ST501-KU3KA.12P

Controller for cooling applications

Order number 900220.02 0

As of: 23.03.2015, software V2.24

Wiring diagram

Product description

The microprocessor-controlled controller ST501-KU3KA.12P consists of a service and a separate power

pack plate and is used for thermostatic temperature regulation in simple refrigerating plants. It is supplied

with 230V AC and has four relay outputs as well as an exit for a DC voltage fan.

The relays can be used for different functions, e.g. for a compressor, a defroster, an alarm relay, etc.. (see

parameters U1-U4). The two resistance sensors seize the refrigerating chamber temperature and the

evaporator temperature.

Sensor: PTC

Range: -55...99

Front size: 106mm x 68mm

Panel cut-out: 87.5mm x 56.5mm

Tightness: front IP65

Connector: cage clamp

Customised Characteristics:

S1=2; P5=0; r1=2; r2=10; c3=2; d0=3; d1=1; d2=5; d3=20; d7=0;

A1=-5; A3=240; A6=0; F5=0; F7=1; F8=71; F9=71; F10=5; b1=4; U3=6;

_C

Order No.: 900220.020 V2.24 1/11

Order No.: 900220.020 V2.24 2/11

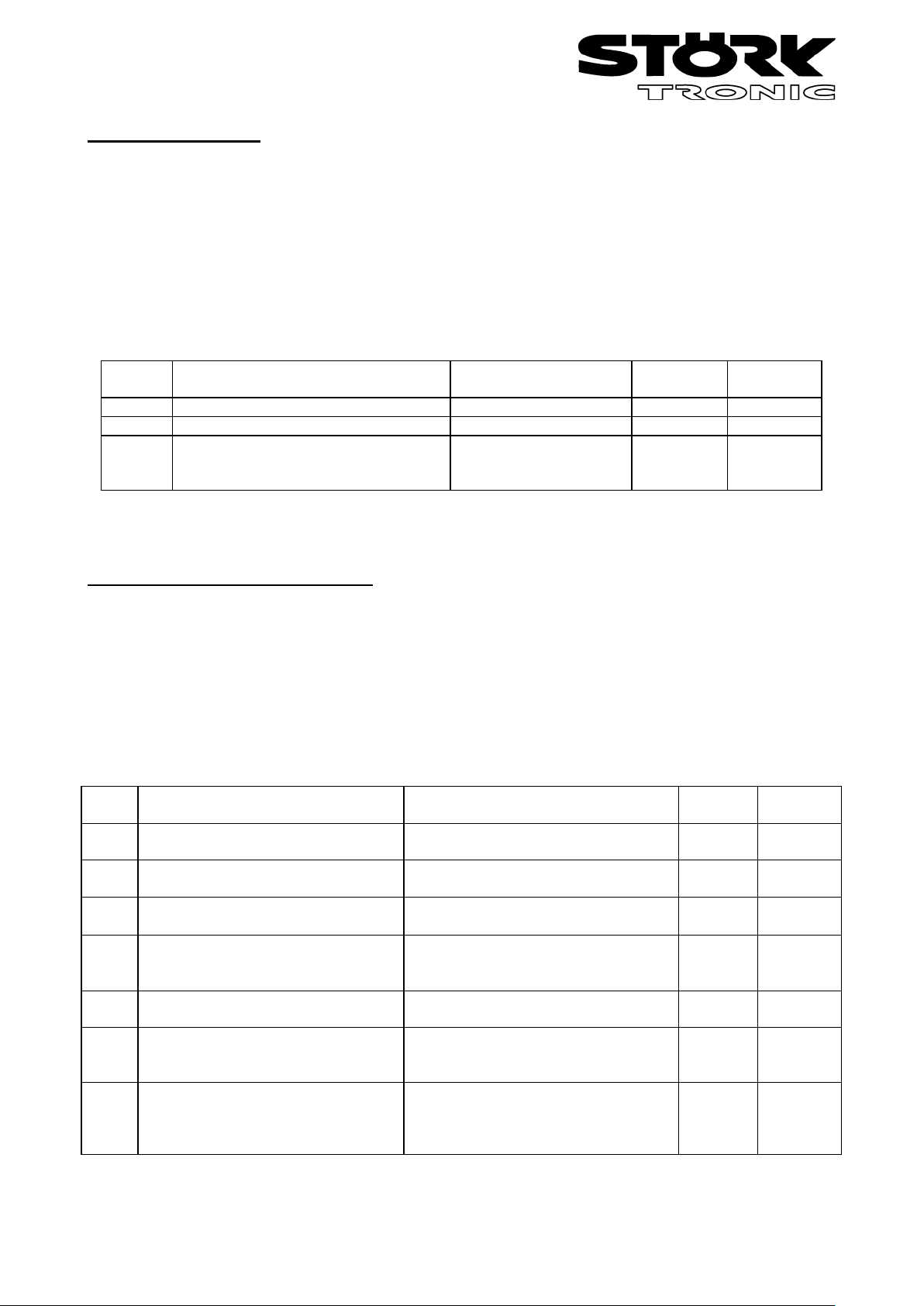

SOFTWARE .12

Parameter

Function

Adjustment range

Standard

setting

Customer

setting

S1

Setpoint

r1...r2

0.0°C

2.0°C

1

2

3

4

5

6

Adjustment options

Key 1: UP

Defrosting can be started any time by pressing the UP-key for 3 seconds. During the

process of defrosting the respective LED is illuminated. The LED flashes if defrosting is

requested, but may not be started yet due to interlock conditions.

Key 2: DOWN

The DOWN key, among other functions, can acknowledge an alarm. The internal

buzzer is then switched off.

Key 3: (if available)

Different functions are assigned to this key by help of parameters, see parameter b1.

(direct switching of a contact, standby function…). The key must be pressed for at least

half a second.

Key 5: SET

While SET key is pressed, the setpoint is indicated.

In addition, the SET key is used for setting parameters

.

Key 6: Standby

With this key the controller is switched to standby mode. Pressing the key a second

time, restarts the unit. The key can be deactivated by setting the respective parameter,

see parameter b3.

First control level:

Parameter setting for the main setpoint.

If none of the keys is pressed, the display indicates the actual value of the temperature. Pressing

the SET key, the setpoint shows on the display.

If the setpoint is to be changed, the SET key is to be kept pressed while adjusting the setpoint with

