User Guide

2

Legal Notice

The information in this document is subject to

change without notice.

STRATASYS, INC. MAKES NO WARRANTY

OF ANY KIND WITH REGARD TO THIS

MATERIAL, INCLUDING, BUT NOT LIMITED

TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. Stratasys, Inc. shall

not be liable for errors contained herein or for

incidental or consequential damages in

connection with the furnishing, performance, or

use of this Material.

This document is protected by copyright. All

rights reserved. Its use, disclosure, and

possession are restricted by an agreement

with Stratasys per software copyright. No part

of this document may be photocopied,

reproduced or translated into another language

without the prior written consent of Stratasys,

Inc. Printed in the USA.

Trademark Credits

© Copyright 2008 Stratasys, Inc. All rights

reserved.

Stratasys, Dimension and CatalystEX are

registered trademarks of Stratasys, Inc.

uPrint is a trademark of Stratasys, Inc.

Windows XP, and Windows Vista are

registered trademarks of Microsoft.

.

Conforms to ANSI/UL std. 60950-1-2003

Certified to CAN/CSA C22.2 no. 60950-1-03

The uPrint by

accordance with the EU Machinery, Low Voltage and Electromagnetic

Dimension system conforms with the following standards,

Compatibility Directives: EU 98/37/EEC, EU 73/23/EEC

amended by 93/68/EEC, EU 89/336/EEC

Stratasys Document Number 206465-0001

in

3

Stratasys, Inc. 7665 Commerce Way Eden Prairie, MN 55344

Phone: 952.937.3000 Fax: 952-937-0070

www.stratasys.com

Declaration of Conformity

Manufacturer Stratasys, Inc.

7665 Commerce Way

Eden Prairie, MN 55344-2080

Type of Equipment 3D Printer

Model Number 180-00108 uPrint 3D Printer

180-00109 uPrint 3D Printer

180-00110 uPrint 3D Printer

We declare under our sole responsibility that the devices mentioned above comply with the

following EU Directives:

Electromagnetic Compatibility 89/336/EEC

(EMC)

Machine 98/37/EC

Low Voltage 73/23/EEC amended by 93/68/EEC

Common Technical Specification EN55022:1998 EN6100-3-2: 2003

Used for demonstration of EN55024:1998 EN6100-3-3: 1995

Compliance EN60950-1:2006

Date of Validity: September 8, 2008

Design and Technical Construction Stratasys, Inc.

File maintained at: 7665 Commerce Way

Eden Prairie, MN 55344-2080

Name of Authorized Signatory: S. Scott Crump

Position Held in Company: Chief Executive Officer

Signature:

4

uPrint™ Limited Warranty

Stratasys, Inc. ("Stratasys") warrants its' uPrint™ 3D Printer system and associated peripheral devices and

replacement parts (collectively, the "Product") purchased from Stratasys or an Authorized Stratasys Reseller to be free

from defects in material and workmanship according to the terms and conditions stated below:

Warranties extend only to the original purchaser of the Product. The warranty on the original Product, as delivered,

extends for one year starting on the date of delivery. Your sole remedy as purchaser under this Limited Warranty shall

be repair or replacement as provided herein.

To preserve your warranty rights, all uPrint™ Products must be installed in accordance with the then-current User

Guide available at www.uPrintDimension.com. During the Limited Warranty period, Stratasys or its' designated

representative will, at their option, repair or replace a defective Product as set forth below. Service Parts and

replacement Products will be furnished on an exchange basis, and will be either new or refurbished. All replaced parts

or replaced Products become the property of Stratasys, and you will be invoiced for replacement parts if defective

parts are not returned as directed by Stratasys under this Limited Warranty.

Stratasys will bear the cost of returned parts, as well as for shipping new or rebuilt replacement parts to you, provided

that you report the warranty claim within the Limited Warranty period and obtain return instructions from Stratasys prior

to return. Replacement parts independently carry a 90-day warranty from date of shipment from Stratasys or

designated representative location. Consumable parts are not covered by this Limited Warranty. Warranty services

may be provided by Stratasys, an Authorized Reseller, or a third party service provider designated by Stratasys.

No coverage or benefits under this Limited Warranty will exist if any of the following conditions apply:

(a)The uPrint™ Product has been subjected to abnormal use, improper or inadequate maintenance, unauthorized

modifications, unauthorized repair, misuse, abuse, exposure to moisture, flooding, fire, electrical problems associated

with incoming power, or other acts which are not the fault of Stratasys, Inc.

(b)Stratasys' Customer Service Department was not notified of the defect or malfunction of the uPrint™ system prior to

expiration of the one year warranty period.

(c)Parts or consumables were installed and used that were not certified or approved by Stratasys.

Stratasys will also not be liable under any circumstances for Product replacement or associated labor, loss of use, loss

of profits, or for any other indirect, incidental, collateral, exemplary, punitive, consequential or special damages, or

losses arising out of the purchase of uPrint™ Products and/or out of this limited warranty, even if Stratasys or its'

designated representative have been advised of the possibility of such damages or claims. To the extent such claims

are not excludable as adjudged by a court of competent jurisdiction, you agree to accept as sole and exclusive remedy,

a payment equal to the original purchase price for the product adjudged to be defective.

SOME COUNTRIES, REGIONS, STATES OR PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

REMEDIES OR OF INCIDENTAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES, OR THE APPLICABLE TIME

PERIODS, SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU. EXCEPT TO THE EXTENT

LAWFULLY PERMITTED, THIS LIMITED WARRANTY DOES NOT EXCLUDE, RESTRICT OR MODIFY, AND IS IN

ADDITION TO THE STATUTORY RIGHTS APPLICABLE TO THE SALE OF THIS PRODUCT TO YOU.

This warranty gives you specific legal rights and you might also have other rights that vary from country/region to

country/region, state to state, or province to province.

EXCEPT FOR THIS LIMITED WARRANTY, AND TO THE FULLEST EXTENT ALLOWED BY LAW, NEITHER

STRATASYS NOR ANY AUTHORIZED RESELLER MAKES ANY OTHER WARRANTY OF ANY KIND, EXPRESS

OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. STRATASYS DOES NOT OFFER, ASSUME OR AUTHORIZE THE OFFER OR ASSUMPTION OF

LIABILITY FOR IT OR FOR ANY OTHER WARRANTY, EITHER EXPRESS OR IMPLIED BY ANY AUTHORIZED

RESELLER OR OTHER INDEPENDENT THIRD PARTY.

Table of Contents 5

Table of Contents

Introduction

How To Use This Guide .................................................................................................................................9

Sections of the User Guide ............................................................................................................................9

Overview... .............................................................................................................................................. 9

Setup... .................................................................................................................................................... 9

Operation... ............................................................................................................................................. 9

Preventive Maintenance... .......................................................................................................................9

Troubleshooting and Maintenance... ....................................................................................................... 9

Support... ................................................................................................................................................. 10

Recycling... .............................................................................................................................................. 10

Overview

Finding More Information ...............................................................................................................................13

Setup

Minimum Requirements: ................................................................................................................................14

Workspace Requirements: ......................................................................................................................14

Facility Requirements & Environmental Specifications: ..........................................................................14

Work Station Requirements: ...................................................................................................................14

Safety ............................................................................................................................................................ 15

Hazard Classifications: ............................................................................................................................15

Unpacking the Startup Kit ..............................................................................................................................16

Unpacking the Material Bay ........................................................................................................................... 17

Unpacking the Printer .................................................................................................................................... 18

Set up the Material Bay and Printer ...............................................................................................................19

Inserting a modeling base ..............................................................................................................................21

Inserting a modeling base: ......................................................................................................................21

Connecting the printer and material bay(s). ...................................................................................................22

Power Cable ..................................................................................................................................................23

Connecting the power cable: ...................................................................................................................23

Network/Crossover Connections ................................................................................................................... 23

Connecting the network cable: ................................................................................................................23

Connecting the crossover cable: ............................................................................................................. 23

Powering ON .................................................................................................................................................24

Powering ON the printer: .........................................................................................................................24

Initial Language Setup ...................................................................................................................................24

Setting your default language: ................................................................................................................24

Software .........................................................................................................................................................25

Installing CatalystEX: ..............................................................................................................................25

Verifying System Software: .....................................................................................................................25

Networking Your Printer .................................................................................................................................25

Establishing communication on a Dynamic network: .............................................................................. 25

Setting the Static Network address: ........................................................................................................26

Connecting Directly To Your PC (if no network is available) .........................................................................27

Connecting directly to the PC with a crossover cable: ............................................................................27

System Software ............................................................................................................................................29

Updating System Software: .....................................................................................................................29

Installing a spool of material into the material carriers ...................................................................................29

Stratasys Document Number 206465-0001

Table of Contents 6

Installing a spool of material into the carrier: ...........................................................................................29

Adding material carriers to the single material bay ........................................................................................31

Adding material carriers to the material bay: ...........................................................................................31

Loading material to the head for the single material bay ...............................................................................31

Adding material carriers to the dual material bays .........................................................................................31

Building a Test Part .......................................................................................................................................32

Operation

Powering On ..................................................................................................................................................33

Display Panel and Keypad .............................................................................................................................33

System Software Overview ............................................................................................................................34

CatalystEX Overview .....................................................................................................................................35

Setting up your STL file for printing ...............................................................................................................36

Opening your STL file with CatalystEX: .................................................................................................. 36

Setting the scale of your STL file: ...........................................................................................................36

Setting the orientation of your STL file: ...................................................................................................36

Selecting the model interior fill for your part: ...........................................................................................37

Selecting the support material fill for your part: ....................................................................................... 37

Adding your STL file to the pack: ............................................................................................................ 37

Printing your STL file: ..............................................................................................................................37

Building a part ................................................................................................................................................38

Starting a build from a remote location: ..................................................................................................38

Starting a build from the display panel: ...................................................................................................38

The display panel during build .......................................................................................................................38

Chamber Lights .............................................................................................................................................39

To set the chamber lights to always on: ..................................................................................................39

Pausing a build ..............................................................................................................................................39

Resuming a build that has been paused ....................................................................................................... 39

Canceling a build ...........................................................................................................................................39

Cancel a build: ........................................................................................................................................39

Removing a completed part ...........................................................................................................................40

Remove a completed part from the printer: .............................................................................................40

Remove a part from the modeling base: ................................................................................................. 40

Removing support material ............................................................................................................................ 41

Emptying the purge bucket ............................................................................................................................ 41

Replacing material for single material bay .....................................................................................................42

Removing material from the printer: ........................................................................................................42

Removing material from the printer: ........................................................................................................42

Dual material bay LED’s ................................................................................................................................43

Replacing material spools ..............................................................................................................................43

Removing a spool of material from the carrier: .......................................................................................43

Installing a spool of material in to the carrier: ..........................................................................................43

Storing material ..............................................................................................................................................43

Auto power down ........................................................................................................................................... 45

Setting up auto power down: ...................................................................................................................45

Cancelling auto power down: ..................................................................................................................45

Powering off ...................................................................................................................................................45

Resuming operations from Standby mode .................................................................................................... 45

Continue operation from Standby mode: .........................................................................................

