Page 1

PARTS AND OPERATION MANUAL

A DIVISION OF MULTIQUIP INC.

PLASTER/MORTAR

MIXERS

MS-40H

STOW

© COPYRIGHT 2002 MULTIQUIP INC.

A DIVISION OF MULTIQUIP INC.

(Steel-Drum Hydraulic)

Revision #1 (05/17/02)

STOW CONSTRUCTION EQUIPMENT PARTS DEPARTMENT:

A DIVISION OF MULTIQUIP INC.

POST OFFICE BOX 6254 FAX: 800-672-7877

CARSON, CALIFORNIA 90749

310-537-3700 • 888-252-STOW [888-252-7869] 800-478-1244

FAX: 310-537-1986 • FAX: 800-556-1986 FAX: 310-631-5032

E-MAIL: stow@multiquip.com • WWW: stowmfg.com

800-427-1244

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

Page 2

PAGE 2 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 3

Page 4

TABLE OF CONTENTS

Here's How To Get Help ........................................... 3

Table Of Contents .................................................... 4

Parts Ordering Procedures ...................................... 5

Operation and Safety Decals ................................... 6

Rules For Safe Operation .....................................7-8

Specifications ........................................................... 9

General Information ............................................... 10

MQ STOW — Mortar Mixer

Controls .................................................................. 11

Electric Motor ......................................................... 12

Towing .................................................................... 13

Paddle Blade Adjustment ....................................... 15

Initial Start-Up ................................................... 16-17

Maintenance .......................................................... 18

Troubleshooting (Engine) ....................................... 19

Troubleshooting (Engine/Mixer) ............................. 20

Explanation Of Codes In Remarks Column ........... 22

Suggested Spare Parts .......................................... 23

Nameplate and Decals......................................24-25

Engine End Paddle Assembly ...........................26-27

Tow End Paddle Assembly ................................28-29

Steel Mixing Drum Assembly ............................30-31

Paddle Shaft Assembly ..................................... 32-33

Hydraulic Assembly...........................................34-35

Frame 3 Assembly ............................................ 36-37

Engine Cover Assembly .................................... 38-39

Engine

Honda Engine Assembly ................................... 40-41

5 HP Motor

Single Phase Electric Motor Assembly ............. 42-43

Three Phase Electric Motor Assembly ..............44-45

Terms and Conditions Of Sale — Parts ................. 46

NOTE

Specification and part number

are subject to change without

notice.

PAGE 4 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 5

PARTS ORDERING PROCEDURES

n

Dealer account number

n

Dealer name and address

n

Shipping address (if different than billing address)

n

Return fax number

n

Applicable model number

n

Quantity, part number and description of each part

n

Specify preferred method of shipment:

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

•

Express account number)*

Airborne Express*

•

Truck or parcel post

•

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Get special freight allowances

when you order 10 or more

line items via FAX!**

n

UPS Ground Service at no charge for freight

n

PS Third Day Service at one-half of actual freight cost

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

Now! Direct TOLL-FREE access

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

Extra Fax DiscountExtra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USA

for Domestic USAfor Domestic USA

Dealers OnlyDealers Only

Dealers Only

Dealers OnlyDealers Only

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 5

800/6-PARTS-7 • 800-672-7877

Page 6

MS-40H HYDRAULIC MIXER — OPERATION AND SAFETY DECALS

Machine Safety Decals

This STOW mixer is equipped with a number of safety decals. These decals are provided for operator safety and maintenance

information. The illustration below shows these decals as they appear on the mixer. Should any of these decals become unreadable,

replacements can be obtained from your dealer.

A DIVISION OF MULTIQUIP INC.

SAFETY INSTRUCTIONS

1. Read owners manuals before operating.

2. Keep unauthorized and untrained people away from machine during operation.

3. Make sure all safety devices are in place before this machine is started.

4. Make sure engine is turned off and spark plug wire is disconnected before cleaning the

machine.

5. Keep hands and fingers away from moving objects.

6. Do not operate machine in an enclosed area. Proper ventilation is required.

7. Never leave machine unattended when operating.

8. Always stop engine and allow engine to cool before adding fuel or oil.

STOW CONCRETE PRODUCTS — A MULTIQUIP COMPANY — CARSON, CALIFORNIA

P/N 924801

PAGE 6 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 7

MS-40H HYDRAULIC MIXER — RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when

operating the MS-40H mixer:

GENERAL SAFETY

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated by persons under 18

years of age.

■

NEVER operate this equipment without proper

protective clothing, shatterproof glasses, steeltoed boots and other protective devices required

by the job.

NEVER touch the hot exhaust manifold, muffler or cylinder. Allow

these parts to cool before

servicing engine or mixer.

■

High Temperatures – Allow the engine to cool before adding

fuel or performing service and maintenance functions. Contact

hot

with

■

The engine section of this mixer (gasoline only) requires an

adequate free flow of cooling air. Never operate the mixer in

components can cause serious burns.

any enclosed or narrow area

where free flow of the air is

restricted. If the air flow is restricted

it will cause serious damage to the

mixer or engine and may cause

injury to people. Remember the

mixer's engine gives off DEADLY

carbon monoxide gas.

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate this equipment under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

Manufacture does not assume responsibility for any accident

due to equipment modifications.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

Always check the machine for loosened threads or bolts before

starting.

■

■

Always refuel in a well-ventilated area, away from sparks and

open flames.

■

Always use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool. DO NOT

machine. Fire or explosion could result

from fuel vapors, or if fuel is spilled on a

hot engine.

NEVER operate the mixer in an explosive atmosphere or near

combustible materials. An explosion or fire could result

causing severe

bodily harm or even death.

smoke around or near the

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 7

Page 8

MS-40H HYDRAULIC MIXER — RULES FOR SAFE OPERATION

■

CAUTION:

Failure to follow instructions in this manual may

lead to serious injury or even death! This

equipment is to be operated by trained and

qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when

operating the MS-40HSHD hydraulic mixers:

GENERAL SAFETY

■

Stop the engine when leaving the mixer unattended.

■

Block the unit when leaving or when using on a slope.

■

Maintain this equipment in a safe operating condition at all

times.

■

Always stop the engine before servicing, adding fuel and oil.

■

NEVER Run engine without air filter. Severe engine may

occur.

■

Always service air cleaner frequently to prevent carburetor

malfunction.

■

Always be sure the operator is familiar with proper safety

precautions and operations techniques before using mixer.

■

Always store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

■

NEVER use accessories or attachments, which are not

recommended by Multiquip for this equipment. Damage to

the equipment and/or injury to user may result.

■

NEVER Run engine without air cleaner. Severe engine

damage may occur.

■

Always read, understand, and follow procedures in Operator’s

Manual before attempting to operate equipment.

■

Always be sure the operator is familiar with proper safety

precautions and operations techniques before using pump.

■

Always store equipment properly when it is not being used.

Equipment should be stored in a clean, dry location out of the

reach of children.

Caution must be exercised while servicing this equipment.

Rotating and moving parts can cause injury if contacted.

■

When towing, an adequate safety chain must be fastened to

the frame, refer to page 13.

■

Keep all inexperienced and unauthorized people away from

the equipment at all times.

■

Unauthorized equipment modifications will void all warranties.

■

Check all fasteners periodically for tightness. Also check

towing tongue bolt, lock nut and wheel lug nuts for wear.

■

Stop the engine and disconnect the spark plug before allowing

anybody’s hands in the mixing drum.

■

Never pour or spray water over the engine or electric motor.

■

Always stand clear of dump handle when mixer is in operation.

Any binding of material between the mixer blades and drum

will cause drum and handle to quickly move in the discharge

position.

■

Depending on type of mixer, test the

the gasoline engine or electric motor before operating. The

purpose of these switches is to shut down the engine or motor

of the mixer.

Emergencies

■

Always know the location of the nearest

and

first aid kit

Also know the phone numbers of the nearest

doctor

invaluable in the case of an emergency.

Maintenance Safety

■

NEVER lubricate components or attempt service on a running

machine.

■

Always allow the machine a proper amount of time to cool

before servicing.

■

Keep the machinery in proper running condition.

■

Fix damage to the machine immediately and always replace

broken parts.

■

Dispose of hazardous waste properly. Examples of potentially

hazardous waste are used motor oil, fuel and fuel filters.

. Know the location of the nearest telephone.

and

fire department

ON/OFF

switch for either

fire extinguisher

ambulance

. This information will be

,

CAUTION:

■

guards and safety devices are attached and in

place.