the keys UP and DOWN.

Please note that the setpoint can only be changed within the set setpoint limits.

General reference

Note that the value is transferred to the captive memory and is safe also after power failure.

Order No.: 900220.020 V2.24 3/11

Parameter

Function

Adjustment range

Standard

setting

Customer

setting

r0

Hysteresis for the compressor contact

1...15 K

2 K

P2

Indication actual value of sensor F2

-

PA

Access to parameter list of the third

Password:: -19

-99...+99

0

Parameter

Function

Adjustment range

Standard

setting

Customer

setting

P0

Indication of actual value of sensor

F1

P1

Calibration sensor F1,

actual value correction

-9.9 ... +9.9 K

0.0 K

P2

Indication of actual value of sensor

F2 (only available if P4≠0)

P3

Calibration sensor F2,

(only available if P4≠0)

-9.9 ... +9.9 K

0.0 K

P4

Evaluation of sensor F2

0: not evaluated

1: evaluated as evaporator sensor

1

P5

Indication mode

0: integrals

2: accuracy 0,1 °C

1 0

P6

Display unit, indication in standby

0: Fahrenheit (“AUS”)

3: Celsius (“OFF”)

1

Second control level:

Setting of control parameters

The parameters can also be set in standby mode. Simultaneously pressing the UP and DOWN key for at

least 4 seconds opens a parameter list containing frequently used parameters (the complete list of all

parameters is to be found on the third control level).

With the UP and DOWN keys the list can be scrolled in both directions.

Pressing the SET key will give you the value of the respective parameter. Pressing also the UP or DOWN

key at the same time the value can be adjusted.

Return to the initial position takes place automatically, if no key is pressed for 45 seconds, or by

simultaneously pressing the UP and DOWN key for approx. 4 seconds.

control level

Parameter P2 is only indicated if P4 ≠ 0.

Third control level (all parameters):

Setting of control parameters

Access to the third control level is granted when selecting parameter PA on the second control level.

Parameter PA is to be set at '-19'. Then the key UP and DOWN have to be simultaneously pressed for

approx.. 4 seconds which will give access to the third control level, beginning with parameter P0. With the

keys UP and DOWN you can scroll the list in both directions. Pressing the SET key will give you the value of

the respective parameter. By pressing the UP or DOWN key at the same time the value can be adjusted.