.......45

Preventive Maintenance

Daily ............................................................................................................................................................... 46

Empty the purge bucket .......................................................................................................................... 46

Inspect the tip wipe assembly ................................................................................................................. 46

Inspect the tip shields ..............................................................................................................................46

Stratasys Document Number 206465-0001

Table of Contents 7

500 Hour maintenance ..................................................................................................................................46

Replace the tip wipe assembly ................................................................................................................46

Replace the tip shields ............................................................................................................................46

2000 Hour maintenance ................................................................................................................................46

Tip replacement ...................................................................................................................................... 46

Troubleshooting and Maintenance

Troubleshooting Checklist .............................................................................................................................47

Fault Determination Codes ............................................................................................................................ 49

Welcome Kit Tools .........................................................................................................................................50

Diagnosing Loss of Extrusion ........................................................................................................................50

Diagnose loss of extrusion: .....................................................................................................................50

Clogged Extrusion Tip ................................................................................................................................... 51

Clearing a clogged extrusion tip: ............................................................................................................. 51

Recovering From Loss of Extrusion ...............................................................................................................53

Cycling Power ................................................................................................................................................55

To cycle power to the printer: ..................................................................................................................55

Tip Wipe Assembly ........................................................................................................................................56

Replacing the tip wipe assembly: ............................................................................................................56

Tip Shield Replacement .................................................................................................................................57

Extrusion Tip Replacement and Calibration .................................................................................................. 59

Removing Tips: .......................................................................................................................................59

Installing Tips: .........................................................................................................................................60

Tip Calibration: ........................................................................................................................................62

Remove Debris Buildup ................................................................................................................................. 63

Vacuum Build Chamber .................................................................................................................................63

Clean Door .....................................................................................................................................................63

Chamber Light Bar .........................................................................................................................................64

Replace chamber light bar: ..................................................................................................................... 64

Support

Registration ....................................................................................................................................................65

Customer Support ..........................................................................................................................................65

Recycling

Removing the EEproms from the material guides .........................................................................................67

Stratasys Document Number 206465-0001

Introduction 8

Introduction

uPrint is designed with ultimate simplicity in mind. The system enables you to build parts quickly, even if

you’ve never used a 3D printer before.

The system models with ABSplus, so modeled parts are strong and durable. ABSplus also ensures you will

be able to drill, tap, sand and paint your creations. With Soluble Support Technology (SST), your

completed parts are quickly available for review and test. uPrint is an innovative combination of proprietary

hardware, software and material technology.

Welcome to the new Dimension of 3D modeling!

Stratasys Document Number 206465-0001

Introduction 9

How To Use This Guide

This User Guide is laid out in easy to follow sections which cover Set-up, Operation, Maintenance, and

Troubleshooting of your uPrint 3D printer. Be sure to read each section carefully so that you will get the

best performance from your system.

Throughout the User Guide, text representing Interface Messages that appear on the Display Panel are

presented in a bold font.

Sections of the User Guide

Overview...

Provides a quick reference for the layout of the printer and its operating components. Overview also

provides a quick reference for sources of additional information.

Setup...

Guides you through the initial printer installation and setup. Topics include:

• Unpacking

• Connecting power

• Installing software

• Connecting to a computer network.

Generally, topics in setup are only accomplished during installation or relocation of the printer.

Operation...

Further develops your understanding of the printer by explaining:

• The User Interface

• Adding and removing material

• Building parts

• Removing completed parts and support material.

The tasks presented are common procedures accomplished during the normal operation of the printer.

Preventive Maintenance...

Lists several tasks to be done on a periodic basis.

Troubleshooting and Maintenance...

In the event your printer has any issues, a troubleshooting checklist, fault determination codes, diagnosing

a Loss of Extrusion, recovering from a Loss of Extrusion, startup and networking issues resolutions are

provided. This section also lists routine procedures that keep your printer functioning at its best.

Stratasys Document Number 206465-0001

Introduction 10

Support...

Guides you through getting technical support and/or service for your uPrint 3D Printer, as well as

consumable products and ordering information.

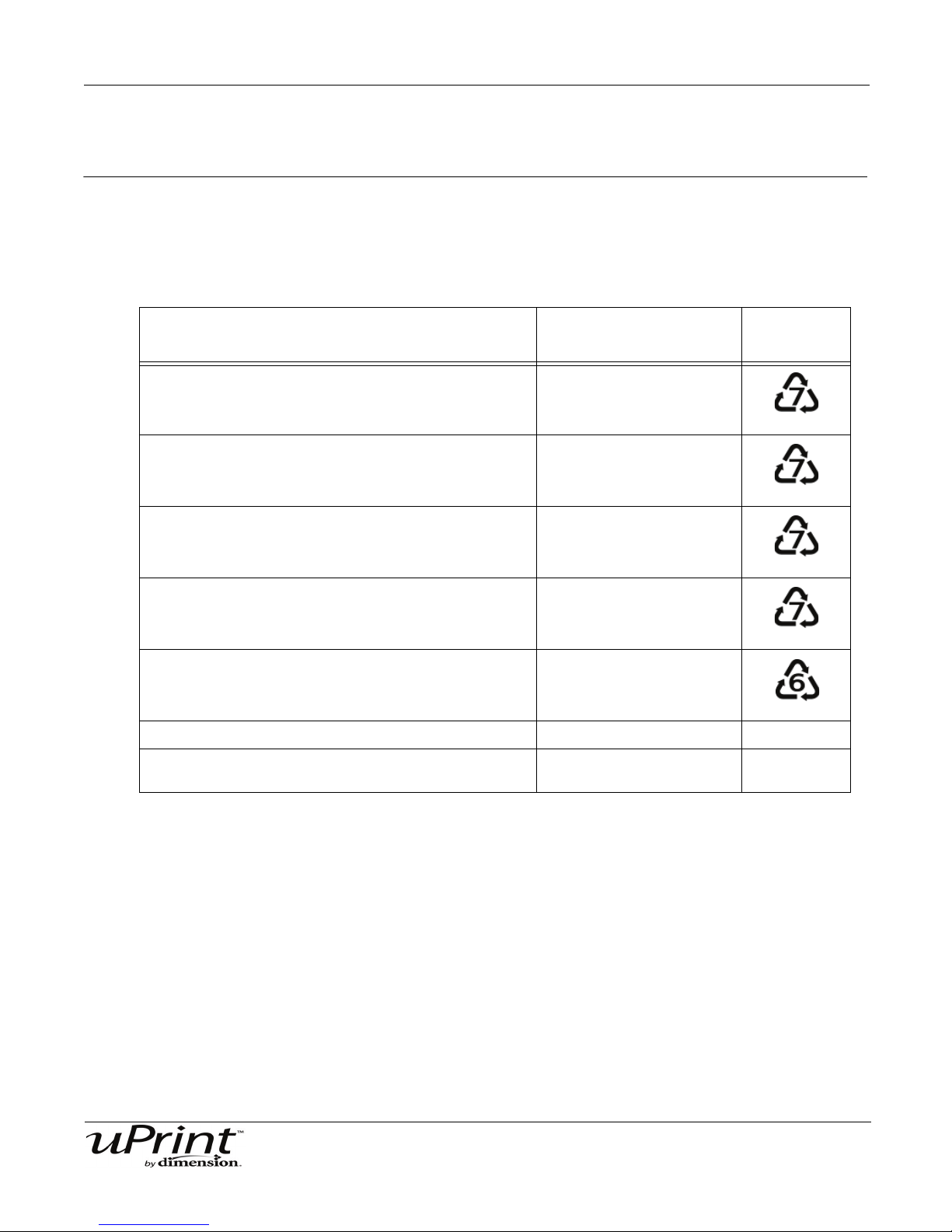

Recycling...

This section will explain which materials for the uPrint system and packaging are recyclable.

Stratasys Document Number 206465-0001

Overview 11

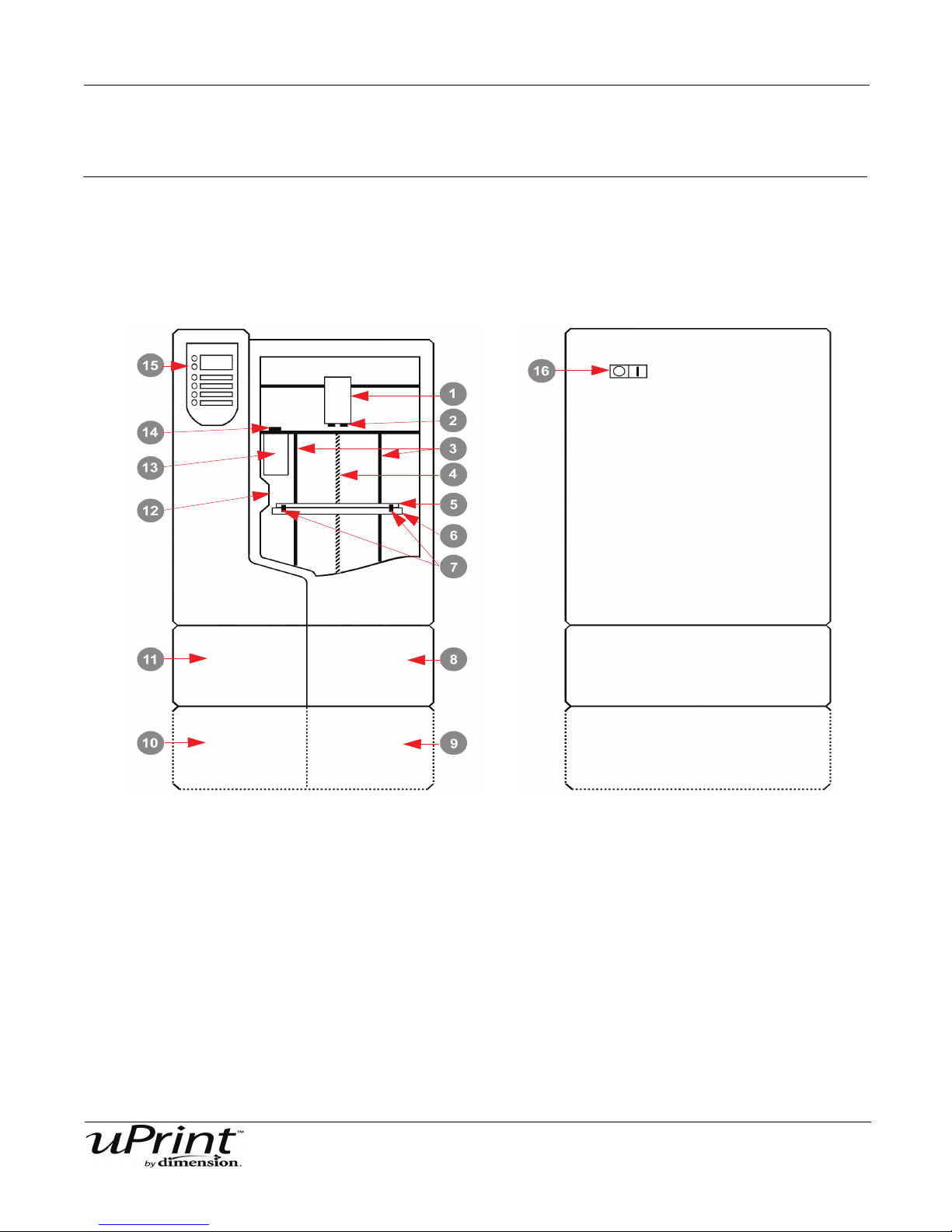

Front View

Left side View

Overview

uPrint builds models from CAD STL files. The system builds three-dimensional parts by extruding a bead

of ABSplus through a computer-controlled extrusion head, producing high quality parts that are ready to

use immediately after completion.