PAGE 8 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

■

DO NOT operate this equipment unless all

■

DO NOT use food or plastic containers to dispose of

hazardous waste. Emergencies

Always know the location of the nearest

and

first aid kit

Also know the phone numbers of the nearest

doctor

invaluable in the case of an emergency.

and

. Know the location of the nearest telephone.

fire department

. This information will be

fire extinguisher

ambulance

,

Page 9

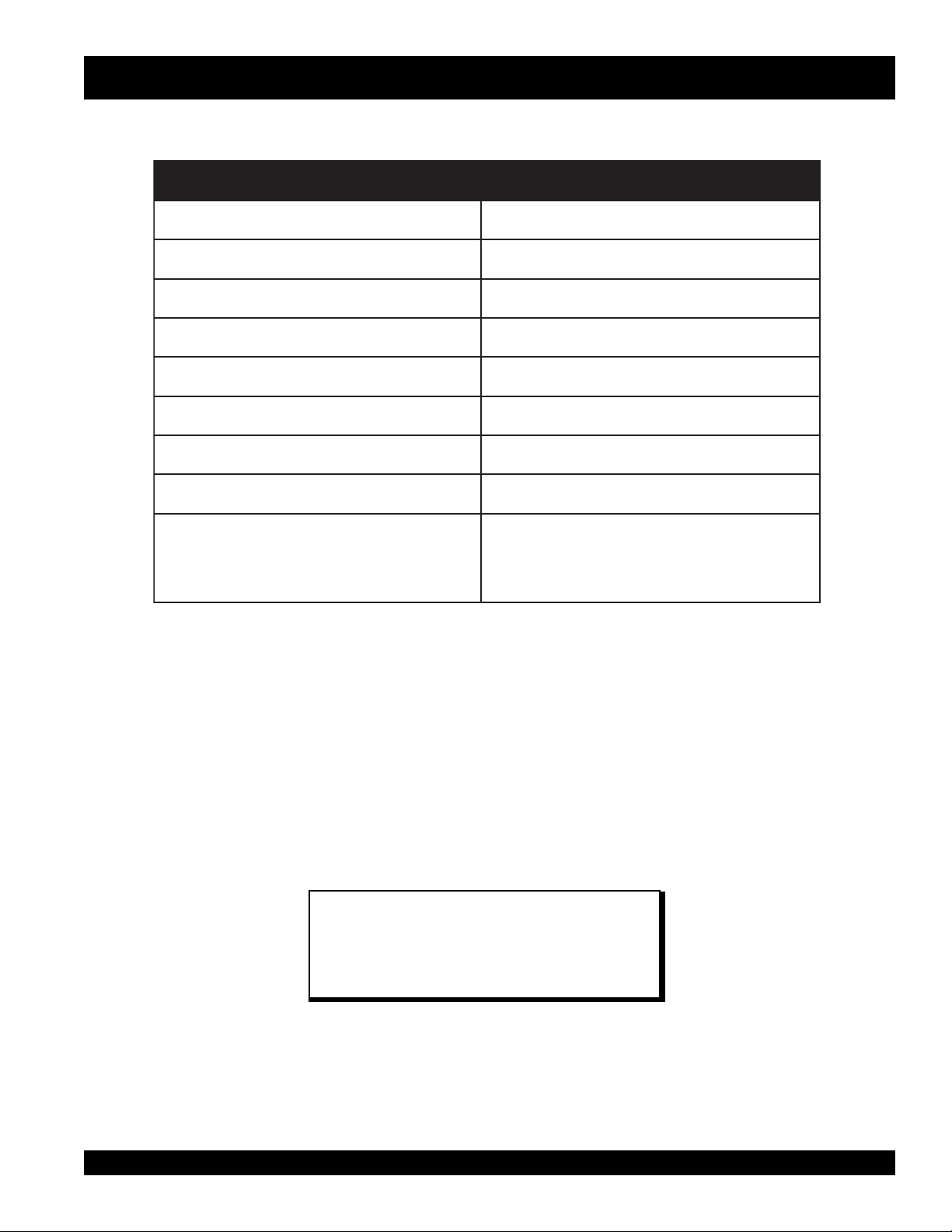

MS-40H HYDRAULIC MIXER — SPECIFICATIONS

rexiMciluardyHH04-SM.1elbaT

)sretil(tf.uc-yticapaC)043(21

sgab-yticapacgaB4ot5.3

).gk(sbl-thgieW)854(010,1

).mc(.ni-HxWxraBwoT/whtgneL )251x031x802(06x15x28

).mc(ni-eldnaHpmuD/WthgieH)191(57

).mc(ni-thgieHegrahcsiD)85(32

evirDciluardyH

noitcApmuDciluardyH/launaM

secruoSrewoP

adnoHPH31

NOTE

In accordance with our established policy of constant

improvement, we reserve the right to amend these

specifications at any time without notice.

cirtcelE064/032esahP-elgniSPH5

cirtcelE064/032esahP-eerhTPH5

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 9

Page 10

MS-40H HYDRAULIC MIXER — GENERAL INFORMATION

GENERAL

The STOW MS-40H plaster and mortar hydraulic mixer is

shipped completely assembled and has been factory tested.

The drum batch capacity of these mixers is between 3.5 and

4.0 bags. With proper care, they will give continuous service

year-after-year.

This mixer can be powered by either gasoline or electric motors.

The power from the engine rotates a hydraulic pump which

provides hydraulic fluid to a

control valve directs fluid to the hydraulic motor which causes

the paddle shaft to rotate. This type of hydraulic pump design

provides high mixing torque and eliminates V-belts, pulleys ect.

BEFORE STARTING

Before starting the engine, read the engine owners manual and

thoroughly understand the safety information.

Check the items listed below:

OIL LEVELS

Be sure to check the oil levels in the engine and hydraulic

reservoir before starting the unit.

HARDWARE

directional control

valve. The

GASOLINE ENGINE CARE

For care and operation of the gasoline engine, refer to the

engine manufacturer’s operating instructions furnished with the

engine. We recommend draining and refilling the engine

crankcase at least every thirty hours of operation. Check the

engine oil level daily.

GASOLINE MIXER OFF/ON SWITCH

This feature is on gasoline engine mixers only. Located on the

side of the engine cover. The purpose of this switch is to start

and stop the mixer in normal operation.

ELECTRIC MOTOR MIXER OFF/ON SWITCH

This feature is on electric motor mixers only. This switch is located

next to the motor. Lift the engine cover to gain access to this

switch. The purpose of this switch is to start and stop the mixer

in normal operation. Never use the electric motor in an explosive

environment.

ENGINE THROTTLE AND CHOKE CONTROLS

Please refer to the engine owners manual for specific

instructions.

Check all hardware on the mixer before starting. Periodically

inspect all hardware. Loose hardware can contribute to early

component failure and poor performance. Use the torque chart

below as a general guideline and keep all hardware tight:

HARDWARE DIA TORQUE (LB./FT.)

5/16"- 18 24

3/8" - 24 37

1/2" - 13 39

1/2" - 13 (Grade 8) 90

PAGE 10 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 11

MS-40H HYDRAULIC MIXER — CONTROLS

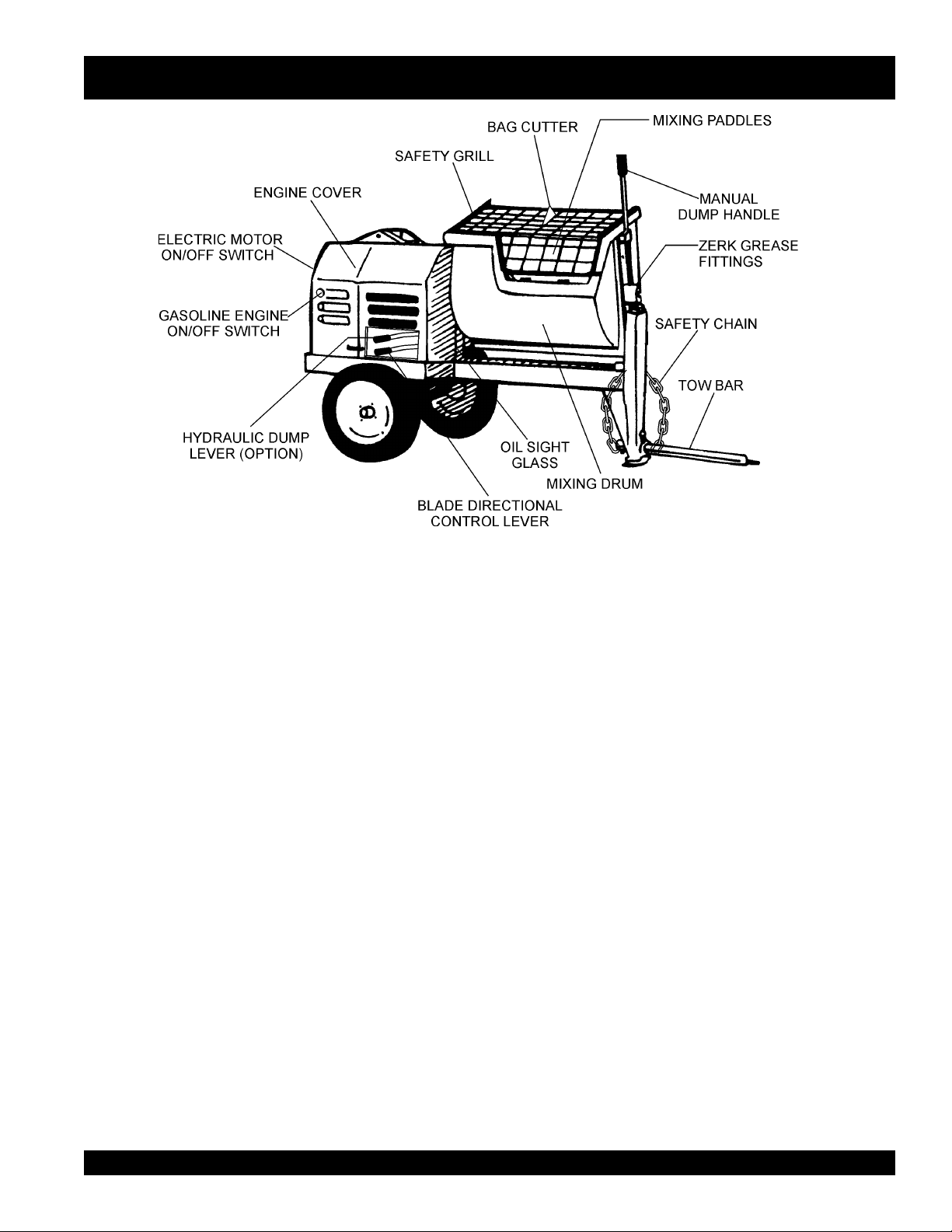

Figure 1. Mixer

Safety Grill — Provided for operator safety. This safety grill is

designed to keep hands and solid objects out of the mixing

drum when in use. This grill should be closed at all times when

mixer is in use. DO NOT remove the grill or grill opening bar.

