Page 1

StorCase® Technology

Data Express® DE300

(P/N S20A120)

Removable

SCSI Wide Ultra160

Drive Enclosure

User's Guide

Page 2

StorCase® Technology

Data Express® DE300

(P/N S20A120)

Removable

SCSI Wide Ultra160

Drive Enclosure

User's Guide

Part No. D89-0000-0156 A01 January 2003

i

StorCase Technology, Inc.

17600 Newhope Street

Fountain Valley, CA 92708-9885

Phone (714) 438-1850 Fax (714) 438-1847

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 3

ii

LIMITED WARRANTY

STORCASE TECHNOLOGY, Incorporated (StorCase) warrants that its products will be free

from defects in material and workmanship, subject to the conditions and limitations set forth

below. StorCase will, at its option, either repair or replace any part of its product that proves

defective by reason of improper workmanship or materials. Repair parts or replacement

products will be provided by StorCase on an exchange basis, and will be either new or

reconditioned to be functionally equivalent to new.

This warranty does not cover any product damage that results from accident, abuse, misuse,

natural or personal disaster, external power surge or failure, or any unauthorized disassembly, repair or modification. StorCase will not be responsible for any software, firmware or other

customer data stored within, or interfacing with a StorCase product.

Duration of Warranty

Seven-Year Warranty: The following StorCase products are covered by this warranty for

a period of seven (7) years from the original date of purchase from StorCase or its authorized

reseller: all Data Express® removable device enclosures and all StorCase interface cables and

accessories specifically intended for use with these products. Data Silo®, Data Stacker® and

InfoStation® products are covered by this warranty for a period of seven (7) years, excepting

the RAID controller, power supply, fan and blower components, which are covered by the

three-year warranty described below.

Three-Year Warranty: The following StorCase products are covered by this warranty for

a period of three (3) years from the original date of purchase from StorCase or its authorized

reseller: all Rhino®JR external expansion chassis and all RAID controller modules. In addition,

the following components of the Data Silo®, Data Stacker®, InfoStation® products are subject

to warranty for a period of three (3) years: all power supplies, fans and blowers.

Warranty Claim Requirements

To obtain warranty service, the defective product must be returned to your local authorized

StorCase dealer or distributor, or, with prior StorCase approval, to the StorCase factory

service center.

For defective products returned directly to StorCase, a Return Material Authorization (RMA)

number must be obtained by calling StorCase Customer Service at (714) 445-3455. The RMA

number must be prominently displayed on the outside of the return package. Shipments must

be freight-prepaid and insured, and must include the product serial number, a detailed

description of the problem experienced, and proof of the original retail purchase date. Products

must be properly packaged to prevent damage in transit. Damage resulting from improper

packaging will not be covered by this warranty. The StorCase factory service center is located

at 17650 Newhope Street, Receiving Dock, Gate #4, Fountain Valley, CA 92780, U.S.A.

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 4

Free Technical Support

StorCase provides free technical support. If you experience any difficulty during the

installation or subsequent use of a StorCase product, please contact StorCases Technical

Support Department prior to servicing your system. This warranty covers only repair or

replacement of defective StorCase products, as described above. StorCase is not liable for,

and does not cover under warranty, any costs associated with servicing and/or installation

of StorCase products.

StorCase Technical Support can be reached in the U.S. at (714) 438-1858 or toll-free at (888)

435-5460 (U.S. and Canada only). StorCase European Technical Support can be reached in

the U.K. at +44 (0) 1932 738900.

Disclaimers

The foregoing is the complete warranty for the products identified above and

supersedes all other warranties and representations, whether oral or written.

StorCase expressly disclaims all warranties for the identified products, which are

not stated herein, including, to the extent permitted by applicable law, any implied

warranty of merchantability or fitness for a particular purpose. In no event will

StorCase be liable to the purchaser, or to any user of a StorCase product, for any

damages, expenses, lost revenues, lost savings, lost profits, or any other

incidental or consequential damages arising from the purchase, use or inability

to use a StorCase product, even if StorCase has been advised of the possibility

of such damages.

iii

Copyright © 2003 StorCase Technology. All rights reserved. All registered

trademarks are the property of StorCase Technology. All other logos and trademarks

are properties of their respective companies.

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 5

iv

Declaration of Conformity

Company Name:

Corporate Office Address:

Manufacturing Address:

Product Name:

Model Number:

Conforms to the following standards:

EMC Directives:

(89/336/EEC)

Safety Standards:

CSA (NRTL/C)

TUV

StorCase Technology, Inc.

17600 Newhope Street

Fountain Valley, CA 92708

17600 Newhope Street

Fountain Valley, CA 92708

Data Express DE300

S20A120

EN 50081-1: 1992 Generic Emission

- EN 55022/CISPR22 Class B

- EN 61000-3-2

- EN 61000-3-3

EN 55024: 1998 Generic Immunity

- EN 61000-4-2 - EN 61000-4-6

- EN 61000-4-3 - EN 61000-4-8

- EN 61000-4-4 - EN 61000-4-11

- EN 61000-4-5

CAN/CSA-C22.2 No. 950-95

UL 1950

EN 60950: 1992 EN 60950/A2: 1993

EN 60950/A1: 1993 EN 60950/A3: 1995

EMI Standards:

EMC Standards:

Year of Manufacture:

Signature:___________________

Full name: Dieter Paul

Position: President

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

FCC Part 15, Class B

AS/NZS 3548 Information Technology Equipment

2001

Page 6

Table of Contents

INTRODUCTION ........................................................................................................................ 1

Packaging Information ................................................................................................... 1

Serial Numbers ............................................................................................................... 1

Package Contents ......................................................................................................... 2

General Description ....................................................................................................... 3

Receiving Frame Front Panel .............................................................................. 4

Receiving Frame Rear Panel............................................................................... 5

INSTALLATION ........................................................................................................................ 7

Installing the Drive into the Carrier................................................................................ 7

Preparation .......................................................................................................... 7

Installation ............................................................................................................ 8

Installing the Receiving Frame ...................................................................................... 9

Selecting the Unit ID Number....................................................................................... 12

Adjusting the Spin Down/Up Timer ............................................................................. 14

APPENDICES ...................................................................................................................... 15

Appendix A - Specifications/Dimensions................................................................... 16

Appendix B - Factory-Installed Options ..................................................................... 18

Data Express Ultra160 Repeater Board ........................................................... 19

Appendix C - Attaching the ON/OFF Key ................................................................... 20

Appendix D - Optional Accessories .......................................................................... 21

Carrying Case .................................................................................................... 21

v

Reader's Comments............................................................................................................... 23