Figure 1: Front and left side view of printer.

1 Extrusion Head 9 Optional Material Bay, Model Side

2 Extrusion Tips 10 Optional Material Bay, Support Side

3 Guide Rods 11 Material Bay, Support Side

4 Lead Screw 12 Door Interlock System

5 Modeling Base 13 Purge Bucket

6 Z Platform 14 Tip Wipe Assembly

7 Modeling Base Retainers (2) 15 Display Panel

8 Material Bay, Model Side 16 Power ON/OFF Switch

Stratasys Document Number 206465-0001

Overview 12

Figure 2: Rear view of printer

1 Optional Material Bay 9 Support Material Tube

2 Optional Model Material Tube 10 UPS Connection

3 Material Bay 11 Material Bay Cable Connector

4 Model Material Tube 12 RJ-45 Network Connector

5 Circuit Breaker 13 Diagnostics Cable Connector

6 AC Power Cord Connector 14 Material Bay Communications Cable

7 Model Material Y Connector 15 Optional Support Material Tube

8 Support Material Y Connector 16 Optional Material Bay Communications Cable

The uPrint system consists of two primary components — the uPrint 3D printer and Material Bay.

CatalystEX is the preprocessing software that runs on Windows XP Pro or Windows Vista platform.

uPrint’s build envelope measures 203 x 152 x 152 mm (8 x 6 x 6 in). Each material carrier contains 492 cc

(30 cu. in.) of usable material — enough to build continuously for about 48 hours without reloading. You

can add an optional material bay that will automatically load more material as a carrier runs out.

Stratasys Document Number 206465-0001

Overview 13

Finding More Information

Other references are available for use with the uPrint system.

CatalystEX Online Help

Simple operating instructions for

CatalystEX are available through

CatalystEX Dynamic Help, which

is included with CatalystEX and

displayed in the Dynamic Help

window. You can also see

CatalystEX Help from the menu

bar - Help>Contents

World Wide Web

Additional information is

available at:

http://www.uPrintDimension.com

Stratasys Document Number 206465-0001

Setup 14

Setup

Minimum Requirements:

Workspace Requirements:

System Specifications

Printer Height 762mm (30 inches)

Printer Width 660mm (26 inches)

Printer Depth 660mm (26 inches)

Printer Weight 62 Kg (137 lbs.)

Material Bay Height 153mm (6 Inches)

Material Bay Width 660mm (26 inches)

Material Bay Depth 660mm (26 inches)

Material Bay Weight 17 Kg (37 lbs.)

Ventilation Requirements 115 mm (4.5 in) minimum space behind unit for air circulation.

153 mm (6 in) minimum space around the printer for air circulation.

Installation Location Stable flat surface capable of holding 100Kg (220 lbs).

Facility Requirements & Environmental Specifications:

Facility Requirements

Dedicated outlet voltage

requirements (Nominal):

Ambient Temperature: 15-30°C (60-86°F) Operating

Relative Humidity: 30-70%, Non-condensing Operating

Network connection: Ethernet 10/100 Base T

Optional UPS for power

interruptions:

BTU/hr 2550 BTU/hr

dBA’s (Decibels) 55dBA MAX Idle and 62dBA MAX Operating

90-132 VAC, 47-63 Hz, 12 Amp minimum (20 Amp recommended)

–or–

195-264 VAC, 47-63 Hz, 7 Amp minimum (10 Amp recommended)

Rated Power – 1440 VA

Output Power – 1500 watts

Work Station Requirements:

You must use a CAD software program that is capable of creating. STL files. For detailed information

See Release Notes... http://www.uPrintDimension.com

Stratasys Document Number 206465-0001

Setup 15

Safety

uPrint is designed to be a safe and reliable 3D printer. However, normal operation will require that you

access areas of the printer that are potentially hazardous.

Hazard Classifications:

Please be aware of the following hazard classifications that are used throughout this guide.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided,

could result in serious injury.

Hot Surface: The hot surface sign indicates the presence of devices with high

temperatures. Always use extra care, and wear safety gloves, when

working around heated components

Gloves: When performing some maintenance procedures, the machine may be

hot and gloves will be required to avoid burns.

Safety Glasses: Wear safety glasses to avoid injury to your eyes.

Lifting Hazard: Lift with two or more people to avoid serious injury.

Recycle: Use proper recycling techniques for materials and packaging.

ESD: Use standard electrostatic discharge (ESD) precautions

when working on or near electrical circuits.