Keep the grill clean by washing it down daily.

Bag Cutter— This feature allows compound mixing bags to be

opened easily, therefore allowing the contents of the bag to fall

directly into the mixing drum.

Mixing Paddles — Used in the mixing of material. This unit

uses four different types of paddles to provide a fast uniform

mix.

Manual Dump Handle — Pull this handle downward to dump

the contents of the drum. Push the handle upward to return the

drum to its vertical position.

Hydraulic Dump Lever (Option) — Pull lever OUT toward

the engine to engage. Once lever is engaged tub (drum) will

automatically discharge material. push lever IN to return mix

position.

Blade Control Lever — Pull lever OUT to mix material, place

lever in CENTER position (neutral) for no mixing, push lever

IN to reverse blade direction.

Mixing Drum — Made of

concrete, mortar, plaster are to be placed into this drum for

mixing. Always clean the drum after each use.

Tow Bar — When towing is required, connect tow bar to a

vehicle. Reference page 13.

Engine Cover — Lift this cover to gain access to the engine

compartment.

ON/OFF Switch (gasoline) — This switch is provided on

with gasoline

engine cover. When activated it will shut down the engine.

ON/OFF Switch (electric) — This switch is provided on mixers

with electric motors. To gain access to this switch, lift the engine

cover. When activated it will shut down the electric motor.

Blade Engagement Lever — Push the lever in, toward the

engine to engage. Once lever is engaged paddle shaft will

rotate. To disengage pull the lever backwards.

Zerk Fitting — There is, on each end of the mixing drum a zerk

grease fitting. These fittings lubricate the dumping mechanism.

Lubricate both fittings at least twice a week.

Oil Sight Glass — Indicates the level of the hydraulic oil in the

reservoir. Oil should be visible within 3/4 height of sight glass.

steel

. Mixing materials such as

mixers

engines only and is located on the side of the

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 11

Page 12

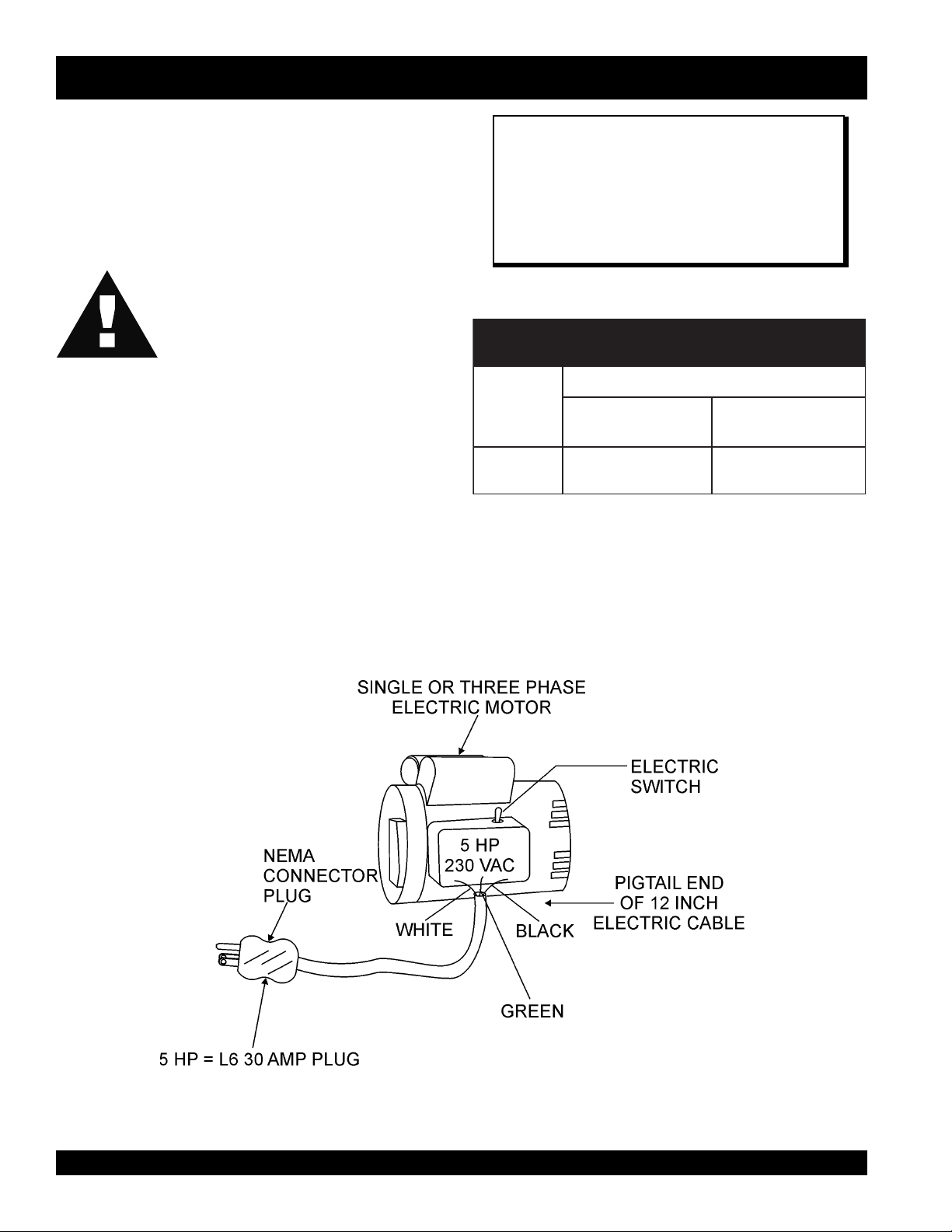

MS-40H HYDRAULIC MIXER — ELECTRIC MOTOR

ELECTRIC MOTOR

For lubrication care and operation of the electric motor, refer to

your electric motor instruction booklet furnished with the motor.

Protect the electric motor from dust as much as possible and

keep ventilating openings clean.

CAUTION:

■

DO NOT spray water at any time on the

electric motor

■

DO NOT operate electric motor in a

explosive environment.

The electric motor for this mixer is available in either a 5 HP

single-phase or 5 HP three-phase configuration. The input voltage

requirement for these motors is either 230 VAC or 440 VAC only.

ELECTRIC MOTOR CONNECTION

A 12 inch electrical cable (Figure 2) with a pigtail at one end is

provided with the electrical motor for hookup to a power source.

Table 1. shows the required NEMA connector for the desired

motor horsepower rating. In addition, Table 2 also shows the

matching NEMA approved connector for the required extension

cord.

.

It is strongly recommended that all electrical wiring be

done by a

should be given to the electric switch as well as the

over-and-under voltage protection devices as per

regulations set forth in the local electrical safety code

handbook.