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 7

vi

List of Figures

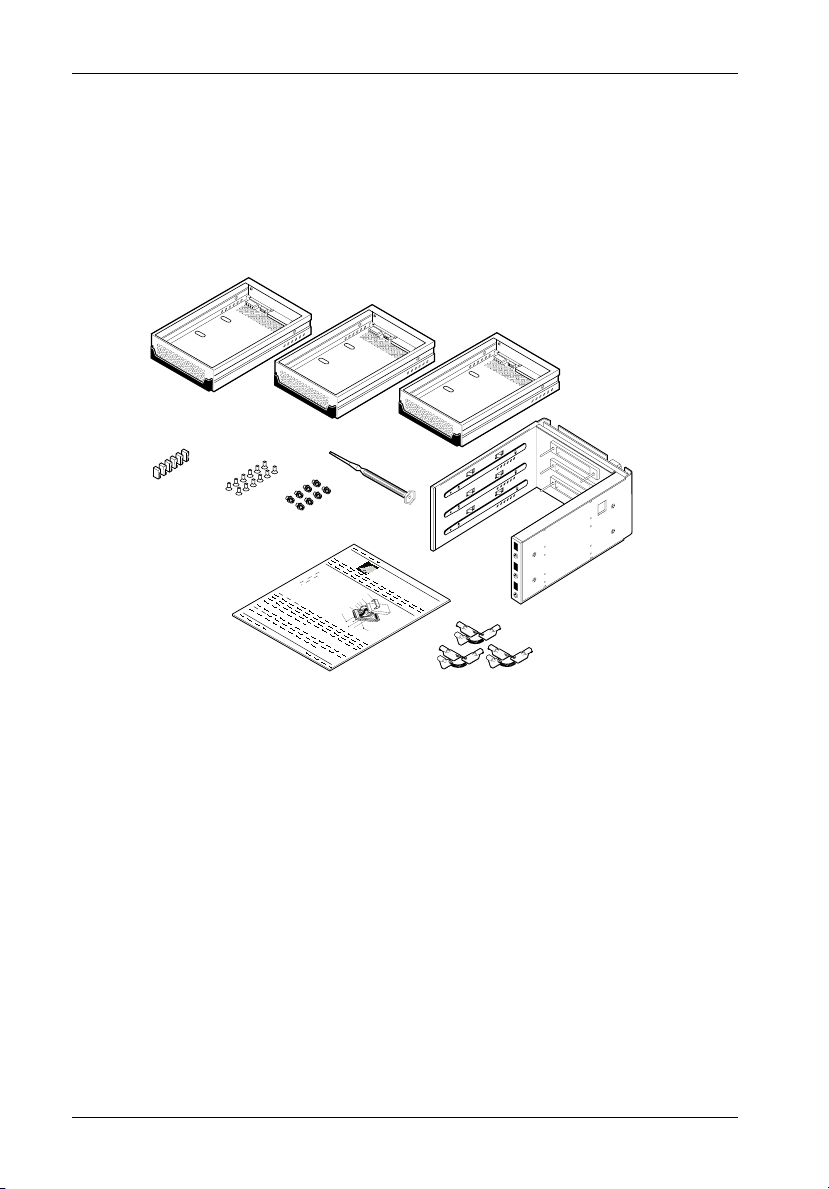

Figure 1: Package Contents ............................................................................................... 2

Figure 2: DE300 Receiving Frame and Carrier .................................................................. 3

Figure 3: Receiving Frame Front Panel .............................................................................. 4

Figure 4: Receiving Frame Unit ID Number and Activity Display ...................................... 5

Figure 5: Receiving Frame (Rear View) ............................................................................ 6

Figure 6: Drive Installation Assembly................................................................................. 8

Figure 7: Receiving Frame Motherboard J3A1, J3B1, J3C1 Option Pins ......................... 9

Figure 8: Receiving Frame Mounting Holes ..................................................................... 11

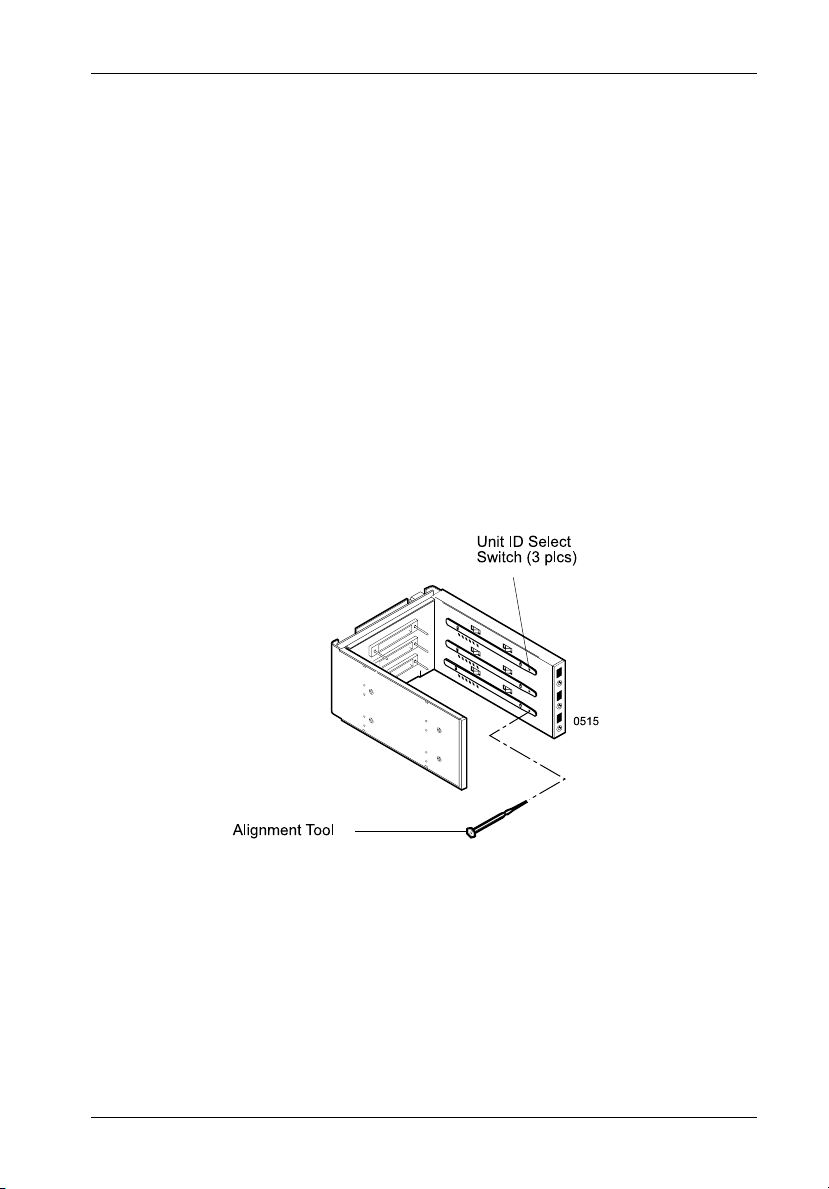

Figure 9: Unit ID Select Switch Location ......................................................................... 13

