Page 1

OPERATION MANUAL

NIGHTHAWK SERIES

MODELS LT-12D, LT-12P

DEDICATED LIGHT TOWER

(DEUTZ/LOMBARDINI DIESEL ENGINE)

(PERKINS DIESEL ENGINE)

Revision #1 (08/15/08)

To find the latest revision of this

publication, visit our website at:

www.multiquip.com

THIS MANUAL MUST ACCOMPANY THE EQUIPMENT AT ALL TIMES.

P/N: 49103

Page 2

PROPOSITION 65 WARNING / REPORTING SAFETY DEFECTS

Diesel engine exhaust and some of

REPORTING SAFETY DEFECTS

If you believe that your vehicle has a defect that could cause a crash or could cause injury or

death, you should immediately inform the National Highway Traffic Safety Administration

(NHTSA) in addition to notifying Multiquip at 1-800-421-1244.

If NHTSA receives similar complaints, it may open an investigation, and if it finds that a safety

defect exists in a group of vehicles, it may order a recall and remedy campaign. However,

NHTSA cannot become involved in individual problems between you, your dealer, or

Multiquip.

To contact NHTSA, you may either call the Vehicle Safety Hotline toll-free at 1-888-327-4236

(TTY: 1-800-424-9153), go to http://www.nhtsa.dot.gov; or write to:

Administrator

NHTSA

1200 New Jersey Avenue S.E.

Washington, DC 20590

You can also obtain information about motor vehicle safety from http://www.safecar.gov.

PAGE 2 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 3

TABLE OF CONTENTS

STOW NIGHTHASTOW NIGHTHA

STOW NIGHTHA

STOW NIGHTHASTOW NIGHTHA

LL

TT

-12 SERIES LIGHT TOWER-12 SERIES LIGHT TOWER

L

T

-12 SERIES LIGHT TOWER

LL

TT

-12 SERIES LIGHT TOWER-12 SERIES LIGHT TOWER

Proposition 65 ................................................................. 2

Reporting Safety Defects ................................................ 3

Table of Contents ............................................................. 3

Safety Message Alert Symbols ................................... 4-5

Rules For Safe Operation ............................................. 6-7

Operation and Safety Decals ........................................ 8-9

Specifications (Light Tower) ........................................... 10

Specifications (Engines) ................................................ 11

Dimensions .................................................................... 12

General Information ....................................................... 13

Components .............................................................. 14-15

Control Panel ............................................................. 16-17

Floodlight Footcandle Plots ........................................... 18

Towing Guidelines ......................................................19-20

Trailer Safety Guidelines ............................................ 21-22

Trailer Wiring Diagram .................................................... 23

Inspection .................................................................. 24-27

Startup Procedure ......................................................... 28

Shutdown Procedure ..................................................... 29

Mast Operation .............................................................. 30

Operation ....................................................................... 31

Maintenance ..............................................................32-36

Troubleshooting (Generator) ........................................... 37

Troubleshooting (Engine) ........................................... 38-39

Troubleshooting (Lamps) ............................................40-42

Schematic Diagram ....................................................... 43

Deutz Engine Wiring ...................................................... 44

Perkins Engine Wiring .................................................... 45

WKWK

WK

WKWK

NOTE

For Deutz/Lombardini Parts

information, please see our LT-12

Deutz F3M1008F Diesel Engine

Parts Manual.

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 3

Page 4

LT-12 SERIES LIGHT TOWER — SAFETY MESSAGE ALERT SYMBOLS

FOR YOUR SAFETY AND THE SAFETY OF OTHERS!

Safety precautions should be followed

at all times when operating this

equipment. Failure to read and

understand the Safety Messages and

Operating Instructions could result in

injury to yourself and others.

This Owner's Manual has been

NOTE

developed to provide complete

instructions for the safe and

efficient operation of the

LT-12 Series Light Tower.

Before using this Light Tower, ensure that the operating

individual has read and understands all instructions in this

manual.

SAFETY MESSAGE ALERT SYMBOLS

The three (3) Safety Messages shown below will inform you

about potential hazards that could injure you or others. The

Safety Messages specifically address the level of exposure

to the operator, and are preceded by one of three words:

DANGER, WARNING, or CAUTION.

DANGER

Potential hazards associated with the

Tower

operation will be referenced with Hazard Symbols

which appear throughout this manual, and will be referenced

in conjunction with Safety Message Alert Symbols.

HAZARD SYMBOLS

WARNING - Lethan Exhaust Gasses

Engine exhaust gases contain

poisonous carbon monoxide. This gas

is colorless and odorless, and can

cause death if inhaled. NEVER operate

this equipment in a confined area or

enclosed structure that does not provide

ample free flow air.

WARNING - Explosive Fuel

Diesel fuel is extremely flammable, and

its vapors can cause an explosion if ignited.

DO NOT start the engine near spilled fuel

or combustible fluids.

DO NOT fill the fuel tank while the engine is running or

hot. DO NOT overfill tank, since spilled fuel could ignite if

it comes into contact with hot engine parts or sparks from

the ignition system. Store fuel in approved containers, in

well-ventilated areas and away from sparks and flames.

LT-12 Series Light

You WILL be

NOT follow directions.

WARNING

You CAN be

NOT follow directions.

CAUTION

You CAN be

KILLED

KILLED

INJURED

PAGE 4 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

or

SERIOUSLY

or

SERIOUSLY

if you DO NOT follow directions.

injured if you DO

injured if you DO

WARNING - Burn Hazards

Engine components can generate extreme

heat. To prevent burns, DO NOT touch

these areas while the engine is running or

immediately after operations. Never

operate the engine with heat shields or heat

guards removed.

CAUTION - Respiratory Hazard

ALWAYS wear approved

protection when required.

respiratory

Page 5

LT-12 SERIES LIGHT TOWER — SAFETY MESSAGE ALERT SYMBOLS

CAUTION - Rotating Parts

NEVER operate equipment with covers,

or guards removed. Keep fingers, hands,

hair and clothing away from all moving

parts to prevent injury.

CAUTION - Accidental Starting

ALWAYS place the power source, circuit

breakers or ON/OFF switch in the OFF

position, when the generator is not in use,

unless connected to transfer switch.

CAUTION - Sight and Hearing Hazards

ALWAYS wear approved eye and

hearing protection.

CAUTION - Equipment Damage Messages

Other important messages are provided throughout this

manual to help prevent damage to your light tower, other

property, or the surrounding environment.

This light tower, other

NOTE

property, or the surrounding

environment could be

damaged if you

instructions.

do not

follow

CAUTION - Over-Speed Conditions

NEVER tamper with the factory settings of

the engine governor settings. Personal injury

and damage to the engine or equipment can

result if operating speed ranges above

maximum allowable.

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 5

Page 6

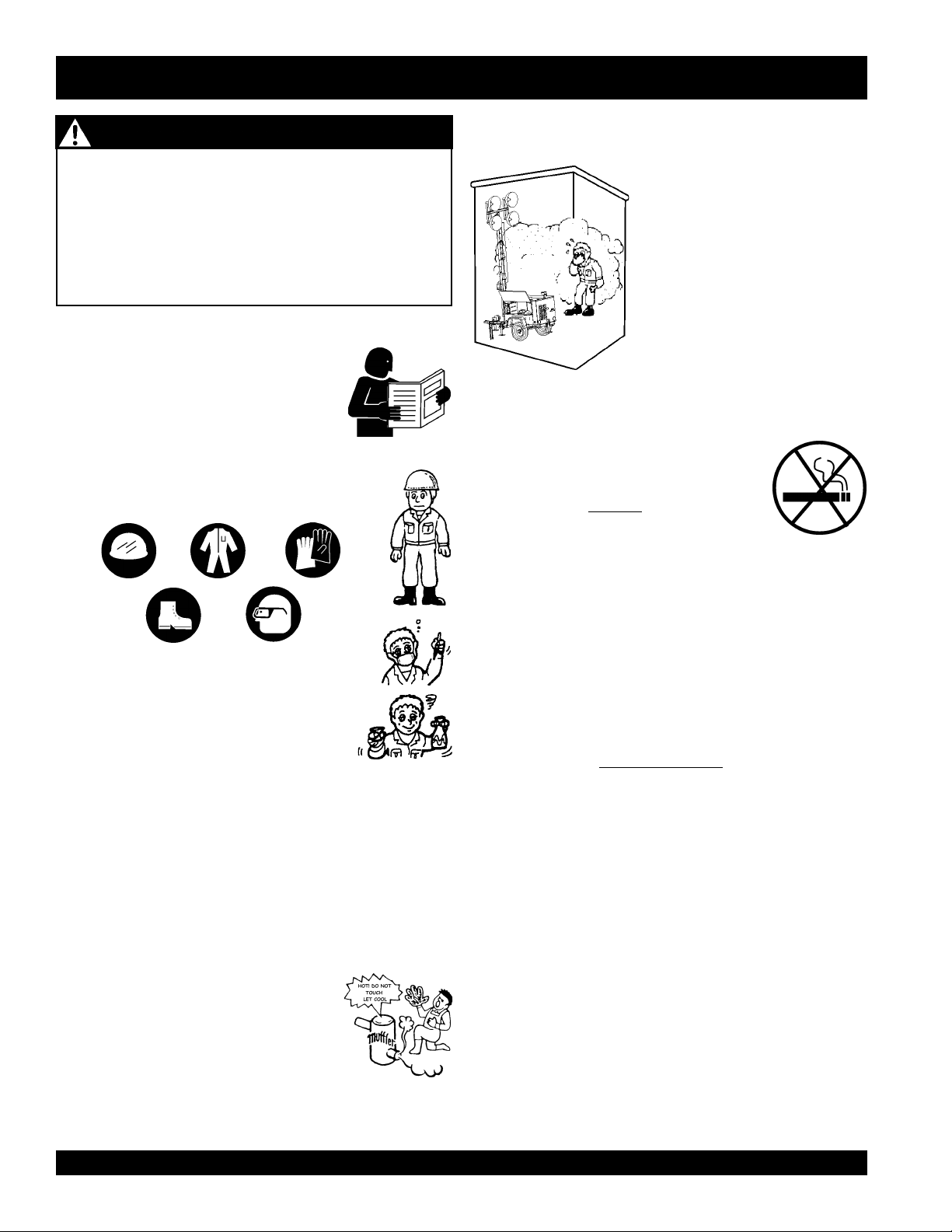

LT-12 SERIES LIGHT TOWER — RULES FOR SAFE OPERATION

■

WARNING - READ THIS MANUAL

Failure to follow instructions in this manual may lead to

Serious Injury

or even

Death

. This equipment is to be

operated by trained and qualified personnel only! This

equipment is for industrial use only.

The following safety guidelines should always be used

when operating the LT-12 Lighttower.

Safety

■

DO NOT operate or service this equipment

before reading this entire manual.

■

This equipment should not be operated

by persons under 18 years of age.

■

NEVER operate this equipment without

proper protective clothing, shatterproof glasses,

steel-toed boots and other protective devices

required by the job.

