GrabCAD Print Software ................................................................................................................................. 37

Insight Software............................................................................................................................................... 37

4 USER INTERFACE ............................................................................ 38

OVERVIEW.............................................................................................................................. 38

Navigation Menu.............................................................................................................................................. 39

Display Area .................................................................................................................................................... 40

WORKING WITH THE BUILD PAGE....................................................................................... 40

Loading a File .................................................................................................................................................. 41

Viewing Print Job Information.......................................................................................................................... 45

Build Status Display......................................................................................................................................... 46

Print Job Controls ............................................................................................................................................ 48

WORKING WITH THE QUEUE PAGE..................................................................................... 50

Adding a Job to the Job Queue ....................................................................................................................... 51

Editing the Job Queue ..................................................................................................................................... 55

Viewing Job Details ......................................................................................................................................... 57

About the Sample Queue ................................................................................................................................ 59

WORKING WITH THE MATERIALS PAGE ............................................................................. 60

Head Status Icons ........................................................................................................................................... 61

Viewing Head Details ...................................................................................................................................... 63

Material Status Icons ....................................................................................................................................... 66

Viewing Material Details .................................................................................................................................. 69

Material Load Controls .................................................................................................................................... 70

vi

Page 7

WORKING WITH THE TOOLS PAGE ..................................................................................... 76

Tools Page Menu ............................................................................................................................................ 77

Navigation Overview........................................................................................................................................ 78

Settings............................................................................................................................................................ 79

Calibration ....................................................................................................................................................... 89

Maintenance.................................................................................................................................................... 91

Network ........................................................................................................................................................... 95

Power ............................................................................................................................................................ 101

Light............................................................................................................................................................... 104

5 OPERATING THE PRINTER ........................................................... 105

BASIC USER OPERATIONS................................................................................................. 105

Powering ON the Printer................................................................................................................................ 105

Powering OFF the Printer.............................................................................................................................. 107

LOADING MATERIAL ............................................................................................................ 108

Material Spool Preparation ............................................................................................................................ 108

Material Spool Installation ............................................................................................................................. 109

UNLOADING MATERIAL ...................................................................................................... 113

Removing Material Spools............................................................................................................................. 114

Material Auto Changeover............................................................................................................................. 115

Handling/Storing Materials ............................................................................................................................ 116

HEAD REPLACEMENT ......................................................................................................... 117

Replacing a Standard Head .......................................................................................................................... 117

Replacing a PLA Head .................................................................................................................................. 119

BASIC JOB BUILD TASKS .................................................................................................... 120

Before a Build ................................................................................................................................................ 120

Preparing the Printer ..................................................................................................................................... 120

Selecting a Job to Build ................................................................................................................................. 122

Information Available During a Build ............................................................................................................. 123

Build Warnings .............................................................................................................................................. 124

Pausing a Build.............................................................................................................................................. 125

Aborting a Build ............................................................................................................................................. 126

After a Build is Complete ............................................................................................................................... 128

CHANGING PRINTER DEFAULTS ....................................................................................... 130

Job Storage ................................................................................................................................................... 130

Part Build Location ........................................................................................................................................ 131

Display Units.................................................................................................................................................. 132

Oven Temperature Control............................................................................................................................ 134

Touchscreen Display Brightness ................................................................................................................... 134

Display Language.......................................................................................................................................... 135

PRINTER STATUS ................................................................................................................ 136

vii

Page 8

Head Odometer Status.................................................................................................................................. 136

Materials Status............................................................................................................................................. 136

Temperature Status....................................................................................................................................... 138

Software Version ........................................................................................................................................... 139

6 CALIBRATION AND ADJUSTMENTS ............................................. 140

TIP CALIBRATION................................................................................................................. 141

Automatic Tip Calibration .............................................................................................................................. 142

Manual Tip Calibration................................................................................................................................... 144

TOUCHSCREEN CALIBRATION........................................................................................... 154

XY GANTRY CALIBRATION.................................................................................................. 156

Z ZERO CALIBRATION ......................................................................................................... 156

TIP WIPE HEIGHT ADJUSTMENT........................................................................................ 157

7 MAINTENANCE ............................................................................... 158

UPDATING CONTROLLER SOFTWARE.............................................................................. 158

GrabCAD Print Method.................................................................................................................................. 158

Insight Software Method................................................................................................................................ 158

EXPORTING SYSTEM CONFIGURATION (.CFG) FILE....................................................... 162

MAINTENANCE SCHEDULE................................................................................................. 163

WEEKLY MAINTENANCE ..................................................................................................... 164

Cleaning the Oven Chamber ......................................................................................................................... 164

Cleaning the Platen ....................................................................................................................................... 164

MONTHLY MAINTENANCE................................................................................................... 165

Clean/Inspect Tip Wipe Assemblies .............................................................................................................. 165

AS NEEDED MAINTENANCE ............................................................................................... 167

Cleaning the Exterior Surface of the Printer .................................................................................................. 167

Cleaning the Touchscreen Display................................................................................................................ 167

Inspecting and cleaning the tip shields.......................................................................................................... 167

Cleaning the Oven Door glass Surfaces ....................................................................................................... 168

CUSTOMER REPLACEABLE UNITS.................................................................................... 169

Powering Off.................................................................................................................................................. 169

Rear Panel..................................................................................................................................................... 170

Right and Left Side Panels ............................................................................................................................ 171

Front Top Cover ............................................................................................................................................ 173

Rear Top Cover ............................................................................................................................................. 174

viii

Page 9

3.3/5/12 VDC ATX Power Supply.................................................................................................................. 175

Oven Thermistor............................................................................................................................................ 176

Material Bays................................................................................................................................................. 177

Replacing a Head .......................................................................................................................................... 180

Head Ribbon Cables ..................................................................................................................................... 181

Touchscreen Display ..................................................................................................................................... 184

Right and Left Side Oven Blowers................................................................................................................. 186

Oven Door Gasket......................................................................................................................................... 188

Z Drive Belt.................................................................................................................................................... 189

Y Bellows....................................................................................................................................................... 191

Oven Light ..................................................................................................................................................... 193

Oven Door Camera ....................................................................................................................................... 195

Oven Door Latch ........................................................................................................................................... 197

Y Blocks......................................................................................................................................................... 200

Top Cover Interlock Sensor and Actuator ..................................................................................................... 202

8 TROUBLESHOOTING ..................................................................... 204

GETTING HELP..................................................................................................................... 204

WARNINGS AND ERRORS................................................................................................... 205

Warnings at Build Start.................................................................................................................................. 205

Errors Preventing a Build from Starting ......................................................................................................... 207

Load/Unload Errors ....................................................................................................................................... 210

Build Pause Warnings ................................................................................................................................... 212

Build Abort Errors .......................................................................................................................................... 214

Head Warnings.............................................................................................................................................. 216

Head Errors ................................................................................................................................................... 216

FINDING A REMEDY............................................................................................................. 217

9 SUPPLEMENTARY INFO ................................................................. 219

DECLARATION OF CONFORMITY....................................................................................... 219

REGULATORY AND ENVIRONMENTAL INFORMATION.................................................... 219

EMC Class A Warning .................................................................................................................................. 219

FCC Statements (U.S.A.) .............................................................................................................................. 219

Canada Electromagnetic compatibility (EMC) ............................................................................................... 220

MSDS (Material Safety Data Sheet).............................................................................................................. 220

Disposal of waste equipment by users in private households in the European Union .................................. 220

ix

Page 10

1 SERVICE AND SUPPORT

This chapter provides information on service and support for the F123 Series as well as safety information and

safety label locations.

SERVICE

If you have a problem with your printer that is not covered in this guide, please contact Stratasys Customer

Support. Contact information is available from the Stratasys website at: http://www.stratasys.com/customer-

support/contact-customer-support.

When calling in for service, always have your printer’s software version (see “Software Version” on page 139)

and hardware serial number available (see “Identifying Your Printer” on page 12). You may also need access to

GrabCAD Print to provide a configuration file from your hardware (see “Exporting System Configuration (.CFG)

File” on page 162).

SOFTWARE SUPPORT

If you have a software problem that is not covered in this guide, please contact Stratasys Customer Support.

Contact information is available from the Stratasys website at: http://www.stratasys.com/customer-support/

contact-customer-support.

When calling in for service, always have your printer’s software version (see “Software Version” on page 139)

and printer serial number available (see “Identifying Your Printer” on page 12). You may also need access to

GrabCAD Print to provide a configuration file from your hardware (see “Exporting System Configuration (.CFG)

File” on page 162).

1

Page 11

SAFETY INSTRUCTIONS

The following basic safety tips are given to ensure safe installation, operation, and maintenance of Stratasys

equipment and are not to be considered as comprehensive on matters of safety. The F123 Series printers are

designed to be safe and reliable rapid prototyping printers. Access to areas of the printer are potentially

dangerous.