Return to the initial position takes place automatically, if no key is pressed for 45 seconds, or by

simultaneously pressing the UP and DOWN key for approx. 4 seconds.

actual value correction

mode

Order No.: 900220.020 V2.24 4/11

1: accuracy 0,5 °C

1: Celsius (“AUS”)

2: Fahrenheit (“OFF”)

Parameter

Function

Adjustment range

Standard

setting

Customer

setting

P7

Sensor type

11: Pt100 2-wire

22: NTC 2-wire

P8

1: not active

measuring values

r0

Hysteresis for the compressor

contact

1...15 K

2 K

r1

Setpoint limitation (minimum)

-50 °C...r2

-50 °C

2.0°C

r2

Setpoint limitation (maximum)

r1...+150 °C

50 °C

10.0°C

r3

Switching sense of compressor

0: cooling

1: heating

0

c0

Start protection of the compressor

after "cooling on"

0...240 min.

0 min.

c1

Start protection after com pr. start

0...240 min.

5 min.

c2

Start protection after compr. stop

0...240 min.

3 min.

c3

Function in the case of error of

0: relay off

2: emergency operation

0

2

d0

Defrosting interval

0 = inactive, no defrosting

1...99 h

8 h 3 h

d1

Defrosting mode

0: electrical

1: with hot gas

0

1

d2

Defrosting temperature

-50...+150 °C

10 °C

5.0°C

d3

Defrosting time limit

1...99 min.

30 min.

20 min.

d6

Indication of the refrigerating

defrosting

0: actual temperature

before the start of defrosting

1

d7

Drainage time

0...15 min.

2 min.

0 min.

A0

Hysteresis for alarm

1...15 K

2 K

-5 K

A1

Minimum limit value

-99.0 ... -0.1 K; 0 = inactive

-10 K

A2

Maximum limit value

+0.1...+99.0 K ; 0 = inactive

10 K

A3

Alarm suppr. time after “cooling on”

0...240 min.

120 min.

240 min.

A6

Alarm suppression time after

temperature alarm

0...240 min.

2 min.

0 min.

A7

Alarm suppression time after

defrosting

0...240 min

15 min.

A9

Switching sense alarm contact

0: relay on

1: relay off

1

F4

Defrosting behaviour

0: ventilator off during defrosting

1: ventilator on during defrosting

1

F5

Ventilator deceleration time after

defrosting

0...240 min.

2 min.

0 min.

F7

Ventilator function at cooling

1: always on

on and sensor F2 < sensor F1

2 1

F8

Ventilator revolution number at

normal cooling operation

0..100%

100

71

F9

Ventilator revolution number at

defrosting

0..100%

100

71

F10

Kick-start

0..60s

0

5

(applies to both sensors)

Software filter

(applies to both sensors)

sensor F1

21: PTC 2-wire

22: PT1000 2-wire

2...64: average value with 2 ... 64

1: relay on

21

8

chamber temperature during

operation

1: temperature determined just

2: on or off together with the

compressor

3: on whenever the compressor is

Order No.: 900220.020 V2.24 5/11

Parameter

Function

Adjustment range

Standard

setting

Customer

setting

b1

Function key A

0: no function

5: actual value sensor F2 (toggle)

0

b2

Function key B

(if available)

see b1

0

b3

Function standby key

0: no function

1: controller on/off (standby)

1

b11

Function switching input E1

0: no function

standby mode

0

b12

Function switching input E2

see b11

0

b13

Function switching input E3

(if available)

see b11

0

b14

Function switching input E4

(if available)

see b11

0

U1

Exit connection K1

0: no connection

9: on, if controller on

1

U2

Exit connection K2

see U1

2

U3

Exit connection K3

(if available)

see U1

3

6

U4

Exit connection K4

(if available)

see U1

4

L0

Own ST-Bus address

0: inactive

1 ... 250

0

L40

Mask for Low-Byte of Status 0

(ST-Bus)

0 ... 255 (binary coded)

Pro

Program version

(if available)

1: controller on/off (standby)

2: Setpoint thermostat 2 (Y1)

3: relay directly, switched off in

standby mode

4: relay directly, regardless of

standby mode

1: controller on/off (standby)

2: starting defrost

3: relay directly, switched off in

standby mode

4: relay directly, regardless of

1: connection to compressor

2: connection to defrost

3: connection to ventilator

4: connection to alarm

5: connection to thermostat 2

6: connection to key A, E1 or E3

7: connection to key B, E2 or E4

8: connection to buzzer

4

Order No.: 900220.020 V2.24 6/11

Parameter description:

The following values can change the equipment characteristics

and are therefore to be set with utmost care.

P0: Indication actual value of sensor F1

The here indicated temperature presents the sum of

actual measured value of feeler F1 and the actual

value correction according to parameter P1.

