Page 1

)

OPERATION AND PARTS MANUAL

Gasoline Crack Saw

Model RCC130H

Revision #1 (11/18/04

STOW CONSTRUCTION EQUIPMENT

A DIVISION OF MULTIQUIP INC.

POST OFFICE BOX 6254

CARSON, CA 90749

310-537-3700 • 888-252-STOW [888-2527869]

FAX: 310-537-1986 • FAX: 800-556-1986

E-MAIL: stow@multiquip.com • WWW:

stowmfg.com

PARTS DEPARTMENT:

800-427-1244

FAX: 800-672-7877

SERVICE

DEPARTMENT/TECHNICAL

ASSISTANCE:

800-478-1244

FAX: 310-631-5032

Page 2

Page 3

TABLE OF CONTENTS

STOW CRACK SAW MODEL RCC130H

Table Of Contents................................................................................................................................. 3-4

Parts Ordering Procedures ................................................................................................................... 6

Notice to Operators............................................................................................................................... 7-8

Operator Instructional Data Sheet ........................................................................................................ 9

Safety Precautions................................................................................................................................ 10

Preparation ........................................................................................................................................11

Operation ........................................................................................................................................... 12

Maintenance, Repair and Storage..................................................................................................... 13

Assembly .............................................................................................................................................. 14

Removing the Crack Saw from the Pallet.......................................................................................... 14

Before Starting the Engine.................................................................................................................... 14

Filling the Engine Crankcase with Oil ................................................................................................ 14

Filling the RCC130H Series Engine Fuel Tank .................................................................................15

Operation .............................................................................................................................................. 15

Theory of Operation........................................................................................................................... 15

Information Relative to the use of Diamond Blades™....................................................................... 15-17

Installing a Diamond Blade™ on the Arbor Shaft.............................................................................. 17

Transporting the Crack Saw .............................................................................................................. 19-20

Starting the RCC130H Series Gasoline Powered Crack Saw On the Job Site................................. 20

Operating the Crack Saw on the Job Site .........................................................................................21-29

Stopping the RCC130H Gasoline Powered Crack Saw .................................................................... 29

Operational Parameters and Techniques for RCC130H Series Crack Saw ..................................... 29-30

Service/Maintenance ............................................................................................................................31

Preventative Maintenance Check List ............................................................................................... 31

Checking V-Belt Tension and Alignment ........................................................................................... 31

Installing a Replacement V-Belt or Pulley ......................................................................................... 32-34

Installing Replacement Bearings on the Arbor Shaft......................................................................... 34-37

Lubrication Requirements.................................................................................................................. 37

Engine Service................................................................................................................................... 38

Troubleshooting .................................................................................................................................... 39-41

Storage ................................................................................................................................................. 42

Specifications.................................................................................................................

Explanation of Code In Remarks Column ............................................................................................ 44

Suggested Spare Parts......................................................................................................................... 45

....................... 43

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 3

Page 4

Component Parts Drawings

Operator Handle Assembly................................................................................................................ 46-47

Drivetrain Assembly........................................................................................................................... 48-49

Frame Assembly................................................................................................................................ 50-51

Dustpan/Vacuum Port Assembly....................................................................................................... 52-53

Wet Cutting Kit Assembly .................................................................................................................. 54-55

Decals ................................................................................................................................................ 56-57

Terms and Condition of Sale —Parts ................................................................................................ 58

TABLE OF CONTENTS

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 4

Page 5

NOTE PAGE

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 5

Page 6

x

PARTS ORDERING PROCEDURES

Dealer account number

Dealer name and address

Shipping address (if different than billing address)

Return fax number

Application Model number

Quantity, part number and description of each part

Specify preferred method of shipment:

please supply the following information:

FedEx or UPS Ground

FedEx or UPS Second Day or Third Day

FedEx or UPS Next Day

Federal Express Priority One

DHL

Truck

When ordering parts,

Note: Unless otherwise indicated by customer, all

orders are treated as “Standard Orders”, and will

ship within 24 hours. We will make every effort to

ship “Air Shipments” the same day that the order is

received, if prior to 2PM west coast time. “Stock

Orders” must be so noted on fax or web forms.

Here’s how to get help...

Please have the model and serial number on

hand when calling.

Parts Department

800-427-1244 Fax: 800-672-7877

310-537-3700 Fax: 310-637-3284

Service Department

800-478-1244 Fax: 310-537-4259

310-537-3700

Warranty Department

800-421-1244, Ext. 279 Fax: 310-537-1173

310-537-3700, Ext. 279

Sales Department

310-661-4242 Fax: 310-604-9237

877-289-7869 (877-BUY STOW)

Place Your Parts Order Via Web or Fa

For Even More Savings!

Extra Discounts!

All parts orders which include complete part numbers

and are received by our automated web parts order

system, or by fax qualify for the following extra discounts:

Ordered Standard Stock orders

via orders ($750 list and above)

Fax 3% 10%

Web 5% 10%

Special freight allowances

when you order 10 or more

line items via Web or Fax!**

FedEx Ground Service at no charge for freight

No other allowances on freight shipped by any other

carrier.

NOTE: DISCOUNTS ARE SUBJECT TO CHANGE

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 6

STOW CONSTRUCTION EQUIPMENT

A DIVISION OF MULTIQUIP INC.

POST OFFICE BOX 6254

CARSON, CA 90749

310-537-3700 • 888-252-STOW [888-252-7869]

FAX: 310-537-1986 • FAX: 800-556-1986

E-MAIL: stow@multiquip.com • WWW: stowmfg.com

Direct TOLL-FREE access

to our Parts Department:

Toll-free nationwide — 800-427-1244

Page 7

IF YOU CAN NOT READ OR DO NOT FULLY UNDERSTAND THE CONTENTS OF THIS

MANUAL, PLEASE CONTACT THE FACTORY FOR PROPER ASSISTANCE BEFORE

ATTEMPTING TO OPERATE THIS PRODUCT.

SI TU NO PUEDES LE'ER O NO COMPRENDES EL CONTENIDO DE ESTE MANUAL

FAVOR DE PONERSE EN CONTACTO CON LA. FABRICA PARA ASSISTENCIA- A

PROPIA ANTES DE INTENTAR PARA OPERAR ESTE PRODUCTO.

SOLLTEN SIE DIESE GEBRAUCHSANWEISUNG NICHT LESEN KOENNEN ODER ES

NICHT VOLLKOMMEN VERSTEHEN, WENDEN SIE SICH BITTE AN DEN HERSTELLER

FUER RICHTIGE HILFE EHE SIE VERSUCHEN DIESES PRODUKT ZU OPERIEREN.

SI VOUS NE LISEZ OU NE COMPRENDRE ENTIEREMENT LES MATIERES DE CE

MANUEL, S'IL VOUS PLAIT, CONTACTEZ L'USINE POUR L'ASSISTANCE APPROPRIEE

AVANT D'UTILISER LE PRODUIT.

NOTICE TO OPERATORS

DANGER

CAUTION

These safety alert symbols identify important safety messages in this manual. When you see these symbols, be

alert to the possibility of personal injury and carefully read the message that follows.

Do not allow anyone to operate the CRACK SAW without first reading this Operator Manual and becoming

familiar with its operation. The manufacturer of the CRACK SAW has gone to great extremes to provide the

owner(s) and/or operator(s) with the finest equipment available for its intended job function of removing covering

materials from concrete and wood floor surfaces. Yet, the possibility exists that the CRACK SAW can be utilized

in and/or subjected to job applications not perceived and/or anticipated by the manufacturer. Such misuse and/or

misapplication of the CRACK SAW can lead to the possibility of serious damage, injury or even death. It is the

responsibility of the owner(s) and/or operator(s) to determine that the CRACK SAW is being utilized and/or

operated within the scope of its intended job function. It is the responsibility of the owner(s) and/or operator(s) to

establish, monitor and constantly upgrade all safety programs and/or practices utilized in and for the operation of

the CRACK SAW. The purpose of such programs is to provide for owner(s') and/or operator(s') safety. Operators

must be instructed to recognize and avoid unsafe conditions associated with their work (29 CFR 1926.21 (b)(2))

and/or applicable updated revisions. It is the responsibility of the owner(s) and/or operator(s) to determine that no

modifications and/or alterations have been made to the CRACK SAW. Modifications and/or alterations can lead to

the possibility of serious damage, injury or even death. It is the responsibility of the owner(s) and/or operator(s) to

make this Operator Manual available for consultation during all phases of operation. Refer to OSHA 2207 and/or

applicable updated revisions which contains all OSHA job safety and health rules and regulations (1926 and

1910) covering construction.