HAZARD TYPES

Stratasys recommends that all services be performed by qualified personnel. All personnel working on or

around the printer should be knowledgeable of what the following hazard classifications mean throughout this

guide.

• Warnings and Cautions precede the paragraph to which they pertain.

Warning: Indicates a potentially hazardous situation which, if not avoided, may

result in injury or death.

Caution: Indicates a situation which, if not avoided, could result in damage to

equipment.

• Notes follow the relative paragraph.

Note: Indicates additional information relative to the current topic.

PRODUCT SAFETY SIGNS

Note: Always read and adhere to safety statements, and be aware of the

following safety signs when you see them on the printer.

Stratasys makes every effort to ensure that our printers are safe and reliable at all times. However, there will be

times when you must access areas of the printer where potentially high voltages, hot temperatures, and/or

moving mechanical components could cause severe injury.

High Voltage: The high voltage sign indicates the presence of high voltages.

Always stay away from any exposed electrical circuitry. It is recommended that

all jewelry be removed.

Hot Surface: The hot surface sign indicates the presence of devices with high

temperatures. Always use extra care when working around heated components.

Always wear the safety gloves provided in the Welcome Kit.

Gloves: The gloves sign indicates that if you enter the area specified by the

symbol you must wear safety gloves (provided in the Welcome Kit) which have

been approved for high temperatures.

2

Page 12

Crushed Hand: The crushed hand sign indicates that a hazard exists where you

could get your hand crushed between two objects. One or more objects move in

the area that you are working.

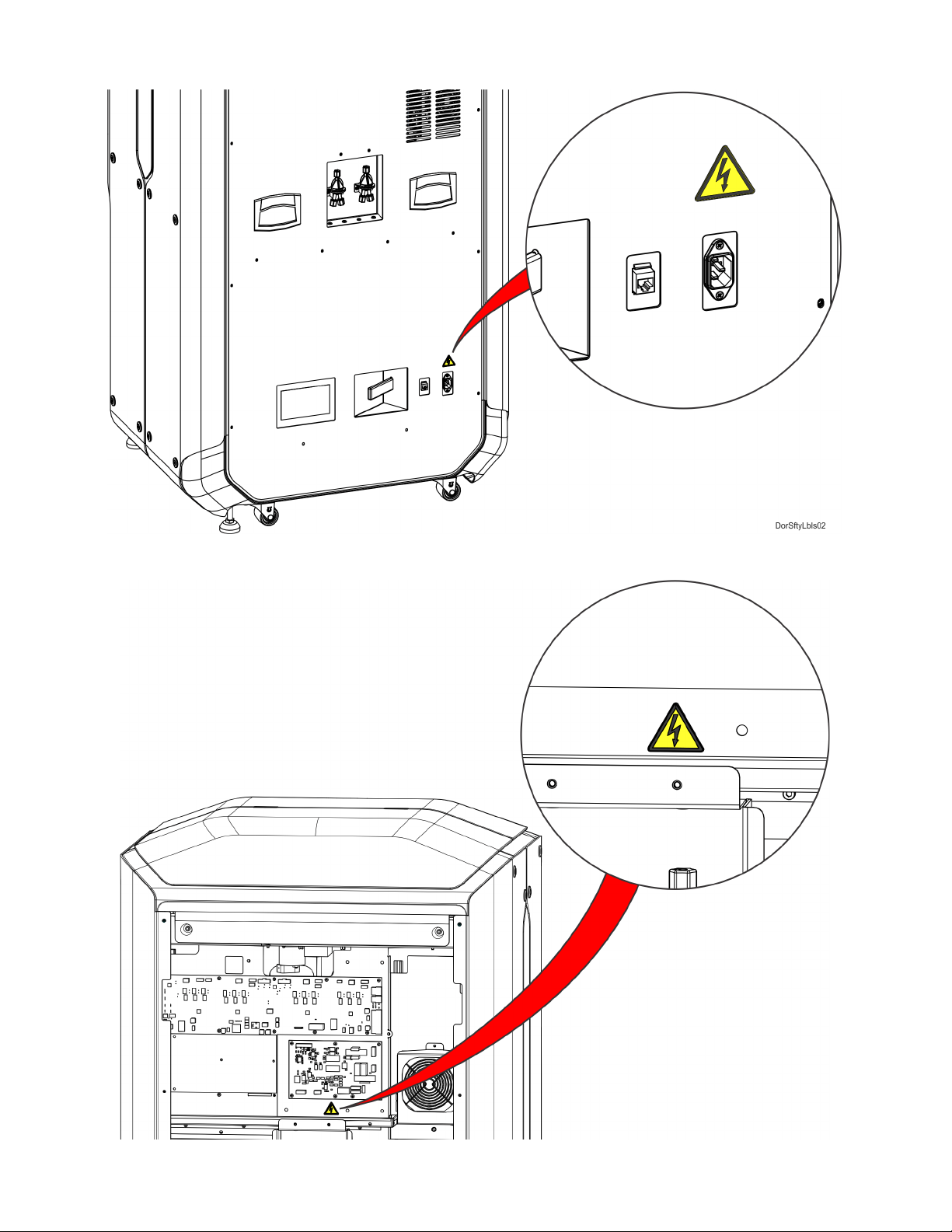

PRODUCT SAFETY LABEL LOCATIONS

Figure 1-1: Oven safety label locations

3

Page 13

Figure 1-2: Rear panel safety label locations

Figure 1-3: Electrical panel safety label locations

4

Page 14

POTENTIAL SAFETY HAZARD AREAS

The following components and areas of the printer are highlighted as potential safety hazards that may cause

system failure or reliability problems if proper safety procedures are not followed.

OVEN

Warning: Always wear safety gloves and long sleeves when working inside the

oven. Components are hot.

Note: Opening the oven door shuts the oven heaters off.

GANTRY

Warning: Never wear a tie, loose clothing or dangling jewelry when working

around moving components of the printer.

Beneath the top cover of the printer is the gantry. This area houses the

mechanical drive components of the X and Y axes. Use extreme caution

whenever accessing this area of the printer.

Z STAGE

Note: The printer’s servo motors are disabled when the oven door and/or top

cover are open. The XY pinch hazard between the timing belts and pulleys is

minimized by locking the oven door and top cover while building and disabling

the motors when the oven door and top cover are open. The oven door and top

cover automatically lock when the printer is building and cannot be opened

while the printer is building. You cannot start a build if the oven door or top

cover are open.

Warning: Never wear a tie, loose clothing or dangling jewelry when working

around moving components of the printer.

The drive belt, pulleys and Z stage servo motor can cause severe injury. The Z

stage crushing hazard is minimized by locking the oven door during Z stage

moves and disabling the Z motor when the oven door is open.

5

Page 15

DOOR LOCKS

Interlock switches are used to communicate the status of the oven door and the top cover to the printer. For

safety reasons, the oven door and top cover must be closed before the X, Y, and Z motors will operate.

GENERAL SAFETY PRACTICES

Abide by these general safety practices when working with this printer.

High Voltage: High voltage is present in the printer.

Warning: Only use an OSHA or CE approved step stool when accessing the

area under the top cover of the printer.

Warning: Always wear safety gloves and long sleeves when working inside the

oven. Components are hot.

ENVIRONMENTAL REQUIREMENTS

• The F123 Series printer is for indoor use only.

• Air quality conditions with excessive solid particulates (conductive or non-conductive) may

result in system damage.

• Air quality conditions in which airborne oils are allowed to accumulate on or within the printer

can damage the plastic components.

• System operating temperature shall be in the range of 59°F to 86°F (15°C to 30°C), with

relative humidity range of 30% to 70% non-condensing.

• System storage temperature shall be in the range of 32°F to 95°F (0°C to 35°C), with relative

humidity range of 20% to 90% non-condensing.

• Altitude shall not exceed 6561.68 feet (2000 m).

• Material storage shall be in the range of 55°F to 86°F (13°C to 30°C), with relative humidity less

than 70%.

• Noise emission (acoustic):

• <32dBA when idle

• <46dBA when building

6

Page 16

2 PRINTER SETUP

1

2

3

4

OR

US Cable

This chapter describes basic setup of the F123 Series.

GENERAL INFORMATION

WELCOME KIT CONTENTS

The printer’s Welcome Kit contains the Welcome Insert document and common tools you will need to maintain

the printer. Use the following figures and tables to identify the contents of the Welcome Kit.