P1: Calibration sensor F1, actual value

correction

This parameter allows the correction of actual value

deviations caused for example by sensor tolerances

or extremely long sensor lines. The regulation

measure value is increased or decreased by the

here adjusted value.

P2: Indication actual value of sensor F2

The here indicated temperature presents the sum of

actual measured value of sensor F2 and the actual

value correction according parameter P3.

P3: Calibration sensor F2, actual value

correction

This parameter allows the correction of actual value

deviations caused for example by sensor tolerances

or extremely long sensor lines. The regulation

measure value is increased or decreased by the

here adjusted value.

P4: Evaluation of sensor F2

Sensor F2 can be used for the determination of the

evaporator temperature (P4=1) or for the second

thermostat (P4=2).

If, in simpler refrigerant plants only the refrigerating

chamber sensor is used, the feeler entrance for

sensor F2 as well as its data recording (P4=0) can

be deactivated here. Among other, parameter d2

has no meaning in the deactivated condition.

P5: Indication mode

The actual value can be indicated with diff er ent

accuracy.

Actual values and parameter values are always set

for highest accuracy.

P6: Display unit, indication in standby mode

This parameter allows display settings (°F or °C) and

("AUS" or "OFF") in standby mode.

P7: Sensor type

This parameter makes it is possible to adjust the

feeler type of both sensors. Depending on the

hardware not all sensor settings are possible.

P8: Filter

This parameter can determine by how many

measured values an average value is to be formed.

r0: Hysteresis for the compressor contact

Parameter r0 sets the temperature margin between

switching off and switching on of the compressor. A

small hysteresis permits a more exact regulation,

however also leads to more frequent switching of the

compressor. The hysteresis is set one-sided above

the setpoint.

r1: Setpoint limitation (minimum)

r2: Setpoint limitation (maximum)

These parameters limit the adjustment range of the

setpoint S1, in order to avoid that the end user sets

inadmissible values for the plant.

The entire adjustment range is equivalent to the

maximum operating range of a PTC sensor.

r3: Switching sense of the compressor

c0: Start protection of the compressor after

"cooling on"

After cooling is switched on (e.g. by switching on the

mains voltage) the start of the compressor is

retarded until the protection running time is over.

This secures e.g. that several cooling units do not

start at the same time and load the electricity supply

net.

c1: Start protection of the compressor after

compressor start

This time protection starts when the compressor is

switched on. After switching the compressor off, a

renewed switching on is impossible until this

protection time runs out. This prevents from too

frequent switching-on of the compressor and thus

increases its life span.

c2: Start protection of the compressor after

compressor stop

This time protection starts when the compressor is

switched off. After switching the compressor off, a

renewed switching on is impossible until this

protection time runs out.

c3: Function in the case of error of refrig erating

chamber sensor F1

Here is determined whether the compressor keeps

running or not in the case of an error of the

refrigerating chamber feeler F1. When deepfreezing, the compressor should normally continue

running, in order to prevent de-frosting of the goods.

At the normal cooling range above 0 °C, a

continuation, however, could lead to frost damages.

In the operation mode "emergency operation" the

compressor is switched on and off in 5 minute

intervals. This results in a clock operation with 50 %

Order No.: 900220.020 V2.24 7/11

cooling performance.

d0: Defrosting interval

The defrosting interval defines the time, after which

a defrosting process is started. With the beginning of

the defrosting process, the defrosting interval starts

anew, which results in periodic defrosting in firm

intervals.

Defrosting can also be started by pressing the key

"manual defrosting" for at least 3 seconds. This

automatically restarts the defrosting interval.

After switching-on cooling, the controller immediately

initiates cooling and starts the first defrosting

process after this interval.

d1: Defrosting mode

This parameter determines whether defrosting is

effected by an electrical heating coil (d1=0) or by

means of hot gas (d1=1).

d2: Defrosting temperature

The defrosting process is terminated when the

evaporator has reached the adjusted temperature.

(Always provide good thermal contact between

evaporator sensors and lamellas).

In case that defrosting takes too long, the time limit

set in "d3" will come into effect.

d3: Defrosting time limit

Here the maximal defrosting time can be adjusted.