The engine of this light tower/generator requires an adequate

free flow of cooling air. NEVER operate the generator in any

■

ALWAYS refuel in a well-ventilated area, away from sparks

and open flames.

■

ALWAYS use extreme caution when

working with flammable liquids. When

refueling, stop the engine and allow it to

cool. DO NOT

machine. Fire or explosion could result from

fuel vapors, or if fuel is spilled on a hot engine.

enclosed or narrow area where free

flow of the air is restricted. If the air

flow is restricted it will cause serious

damage to the generator engine

and may cause injury to people.

Remember the engine of the light

tower/generator gives off DEADLY

carbon monoxide gas.

smoke around or near the

■

■

■

NEVER operate this equipment when not

feeling well due to fatigue, illness or taking

medicine.

■

NEVER operate the saw under the

influence or drugs or alcohol.

■

NEVER use accessories or attachments, which are not

recommended by Stow for this equipment. Damage to the

equipment and/or injury to user may result.

■

Manufacturer does not assume responsibility for any accident

due to equipment modifications. Unauthorized equipment

modification will void all warranties.

■

Whenever necessary, replace nameplate, operation and

safety decals when they become difficult read.

■

ALWAYS check all the bolts on the light tower for tightness.

■

NEVER touch the hot exhaust manifold,

muffler or cylinder. Allow these parts to

cool before servicing engine or

generator.

■

High Temperatures – Allow the engine

to cool before adding fuel or performing service and

maintenance functions. Contact with

cause serious burns.

hot

components can

■

■

■

■

■

■

■

■

NEVER operate the light tower/generator in an explosive

atmosphere or near combustible materials. An explosion or

fire could result causing severe

Topping-off to filler port is dangerous, as it tends to spill fuel.

ALWAYS make sure that the light tower/generator is secure

on level ground so that it cannot slide or shift around,

endangering workers. Also keep the immediate area free of

bystanders.

ALWAYS use a

floodlight, or replace any damaged fixture wiring.

NEVER leave any grease or oil residue on glass surface

when replacing or removing bulbs. This can create hot spots,

reducing the service life of the bulb or causing outer jacket

to burst.

ALWAYS make sure trailer is leveled with all outriggers

extended before raising tower. Outriggers must remain

extended while tower is up.

ALWAYS keep area behind trailer clear of people while

raising and lowering mast.

NEVER remove safety pin or pull mast locking pin while

tower is in an raised position!

CHECK the mast and winch cables for wear. If any problem

occurs when lower or raising the tower STOP immediately!

Contact a trained technician for assistance.

NEVER pivot or retract mast while unit is operating.

trained technician

bodily harm or even death.

to install and remove a

PAGE 6 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 7

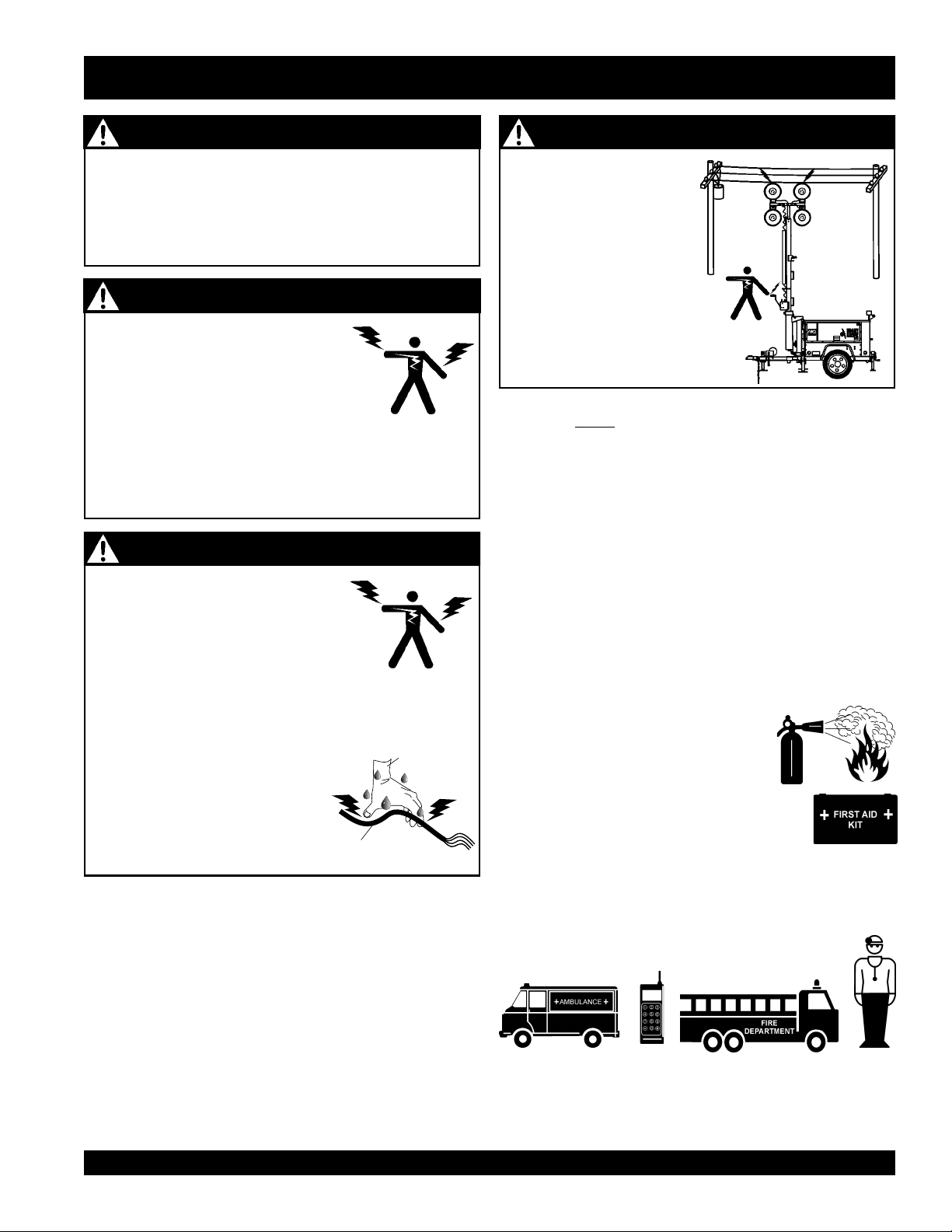

LT-12 SERIES LIGHT TOWER — RULES FOR SAFE OPERATION

DANGER - High Danger Areas

The

5 DANGER

High DANGER

understand these areas could result in

Electrical

Shock, Electrocution

items listed below are considered

areas and should be adhered to. Failing to

Bodily Harm,

, and even

Death! Please

pay close attention when operating the light tower.

DANGER - Grounding the LT-12 for Operation

The LT-12 Light tower is equipped with

a

ground terminal

ALWAYS complete the

path

from the light tower to an external

for your protection.

grounding

grounding source.

ALWAYS make certain the light tower is well grounded and

securely fastened to a good earth ground (ground rod). The

possibility exists of

even Death

Electrical Shock, Electrocution, and

if the light tower is not grounded.

DANGER - Electric Shock Hazards

NEVER operate the LT-12 Light tower

or handle any electrical equipment

while standing in water, while bare

foot, while hands are wet, or in the

rain. A dangerous

could occur causing

electrical shock

Severe Bodily Harm or even Death.

ALWAYS keep electrical cords in good condition. Worn,

bare or frayed wiring can cause electrical shock, thus

causing

Bodily Harm or even Death

.

WET

HANDS

NEVER grab or touch a live power

cord with wet hands, the possibility

exists of

Electrocution, and even Death!

■

Electrical Shock,

POWER

CORD

(POWER ON)

NEVER use the light tower mast as a crane. DO NOT lift

anything with the mast.

■

NEVER attach anything to the light tower mast.

DANGER - Overhead Obstruction Danger

ALWAYS make sure the area

above Light tower is open

and clear of overhead power

lines and other obstructions.

The tower extends in excess

of 30 ft. (9 meters). Contact

with overhead powerlines or

other obstructions could result

in equipment damage,

Serious Injury or Death

■

NEVER touch bulbs while in use. Bulbs become extremely

!

hot when in use! Allow bulbs and fixture to cool at least 1015 minutes before handling.

■

ALWAYS retract the mast before lowering the tower to

transport position.

Maintenance Safety

■

NEVER lubricate components or attempt service on a running

light tower/generator.

■

ALWAYS allow the light tower/generator a proper amount of

time to cool before servicing.

■

Keep the light tower/generator in proper running condition.

■

Fix damage to the light tower/generator immediately and

always replace broken parts.

Emergencies

■

ALWAYS know the location of the

nearest

■

ALWAYS know the location of the nearest

first aid kit

■

In emergencies

or

numbers of the nearest

department

fire extinguisher

.

.

always

keep a phone on the job site

know the location of the nearest phone

. Also know the phone

ambulance, doctor

. This information will be invaluable in the case

and

fire

of an emergency.

■

ALWAYS keep the immediate area surrounding the light

tower clean, neat, and free of debris.

■

ALWAYS lower the tower when not in use, or if high winds or

electrical storms are expected in the area.

■

NEVER pivot or retract mast while unit is operating.