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 7

Page 8

CAUTION

The concept of frame mounted type Crack Saws has been successfully utilized for many years as a

practical solution to many types of random crack sawing requirements. The basic concept is proven and

well accepted within the associated marketplaces. Use of a Crack Saw requires strenuous work activity.

This type of work activity can be considered to be greater in magnitude than that experienced with the

use of many other types of both light construction and lawn and garden related equipment. This type of

work activity should only be attempted by operators of adequate physical size and stature, mental

awareness and physical strength and condition. The body parts most noticeably affected during the

planing process are the arms, hands, wrists, shoulders, lower back and legs. The process can also

produce excessive stress/strain directly to the back muscles, spinal vertebrae and many other body

parts. Back related pain can be a side effect of utilizing a Crack Saw. An operator with a chronic back

related problem or a history of back and/or other medically related problems should not attempt to utilize

the Crack Saw. Use of the Crack Saw may only aggravate this and any other medically related problem.

Because of the diverse type of prevailing job applications, job site conditions, operator experience levels

and operator physical characteristics, no warranty, guarantee, representation and/or liability is made by

the manufacturer as to the absolute correctness or sufficiency of any operational procedure, operational

position and/or technique. There is no absolute guarantee that an operator of any given experience level,

physical size and/or physical condition will be immune to the possibility of and/or probable physical side

effects of the normal use of the Crack Saw. Each potential operator must be made aware of and assume

the operational and physical liability described and/or associated with the use of the Crack Saw. Improper

use of the Crack Saw can result in property damage and/or personal injury, including death. Each

potential operator not willing to assume the operational and physical liability described and/or associated

with the use of the Crack Saw, should not operate it. Proper levels of operator experience, skill and

common sense are essential for maximizing the safe and efficient operation of the Crack Saw.

Record the CRACK SAW and electric motor serial numbers in the spaces provided below.

_______________ Model Number

_______________ Serial Number

_______________ Date of Purchase

Specifications and design are subject to change without notice or obligation. All specifications are general in

nature and are not intended for specific application purposes. STOW A Division of Multiquip reserves the right to

make changes in design, engineering or specifications and to add improvements or discontinue manufacture at

any time without notice or obligation. STOW and its agents accept no responsibility for variations which maybe

evident in actual products, specifications, pictures and descriptions contained in this publication.

NOTICE TO OPERATORS

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 8

Page 9

The following undersigned operators of the RCC130H CRACK SAW described and/or pertaining to this Operator

Manual have received formal safety and operational information/instruction from the undersigned

owner(s)/instructor(s) in accordance to OSHA 29 CFR 1926.21 (b)(2) and/or applicable updated revisions

pertaining to, but not necessarily limited to the:

1) READING, COMPREHENSION AND ACKNOWLEDGEMENT OF THE MATERIAL COMPRISING THE

ENTIRE CONTENTS OF THE APPLICABLE OPERATOR MANUAL AND APPLICABLE SAFETY AND

OPERATIONAL INFORMATION VIDEO TAPE FOR THE CRACK SAW.

2) FORMALIZED OPERATOR SAFETY PROGRAM TO BE DEVISED BY THE OWNER OF THE CRACK SAW

IN CONJUNCTION WITH THE CONTENTS OF THE APPLICABLE OPERATOR MANUAL AND THE

APPLICABLE SAFETY AND OPERATIONAL INFORMATION VIDEO TAPE FOR THE CRACK SAW.

4) LOCAL LAWS, REGULATIONS AND CUSTOMS RESEARCHED FOR AND/OR BY THE OWNER OF THE

CRACK SAW AND DEEMED APPLICABLE TO THE SAFE AND PROPER USE AND/OR OPERATION OF

THE CRACK SAW FOR ANY SPECIFIC JOB APPLICATION.

5) FORMALIZED MAINTENANCE PROGRAM FOR THE CRACK SAW TO BE DEVISED BY THE OWNER OF

THE CRACK SAW IN ACCORDANCE WITH, BUT NOT NECESSARILY LIMITED TO, THE SPECIFICATIONS,

GUIDELINES AND OPERATIONAL INFORMATION CONTAINED IN THE APPLICABLE OPERATOR

MANUAL.

6) COMPREHENSIVE OPERATIONAL INSTRUCTIONS FOR THE CORRECT AND PROPER USE OF THE

CRACK SAW AS PER THE CONTENTS OF THE APPLICABLE OPERATOR'S MANUAL, SAFETY AND

OPERATIONAL INFORMATION VIDEO TAPE AND APPLICABLE MATERIAL INCLUDED IN THE NATIONAL

ELECTRIC CODE®.

_______________ Operator _______________ Owner/Instructor __________ Date

_______________ Operator _______________ Owner/Instructor __________ Date

_______________ Operator _______________ Owner/Instructor __________ Date

_______________ Operator _______________ Owner/Instructor __________ Date

_______________ Operator _______________ Owner/Instructor __________ Date

_______________ Operator _______________ Owner/Instructor __________ Date

NOTE: INSERT COPIES OF THIS PAGE WITHIN THE OPERATOR'S MANUAL IF SPACE FOR ADDITIONAL

OPERATORS IS REQUIRED.

OPERATOR INSTRUCTIONAL DATA SHEET

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 9

Page 10

SAFETY PRECAUTIONS

THE FOLLOWING SAFETY PRECAUTIONS

PROVIDE SOME COMMON SENSE GUIDES TO

PROMOTE SAFETY AND EFFICIENCY WITH THE

CRACK SAW. NO WARRANTY, GUARANTEE OR

REPRESENTATION IS MADE BY THE

MANUFACTURER AS TO THE ABSOLUTE

CORRECTNESS OR SUFFICIENCY OF ANY

INFORMATION OR STATEMENT. THESE SAFETY

PRECAUTIONS ARE INTENDED TO DEAL

PRINCIPALLY WITH COMMON PRACTICES AND

CONDITIONS ENCOUNTERED IN THE USE OF

THE CRACK SAW AND ARE NOT INTENDED TO

BE ALL INCLUSIVE. PROPER LEVELS OF

OPERATOR EXPERIENCE, SKILL AND COMMON

SENSE ARE ESSENTIAL FOR SAFE AND

EFFICIENT OPERATION.

THE ENGINE EXHAUST FROM THIS PRODUCT

CONTAINS CHEMICALS KNOWN TO THE STATE

OF CALIFORNIA TO CAUSE CANCER, BIRTH

DEFECTS OR OTHER REPRODUCTIVE HARM.

THIS STATEMENT IS MADE IN COMPLIANCE TO

CALIFORNIA PROPOSITION 65..

DANGER

DANGER

DANGER

INCORRECT USE OF THE CRACK SAW CAN

RESULT IN PROPERTY DAMAGE, PERSONAL

INJURY OR EVEN DEATH. TO REDUCE THIS

POSSIBILITY, GIVE COMPLETE AND UNDIVIDED

ATTENTION TO THE JOB AT HAND AND

FOLLOW THESE SAFETY PRECAUTIONS:

PREPARATION.

1) This Crack Saw is specialized type of powered

equipment, designed for a specific job function and

requires adequate and thorough instruction

BEFORE it is operated. The size, power, complexity

and operating characteristics of this type of powered

equipment would dictate that each operator must

receive adequate, professional instruction regarding

the proper operation of this Crack Saw before being

allowed to utilize it. BEFORE attempting to utilize

this Crack Saw, read this Operator's Manual, the

applicable Safety and Operational Information Video

Tape and the material supplied by the engine

manufacturer to familiarize each operator with its

correct operating procedures. Avoid the urge not to

take the necessary time to read this Operator's

Manual before operating the Crack Saw. DO NOT

OPERATE THE CRACK SAW UNTIL EACH

OPERATOR COMPLETELY COMPREHENDS THE

CONTENTS OF THIS MANUAL AND THE

APPLICABLE SAFETY AND OPERATIONAL

INFORMATION VIDEO TAPE.

2) Develop a comprehensive program for the safe

operation of the Crack Saw by its owner(s) and/or

operator(s). Such a program will include, but is not

limited to: instructional requirements for operation,

applicable OSHA requirements, local laws and

regulations, job site safety and a Crack Saw

maintenance program. Constantly examine and

upgrade this program to guarantee owner(s) and/or

operator(s) safety. Each operator must be fully

instructed regarding the specifics of this safety

program.

3) Determine that the Crack Saw is in its original,

factory configuration and has not been modified in

any manner. Many modifications can result in

potentially dangerous configurations that can lead to

property damage and/or personal injury. If there are

any questions about possible modifications made to

the Crack Saw, contact the Customer Service

Department for specific information BEFORE

utilization. There is no charge for this service. Do not

operate the Crack Saw without the use of the

original equipment V-belt and diamond blade

guards. Use of the Crack Saw without an approved

belt guard and/or diamond blade guard can lead to

property damage and/or personal injury.