Figure 2-1: Welcome Kit Contents - Documents and Cables

Euro Cable

Table 2-1: Key for Figure 2-1

Welcome Insert

1

Document

RJ45 Cable This cable is used to establish a network connection between the F123 Series printer and

2

3 USB Flash Drive The printer features 3 USB ports (see Figure 3-3 on page 22 for port locations). As an

4 AC Cable (US or

Euro)

Contains instructions for downloading the F123 Series User Guide (this document).

your Ethernet network. See “Making the Network Connection” on page 13.

alternate method to sending job files to the printer via GrabCAD Print, this flash drive can

be used to store processed job files which you build frequently (see “Adding a Job to the

Job Queue” on page 51).

This cable provides the power connection to the printer. See “Connecting the Power

Cable” on page 13. When connecting the cable, select the cable appropriate for your

location (US cable or Euro cable).

7

Page 17

Figure 2-2: Welcome Kit Contents - Tools

1

2

3

4

5

6

Table 2-2: Key for Figure 2-2

Leather

1

Safety

Gloves

2 Needle

Nose Pliers

(extra slim)

3 Needle

Nose Pliers

1

/8)

(7

4 5” Cutters These are used to cut a material spool’s filament when unloading and removing materials from the

5 Loupe

Magnifier

6 Scraper This tool is used to scrape parts or material off the substrate.

Printer components may be extremely hot. To prevent burns or other injuries, these gloves should

be worn any time you see the gloves safety sign throughout this document. See “Product Safety

Signs” on page 2.

Occasionally, you may need to use pliers to aid in the clearing of debris which have accumulated

on the head and/or tips (see “Clean/Inspect Tip Wipe Assemblies” on page 165).

Occasionally, you may need to use pliers to aid in the clearing of debris which have accumulated

on the head and/or tips (see “Clean/Inspect Tip Wipe Assemblies” on page 165).

printer. See “Unloading Material” on page 113.

This tool is included to aid you with performing a Manual Tip Calibration which requires you to view

small toolpath relationships. See “Manual Tip Calibration” on page 144.

8

Page 18

Figure 2-3: Welcome Kit Contents - Cleaning Supplies & Storage Materials

1

2

3

Table 2-3: Key for Figure 2-4

Touchscreen

1

Cleaning Kit

2 Microfiber Cloth Various components of the printer may become dirty and occasionally need to be cleaned.

3 Resealable Bag (x6) When unloaded, non-empty model and support material spools should be stored within these

From repeated use, the touchscreen may become dirty and occasionally need to be cleaned.

Only use suitable LCD cleaning agents when cleaning the touchscreen. See “Cleaning the

Touchscreen Display” on page 167 for cleaning instructions.

Only use a suitable microfiber cloth to clean these components. See “Cleaning the Exterior

Surface of the Printer” on page 167 for cleaning instructions using this cloth.

bags to prevent moisture from contacting the spool’s filament (see “Handling/Storing

Materials” on page 116).

9

Page 19

Figure 2-4: Additional Components - Startup Materials

1

2-4

5

6

The following items are not located within the Welcome Kit. Instead, they can be found within the oven chamber

and the storage drawer. The items found within the oven chamber must be removed before powering the printer

ON.

Table 2-4: Key for Figure 2-4

1 Substrate (x16) A substrate is the surface upon which a part is built. The same substrate is used for all model materials,

2 ABS Model Material

3 QSR Support

4 PLA Material Spool

5 PLA Model Head Print head for use with PLA model material only (see “Print Heads” on page 33).

6 PLA Cooling Module Cooling module to be used in conjunction with the PLA model head (see “Print Heads” on page 33).

including PLA. See “Preparing the Printer” on page 120 for more information.

Material spool containing 60 in

Spool

Material spool containing 60 in

Material Spool

Material spool containing 60 in

3

(984 cc) of ABS model material (see “Materials Used” on page 34).

3

(984 cc) of QSR support material (see “Materials Used” on page 34).

3

(984 cc) of PLA material (see “Materials Used” on page 34).

10

Page 20

BASIC SETUP

Jackscrew

Locknut

Follow the Site Preparation Guide to ensure that your facility is effectively and safely prepared for printer

installation. Do not proceed with the following sections until the “Unpacking the Printer” section of the Site

Preparation Guide has been completed. When installation is complete, perform the following setup tasks.

• Verify that the startup materials have been removed from the oven chamber. If not, remove these

items. See “Additional Components - Startup Materials” on page 10 for details on the startup

materials.

• Open the top cover and ensure that the orange clip has been removed from the X belt, and the

orange tie wrap has been removed from the X motor. If not, remove the orange clip and/or orange tie

wrap securing these components.

STABILIZING THE PRINTER

Caution: The stability pads are used to stabilize the printer after it has been

moved to its desired operating location. The stability pads must be set prior to

printer operation.

To stabilize the printer:

1. Roll the printer to its desired operating location and verify that minimum space requirements

have been met.

Side Clearance Minimum 4 inches (10.16 cm) on each side

Rear Clearance Minimum 6 inches (15.24 cm)

Front Clearance Minimum 20 inches (50.80 cm)

Overhead Clearance Minimum 20 inches (50.80 cm)

2. Thread the stability pad jackscrew downward until the stability pad makes contact with the floor

(see Figure 2-5).

3. Turn the jackscrew an additional 1-2 turns downward and set the locknut firmly against the lower

frame member (see Figure 2-5).

Note: Ideally, each caster wheel will remain in slight contact with the floor and

using minimal force, be able to be rotated.

4. Repeat step 2 and step 3 to set all remaining stability pads.

Figure 2-5: Stability Pad Jackscrew Adjustment

11

Page 21

IDENTIFYING YOUR PRINTER

Serial Number Tag

Use the following tags to identify your printer:

• Serial Number Tag - Refer to this number when requesting service. You can also locate the printer’s

serial number via the Maintenance page of the User Interface (see “Serial Number” on page 94 for

more information).

• Model Tag - The printer’s model number, part number and power requirements are given on this tag.

This tag also lists all patent numbers associated with the printer, some FCC compliance information,

voltage warnings, and the Stratasys web address.

Both tags are located on the back side of the printer near the bottom, and are typically placed near the printer’s

power connection. Use the information on these tags when identifying your printer with Customer Support.

Figure 2-6: ID Tag Locations

12

Page 22

MAKING THE NETWORK CONNECTION

Ethernet Network

Power Cable

Connection

Processed job files can be transferred from GrabCAD Print to the F123 Series printer through your facility’s

Ethernet network. An RJ45 network connector is located on the right, rear corner of the printer (as viewed from

the rear). See Figure 2-7 for the network connection location.

Note: A 15 foot (4‘.6m) network patch cable is supplied with the printer and

located in the welcome kit. Facilities having network connection points

further from the printer than can be reached by the supplied cable are

responsible for the procurement of an appropriate cable.

CONNECTING THE POWER CABLE

To connect the power cable:

1. Connect the male end of the supplied power cord (US or Euro) directly into a grounded electrical

outlet.

2. Connect the female end of the power cord directly into the socket located on the back of the

printer (see Figure 2-7).

Warning: The power cord serves as the disconnect device. The socket outlet

must be easily accessible.

Figure 2-7: Rear Connections

13

Page 23

CONFIGURING THE NETWORK

This section is provided in case you need to change your network settings. Within the Network page you can set

your printer’s address type to Static, Dynamic (DHCP), or Wi-Fi; Dynamic is selected by default.

• Static address - you must enter an IP address, subnet mask, and gateway address for the printer

(provided by the system administrator). Once entered, the address will not change.

• Dynamic address (DHCP) - a network server or PC will generate an IP address for the printer. A

different IP address may be generated from time to time by the server or PC.

• Wi-Fi address - the printer will scan for and allow you to connect to an available Wi-Fi network (if the

Wi-Fi dongle has been installed).

NETWORK ADDRESS CONFIGURATION

To configure your printer’s network address settings:

1. Power ON the printer, see “Powering ON the Printer” on page 105.

2. Open the Tools page by pressing the To ol s button within the Navigation Menu (see Table 4-1 on

page 39).

3. Open the Network page by pressing the Network button within the Tools page (see Figure 4-34

on page 76).

4. The Connection Type row allows you to select between a wired or wireless network. The option

selected will determine the configurable settings displayed within the Network page.

• Selecting the Wired option will allow you to select between a Dynamic or Static network mode.

• Selecting the Wireless option will configure the pinter to use a Wi-Fi network. You will need to scan

for a wireless network and enter the security settings for the selected network (if required) to

complete the configuration. Please note that the availability of the Wireless option depends upon the

configuration purchased with your printer.

5. After selecting the radio button corresponding to the connection type you’d like to use (wired or

wireless) press the Back button in the upper-left corner of the page to return to the Network page.

6. For wired networks:

A. The Network Mode row will be displayed. Press anywhere within this row.

B. Select either the Static or Dynamic radio button to enable that network address type.

Depending on the option selected, you may need to configure additional information within

the Network page.