PH5745049N/PP03-6L845049N/PR03-6L

NOTE

licensed electrician

. Special attention

noitamrofnIgniriWrotoMcirtcelE.2elbaT

rotoM

rewopesroH

gnitaR

rotcennoCgulPAMENAMENgnitaM

esahPelgniS-tloV032

rotcennoCelcatpeceR

Figure 2. Single Phase Electric Motor with 12 inch Pigtail Cable

PAGE 12 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 13

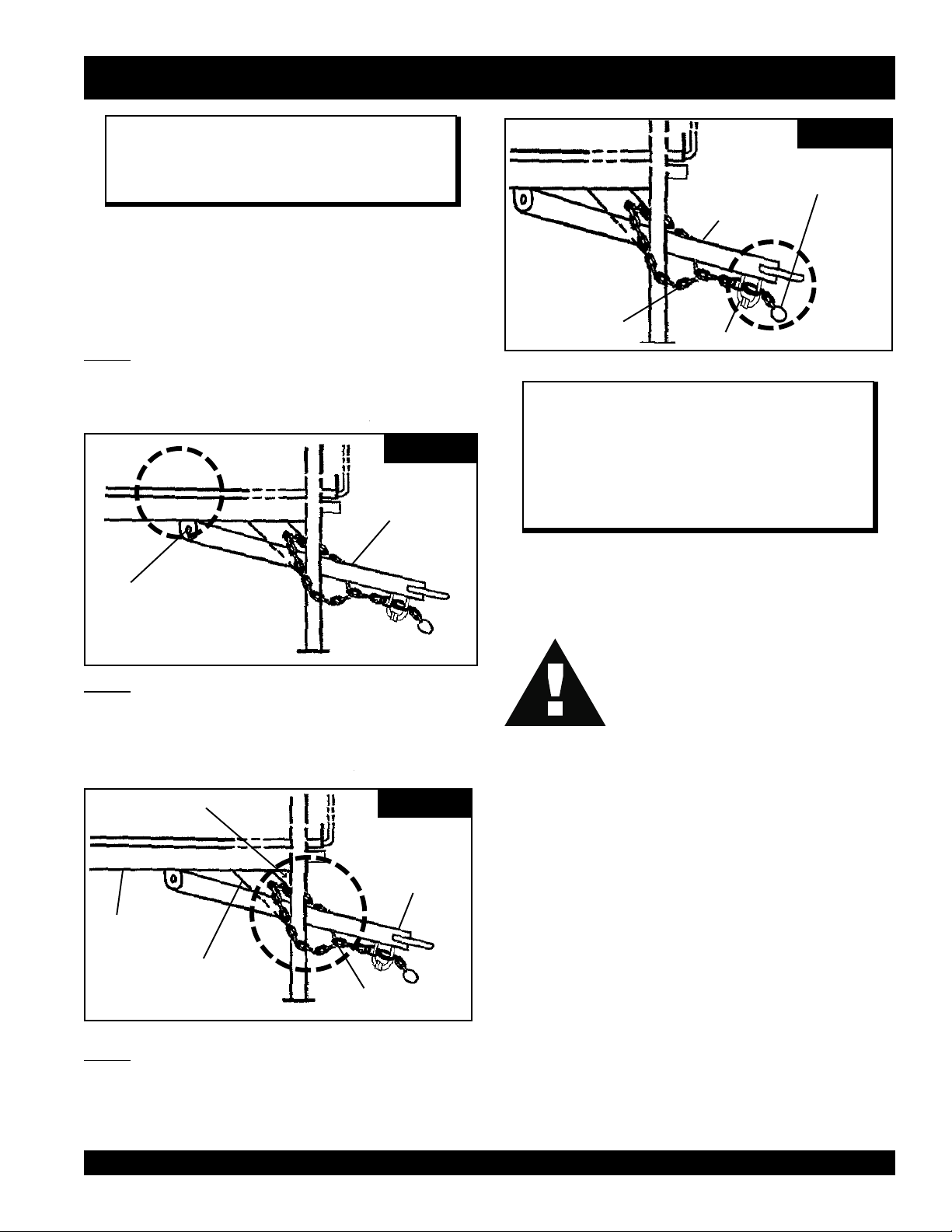

MS-40H HYDRAULIC MIXER — TOWING

NOTE

Before towing, check with local and state laws for proper

compliance.

The tow bar and chain must be properly attached to the mixer

and towing vehicle prior to towing. Refer to the following

installation instruction:

Step 1.

Insert the Draw Bar into the main frame. Secure, utilizing the 3/4"

bolt (grade 5) and nylock nut. Tighten to 100 foot pounds.

STEP 1

DRAW BAR

BOLT & NUT

REMOVE EXCESS

CHAIN (SLACK)

It is critical that the length of the chain be properly

adjusted, to prevent the

stand from dropping to the ground (contact) in the event

the Draw Bar becomes disconnected from the towing

vehicle.

If a new safety chain is required use P/N 13363. For a new

connector link use P/N 01004.

STEP 3

VEHICLE

CONNECTOR LINK

DRAW BAR

BOTTOM CONNECTOR LINK

NOTE

Draw Bar

and the front mixer

CAUTION:

Step 2.

Install the chain through the hole located between the frame

gusset and frame angle. Loop the chain together and place under

the Draw Bar. Secure with connector link.

INSERT CHAIN THROUGH

THE HOLE

FRAME ANGLE

FRAME GUSSET

CONNECTOR LINK

Step 3.

STEP 2

DRAW BAR

BALL HITCH COUPLER

1. Check vehicle hitch, ball, and coupler for signs of wear or

damage. Replace any parts that are worn or damaged

before towing.

2. Use only the 2" ball diameter as indicated on your coupler.

Use of any other ball diameter will create an extremely

dangerous condition which can result in separation of the

coupler and ball or ball failure.

3. Be sure the coupler is secured to the hitch ball and the lock

lever is down tight and locked.

Recheck tightness again after towing about 50 miles.

4. Check that trailer safety chains are properly connected.

■

Check the following before towing:

Extend the chain along the length of the Draw Bar, remove excess

chain (slack) and secure to bottom connector link. Secure the

chain to the towing vehicle, using the connector link.

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 13

Page 14

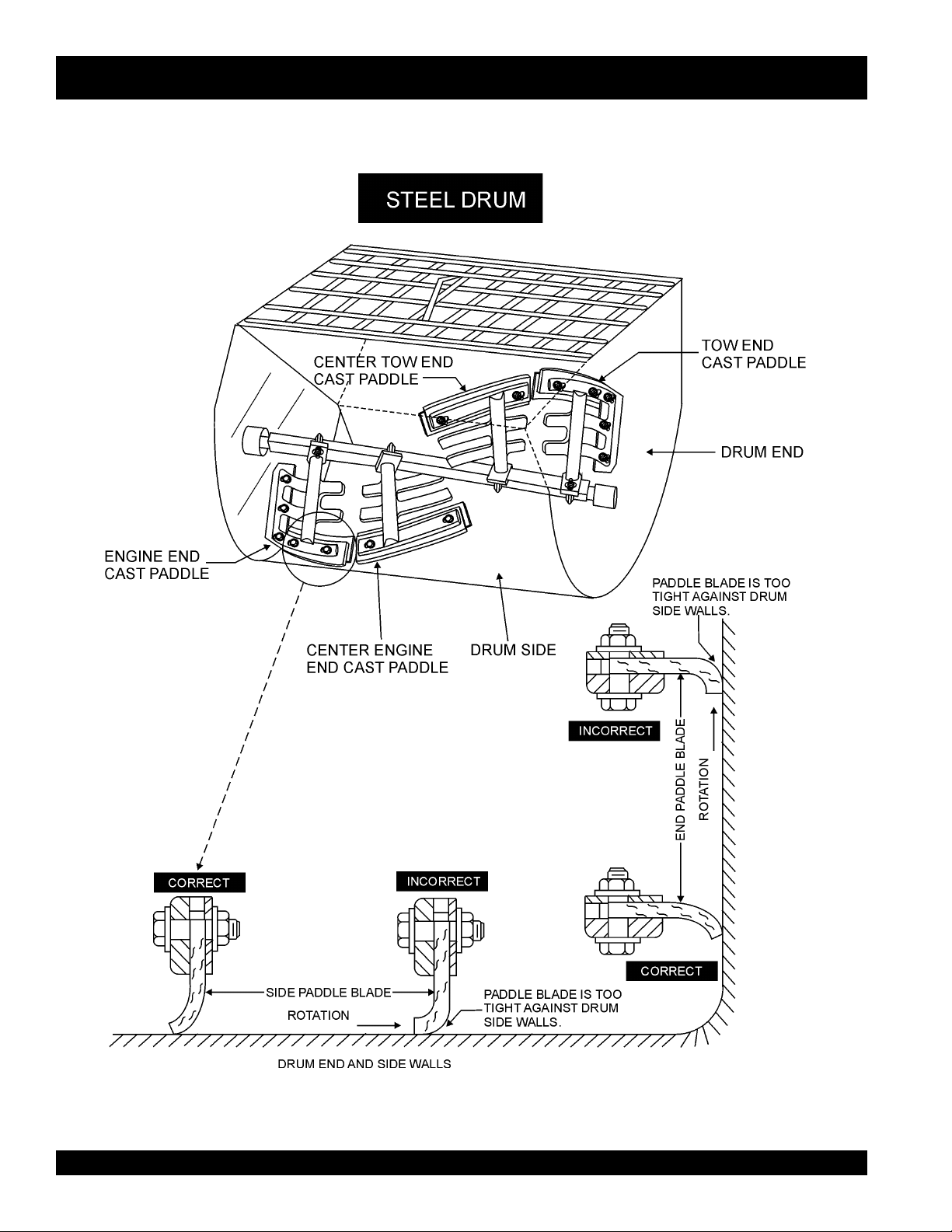

MS-40H HYDRAULIC MIXER — PADDLE BLADE ADJUSTMENT

Figure 3 illustrates the paddle blade adjustment when using a steel drum. If material builds up on the drum, use a rubber mallet to

dislodge the material without adverse effect to the drum.

Figure 3. Paddle Blade Adjustment, Steel Drum

PAGE 14 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 15

MS-40H HYDRAULIC MIXER — NOTE PAGE

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 15

Page 16

MS-40H HYDRAULIC MIXER — INITIAL START-UP

This section is intended to assist the operator with the initial

start-up of the STOW MS-40H hydraulic mixer. It is extremely

important that this section be read carefully before attempting to

use the mixer in the field.