4) Minors should never be allowed to operate the

Crack Saw. Bystanders, especially children and

animals, should not be allowed in the area where the

Crack Saw is in use. The sawing process can result

in flying particles being emitted at high velocity and

striking the operator and/or onlookers. This can lead

to the possibility of property damage and/or personal

injury. Keep all body parts, loose clothing, foreign

objects and onlookers clear of the rotating diamond

blade, caster wheels, main wheels and flying

particles.

5) Operators must be in adequate physical

condition, mental health and not under the influence

of any substance (drugs, alcohol, etc.) which might

impair vision, dexterity or judgment. Working with

the Crack Saw is strenuous. If you have any

condition that might be aggravated by strenuous

work, check with your doctor BEFORE operating the

Crack Saw. Guard against the possibility of back

related injuries. Always lift the Crack Saw with leg

muscles and not with the back.

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 10

Page 11

SAFETY PRECAUTIONS

6) Prolonged use of the CRACK SAW (or other,

similar machines) exposes the operator to vibrations

which may produce Whitefinger Disease (Raynaud's

Phenomenon). This phenomenon reduces the

hand's ability to feel and regulate temperature,

produces numbness and burning sensations and

may cause nerve and circulation damage and tissue

necrosis. Antivibration systems do not guarantee

that you will not sustain Whitefinger Disease.

Therefore, continuous and regular users should

closely monitor the condition of their hands and

fingers. After each period of use, exercise to restore

normal blood circulation. If any of the symptoms

appear, seek medical advice immediately.

7) Clothing must be sturdy and snug fitting, but allow

complete freedom of movement. Never wear loose

fitting jackets, scarves, neckties, jewelry, flared or

cuffed pants or anything that could become caught

on controls or moving parts. Wear long pants to

protect your legs. Protect your hands with heavy

duty, nonslip gloves to improve your grip. Good

footing is most important when operating the

CRACK SAW. Wear sturdy boots with nonslip soles.

Steel-toed safety shoes are highly recommended.

Keep shoes properly laced. Never wear tennis

shoes or other, similar type shoes which afford little

or no protection. Wear an approved safety hard hat

to protect the operator'(s') head(s) where there is a

danger of head injuries. Noise, generated by the

operation of the CRACK SAW and the actual

process itself, can damage your hearing. Wear

approved sound barriers (ear plugs or ear mufflers)

to protect your hearing. Continuous and regular

operators should have their hearing checked

regularly.

8) Visually inspect the Crack Saw, components,

tools and accessories for damaged or worn parts.

BEFORE each use:

a) Disconnect the engine spark plug wire or power

source cable.

b) Clean and remove all accumulated foreign matter

from the wheels and determine that each rotates

freely.

c) Clean and remove all accumulated foreign matter

from inside the main frame area.

d) Inspect the V-belt drive for proper tension, wear

and general condition. Replace each component as

necessary.

e) Inspect the arbor shaft and diamond blade guard

assemblies for excessive wear and structural

integrity. Replace each component as necessary.

The arbor shaft rotates at high speed during the

specific process and can be subject to high wear

rates if the installed diamond blade is not properly

maintained and/or replaced at regular service

intervals.

f) Determine that operator controls work freely, all

safety devices are operative and information decals

are readable.

g) Check to see that the Crack Saw and all related

accessories are in good, mechanical condition

BEFORE utilization.

h) Reconnect the spark plug wire or power source

cable as applicable

9) Contact appropriate representatives to determine

if/where electrical cables, gas lines and other

hazardous items are buried under the work surface

BEFORE utilization. The Crack Saw and related

accessories are not insulated. Contact with buried

electrical cables, gas lines and other hazardous

items can result in electrocution and/or an explosion.

10) Know how the controls operate. Know how to

stop the engine or electrical motor quickly in an

emergency. Always start the engine or electric motor

according to the instructions as outlined in this

manual to minimize the possibility of unexpected

contact with the work surface. Unexpected contact

with the work surface can cause loss of machine

control, and the possibility of property damage

and/or personal injury.

11) Never exceed the recommended capacities of

the Crack Saw. Refer to the Specifications section

of this manual for more detailed information.

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 11

Page 12

SAFETY PRECAUTIONS

OPERATION.

1) Give complete and undivided attention to the job

at hand. Do not chew gum, smoke and/or use

smokeless tobacco while utilizing the Crack Saw. Do

not attempt to eat and/or drink while utilizing the

Crack Saw. Determine that eyeglasses and/or

hearing aid devices are properly secured

Use of the Crack Saw is strenuous and causes

fatigue. Help prevent the cause of an accident. Plan

to take work breaks as required to help maintain

proper mental and physical alertness.

2) This CRACK SAW is not sealed or insulated. Do

not operate the CRACK SAW in an explosive

atmosphere or near combustible materials. Refer to

current OSHA® rules and regulations.

3) Gasoline is an extremely flammable fuel. Use

extreme caution when handling gasoline or mixing

fuel. Always utilize UL®, CSA® OR CE approved

containers for the storage and transportation of fuel.

Do not smoke or bring fire or flame near the fuel.

Always shut off the engine and allow it to cool before

refueling. Never remove the fuel tank filler cap while

the engine is running. Never operate an engine

without a fuel tank filler cap. Select bare ground for

fueling and move at least 10 feet from the fueling

spot before starting the engine. Wipe off any spilled

fuel before starting the engine and check for

leakage. If a fuel or oil leak is found, do not start or

run the engine until the leak is fixed and the spillage

has been wiped away. Take care not to get fuel or

oil on your clothing. If this happens, change your

clothing immediately. Before operating the Crack

Saw refer to the Specifications section of this

manual for more detailed information regarding fuel

and lubrication requirements.

4) The Crack Saw is designed for use by one

operator. Use of the Crack Saw by more than one

operator can lead to confusion and loss of control,

resulting in property damage and/or personal injury.

If it is felt that more than one person is required to

operate the Crack Saw, STOP and contact the

Customer Service Department for specific

operational and service/maintenance information.

There is no charge for this service.

5) Do not operate the Crack Saw with onlookers

close by. Caution all onlookers to stand clear. The

sawing process can result in flying particles being

emitted at high velocity and striking the operator

and/or onlookers. This can lead to the possibility of

property damage and/or personal injury. Keep all

body parts, loose clothing and foreign objects clear

of the rotating diamond blade.

6) Start the engine or electric motor according to the

instructions as outlined in this manual to minimize

the possibility of unexpected contact with the work

surface. Unexpected contact with the work surface

can cause the loss of machine control and the

possibility of property damage and/or personal

injury.

7) Start and operate the Crack Saw only in a well

ventilated area. Carbon Monoxide fumes given off

by an engine are poisonous. Breathing these fumes

can result in property damage and/or personal

injury. Operate the Crack Saw only when/where

visibility and light are adequate for the job at hand.

Work carefully. Always hold the operator handle

firmly with both hands. Wrap your fingers around the

handle, keeping it cradled between your thumbs and

fingers. Always make sure the operator handle is in

good condition and free of moisture, pitch, oil or

grease. Wear gloves to improve your grip. Never

leave the Crack Saw running unattended.

8) Special care must be exercised on slippery

conditions and on difficult, uneven surfaces. Watch

for cracks, high spots and other, surface

irregularities. Keep proper footing and balance at all

times. The normal use of this machine is on level

surfaces. Other terrains can be dangerous and

should be avoided. Only properly trained operators

should attempt these techniques.

9) Never start the engine or electric motor with the

Crack Saw directly over cracked, uneven or irregular

surfaces. Start the engine or electric motor

according to the instructions as outlined in this

manual.

10) Contact with a hot, engine muffler can cause

property damage and/or personal injury. Remain

clear of a hot, engine muffler. Do not over speed the

engine by altering the governor setting or by

disconnecting the engine governor. Serious damage

to the engine and/or personal injury can result.

11) Clean and remove all accumulated foreign

matter from inside the main frame area after each

use. This practice will maximize bearing and V-belt

service life.

12) Because this Crack Saw is classified as a low

cost, hand held, low horsepower, portable type

machine, it is limited in the number of practical

and/or suitable job applications. A particular job site,

actual surface conditions, job specifications and

operator skill/common sense may dictate that a

different type of machine (with characteristics of

higher purchase cost, being mounted to a carrier

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 12

Page 13

SAFETY PRECAUTIONS

vehicle, with greater horsepower and less mobility),

method and/or process be utilized to properly

complete the job with the degree of efficiency and

safety required. Contact the Customer Service

Department for specific information regarding

suitable job applications, job sites surface conditions

and operator experience/skill/common sense

recommendations for this Crack Saw BEFORE

utilization. There is no charge for this service.