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 7

Page 8

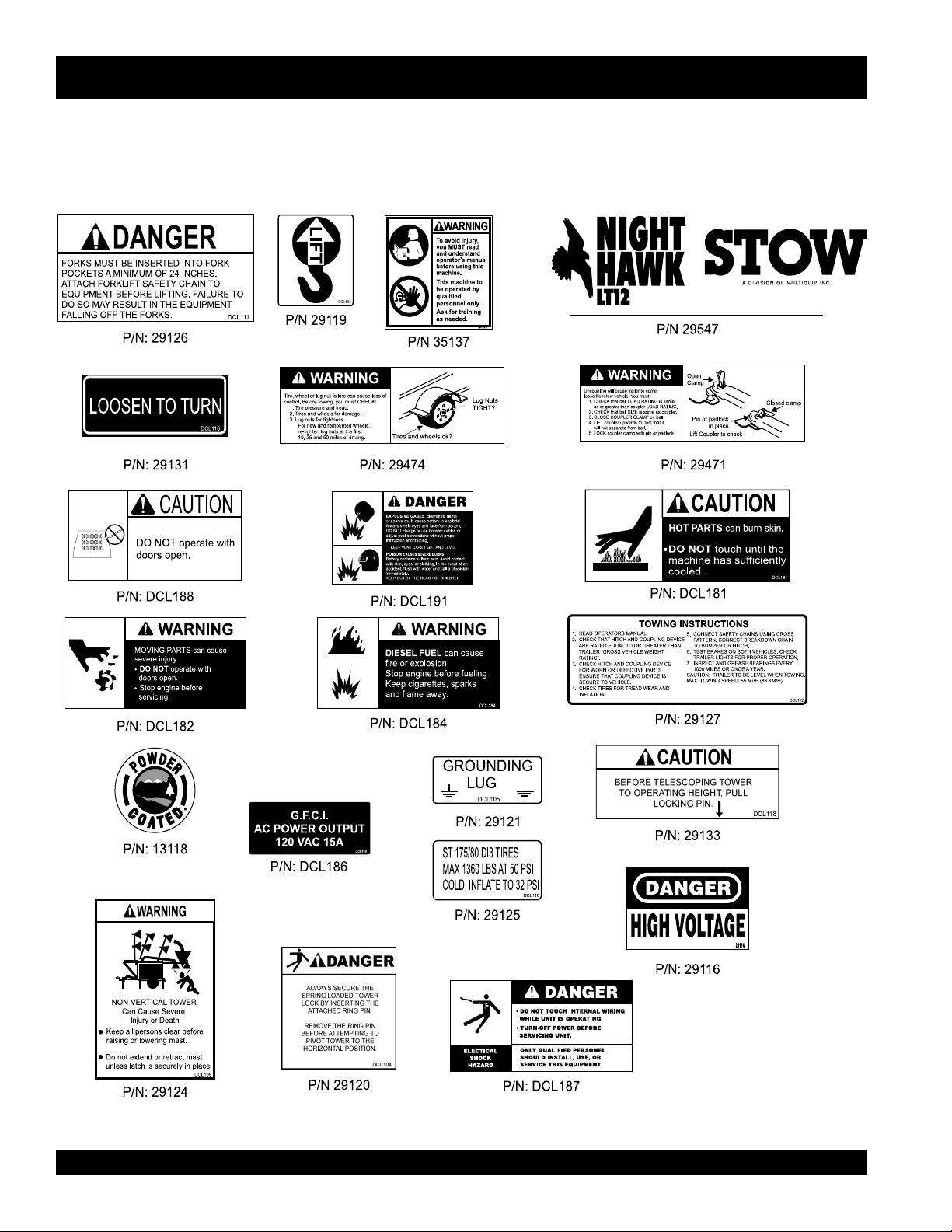

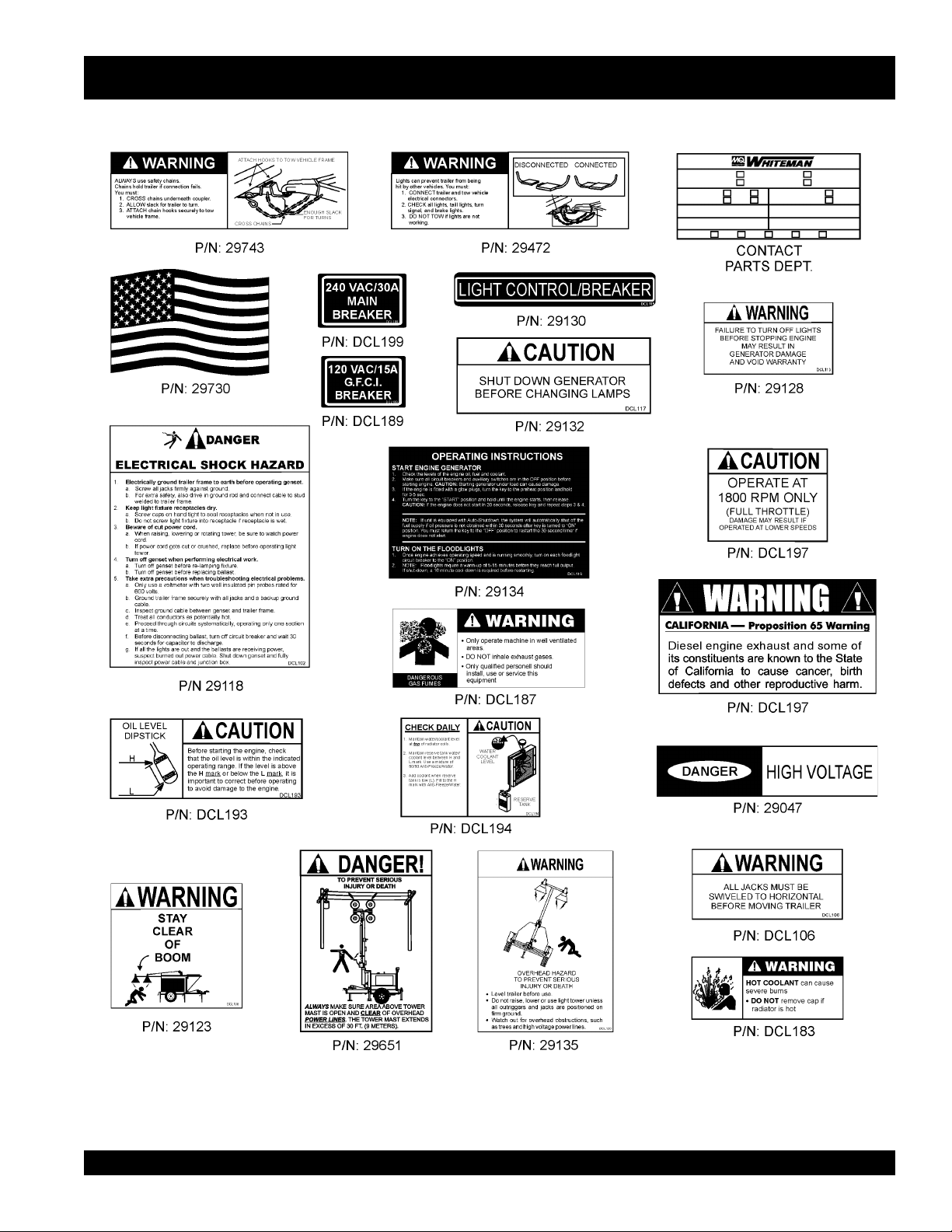

LT-12 SERIES LIGHT TOWER — OPERATION AND SAFETY DECALS

Machine Safety Decals

This dedicated light tower is equipped with a number of safety decals. These decals are provided for operator safety and maintenance

information. The illustration below and on the next page shows these decals as they appear on the machine. Should any of these

decals become unreadable, replacements can be obtained from your dealer.

Figure 1. Operation and Safety Decals

PAGE 8 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 9

LT-12 SERIES LIGHT TOWER — OPERATION AND SAFETY DECALS

Figure 1. Operation and Safety Decals (Continued)

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 9

Page 10

LT-12 SERIES LIGHT TOWER — SPECIFICATIONS (LIGHT TOWER)

SNOITACIFICEPS.1ELBAT

ledoMrewoTthgiL

ledoMenignE

)yrD(thgieW ).gk007(.sbl055,1

snoisnemiD3elbaTeeS

stnioPtroppuS5

.tesneGhtiwytilibatSdniW )hpk64.08(hpm5

sthgildoolF edilaHlateMttaW000,1-4

snemuL000,044

egarevoCthgiL serca7ot5

noitanimreTthgiL gulpDQnip-3x4

snoi

tacificepSrotareneG

tuptuOelcatpeceRICFG )ylnoSU(A51@CAV021

tuptuOelcatpeceRkcoL-tsiwT )ylnoSU(A52@CAV042

D21-TLP21-TL

/F8001m3FztueD

3001WDLinidrabmoL

enignEleseiD

6

01-301snikreP

seiD

enignEle

)spmA(rekaerBtiucriCICFGA51

)spmA(rekaerBtiucriCkcoL-tsiwTA52

)sttaW(tuptuOsuounitnoCW000,6

esioN.bd37

yticapaCdnatskcaJ ).gk709(.sbl000,2

epyThctiH )elbiliavatiKeltniPlanoitpO(l

eziSeriT ).mm033(.ni31

eziSmiReriT )mm411x033(.ni5.4x31

yticapaCelxA ).gk709(.sbl000,2

epyTbuHguL-5

ep

yTnoisnepsuSfaeL-3

yticapaChcniW ).gk086(.sbl005,1

)m7(.tf32@leveL

noitacificepSreliarT

laB.ni2

rotcennoCthgil-liaTlacirtcelEeriW-4

eriWepoRhcniW.ni61/3

PAGE 10 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 11

LT-12 SERIES LIGHT TOWER — SPECIFICATIONS (ENGINES)