Figure 10: Device Spin Down/Up Timer Switch ................................................................ 14

Figure A-1: DE300 Physical Dimensions.............................................................................. 17

Figure B-1: DE300 Repeater Board Details ......................................................................... 19

Figure B-2: Attaching the Repeater Board .......................................................................... 19

Figure C-1: Attaching the ON/OFF Key ............................................................................... 20

Figure D-1: Carrying Case .................................................................................................... 21

List of Tables

Table 1: J3A1, J3B1, J3C1 Option Pin Signal Descriptions ............................................... 10

NOTICE: This User's Guide is subject to periodic updates without notice. While reasonable

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

efforts have been made to ensure the accuracy of this document, StorCase

Technology, Inc. assumes no liability resulting from errors or omissions in this

publication, or from the use of the information contained herein.

Please check the StorCase web site at http://www.storcase.com or contact your

StorCase representative for the latest revision of this document.

Page 8

Introduction 1

INTRODUCTION

PackagingInformation

The StorCase Technology Data Express® system is shipped in a container designed to provide

protection and prevent damage during shipment. The Data Express unit was carefully

inspected before and during the packing procedure at the factory. Bent or broken connectors,

or evidence of other damage to the Data Express should be reported to the shipper immediately.

Refer to Figure 1 for the package contents.

If the wrong Data Express model has been received, please call your reseller or StorCase at

(800) 435-0642 to arrange for a Return Material Authorization (RMA). StorCase cannot accept returns which do not display an RMA number on the outside of the package. Return the

unit with all the original packing materials.

Before removing any component from its packaging, discharge any static electricity by

touching a properly grounded metal object.

Serial Numbers

Both the DE300 receiving frame and carriers are labeled with serial numbers. These numbers

must be reported to the StorCase Customer Service Representative in order to receive a Return

Material Authorization (RMA) for warranty claims. Locate the serial number labels and record

the numbers in the spaces provided below.

Receiving Frame:

Drive Carriers:

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 9

2 Introduction

PackageContents

The DE300 package contents include the following items. If any item is missing or damaged,

contact your StorCase dealer for a replacement.

1

5

6

1. Drive Carrier

2. Receiving Frame

3. Drive Lock Keys

4. Insert Sheet

5. Jumper Plugs

7

4

8

D

ata E

xpress

C

a

C

b

le

o

(

v

P

e

r

r

o

v

i

d

e

d

)

D

i

s

(

k

N

D

o

t

r

i

I

v

n

e

c

l

u

d

e

d

P

)

o

w

e

r

I

/

O

C

a

C

b

a

l

e

b

I

l

D

e

S

e

le

c

t

C

D

a

r

i

b

v

l

e

e

C

a

r

r

i

e

r

D

r

i

H

v

e

a

P

r

M

d

h

w

o

3

i

l

u

a

l

/

i

1

n

p

r

e

6

t

s

i

n

(

F

#

4

g

l

e

a

6

a

t

-

3

)

H

2

D

x

C

a

S

b

l

c

e

r

#

e

C

0

w

6

1

o

F

-

5

s

v

3

1

l

a

e

2

(

t

2

r

x

H

p

D

3

l

c

/

1

s

)

6

6. #6-32 Phillips Flat Hd.

Mounting Screws

7. #6-32 Phillips Pan Hd.

Mounting Screws

8. Alignment Tool

Figure 1: Package Contents

2

0509c

3

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 10

Introduction 3

GeneralDescription

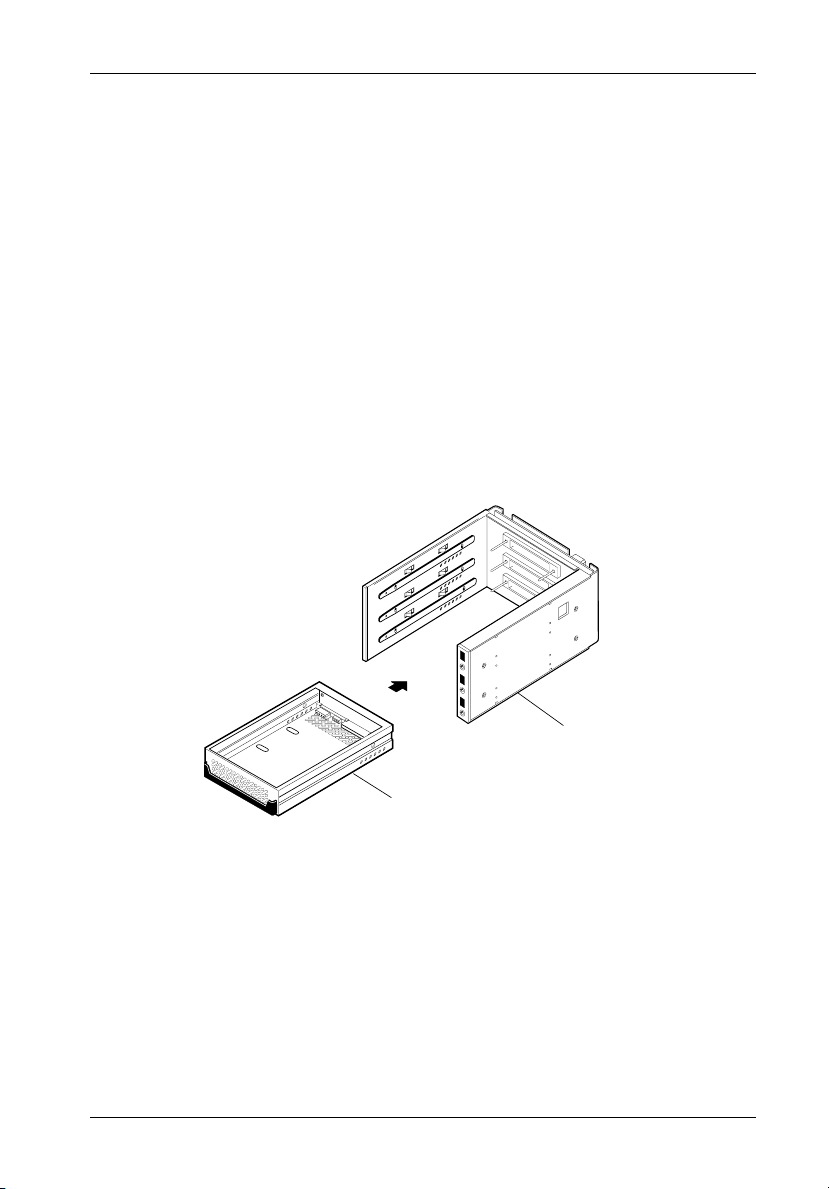

The StorCase Technology Data Express® DE300 (P/N S20A120) is composed of a receiving

frame which supports most 68-pin SCSI Ultra160 interfaces, and fits within a 5.25" full-height

peripheral slot. This 16-bit I/O can support up to 160MByte/sec transfer rates. The receiving

frame contains three (3) removable drive carriers designed to provide durable and reliable

mounting for 3.5" form factor x 1" high (low-profile) SCSI drives (Figure 2).