Stratasys Document Number 206465-0001

Setup 16

A

B

C

A

B

C

See Figure 4

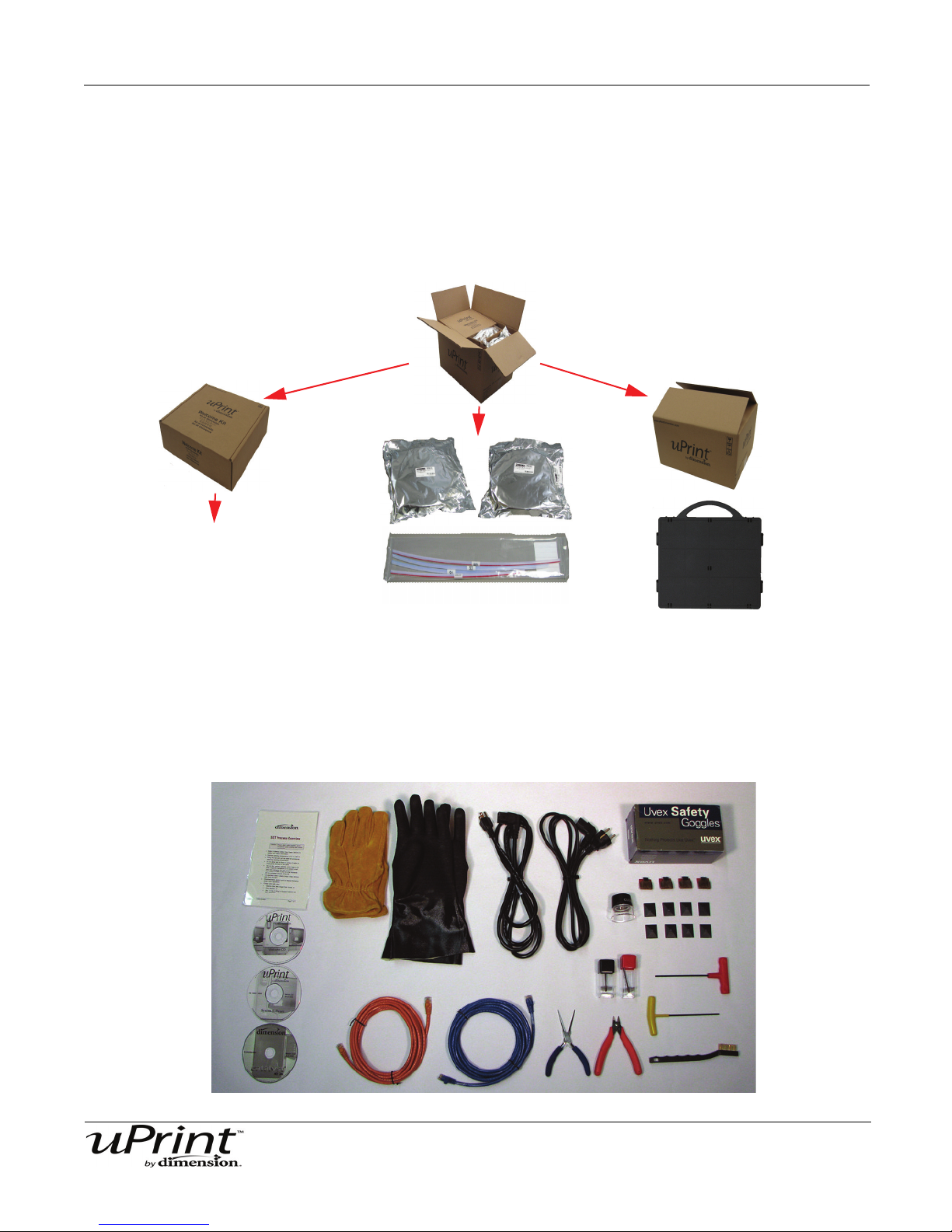

Unpacking the Startup Kit

1. Carefully cut the top of the box, open and remove the contents.

2. Remove the welcome kit box and open.

3. Remove the model and support material spools.

4. Remove the material guide tubes.

5. Remove the box of substrates.

Figure 3: Startup Kit

Figure 4: Welcome Kit Contents

Stratasys Document Number 206465-0001

Setup 17

A

B

C

A

B

C

M

S

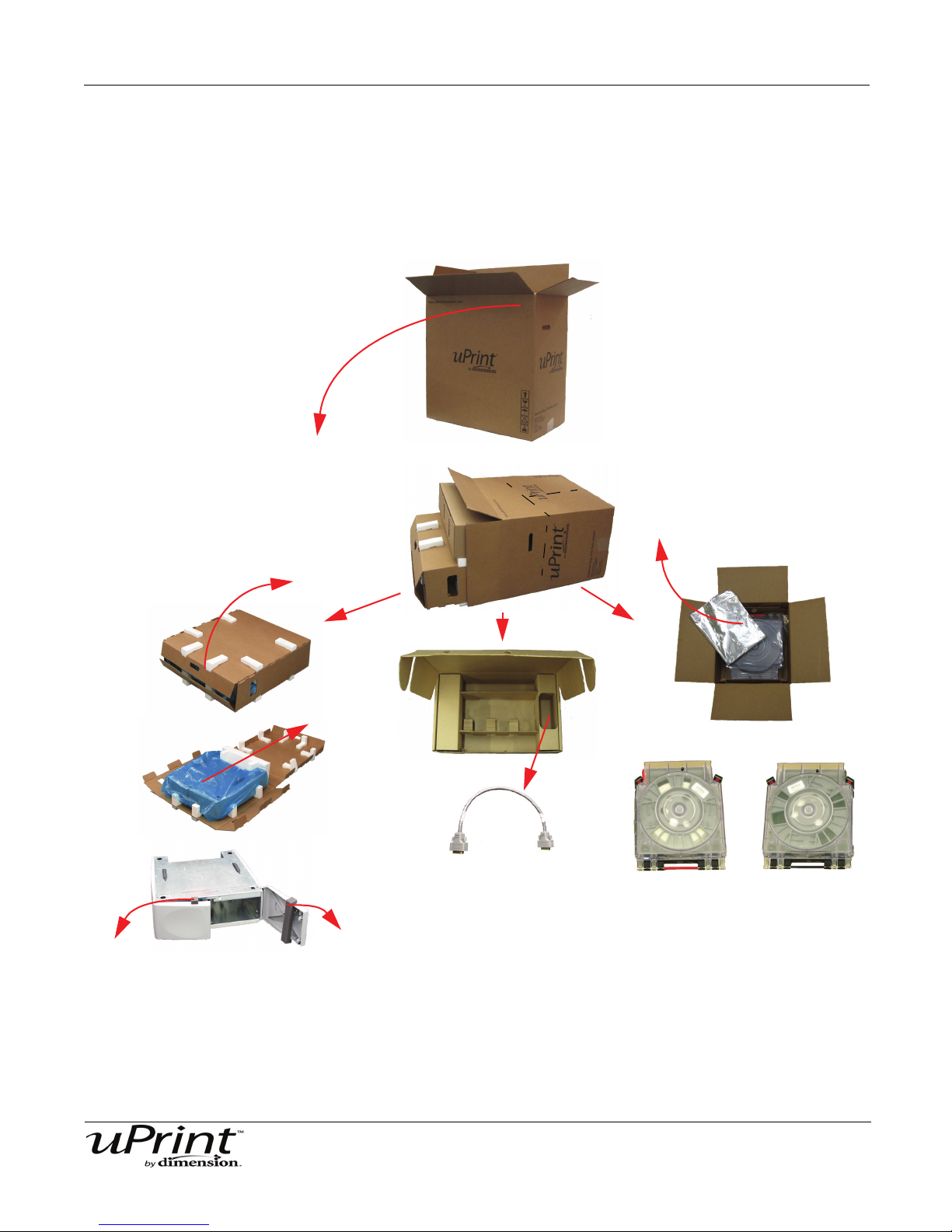

Unpacking the Material Bay

1. Carefully cut the top of the box, open and lay it on its side.

2. Remove the material bay cable.

3. Remove the material bay.

4. Remove the model and support carriers.

Figure 5: Material Bay

Stratasys Document Number 206465-0001

Setup 18

1

2

3

4

5

6

A

B

C

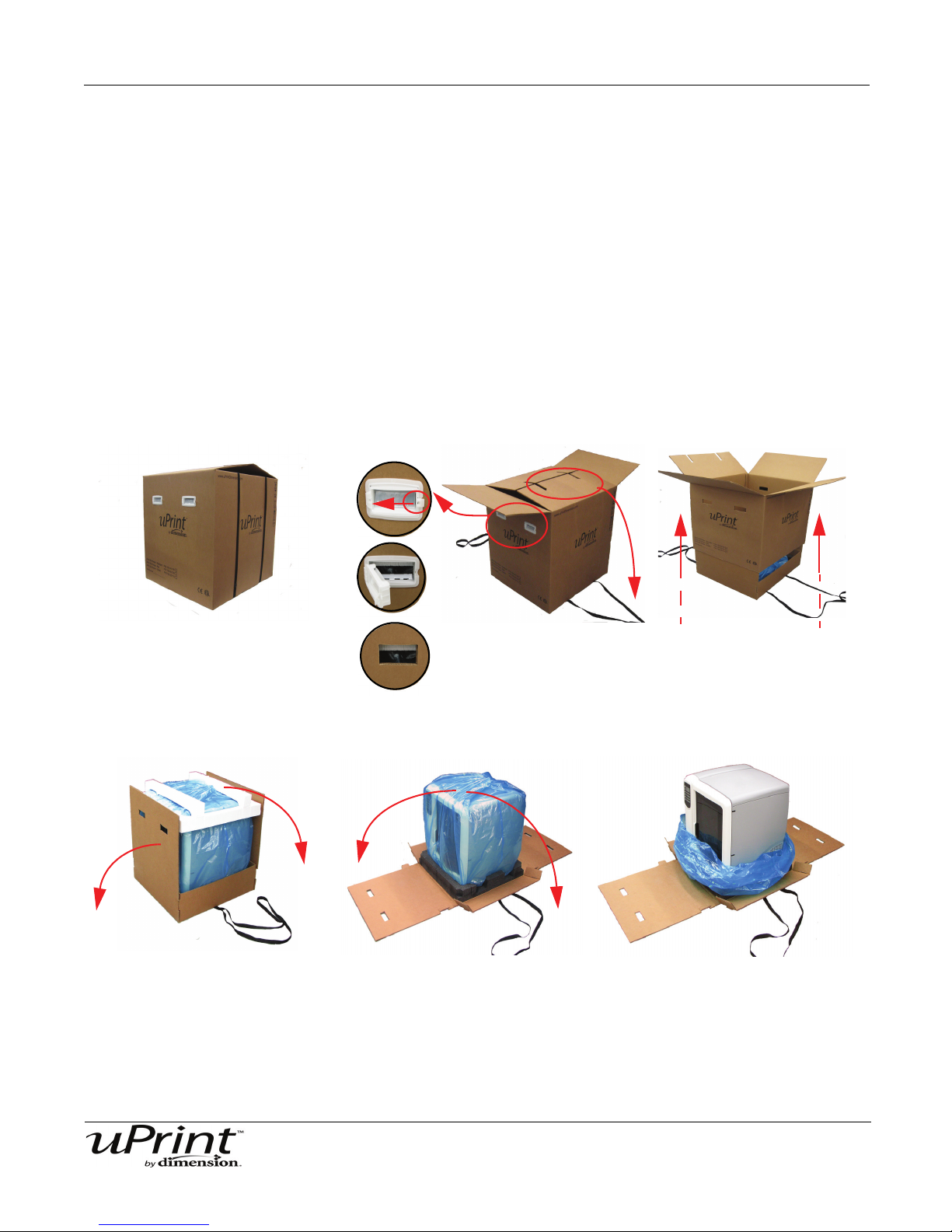

Unpacking the Printer

1. Place the printer close to the area where it will be located.

2. Remove the handles from the box.

3. Carefully cut the top of the box open, do NOT cut the straps that contain the box.

4. Unfold the top of the box and remove the straps.

5. Remove the handles, pulling the tabs outward.

6. Raise the outer box up and off of the inner box.

7. Fold down the sides of the inner box to reveal the printer.

8. Remove the foam from the top of the printer.

9. Cut the top of the blue plastic bag the printer is enclosed in.

10. Lower the plastic bag, the printer should now be visible.

Figure 6: uPrint 3D Printer

Stratasys Document Number 206465-0001

Setup 19

Set up the Material Bay and Printer

Once the Printer and the Material Bay are unpacked, they will need to be aligned and stacked before

operation.

1. Place the Material Bay on a stable, flat surface where you will have your uPrint 3D printer located.

2. The Material Bay has 4 holes for the feet and 2 holes for the alignment pins. See Figure 7. These must

be seated properly for mechanical stability.

3. Align the 4 feet and 2 two pins on the bottom of the printer with the holes on top of the Material Bay and

set in place.

See Figure 7.

LIFTING HAZARD

Use proper moving and lifting techniques when positioning the unit.

Figure 7: System Stacked (Shown with optional Material Bay)

4. Open the printer door and remove the substrate and VCI emitter and discard. See Figure 8.

5. Remove the shipping foam from the Z stage guide rods and recycle. See Figure 8.

6. Remove the belt retaining clips and recycle. See Figure 8.

Stratasys Document Number 206465-0001

Setup 20

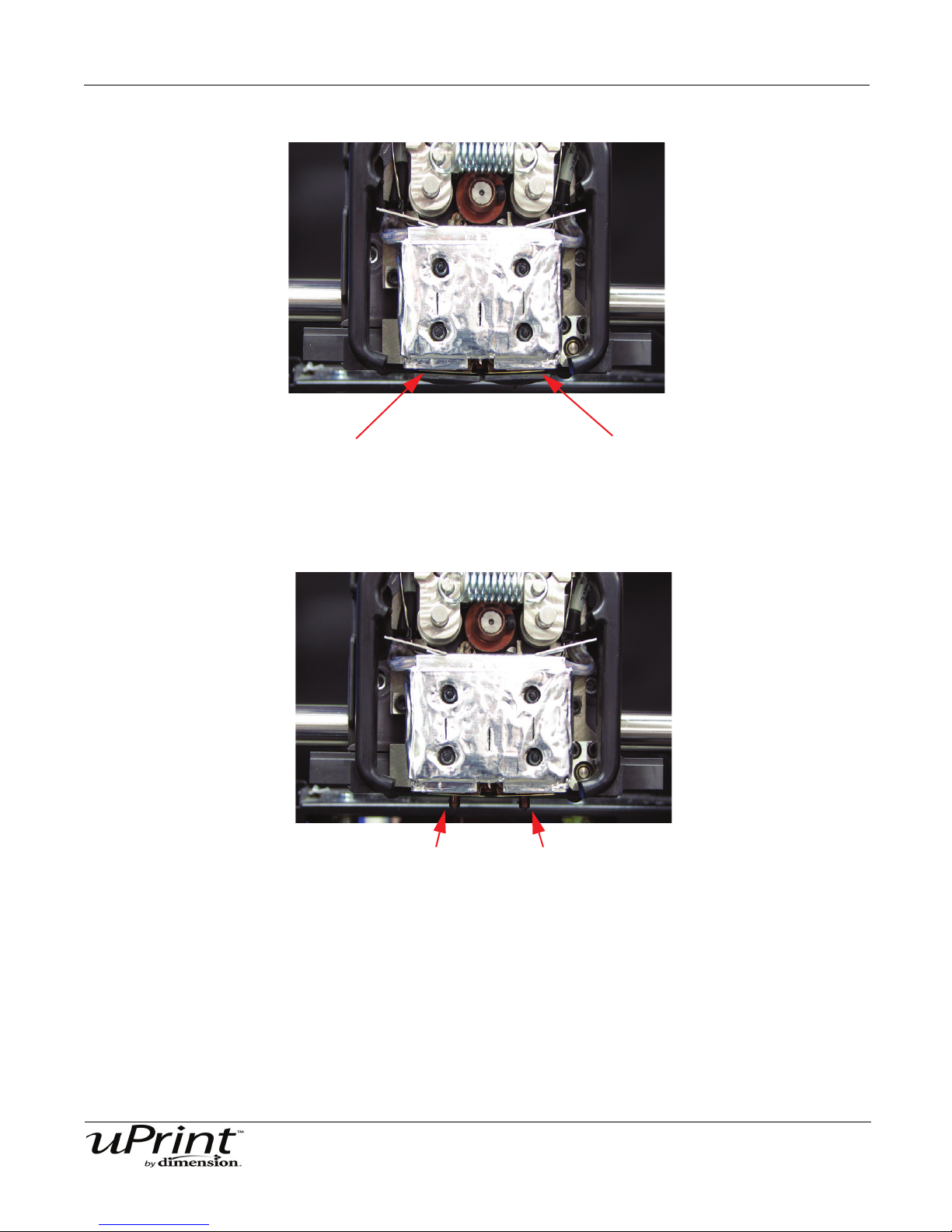

Remove belt retaining clips

and recycle.