snoitacificepSenignE.2elbaT

epyTenignE enignEleseiDretil1,rednilyc-3,ekorts-4detaripsA

ekortSXeroB )mm

tnemecalpsiD )cc459(.ni.uc12.85

ybdnatStuptuOxaM .M.P.R008,1ta.P.H21

M .M.P.R008,1ta.P.H5.01

ledoMsnikreP

leseiD01-301

enignE

IdradnatS.M.P.R008,1

epyTleuFleuFleseiD2.0N

emirPtuptuOxa

yticapaCknaTleuF )sretiL311(snollaG.S.U03.xorppA

sthgiL4htiWemiTnuRsruoH46

deepSeld

yticapaCliOebuL )sretiL5.3(stniP.S.U4.7

metsySgnilooCdelooc-reta

yticapaCtnalooC )sretiL8.3(stniP.S.U0.8

dohteMgnitratStratScirtcelE

epyTyrettaB21puorG

W

27xmm57(.ni38.2X.ni59.2

)yrD(thgieWlatoT).gK

)teW(thgieWlatoT).gK031(.sbl782

epyTenignE enignEleseiD,rednilyc-3

tnemecalpsiD )cc8201(.ni.uc37.26

ybdnatStuptuOxaM .M.P.R008,1ta.P

inidrabmoL

WDLledoM

leseiD/3001

enignE

ro

ledoMztueD

F800M3F

leseiD

enignE

epyTleuFleuFleseiD2.0N

yticapaCknaTleuF )sretiL311(snollaG.S.U03.xorppA

sthgiL4htiWemiTnuRsruoH46

deepSeldIdradnatS.M.P.R008,

yticapaCpmuSliO )sretiL63.2(strauQ.S.U5.2

metsySgnilooCdelooc-diuqiL

dohteMgnitratSt

epyTyrettaB42puorG

.H21

1

721(.sbl082

ratScirtcelE

)yrD(thgieWlatoT).gK58(.sbl3.781

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 11

Page 12

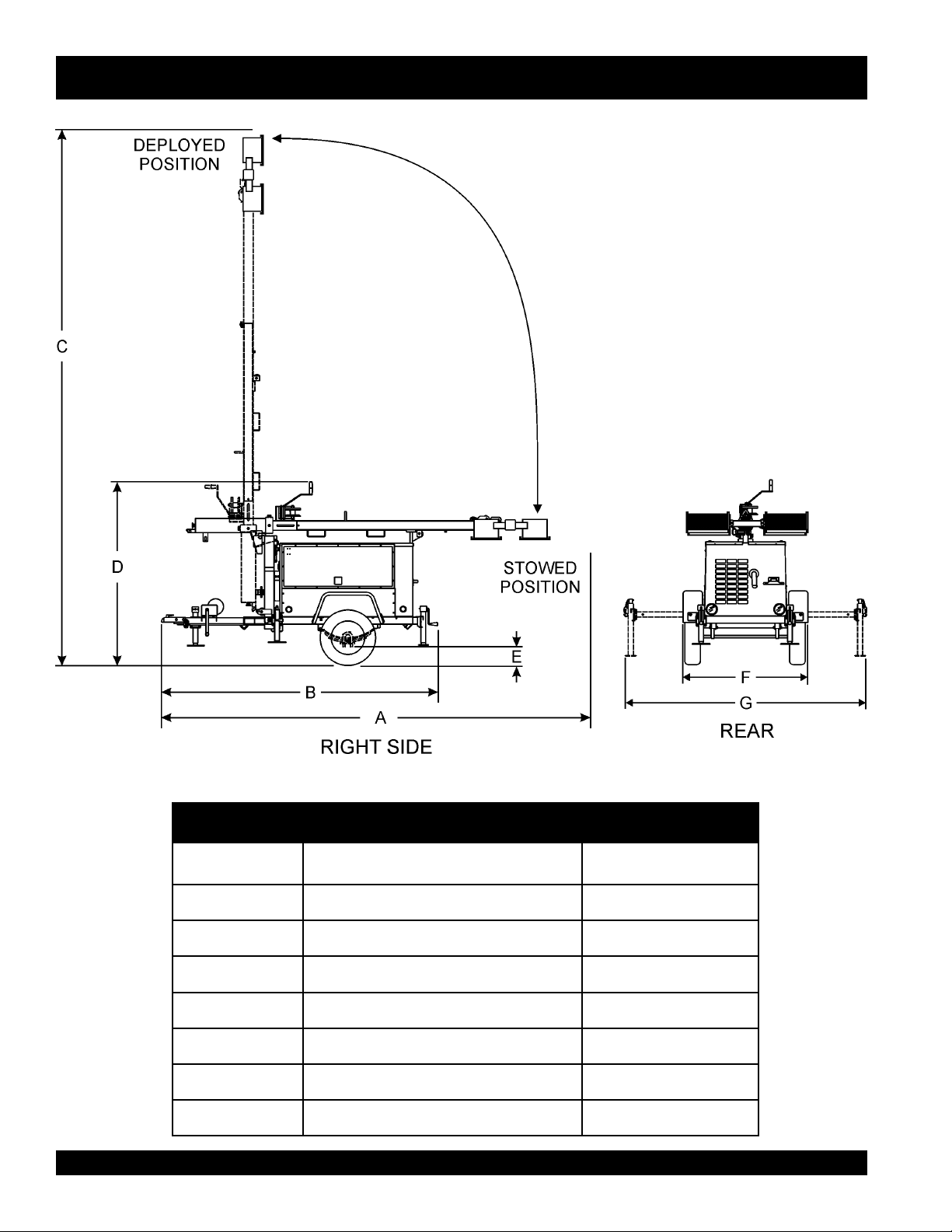

LT-12 SERIES LIGHT TOWER — DIMENSIONS

Figure 2. Dimensions

SNOISNEMID.3ELBAT

retteLecnerefeRnoitpircseD).mm(.ninoisnemiD

A)noitisoPdewotStsaM(htgneL).mc134(.ni071

B)noitisoPdeyolpeDtsaM

C)noitisoPdeyolpeDtsaM(thgieH.xaM)m6.9(.tf5.13

D)noitisoPdewotStsaM(thgieH).mc781(.ni4

E)elxAmorF(ecnaraelCdnuorG).mc02(.ni8

F)ydaeRwoT(htdiW).mc921(.ni15

G)deyolpeDsreggirtuO(htdiW).mc672(.ni901

PAGE 12 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

(htgneL).mc652(.ni101

7

Page 13

LT-12 SERIES LIGHT TOWER — GENERAL INFORMATION

The Stow LT-12 Series Light Tower is a dedicated general

purpose floodlight tower intended for emergency and remote

lighting conditions.

The light tower can be raised vertically in excess of 31.5 feet

(9.6 meters) by means of a manual winch. The tower tensioning

system is designed to provide the necessary tension to safely

control the pivot of the tower. Outriggers and rear support stand

must be deployed prior to raising the mast.

DANGER - Overhead Obstruction Danger

ALWAYS make sure the area

above Light tower is open and

clear of overhead power lines

and other obstructions. The

tower extends in excess of 30

ft. (9 meters). Contact with

overhead powerlines or other

obstructions could result in

equipment damage,

Injury or Death

Serious

!

For ease of service or transport, each floodlight is equipped

with a quick-disconnect connector that allows the lamp fixture to

be removed quickly. This feature is extremely useful during

transport of the light tower over rough terrain. It is always best to

remove the floodlights and pack them safely so they will not get

damaged.

As an added feature, the LT-12 is available with two auxiliary

output receptacles. The upper most receptacle(twist-lock),

located at the front of the light tower, can provide 240 VAC at 25

amps. The bottom receptacle is a GFCI receptacle which can

supply 120 VAC at 15 amps. These receptacles that can be used

for light power tools or other similar applications.

NOTE

Some LT-12 Light towers are

equipped with a Lombardini

Diesel Engine. All procedures &

references to Deutz engines in

this manual may be applied to

Lombardini engines unless

specifically noted otherwise.

The lighting system of Stow's LT-12 Series Light Tower is

comprised of 4 "Metal Halide" 1000 watt lamps. Each lamp has

an output of 110,000 lumens yielding a total of 440,000 lumens

for all four floodlights. Typical lighting coverage is between 5 to 7

acres.

Each floodlight requires a ballast for starting. Located on the

control panel of the generator is a weather resistant ballast box

that the contains the ballast for each floodlight. The control panel

contains four ON/OFF circuit breakers for each floodlight.

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 13

Page 14

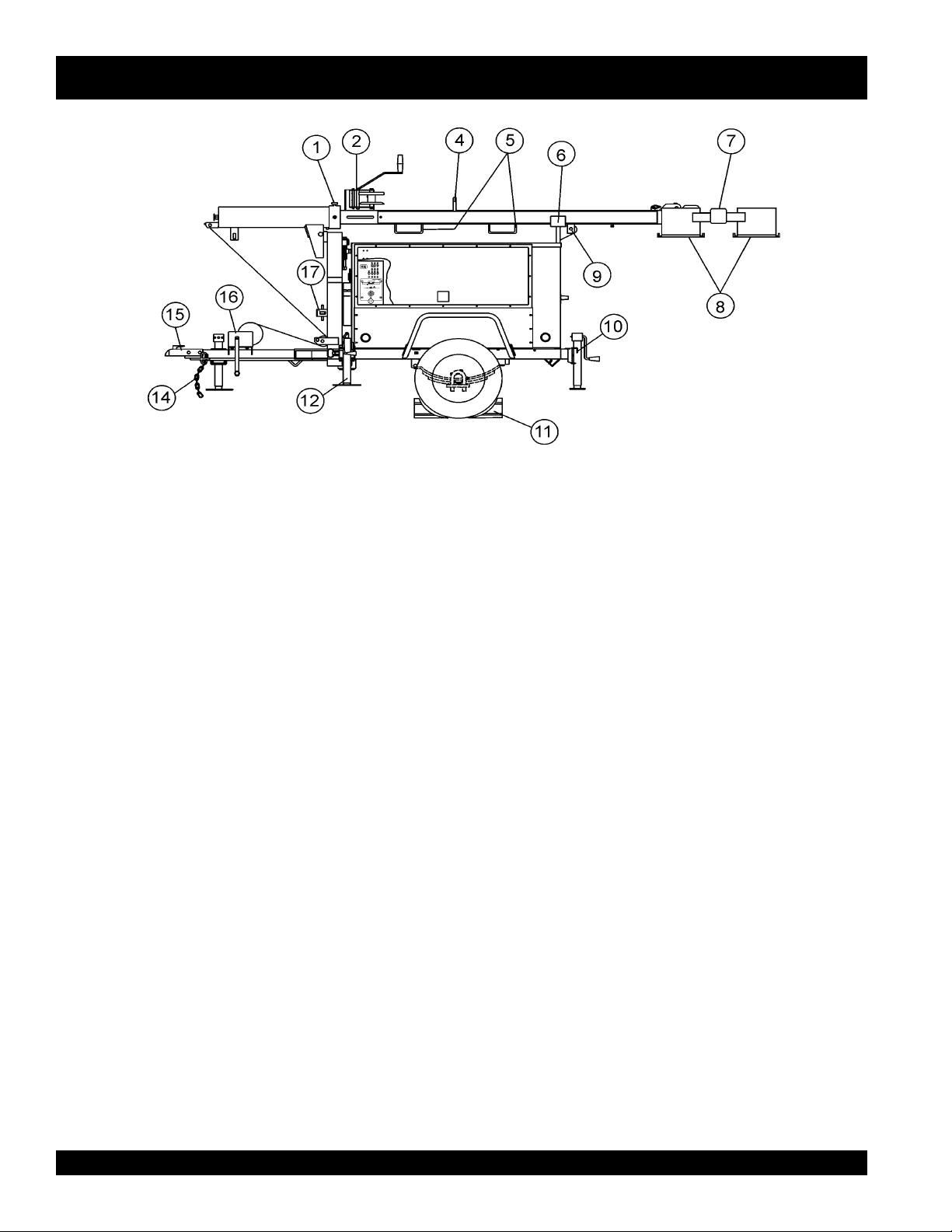

LT-12 SERIES LIGHT TOWER — COMPONENTS

Figure 3. Major Components (Control Panel Side)

Figure 3 and 4 shows the location of the controls and components

for the LT-12 Series Light Tower. The functions of each control is

described below:

1. Mast Rotation Locking Knob – Unscrew this knob to

release mast for rotation.

2. Vertical Mast Extension Winch – Use this winch to extend

the mast to the desire height. Maximum height is approximately 31.5 feet (9.6 meters).

3. Mast Rotation Handle – Grip this handle to rotate mast to

desired position. To lock mast tighten mast rotation locking

knob.

4. Lifting Bail – When lifting of the light tower by crane is

required, use this lifting bail. Note: this lifting bail is balanced

for a

fully configured

components will un-balance the lifting bail.

5. Forklift Pockets – When lifting of the light tower is required,

use these fork lift pockets to lift the light tower. Remember to

insert the forks of the fork lift a minimum of 24 inches into the

mast fork lift pockets.

6. Mast Cradle Support – When towing of the light tower is

required, place the tower mast into the cradle support. Make

sure tower release pin has been inserted and mast is locked.

light tower; removal of any light tower

9. Tower Lock/Release Pin – Pull this pin to release tower

mast from cradle support.

10. Jack Stands – There are two trailer jack stands, which are

located at the front and rear of the trailer. Use these 2 jack

stands to level and support the light tower.

11. Chock Blocks – Place these blocks (not included as part of

the light tower package) under each trailer wheel to prevent

rolling.

12. Outrigger Jacks – Use these 2 outrigger jacks to level and

support the light tower.

13. Control Panel/ Ballast Compartment – This panel contains the ON/OFF circuit breakers for each flood light. In

addition, located behind the control panel are the ballasts

and electrical components for each floodlight.