Figure 2-8: Wired Network Selection

14

Page 24

• If the Static option is enabled, you must manually configure the IP Address, Subnet Mask, and

Gateway Address fields.To configure this information simply touch a field on the screen to select

it and then use the keypad displayed to enter address information.

• Touch anywhere on the screen outside of the keypad to exit and close the keypad.

Figure 2-9: Static Network Configuration

• Scroll to the bottom of the page and press the Apply button when finished to save the

network configuration.

• Press the Back button in the upper-left corner of the page to return to the Network page.

Figure 2-10: Apply Changes Button

15

Page 25

• If the Dynamic option is enabled, no additional configuration is necessary as a network server or

PC will automatically generate an IP address for the printer. A different IP address may be

generated from time to time by the server or PC; the generated IP address will be displayed

within the IP Address field of the Network page, and corresponding Subnet Mask and Gateway

Address information will also be displayed.

• Press the Back button to exit the page and return to the Tools page.

Figure 2-11: Dynamic Network Configuration

7. For wireless networks:

A. The Available Networks row will be displayed (Wi-Fi dongle must be installed). Press

anywhere within this row.

B. Press the Scan button; the printer will scan for an available wireless (Wi-Fi) network.

16

Page 26

Figure 2-12: Scan for Wireless Network

C. A list of available networks will be displayed; select the wireless network you’d like to

connect to by pressing anywhere within the row.

D. A page will be displayed containing the details of the selected Wi-Fi network. Within this

page use the keyboard to enter the password and/or username required to connect to the

network.

Figure 2-13: Enter Wi-Fi Network Information

17

Page 27

E. When finished, touch anywhere on the screen outside of the keypad to exit and close the

keypad.

F. Scroll to the bottom of the page and press the Connect button to save the network

configuration.

Figure 2-14: Connect Button

G. Press the Back button to exit the page and return to the Network page. The name of the

selected wireless network will be displayed within the Available Networks row.

H. Press the Back button to exit the page and return to the Tools page. The Network button will

refresh and a blue indicator will be displayed indicating that the printer is configured for a

Wi-Fi network.

Figure 2-15: Enter Network Settings Dialog

18

Page 28

INSTALLING GRABCAD PRINT

Install the GrabCAD Print software on a facility workstation. Navigate to http://help.grabcad.com/article/197-

sign-up-download-and-install and follow the on-screen instructions.

CONNECTING TO THE F123 SERIES PRINTER

Add the F123 Series printer to the GrabCAD Print application. Navigate to http://help.grabcad.com/article/198-

connect-your-printers and follow the on-screen instructions.

SETTING THE PRINTER’S DATE AND TIME

In order to ensure accurate build times, the printer’s clock must be set correctly. If you find that your printer’s

date and/or time are incorrect you can update them using GrabCAD Print. To do so, navigate to

http://help.grabcad.com/article/196-printer-firmware-management and follow the procedure for “Changing your

printer’s clock time”.

UPDATING THE CONTROLLER SOFTWARE VERSION

Update the Controller Software if necessary. See “Updating Controller Software” on page 158.

ADJUSTING THE TIP WIPE HEIGHT

If necessary, adjust the tip wipe height. See “Tip Wipe Height Adjustment” on page 157.

19

Page 29

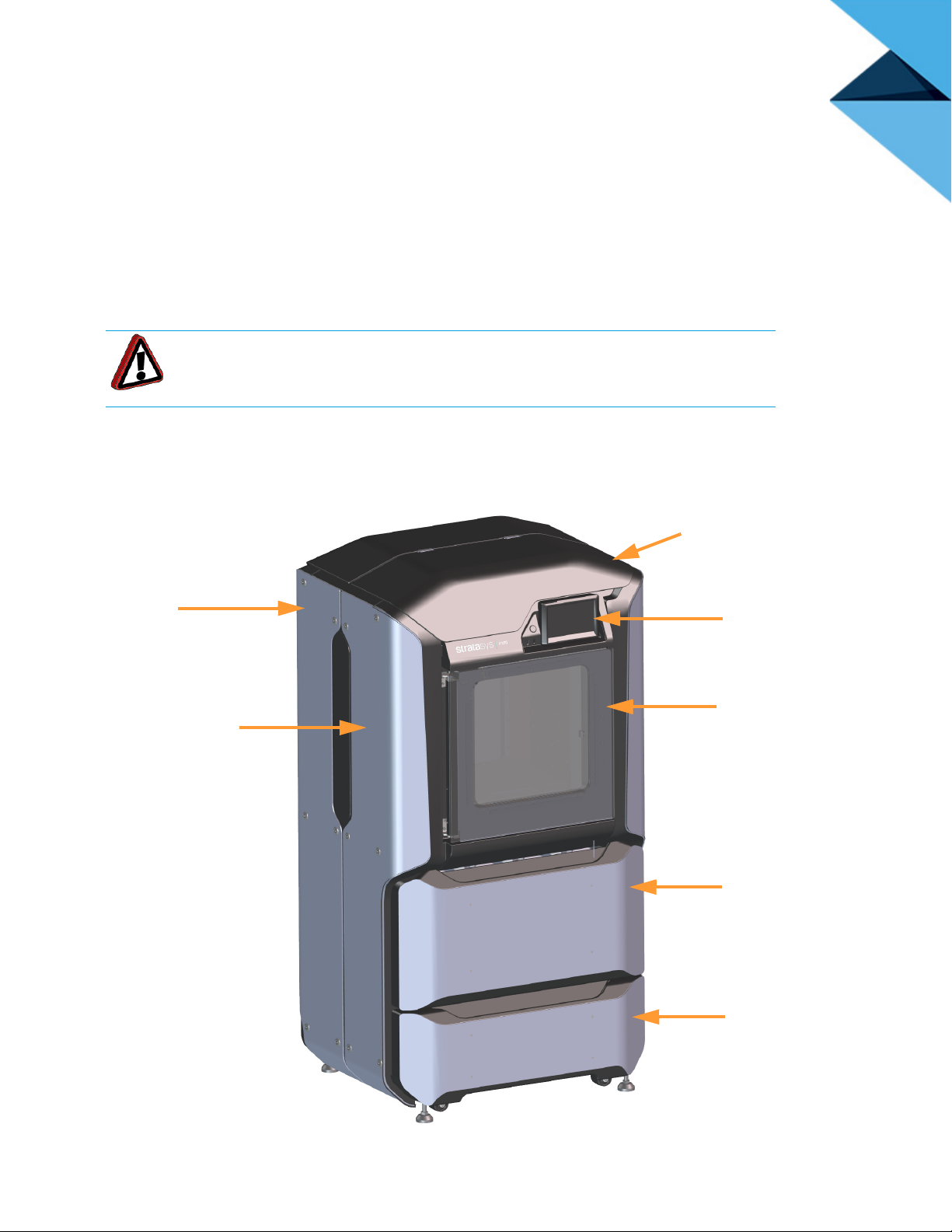

3 SYSTEM COMPONENTS

To p C o ve r

Material

Bay

Drawer

Oven Door

Interface Panel

Front Side Panel

(left & right)

Storage

Drawer

Rear Side Panel

(left & right)

This chapter describes the components of the F123 Series. Information regarding the materials and tips that

can be used by the printer is also included in this chapter.

PRINTER OVERVIEW

ACCESS DOORS AND PANELS

Warning: Do not energize when the rear panel is not secured in place.

This printer has been designed to allow easy access to the most frequently accessed areas on the system.

Doors and panels are highlighted in Figure 3-1 and Figure 3-2.

Figure 3-1: Access Doors and Panels - Front View

20

Page 30

Figure 3-2: Access Doors and Panels - Rear View

Rear Panel

TOP COVER

Allows access to the gantry and head assemblies.

OVEN DOOR

Allows access to the platen, tip wipe assemblies, purge area, and completed parts for removal. The printer’s

camera is also housed within the oven door.

MATERIAL BAY DRAWER

Allows access to the material bay components (material bays, material spools, and the material drive

controllers).

STORAGE DRAWER

Provides a built-in area which can be used for miscellaneous storage of spare parts, tools, etc., as needed.

RIGHT & LEFT SIDE PANELS

The right and left side panels provide access to the oven chamber fans.

REAR PANEL

The rear panel provides access to the electronics bay.

21

Page 31

INTERFACE PANEL

Touchscreen

User Interface

Power Button

Front USB Ports, 1 Additional in Rear

The interface panel houses the printer’s touchscreen user interface, power button, and USB ports.

Figure 3-3: Interface Panel

TOUCHSCREEN USER INTERFACE

Allows for user control of the printer. From the User Interface you can access various screens to select jobs for

building, control jobs in the process of being built, change materials, perform calibrations, and configure your

printer’s settings and maintenance options. The touchscreen visually displays the operational state of the printer

as well as any warning information available.

See “4 User Interface” on page 38 for detailed information on the components and pages of the User Interface.