MAINTENANCE, REPAIR AND STORAGE.

1) Use only genuine, approved replacement parts

and accessories for maintenance and repair. Use of

parts and accessories manufactured by others can

result in property damage and/or personal injury.

2) Follow the Service instructions as outlined in the

appropriate section of this manual.

3) Always stop the engine or electric motor and

disconnect the spark plug wire or power source

cable BEFORE checking or working on the Crack

Saw.

4) Always properly maintain the Crack Saw.

Frequently check all fasteners and individual parts.

Built in safety features are effective only if they are

maintained in good working condition. Replace any

questionable part or assembly with a genuine,

factory approved, replacement part. Do not forsake

proper maintenance for the price of a few

replacement parts. Proper maintenance does not

cost...it actually pays dividends. Do not attempt any

maintenance repair work not described in this

manual. Have such work performed at your dealer's

service facility.

5) A worn or damaged engine muffler is a fire hazard

and may cause loss of hearing. Check to see that

the muffler is in good condition. If the muffler is

equipped with a spark arresting device, determine

that it is in proper working condition at regular

service intervals. Replace the spark arresting device

with an approved replacement if there is any

question of it integrity. It is the responsibility of the

owner(s) and/or operator(s) to provide for and

properly maintain a USDA approved, spark arresting

muffler in an operating area specified by law. Check

with appropriate governing agencies for more

specific information. The Crack Saw must not be

operated if the muffler is faulty or has been

removed. Contact with a hot engine muffler can

cause property damage and/or personal injury.

6) Do not operate the Crack Saw without the use of

factory approved V-belt and diamond blade guards

that are maintained in proper structural condition.

Frequently inspect the guards for signs of wear,

cracks and other signs of fatigue. If there is any

question regarding the structural integrity and/or

condition of the belt guard, properly dispose and

replace with a genuine, factory approved,

replacement part only.

7) Maintain all safety and operation decals in proper

condition. If any decal becomes damaged and/or

unreadable, replace with a genuine, factory

approved, replacement part only.

8) The Crack Saw utilizes many self locking type

hexagon head nuts to minimize the effects of

vibration. Replace all self locking hardware with

genuine, factory approved, replacement parts only.

9) Consult the material supplied by the engine or

electric motor manufacturer for specific information

relative to proper operational, lubrication and

storage requirements.

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 13

Page 14

ASSEMBLY INSTRUCTIONS/OPERATIONS

Assembly

The RCC130H Crack Saw is shipped from the

factory secured on a specially designed wooden

pallet and protected from external damage by a

corrugated carton or wood crate. If shipped with a

corrugated carton, the Crack Saw can be secured to

the pallet by wood laths nailed to the pallet body.

Remove the carton or crate immediately upon

receipt using suitable tools to remove the nails.

REMOVING THE CRACK SAW FROM THE

PALLET.

Tools Required:

1 each, pliers.

1 each, claw hammer or a hammer and an

appropriate pry bar.

The Crack Saw is secured to the pallet with steel

banding. Using the pliers, cut and remove the

banding. The Crack Saw can then be removed from

the pallet.

DANGER

WEAR SAFETY GLASSES AND OTHER

APPROPRIATE SAFETY APPAREL WHEN

CUTTING THE STEEL BANDING AND/OR

REMOVING THE CORRUGATED/WOOD

SHIPPING CRATE.

Visually inspect the shipment for freight damage

and/or missing parts. If shipping damage is evident,

contact the delivering carrier immediately to arrange

for an inspection of the damage by their claims

representative. Federal law requires that a claim be

filed within a specific time period. If missing parts are

detected, notify your dealer who will assist you in

obtaining them.

The Crack Saw is shipped from the factory

completely assembled. If ordered with the Crack

Saw, attachments or accessories are normally

shipped separately to minimize the potential for loss

during shipment.

Check all fasteners for proper security. Consult a

fastener torque chart for the proper torque value if

any fastener is found to require retorquing.

Before Starting the Engine

FILLING THE ENGINE CRANKCASE WITH OIL.

Note: The RCC130H Crack Saw is shipped with oil

in the engine crankcase. Fuel is drained from the

fuel tank and will be marked accordingly by factory

personnel.

Tools Required:

1 each, small, clean funnel.

The RCC130H Series Crack Saw comes equipped

with a Honda 13 HP gasoline engine. The engine is

not normally pre-serviced at the factory (see note

above) and will require the addition of oil in the

crankcase before being placed in service. Consult

the material supplied by the engine manufacturer for

the engine that has been ordered with your Crack

Saw. Carefully review this material to become

familiar with specific operating characteristics,

recommendations and service requirements.

1) Determine the location(s) of both the oil filler and

oil drain plug(s).

2) Wipe oil, dust and accumulated dirt from the filler

plug area.

3) Using the funnel, fill the engine crankcase with a

high grade motor oil. Consult the material supplied

by the engine manufacturer for proper amount,

weight and service classification.

4) Replace the oil filler plug and tighten. Wipe off

any excess oil spilled on the engine crankcase and

Crack Saw.

5) Do not operate the engine unless proper oil level

is maintained as per the material supplied by the

engine manufacturer.

FILLING THE RCC130H FUEL TANK.

Tools Required:

1 each, small, clean funnel.

CAUTION

Never mix oil with gasoline. Four cycle engines

are not designed to be operated with oil mixed

with the gasoline.

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 14

Page 15

ASSEMBLY INSTRUCTIONS/OPERATIONS

1) Determine the location of the fuel tank filler cap.

2) Carefully clean the filler cap and surrounding area

to insure that no dirt or debris falls into the fuel tank.

Remove the filler cap.

3) Using the funnel, fill the fuel tank with fresh, clean

fuel according to the specifications outlined in the

material supplied by the engine manufacturer. Do

not overfill the tank or spill any fuel. If the fuel tank

incorporates a screen mesh to prevent debris from

falling into the tank, do not remove to increase the fill

rate. Replace the filler cap. Wipe away any excess

spilled fuel.

DANGER

MANY FUELS ARE EXTREMELY FLAMMABLE.

DO NOT SMOKE NEAR THE FUEL TANK. DO

NOT FILL THE FUEL TANK WITH THE ENGINE

RUNNING OR IF IT IS HOT. ALLOW AMPLE TIME

BETWEEN EACH REFUELING FOR THE ENGINE

TO COOL.

Operation

THEORY OF OPERATION.

The RCC130H Crack Saw operates on the principle

of transmitting horsepower through a V-Belt

transmission directly to an industry standard, 8 inch

diameter, diamond segment blade of various widths.

The crack sawing process is directly controlled by

these conditions:

a) The use of a suitable mechanism (diamond blade)

of proper design and configuration to penetrate the

work surface and remove material while delivering

acceptable service life.

b) Sufficient static weight supporting the diamond

blade to allow it to effectively penetrate the work

surface and remove material.

c) Adequate horsepower capable of rotating the

diamond blade at industry recognized speeds

against the work surface to deliver acceptable

productivity rates.

Since no two materials are exactly alike, no two

work surface materials can be sawed by the exact

same method. The nature of the sawing process,

along with operator experience, skill and common

sense, would suggest that efficient and productive

crack sawing is a matter of trial and error.

Combinations of diamond blade type, condition, and

feed rate are direct factors that will also determine

the overall success of the job application.

INFORMATION RELATIVE TO THE USE OF

DIAMOND BLADES.

Safety requirements always override performance

considerations. Diamond blade technology has

made such rapid advances during the past few

years that a diamond blade, properly used, on well

designed and well maintained equipment, can

provide the lowest cost per cut of any of the

methods of cutting now in use. But, put that same

blade onto a piece of poorly maintained equipment

and in the hands of a poorly trained operator and the

cost of cutting can virtually put you out of business.

The members of the Saw Manufacturer's Institute

have been a significant contributor to the state of the

diamond blade art. We hope that some of the

knowledge and experience that we have

accumulated in our many years in the business can,

through this booklet, assist you in keeping your cost

down to an absolute minimum.

Of all the problems that confront diamond blade

users, blade wear is the most difficult to accurately

evaluate. Reporting life performance of identical

diamond blade specifications operating under

seemingly identical conditions tend to be

inconsistent.

Masonry blade operators frequently report blade life

in terms of hours, days or weeks. However, these

reports neglect to mention type of material being cut,

the size of the cuts, and the number of cuts per day.