The S20A120 allows a drive to be removed and transported to another S20A120-equipped

computer or expansion chassis, and also provides the ability to secure sensitive data by

removing and storing the drive safely for future use.

NOTES: The S20A120 carrier supports most 68-pin SCSI Ultra160 interfaces, except Fujitsu

Alegro6 10K RPM drives (these drives have different spacing between the 68-pin

and DC power connectors and will not mate with the drive carrier board).

For SCSI Ultra160 operation, the DE300 requires Ultra160 chassis and cabling.

0510d

Receiving

Frame

Drive

Carrier

Figure 2: DE300 Receiving Frame and Carrier

This User's Guide describes the steps required to install the DE300 removable enclosure inside

a computer peripheral bay or external expansion chassis. This guide supplements documentation

provided with the host computer system, operating system, and the drive to be installed within

the carrier.

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 11

4 Introduction

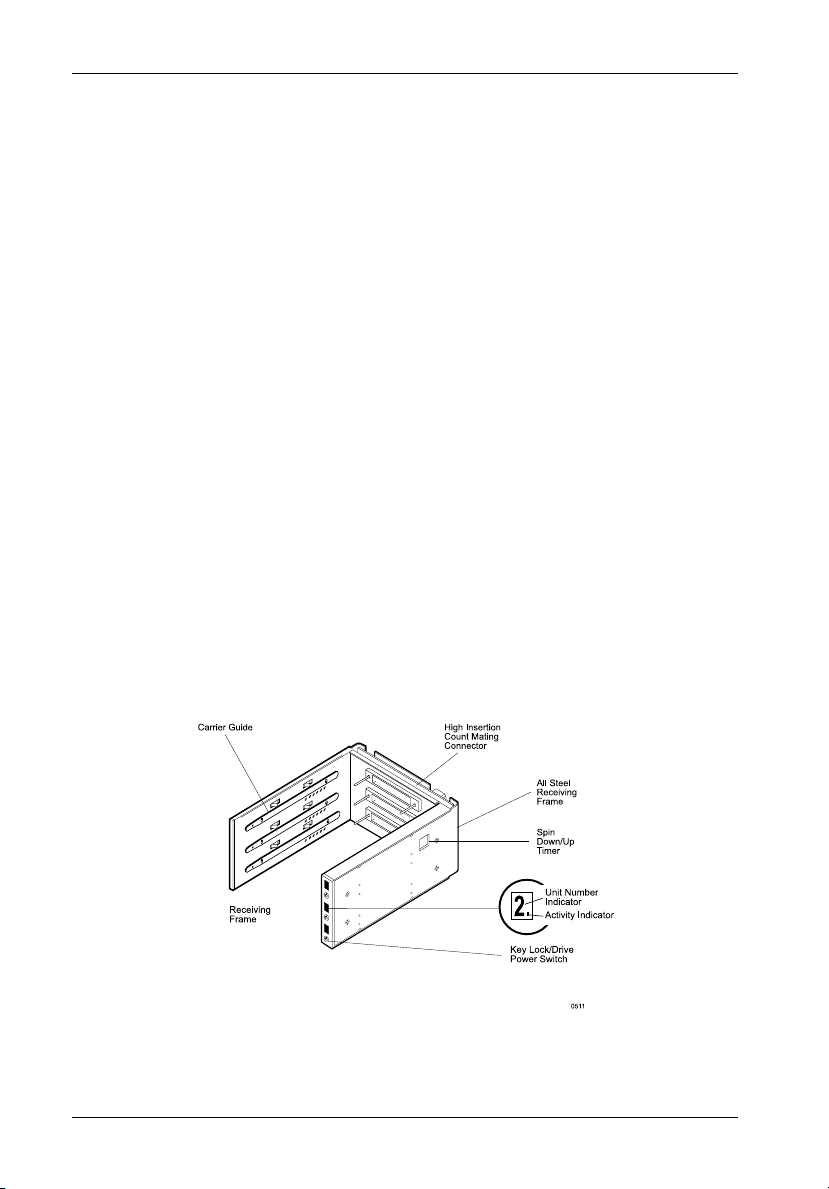

ReceivingFrameFrontPanel

(Figure 3)

Key Lock/Drive Power Switch- This key switch assures proper seating of the

drive carrier within the receiving frame, turns power to the drive carrier on and off,

and prevents unauthorized removal or installation of the carrier. For the computer

to access data on the DE300 drive, the key must be turned counterclockwise to the

locked position. The key can be configured as either fixed or removable as shown

in Appendix C.

Unit ID Number Indicator- This LED displays the physical address of the DE300

device carrier if the carrier is installed and locked in the receiving frame or if the

carrier is removed from the receiving frame. If the carrier is installed but not locked

in the receiving frame, a "u" will be displayed to indicate an unlocked condition. The

unit ID number is selected by means of the unit ID select switch inside the receiving

frame using a special alignment tool supplied with the DE300 (see Figure 9).

Activity Indicator- A small dot next to the unit ID number illuminates to indicate when

the host computer is accessing the data on the DE300 carrier. This dot will flash

during communication with the host computer.

Device Spin Down/Up Timer- This timer controls the length of time that the activity

indicator flashes during device spin down/up, providing a visual indication of drive

activity. Refer to Figure 10 for timer settings.