14. Safety Chain – Always attach safety chain to the towing

vehicle. Never tow the light tower with the safety chain

unattached.

15. Ball Hitch Coupler – Attach this coupler to the towing

vehicle. Use only the specified ball diameter as indicated on

your coupler. Use of any other ball diameter will create an

extremely dangerous condition which can result in separation of the coupler and ball or ball failure.

7. T-Bar – Allows the floodlights to be mounted vertically or

horizontally.

8. Flood Light – 1000 watt "Metal Halide" type bulb with a

110,000 lumens capacity. Light coverage is typically between 5 to 7 acres.

PAGE 14 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

16. Vertical Mast Winch – Use this winch to raise the mast the

17. Mast Locking/Release Pin – Pull this pin to start placing the

to the vertical position. Once mast is in the full vertical position

the locking pin engages automatically.

tower mast in the vertical position.

engages when tower mast has reached full vertical position.

Locking pin automatically

Page 15

LT-12 SERIES LIGHT TOWER — COMPONENTS

Figure 4. Major Components (Front/Rear)

18. Engine Exhaust Pipe – Directs engine exhaust to the rear

of the light tower. NEVER block this exhaust pipe with obstructions. ALWAYS place the generator in an area free of

obstructions.

21. Tires – This light tower uses a ST175-13C size tire. Replace

22. Documentation Box – Contains information regarding the

CAUTION - Burn Hazard

23. 240 VAC Twist-Lock Receptacle – This twist-lock recep-

The exhaust pipe will become extremely hot

when the engine is in use. NEVER touch the

exhaust pipe when the engine is running. The

possibility exists of severe burns to the skin.

Allow the exhaust pipe to

touching.

19. License Light – This light illuminates the license plate.

Whenever towing of the light tower is required, make sure this

light is operational.

20. Brake Lights – Before towing the light tower, make sure that

these lights are operational and are working correctly. NEVER

tow the light tower if these lights are inoperative.

cool

before

24. 120 VAC GFCI Receptacle – This GFCI receptacle provides

with only recommended tire size. NEVER tow light tower with

bad or worn tires.

light tower.

tacle provides 240 VAC, 25 amps.

120 VAC, 15 amps.

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 15

Page 16

LT-12 SERIES LIGHT TOWER — CONTROL PANEL

Figure 5. Control Panel Components and Indicators

PAGE 16 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 17

LT-12 SERIES LIGHT TOWER — CONTROL PANEL

Figure 5 shows the location of the basic control panel components

for the LT-12 Light Tower. Listed below is a brief explanation of

each control or component.

1. Internal Cabinet Light Switch – This switch controls the

internal cabinet light for the light tower control panel. When

the cabinet door is raised, the light will automatically come

on. When the cabinet door closes, the switch is depressed

and the light turns off.

2. Internal Cabinet Light – Provides illumination for the LT-

12 control panel during nighttime operation. The light is

activated when the cabinet door is raised.

3. Hour Meter – This digital hour meter indicates the number

of hours machine has been in use.

4. Main Circuit Breaker – A double-pole 25 amp, ON/OFF

circuit breaker which protects the 240 VAC twist-lock

receptacle from overload. In addition it allows voltage to be

supplied to the GFCI receptacle and 15 amp breakers (4).

5. GFCI Receptacle Circuit Breaker – A single-pole, 15

amp, ON/OFF circuit breaker which protects the GFCI

receptacle from overload.

6. Flood Light Circuit Breakers – A single-pole, 15 amp,

ON/OFF circuit breaker for each floodlight (4).

10. Pre-Heat Indicator Light/Battery Charge Light –

Indicates when the glow plugs have been heated up for

starting the engine. If the light is flashing, a low battery

charge is detected.

11. Ignition Key Switch – Insert key into ignition switch and

turn clockwise to the ON position to warm the glow plugs.

When glow plug indicator light goes OFF, turn the key to

the START position. Release key when engine starts.

12. Normal Operation Indicator Light – This

indicator light is illuminated when the engine is

functioning normally.

13. Low Oil Shutdown Indicator Light – This

indicator light is illuminated when the engine

has shut down due to low oil pressure. Service

as needed.

Items 12 - 18 refer to the

Lombardini Engine

Control Panel only. See

Figure 5.

OK

Items 7 - 11 refer to the

Perkins Engine Control

Panel only. See Figure 5.

7. Air Filter Indicator Alarm Light – This alarm light flashes

when a problem with the air filter is detected. Service as

required.

8. Water Temperature Alarm Light – This alarm light flashes

when the water temperature becomes to hot for normal

engine operation. Service as required.

9. Oil Pressure Alarm Light – This alarm light flashes when

the oil pressure has fallen to low for normal engine

operation. Service as needed.

14. High Temperature Indicator Light – This

indicator light is illuminated when the engine has

shut down due to high water temperature. Service

as needed.

15. Alternator Indicator Light – This indicator light

is illuminated when the engine has shut down

due to high water temperature. Service as

needed.

16. Glow Plug Indicator Light – This indicator light

is illuminated when the glow plugs have been

heated for starting the engine.

17. Air Filter Restriction Indicator Light – This

indicator light is illuminated when the engine

has shut down due to blockage in the air filter.

Service as needed.

18. Ignition Key Switch – Insert key into ignition

switch and turn clockwise to the ON position to

warm the glow plugs. When glow plug indicator

light goes OFF, turn the key to the START position.

Release key when engine starts.

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 17

Page 18

LT-12 SERIES LIGHT TOWER — FLOOD LIGHT FOOTCANDLE PLOT

Figure 6. Floodlight Footcandle Plot (Area Coverage)

PAGE 18 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 19

LT-12 SERIES LIGHT TOWER — TOWING GUIDELINES

■

Towing Safety Precautions

CAUTION - Local Towing Regulations

Check with your county or state safety towing regulations

department before towing your

To reduce the possibility of an accident while transporting the

light tower on public roads, always make sure that the trailer and

the towing vehicle are in good operating condition and both

units are mechanically sound.

The following list of suggestions should be used when towing

the light tower:

NOTE

■

Make sure that the hitch and coupling of the towing vehicle

are rated equal to, or greater than the trailer "gross vehicle

weight rating" (GVWR). See Table 1 for light tower weight.

■

ALWAYS inspect the hitch and coupling for wear. NEVER

tow the light tower's trailer with defective hitches, couplings,

chains etc.

■

CHECK the tire air pressure on both the towing vehicle and

the trailer. Also check the tire tread wear on both vehicles.

■

ALWAYS make sure the trailer section of the light tower is

equipped with a "Safety Chain".

■

ALWAYS attach trailer's safety chain to frame of towing

vehicle.

■

ALWAYS make sure that the vehicle and trailer directional,

backup, brake, and trailer lights are connected properly and

are working properly.

■

Remember in most cases the maximum speed unless

otherwise posted for highway towing is 55 MPH, however

before towing your light tower, check your local state, and

county vehicle towing requirements. Recommended off-road

towing is not to exceed 15 MPH or less depending on type of

terrain.

■

Place

chocked blocks

while parked.

■

Depending on soil conditions and location it may be

necessary to place

bumper to prevent

support blocks

tipping

light tower

Remember, when transporting of the

light tower is required,

remove the floodlights

them safely so they will not get

damaged.

underneath wheel to prevent

, while parked.

.

always

and pack

rolling,

underneath the trailer's

Inflate tires to correct pressure, inspect tires for cuts, and

excessive wear. See Table 3 (Tire Wear Troubleshooting).

■

Check wheel mounting lug nuts with a torque wrench.

Torque wheel lug nuts as described in the "

Requirements

■

Check tightness of hanger bolt, shackle bolt, and U-blots

nuts, torque suspension hardware per Table 4.

■

Avoid sudden stops and starts. This can cause skidding, or

jackknifing. Smooth, gradual starts and stops will improve

gas milage.

■

Avoid sharp turns to prevent rolling.

■

Swivle all jackstands parallel to the ground before

transporting.

■

DO NOT transport light tower with fuel in the generator fuel

tank.

CAUTION - Defective/Damaged Trailer Couplings

If the trailer coupler is deformed replace entire coupler. NEVER

tow the light tower with a defective trailer coupler. There exist

the possibility of the trailer separating from the towing vehicle.

Light Tower Trailer Vehicle Connection

1. Check the vehicle hitch ball, and trailer coupler for signs of

wear or damage. Replace any parts that are worn or

damaged before towing.

2. Use only the 2-inch ball diameter as indicated on the trailer's

coupler. Use of any other ball diameter will create an

extremely dangerous condition which can result in

separation of the coupler and ball or ball failure.

3. Be sure the coupler is secured to the hitch ball and the lock

lever is down (locked).

4. Attach safety chains as shown in Figure 7. Remember to

cross

5. After towing for about 50 miles recheck the entire towing

system for tightness.

Recommended Maintenance

1. Smear ball socket and clamp face with chassis grease.

Periodically oil pivot points and wear surfaces of the coupler

with SAE 30 W motor oil.

2. When parking or storing the light tower, keep the coupler off

the ground so dirt and other debris will not build up in the

ball socket.

Lug Nut Torque

", Table 5.

the safety chains.

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 19

Page 20

LT-12 SERIES LIGHT TOWER — TOWING GUIDELINES

Figure 7. Safety Chains/ Trailer Coupler Hook-up

PAGE 20 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 21

LT-12 SERIES LIGHT TOWER — TRAILER SAFETY GUIDELINES

Tires/Wheels/Lug Nuts

Tires and wheels are a very important and critical components

of the trailer. When specifying or replacing the trailer wheels it is

important the wheels, tires, and axle are properly matched.

WARNING - Wheel Repair/Modification

DO NOT attempt to repair or modify a

wheel. DO NOT install an inter-tube to

correct a leak through the rim. If the rim

is cracked, the air pressure in the intertube may cause pieces of the rim to

explode (break-off) with great force and

can cause serious eye or bodily injury.

Tires Wear/Inflation

Tire inflation pressure is the most important factor in tire life.

Pressure should be checked cold before operation. DO NOT

bleed air from tires when they are hot. Check inflation pressure

weekly during use to insure the maximum tire life and tread

wear.

Table 3 (Tire Wear Troubleshooting) will help pinpoint the causes

and solutions of tire wear problems.

Suspension

The leaf suspension springs and associated components

(Figure 8) should be visually inspected every 6,000 miles for

signs of excessive wear, elongation of bolt holes, and loosening

of fasteners. Replace all damaged parts (suspension) immediately. Torqued suspension components as detailed in Table 4.

WARNING - Safety Glasses Required

ALWAYS

removing or installing force fitted parts.