POWER BUTTON

Allows you to power the printer ON and OFF (see “Powering ON the Printer” on page 105 and “Powering OFF

the Printer” on page 107 more information).

USB PORTS

The printer’s USB ports allow you to easily upload job files to be built. After plugging a USB flash drive into any

of the USB ports you can access the flash drive’s contents via the Queue page (see “Working with the Queue

Page” on page 50 for details).

22

Page 32

OVEN COMPONENTS

Tip Wipe

Assemblies

(model left,

support right)

Platen

Oven Door

Camera

Oven

Light

Purge

Chute

Oven

Door

Gasket

The oven consists of the oven door and everything that you see through the oven door window, including the

platen, tip wipe assemblies, purge chute, and oven heaters. The printer’s camera is housed within the frame of

the oven door.

Figure 3-4: Oven Components

OVEN DOOR

The oven door (see Figure 3-4) utilizes an electromagnetic lock along with optical sensors. The oven door

remains locked while the printer is building and automatically unlocks when it is safe for you to access the

components of the oven. You cannot open the oven door when the printer is building. The top cover will

automatically unlock in conjunction with the oven door, allowing you to manually open the top cover. The oven

door must be open prior to opening the top cover. The oven door gasket, which runs around the perimeter of the

oven door frame, helps to provide an airtight seal when the oven door is closed.

The oven door window is composed of 2 panes of tempered glass.

23

Page 33

CAMERA

The printer’s camera is housed within the frame of the oven door and provides remote monitoring capabilities

while a part is building. Using the GrabCAD Print application installed on your workstation PC, you can view the

part as it is building allowing you to remotely monitor part build quality. Pictures are automatically taken at a set

interval via GrabCAD Print. Please note that the camera image displayed will include some reflection as a result

of the oven door’s glass.

Figure 3-5: Camera Location

24

Page 34

OVEN LIGHT

Oven Light

A single light pipe is mounted on the front upper edge of the oven and is used to illuminate the oven chamber

(Figure 3-6). The light pipe consists of nine high-temperature LEDs; each LED is rated at 1-watt. The oven light

is powered by 12 VDC.

The Light button within the Tools page indicates the current state of the oven light and allows you to manually

turn the light ON of OFF (see “Light” on page 104).

Figure 3-6: Oven Light Location

25

Page 35

PLATEN

Platen

Tip Offset

Calibration

Targets

The steel platen provides the level surface on which parts are built. A substrate is securely affixed to the platen

using the substrate ejection handle. After placing a substrate on the platen lifting up on the handle will lock the

substrate into its build position; pressing down on the handle will release the substrate from the platen for

removal.

The tip offset calibration targets are located on the rear center portion of the platen. These targets are used

when determining the X and Y offset between model and support tips after either head has been replaced

(during an automatic Tip Offset Calibration).

Figure 3-7: Platen Components

26

Page 36

TIP WIPE ASSEMBLIES

Tip Wipe Assembly

Model = left

Support = right

Two tip wipe assemblies are located in the rear of the oven, one for model and one for support. Each assembly

consists of a flicker and a brush. The tip wipe assemblies keep the printer’s tips and tip shields free of purged

material debris and material buildup.The tip wipe assemblies are mounted behind the purge chute and extend

through the purge chute via two slots cut into the chute’s exterior.

After material is purged from a tip, the tip passes across the tip wipe assembly. The flicker cuts the purged

material from the end of the tip and knocks it into the purge chute. The brush cleans the tip and tip shield.

Purged material debris is guided down from the tip wipe assemblies to the bottom of the oven chamber via the

purge chute.

Figure 3-8: Tip Wipe Assemblies

27

Page 37

PURGE CHUTE

Purge Chute

Purged

material

debris will

accumulate

here

The purge chute is located in the back of the oven. Purged material debris is guided down from the tip wipe

assemblies to the bottom of the oven chamber via the purge chute. Material debris exits the purge chute via an

opening at the bottom of the chute and then accumulates in the bottom of the oven chamber. Accumulated

material debris should always be cleaned on a weekly basis, or as needed if excessive accumulation occurs,

see “Cleaning the Oven Chamber” on page 164 for instructions.

Figure 3-9: Purge Chute Location

Figure 3-10: Oven Chamber Cleaning Location

28

Page 38

MATERIAL BAY DRAWER COMPONENTS

Material

Bays

(2 or 4

Material

Bay

Drawer

The model and support material bays are accessible by opening the material bay drawer on the front of the

printer. The material bay drawer does not contain any locking mechanisms and can be opened while the printer

is building.

Figure 3-11: Material Bay Drawer Components

MATERIAL BAYS

The F270 and F370 printers have four operating material bays - two model and two support. The two left-most

bays hold model material while the two right-most bays hold support material. The F170 printer has two

operating material bays - one model and one support. The left bay holds model material while the right bay

holds support material.

While building, one model and one support spool will be active. An active spool has material filament loaded to

the head, as indicated by a solid blue pathway between the Material Status Icon and corresponding Head

Status Icon, a solid blue Head Status Icon, and a solid blue border around the Material Status Icon on the

touchscreen display (see “Materials Status” on page 136 for more information). For applicable printer models,

you can replace inactive spools without pausing the printer.

Note: The auto changeover capability automatically loads a second spool during

a build when the first spool runs out of material (see “Material Auto Changeover”

on page 115). Auto changeover is only applicable for the F270 and F370

printers.

29

Page 39

MATERIAL DRIVE CONTROLLER

Material Drive

Controller

Each individual material bay has a material drive controller. The material drive controller feeds filament from a

material bay to the head. The material drive controller is located on the back side of the material bay and

contains a small 12 VDC motor which drives filament up to the head. The material drive controller is a nonserviceable item and is instead replaced along with the replacement of a material bay.

The material drive controller contains a mechanical filament present switch which detects the presence of

material within the material drive during the load and unload process. This switch also detects errors. If the

material drive controller detects that filament has broken within the material bay or the end of filament is

reached, the printer will pause to allow for recovery.

Figure 3-12: Material Drive Details

30

Page 40

STORAGE DRAWER

Storage

Drawer

Directly below the material bay drawer is a storage drawer which can be used to store spare parts or tools, as

needed.

Figure 3-13: Storage Drawer

31

Page 41

GANTRY

Y Servo Motor (2x)

X Drive Belt

Model Head

Assembly

Y Drive Belt (2x)

X Servo Motor

Toggle Plate Assembly

Support Head

Assembly

To access the gantry or the heads, you must first open the top cover. The top cover utilizes a mechanical locking

mechanism. The top cover remains locked while the printer is building and automatically unlocks when the oven

door is opened. The printer cannot resume building if the top cover and/or oven door are open.

The gantry moves the head in the X and Y directions when building a part. The gantry assembly is located under

the top cover. The entire gantry is outside of the oven; only the bottom of the head protrudes into the oven. The

gantry and its drive motors are thermally shielded from the oven via flexible heat shields. To move the head, the

gantry utilizes one X and two Y servo motors attached to timing belts.

Figure 3-14: Gantry Assembly

32

Page 42

PRINT HEADS

Support Head

Assembly

Model Head

Assembly

Head Release Lever

(one per head assembly)

The F123 printer utilizes two print head assemblies, one for model and one for support. Once a head has been

used for model or support, it can only be used for that designated material (model or support) thereafter. The

heads are designed for use with a range of modeling materials. The heads extrude model material and support

material with two identical liquefiers. A single blower fan, mounted above the tip liquefier entrances, cools the

incoming material at the liquefier entrances.

Head life is directly related to the amount of build time for the head. Heads are a replaceable consumable item

and should be changed once the head’s odometer reaches 1500 build hours (see “Viewing Head Details” on

page 63 for information on head odometers). You will receive a warning when the head’s odometer reaches

1350 build hours, reminding you to order a replacement head as the head is nearing its odometer limit. You can

continue using a head which has exceeded its odometer limit, but it is highly recommended that you change the

head as part quality will be unpredictable. The corresponding Head Status Icon will be displayed in its warning

state on the User Interface (see Table 4-6 on page 61 for icon states). The entire model or support head

assembly is replaced as a single unit (see “Head Replacement” on page 117 for instructions). The Head

Release Lever locks and unlocks the associated head into or out of its seated position.

When building with PLA material a specialized PLA head is used. The PLA head is dark gray while standard

heads are black. The PLA head must be installed into the model head location within the gantry. A cooling

module is used in conjunction with the PLA model head and must be installed into the support head location

within the gantry (see Table 2-4 on page 10 for help identifying the cooling module). When building with PLA

material, the PLA model head extrudes both model and support materials. (See “Replacing a PLA Head” on

page 119 for instructions on replacing a PLA head or the associated cooling module).