Figure 3: Receiving Frame Front Panel

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 12

Introduction 5

Figure 4: Receiving Frame Unit ID Number and Activity Display

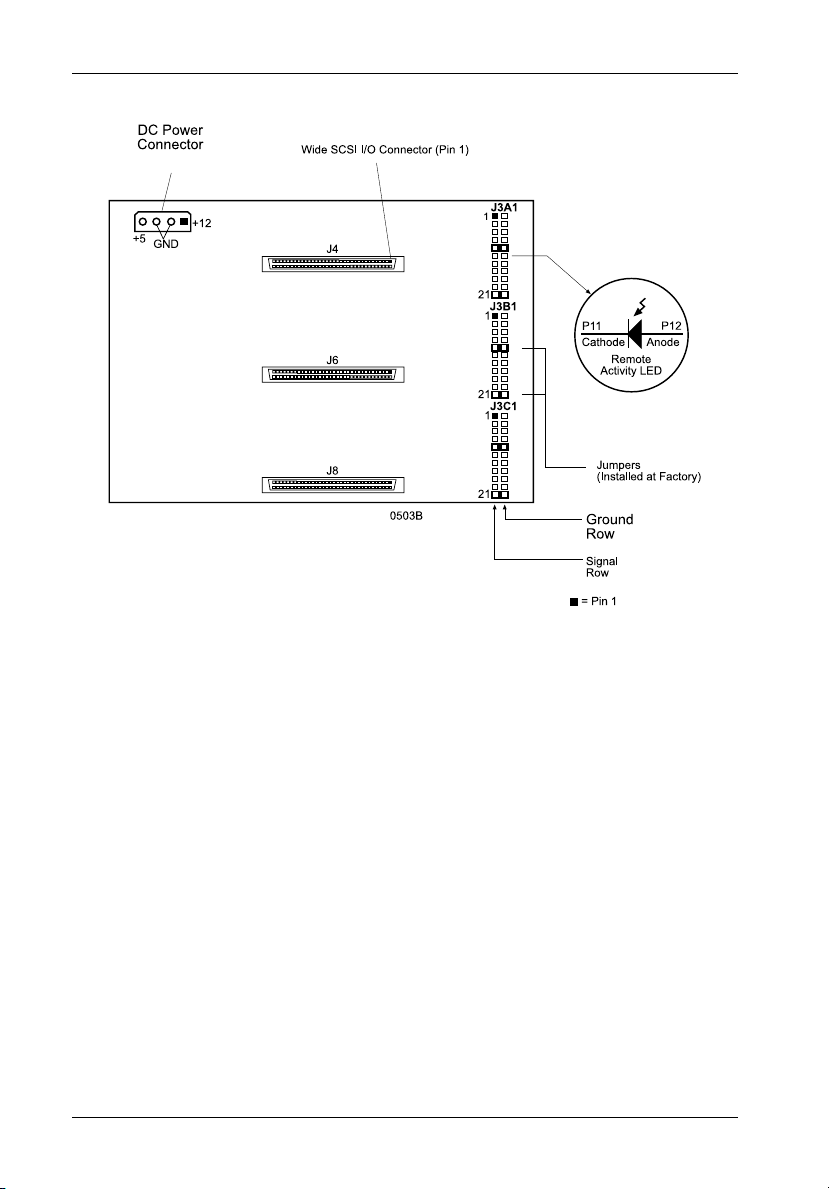

ReceivingFrameRearPanel

(Figure 5)

I/O Connectors (J4, J6, and J8) - These connectors provide a standard interface for

all SCSI signals.

DC Power Connector - A standard 4-pin DC power connector is used to accept DC

power.

ID Select Connectors (J3A1, J3B1, and J3C1) - Pins 1-8 of these connectors provide

unit SCSI ID selection for the computer system or expansion chassis. For remote ID

selection through an expansion chassis, an appropriate cable must be attached to these

pins and the unit ID must be set to "0". The unit ID can be set with a rotating switch located

inside the receiving frame (Figure 9).

Remote Activity LED (RLED) - These pins provide power for a remote LED device

activity indicator (Pin 11=Cathode, Pin 12=Anode).

Jumpers - These jumpers were installed at the factory. Do not remove!

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 13

6 Introduction

Figure 5: Receiving Frame Motherboard (Rear View)

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 14

Installation 7

INSTALLATION

InstallingtheDriveintotheCarrier

Preparation

While performing the steps in this section, work on a soft surface to prevent excessive shock

to the drive being installed. Also refer to the manufacturer's documentation provided with the

drive.

NOTE: A #2 Phillips screwdriver will be required during this procedure.

1. Remove the drive from its protective packaging.

2. Plastic Drive Bezel: If the drive came equipped with a plastic front bezel,

remove it.

3. SCSI Drive Termination: The DE300 does not provide onboard termination.

External termination must be provided. Refer to the documentation provided by

the drive manufacturer for termination information.

4. ID Select Jumpers: Locate the ID select jumper positions on the drive, and

remove any jumper plugs in this area (the S20A120 drive carrier board will plug

into this section of the drive).

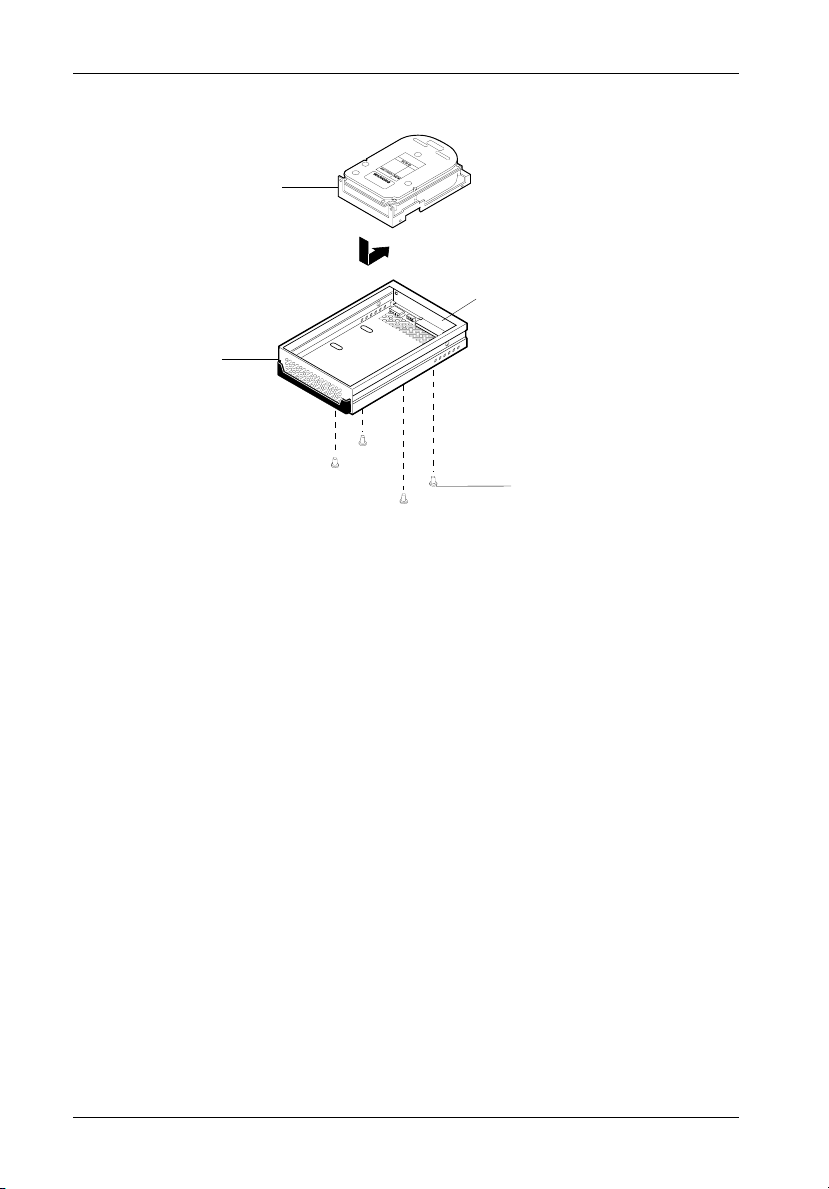

Installation

1. Carefully insert the drive into the carrier. Slide the drive towards the Drive

Carrier Board, so that the I/O, DC power, and ID select connectors on the drive

mate with their respective connectors on the drive carrier board (Figure 6).