In addition, the amount and the cleanliness of the

water and the amount of pressure the operator

applies to the cut have an effect on blade life.

Obviously, trying to compare the life of one diamond

blade with another, simply on the basis of hours, is

analogous to trying to compare a set of tires on one

car with an identical set on another car...it is virtually

impossible. There are just too many variables...the

weight of the car, the types of roads driven on, the

condition of the car...particularly the suspension, the

manner in which the operator handles the car, etc.

Just as many variables apply to diamond blades.

So, the next time you have reason to compare blade

life, keep these variables in mind. Some of the

problems arising from these variables can be quickly

identified, and possibly corrected"...

Excerpt from: Rx for Diamond Blades, Problems,

Causes, Effects, Remedies, published by the

Masonry and Concrete Manufacturers Institute.

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 15

Page 16

ASSEMBLY INSTRUCTIONS/OPERATIONS

DANGER

IMPROPER USE OF A DIAMOND BLADE WITH

THE CRACK SAW CAN RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

DANGER

PROPER OPERATIONAL USE OF A DIAMOND

BLADE THAT DOES NOT MEET INDUSTRY

SPECIFICATIONS AND/OR SAFETY

STANDARDS WITH THE CRACK SAW CAN

RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

General Information.

1) " Only mature, properly instructed adults should

be permitted to operate machinery and tools.

2) Only utilize the blade to cut the material it is

designed and intended to cut. Blades intended for

masonry material (stone, concrete bricks, blocks) or

blades for steel or ductile iron must only be used in

those materials. If you need to cut a material other

than the ones listed above, you must use a blade

that has been designed for that specific material.

Use of a blade in the wrong material may involve a

considerable safety risk. It may also reduce the life

of the blade or damage the blade.

3) Inspect all diamond blades for damage before

use.

4) Never use a new or used diamond blade that

shows damage such as cracks, missing segments,

damage to the arbor hole or by the flange washers,

or other appearances not consistent with the

appearance of a new blade. These are indications of

previous improper use. If you have any doubt about

the safety of a blade, contact the Customer Service

Department of the blade manufacturer for

assistance. If you do not know the name of the blade

manufacturer, contact the Customer Service

Department of General Equipment Company for

assistance. There is no charge for this service.

5) Always check that the two mounting flanges are

of the same diameter and that they are clean and

flat. The flanges should not have any cracks or show

any abnormal wear. Make sure that the arbor bolt or

nut is the correct one for the equipment without

damage to the threads. Improper or damaged flange

washers and/or damaged fasteners can damage the

blade or cause the blade to come loose from its

mount. A blade that comes loose can cause serious

bodily injury or death to the operator or bystander. If

there are any questions regarding the suitability of a

specific mounting flange, contact the Customer

Service Department for assistance BEFORE utilizing

the diamond blade. There is no charge for this

service.

6) Always make sure that the arbor hole in the blade

matches the one on the equipment. Do not force the

blade onto the spindle. Do not use an arbor shaft

(spindle) and blade combination of different sizes.

Proper fit is achieved when the blade slides onto the

arbor without having more than 0.1 mm (0.005 inch)

radial play.

7) Always tighten the bolt or nut for the flange

washers in accordance with the equipment

manufacturer's specifications.

8) Always make sure that the equipment used is in

good operating condition in accordance with the

manufacturer's specifications. Do not operate the

equipment unless the guards are in good condition,

in the proper place and secure. If the equipment

appears to be missing any fasteners or has any

parts that appear loose or worn, do not operate the

equipment until the appropriate repairs are

performed. Always make sure the blade you intend

to use with the equipment meets all the equipment

manufacturer's specifications.

9) Do not operate the equipment with other than the

recommended blade sizes. This can result in severe

blade damage. Contact the machine manufacturer

for advice.

10) Make sure that the spindle speed on the

machine does not exceed the maximum RPM

indicated on the diamond blade. This can result in

blade breakage. Check the blade shaft with a

tachometer to verify that the equipment's maximum

RPM does not exceed the manufacturer's

specifications.

11) Blades designed for wet cutting must be cooled

by an adequate, continuous water flow to each side

of the blade. Lack of enough coolant will cause

excessive heat, poor blade performance and

possible segment loss.

12) Blades designed for dry cutting may be used

without water coolant. However, dry cutting blades

can overheat which will result in loss of blade

tension and may ruin the blade. The risk is greatest

during long continuous cutting. Most overheating

problems can be avoided by lifting the blade out of

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 16

Page 17

ASSEMBLY INSTRUCTIONS/OPERATIONS

the cut and letting it cool by rotating in the air for 15

to 20 seconds after every one minute of cutting.

13) Do not force the tool into the material to be cut.

A properly working diamond tool will grind the

material without excessive force being applied. If

excessive force is needed, it indicates there is

damage to the blade to the blade or the wrong blade

is being used.

14) Always inspect the diamond blade and the

equipment any time you stop during the cut. If you

notice any difference in performance as your work

progresses, immediately STOP and inspect the

equipment and the diamond tool.

15) Do not operate any diamond tool without full

knowledge about appropriate cooling of the tool. If a

tool is not cooled properly, the blade core can

become damaged resulting in the segments coming

loose or the blade core (the steel) breaking. This

can result in serious bodily injury or death to the

operator or bystander.

16) Do not allow any bystanders in the work area.

Never allow anyone to stand in front of a saw that is

about to be started or is running.

Standards.

The manufacturing of machinery and grinding

wheels and the usage of these products are covered

in several OSHA and ANSI standards. The most

applicable standard for these products is ANSI B7.1

and B7.5. Copies of these standards can be

obtained from the American National Standards

Institute, 1430 Broadway, New York, NY 10018.

Personal Safety Equipment.

1) Always wear dust masks (respirators) approved

for use in concrete and stone dust.

2) Always wear approved eye protection such as

goggles or face shield.

3) Always wear approved hearing protection.

4) Always wear approved head protection.

5) Always wear approved safety footwear.

6) Always wear approved gloves.

Note.

In the manufacturing of all diamond blades different

metals are used such as Boron, Copper, Colbalt,

Nickel, Iron, Tungsten, Molybdenum, Tin, etc., as

outlined in the Material Safety Data Sheet (MSDS).

This product as sold presents no hazard although,

during use, small amounts of these metal

substances may be released into the dust or slurry

generated from the material being cut or ground.

Prolonged exposure to excessive amounts of dust

and slurry may cause respiratory disease, skin

irritation or cancer.

Common Sense.

Almost all accidents are avoidable if you apply

caution and common sense. Follow all safety

precautions at all times. If you are not sure...simply

don't do it. Ask for advice. Used improperly or

carelessly any tool is dangerous and may cause

severe bodily injury or death. If tools are used with

caution, proper techniques and common sense, they

will do an excellent job for you"...

Excerpt from: Instructions for the Safe Use of

Diamond Tools, published by Dimas Industries.

INSTALLING A DIAMOND BLADE ON THE

ARBOR SHAFT.

Tools required:

1 each, 3/4 inch wrench.

1 each, PN CS8-0400 1-1/2 inch wrench or

equivalent.

DANGER

WHEN INSTALLING A DIAMOND BLADE ON THE

ARBOR SHAFT ALWAYS WEAR THE

APPROPRIATE SAFETY EYEWEAR AND

APPAREL TO MINIMIZE THE POTENTIAL FROM

FLYING DEBRIS. FLYING DEBRIS CAN RESULT

IN PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

1) Disconnect the spark plug wire.

2) Rotate the height adjustment lever

counterclockwise to raise the blade to its maximum

position above the work surface. FIGURE 1.