DO NOT use your mixer until this section is thoroughly

understood.

STARTING THE ENGINE (gasoline only)

The following steps outline the procedure for starting the engine.

Depending on the type of engine employed in the mixer the

steps may vary slightly. If your mixer has an electric motor

disregard this section.

1. Move the fuel shut-off lever (Figure 5) to the ON position.

CAUTION:

Failure to understand the operation of theMS-

40H hydraulic mixer could result in severe

damage to the mixer or personal injury.

See Figure 1 (page 11) for the location of any control referenced

in this manual.

LUBRICANTS

ENGINE OIL

1. Remove the engine oil dipstick from its holder.

2. Determine if the engine oil is low, add correct amount of

engine oil to bring oil level to a normal safe level.

HYDRAULIC OIL RESERVOIR

1. Make sure the hydraulic reservoir is full. Hydraulic oil

should be visible within 3/4 height of the sight glass (Figure

4). If low use grade AWD 46 hydraulic oil or equivalent.

2. To start a cold engine, move the choke lever (Figure 6) to

the CLOSED position.

Figure 5. Fuel Shut-OFF Lever

Figure 4. Sight Glass

ZERK GREASE FITTINGS

1. Check the zerk grease fittings at each end of the mixing

drum. These grease fittings lubricate the dumping

mechanism. If the dumping handle is stiff or hard to move

3. Move the throttle lever (Figure 7) away from the slow

position, about 1/3 of the way toward the fast position.

lubricate these fittings.

FUEL

1. If your mixer has a gasoline engine, determine if the engine

fuel is low. If fuel is low, remove the fuel filler cap and fill

unleaded

with

gasoline.

CAUTION

Handle fuel safely. Motor fuels are highly

if

mishandled. DO NOT smoke while refueling. Do not attempt to refuel

mixer if the engine is hot or running. Always allow engine to

refueling.

PAGE 16 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

flammable

and can be dangerous

cool

before

Figure 6. Choke Lever

Figure 7. Throttle lever Lever

Page 17

MS-40H HYDRAULIC MIXER — INITIAL START-UP

4. Turn the engine switch (Figure 8) to the ON position.

Figure 8. Engine ON/OFF Switch

5. Located on the engine cover is the main

(Figure 9). Pull this switch outward to start the engine.

start/stop

switch

MIXING

1. The paddle shaft inside the drum should be rotating at this

time.

2. Lift the mixing bag compound onto the steel grate over the

bag cutter and let the contents fall into the drum.

3. Add water, and mix compound to desired consistency, then

dump.

NOTE

Be sure to stand clear of the

mixer is operational. Any binding of material between

the mixer blades and the drum will cause the drum

handle to move to the discharge position, thus causing

bodily harm.

STARTING THE ELECTRIC MOTOR

1. After the electric motor has been connected to a power

source by a licensed electrician it can then be ready for

use.

2. Set the electric motor's ON/OFF switch (Figure 11) to the

ON position.

dump handle

when the

Figure 9. Main ON/OFF Switch

6. Pull the

resistance, then pull briskly. Return the starter grip gently.

Push the clutch lever forward, toward the tow tongue end

of the mixer. When engine starts adjust throttle lever so that

paddle shaft inside mixer rotates between 30 - 40 RPM's.

The number of RPM's will vary depending on engine type

and load.

starter grip

Figure 10. Starter Grip

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 17

(Figure 10) lightly until you feel

Figure 11. Main ON/OFF Switch

3. Engage the control lever and verify that the paddle shaft is

rotating, then follow steps 1, 2 and 3 outlined in the mixing

section above.

STOPPING THE MIXER (gasoline)

1. Push the main

the engine.

Tur n the fuel shut-off valve to the OFF position

2.

3. Disconnect the spark plug.

4. Clean drum of all debris and foreign matter.

STOPPING THE MIXER (electric)

1. Place the electric motor's

the OFF position.

2. Disconnect the electric motor's extension cord from its

power source.

3. Clean drum of all debris and foreign matter.

start/stop

switch (Figure 9) inward to stop

start/stop

switch (Figure 10) in

Page 18

MS-40H HYDRAULIC MIXER — MAINTENANCE

WHEEL BEARINGS

After every 3 months of operation, remove the hub dust cap and

inspect the wheel bearings. Once a year, or when required,

disassemble the wheel hubs remove the old grease and repack

the bearings forcing grease between rollers, cone and cage

with a good grade of high speed wheel bearing grease (never

use grease heavier than 265 A.S.T.M. penetration (“No. 2.”) Fill

the wheel hub with grease to the inside diameter of the outer

races and also fill the hub grease cap.

Reassemble the hub and mount the wheel. Then tighten the

adjusting nut, at the same time turn the wheel in both directions,

until there is a slight bind to be sure all the bearing surfaces are

in contact.

Then back-off the adjusting nut 1/6 to 1/4 turn or to the nearest

locking hole or sufficiently to allow the wheel to rotate freely

within limits of .001" to .010" end play. Lock the nut at this position.

Install the cotter pin and dust cap, and tighten all hardware.

SHAFT SEALS

CAUTION:

IMPORTANT -DRUM HEAD SEAL CARE

Grease seals every 40 hours of operation using

any grade #1 lithium base grease. Apply

grease until visible inside of mixing tub (over

grease). This will purge seal system of

contamination.

PADDLE SHAFT BEARINGS

The paddle shafts in theSTOWMS-40H hydraulic mixers rotate

in sealed ball bearings, which require no additional lubrication

as they are packed and sealed at the factory.

There is, on each end of the mixing drum, an zerk grease fitting.

Oil these fittings two or three times each week as they lubricate

the dumping mechanism of the mixing drum.

CAUTION:

BEARING BRACKET

Grease the bearing bracket every month.

CLEANING

Always disconnect the spark plug wire before cleaning the inside

of the drum.

Never pour or spray water over the gasoline engine or electric

motor.

For consistent performance, long life and high quality mixing,

thoroughly clean the mixer inside and out at the end of each

day’s operation. To prevent lumps of dried mortar from forming

and contamination of future batches, do not allow a buildup of

materials to form on the blades or anywhere inside the drum.

■

Failure

two or three times a week will cause the

dumping mechanism to stiffen, making the

mixer hard to dump.

to lubricate the zerk grease fittings

PAGE 18 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 19

MS-40H HYDRAULIC MIXER — TROUBLESHOOTING (ENGINE)

Practically all breakdowns can be prevented by proper

handling and maintenance inspections, but in the event of a

breakdown, please take a remedial action following the

diagnosis based on the Engine Troubleshooting (Table 3)

information shown below and on the proceeding page. If the

problem cannot be remedied, please leave the unit just as it

is and consult our company's business office or service

MOTPMYS MELBORPELBISSOP NOITULOS

?tignihcaersi

?leuFoN leuFddA

?knatleufniretaW .knatleufecalperrohsulF

?deggolcretlifleuF retlifleufecalpeR

?roterubrackcutS .msinahcemtaolfkcehC

gnitratsrooP

?dersigulpkrapS .tinunoitingirotsinartkcehC.deluofsigulpkrapS

leuffieesotroterubractcepsnI

?etihw-eulbsigulpkrapS

GNITOOHSELBUORTENIGNE.3ELBAT

enilleufkcehC

erastejroterubraC.gnikaelriadetcejni,noisserpmoctneiciffusnI

.)wolfrevo(deggolc

?gulp

?liooN .deriuqersalioddA

?gnitratsnopu

?esool

"noisserpmoc

"noisserpmoc"

on"tuptuorewoptneiciffusnI

?esoolsigulpkrapS .gulpkrapsecalpeR

?sgnirnotsipnroW .sgnirnotsipecalpeR

tuptuorewoptneiciffusnI

?daeh

krapsfopittatneserpkrapsoN

sknilbpmalmralaerusserpliO

?revonruttonlliwenignE .tniojlexayrassecenfidnanotsipdnarednilycecalpeR

stlobgnitcennocdaehrednilyC

?degamadteksagdaehrednilyC .teksagdaehrednilycecalpeR

?taesevlavfonoitcnuflaM .sevlavtaes-eR

renaelc-rianinoitcnuflaM

?deggolcretlifria,metsys

ecafretnimorfnignikaelriA

rednilycdnaroterubracneewteb

.deluoffigulpkrapsecalpeR.nekorbhctiwspotS/tratS

."rosneslio"tiucricnwodtuhscitamotuAkcehC

.stlobgnitcennocdaehrednilycnethgiT

.retlifriaecalperronaelC

.teksagdaehrednilyc

.nekorbrodekcarcdrocegatlovhgih,nekorbtinunoitingirotsinarT

ecalpeR.daehrednilycdnaroterubracneewtebstlobnethgiT

?metsysleufninoitcnuflaM

.retlifleufecalperronaelC

.roterubracecalperronaelC

.taolfroterubrackcehC

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 19

Page 20

MS-40H HYDRAULIC MIXER — TROUBLESHOOTING (ENGINE/MIXER)