Figure 3-15: Head Assemblies

33

Page 43

MODELING MATERIALS

MATERIALS USED

The F123 Series can use a variety of model materials, in a range of colors. QSR Soluble Release support

material is used in conjunction with all model materials, except for PLA. When building with PLA material, PLA is

used for both model and support materials (see Table 3-3 for model and support compatibility information).

Table 3-1 lists the material types available for use with each printer model.

Table 3-2 lists color availability by model material type.

Table 3-1: Available Materials

Printer Model Available Materials

F170

F270

F370

ABS, ASA, PLA

ABS, ASA, PLA

ABS, ASA, PLA, PC-ABS

Table 3-2: Color Options

Material Type Solid Color Options Translucent Color Options

ASA Ivory, Black, White, Dark Gray, Light Gray,

Red, Blue, Orange, Green, Yellow

ABS Ivory, Black, White, Dark Gray, Red, Blue,

Orange, Green, Yellow

PLA Black, White, Medium Gray, Light Gray,

Red, Blue

PC-ABS Black, White

Natural, Red, Yellow, Green, Blue

34

Page 44

MATERIAL SPOOL MEMORY CHIP

Memory Chip

Filament Tail Capture

Locations

Filament Guide

Channels

Each material spool has an axle with a memory chip; this memory chip recognizes the spool’s material type and

tracks the spool’s volume. The F123 Series utilizes a different memory chip than other Stratasys materials and

as a result, only F123 Series compatible spools can be used to build parts on the printer.

Figure 3-16: Material Spool Memory Chip Location

When a spool is installed, its memory chip is read and the spool’s information is reported to the printer. The

spool’s material type and volume are displayed within the Materials page of the User Interface (see “Working

with the Materials Page” on page 60 for more information). If a non-compatible spool is installed an error will be

displayed on the User Interface.

Each build file contains an estimate of the amount of model and support material required to complete the build.

When initiating a build, this estimate is compared to the amount of material available on each spool. If there is

not enough material available to complete the build, you will be warned and given the option to change spools or

install additional spools before starting the build.

Note: A specific prompt will only be displayed if a spool volume related issue is

detected. See “Warnings and Errors” on page 205 for details.

35

Page 45

TIPS AND SLICE HEIGHT

The F123 Series utilizes a T14 tip for all model and support materials. Tips are a component of the associated

head assembly and cannot be changed individually. Instead, the entire head assembly is replaced as a single

unit.

Table 3-3 lists the types of model material available for use with the printer and their corresponding support

material.

Table 3-4 lists available slice heights.

Table 3-3: Available Material Types

Model Material Support Material

ASA QSR

ABS QSR

PLA PLA

PC-ABS QSR

Table 3-4: Slice Height

Model Tip Slice Height (in) Slice Height (mm) Material

T14 0.005 0.127 ABS, ASA, PC-ABS

*Available in “Draft” mode only

0.007 0.178 ABS, ASA, PC-ABS

0.010 0.254 ABS, ASA, PC-ABS, PLA*

0.013 0.330 ABS, ASA, PC-ABS

36

Page 46

SOFTWARE

CONTROLLER SOFTWARE

Controller Software is installed during the manufacturing process, and can be updated as new versions become

available (see “Updating Controller Software” on page 158 for instructions). Controller Software is the software

used to control the printer.

GrabCAD PRINT SOFTWARE

The printer builds parts by processing an original CAD or STL file into a Stratasys CMB file which is then

downloaded to the printer. GrabCAD Print is the software used to process files and then transfer them to the

printer to be built. As part of the initial installation and setup process, you must download and install GrabCAD

Print software. You must download this software before you will be able to build a part on the printer. To

download GrabCAD Print navigate to http://help.grabcad.com/article/197-sign-up-download-and-install and

follow the on-screen steps.

Jobs are sent to the printer in CMB format and placed into the Job Queue (see “Working with the Queue Page”

on page 50 for information on the Job Queue.) The header of the CMB file contains the processed job’s basic

information.

The GrabCAD Print Help documentation includes detailed information on how to connect to your printer,

process parts, edit the Job Queue, etc. The Help file can be accessed from either the application’s Help Menu or

directly from the GrabCAD website.

INSIGHT SOFTWARE

Insight is a software application used for processing STL files. Insight provides the user with the ability to utilize

advanced features and manipulate numerous parameters within the file. For most applications, GrabCAD Print

software will provide sufficient capabilities. However, in some cases, the advanced capabilities of Insight may be

required.

When using Insight with the F123 Series, use the following process:

1. Open and process the STL file.

Note: Insight will only process STL files.

2. When completed, save the CMB file to a known location.

3. In GrabCAD Print, navigate to File > Import File and select the CMB file you wish to import.

4. Continue with normal work flow using GrabCAD Print.

37

Page 47

5

Navigation

Menu

Display

Area

4 USER INTERFACE

This chapter provides an overview of the F123 Series User Interface (UI). Specific printer operation information

and procedures can be found in “5 Operating the Printer” on page 105. You must power ON the printer prior to

using the touchscreen, see “Powering ON the Printer” on page 105 for instructions.

OVERVIEW

The User Interface is composed of a touchscreen located on the front right face of the printer (see Figure 3-1 on

page 20). Each page of the UI is composed of two main areas of functionality; these items are highlighted in

Figure 4-1.

Figure 4-1: User Interface Overview

The touchscreen is designed to reduce glare; therefore, it is best to view the touchscreen when standing in front

of the printer with the screen to your right. Viewing the touchscreen from any other angle may inhibit a clear view

of the screen's display. The touchscreen is easy to use and allows you to:

• Access material load, unload, and calibration functions.

• Monitor printer status.

• Monitor material/head statuses (types loaded/installed, spool volumes, head odometers, etc.) and

change materials and/or heads when necessary.

• Monitor build progress (name of job being built, materials usage information, estimated completion

time, etc.).

• Access network configuration information and change printer defaults.

• Access the Job Queue and Sample Queue (internal storage).

38

Page 48

NAVIGATION MENU

Navigation

Menu

indicator

graphic

The Navigation Menu provides one-touch access to the Build, Queue, Materials, and Tools functions of the

printer (see Figure 4-1 for details). The User Interface is broken up into several pages of related functionality.

Selecting a button from the Navigation Menu will open the button's corresponding page, allowing you to perform

tasks within that page. If a page contains sub-pages, additional buttons corresponding to these items will be

displayed within the page’s Display Area.

The buttons in the Navigation Menu are mutually exclusive, meaning only one button may be selected at a time.

In some cases, a notification badge will be displayed within the button indicating a warning related to the

functionality of the corresponding page. Buttons can appear as follows:

Note: The bottom-most button in the Navigation Menu is non-functional.

Table 4-1: Navigation Menu - Button States

Selected

Button Name

Build Button

Queue Button N/A N/A N/A N/A

Materials Button

Tools Button N/A N/A N/A N/A

State

Unselected

State

Warning

State

Unselected

Unselected Selected

Selected

Error

State

Unselected

N/A N/A

Selected

After selecting a button from the Navigation Menu, a white indicator graphic will be displayed along the

left-center edge of the button. This graphic indicates which Navigation Menu item is currently selected, making it

easy for you to recognize which page of the UI you’re utilizing.

Figure 4-2: User Interface Overview

39

Page 49

DISPLAY AREA

Notifications

Display

Print Job

Information

Panel

Print

Job

Controls

Build

Status

Display

The Display Area contains the body portion of each page of the User Interface; this is where you can select from

available functions and view current status. After selecting a button from the Navigation Menu, the Display Area

will refresh and the main page corresponding to the selected button will be displayed. The information and

buttons/icons shown within the Display Area will vary depending on which main page of the UI was selected.