According to this time frame, defrosting is terminated

even if the evaporator is not warm enough to be icefree.

d6: Indication of the refrigerati n g chamber

temperature during defrosting

It is to be assumed that the refrigerating chamber

temperature slightly rises during the defr os ting

process. d6=0 indicates the actual refrigerating

chamber temperature during the defrosting process.

d6=1 indicates the temperature determined just

before the start of defrosting until the setpoint of the

refrigerating chamber is reached again after the

defrosting process is completed. Thus, an irritation

of the operator during defrosting can be avoided. In

the case of emergency, the display flashes and the

actual temperature of the refrigerating chamber is

indicated.

d7: Drainage time

Completed defrosting is immediately followed by a

drainage period, in order to let the evaporator drip

off. During drainage time, the exits compressor and

ventilator are switched off .

A0: Switching hysteresis for alarm

The hysteresis of the alarm contact is

asymmetrically, set downward at the maximum

alarm value upward at the minimum alarm value.

A1/A2: Minimum/maximum limit values

The limit values serve for monitoring of the

refrigerating chamber temperature. They are

relative, i.e. going along with the setpoint S1 of the

refrigerating chamber. Alarm is released when

exceeding maximum limit value or when falling

below the minimum limit value:

The actual value display flashes, the buzzer (if

available) goes off intermittently and the actual

temperature of sensor F1 is indicated (if there is no

sensor error).

At A1=0 or A2=0 the respective limit value alarm is

inactive.

The buzzer can be turned off with the DOWN key,

the display continues flashing until the alarm is

turned off.

A3: Alarm suppression time after “cooling on”

After switching cooling on, an alarm is suppressed

for the adjusted time, i.e. the refrigerant plant can

get to work temperature without releasing alarm.

A6: Alarm suppression time after temperatu re

alarm

If the refrigerating chamber temperature exceeds the

limit values adjusted at A1, A2, normall y a

temperature alarm should be released.

With the suppression time set at A6 the alarm

release can be delayed.

A7: Alarm suppression time after defrosting

Temperature alarm is avoided for the adjusted time

after defrosting, in order to enable the plant t o get

back to the normal operating conditions (see A1,

A2).

A9: Switching sense alarm exit

Depending on application, the alarm exit requires a

normally-closed or a normally-open contact. At

setting A9=1 the relay tightens in normal operation

and opens in the case of emergency. That way also

a voltage failure of the controller can be detected

(relay dead = alarm) for an external alarm chain.

F4: Defrosting behaviour

At F4=0 the ventilator is switched off during

defrosting.

At F4=1 the ventilator continues to run also during

defrosting (normal cooling range above 0°C).

F5: Ventilator deceleration time afte r defrosting

Following drainage time d7, start of the ventilator

can be delayed until the evaporator has sufficiently

cold air again. If the ventilator started immediately,

the warm air resulting from the defrosting process

would probably be blown into the refrigerating

chamber.

Order No.: 900220.020 V2.24 8/11

F7: Ventilator function at cooling operation

At F7=1 the ventilator is always on (except possibly

for a defrosting process, see parameter F4).

At F7=2 the ventilator is always on or off together

with the compressor.

At F7=3 the ventilator is switched on whenever the

compressor is on and the evaporator temperature

(sensor F2) is below the refrigerating chamber

temperature (sensor F1). The ventilator is switched

off whenever the evaporator is switched off, whereas

parameter F5 is not active. In the case of sensor

error the ventilator reacts as in the setting F7=2.

F8: Ventilator revolution number at normal

cooling operation

This parameter determines the ventilator revolution

number at normal cooling operation.

F9: Ventilator revolution number at de frosting

This parameter determines the ventilator revolution

number at defrosting.

F10: Kick-start (in seconds)

If necessary, this is an option to set a time during

which the ventilator starts with the maximum number

of revolutions for stable operation. This parameter is

only efficient, if the ventilator is newly started.

b1: Function key A

b2: Function key B (if available)

At setting = 0 the respective key has no function.

At setting = 1 the controller is switched to standby

mode

At setting = 2 the key is linked with the function

“setpoint Y1 for the thermostat 2 indicate/adjust”

At setting = 3 a relay (indicated with parameter Ux)

can be switched on or off directly with the key. In

standby mode the key is locked and the

corresponding relay switched off. After restarting the

corresponding relay remains switched off.

At setting = 4 a relay (indicated with parameter Ux)

is switched despite of the standby mode. The

condition of the exit is maintained until the key is

pressed again or until it is changed by an external

switching entrance. After net interruption, the

condition before power failure is re-installed.