)DEUNITNOC(GNITOOHSELBUORTENIGNE.3ELBAT )

MOTPMYS MELBORPELBISSOP NOITULOS

tuptuorewoptneiciffusnI

staehrevodna"noisserpmoc"

leufhcumotsnruB

ylsuoinitnocsiroloctsuahxE

"ETIHW"

ylsuoinitnocsiroloctsuahxE

"KCALB"

?stcudorp

?ytisocsiv

?sgnirnroW sgnirecalpeR

?nafgniloocninoitcnuflaM .nafgniloocecalperrokcehC

?deggolcretlifekat-niriA .retlifekat-niriaecalperronaelC

tsuahxefonoitalumuccarevO

?gulpkrapsgnorW .gulpkrapsepytdetseggusserutcafunamhtiwgulpkrapsecalpeR

gnorwsiliognitacirbuL

?deggolcrennaelcriA .renaelcriaecalperronaelC

tesneebtonsahevlavekohC

?noitisoptcerrocehtot

nolaes,evitcefedroterubraC

?nekorbroterubrac

tnemtsujdaroterubracrooP

?hcirootsnurenigne"

.sevlavkcehcdnanaelC

.yrassecenfiecalper,relffumkcehC

.ytisocsivtcerrochtiwliognitacirbulecalpeR

.noitisoptcerrocehtotevlavekohctsujdA

.laesroroterubracecalpeR

.roterubractsujdA

GNITOOHSELBUORTREXIM.4ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?niprotcennocnekorB

.etatortonlliwsedalbelddaP

?murdnilairetam/thgiewevissecxE .murdehtnilairetamehtfoemosevomeR

.sdne

.rewopfossoL diulfciluardyhwoL .wolfidiulfddA.ssalgthgisdiulfciluardyhkcehC

murdmorfgnikaellairetaM

?slaes

?deggolcretlifria

.)tlit(egrahcsidottluciffidmurD

?stekcarb

tfahselddapevitcefedronroW

,metsysrenaelc-rianinoitcnuflaM

troppusmurdnrowroevitcefeD

?thgitootdetsujdasedalB .murdfosllawedishcuottsomlayehtlitnusedalbtsujdA

.slaesecalperrotsujdA

.retlifriaecalperronaelC

.ecalperrotekcarbotesaergylppA

.gniredronehw5123N/PesU.niprotcennocecalpeR

PAGE 20 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 21

MS-40H HYDRAULIC MIXER — NOTE PAGE

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 21

Page 22

EXPLANATION OF CODE IN REMARKS COLUMN

How to read the marks and remarks used in this parts book.

Section 1: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Section 2: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial number

range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model number

or model number variant.

Section 3: Items Found In the “Items Number” Column

All parts with same symbol in the number column,

■

, belong to the same assembly or kit.

Note: If more than one of the same reference number is listed,

the last one listed indicates newest (or latest) part available.

NOTE

The contents of this parts catalog are subject to

change without notice.

, #, +, %, or

*

PAGE 22 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 23

MS-40H HYDRAULIC MIXER— SUGGESTED SPARE PARTS

MS40H 1 TO 3 UNITS

Qty. P/N Description

6 ............ 491010 ............ RUBBER LATCH ASSY.

1 ............ EM200293 .......PADDLE ARM TOW SIDE

1 ............ EM200294 ....... PADDLE ARM CENTER TOW SIDE

1 ............ EM200295 ....... PADDLE ARM CENTER ENGINE SIDE

1 ............ EM200296 ....... PADDLE ARM ENGINE SIDE

3 ............ EM200863 ....... RUBBER BLADE KIT (STEEL DRUM)

2 ............ EM200297 ....... U-BOLT

2 ............ EM200268 ....... U-BOLT

2 ............ 3530 ................PADDLE SHAFT, SEAL KIT

2 ............ EM902153 ....... BEARING, PADDLE SHAFT

3 ............ 3215 ................CONNECTOR BOLT

MS40H 5 TO 10 UNITS

Qty. P/N Description

10 .......... 491010 ............ RUBBER LATCH ASSY.

2 ............ EM200293 .......PADDLE ARM TOW SIDE

2 ............ EM200294 ....... PADDLE ARM CENTER TOW SIDE

2 ............ EM200295 ....... PADDLE ARM CENTER ENGINE SIDE

2 ............ EM200296 ....... PADDLE ARM ENGINE SIDE

6 ............ EM200863 ....... RUBBER BLADE KIT (STEEL DRUM)

4 ............ EM200297 ....... U-BOLT

4 ............ EM200268 ....... U-BOLT

4 ............ 3530 ................PADDLE SHAFT, SEAL KIT

4 ............ EM902153 ....... BEARING, PADDLE SHAFT

5 ............ 3215 ................CONNECTOR BOLT

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 23

Page 24

MS-40H HYDRAULIC MIXER — NAME PLATE AND DECALS

NAME PLATE AND DECALS

PAGE 24 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 25

MS-40H HYDRAULIC MIXER — NAME PLATE AND DECALS

NAME PLATE AND DECALS

NO PART NO PART NAME QTY. REMARKS

1

*

2

*

3 PLATE, SERIAL NO............................. 1 ........ CONTACT MQ PARTS DEPT. W/MODEL & S/N

4

*

5

*

6

*

7

*

SEE DECAL ILLUSTRATIONS ON PAGE 6.

EM948423 DECAL : CAUTION 2

924801 DECAL : SAFETY INSTRUCTIONS 1

TBD DECAL : MQ STOW 1

DCL151 DECAL : INSPECT TOWING 2

13238 DECAL : DUMP CONTROL 1

511764 DECAL : DRIVE CONTROL 1

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 25

Page 26

MS-40H HYDRAULIC MIXER — ENGINE END PADDLE ASSY.

ENGINE END PADDLE ASSY.

PAGE 26 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 27

MS-40H HYDRAULIC MIXER — ENGINE END PADDLE ASSY.

ENGINE END PADDLE ASSY.

NO PART NO PART NAME QTY. REMARKS

3 EM200296 PADDLE ARM ENGINE END 1

4 EM200295 PADDLE ARM CENTER ENGINE END 1

5 0300B FLAT WASHER 5/16 28

6 0161D HEX NUT 5/16 14

7

# EM203433 END BACK-UP BLADE 2

*

8 0161C LOCK WASHER 5/16 14

9 1207 HHCS 5/16-18 1 3/4" 14

11 EM200292 PADDLE ARM INSERT CASTING 8

12 EM200297 END PADDLE U-BOLT 2

13 EM200268 CENTER PADDLE J-BOLT 2

14

# EM203432 CENTER BACK-UP BLADE 4

*

15 5054A LOCK WASHER 1/2" 8

16 968011 HEX NUT 1/2-13 8

17

18

EM200212 SIDE RUBBER BLADE 4

*

EM200213 END RUBBER BLADE 2

*

EM200863 RUBBER BLADE KIT (STEEL DRUM ONLY)..... 1 ........ INCLUDES ITEMS W/

AND MTG. HDW.

*

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 27

Page 28

TOW END PADDLE ASSY.

MS-40H HYDRAULIC MIXER — TOW END PADDLE ASSY.

PAGE 28 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 29

MS-40H HYDRAULIC MIXER — TOW END PADDLE ASSY.

TOW END PADDLE ASSY.

NO PART NO PART NAME QTY. REMARKS

1 EM200293 PADDLE ARM TOW END 1

2 EM200294 PADDLE ARM CENTER TOW END 1

5 0300B FLAT WASHER 5/16 28

6 0161D HEX NUT 5/16 14

7

# EM203433 END BACK-UP BLADE 2

*

8 0161C LOCK WASHER 5/16 14

9 1207 HHCS 5/16-18 1 3/4" 14

11 EM200292 PADDLE ARM INSERT CASTING 8

12 EM200297 END PADDLE U-BOLT 2

13 EM200268 CENTER PADDLE U-BOLT 2

14

# EM203432 CENTER BACK-UP BLADE 4

*

17 5054A LOCL WASHER 1/2" 8

18 968011 HEX NUT 1/2-13 8

19

20

EM200212 SIDE RUBBER BLADE 4

*

EM200213 END RUBBER BLADE 2

*

EM200863 RUBBER BLADE KIT (STEEL DRUM ONLY)........1 ..... INCLUDES ITEMS W/

EM203028 HDW. KIT, (FOR RUBBER BLADES) .................... 1 ..... INCLUDED IN BLADE KITS

AND MTG. HDW.

*

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 29

Page 30

STEEL MIXING DRUM ASSY.

MS-40H HYDRAULIC MIXER — STEEL MIXING DRUM ASSY.

PAGE 30 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 31

MS-40H HYDRAULIC MIXER — STEEL MIXING DRUM ASSY.

STEEL MIXING DRUM ASSY.