WORKING WITH THE BUILD PAGE

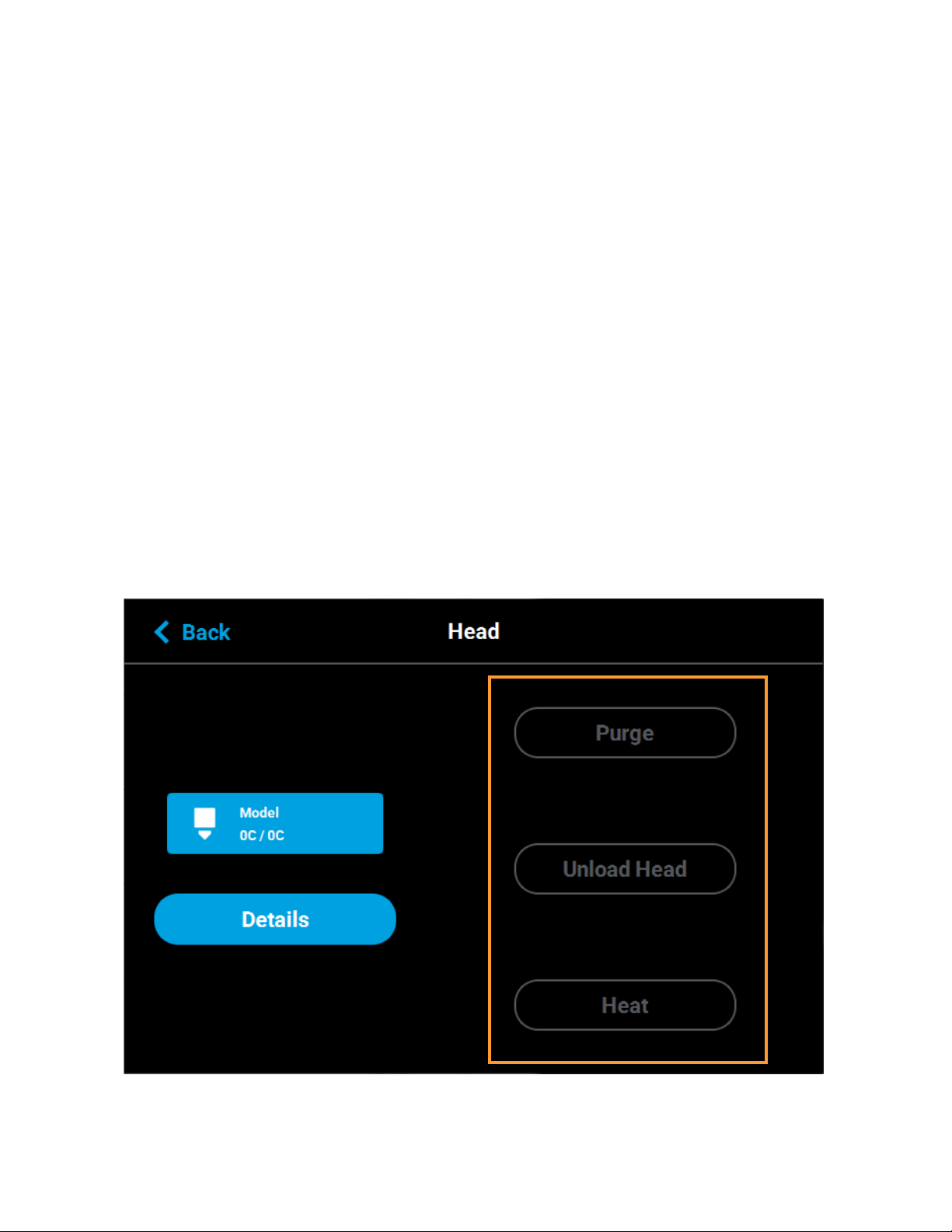

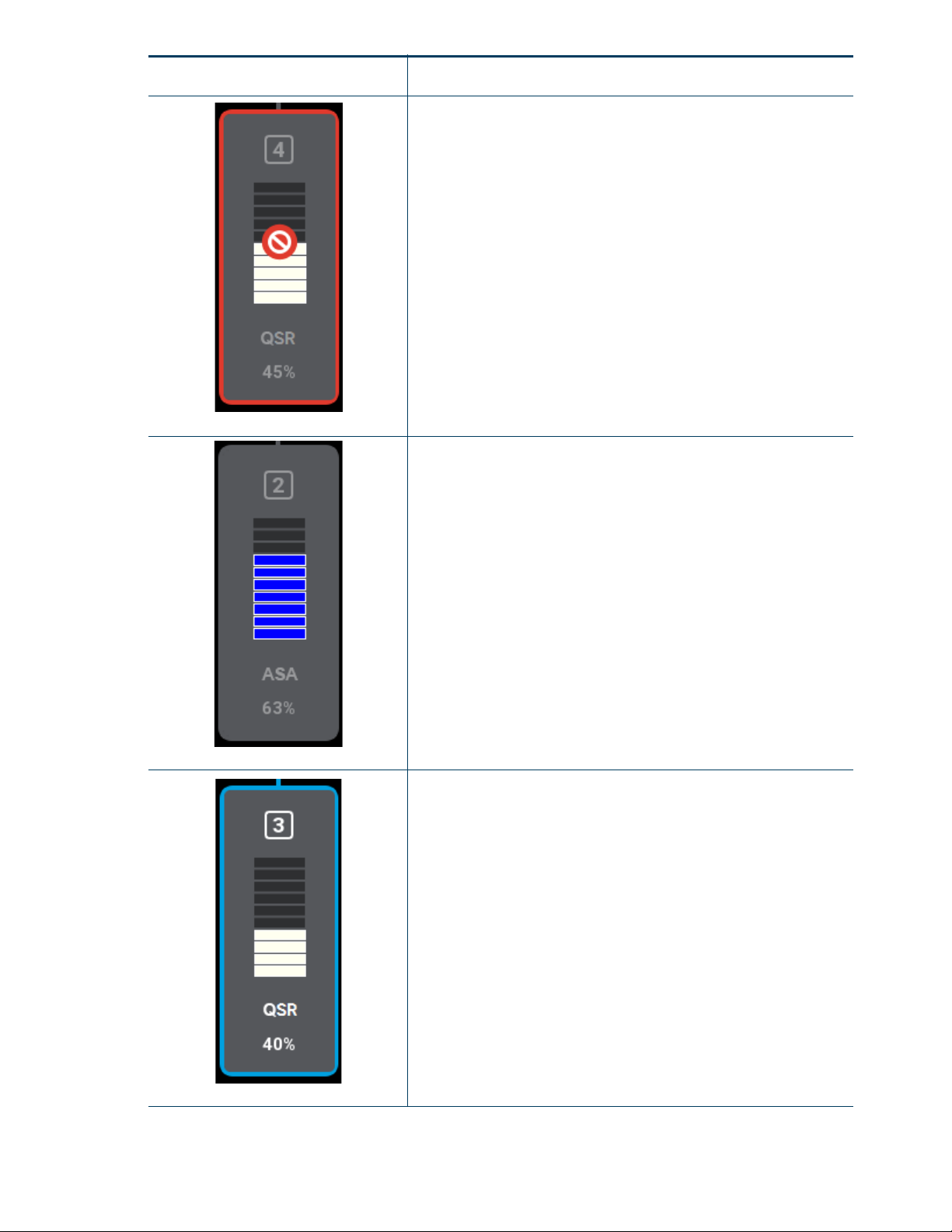

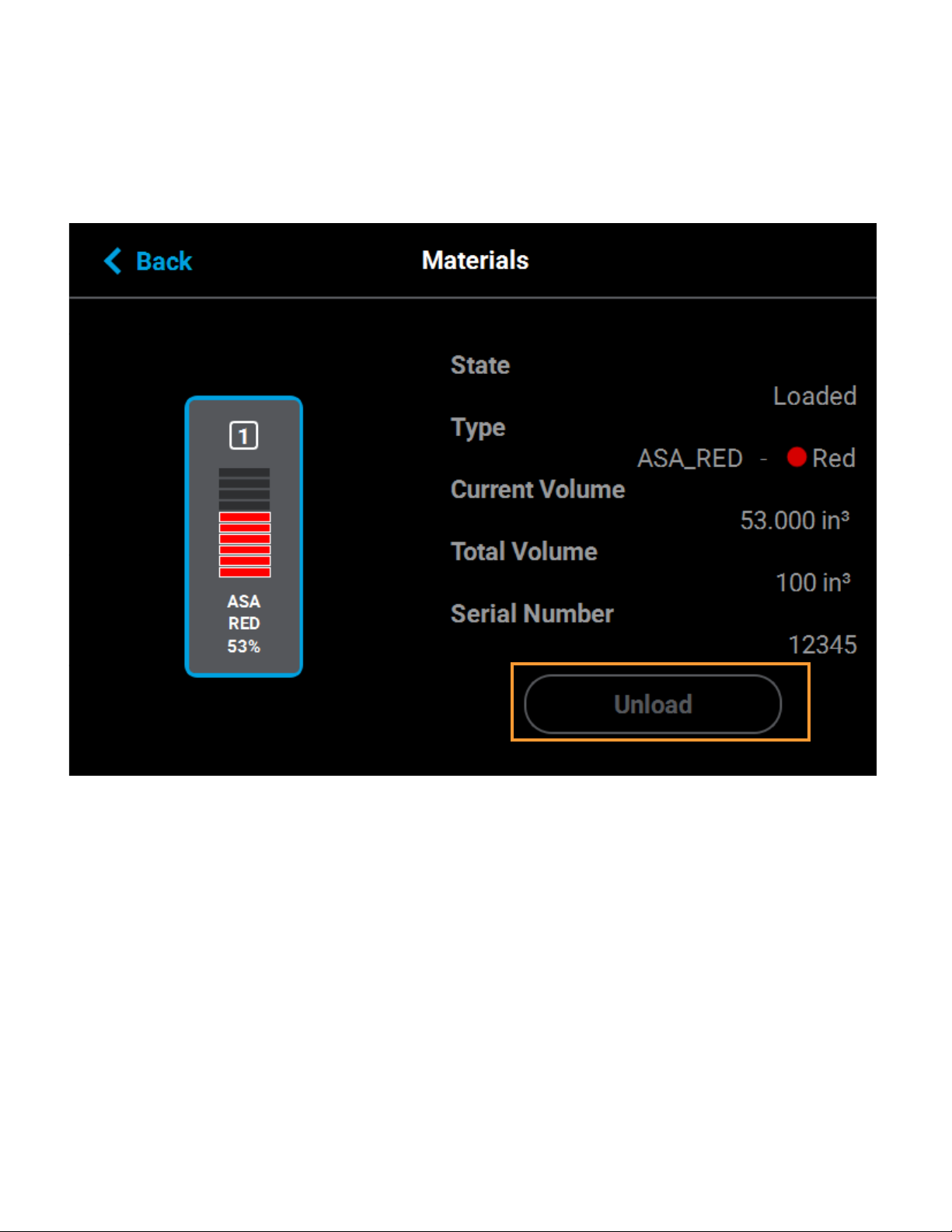