Remove modeling base with

VCI emitter and discard

Remove shipping foam

from Z stage guide rods

and recycle.

Figure 8: Open the chamber door and remove shipping materials

WARNING

The Lead Screw and Guide Rods are lubricated with a thin coat of Krytox

grease. Krytox grease can cause skin irritation. Be careful not to get the

grease on your hands or clothing.

Stratasys Document Number 206465-0001

Setup 21

Align tabs with slots

Inserting a modeling base

The modeling base is the tray the printer uses to build the models on. You will need to use a new modeling

base for every build.

Inserting a modeling base:

1. Make sure the two retainers are turned down so they do not interfere with modeling base installation.

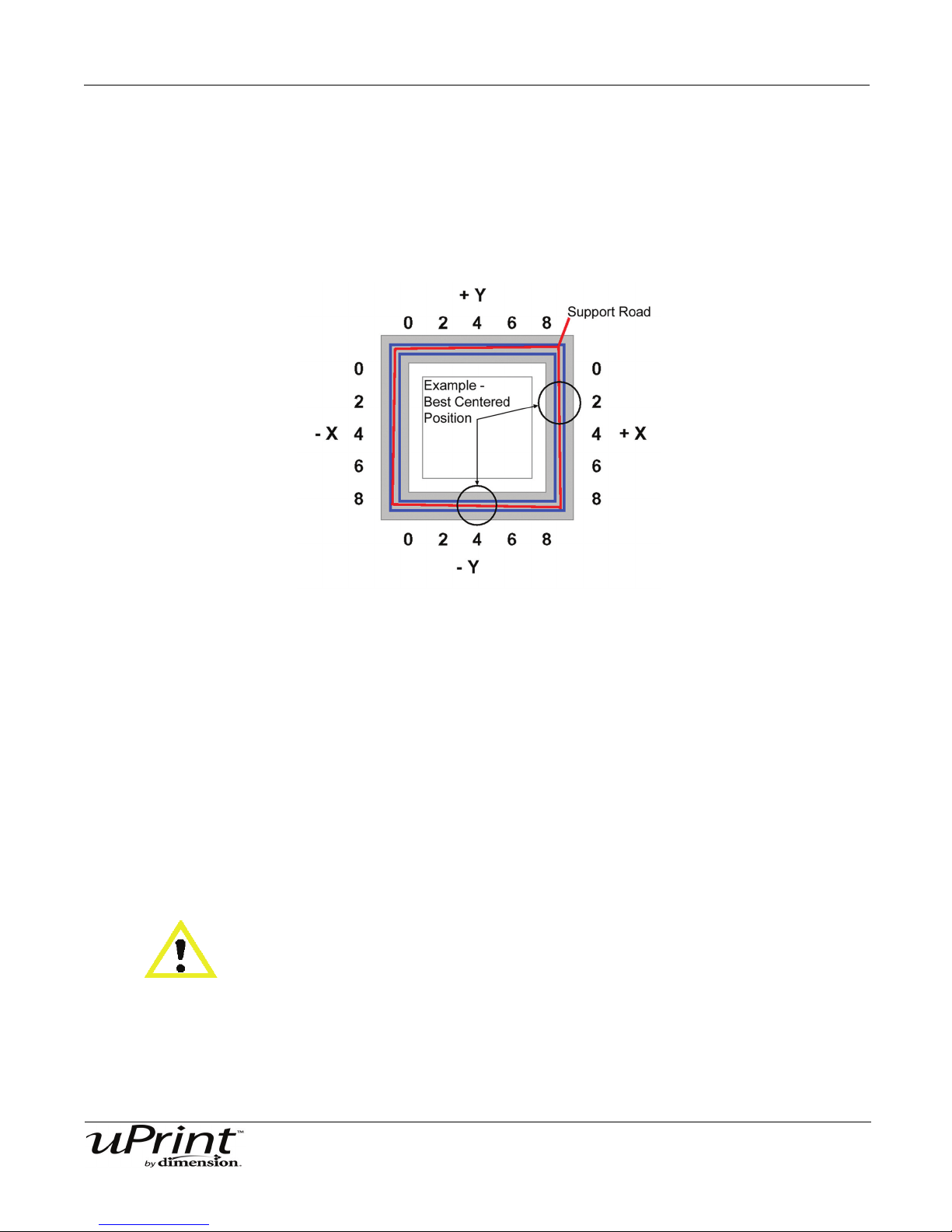

2. Set the modeling base on the Z platform aligning the tabs on the modeling base with the slots on the

metal tray. See Figure 9.

Figure 9: Z Platform Slots

3. Slide the modeling base down and toward the back of the unit until its front edge (with the handle) is

flush with the front edge of the tray. See Figure 10.

Figure 10: Slide modeling base in place

4. Secure the modeling base with the two retainers by turning them up. See Figure 11.

Figure 11: Turn retainers to lock modeling base in place.

Stratasys Document Number 206465-0001

Setup 22

Remove only if

using the optional

material bay

Firmly push tubes

into fittings

Connecting the printer and material bay(s).

1. Connect the material tubes from the material bay(s) to the printer. The material tube with the red stripe

is for the model material and the material tube with the black stripe is for support material. See Figure

12.

Figure 12: Material Tube connections

2. Connect the material bay communication cable(s) from the material bay(s) to the printer. Do NOT con-

nect the material bay communication cable(s) while the printer is powered on. See Figure 13.

Figure 13: Material Bay Communication Cable

Note:

If you are using the optional second material bay, the longer

material tubes are for the lower material bay and the shorter

material tubes are for the upper material bay.

Stratasys Document Number 206465-0001

Setup 23

Power Cable

Connecting the power cable:

1. Connect the power cable to the back of the printer.

2. Connect the power cable to the dedicated power outlet. See Figure 14.

Note:

Do not use an extension cord or a power strip, using these can

possibly cause intermittent power issues.

Figure 14: Power cable connection

Network/Crossover Connections

Connecting the network cable:

1. Connect the network cable (blue) to the network connection at the back of the printer.

2. Connect the network cable to the dedicated outlet or network hub.

If not using a network and connecting directly to a PC, you will need to use a crossover cable.

Connecting the crossover cable:

1. Connect the crossover cable (orange) to the network connection at the back of the printer.

2. Connect the crossover cable to the computer that will be sending the parts to the printer.

Figure 15: Network connection

Stratasys Document Number 206465-0001

Setup 24

1

2

Powering ON

The circuit breaker is located at the lower left corner on the rear of the printer. The power switch is located

on the left panel towards the rear of the printer. After the power switch is turned on the printer will boot up

within a few minutes. See Figure 16.

Figure 16: Circuit Breaker and Power Switch

Powering ON the printer:

1. Turn the circuit breaker to the ON position.

2. Turn the power switch to the ON position.

Note:

After powering the printer ON, it may take up to 5 minutes for the

software to boot up completely.

Initial Language Setup

Upon first start up of the uPrint 3D printer, you will need to set your default language.

Setting your default language:

1. From the display panel press Maintenance.

2. Press Setup.

3. Press Select Language.

4. Select the default language you will be using and press the corresponding button.

• English

• Spanish

• Italian

•German

•French

•Chinese

• Japanese

5. The display panel will ask Are You Sure? Press Yes.

Stratasys Document Number 206465-0001

Setup 25

Software

There are two software programs that work with uPrint. First there is CatalystEX which is the

preprocessing software that controls the uPrint 3D printer. The second software program is the system

software, which is factory installed on the printer. Because there are occasional changes to this software,

you will have to verify that you have the latest version installed.

Installing CatalystEX:

1. Insert the CatalystEX installation CD into your CD-ROM drive of the computer that will be used.

2. Click the Install button. If autorun is enabled on your computer, this should come up in a pop up win-

dow after you insert the CatalystEX CD. If autorun is not enabled on your computer you will have to

navigate to the CD-ROM directory and launch the setup application.

3. Follow the prompts to finish loading the CatalystEX software.

Note:

CatalystEX’s installation setup allows you to change or confirm

the target installation directory. To install CatalystEX in a directory

other than the default, type the path and directory name in the

dialogue box when prompted.

Verifying System Software:

1. Press Maintenance on the uPrint display panel.

2. The display will show the current version number and build number the printer has installed. Compare

this build number to the build number that is on the CD from the start up kit. If the build numbers do not

match, see “System Software” on page 29.

Networking Your Printer

There are two methods of connecting your printer to your computer, over a network and a direct connection

to your PC. This section describes how to set up communication over a network. For instructions on setting

up a direct PC connection, see “Connecting Directly To Your PC (if no network is available)” on page 27

You will need to establish communication between your PC and printer before you can send files to be

built. How you establish this communication is dependent upon how your computer network is configured.

In many cases, it is a simple matter of letting the CatalystEX software find your printer. In some situations

you may need to set the network address for your printer and possibly record the IP address in the

CatalystEX program.

Establishing communication on a Dynamic network:

If you are on a Dynamic network (or not sure of your network type) follow these steps to allow the

CatalystEX software to ‘find’ your printer and establish communication.

1. Plug in the network patch cable from your network to the rear of the uPrint 3D Printer. (A network cable

(blue) is included with the Start Up Kit.)

2. Make sure the printer is ‘ON’ and determine the Unique Device Name (UDN) for your printer.

A. From Idle (or Ready to Build), press Maintenance on the display panel. The display will show

Maintenance and the software version.