NO PART NO PART NAME QTY. REMARKS

1 203449 MOVEABLE GRATE 1

2 7170 CLIP 1

3 13211 FLAT WASHER 1/2 USS 1

4 13276Y GRATE LATCH BAR 1

5 10176 LOCK NUT 1/2-13 13

6 0447 FLAT WASHER 1/2 5

7 1162A CAP, ZERK FITTING 4

8 2621 ZERK FITTING 4

9 3242 SCREW, HHCS 1/2-13 X 1-3/4 4

10 13260Y FRONT DUMP SUPPORT BRACKET 1

11 3249 DUST CAP 1

12 5218 SCREW HHCS 12-13 X 1-1/2 9

13 924015 COTTER KEY 2

WITHOUT HYDRAULIC DUMP

14 511852Y BEARING HOUSING REAR 1

WITH HYDRAULIC DUMP

14 3291Y BEARING HOUSING REAR 1

MANUAL DUMP

15 13228 CLEVIS PIN (W/DUMP) 1

16 3327 DUMP CYLINDER 1

17 13259Y REAR DUMP SUPPORT BRACKET 1

18 3413 LOCK NUT 1-8 1

19 13286 SPACER 1

20 13285 SCREW, HHCS 1-8 X 8 1

21 8151 FLAT WASHER 1

22 512245Y STEEL DRUM W/GRATES ................................. 1 ........ S/N GE210001

23 EM201537Y MANUAL DUMP HANDLE .................................. 1 ........ DO NOT USE WITH HYDRAULIC DUMP

24 3291 YBEARING HOUSING FRONT.......................... 1 ........ S/N GE210001

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 31

Page 32

STEEL PADDLE SHAFT ASSY.

MS-40H HYD. MIXER — PADDLE SHAFT ASSY.

PAGE 32 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 33

MS-40H HYD. MIXER — PADDLE SHAFT ASSY.

STEEL PADDLE SHAFT ASSY.

NO PART NO PART NAME QTY. REMARKS

1 3061 SPACER 14

2

*

3

*

4 3024 SPRING 2

5 13002 BEARING SEAL 2

6 3131 O-RING 2

7 EM902153 BALL BEARING 2

8 3347 SPECIAL NUT 1

9 13108 SPACER 1

10 13156 COUPLER 1

11 3215 HHCS 1/2-13 X 3.1/2" 1

12 3047 SPACER 1

13 8164 CASTLE NUT 1-20 1

14 5028B COTTER PIN 1

15 13257 PADDLE SHAFT 1

16 13156 DRIVE COUPLER 1

3494 OUTER SEAL 2

3019 INNER SEAL 4

3530 PADDLE SHAFT SEAL KIT .................................... 1 .... INCLUDES ITEMS W/

*

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 33

Page 34

HYDRAULIC ASSY.

MS-40H HYDRAULIC MIXER — HYDRAULIC ASSY.

PAGE 34 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 35

MS-40H HYDRAULIC MIXER — HYDRAULIC ASSY.

HYDRAULIC ASSY.

NO PART NO PART NAME QTY. REMARK

1 3323 HYDRAULIC MOTOR 1

2 3365 FITTING, STRAIGHT W/O-RING 3

3 13243 MOTOR HOSE, 16" 1

4 3231 SPACER 3

5 3242 HHCS 1/2-13 X 1.3/4" 4

6 10133 LOCK NUT 3/8-16 1

7 3327 DUMP CYLINDER ....................................... 1 ....... WITH DUMP (HYDRAULIC DUMP CYLINDER)

8 0131A HHCS 1/4-20 X 3/4" 2

9 0181B LOCK WASHER 1/4" 2

10 3353 OIL FILLER CAP 1

11 3369 FITTING, 90 DEG. ...................................... 2 ....... WITH DUMP (HYDRAULIC DUMP CYLINDER)

12 10136 FLAT WASHER 3/8" 2

13 13198 CYLINDER HOSE ....................................... 2 ....... WITH DUMP (HYDRAULIC DUMP CYLINDER)

14 13153 CAP 2

15 13196 VALVE PRESSURE HOSE ......................... 1 ....... GAS ENGINE ONLY

16 3367 FITTING, 90 DEG. 3/4" HOSE BARB 2

17 3462 TANK RETURN HOSE 3

18 0857 SHSS 5-16-24 X 1/2" 2

19 8051 OIL FILTER ASSY. 1

19 8163 OIL FILTER 1

20 3461 FITTING, 45 DEG. 3/4" HOSE BARB 1

21 3333 HOSE CLAMP 6

22 13219 FITTING 90 DEG. 1

23 13220 FITTING 2

24 13210 STRAINER 1

25 13213 URETHANE SPRING 2

26 13147 MOTOR TORQUE ARM 1

27 3336 OIL SIGHT GAUGE 1

28 3215 HHCS 1/2-13 X 1.3/4" 1

29 13156 DRIVE COUPLER 1

30 3322 FITTING, 90 DEG. W/O-RING.................... 1 ....... GAS ENGINE ONLY

31 1284 HHCS 3/8-16 X 1.3/4" 3

32 0166A LOCK WASHER 3/8" 3

33 3316 VALVE ASM ................................................. 1 ....... WITH DUMP (HYDRAULIC DUMP CYLINDER)

34 13217 HHCS 3/8-16 X 6" 1

35 10176 LOCK NUT 1/2-13 5

36 3321 FITTING, 45 DEG. W/O-RING.................... 2 ....... WITH DUMP (HYDRAULIC DUMP CYLINDER)

37 3314 FITTING, STRAIGHT W/O-RING 2

38 13244 MOTOR HOSE 22" 1

39 13216 FITTING 90 DEG W/O-RING 1

40 510263 FITTING 90 DEG STRAIGHT EL 1

41 13225 HANDLE 1

42 13226 HANDLE 1

43 13212 GROMMET 1

44 3407 KNOB 2

10477 SEAL KIT (DUMP CYLINDER) 1

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 35

Page 36

MS-40H HYDRAULIC MIXER — FRAME 3 ASSY.

FRAME 3 ASSY.

5 LUG HUB AND WHEEL (1-1/16 AXLE SPINDLE)

S/N GE21000 -

PAGE 36 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 37

MS-40H HYDRAULIC MIXER — FRAME 3 ASSY.

FRAME 3 ASSY.

5 LUG HUB AND WHEEL (1-1/16 AXLE SPINDLE)

NO PART NO PART NAME QTY. REMARK

1 13212 GROMMET ............................................................. 1 .... WITH DUMP (HYDRAULIC DUMP CYL.)

2 EM941280 LUG NUT 8

3 13365Y MAIN FRAME 1

4 10133 LOCK NUT 3/8-16 1

5 0447 FLAT WASHER 1/2" 1

6 10176 LOCK NUT 1/2-13 12

7 511493Y GRATE LATCH 1

8 1023 HHCS 3/8-16 X 1.1/4" 1

9 13280Y DRUM LOCK LEVER .............................................. 1 .... W/O DUMP (MANUAL ONLY)

10 3102Y HANDLE GRIP ........................................................ 1 .... W/O DUMP (MANUAL ONLY)

11 EM941278 DUST CAP 2

12 3148 SAFETY CHAIN ASM 1

13 3028 U-BOLT 2

14 3215 HHCS 1/2-13 X 3.1/2" 1

15 HLC-1 TOW BAR (LOOP) 1

15 HPC-1 TOW BAR (1 " PIN) 1

15 HBC-1 TWO BAR (BALL HITCH 2 -INCH) 1

16 511699 AXLE 1

17 5218 HHCS 1/2-13 X 1.1/2" 4

18 3043 HHCS 1/2-13 X 6" 2

19 3076 AXLE SPRING 2

20 3018 LEAF SPRING 2

21 19045 WHEEL & TIRE 2

22 EM968302 CASTLE NUT 2

23 0183 COTTER PIN 2

24 EM923161 FLAT WASHER 3/4" 2

25 EM903168 BEARING CONE INNER 4

26 EM903169 BEARING CUP INNER 4

27 EM914324 SEAL 2

28 EM941277 HUB W/BEARING CUPS (4-LUG) 2

30 EM903113 BEARING CONE OUTER 2

31 EM903012 BEARING CUPS OUTER 2

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 37

Page 38

ENGINE COVER ASSY.

MS-40H HYDRAULIC MIXER — ENGINE COVER ASSY.

PAGE 38 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 39

MS-40H HYDRAULIC MIXER — ENGINE COVER ASSY.

ENGINE COVER ASSY.

NO PART NO PART NAME QTY. REMARKS

1 511580Y ENGINE COVER-STEEL 1

2 509726Y LATCH PIN ASSY. 2

3 491010 RUBBER LATCH ASSY. 2

4 1284 SCREW, HHCS 3/8-16 X 1.1/2” 4

5 4001 FLAT WASHER 3/8” 8

6 10133 LOCK NUT 3/8-16 4

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 39

Page 40

ENGINE ASSY.

MS-40H HYDRAULIC MIXER — ENGINE ASSY.

PAGE 40 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 41

MS-40H HYDRAULIC MIXER — ENGINE ASSY.

ENGINE ASSY.