Failure to comply may result in serious

injury.

wear safety glasses when

Figure 8. Major Suspension Components

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 21

Page 22

LT-12 SERIES LIGHT TOWER — TRAILER SAFETY GUIDELINES

metI ).sbL-.tF(euqroT

STNEMERIUQEREUQROTNOISNEPSUS.4ELBAT

"8/3TLOB-U

"61/7TLOB-U

"2/1TLOB-U

ELKCAHSTLOB

GNIRPSEYETLOB

DLUOHSEPYT

ELKCAHSTLOB

GUNSTIF.YLNOSTRAPTSUMETATOR.YLEERF

GNIKCOLSTUNRORETTOCSNIPERADEDIVORPOT

NIATERTLOB-TUN.YLBMESSA

RE

03-NIM53-XAM

54-NIM06-XAM

-NIM5405-XAM

03-NIM05-XAM

Lug Nut Torque Requirements

It is extremely important to apply and maintain proper wheel

mounting torque on the trailer. Be sure to use only the fasteners

matched to the cone angle of the wheel. Proper procedure for

attachment of the wheels is as follows:

1. Start all wheel lug nuts by hand.

2. Torque all lug nuts in sequence. See Figure 9. DO NOT

torque the wheel lug nuts all the way down. Tighten each lug

nut in 3 separate passes as defined by Table 5.

STNEMERIUQEREUQROTERIT.5ELBAT

eziSleehW

ssaPtsriF

SBL-TF

"2152-0204-5356-05

"3152-0204-5356-05

"4152-0206-05021-09

"5152-0206-05021-09

"6152-0206-05021-09

3. After first road use, retorque all lug nuts in sequence. Check

all wheel lug nuts periodically.

ssaPdnoceS

SBL-TF

ssaPdrihT

SBL-TF

Figure 9. Wheel Lug Nuts Tightening Sequence

NOTE

NEVER!

use an pneumatic air gun

to tighten wheel lug nuts.

PAGE 22 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 23

LT-12 SERIES LIGHT TOWER — TRAILER WIRING DIAGRAM

Figure 10. Typical Trailer Wiring Diagram

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 23

Page 24

Before Starting

LT-12 SERIES LIGHT TOWER — INSPECTION

1. Read

2. Clean the light tower, removing dirt and dust,

3. Check the air filter for dirt and dust. If air filter is dirty, replace

4. Check all fastening nuts and bolts for tightness.

all safety instructions

beginning of manual.

particularly the engine cooling air inlet and

air cleaner.

air filter with a new one as required.

WARNING - Ventillation Requirements

Ensure adequate ventilation when operating

the lighttower in enclosed areas. The engine

exhaust contains noxious elements.

Indoor Installation

Exhaust gases from diesel engines are extremely poisonous.

Whenever an engine is installed indoors the exhaust fumes must

be vented to the outside. The engine should be installed at least

two feet from any outside wall. Using an exhaust pipe which is

too long or too small can cause excessive back pressure which

will cause the engine to heat excessively and possibly burn the

valves.

at the

5. When checking the engine oil, be sure to check if the oil is

clean. If the oil is not clean, drain the oil by removing the oil

drain plug, and refill with the specified amount of oil as

outlined in the Perkins or Lombardini-Deutz Engine

Owner's Manuals. Oil should be warm before draining.

Figure 11. Dipstick

Eliminate the danger of deadly carbon monoxide gas. Remember

that exhaust fumes from any gasoline or diesel engine are very

poisonous if discharged in a closed area. If the light tower is

installed indoors, you must make provisions for venting the

engine exhaust to the outside of the building.

Engine Oil Check

1. To check the engine oil level, place the make sure the light

tower is placed on secure level ground with the engine

stopped.

2. Remove the

clean.

3. Insert and remove the dipstick from its holder. Check the oil

level shown on the dipstick.

4. If the oil level is low, add oil through the oil filler hole, DO NOT

overfill. Fill to the normal operating level as shown on the

dipstick (Figure 28). Verify that the oil level is maintained

between the two notches as shown in Figure 11. Always fill

with recommended type oil as listed in Table 6. Reference

Table 2 for engine oil capacity.

filler cap/dipstick

from its holder and wipe it

Other types of motor oils may be substituted if they meet the

following requirements:

z

API Service Classification CH-4

z

API Service Classification CG-4

z

API Service Classification CF-4

z

ACEA Specification E3

z

ACEA Specification E2

PAGE 24 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 25

LT-12 SERIES LIGHT TOWER — INSPECTION

Fuel Check

CAUTION - Diesel Fuel Safety

Diesel fuel

to your health and the surrounding

environment. Avoid skin contact and/or

inhaling fumes. DO NOT smoke while

refueling. DO NOT attempt to refuel the light

tower if the engine is

1. To check the engine fuel level, make sure the light tower is

placed on secure level ground with the engine stopped.

2. Lift the light tower access door (Figure 12) opposite the

control panel. Set the door support latch in place to keep the

door open (up).

and its vapors are dangerous

hot! or running

.

Battery Check

WARNING - Battery Safety

The operator MUST wear the appropriate

protective equipment and clothing while

handling the battery.

Failure to wear protective equipment or clothing

could result in SERIOUS INJURY.

Battery - The 12-volt DC battery

(Figure 13) is shipped dry, and will require

a proper electrolyte level for operation.

When servicing of the battery is required perform the following:

z

A face shield and rubber gloves should be worn while

handling and servicing battery's electrolyte.

z

Disconnect battery terminal clamps, and remove the battery

from the generator cabinet when servicing is required.

Figure 13. Battery

z

DO NOT overfill the battery.

WARNING - Battery Service Safety

Figure 12. Adding Fuel

3. Remove the fuel cap from the fuel tank as shown in Figure 12.

CAUTION - Diesel Fuel Safety

ALWAYS

NOT fill the fuel tank beyond its capacity. DO NOT

TOP-OFF.

4. Pay attention to the fuel tank capacity when replenishing fuel.

5. Wipe up any spilled fuel

fill the fuel tank with clean, fresh

The fuel tank cap must be closed tightly after filling. Handle

fuel in a safety container. If the container does not have a

spout, use a funnel. Wipe up any spilled fuel immediately.

immediately!

#2 diesel fuel.

DO

Overfilling the battery may cause the electrolyte to overflow

resulting in corrosion to nearby components. Immediately wash

off any spilled electrolyte (battery acid).

Additionally, when connecting the positive (+)

cable to the battery's positive (+) terminal post,

DO NOT allow contact of the wrench or any

metallic part to come in contact with the battery's

negative (-) terminal post. This may result in an

electrical short circuit or an explosion.

NOTE

Electrolyte is an acid and must be handled with

caution. Servicing instructions from the electrolyte

manufacturer must ALWAYS be followed to ensure

safety. Serious injury can result from careless

handling and noncompliance to safety handling

instructions.

Use only

battery. Tap water can

operating life of the battery.

distilled

water in the

reduce

the

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 25

Page 26

LT-12 SERIES LIGHT TOWER — INSPECTION

Coolant (Ethylane Glycol [Green] / Water — 50/50 mix)

Use only drinkable tap water. If hard water or water with many

impurities is used, the inside of the engine and radiator may

become coated with deposits and cooling efficiency will be

reduced.

An anticorrosion additive added to the water will help prevent

deposits and corrosion in the cooling system. See the engine

manual for further details.

WARNING - Radiator Burn Hazard

If adding coolant/antifreeze mix to the

radiator, DO NOT remove the radiator cap

until the unit has completely cooled. The

possibility of hot! coolant exists which can

cause severe burns.

Day-to-day addition of coolant is done from the recovery tank.

When adding coolant to the radiator, DO NOT remove the radiator

cap until the unit has completely cooled. See Table 7 for engine

and radiator, coolant capacities. Make sure the coolant level in

the recovery tank is always between the "H" and the "L" markings.

Cleaning the Radiator

The engine may overheat if the radiator fins become overloaded

with dust or debris. Periodically clean the radiator fins with

compressed air. Cleaning inside the machine is dangerous, so

clean only with the engine turned off and the

terminal disconnected.

Air Cleaner

Periodic cleaning/replacement is necessary. Inspect it in

accordance with the Perkins, Lombardini or Deutz Engine

Owner's Manuals.

Fan Belt Tension

A slack fan belt may contribute to overheating, or to insufficient

charging of the battery. Inspect the fan belt for damage and wear

and adjust it in accordance with the Perkins, Lombardini or

Deutz Engine Owner's Manuals.

The fan belt tension is proper if the fan belt bends 10 to 15 mm

(Figure 14) when depressed with the thumb as shown below.

NOTE

YTICAPACTNALOOC.7ELBAT

When the antifreeze is mixed with

water, the antifreeze mixing ratio

must be

less than 50%.

negative

battery

epyTenignEyticapaCtnalooC

01-301snikreP)sretiL7.4(.tq5

3001WDLinidrabmoL)sretiL9.4(.

tq81.5

F8001M3FZTUED)sretiL9.4(.tq81.5

Operation Freezing Weather

When operating in freezing weather, be certain the proper amount

of antifreeze (Table 8) has been added.

EZEERF-ITNA.8ELBAT

SERUTAREPMETGNITAREPO

%loV

tnioPgnizeerFtnioPgnilioB

ezeerF-itnA

C°F°C°F°

0442-21-601222

0573-43-8016

22

Figure 14. Fan Belt Tension

WARNING - Rotating Parts Hazard

NEVER

running.

place hands near the belts or fan while the engine is

PAGE 26 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 27

LT-12 SERIES LIGHT TOWER — INSPECTION

WARNING - Respiratory Hazard

The engine's exhaust contains harmful

emissions. ALWAYS ventilate the exhaust

when operating inside tunnels, excavations

or buildings. Direct exhaust away from

nearby personnel.

Before starting the engine perform the following:

1. Be sure to

main circuit breaker and all lamp (4) circuit breakers to the

OFF position prior to starting the engine.

2. NEVER start the engine with any circuit breakers in the ON

position.

3. Make sure light tower is placed on

with chock blocks underneath each wheel to prevent the

light tower from rolling.

4. Outriggers have been fully extended to prevent the trailer

from tipping.

5. All tower mast sections have been raised to the desired

height.

disconnect the electrical load

and switch the

secure level ground

6. Bottom tower mast is locked in place.

7. Light tower trailer support stands have been positioned

properly and the trailer is level.

8. Flood lights have been adjusted to desired position.

9. Chocked blocks have been positioned under each wheel to

prevent trailer from rolling.

10. Flood lights DO NOT interfere with any overhead

obstructions.

11. Flood light power cables have been plugged into the

appropriate receptacles (J1-J4) on the T-Bar assembly.

12. Light tower trailer frame has been grounded correctly.

NOTE

DO NOT attempt to start the engine

until all the conditions referenced

in steps 1 through 12 have been

met.

DANGER - Overhead Obstruction Danger

ALWAYS make sure the area

above Light tower is open and

clear of overhead power lines

and other obstructions. The

tower extends in excess of 30

ft. (9 meters). Contact with

overhead powerlines or other

obstructions could result in

equipment damage,

Injury or Death

Serious

!

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 27

Page 28

LT-12 SERIES LIGHT TOWER — STARTUP PROCEDURES

Starting the Engine

The Night-Hawk LT-12 Series Light Tower is available with two

types of engines (Perkins or Lombardini/Deutz). The engine start-

ing procedure contained within this manual will address both

engines..