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 17

Page 18

ASSEMBLY INSTRUCTIONS/OPERATIONS

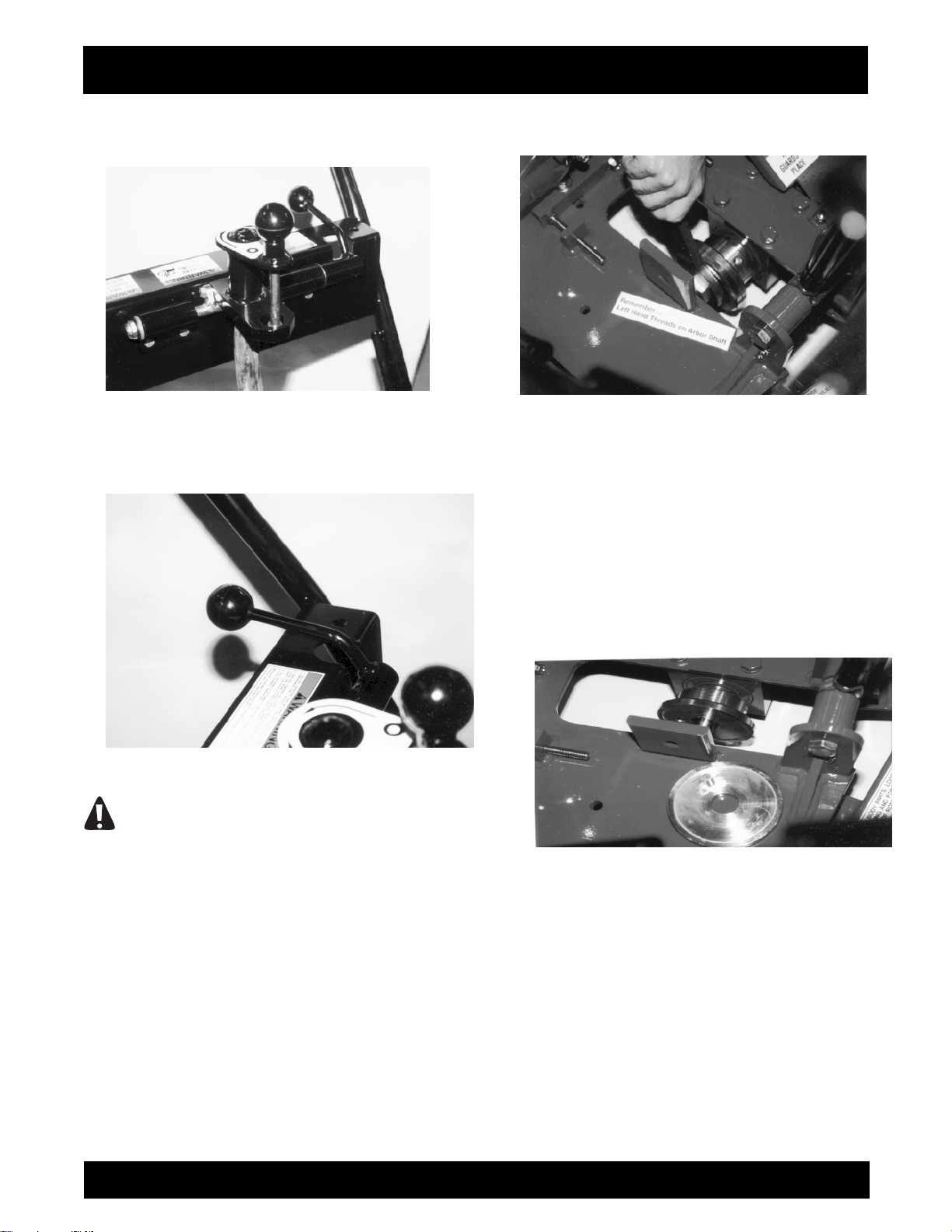

FIGURE 1

3) Position the quick change height lever over center

to its rear most (up) position. FIGURE 2.

FIGURE 2

DANGER

IMPROPER BLADE POSITION DURING THE

STARTING PROCEDURE CAN ALLOW THE

BLADE TO CONTACT THE WORK SURFACE

BEFORE THE OPERATOR CAN ASSUME A

PROPER OPERATING POSITION. THIS

OCCURRENCE CAN RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

4) Remove the blade guard from the main frame

with the 3/4 inch wrench to expose the arbor shaft.

Using the 1-1/2 inch wrench, remove the hexagon

nut and hub flange from the shaft. The arbor shaft

incorporates left hand threads. FIGURE 3.

FIGURE 3

5) Inspect the hub flange, hub body and arbor shaft

for proper structural integrity. Determine that all

components are free from surface imperfections

including, but not limited to corrosion, cracks,

warpage and material build-ups. Remove any

material build-up from the mating surfaces of the

hub components. Replace any questionable

component with a factory approved replacement

part only. If there are any questions regarding the

suitability of a specific component, contact the

Customer Service Department for assistance

BEFORE utilizing the Crack Saw. There is no

charge for this service. FIGURE 4.

FIGURE 4

6) Inspect the diamond blade for proper structural

integrity as outlined above. If there are any

questions regarding the suitability of a diamond

blade, contact the specific manufacturer or the

Customer Service Department of General

Equipment Company for assistance BEFORE

utilizing it with the Crack Saw. There is no charge for

contacting the Customer Service Department of

General Equipment Company.

7) Proper blade rotation direction is marked on the

side of the blade blank. The Crack Saw is of a down

cut type design as viewed by the operator. The

diamond blade is intended rotate toward the

operator to enhance visibility and overall productivity

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 18

Page 19

ASSEMBLY INSTRUCTIONS/OPERATIONS

while following a random crack. Determine the

correct rotation orientation for the diamond blade

and install it on the arbor shaft. FIGURE 5.

8) Reinstall the hub flange on the arbor shaft and

align the stud directly with the corresponding hole in

the blade blank and hub body. The stud is not

designed to drive the diamond blade. FIGURE 6.

DANGER

DO NOT UTILIZE A DIAMOND BLADE THAT

DOES NOT INCORPORATE A DRIVE HOLE FOR

THE HUB FLANGE STUD. DO NOT UTILIZE A

DIAMOND BLADE THAT HAS AN EXCESSIVELY

WORN DRIVE HOLE. DO NOT OPERATE THE

CRACK SAW WITH THE HUB FLANGE

REVERSED FROM ITS NORMAL OPERATING

CONFIGURATION TO ENABLE THE USE OF A

DIAMOND BLADE WITHOUT A DRIVE HOLE.

THE RESULT CAN BE PROPERTY DAMAGE

AND/OR PERSONAL INJURY.

FIGURE 5

FIGURE 6

9) Reinstall the hexagon nut and tighten with the

wrench until the hub flange and body components

exert consistent, firm clamping pressure against the

blade blank. The arbor shaft incorporates left hand

threads, making the hexagon nut semi selftightening against the hub and blade.

10) Reinstall and tighten the Blade Guard to the

main frame.

DANGER

DO NOT OPERATE THE CRACK SAW WITHOUT

THE BLADE GUARD PROPERLY INSTALLED.

OPERATION OF THE CRACK SAW WITHOUT

THE BLADE GUARD PROPERLY INSTALLED

CAN RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

11) Reconnect the engine spark plug wire.

DANGER

UNEXPECTED MACHINE START UP CAN

RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

12) To remove the diamond blade from the arbor

shaft, reverse the steps as outlined above.

TRANSPORTING THE CRACK SAW.

Application: All Models.

The Crack Saw has an operational weight that

prohibits one person from loading and/or unloading it

alone by conventional, physical efforts.

DANGER

DO NOT ATTEMPT TO LIFT THE CRACK SAW

UP INTO A TRANSPORTATION VEHICLE WITH

THE USE OF ONE PERSON ALONE. DO NOT

ATTEMPT TO LOWER THE CRACK SAW FROM

A TRANSPORTATION VEHICLE WITH THE USE

OF ONE PERSON ALONE. LIFT AND/OR LOWER

THE CRACK SAW ONLY BY THE USE OF A

POWER TAILGATE UNIT, A SUITABLE HOIST

UNIT OF PROPER CAPACITY AND/OR

CONFIGURATION OR BY THE USE OF A

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 19

Page 20

ASSEMBLY INSTRUCTIONS/OPERATIONS

PROPER QUANTITY OF PERSONNEL IN

PROPER PHYSICAL CONDITION.

The integral lifting bail device(s) can be used to

facilitate lifting by a mechanical device incorporating

a chain and suitable attachment device. The location

of the lifting bail(s) may not always locate the exact

position of the center of gravity for the Crack Saw.

Typical Hoisting Configuration

FIGURE 7 depicts a typical hoisting configuration for

a Crack Saw with a mechanical lifting device.

FIGURE 10

DANGER

EXERCISE EXTREME CAUTION WHEN

UTILIZING A MECHANICAL DEVICE FOR

LIFTING THE CRACK SAW. UTILIZE THE

MECHANICAL DEVICE IN ACCORDANCE TO

BOTH ITS STATED STATIC AND DYNAMIC

LOADING ENVELOPES. DO NOT UTILIZE THE

MECHANICAL DEVICE UNTIL THIS

INFORMATION IS PROPERLY KNOWN AND

UNDERSTOOD BY ALL APPLICABLE

PERSONNEL. FAILURE TO PROPERLY UTILIZE

THE MECHANICAL DEVICE CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

8) Once on the job site, the Crack Saw can be

lowered to the work surface by reversing the above

steps.

General Transportation Information.