NO PART NO PART NAME QTY. REMARK

1 GX390K1QX2 HONDA ENGINE 13 HP 1

2 3396 KILL BUTTON 1

3 10133 LOCK NUT 3/8-16 4

4 1475 WIRE CONNECTOR 1

5 1665 HHCS 3/8-16 X 2" 4

6 10136 FLAT WASHER 3/8" 4

7 0310 SQ. KEY 1/4 X 1/4 X 1.1/2" 1

8 0622C SHSS 5/16-18 X 1/2" 2

9 3325 PUMP MOUNT 1

10 2126 SQ. KEY 3/16 X 3/16 X 13/16" 2

11 13374 HDRAULIC PUMP SINGLE SHAFT 1

12 3419 COUPLER (ENGINE END) 1

13 3418 COUPLER INSERT 1

14 3420 COUPLER (PUMP END) 1

15 0166A LOCK WASHER 3/8" 6

16 1023 HHCS 3/8-16 X 1.1/4" 6

17 EM203149 MUFFLER PIPE 1

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 41

Page 42

MS-40H HYDRAULIC MIXER — 1f- 5 HP ELECTRIC MOTOR ASSY.

SINGLE PHASE, 5 HP ELECTRIC MOTOR ASSY.

PAGE 42 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 43

MS-40H HYDRAULIC MIXER — 1f- 5 HP ELECTRIC MOTOR ASSY.

SINGLE PHASE, 5 HP ELECTRIC MOTOR ASSY.

NO PART NO PART NAME QTY. REMARK

1 3414 5 HP ELECTRIC MOTOR (SINGLE PHASE) 1

2 1023 SCREW, HHCS 3/8-16 X 1-1/4 2

3 0166A LOCK WASHER 3/8 4

4 0205 SCREW, HHCS 3/8-16 X 1 2

5 13291 SWITCH MOUNTING PLATE 1

6 8133 SCREW, RHMS 8-32 X 3/4 3

7 0310 SQUARE KEY 1/4 X 1/4 X 1-1/2 1

8 0622C SCREW, 5/16 -18 X 1/2 2

9

*

10 13292 MOTOR MOUNT BLOCK 2

11 3421 COUPLER (MOTOR END) 1

12 3418 COUPLER INSERT 1

13 3420 COUPLER (PUMP END) 1

14 3416 PUMP MOUNT 1

15 5054A LOCK WASHER 1/2 4

16 2691 SCREW, HHCS 1/2 -13 X 1 4

17 13375 HRDRAULIC PUMP SINGLE SHAFT 1

18 2203 FLAT WASHER #10 6

19 10019 LOCK NUT 10-32 3

20 8156 SCREW, HHCS 3/8-16 X 2-1/2 2

21 10136 FLAT WASHER 3/8 8

22 1665 SCREW, HHCS 3/8-16 X 2 2

23 10133 LOCK NUT 3/8-16 4

940228 SWITCH BOX (3 PHASE) 1

940198 HEATER ELEMENT ........................................................ 3 ............. INCLUDES ITEM W/

*

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 43

Page 44

MS-40H HYDRAULIC MIXER — 3f- 5 HP ELECTRIC MOTOR ASSY.

THREE PHASE, 5 HP ELECTRIC MOTOR ASSY.

PAGE 44 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 45

MS-40H HYDRAULIC MIXER — 3f- 5 HP ELECTRIC MOTOR ASSY.

THREE PHASE, 5 HP ELECTRIC MOTOR ASSY.

NO PART NO PART NAME QTY. REMARK

1 3481 5 HP ELECTRIC MOTOR (THREE PHASE) 1

2 1023 SCREW, HHCS 3/8-16 X 1-1/4 2

3 0166A LOCK WASHER 3/8 4

4 0205 SCREW, HHCS 3/8-16 X 1 2

5 13291 SWITCH MOUNTING PLATE 1

6 8133 SCREW, RHMS 8-32 X 3/4 3

7 0310 SQUARE KEY 1/4 X 1/4 X 1-1/2 1

8 0622C SCREW, 5/16 -18 X 1/2 2

9

*

10 13289 MOTOR MOUNT BLOCK 2

11 3421 COUPLER (MOTOR END) 1

12 3418 COUPLER INSERT 1

13 3420 COUPLER (PUMP END) 1

14 3416 PUMP MOUNT 1

15 5054A LOCK WASHER 1/2 4

16 2691 SCREW, HHCS 1/2 -13 X 1 4

17 13375 HYDRAULIC PUMP SINGLE SHAFT 1 I

18 2203 FLAT WASHER #10 6

19 10019 LOCK NUT 10-32 3

940228 SWITCH BOX (3 PHASE) 1

940198 HEATER ELEMENT .............................................. 3 ............ INCLUDED W/

*

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 45

Page 46

Effective: July 1, 2000

TERMS AND CONDITIONS OF SALE — PARTS

PAYMENT TERMS

Terms of payment for parts are net 10 days.

FREIGHT POLICY

All parts orders will be shipped collect or

prepaid with the charges added to the invoice.

All shipments are F.O.B. point of origin.

Multiquip’s responsibility ceases when a signed

manifest has been obtained from the carrier,

and any claim for shortage or damage must be

settled between the consignee and the carrier.

MINIMUM ORDER

The minimum charge for orders from Multiquip

is $15.00 net. Customers will be asked for

instructions regarding handling of orders not

meeting this requirement.

RETURNED GOODS POLICY

Return shipments will be accepted and credit

will be allowed, subject to the following

provisions:

1. A Returned Material Authorization must

be approved by Multiquip prior to shipment.

2. To obtain a Retur n Material Authorization,

a list must be provided to Multiquip Parts

Sales that defines item numbers,

quantities, and descriptions of the items to

be returned.

a. The parts numbers and descriptions

must match the current parts price

list.

b. The list must be typed or computer

generated.

c. The list must state the reason(s) for

the return.

d. The list must reference the sales

order(s) or invoice(s) under which

the items were originally purchased.

e. The list must include the name and

phone number of the person

requesting the RMA.

3. A copy of the Return Material

Authorization must accompany the return

shipment.

4. Freight is at the sender’s expense. All

5. Parts must be in new and resalable

6. The following items are not returnable:

7. The sender will be notified of any material

8. Such material will be held for 5 working

9. Credit on returned parts will be issued at

10. In cases where an item is accepted for

11. Credit issued will be applied to future

PRICING AND REBATES

parts must be returned freight prepaid to

Multiquip’s designated receiving point.

condition, in the original Multiquip package

(if any), and with Muiltiquip part numbers

clearly marked.

a. Obsolete parts. (If an item is listed

in the parts price book as being

replaced by another item, it is

obsolete.)

b. Any parts with a limited shelf life

(such as gaskets, seals, “O” rings,

and other rubber parts) that were

purchased more than six months

prior to the return date.

c. Any line item with an extended dealer

net price of less than $5.00.

d. Special order items.

e. Electrical components.

f. Paint, chemicals, and lubricants.

g. Decals and paper products.

h. Items purchased in kits.

received that is not acceptable.

days from notification, pending

instructions. If a reply is not received

within 5 days, the material will be returned

to the sender at his expense.

dealer net price at time of the original

purchase, less a 15% restocking charge.

which the original purchase document

can not be determined, the price will be

based on the list price that was effective

twelve months prior to the RMA date.

purchases only.

Prices are subject to change without prior

notice. Price changes are effective on a specific

date and all orders received on or after that date

will be billed at the revised price. Rebates for

price declines and added charges for price

increases will not be made for stock on hand at

the time of any price change.

Multiquip reserves the right to quote and sell

direct to Government agencies, and to Original

Equipment Manufacturer accounts who use

our products as integral parts of their own

products.

SPECIAL EXPEDITING SERVICE

A $20.00 to $50.00 surcharge will be added to

the invoice for special handling including bus

shipments, insured parcel post or in cases

where Multiquip must personally deliver the

parts to the carrier.

LIMITATIONS OF SELLER’S LIABILITY

Multiquip shall not be liable here under for

damages in excess of the purchase price of the

item with respect to which damages are claimed,

and in no event shall Multiquip be liable for loss

of profit or good will or for any other special,

consequential or incidental damages.

LIMITATION OF WARRANTIES

No warranties, express or implied, are made in

connection with the sale of parts or trade

accessories nor as to any engine not

manufactured by Multiquip. Such warranties

made in connection with the sale of new,

complete units are made exclusively by a

statement of warranty packaged with such

units, and Multiquip neither assumes not

authorizes any person to assume for it any

other obligation or liability whatever in

connection with the sale of its products. A part

from such written statement of warranty, there

are no warranties, express, implied or statutory,

which extend beyond the description of the

products on the face hereof.

PAGE 46 — STOW MS-40H HYDRAULIC MIXER— PARTS & OPERATION MANUAL — REV. #1 (05/17/02)

Page 47

NOTE PAGE

STOW MS-40H HYDRAULIC MIXER — PARTS & OPERATION MANUAL — REV. #1 (05/17/02) — PAGE 47

Page 48

PARTS AND OPERATION MANUAL

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

^^^^^*^^^^^^^^^^^^^^^^^^^^^^^^^*^6668

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

MULTIQUIP INC.

POST OFFICE BOX 6254

CARSON, CA 90749

310-537-3700 • 800-421-1244

FAX: 310-537-3927

E-MAIL: mq@multiquip.com

WWW: multiquip.com

Quebec, Canada • Manchester, UK • Rio De Janiero, BR • Guadalajara, MX

Atlanta • Boise • Dallas • Houston • Newark

Loading...

Loading...