Starting the Engine (Perkins Engines)

Open

1.

2. Insert the ignition key into the ignition switch (Figure 15).

the access panel door on the right-side of the light

tower (opposite the fuel tank). Set the door latch in place to

hold the door open (up)

Turn the ignition key clockwise to the ON position. The preheat indicator lamp will be lit, wait for this indicator lamp to

go OFF. When the lamp goes OFF this indicates that the

glow plugs have been pre-heated and the engine can now

be started.

Starting the Engine (Lombardini/Deutz Engines)

1.

Open

tower (opposite the fuel tank). Set the door latch in place to

hold the door open (up)

2. Insert the ignition key into the ignition switch (Figure 16).

Turn the ignition key clockwise one click to the ON position.

The pre-heat indicator lamp will be lit, wait for this indicator

lamp to go OFF. When the lamp goes OFF this indicates

that the glow plugs have been pre-heated and the engine

can now be started.

the access panel door on the right-side of the light

3. Continue turning the ignition key all the way clockwise, when

the engine has started, release the key.

4. Before placing the light tower into actual operation, let the

engine run for 3-5 minutes. Listen of any abnormal sounds

or smells that would be associated with a defective light

Figure 15. Perkins Ignition Switch

3. Continue turning the ignition key in a clockwise direction to

the START position, when the engine has started, release

the key.

4. Before placing the light tower into actual operation, let it run

for 3-5 minutes. Listen of any abnormal sounds or smells

that would be associated with a defective light tower. If any

abnormal conditions occur, shut-down the light tower and

correct the problem.

tower. If any abnormal conditions occur, shut-down the light

tower and correct the problem.

Figure 16. Lombardini/Deutz Ignition Switch

PAGE 28 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 29

LT-12 SERIES LIGHT TOWER — SHUTDOWN PROCEDURES

Normal Shut-down

1. If a load is attached to the generating set of the light tower,

remove the load

2. Set CB-1 thru CB-4 on the control panel to the OFF position.

3. Place the MAIN circuit breaker (Figure 5, Item 4) on the

control panel to the OFF position.

4. Wait a few seconds and observe that flood all floodlights

are OFF.

5. Let the engine idle for a few minutes with no load.

6. Turn the ignition key to the OFF position. Store key in a safe

location.

7. Lower light tower mast and place in stow position as outlined

in the Pre-Setup section of this manual.

8. Place outriggers in tow position, and remove chock blocks.

9. Store light tower in a clean, dry location out of the reach of

children and bystanders.

.

Emergency Shut-down

1. Turn the ignition key to the OFF position.

NOTE

Allow flood lights to cool (15

minutes) if service or removal of

bulb is required.

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 29

Page 30

LT-12 SERIES LIGHT TOWER — MAST OPERATION

DANGER - Overhead Obstruction Danger

ALWAYS make sure the area above Light tower is open and

clear of overhead power lines and other obstructions. The

mast extends in excess of 30 ft. (9 meters). Contact with overhead

powerlines or other obstructions could result in equipment

damage,

DO NOT stand behind the trailer while the mast is being raised

or lowered. Serious Injury could result if the mast falls down.

Outriggers and Support Stands

1. Make sure both outriggers are extended. To extend the

2. As soon as the pin clears the travel position hole, release it

Serious Injury or Death

outriggers, pull the locking pin on the outrigger and hold

while sliding out the outrigger assembly.

and continue sliding out the outrigger. The pin must snap

into the outrigger locking hole in the extended position.

!

Raising Mast (Top and Center Tower Sections)

Once the tower mast has been locked into its vertical position,

the top and center tower sections can now be raised. These two

tower sections allow the flood lights to be extended upwards in

excess of 30 ft. Perform the following steps when extending the

floodlights:

1. Locate the "vertical mast extension hand winch", see Figure

3, Item 2.

2. Turn the vertical mast extension hand winch lever clockwise,

and observe that the flood lights begin to climb upward.

3. Continue turning the hand winch lever in the clockwise

direction until the desired height has been reached.

4. Release the hand winch lever, this winch is of the self-locking

type. The tension on the cable will keep the mast sections in

place.

Lowering Mast (Top and Center Tower Sections)

1. Turn the vertical mast extension hand winch lever counterclockwise, and observe that the flood lights begin to drop

downward.

2. Continue turning the hand winch lever counter-clockwise

until the top and center mast sections have been fully

retracted (slack in the cable).

3. After extending all outriggers, rotate all trailer

into the foot down position, then turn the crank handle on the

jack stands

4. Check behind the light tower and make sure all personnel

and objects are clear of the mast.

Raising Mast (Lower Mast Section)

Follow the steps below to raise the lower mast:

1. To release the mast from the support stand locking cradle,

PULL the large cradle locking pin (see Figure 3, item 9).

This will unlock the mast from the horizontal position.

2. Remove the bottom mast quick release locking pin (see

Figure 3, Item 17) before raising tower to the vertical position.

3. To place the mast in the vertical position, TURN the vertical

winch hand lever (Figure 3, item 16) clockwise until the

mast is pointing upwards at 90 degrees.

4. Once the mast in the vertical position and the mast lock

captures the swivel base tab, insert the quick release locking

pin to prevent the mast from falling.

clockwise to lower it and level the light tower.

jack stands

Lowering Mast (Lower Lower Section)

1. Remove the quick release locking pin to allow the mast

section to be lowered to the horizontal section. Hold the

locking pin open until the swivel base tab clears the lock.

2. Turn the vertical mast hand winch lever counter-clockwise,

and observe that bottom tower mast begins to approach the

horizontal position.

3. Continue turning the vertical hand winch lever in the counterclockwise direction. As the lower tower mast approaches

the locking cradle, pull the tower release pin to allow the

tower mast to rest in the cradle.

4. Once the lower mast is resting in the cradle of the tower

support stand, align the hole on the mast with the hole on

the cradle and insert locking pin.

PAGE 30 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 31

LT-12 SERIES LIGHT TOWER — OPERATION

Turning On the Flood Lights

Main Circuit Breaker

The

breakers

(10 amps each) are located on the upper control panel

(25 amps), and 4

floodlight circuit

(Figure 20). Please note that there is one 10 amp circuit breaker

for each floodlight.

1. Place the

Main circuit breaker

(Figure 17) on the control

Applying an External Load

The Night-Hawk LT-12 Series Light Tower is available with two

auxiliary output receptacles (Figure 18). The upper most

receptacle (twist-lock) located at the front of the light tower can

provide 240 VAC at 25 amps. The bottom receptacle is a GFCI

receptacle which can supply 120 VAC at 15 amps.

panel to the ON position.

2. Set CB-1 on the control panel to the ON position.

3. Wait a few minutes for the ballast to activate. Observe that

flood light #1 is ON.

5. Repeat steps 2 and 3 for flood lights 2 through 4 (CB-2

through 4).

6. If all the

flood light circuit breakers

are in the ON position

(up), then all of the lights should be on.

7. If any of the flood lights are not ON refer to the troubleshooting

section of this manual.

8. CLOSE all cabinet doors.

Figure 18. 120/240 VAC Output Receptacles

Figure 17. Control Panel Circuit Breakers

NEVER operate the light tower with

the engine compartment doors

NOTE

open. Operation with the doors

open may cause insufficient cooling to the unit, and damage may

result.

DANGER - Electric Shock Hazards

WET

HANDS

NEVER grab or touch a live power

cord with wet hands, the possibility

exists of electrical shock,

electrocution, and even death!

POWER

CORD

(POWER ON)

Testing the 120 VAC GFCI Receptacle

Pressing the

tripped. Pressing the "

reset

button resets the GFCI receptacle after being

Test Button

" (See Figure 19) in the center

of the receptacle will check the GFCI function. Both receptacles

should be tested at least once

a month.

Figure 19. GFCI Test Button

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 31

Page 32

LT-12 SERIES LIGHT TOWER — MAINTENANCE

Use Table 9 shown below as a general checklist to be performed

on a daily basis. For more detailed maintenance refer to the

Perkins or Lombardini/Deutz engine service manuals.

ECNANETNIAM/NOITCEPSNI.9ELBAT

srH01

YLIAD

srH002 srH005 srH0001

sleveLdiulFenignEkcehC X

retliFleuFkcehC X

)deppiuqefi(rotacidnItsuDrenaelCriAkcehC X

dnuorAklaWlausiV/skaeLrofkcehC X

straPfogninesooLrofkcehC X

1

*retliFdnaliOenignEecalpeR

X

yrettaBecivreS X

ENIGNE

2

*retliFleuFegnahC

edistuOdnaedisnI,tinUnaelC X

noitcetorPtnalooCkcehCdnarotaidaRnaelC

X

X

leveL

tnemelEretliFriAecalpeR X

statsomrehTtseT X

rotaidaRhsulF/spmalCdnasesoHllakcehC X

knaTleuFfoedisnInaelC X

ROTARENEG

1

*

2

*

PAGE 32 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

smhoM3revOecnatsiseRnoitalusnIerusaeM

.ylnoemittsrif,sruoh001taretliffnalioenigneecalpeR

.ylnoemittsrif,sruoH052taretlifleufecalpeR

X

Page 33

LT-12 SERIES LIGHT TOWER — MAINTENANCE

Check Cable Wear

The wire rope (cable) that raises and extends the mast is a very

important part of the light tower. There is one cable/hand winch

system, located on the tounge of the trailer, that raises and

Servicing the Mast Extension Cable System:

To replace the cable in the mast extension cable system, use the

following steps (Reference Figure 21):

1. Lower the mast to the horizontal resting position.

extends the light tower mast. There is a second cable/hand winch

system located on the mast that serves to raise and lower the two

extendable sections of the mast.

2. Inspect the cable clamps, pulleys, and other components for

worn or damaged parts. If either of the cables on the mast

needs to be replaced, they should both be replaced at the

DANGER - Light Tower Cable System Safety

Wire rope (cable) will fail if it is worn, frayed, misused, crushed,

kinked or damaged in any way. ALWAYS check the cables and

pulleys for any abnormalities before use.

DO NOT use it if there is even the slightest cause for

same time.

3. Disassemble the mast by disconnecting the cables form the

mast and sliding the sections apart. The lower cable can be

disconnected from the winch.

WARNING - Mast Service Safety

concern and replace any damaged cables or pulleys

immediately.

The mast sections are heavy and awkward to handle. Use

proper lifting devices and procedures when servicing the mast

Servicing the Mast Raise/Lower Cable System:

To replace any components in the mast raise/lower cable

system, use the following steps (Reference Figure 20):

1. Lower the mast to the horizontal resting position.

2. Inspect the cable clamps, pulleys, and other components for

worn or damaged parts.

3. Disconnect the cable from the ball socket pin and remove

from the mast pulley and cable sheave. Detatch the cable

from the hand winch as necessary.

4. Replace the pulley and the cable as needed.

5. Re-thread the cable through the pulley and reattach the cable

to the ball socket pin.

6. Raise and lower the mast several times to verify correct

operation.

and its components.