B. From the display panel press System.

C. From the display panel press Set Network. The top window displays: Network Admin - Dynamic

IP Address; UDN.

Stratasys Document Number 206465-0001

Setup 26

D. The UDN for your printer is listed here. This is preset at the factory and cannot be changed.

3. From your PC, start the CatalystEX application.

A. From the General Tab, click the Manage 3D Printers button.

B. Click the Add from Network button in the lower right corner of the pop-up window.

C. A new pop-up, Add 3D Printer, should list your printer in the main window (identified by its UDN,

or Unique Device Number). Click on the printer in this window and enter a Name and Location

(Your choice) in the lower portion of the pop-up window.

D. Click Add Printer and you are ready to print. Close the 3D Printer pop-up window.

Note:

If your printer is not displayed in the “Add 3D Printer” pop-up

window, you are not using a Dynamic Network. You will need to

set up a Static Network address.

Setting the Static Network address:

1. Obtain your static network address from your Network Administrator.

2. From Idle (or Ready to Build), press Maintenance on the display panel. The display will show Main-

tenance and the software version.

3. Press System.

4. Press Set Network. The top window displays: Network Admin - Static IP Address; UDN.

5. Press Static IP to display current settings. For example:

IP Address: 192.000.000.001

NM Address: 255.255.000.000

GW Address: 198.000.000.001

Note:

These values are the factory defaults and must be changed for

your network. If these values are not changed the printer will

continue to restart itself until they are changed.

6. Look for the cursor beneath the first digit of the IP Address. The cursor does not blink. To update the IP

Address:

Press Increment to increase the value one digit at a time.

Press Next Digit to move the cursor one place to the right.

Press Last Digit to move the cursor one place to the left.

7. Use the three functions listed above to set your IP Address.

8. After setting the final digit of the IP Address, move the cursor one more place to the right. The cursor

moves to the NM (or Netmask) address. Follow the same steps for setting the NM and GW addresses.

9. When you have finished setting the addresses, from the display panel press Done. The display will

show: Change IP, Netmask and Gateway?

10. Press Yes. The panel then displays Resetting Network and after a moment returns to Idle or starts

warming up.

11. From your PC, Start the CatalystEx application.

A. From the General Tab, click the Manage 3D Printers button.

B. Click the Add from Network button in the lower right corner of the pop-up window.

Stratasys Document Number 206465-0001

Setup 27

C. A new pop-up window, Add 3D Printer, should list your printer in the main window (identified by its

UDN). Click on the printer in this window and enter a Name and Location (your choice) in the lower

portion of the pop-up window.

D. Click Add Printer and you are ready to go. Close the 3D Printer pop-up window.

12. If your printer is not displayed in the Add 3D Printer pop-up window, you will need to add the printer IP

address manually.

A. From the General Tab, click the Manage 3D Printers button.

B. Click the Add Manually button in the lower right corner of the pop-up window.

C. In the pop-up window Add 3D Printer, enter a Name and Location (your choice) for your printer in

the appropriate fields.

D. Enter the IP Address for your printer in the appropriate field. It will be the same address as the one

listed in step 4.

E. Select the appropriate printer type from the drop down list.

F. Click Add Printer and close the 3D Printer pop-up window.

13. If you are unable to connect the printer to your PC, contact your Network Administrator.

Connecting Directly To Your PC (if no network is available)

You can also connect the uPrint 3D printer directly to your PC without the use of a network. This is most

easily accomplished with the printer in Dynamic Network mode (as received from the factory).

Connecting directly to the PC with a crossover cable:

1. Connect a crossover cable from your printer directly in to the network port on your PC. (A crossover

cable (orange) is included with the Startup Kit)

2. Make sure the printer is “ON” and determine the Unique Device Name (UDN) for your printer.

A. From Idle (or Ready to Build), from the display panel press Maintenance. The panel diplays

System Maintenance and the Software version.

B. Press the System button. The top window displays: Network Admin - Dynamic IP Address;

UDN.

The UDN for your printer is displayed here. This is preset at the factory and cannot be changed.

3. From your PC, start the CatalystEX application.

A. From the General Tab, click the “Manage 3D Printers” button.

B. Click the “Add from Network...” button in the lower right corner of the pop-up window.

C. A new pop-up window, “Add 3D Printer”, should list your printer in the main window (identified by

its UDN). Click on the printer in this window and enter a Name and Location (your choice) in the

lower portion of the pop-up window.

Note:

It may take up to 1 minute for your printer to appear in the pop-up

window.

D. Click “Add Printer” and you are ready to go. Close the “3D Printers” pop-up window.

4. If the printer does not appear in the pop-up window:

Stratasys Document Number 206465-0001

Setup 28

A. Close the Add 3D Printer pop-up window and click the Add Manually button in the 3D Printers

pop-up window.

B. in the pop-up window Add 3D Printer, enter a Name and Location (your choice) for your printer in

the appropriate fields.

C. Enter the Dynamic IP Address for your printer (from Step 2B) in the appropriate field.

D. Select the appropriate printer type from the drop down list.

E. Click Add Printer and close the 3D Printer pop-up window.

F. If you get an “Error: Unable to connect to printer” message it may be that your PC is not

configured for Dynamic Networking. To configure your PC for Dynamic Networking:

i. From the Control Panel of your PC, double click on Network and Internet Connections.

ii. Double click on Network Connections, then double click on Local Area Connection.

iii. Scroll the Local Area Network Connection Properties window to find the Internet Protocol

(TCP/IP) selection. Click on Internet Protocol (TCP/IP) and then click on the Properties

button.

iv. From the General tab of the Internet Protocol (TCP/IP) properties pop-up window, click on

the Obtain IP Address Automatically radio button.

v. Click OK and then OK again.

vi. After allowing your PC a minute or so to adjust to the new setting, your PC should connect to

your printer.

vii. If you are still unable to connect to your printer, recheck your connections and settings.

Stratasys Document Number 206465-0001

Setup 29

Push in

Pull out

System Software

The system software is factory loaded on the printer. Due to occasional changes you may need to update

the printer system software.

Updating System Software:

1. From the uPrint display panel, press Maintenance.

2. Press System.

3. Press Load Upgrade. The printer will then display “Send upgrade from workstation” followed by

the printer’s IP Address.

4. Open CatalystEX and click on the Printer Services tab.

5. Click on the Update Software button. CatalystEX will now connect to the printer and will prompt you to

locate the upgrade file. Direct the software to the CD the upgrade file is on. The update will automati-

cally be loaded on to the printer. After the update has been loaded, the display will show Verifying

update.

6. When the verification has completed, the display will show Reboot to complete. Select Yes. The

printer will now reboot and return to Idle.

Press the maintenance button and verify the updated version was installed correctly.

Installing a spool of material into the material carriers

An instructional video can be viewed at http://www.uPrintDimension.com

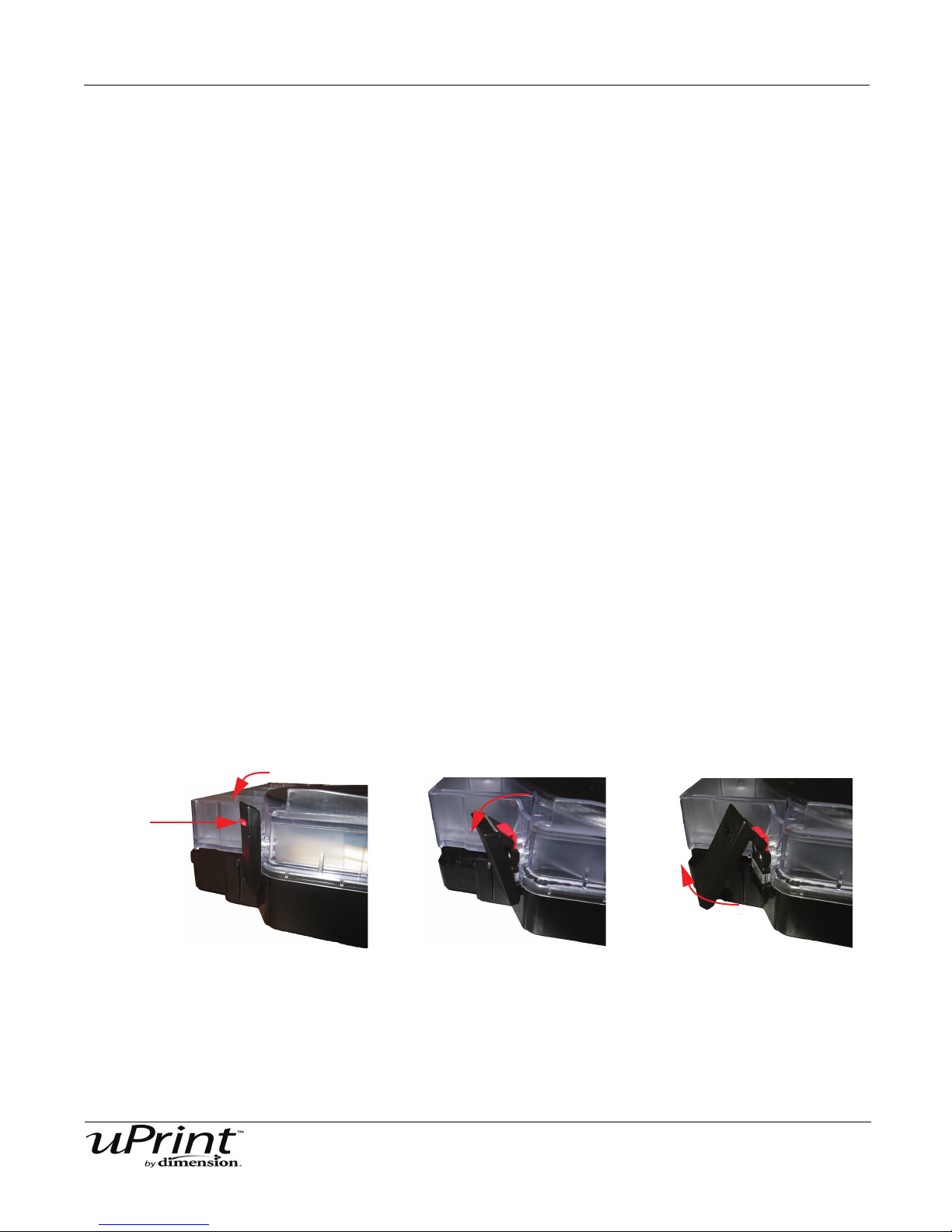

Installing a spool of material into the carrier:

1. For new carriers, remove the carrier from shipping box. Place on a flat surface, unlatch and open. See

Figure 17.

Note:

Save the enclosed storage bag for later use. The storage bag will

be used to store material spools when they are not in use, and

will help keep moisture out of the material.