When transporting the Crack Saw on a motor

vehicle, the fuel tank breather vent (if so equipped)

must be completely closed to eliminate the

accidental seepage of fuel and resulting potential fire

and environmental hazards. To minimize the

possibility of damage to the Crack Saw, always

transport in its normal, upright position. All

equipment must be secured in/on vehicles with

suitable strapping or tie-downs. Personnel should

not be transported in the same compartment as

equipment and fuel supplies. Consult applicable

OSHA, AGA, CGA, etc. regulations for the proper

transportation of flammable gases.

STARTING THE RCC130H SERIES GASOLINE

POWERED CRACK SAW ON THE JOB SITE.

1) Position the Crack Saw on a flat and level surface

of firm foundation.

2) Rotate the height adjustment lever

counterclockwise to raise the blade to its maximum

position above the work surface. FIGURE 15.

FIGURE 15

3) Position the quick-change height lever over

center to its rear most (up) position. FIGURE 16.

FIGURE 16

DANGER

IMPROPER BLADE POSITION DURING THE

STARTING PROCEDURE CAN ALLOW THE

BLADE TO CONTACT THE WORK SURFACE

BEFORE THE OPERATOR CAN ASSUME A

PROPER OPERATING POSITION. THIS

OCCURRENCE CAN RESULT IN IMPROPER

DAMAGE AND/OR PERSONAL INJURY.

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 20

Page 21

ASSEMBLY INSTRUCTIONS/OPERATIONS

4) Refer to the material supplied by the engine

manufacturer for the correct starting, operation and

stopping procedures.

5) The RCC130H Series Crack Saw is equipped

with a non slip type foot pad to provide additional

stability during the engine starting process. FIGURE

17 depicts a proper operator position for starting the

Crack Saw.

FIGURE 17

6) The RCC130H Series gasoline powered Crack

Saw is not equipped with a centrifugal clutch

assembly. The gasoline engine is directly coupled to

the arbor shaft by a V-belt reduction.

DANGER

AS SOON AS THE ENGINE STARTS, THE

OPERATOR MUST BE IN A POSITION TO

ASSUME DIRECT AND FULL CONTROL OF THE

CRACK SAW. FAILURE TO ASSUME DIRECT

AND FULL CONTROL CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL

INJURY.

7) Allow the engine to properly "warm up" and

operate without the requirement for choking. Check

for excessive machine noise and/or vibration.

DANGER

DO NOT OPERATE A GASOLINE ENGINE IN

CLOSED SPACES WITHOUT PROPER

VENTILATION. GASOLINE ENGINES PRODUCE

CARBON MONOXIDE FUMES. BREATHING

CARBON MONOXIDE FUMES CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL

INJURY. EXCESSIVE LEVELS OF CARBON

MONOXIDE CAN CAUSE DEATH.

8) Stop the engine in accordance with the

instructions as described in the material supplied by

the engine manufacturer.

CAUTION

If the Crack Saw and/or an individual

component/accessory does not appear to be

functioning properly, STOP and do not further

operate the Crack Saw until the proper

corrective action has been completed. If there

are any questions regarding the proper

operation of the Crack Saw, contact the

Customer Service Department BEFORE further

utilization. There is no charge for this service.

OPERATING THE RCC130H CRACK SAW ON

THE JOB SITE.

DANGER

THE SAWING PROCESS PRODUCES

EXCESSIVE NOISE, VIBRATION AND FLYING

DEBRIS. ALL OPERATORS AND WORK

PERSONNEL IN THE VICINITY OF THE CRACK

SAW MUST WEAR APPROPRIATE SAFETY EYE

WEAR AND HEARING PROTECTION DEVICES.

OTHER SAFETY APPAREL AND/OR

PROCEDURES, DEEMED NECESSARY BY

SUPERVISORY PERSONNEL MUST ALSO BE

WORN AND/OR PRACTICED BY ALL

APPROPRIATE PERSONNEL.

DANGER

EXERCISE EXTREME CAUTION WHEN

OPERATING THE CRACK SAW IN THE VICINITY

OF DECK INSERTS, PIPES, COLUMNS,

OPENINGS, LARGE CRACKS, UTILITY OUTLETS

OR ANY OBJECT PROTRUDING FROM THE

SURFACE. CONTACT WITH SUCH OBJECTS

CAN LEAD TO LOSS OF MACHINE CONTROL,

RESULTING IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

DANGER

DO NOT OPERATE A GASOLINE ENGINE IN

CLOSED SPACES WITHOUT PROPER

VENTILATION. GASOLINE ENGINES PRODUCE

CARBON MONOXIDE FUMES. BREATHING

CARBON MONOXIDE FUMES CAN RESULT IN

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 21

Page 22

ASSEMBLY INSTRUCTIONS/OPERATIONS

PROPERTY DAMAGE AND/OR PERSONAL

INJURY. EXCESSIVE LEVELS OF CARBON

MONOXIDE CAN CAUSE DEATH.

1) The Crack Saw is of a downcut type design as

viewed by the operator. The diamond blade is

intended to rotate toward the operator to enhance

visibility and overall productivity while following a

random crack. The down cut action results in a "self

propelled" effect toward the operator that

substantially enhances machine control and reduces

fatigue as long as the diamond blade does not come

in direct contact with a protruding obstruction from

the floor. Direct contact with such an obstruction can

result in rapid and jerky directional movement of the

machine. In most operating situations, direct contact

with a protruding obstruction from the floor will result

in serious damage to the diamond blade. This

occurrence may not allow the operator to remain in

proper control of the machine.

DANGER

ALWAYS MAINTAIN PROPER CONTROL OF THE

CRACK SAW. IF AN OPERATOR LOOSES

CONTROL OF THE MACHINE, A "RUNAWAY"

CRACK SAW CAN RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

BECAUSE OF THE UNIQUE OPERATING

CHARACTERISTICS OF THE CRACK SAW,

THERE IS NO PROVISION FOR THE ELECTRIC

MOTOR/ENGINE TO AUTOMATICALLY STOP IF

THE OPERATOR FAILS TO MAINTAIN PROPER

CONTROL.

DANGER

WHEN OPERATING THE CRACK SAW ON

ABOVE GROUND FLOOR LEVELS, EXERCISE

EXTREME CAUTION TO PREVENT LOSS OF

CONTROL THAT COULD ALLOW THE MACHINE

AND/OR OPERATOR TO FALL DOWN TO

LOWER LEVELS. SUCH AN OCCURRENCE CAN

RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

2) The crack sawing process is not intended to

require additional weight to be applied to the

machine for the purpose of increasing productivity

and/or stability. No provision for attaching weight is

made.

DANGER

DO NOT OPERATE THE CRACK SAW WITH

ADDITIONAL WEIGHT APPLIED DIRECTLY TO

THE MACHINE TO INCREASE PRODUCTIVITY

RATES AND/OR MACHINE STABILITY.

PROPERTY DAMAGE AND/OR PERSONAL

INJURY CAN RESULT. PRODUCTIVITY AND/OR

STABILITY RELATED PROBLEMS SHOULD BE

DIRECTED TO SPECIFIC MECHANICAL

PROBLEMS WITH THE MACHINE,

OPERATIONAL PROCEDURES AND/OR

SPECIFIC MECHANICAL PROBLEMS

ASSOCIATED WITH THE DIAMOND BLADE.

CONTACT THE CUSTOMER SERVICE

DEPARTMENT FOR ASSISTANCE. THERE IS NO

CHARGE FOR THIS SERVICE.

3) The Crack Saw is designed to be pulled toward

the operator during normal operation to enhance

visibility and overall productivity while the blade

follows a random crack.

CAUTION

Operating the Crack Saw by pushing it forward

will substantially reduce overall productivity and

reduce operator control. The diamond blade will

deposit dust and residue materials under the

feet of the operator. This configuration will not

allow the machine to be utilized with a vacuum

system. This occurrence can also reduce

operator stability on the work surface and lead

to property damage and/or personal injury.

4) Position the Crack Saw over the random crack

with the diamond blade directly above and parallel

with the crack direction. Align the front casters of the

machine parallel with the crack direction to maximize

operator control at the start of the sawing process.

FIGURE 23.

FIGURE 23

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 22

Page 23

5) Turn the height adjustment lever clockwise to

lower the blade into the crack until the desired

sawing depth is achieved. Each full turn of the crank

lever will raise/lower the blade approximately 1/16

inch.