4. There are two pulleys in the mast raise/lower cable system.

They should be removed, and replaced if worn or damaged,

as they can cause premature cable failure if they are in poor

condition.

5. Reassemble the mast extension cable system by connecting

the cable to the bottom of the upper mast and sliding the

upper mast into the opening of the center mast. Connect the

second cable to the bottom of the center mast and slide the

center mast into the opening of the lower mast, observing

proper lifting techniques.

6. Route the upper mast cable through the center mast pulley

and connect the free end of the cable to the lower mast ankle

shackle. Route the center mast cable through the lower mast

pulley and connect the free end of the cable to the hand

winch at the bottom of the lower mast.

Figure 20. Mast Raise/Lower Cable System

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 33

7. Raise, extend, retract and lower the mast several times to

verify correct operation.

CENTER

MAST

PULLEY

UPPER

MAST

LOWER

MAST

PULLEY

CENTER

MAST

LOWER

MAST

SHACKLE

ROUTE TO

HAND WINCH

LOWER

MAST

Figure 21 Mast Extension Cable System

Page 34

LT-12 SERIES LIGHT TOWER — MAINTENANCE

General Inspection

Prior to each use, the generating set should be cleaned and

inspected for deficiencies. Check for loose, missing or damaged

nuts, bolts or other fasteners. Also check for fuel or oil leaks.

Air Cleaner

50 hours

Every

ON, clean the air cleaner element.

1. Un-latch the holding clips and take out the air cleaner

element.

2. Clean the inside of the body and cover using a damp cloth.

3. Blow dry with compressed air (0.69Mpa {7kgf.cm

99.4 PSI} maximum) against the side of the element along

the pleats. Then blow dry against outside along the pleats,

then against inside again.

4. Remove one seal each time the element is cleaned.

5. Replace the outer element after cleaning it 6 times or after

one year. Replace the outer element if indicator is red even

after cleaning it.

6. If seal washer is damaged or the threads of wing nut are

damaged, replace.

7. Remove evacuator valve and clean it with compressed air.

Reinstall.

: Check dust indicators on control panel. If light is

Fuel Addition

Add diesel fuel (the grade may vary according to season and

locations). Always pour through the mesh filter.

Removing Water from the Tank

After prolonged use, water and other impurities accumulate in

the bottom of the tank. Occasionally remove the drain cock and

drain the contents. During cold weather, the greater the empty

volume inside the tank, the easier it is for water to condense.

This can be reduced by always keeping the tank as full as

possible.

Air Removal

2

If air enters the fuel injection system of a diesel engine, starting

,

becomes impossible. After running out of fuel, or after

disassembling the fuel system, bleed the system according to

the following procedure.

To restart after running out of fuel, squeeze the fuel primer bulb

to pump fuel into the engine. This unit is equipped with an

automatic air bleeding system.

Service Daily

If engine is operating in very dusty and dry grass conditions, a

clogged air cleaner will result in high fuel consumption, loss of

power and excessive carbon buildup in the combustion chamber.

Cleaning the Fuel Strainer

Clean the fuel strainer if it contains dust or water. Remove dust or

water in the strainer cap and wash it in diesel. Securely fasten

the fuel strainer cap so that fuel will not leak. Check the fuel

strainer every 200 hours of operation or once a month.

Check Oil Level

Check the crankcase oil level prior to each use, or when the fuel

tank is filled. Insufficient oil may cause severe damage to the

engine. Make sure the generator is level. The oil level must be

between the two notches on the dipstick as shown in Figure 14.

PAGE 34 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 35

LT-12 SERIES LIGHT TOWER — MAINTENANCE

WARNING - Radiator Burn Hazard

Allow engine to

radiator. Flushing the radiator while

will damage radiator. In addition the

possibility of

cause severe burns.

Flushing Out Radiator and Changing Coolant

1. Stop the engine and allow to cool. Tighten valve of the

corrosion resistor (if equipped).

2. Turn water filer cap slowly and remove it.

3. Prepare a container to catch the coolant, then open drain

plug of the radiator or heat exchanger and drain plug of the

engine, and drain the coolant.

4. After draining the coolant, close drain plugs and fill with tap

water.

5. When the water level is near the mouth of the water filler,

open drain plugs and start the engine, and run at low idling.

Keep the engine running at low idling and flush the radiator

for about 10 minutes.

6. Adjust the flow of the water flowing in and draining out to

ensure that the radiator is always full during the flushing

operation. While flushing water through the system, watch

carefully the water inlet hose does not come out of the radiator

filler port.

7. After flushing, stop the engine, open drain plug and drain

the water, then close drain plugs.

cool

when flushing out

hot!

hot!

coolant exists which can

14. Drain the water inside reserve tank, clean the inside of the

reserve tank, then fill with coolant/water mixture to between

the full and low lines.

15. Stop the engine, wait for 3 minutes, add tap water until the

water level reaches near the water filer port, then tighten the

radiator cap.

Changing Oil

1. Make sure the oil is cool before changing.

2. Set a container directly under the drain plug of the oil pan.

Loosen the drain plug slowly.

3. Check the drained oil for excessive metal particles or foreign

material. Contact the distributor if there is metal particles or

foreign material.

4. Using a filter wrench, turn filter cartridge to the left to remove

it. If the filter cartridge is filled with a large amount of oil, wait

10 minutes or so before removing. Make sure there is no old

gasket stuck on the filter holder.

5. Tighten drain plug. Clean the filter holder, fill the new filter

cartridge with clean engine oil, coat the packing and thread

of the new filter cartridge with engine oil, then install it to the

filter holder. Tighten until the gasket surface contacts the

seal surface of the filter holder, then tighten it a further 3/4 to

1 turn.

6. Add engine oil through oil filler until the oil level is between

the H and L marks on the dipstick.

7. Run the engine at idling for a short time, then stop the engine.

Recheck the oil level and fill as necessary.

8. After draining the water, flush the system with a flushing

agent. See instructions on flushing agent label.

9. After flushing, open drain plugs and drain out all the water,

then close drain plugs and add tap water so the water level

is near the mouth of the water filler.

10. When the water level is near the mouth of the water filler,

open drain plugs and start the engine, run at low idling and

continue to flush the system until clean water comes out.

Adjust the flow of the water flowing in and draining out to

ensure the radiator is always full during the flushing

operation.

11. When clean water comes out, stop the engine, drain all the

water, then close drain plugs.

12. Remove the corrosion resistor (if equipped) and open valve.

13. Supply water until it flows over the water filler.

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 35

Page 36

LT-12 SERIES LIGHT TOWER — MAINTENANCE

Replacing Fuel Filter

1. Set the container under the filter cartridge to catch fuel.

2. Using a filter wrench, turn the filter cartridge to the left to

remove it.

3. Clean the filter holder, fill the new filter cartridge with fuel,

coat the packing surface of the filter cartridge with engine

oil, then install the cartridge to the filter holder.

4. When installing, tighten until the packing surface contacts

the seal surface of the filter holder then tighten a further 2/3

of a turn. If the filter cartridge is tighten too much, the packing

will be damaged and will cause fuel leakage. Fuel leakage

will occur if the filter cartridge is not tightened enough. Always

tighten to the correct angle.

5. Squeeze the fuel primer bulb to pump fuel back into the

engine.

6. Replace Corrosion resistor cartridge (if equipped)

7. Screw in valves at the top of the corrosion resistor.

8. Using a filter wrench, turn the cartridge to the left to

remove it.

9. Coat the seal surface of the new cartridge with engine oil

and install it to the filter holder.

Light Tower Storage:

For storage of the generator for over 30 days, the following is

required:

z

Fill the fuel tank completely. Treat with fuel stabilizer if

necessary.

z

Completely drain oil from the crankcase and refill if necessary

with fresh oil.

z

Clean the entire light tower, internal and external.

z

Disconnect the negative terminals of the battery and cover

it, or remove it from the generator and store it separately.

z

If the ambient temperature is expected to drop below 0

add antifreeze to the radiator.

z

Cover the light tower and store in a clean, dry place away

from children and non-qualified personnel.

Removal From Long Term Storage:

z

Apply oil to the engine valve and rocker arms, and examine

the operating condition of the valves.

z

Change the oil in engine oil pan.

z

Replace all the filters.

z

Flush the inside of the cooling system.

o

C,

z

10. Tighten until he packing surface contacts the seal surface of

the filter holder, then tighten a further 2/3 of a turn.

11. Open valves.

Drain the water from the fuel tank and bleed the air from the

fuel system.

z

If the engine has not been started for more than one year,

contact your Perkins or Lombardini/Deutz distributor to have

engine overhauled.

PAGE 36 — LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08)

Page 37

LT-12 SERIES LIGHT TOWER — TROUBLESHOOTING (GENERATOR)

Practically all breakdowns can be prevented by proper handling and maintenance inspections, but in the event of a

breakdown, please take a remedial action following the diagnosis based on the Generator Troubleshooting (Table 10)

information shown below and on the following page. If the problem cannot be remedied, please leave the unit just as it is

and consult our company's business office or service plant.

GNITOOHSELBUORTROTARENEG.01ELBAT

MOTPMYS MELBORPELBISSOP NOITULOS

?esoolnoitcennocgniriwsI .riaperdnagniriwkcehC

tuptuOegatloVoN

?reifitcerevitcefeD .ecalperdnakcehC

tuptuOegatloVwoL

tuptuOegatloVhgiH

?daolnitiucriCtrohS .riaperdnadaolkcehC

deppirTrekaerBtiucriC

retratsdnatratsotsliafenignE

etatortonseod

?tnerrucrevO .ecuderdnastnemeriuqerdaolmrifnoC

?yrettabdaeD .yrettabecalpeR

?evitcefedrotalugeregatlovsI .yrassecenfiecalpeR

?tcerrocdeepsenignesI ."hgiH"otrevelelttorhtenignenruT

?esoolsnoitcennocgniriwsI .riaperdnagniriwkcehC

?evitcefedrotalugeregatlovsI .yrassecenfiecalpeR

?esoolsnoitcennocgniriwsI .riaperdnagniriwkcehC

?evitcefedrotalugeregatlovsI .yrassecenfiecalpeR

?rekaerbtiucricevitcefeD .ecalperdnakcehC

hctiwsnoitingievitcefeD .hctiwsnoitingiecalpeR

?retratsevitcefeD .retratsecalpeR

?esufdenruB .esufecalpeR

retratsdnatratsotsliafenignE

setatorseod

?leufoN )leufleseid2.oN(leufddA

LT-12 SERIES LIGHT TOWER — OPERATION MANUAL — REV. #1 (08/15/08) — PAGE 37

?tiucrictaeh-erpnekorB tiucrictaeh-erpkcehC

?gniriwevitcefeD ?gniriwkcehC

Page 38

LT-12 SERIES LIGHT TOWER — TROUBLESHOOTING (ENGINE)

Practically all breakdowns can be prevented by proper handling and maintenance inspections, but in the event of a

breakdown, please take a remedial action following the diagnosis based on the Engine Troubleshooting (Table 11) information