At setting = 5 the actual value of sensor 2 can be

indicated. At setting P4=0 the key has no function.

b3: Function key 3 (standby)

At setting b3=0 the function of the key can be

deactivated.

b11: Function external entrance E1

b12: Function external entrance E2

b13: Function external entrance E3

b14: Function external entrance E4

Depending on existing hardware there are no or not

all external entrances.

At setting = 1 the controller is switched to the

standby mode.

At setting = 2 defrosting of both controllers is started.

At setting = 3 a relay (indicated with parameter Ux)

is switched on or off directly. In standby mode it is

locked and the relay is switched off.

At setting = 4 a relay is switched directly (indicated

with parameter Ux) regardless of the standby mode.

After net interruption the condition before power

failure is re-installed.

U1: Exit connection K1

U2: Exit connection K2

U3: Exit connection K3

U4: Exit connection K4

Depending on existing hardware there may not be

all output relays. This parameter assigns the

respective relay to the internal controller exits, to

function key 1 or 2, to one external entrance or the

buzzer.

At setting =6 or =7 the relay is switched manually. It

changes its condition with each pressure of the key

and adopts the condition of the respective switching

entrance whenever the latter changes. If the

corresponding key or switching entrance has not

been released for this function (see parameters b1,

b2 and b11 to b14), the relay remains switched off.

The buzzer connection in its function is comparable

to the alarm connection. The buzzer, however, can

be switched off with the DOWN key.

L0: Own ST-Bus address

Reserved for ST-Bus

L40 :Mask for Low-Byte of Status 0 (ST-Bus)

Reserved for ST-Bus

Pro: Program version

This parameter shows the program version.

Order No.: 900220.020 V2.24 9/11

Status messages

Message

Cause

Error elimination

ON/OFF

Standby modus, no regulation

Switch on by key or switching input

Temperature

Refrigerating chamber temperature

(parameter A1, A2)

E0

Refrigerating chamber sensor F1 error,

Control sensor.

parameter c3.

E1

Sensor F2 error,

Control sensor.

At setting [c3=2] see parameter Y6.

EP

Data loss at parameter memory (basic

contact 1 and 2 are dead)

If error cannot be eliminated by switching

on/off, the controller must be repaired.

indication flashes

flashes

flashes

beyond alarm limits

break or short-circuit

break or short-circuit

Controller operates according to with

At setting [c3=1] the controller operates in

timed defrosting modus (defrosting time

as set in d3).

Error message E0, E1 and EP changes in the display with the actual value of sensor F1, unless the latter is

defective. This happens independently from the selected indication mode. After the error is eliminated and

confirmed with the DOWN key, the previously set indication mode becomes active again.

If there is a connection to the buzzer with parameters U1... U4, the buzzer can be switched off with the

DOWN key.

Order No.: 900220.020 V2.24 10/11

Technical data of ST501-KU3KA.12P

Measuring input

F1: Temperature sensor, refrigerating chamber

F2: Temperature sensor, evaporator

Measuring range: PTC (KTY81-121) -50°C...+130°C

PT1000 -99°C...+300°C

NTC -40°C...+105°C

Pt100 -80°C...+400°C (resistance < 1 Ohm)

Accuracy: ±0.5K ± 0.5 % at 25°C, without sensor

±1K ± 0.5 % of scale range (0 – +55°C), without sensor

Outputs

K1: Relay, 30(6)A 250V~, normally-open contact, function see U1,

permanent current max. 16(6)A, limited by connectors and/or conductive strips

K2: Relay, 16(2.2)A 250V~, normally-open contact, function see U2

K3: Relay, 16(2.2)A 250V~, normally-open contact, function see U3

K4: Relay, 16(2.2)A 250V~, normally-open contact, fan

voltage output for DC-fan: 0..24V, max. 800mA (corresponds 20W)

Display

One 3-digit LED-Display, height 13 mm, for temperature indication

Three LEDs, diameter 3mm, for status display of the outputs

Power supply

230V 50/60Hz, power consumption max. 40 VA

Connectors

Cage clamp 5 x 3-pole, for cable up to 2.5mm²

Cage clamp 1 x 6-pole, for cable up to 1.5mm²

Ambient conditions:

Storage temperature: -20...+70°C

Operating temperature: 0...+55°C

Relative humidity: max. 75% without dew

Weight

ca. 500g, without sensor

Enclosure

Front IP65, IP00 from back

Installation data

The unit is to be installed in an instrument panel.

Front size: 106 x 68 mm

Installation depth: ca. 60 mm with connector

Power plate: 100 x 160mm

Order No.: 900220.020 V2.24 11/11

Loading...

Loading...