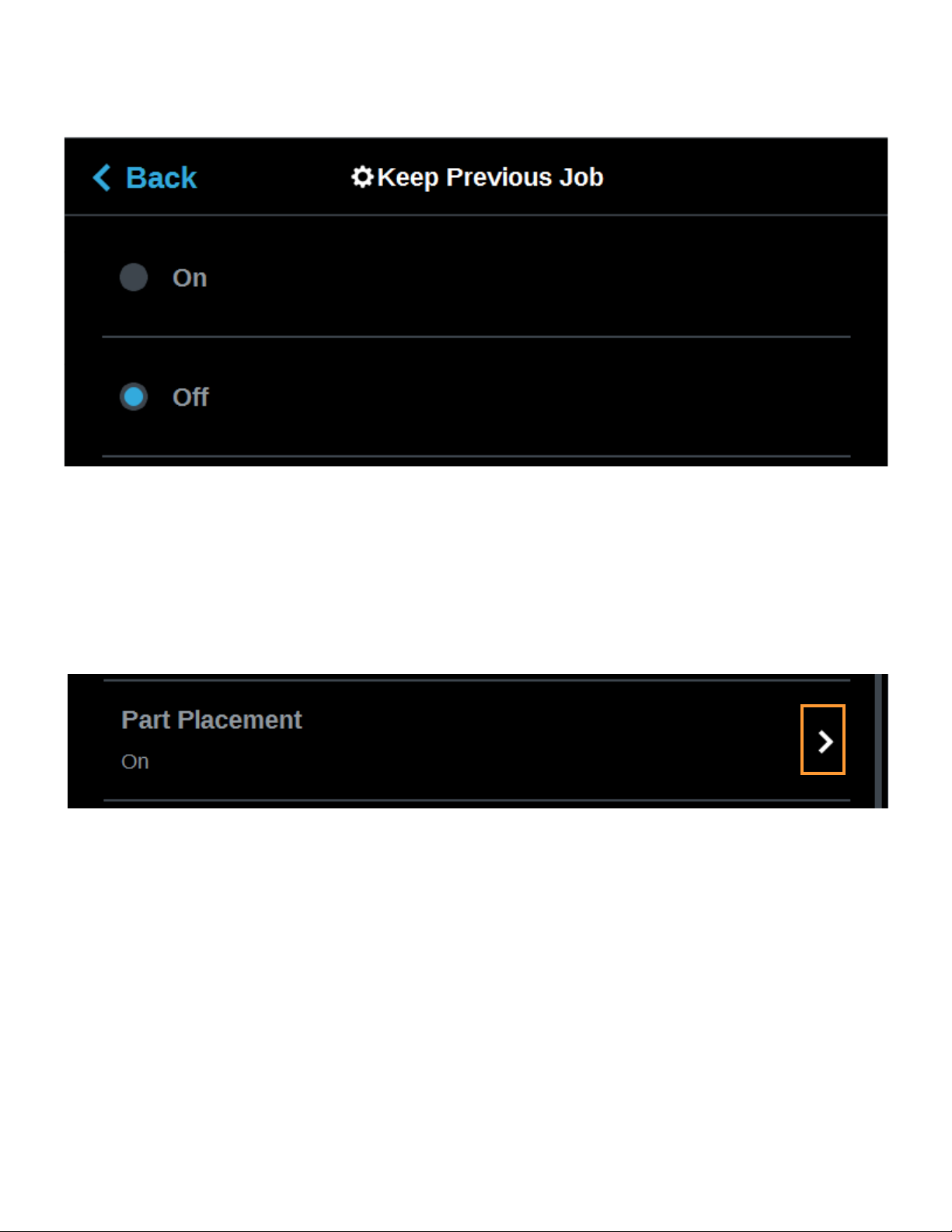

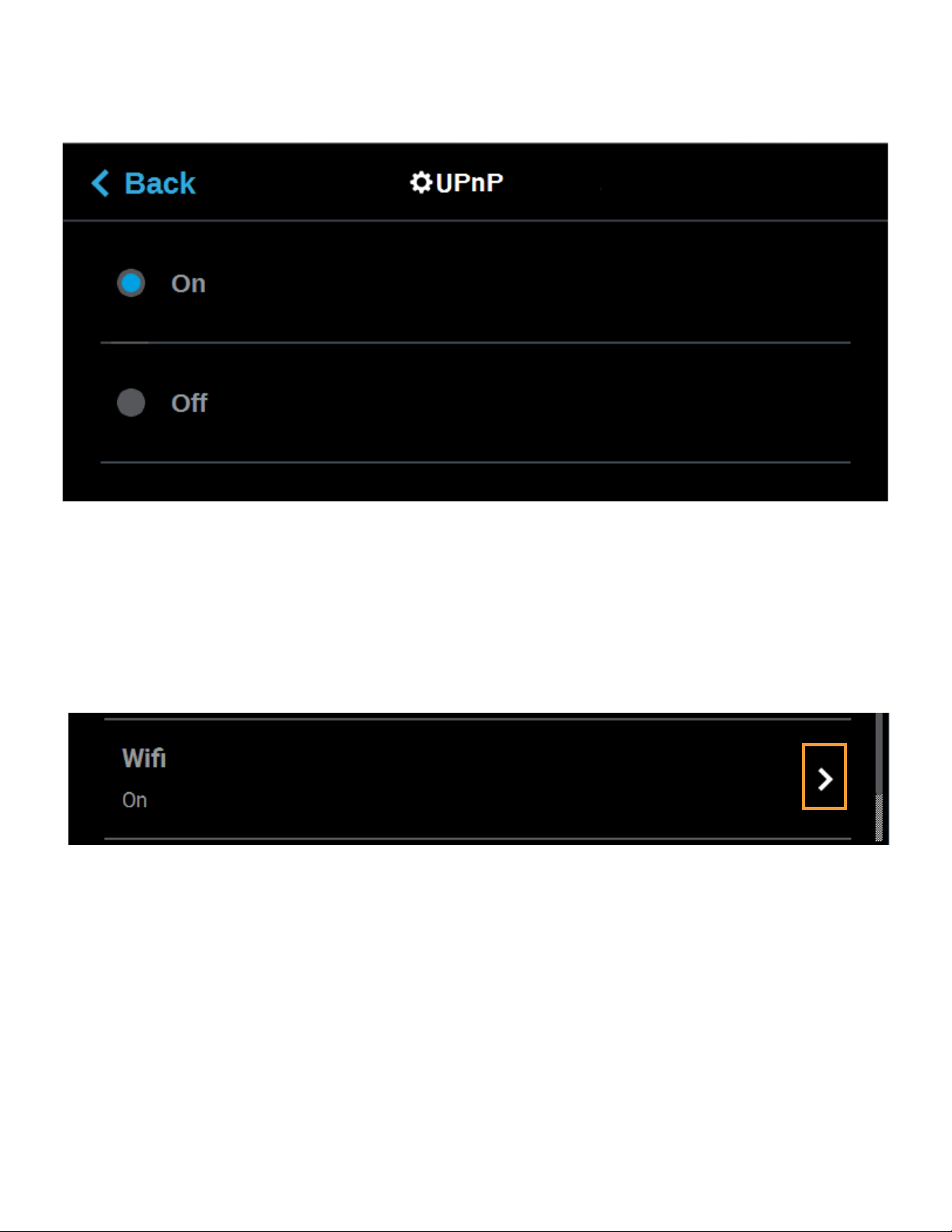

The Build page is composed of the three main areas of functionality that are necessary for building parts on the