NOTE: The S20A120 carrier supports most 68-pin SCSI Ultra160 interfaces, except

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Fujitsu Alegro6 10K RPM drives (these drives have different spacing between

the 68-pin and DC power connectors and will not mate with the drive carrier

board).

2. Fasten the drive into place with four (4) #6-32 Phillips Flat Hd. screws (Figure

6).

Page 15

8 Installation

Drive

(Not Included)

Drive Carrier

Board

Drive

Carrier

0512b

#6-32 x 3/16 Phillips

Flat Head Screw

Figure 6: Drive Installation Assembly

(4 each)

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 16

Installation 9

InstallingtheReceivingFrame

NOTE: For SCSI Ultra160 operation, the DE300 requires Ultra160 chassis and cabling.

The drive should be installed into the carrier before installing the receiving frame into the

mounting bay of a computer or expansion chassis.

NOTE: Use a #2 Phillips screwdriver during this procedure.

1. Turn OFF power to the computer.

2. Open the computer system according to the manufacturers instructions. If

necessary, temporarily remove any expansion boards that may make installation

difficult.

3. To select the DE300 unit ID remotely through the computer system or external

expansion chassis, the appropriate cable from the system must be connected to

option pins (1-8 on connectors J3A1, J3B1, J3C1) on the rear of the receiving frame

(Figure 7 and Table 1). Set the unit ID to "0" for remote ID selection (Figure 9).

Figure 7: Receiving Frame Motherboard J3A1, J3B1, J3C1 Option Pin Connector

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 17

10 Installation

Table 1: J3A1, J3B1, J3C1 Option Pin Signal Descriptions

PIN Signal Function

1 ID0 SCSI ID

2 GND Ground

3 ID1 SCSI ID

4 GND Ground

5 ID2 SCSI ID

6 GND Ground

7 ID3 SCSI ID

8 GND Ground

9 GND Drive Synchronization Signal

10 GND Spare Ground

11 RLEDC Remote LED Cathode

12 RLEDA Remote LED Anode

13 DFAULT Force Drive Fault Signal to Display

14 GND Ground

15 CIF1 Reserved

16 GND Ground

17 CIF2 Reserved

18 GND Ground

19 CIF3 Reserved

20 GND Ground

21 LKA Disable Isolator Functions

22 LKB Disable Isolator Functions

IMPORTANT NOTE: In order to use remote ID selection from a computer or expansion

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

chassis, the Unit ID number on the Data Express receiving frame

must be set to "0" with the provided alignment tool. Refer to the

section "Selecting the Unit ID Number" later in this manual for the

Unit ID selection procedure.

Page 18

Installation 11

4. With the drive carriers locked into place inside the receiving frame, install the DE300

receiving frame into the drive opening in the computer or expansion chassis. Use the

appropriate guides to position the DE300, and fasten it into place with eight (8) #6-32

Phillips screws provided. Figure 8 illustrates the location of the mounting holes.

Mounting holes are provided on each side and the bottom of the receiving frame to

accommodate a variety of mounting configurations. Use the mounting holes which best

suit the computer or expansion chassis configuration.

Front of Unit

Mounting

Holes

(Right)

0520

Mounting

Holes

(Bottom)

Figure 8: Receiving Frame Mounting Holes

5. Adjust the front of the receiving frame so the carrier slides freely in and out on the

receiving frame guides. The position of adjoining peripheral units may require

adjustment.

6. To connect a drive to a remote activity LED in the computer system or expansion chassis,

connect the appropriate cable(s) to the receiving frame motherboard connectors J3A1,

J3B1, and J3C1 Pins 11 & 12 as shown in Figure 5.

7. Connect the I/O cable from the host adapter to the receiving frame. The Pin 1 indicator

on the cable must be properly aligned. Refer to Figure 5 for the correct Pin 1 location.

NOTE: No onboard termination is provided on the DE300. External termination

must be provided.

9. Connect the power cable from the DC power supply in the computer or expansion

chassis to the power connector on the DE300 receiving frame. Refer to Figure 5 for

the DE300 receiving frame power connector location.

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 19

12 Installation

9. Replace any expansion boards that may have been removed earlier. Replace the

system cover according to the manufacturers instructions.

10. Reconnect any system or peripheral cables removed earlier.

11. If the DE300 has been installed into an external expansion chassis, connect the SCSI

and power cables to the chassis. If the expansion chassis is at the end of a daisy

chain, make certain that it is properly terminated. Refer to the computer system and

expansion chassis manuals for further information. Turn ON the expansion chassis

power before turning on the computer system power.

12. Turn ON power to the computer. If the installation has been successful, and all cables

have been properly attached, the system should boot normally. Although the

computer may not recognize the DE300 yet, the appropriate front panel LED indicators

on the DE300 should illuminate. If the system does not boot properly, there could be

a SCSI ID conflict. Refer to the following section "Selecting the Unit ID Number".

NOTE: The lock on the DE300 receiving frame functions as a lock and a DC power

switch for the carrier unit. The lock must be engaged (turned counterclockwise)

in order to supply power to the carrier and installed drive unit.

13. The new drives may need to be formatted or initialized prior to use with the operating

system and applications software. Additionally, an appropriate driver may need to

installed for the host controller to recognize the newly installed device. Refer to the

drive and/or computer manufacturer's documentation for formatting information.

Refer to the host controller instructions for driver

information.

SelectingtheUnitID Number

Each SCSI device on the computer system requires a separate SCSI ID number.

16-bit SCSI interface protocol permits 16 (0-15) unique SCSI ID numbers. Usually, ID7 is

reserved for the host controller. If the computer system has any internal or external SCSI

devices, some ID numbers may already be reserved. For instance, if the computer system

is already equipped with an internal SCSI hard drive, the drive may be designated as SCSI

device "0". Refer to the computer system documentation for additional information.

1. Verify that power is turned on to the DE300 receiving frame by turning on the computer

or external expansion chassis. A number should appear in the unit ID display window

if the carrier is locked into place.