Figure 17: Opening the carrier

2. Remove the material spool from the shipping box. Tear open the bag and discard (the bag will have a

notch for tearing open). Note how the material and material guide are held in place under a clear mate-

rial retaining band. See Figure 18.

Stratasys Document Number 206465-0001

Setup 30

Foil bag

Material spool

Retaining band

Material detent

Material guide

Figure 18: Removing the material spool

3. Remove the material retaining band. Be sure to remove the entire retaining band. DO NOT remove the

material guide from the spool at this time.

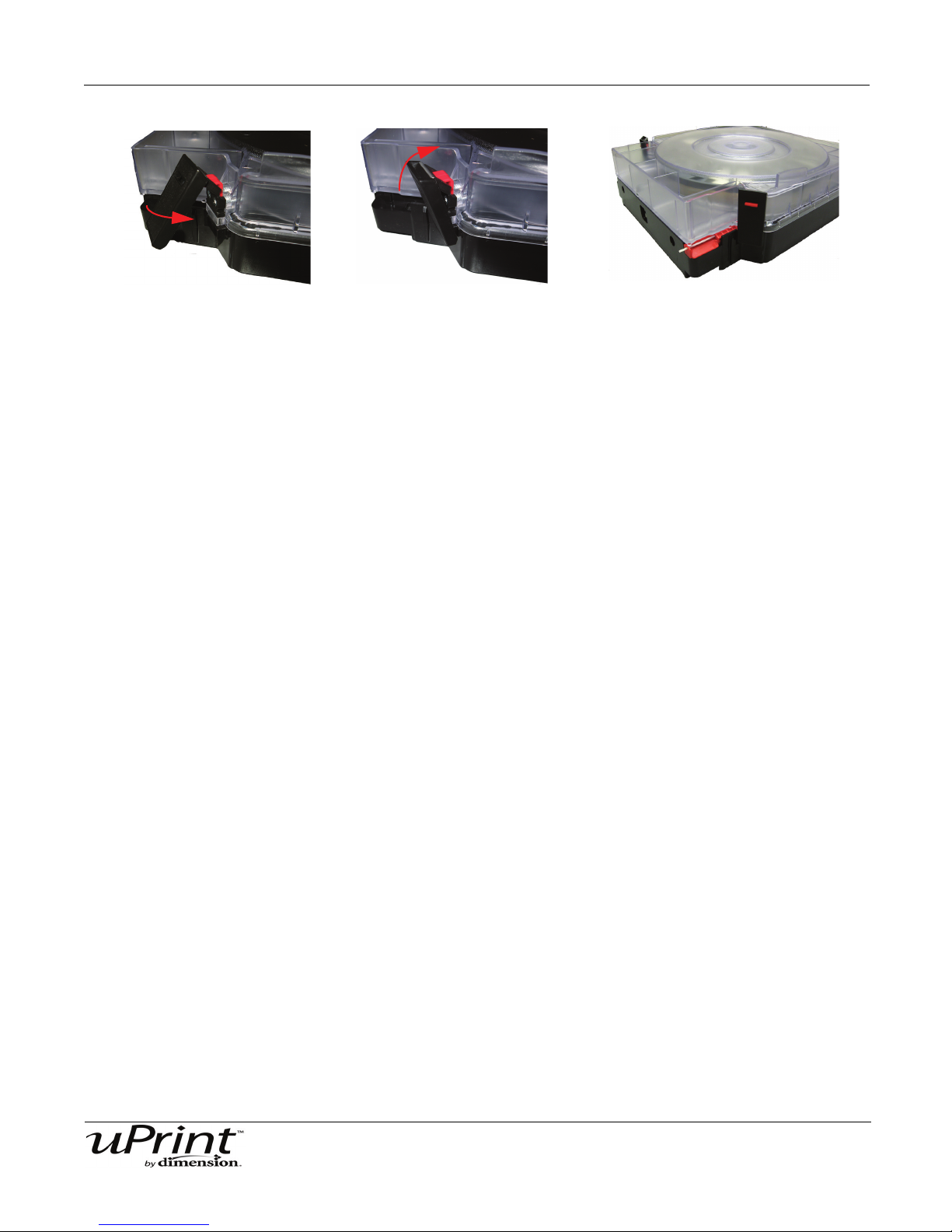

4. Place the spool in to the carrier with the material guide facing up.

5. Remove the material guide from the spool holding location.

6. Carefully remove material from the spool detent. See Figure 19 and Figure 20.

Figure 19: Place model material spool in to model material carrier

Figure 20: Place support material spool in to support material carrier

7. Place the model material guide into position see Figure 19 for model and Figure 20 for support.

Note:

Model and Support Carriers are different. The material guide

tubes install on the opposite side. See Figure 19 and Figure 20.

8. Close the carrier with the material guide in place. Latch both buckles completely (the red tab must

snap in to place on each buckle).

Material must protrude at least 1mm (0.04 inch) but not more than

See Figure 21.

Note:

30mm (1.18 inch) from the end of the material guide.

Stratasys Document Number 206465-0001

Setup 31

Figure 21: Latching the Carrier

Adding material carriers to the single material bay

Once the carriers have been filled, you will need to add the carrier into the material bay.

An instructional video can be viewed at http://www.uPrintDimension.com

Adding material carriers to the material bay:

1. From the display panel press Material, the display will show Add/Remove.

2. Add the model and support carriers to the material bay by inserting the carriers into the material bays

and latching into place.

Loading material to the head for the single material bay

1. Once the material carriers have been added to the material bays, press Load... next, press Load

Both. The display will show Loading Model. After the model material has loaded to the head the

display will show Loading Support.

Note:

It can take up to 5 minutes for the printer to load the material to

the head.

2. When the printer has finished loading support material to the head, press Done... the display will show

Wait for Part or Ready to Build (if a part is in the queue) and will also show the amount of material

remaining in the model and support carriers.

Adding material carriers to the dual material bays

Once the carriers have been filled, you will need to add the carrier into the material bay.

An instructional video can be viewed at http://www.uPrintDimension.com

Adding material carriers to the material bays:

1. From the display panel press Material, the display will show Add/Remove.

2. Add the model material carriers to the M1 and M2 material bays by inserting the carriers into the mate-

rial bays and latching into place.

3. Add the support material carriers to the S1 and S2 material bays by inserting the carriers into the mate-

rial bays and latching into place.

Stratasys Document Number 206465-0001

Setup 32

Loading material to the head for the dual material bays

1. Once the material carriers have been added to the material bays, press Load... Select Materials will

now be displayed.

2. Select the material bays that you want to be active, or loaded to the head. Select Next Model for the

next model bay, this will toggle between M1 and M2, or Next Support for the next support bay, this will

toggle between S1 and S2. A carrot will be placed next to the material bay that will be activated.

3. When the material bays have been selected, you can now press Load Selected. The display will show

Loading and the model material bay that has been selected. After the model material has been loaded

to the head, the display will show Loading and the support material bay that has been selected.

4. After the selected material bays have been loaded to the head, the display will show Preparing and

the inactive model material bay. This will repeat for the inactive support material bay. An asterisk will be

placed next to the model and support material bays that are active.

Note:

It can take up to 5 minutes for the printer to load the material to

the head.

5. When the material has been loaded to the head and the secondary material bays have been prepared,

press Done... the display will show Wait for Part or Ready to Build (if a part is in the queue) and will

also show the amount of material remaining in both model and both support carriers.

Building a Test Part

Factory test parts have been pre-loaded into the operating system of your printer. To familiarize yourself

with the system, it is recommended that you build one of these test parts before attempting to build one of

your own files.

Once the printer has reached Idle, material has been loaded and a modeling base has been installed, you

can build a test part with the printer.

1. From the display panel press Maintenance.

2. Press System.

3. Press Test Parts and select the sample wrench.

• The printer will automatically start to print the test part.

When the part is finished, follow the steps under “Remove a completed part from the printer:” on page 40.

Stratasys Document Number 206465-0001

Operation 33

Display Panel

Lower Displays

Keypad Buttons

Operation

Powering On

Refer to “Powering ON the printer:” on page 24 for instructions.

Display Panel and Keypad

The main user interface to the uPrint 3D Printer is the Display Panel and Keypad. See Figure 22.

Figure 22: uPrint display panel and keypad

The uPrint display panel and keypad consist of a multiple-line LCD display on top, and four single-line

displays, each with one button. The top line in the large display always shows the printer status. The

display shows status information, menu’s and error codes.

Occasionally there will be an item blinking in the lower displays.

The blinking item is usually the next, most logical selection.

Note:

Stratasys Document Number 206465-0001

Operation 34

Idle

Wait for Part

Material

Standby

Maintenance

System

Setup

Machine

• Set Network

• Load Upgrade

• Test Parts

• Lights Always On

• Select Language

• Disable UPnP

• Gantry

• Tips

• Head

Start Part

Building

• Pause

• Show Time

• Lights Off

• Auto Power Down

• Load Material

• Unload Material

• Replace Material

System Software Overview

This is a brief overview of the sections on the Display Panel.

• Idle: If there is no part being built and no part in the build queue, the display will show that the

printer is Idle.

• Wait for Part or Start Part: If the printer is in Idle, you can set it to wait for a part. If the printer has

a part in the build queue, you can press Start Part to start a build.

• Building: If the printer is building a part, you can choose to Pause, set the lights either ON or OFF,

view the print time or material remaining and set the printer to auto power down.

• Material: From this section you can load material, unload material or replace material.

• Standby: From this section you can set the printer to Standby mode.

• Maintenance: From this section you can make changes to the System, Setup or Machine.

Figure 23: Display panel hierarchy

Stratasys Document Number 206465-0001

Operation 35

CatalystEX

General Tab

Orientation Tab

Pack Tab

Printer Status Tab

Printer Services Tab

• Auto orientation

• Part rotation

• STL scale

• Change views

• Insert Pause

• Insert CMB file

• Pack name

• Clear pack

• Printer status

• Job queue

• Manage queue

• Printer history

• Export configuration

• Printer time

• Printer password

• Printer information

• Update software

• Layer resolution

• Model interior

• Support fill

• Number of copies

• STL units

• STL scale

CatalystEX Overview

This is a brief overview of the sections in the CatalystEX software.

• General tab: This section is where you can select the type model fill and support fill. You can also

change the STL units and STL scale in this section.

• Orientation tab: This section allows you to rotate and resize your parts. You can also change the

view and auto orient your part or insert a pause.

• Pack tab: This section shows you which parts are in the pack for printing. You can add parts, move

the parts around to make a better fit or clear the pack from this section.

• Printer Status tab: This section shows you the amount of material remaining for both model and

support as well as which parts are in the Build Queue.

• Printer Services tab: From this section you can check the printer history, set the printer time, set

the printer password, update printer software, get printer info and export configuration files.