6) Following the random crack direction and/or

pattern with the blade is accomplished by viewing

the blade and crack in the louvered opening in the

blade guard. The louvers are intended to provide

protection for the operator in the event that a

diamond segment becomes separated from the

blade blank. Probable causes for such occurrences

are discussed in detail in the Troubleshooting

section of this manual.

a) The geometric design of the louvered blade guard

is intended to provide a high mathematical

percentage of protection for the operator in a normal

operating position as described in this manual. The

mathematical percentage will decrease for operating

positions not described in this manual.

b) In the event of diamond segment separation from

the blade blank, there is a high mathematical

probability that the segment will be thrown forward

against the dust pan located under the main frame

or directly against the forward (non louvered) section

of the blade guard. The manufacturer has

conducted extensive testing to substantiate this

theory. In actual field tests, diamond segments were

purposely separated from the blade blanks through

abusive operational techniques. In all field tests, no

separated diamond segments made direct contact

with the blade guard louvers.

c) In the very low probability that a diamond

segment would make direct contact with the blade

guard louvers, the geometric design has a high

mathematical probability to not allow the segment to

penetrate the vertical plane as defined by the

location of the louvers. The spaces, angle

orientation and number of louvers minimize the

mathematical probability that a segment can

penetrate the vertical plane, exit the louvers and

eventually strike the operator.

d) The geometric configuration of the louvers are

designed to allow for adequate and/or proper

visibility for the operator during the sawing process.

With use, concrete and/or asphalt dust will

accumulate at the bottom of the blade guard

opening. At regular intervals, this material should be

removed to enhance operator visibility during the

sawing process.

ASSEMBLY INSTRUCTIONS/OPERATIONS

DANGER

DO NOT MODIFY THE ORIGINAL OPERATING

CONFIGURATION FOR THE LOUVERS FOR ANY

REASON. MODIFICATIONS TO THE LOUVERS

CAN RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

7) Proper operator posture and stance will enhance

operational safety and overall productivity. FIGURE

24 depicts a proper operator's position. FIGURE 25

depicts an improper operator's position that can

accelerate fatigue, decrease productivity and reduce

safety. The downcut orientation of the diamond

blade will normally produce a "self-propelled" effect

against the operator. This effect is intended to

reduce the operator fatigue associated with the

operation of the machine and to increase overall

productivity.

8) In some operating conditions, it may be

necessary for the operator to apply a resisting force

(push) against the operator handle to counteract the

"self-propelled effect. In some other operating

conditions, it may be necessary for the operator to

apply a force (pull with) to the operator handle in

order to assist the sawing action of the Crack Saw.

FIGURE 24

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 23

Page 24

FIGURE 25

The amount and direction of forces to apply to the

operator handle are governed by, but not

necessarily limited to the following factors:

a) Average Random Crack Width.

b) Diamond Blade Saw Width.

c) Sawing Depth.

d) Tensile strength of the material being sawed.

e) Matrix material of the diamond blade segments in

consideration of the aggregate type, amount and/or

hardness contained in the material being sawed.

f) Service condition of the diamond blade segments.

g) Operating RPM speed range for the diamond

blade.

9)For normal job applications, operate the engine at

a maximum, governed speed of 3450 RPM. Consult

the material supplied by the engine manufacturer

and the Specifications section for specific

information. If you have any questions regarding

specific job applications, contact the Customer

Service Department for information. There is no

charge for this service. Additional information can be

obtained from the Masonry and Concrete Saw

Manufacturers Institute, 30200 Detroit Road,

Cleveland, OH 44145-1967.

ASSEMBLY INSTRUCTIONS/OPERATIONS

DANGER

THE CRACK SAW IS DESIGNED FOR THE

ENGINE TO OPERATE AT A MAXIMUM,

GOVERNED SPEED OF 3450 RPM. THIS ENGINE

SPEED AND THE V-BELT REDUCTION SYSTEM

ALLOWS THE DIAMOND BLADE TO OPERATE

WITHIN THE INDUSTRY ACCEPTED RPM SPEED

RANGE. FIELD CHANGES AND/OR

ALTERATIONS MADE TO THE FACTORY SET

ENGINE SPEED RANGE AND/OR V-BELT

PULLEY(S) CAN ALLOW THE DIAMOND BLADE

TO OPERATE OUTSIDE THE INDUSTRY

ACCEPTED RPM SPEED RANGE. THIS

OCCURRENCE CAN RESULT IN PROPERTY

DAMAGE AND/OR PERSONAL INJURY.

10) The wide variety of potential work surface

materials along with the corresponding variety of job

site environments, make it impossible to develop a

standardized operating procedure for the Crack

Saw. Use of the Crack Saw will require constant trial

and error testing until satisfactory results are

achieved. Experience gained over time and common

sense will help minimize the amount of necessary

testing. Many factors will directly affect the operating

parameters and/or techniques utilized for a

specialized job application. Some of these factors

include:

a) Work surface material yield and tensile values. As

a general rule, these values will determine material

removal rate per unit of time. Materials with high

yield and tensile values will characteristically

resist/limit material penetration. For such materials,

the accepted procedure is to make a number of

multiple passes over the work surface rather than

attempt to make a single, deep pass. The net effect

is to actually increase productivity: more material

removed in less time. Other added benefits to this

technique are decreased vibration, less operator

fatigue and increased component service life.

b) The width of the random crack in comparison to

the required cutting width and depth. For example, if

the random crack has an average width of 1/8 inch,

productivity rates will be greater with the use of a 1/4

inch wide blade over that delivered by a 1/2 inch

wide blade. The same analogy can also be used for

the cutting depth. Productivity rates will be greater

for a 1/2 inch deep cut than a 1-inch deep cut.

Deeper cuts also require additional time for the

blade to "clear itself" when following a random crack

pattern.

RCC130H-CRACK SAW OPERATION AND PARTS MANUAL REV #1 (11/18/04) PAGE 24

Page 25

ASSEMBLY INSTRUCTIONS/OPERATIONS

11) The sawing process on many work surface

materials can produce sparks, dust and other

foreign particle contamination.

DANGER

SPARKS PRODUCED BY THE ACTION OF THE

DIAMOND BLADE AGAINST THE WORK

SURFACE (FOR EXAMPLE: STRIKING ANCHOR

BOLTS) MAY COME IN CONTACT WITH

MATERIALS THAT CAN RESULT IN A FIRE

AND/OR EXPLOSION. THIS OCCURRENCE CAN

RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY.

DANGER

THE CREATION OF DUST AND OTHER FOREIGN

PARTICLE CONTAMINATION FROM THE

OPERATIONAL PROCESS CAN RESULT IN

PROPERTY DAMAGE AND/OR PERSONAL

INJURY. FOR SUCH OPERATING CONDITIONS,

ALWAYS WEAR A NIOSH/MSHA APPROVED

DUST/MIST RESPIRATOR. CONSULT

APPLICABLE OSHA REGULATIONS FOR

SPECIFIC INFORMATION.

12) Dust and other particle contamination can be

controlled by the following methods:

a) The Crack Saw is equipped with a 3 inch outside

diameter vacuum tube adaptor located at the front of

the machine. An industrial type vacuum system can

be attached to the Crack Saw to remove/control dust

and other particle contamination from the work

surface. A hose clamp is sometimes required to

properly secure the vacuum hose to the vacuum

tube. FIGURE 26.

CAUTION

Use of a vacuum system with the Crack Saw will

not totally eliminate or provide 100 per cent dust

and other particle contamination removal from

the atmosphere and work surface. Secondary

dust and other particle contamination removal

procedures from the atmosphere and work

surface will normally be required.

FIGURE 26

DANGER

ALWAYS UTILIZE A VACUUM SYSTEM TO

OPERATE WITHIN THE SPECIFIC JOB SITE

REQUIREMENT. DUST MATERIAL CAN MEET

CLASS II OR CLASS III SPECIFICATIONS OF

THE NATIONAL ELECTRIC CODE® FOR

HAZARDOUS LOCATION CLASSIFICATIONS.

CONSIDERATION MUST ALSO BE GIVEN TO

THE CREATION OF HAZARDOUS TYPE

MATERIALS REQUIRING SPECIFIC DISPOSAL

PROCEDURES. DETERMINE THAT THE

VACUUM SYSTEM IS PROPERLY DESIGNED TO

OPERATE WITHIN THESE ATMOSPHERES.

CONSULT CURRENT NATIONAL ELECTRIC

CODE®, OSHA AND ENVIRONMENTAL

PROTECTION AGENCY REGULATIONS FOR

SPECIFIC INFORMATION.

b) A water stream directed to the blade can be an

effective method of reducing dust effects and

increasing service life at the same time. The optional

RCCWC Wet Sawing Kit can be installed to direct a

continuous stream of water to both sides of the

diamond blade. FIGURE 27. The kit includes a

standard globe type valve to control water feed rates

and is directly coupled to a water hose. Potential

negative effects of this procedure is that the water

and slurry mixture will require additional time for

disposal and proper drying before