2. Unlock the DE300 carrier from the receiving frame. The unit ID number will begin

flashing, indicating that the drive is spinning down. The length of time that the unit ID

number flashes is controlled by a small timing switch located on the side of the receiving

frame. Refer to Figure 10 for the location of the Device Spin Down/Up Timer on the

receiving frame. A "u" will be displayed once the drive has completed spin down and

is ready to be removed from the receiving frame. The indicator will return to the SCSI

ID number when the carrier is removed from the receiving frame.

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 20

Installation 13

WARNING: Unlocking the carrier unit switches DC power off to the drive.

3. Use the alignment tool supplied with the DE300 to select the ID number of the disk drive.

Refer to Figure 9 for the location of the ID select switch inside the receiving frame.

WARNING: Selecting an invalid ID number, or selecting the same unit ID

4. After selecting an appropriate unit ID number, replace the DE300 carrier in the receiving

frame, and LOCK IT IN PLACE.

5. The new drive may need to be formatted or initialized prior to use with the operating

system and applications software. Refer to the drive and/or computer manufacturer's

documentation for formatting information.

Since drives require a short amount of time to spin down, allow

at least 15 seconds before pulling the carrier unit out of the

receiving frame to avoid possible damage to the drive.

number on different devices may cause unpredictable results

and the computer system may not recognize the installed

device(s). If the computer system can not recognize the boot

disk, the computer system may fail to start-up properly.

Figure 9: Unit ID Select Switch Location

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 21

14 Installation

Adjusting the Spin Down/Up Timer

NOTE: The timer for device spin down is controlled by a small selector, located in a cutout

on the side of the DE300 receiving frame as shown in Figure 10. The amount of

time required for a drive to spin down is approximately 15 seconds or more. This

number can vary depending on the type of SCSI device and manufacturer (some

drives may require 45 seconds or more). The factory configuration is set for 20

seconds. A different delay time may be selected with the provided alignment tool.

Refer to the SCSI device manufacturers manual for more information on required

device spin down time.

Spin Down/Up Time

0 = 10 SECONDS 8 = 50 SECONDS

1 = 15 SECONDS 9 = 55 SECONDS

2 = 20 SECONDS A = 60 SECONDS

3 = 25 SECONDS B = 65 SECONDS

4 = 30 SECONDS C = 70 SECONDS

5 = 35 SECONDS D = 75 SECONDS

6 = 40 SECONDS E = 80 SECONDS

7 = 45 SECONDS F = 85 SECONDS

0445

C

E

A

0

2

4

6

8

Front of

Receiving

Frame

Figure 10: Device Spin Down/Up Timer Switch

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 22

Appendix A - Specifications/Dimensions 15

APPENDICES

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 23

16 Appendix A - Specifications/Dimensions

Appendix A - Specifications/Dimensions

SCSI Data Express subsystems conform to the Small Computer Systems Interface (SCSI)

Standard set by the American National Standards Institute (ANSI).

Environmental Specifications

Operating Storage

Ambient Temperature 0° C to 50° C -45° C to 75° C

Relative Humidity

Altitude -1000 to 50,000 ft -1000 to 50,000 ft

(2)

Shock

(1)

Non-condensing with maximum gradient of 10% per hour.

(2)

11 msec pulse width 1/2 sine wave.

Physical

Specifications Carrier Receiving Frame

Height 1.07" (27.2mm) 3.38" (85.9mm)

Width 4.67" (118.5mm) 5.88" (149.2mm)

Depth 7.38" (187.4mm) 8.15" (207mm)

Weight 1.3lb (0.59kg) 2.4lb (1.09kg)

(1)

With carrier removed.

(1 )

10% to 80% 10% to 90%

-304m to 15240m -304m to 15240m

10g 60g

(2)

Chassis Reliability/Maintainability

MTBF 500,000 Hours

MTTR 5 Minutes

Preventive

Maintenance None

Electrical Specifications

Input +5V 200mA

+12V 1.2mA

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 24

Appendix A - Specifications/Dimensions 17

Receiving Frame

with Carriers

Installed

2.06

(52.3mm)

3.13

(79.2mm)

3.38

(85.9mm)

Carrier

Only

1.07

(27.2mm)

5.88

(149.2mm)

4.67

(118.5mm)

5.50

(139.7mm)

0.32

(8.1mm)

8.15

(207.0mm)

3.13

(79.2mm)

7.38

(187.4mm)

4.70 (11.9mm)

1.25 (31.8mm)

0.39 (9.9mm)

#6-32 x 8

(Side)

(3.8mm)

#6-32 x 4

(Bottom)

0.25

(6.3mm)

4.70 (11.9mm)

0.15

3.75

(95.3mm)

1.75

(44.5mm)

0522b

Figure A-1: DE300 Physical Dimensions

(Dimensions are for reference only)

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 25

18 Appendix B - Factory-Installed Options

Appendix B - Factory-Installed Options

Data Express Ultra160 Repeater Board

The Data Express Ultra160 Repeater Board (P/N S20A130) is an upgrade attachment for the

S20A120 (cable-less 68-pin DE300) receiving frame (Figure B-1). This attachment provides

a repeater function, as described below.

Repeater Function

Specifically in LVD/Single-Ended implementations, unknown system components and their

combinations may produce impedance mismatches, excessive capacitance loading and/or

noise interference within the system, potentially introducing intermittent incompatibility issues.

To minimize these unpredictable effects caused by varying system specifications, StorCase

recommends the Data Express Repeater Board on all Ultra160 Data Express receiving frames.

This Repeater Board provides a signal repeater function that allows the Data Express drive

enclosure to contribute to improved signal quality to and from the drive.

For more information and data, please refer to the Repeater Board Benefits and Downward

Compatibility technical papers on our web site at: http://www.storcase.com/tools

Attaching the Repeater Board

The S20A120 may be purchased with the Repeater Board factory-installed. If the board has

not already been attached to the S20A120 receiving frame, follow the instructions below to

add the board.