Figure 24: CatalystEX hierarchy

For detailed information about the many file processing options

available in CatalystEX, refer to CatalystEX Dynamic Help.

For more information about STL files, CMB files, part orientation,

modeling envelope placement, print “job” efficiency and other

print controls, refer to the CatalystEX Dynamic Help.

Note:

Stratasys Document Number 206465-0001

Operation 36

Setting up your STL file for printing

This section describes how to:

• Open your STL file with the CatalystEX software.

• Setting the scale and orientation of the part.

• Model material fill type.

• Support material fill types.

• Adding your part to the pack

• Printing your part.

Opening your STL file with CatalystEX:

1. Create an STL file using your CAD software. Refer to your CAD software help section for more

information about converting your CAD drawing into STL files.

2. Open the CatalystEX software.

3. From the File menu select Open STL...

4. Navigate to and Select the STL file that you have created.

Setting the scale of your STL file:

Before you process a part for printing, you can change the size of the part within the build envelope. Every

part has a pre-defined size within the STL file. After you have opened the file you can change the size of

the part produced from the STL file by changing the scale. The scale always relates to the original STL file

size definition.

For example: a cube that is defined as 2 X 2 X 2 can be built to be 4 X 4 X 4 by simply changing the scale

to 2.0. If after changing the scale to 2.0, you decide that a size of 3 X 3 X 3 would be preferred, change the

scale to 1.5 - the scale relates to the original size of 2.0, NOT the resulting 4.0 from the first scale change.

1. Click within the scale input box to type a scale of your choice.

Setting the orientation of your STL file:

The Orientation tab has an expanded model window. It provides options for viewing a part, measuring a

part, orienting a part, processing a part and viewing the layers of a part. How a part is oriented in the

modeling window will determine how the part is oriented when it prints on the modeling base.

Orientation impacts the build speed, part strength, surface finish and material consumption. Orientation

can also affect the ability of CatalystEX to repair any problems with the STL file.

You can choose to Auto Orient your part, which allows CatalystEX to determine the best orientation for the

part, or you can manually change the orientation of your part.

Orientation Considerations:

• Build Speed - Closely related to material use. In general terms, a lesser amount of supports will

allow for a greater build speed.

Another factor affecting build speed is the axis orientation. The printer can build faster across the

X-Y plane than it can along the Z axis. Therefore, orienting a part so that it is shorter within the

modeling envelope will produce a quicker build.

Stratasys Document Number 206465-0001

Operation 37

• Part Strength - A 3D part is stronger within a layer than it is across layers. Depending upon what

you want your part to demonstrate, you may need to orient your part to have its greatest strength

across a specific area. For example a tab that needs to be squeezed would be weakest if you are

squeezing across layers.

• Surface Finish - Much like orienting for strength, orienting a part for surface finish will allow the

printer to provide the smoothest finish for a specific area.

• STL File Repair - It is possible for an STL file to have errors while appearing to be trouble free. If

the STL file contains errors, CatalystEX may have problems processing the file. CatalystEX has

the ability to automatically correct some STL file errors. Part orientation can impact this automated

repair function.

Selecting the model interior fill for your part:

This establishes the type of fill used for the interior, solid areas of the part. There are three types of model

interior that you can choose from.

• Solid - Used when a stronger, more durable part is desired. Build times will be longer and more

material will be used.

• High Density Sparse - This is the default model interior style and is highly recommended. Build

times will shorter, less material will be used and the possibility of part curl for geometries with large

mass will be greatly reduced.

• Low Density Sparse - The interior will be “honeycombed” or “hatched”. This style allows for the

shortest build times and lowest material usage but will decrease the strength of the part.

Selecting the support material fill for your part:

Support material is used to brace the model material during the build process. It is removed when the part

is complete. Support fill options will effect the support strength and build time of the print.

• Basic - May be used for most parts. It uses a consistent spacing between support raster toolpaths.

• Sparse - Minimizes the amount of support material. Sparse uses a much larger spacing between

raster toolpaths than basic supports.

• Minimal - Used for small parts that have small features in need of supports. It is designed to make

support removal easier on the small parts. DO NOT use minimal supports on large parts or parts

with tall columns of support.

• Surround - The entire model is surrounded by support material. Typically used for tall, thin mod-

els.

Adding your STL file to the pack:

The Add to Pack button is found on the General tab, Orientation tab and Pack tab.

When you click on the Add to Pack button, CatalystEX will add the file that is currently in the model

window (General tab or Orientation tab) to the pack preview window (Pack tab).

If the file in the model window has not been processed for print, processing will occur before the file is

added to the pack. Each additional click will add another copy of the file to the pack.

Printing your STL file:

The Print button is found on the General tab, Orientation tab and Pack tab.

Stratasys Document Number 206465-0001

Operation 38

Printer status

Model file name

Model material

remaining

Support material

remaining

• If there is a pack currently open in the pack preview window, you will be prompted as to whether or

not you want to clear the pack contents and then print the part or to add the part to the pack.

CatalystEX will now process all parts in the pack and create a CMB file from which the printer will print the

pack.

Building a part

If a part has not been sent to your printer for building, the build queue will be empty. If the build queue is

empty the display panel will show Idle or Ready to build.

Choose whether or not you want to start a build from a remote location or from the display panel at the

printer.

Starting a build from a remote location:

The lower display will show Wait for Part and it will be flashing.

1. From the display panel press Wait for Part. The display will ask Is Model Base Installed?

2. Press Yes. Waiting for Part will now be on the display.

3. From your CatalystEX workstation, send a part to the printer. The printer will automatically start to build

the model. See “Setting up your STL file for printing” on page 36 for detailed instructions.

Starting a build from the display panel:

1. From your CatalystEX workstation, send a part to the printer. The display will show Ready to Build

and the name of the first file that is in the queue waiting to be built.

2. From the display panel press Start Model to start building the model.

The display panel during build

The top two lines of the display panel will show the printer status. See Figure 25. The bottom line of the

display panel will show the amount of model and support material that remains in the carriers.

Figure 25: Display panel during build

Note:

If a material amount is flashing, it indicates that the remaining

material will not be enough to complete the current build.

Stratasys Document Number 206465-0001

Operation 39

Chamber Lights

When a part starts to build, the chamber lights are automatically ON. You can toggle the lights ON or OFF

through the display panel.

You can also turn the light on permanently.

To set the chamber lights to always on:

1. From Idle or Ready to Build, on the display panel press Maintenance.

2. Press Setup.

3. Press Lights Always On.

Repeat this process to turn this option off.

Pausing a build

While building a part, you may want to pause the build to allow for material replacement. To pause the

build at any time, from the display panel press Pause.

Note:

When the build process is paused, the printer completes the

current tool path before pausing.

Resuming a build that has been paused

If you have pressed Pause, and are ready to resume building the part, press Resume and the printer will

resume printing.

Canceling a build

You can cancel a build at any time while the part is building.

Cancel a build:

1. From the display panel press Pause.

2. Once the printer stops building, press Cancel Build.

3. The display will ask Are you Sure? Press Yes.

4. The display will show Build Stopped followed by the file name. You will then be prompted to remove

the part and replace the modeling base.

5. Remove the part and replace the modeling base. Once the chamber door has been opened and

closed, the display will ask Part Removed? Press Yes ONLY after you have removed the part and

replaced the modeling base.

CAUTION

If you press Yes before removing the part, the printer can be damaged.

Stratasys Document Number 206465-0001

Operation 40

Removing a completed part

When the printer has completed building a part, the display will show Completed followed by the file

name. It will also show Remove Part and Replace Modeling Base.

CAUTION

The modeling base will be hot, wear gloves when removing the part from the

printer.

Remove a completed part from the printer:

1. Open the chamber door.

2. Turn the modeling base retainers down and remove the modeling base by sliding out and pulling up.

3. Insert a new modeling base by sliding in and pushing down, turn the retainers up to lock the modeling

base in place.

4. Close the chamber door.

5. After you have opened and closed the door, the display will show Part Removed? ONLY after remov-

ing the part and replacing the modeling base, from the display panel press Yes.

CAUTION

If you press Yes before removing the part, the printer can be damaged.

• After you press Yes, the display will show the status as Idle or Ready to Build for the next part in

the queue.

Remove a part from the modeling base:

1. After removing the modeling base from the printer, firmly flex the modeling base back and forth with

your hands to loosen the part.

2. Pull the part off of the modeling base or use a putty knife to completely remove the part.

Note:

Parts are easier to remove from the modeling base when it is still

warm.

Stratasys Document Number 206465-0001

Operation 41

Purge Bucket

Purge Bucket Mounts

Removing support material

uPrint uses soluble support material, designed to allow you to simply wash it away. Your part is left with a

smooth and clean finish with the fine details intact. The soluble support material can be removed by hand

with relative ease, but is designed to be dissolved from your parts for hands free finishing.

Warning:

Support material is sharp, wear safety glasses and gloves when removing

support material.

Refer to the SST process guide for details regarding the removal of soluble support material. A copy of the

SST Process Guide can be found at http://www.uPrintDimension.com

Emptying the purge bucket

Empty the purge bucket after each build. This will ensure the purge bucket does not over fill which can

cause part quality issues or damage to the printer.

WARNING

Wear gloves when emptying the purge bucket.

1. With a gloved hand, lift up on the purge bucket and pull it off of the 2 mounts. See Figure 26

Figure 26: Emptying the purge bucket

Stratasys Document Number 206465-0001

Operation 42

2. Empty the purge bucket.

3. Place the purge bucket over the 2 mounts and push down to lock in place.

CAUTION

When reinstalling the purge bucket, make sure that it locks on both mounts

and hangs flush with the chamber wall to avoid damage.

Replacing material for single material bay

Removing material from the printer:

1. From the display panel press Material... The display will show Add/Remove and S1(remaining%)

and M1(remaining%). Asterisks will mark the currently active material bays (the material bays that are

currently loaded to the head).

2. Press Unload...

3. Press Unload both, Unload Model or Unload Support, depending on which you need to replace.

4. The printer will now unload material from the head. When the material has unloaded, you will need to

replace the material carriers.

5. Once the material carriers have been replaced press Load...

6. Press Load Model, Load Support or Load both depending on which material you are replacing.

7. After material has been loaded to the head press Done... the display will show Wait for Part or Ready

to Build (if a part is in the queue) and will also show the amount of material remaining in the model

and support carriers.

Replacing material for dual material bays

Removing material from the printer:

1. From the display panel press Material... The display will show Add/Remove and S1%,

S2(remaining%) and M1, M2 (remaining%). Asterisks will mark the currently active material bays (the

material bays that are currently loaded to the head).

2. Press Unload...

3. Press Unload both, Unload Model or Unload Support, depending on which you need to replace.

4. The printer will now unload material from the head. When the material has unloaded, you will need to

replace the material carriers.