NOTE: The device carriers should be locked into the receiving frame prior to the

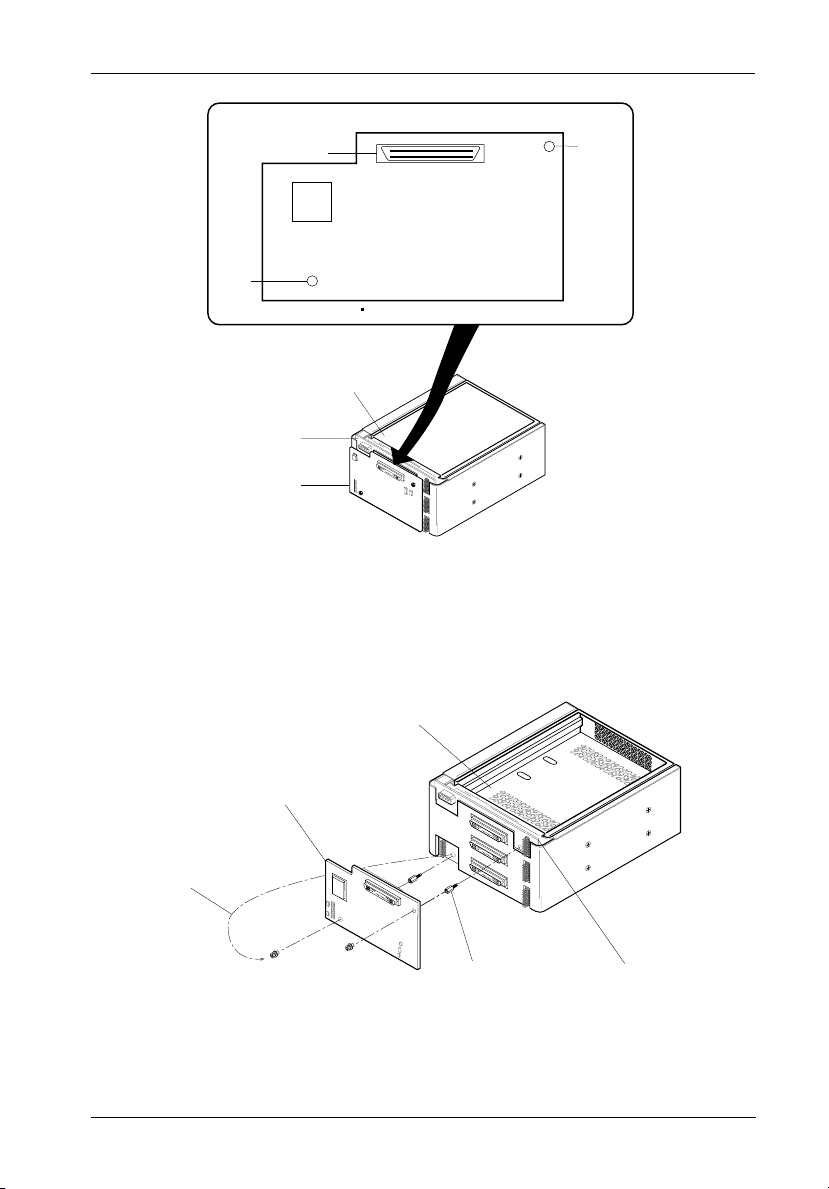

1. Remove the two (2) screws from the receiving frame motherboard and set aside (Figure

B-2).

2. Attach the two (2) stand -offs (provided) to the mounting holes on the receiving frame

motherboard.

4. Carefully align the connectors of the repeater board with the connectors on the

receiving frame motherboard and gently push the board into position. Make certain that

all connectors are properly mated.

5. Secure the board to the receiving frame stand-offs with the same two (2) screws from

Step 2 (Figure B-2).

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

following procedure to maintain proper connector alignment between the

receiving frame and the device carriers.

Page 26

Appendix B - Factory-Installed Options 19

S20A130

I/O Connector

Mounting

Hole

DE300

Receiving Frame

Motherboard

Repeater Board

(Installed)

Carriers

(Installed)

Repeater Board Detail

= Pin 1

Mounting

Hole

0518b

Figure B-1: DE300 Repeater Board Details

Carriers

Installed

Repeater

Board

Remove Mounting

Screws and use to

Fasten Repeater

Board (2 plcs)

Stand-offs

(Replace Motherboard

Mounting Screws)

Receiving Frame

Motherboard

0480b

Figure B-2: Attaching the Repeater Board

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 27

20 Appendix C - Attaching the ON/OFF Key

Appendix C - Attaching the ON/OFF Key

The following information will provide the necessary steps to attach the ON/OFF key to the

key lock mechanism so that it is non-removable, preventing accidental key loss. The procedure

can be reversed at a later date to revert back to a removable key.

1. Make certain power is off to the receiving frame.

Locate the rectangular-shaped key lock mechanism access hole on the inside of the receiving

frame. Note that the pawl is in an upright position.

Insert the key into the key lock.

2. Rotate the key 90 degrees counterclockwise so

that the pawl is visible in the access hole as

shown in the figure at left.

3. Using the provided alignment tool, unscrew and

remove the pawl from the access hole.

4. Rotate the key 180 degrees clockwise.

5. Reinstall the pawl into the access hole with the

alignment tool.

Your key is now attached to the key lock mechanism.

Figure C-1: Attaching the ON/OFF Key

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 28

Appendix D - Optional Accessories 21

Appendix D - Optional Accessories

Carrying Case

Drive

Carrier

Remove this

Piece of Foam

0524a

DX300-DE-C

Carrying Case

Figure D-1: Carrying Case

The optional molded plastic carrying case is designed to transport the DE300 carrier from one

location to another in a safe, impact and moisture resistant environment. Its compact

dimensions, 7 long x 9 wide x 4 high, make it easy to carry and to store. The foam lining

is contoured to fit a single Data Express carrier with a 1-inch form factor. Contact StorCase

for further details and ordering information.

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 29

22 Appendix D - Optional Accessories

This Page Left Blank Intentionally.

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Page 30

Reader's Comments 23

Reader's Comments

Please take a few moments when your computer system is up and running to send us your

ideas and suggestions for improving our products and documentation. Did the installation go

smoothly for you? Are there any changes you would like us to make, either with the hardware

itself, or with the installation instructions? Everyone at StorCase Technology is working

toward the goal of providing you with the highest quality, most cost effective, products

available on the market, and we need your comments to guide our efforts. We look forward

to hearing from you soon!

Date:

Your Name:

Address:

Telephone: ( )

To mail this page, carefully remove it from the manual, fold it, staple or tape it shut, and drop

it in the mail. To FAX this page, carefully remove it from the manual (or make a photocopy) and

FAX it to us at (714) 438-1847. Thank you for taking the time to help us make our products

better!

S20A120 User's Guide - Rev. A01 StorCase Technology, Inc.

Page 31

24 Reader's Comments

FOLD ALONG THIS LINE AND STAPLE SHUT

NO POSTAGE

NECESSARY

IF MAILED

IN THE

UNITED STATES

CUT ALONG THIS LINE FROM BOTTOM TO TOP OF PAGE

BUSINESS REPLY MAIL

FIRST CLASS MAIL PERMIT NO. 10686 SANTA ANA, CA

POSTAGE WILL BE PAID BY ADDRESSEE

TECHNOLOGY CORPORATION

17600 NEWHOPE STREET

FOUNTAIN VALLEY CA 92708-9885

StorCase Technology, Inc. S20A120 User's Guide - Rev. A01

Loading...

Loading...