RA7000 and ESA10000

Storage Subsystems

User's Guide

EK–SMCPP–UG. A01

Digital Equipment Corporation

Maynard, Massachusetts

First Edition, July 1997

The information in this document is subject to change without notice and should not be

construed as a commitment by Digital Equipment Corporation. Digital Equipment

Corporation assumes no responsibility for any errors that may appear in this document.

Restricted Rights: Use, duplication, or disclosure by the U.S. Government is subject to

restrictions as set forth in subparagraph (c) (1) (ii) of the Rights in Technical Data and

Computer Software clause at DFARS 252.227-7013.

Digital Equipment Corporation does not give a warranty of any kind regarding the

fitness or applicability of the information content for a particular purpose. The user

assumes all responsibility for understanding the interrelationships of this enclosed

information with other affected software or system products.

The disclosure of this information does not grant to the user a license under any patents,

pending patents, trademarks, or copyrights or other rights of Digital Equipment

Corporation, or of any third party.

FCC Notice: This equipment generates, uses, and may emit radio frequency energy.

The equipment has been type tested and found to comply with the limits for a Class A

computing device pursuant to Subpart J of Part 15 of FCC Rules, which are designed to

provide reasonable protection against such radio frequency interference when operated

in a commercial environment. Any changes or modifications made to this equipment

may void the user's authority to operate the equipment. Operation of this equipment in a

residential area may cause interference, in which case the user, at his own expense, may

be required to take measures to correct the interference.

UNIX is a registered trademark in the United States and other countries, licensed

exclusively through X/Open Company, Ltd.

Microsoft is a registered trademark and Windows and Windows NT are trademarks of

Microsoft Corporation.

All other trademarks and registered trademarks are the property of their respective

owners.

DIGITAL, the DIGITAL logo, and StorageWorks are trademarks of Digital Equipment

Corporation.

Copyright © Digital Equipment Corporation 1997 All Rights Reserved

Printed in U. S. A

Contents

Revision Record

About This Guide

........................................................................................................ ix

...................................................................................................... xi

1 Product Description

1.1 Subsystem Overview................................................................................................. 1–1

1.2 Major Components.................................................................................................... 1–4

1.2.1 HSZ70 RAID Array Controllers............................................................................. 1–5

1.2.2 SCSI Buses............................................................................................................ 1–6

1.2.3 Single-Ended I/O Module (SE I/O)........................................................................1–7

1.2.3.1 Expanding the UltraSCSI Bus..............................................................................1–8

1.2.3.2 Controlling the Internal SCSI Bus....................................................................... 1–9

1.2.3.3 Controlling the External SCSI Bus...................................................................... 1–9

1.2.3.4 Controlling the Fault Bus.................................................................................... 1–9

1.2.3.5 “Warm Swapping” I/O Modules and Cables ....................................................... 1–9

1.3 Error Detection and Reporting.................................................................................1–10

1.3.1 Fault Bus............................................................................................................. 1–10

1.3.2 Environmental Monitor Unit (EMU).................................................................... 1–11

1.3.2.1 Controller Status............................................................................................... 1–11

1.3.2.2 I/O Module Status............................................................................................. 1–12

1.3.2.3 Enclosure Configuration Information................................................................ 1–12

1.3.2.4 EMU Front Panel.............................................................................................. 1–13

1.3.3 Power Verification and Addressing (PVA) Module.............................................. 1–15

1.3.3.1 Monitoring Power Supply Operation................................................................. 1–16

1.3.3.2 Master Enclosure Controlled Power Shutdown ................................................. 1–17

1.3.3.3 Expansion Enclosure Initiated Power Shutdown................................................ 1–18

1.3.3.4 PVA UPS (Uninterruptable Power Supply) Options.......................................... 1–19

1.4 Storage Device SBBs............................................................................................... 1–19

1.5 Power Configuration................................................................................................ 1–20

1.5.1 AC Power Entry Controllers................................................................................ 1–20

1.6 Power Supply SBBs................................................................................................. 1–22

1.7 Standard (4 + 1) Power Configuration ..................................................................... 1–23

1.8 Redundant (4 + 4) Power Configuration................................................................... 1–25

1.9 ECB SBBs............................................................................................................... 1–26

EK–SMCPP–UG. A01 iii

RA7000 nd ESA10000 Storage Subsystems

1 Product Description (continued)

1.10 Subsystem Cooling................................................................................................ 1–28

1.11 Setting the PVA SCSI Address.............................................................................. 1–30

1.11.1 DIGITAL Supported Master PVA Address........................................................ 1–31

1.11.2 DIGITAL Supported Expansion PVA Addresses................................................ 1–32

1.11.3 Non-Supported PVA SCSI Bus Addresses ......................................................... 1–32

2 Unpacking and Installation for the RA7000 and ESA10000 Storage Subsystems

2.1 Installing the RA7000................................................................................................ 2–1

2.1.1 Site Preparation..................................................................................................... 2–2

2.1.2 Unpacking the RA7000 Subsystem Enclosure........................................................ 2–2

2.1.3 Removing the RA7000 from the Pallet ..................................................................2–3

2.1.4 Placing the RA7000 Storage Enclosure.................................................................. 2–5

2.1.5 Connecting the Enclosure to the Host .................................................................... 2–5

2.2 Installing the ESA10000............................................................................................ 2–6

2.2.1 Site Preparation..................................................................................................... 2–6

2.2.2 Unpacking the ESA10000 Subsystem Enclosure....................................................2–7

2.2.3 Removing the ESA10000 from the Pallet............................................................... 2–9

2.2.4 Moving the ESA10000 to It’s Designated Site..................................................... 2–13

2.2.5 Joining Adjacent ESA10000’s ............................................................................. 2–13

2.2.6 Leveling the Cabinet............................................................................................ 2–16

2.3 Installing Additional Components ........................................................................... 2–16

2.3.1 Installing the BA370 Rack-Mountable Enclosure................................................. 2–16

2.4 Cabling a Master Enclosure to an Expansion Enclosure(s) ....................................... 2–24

2.4.1 Cabling Sequence................................................................................................ 2–24

2.4.2 Attaching the SE I/O Cables................................................................................ 2–24

2.4.2.1 Single Expansion Unit...................................................................................... 2–25

2.4.2.2 Two Expansion Units........................................................................................ 2–26

2.4.3 Attaching the EMU Communications Cable......................................................... 2–27

2.4.4 Setting the PVA Addresses.................................................................................. 2–28

2.5 Connecting SCSI Bus Cables to the ESA10000........................................................ 2–30

2.6 Installing SBBs........................................................................................................ 2–32

2.6.1 Installing SBB Disk Drives.................................................................................. 2–32

2.6.2 Installing SBB Power Supplies............................................................................ 2–34

2.6.3 Installing the AC Input Power Controller............................................................. 2–35

2.6.4 Installing the External Cache Battery (ECB) ........................................................ 2–36

3 Configuring the Storage Cabinet

3.1 Configuring the EMU................................................................................................3–1

3.1.1 Connecting the EMU Communications Bus........................................................... 3–2

3.1.2 Setting the Temperature Sensors............................................................................ 3–2

3.1.3 Setting the Blower Speed Control.......................................................................... 3–3

3.1.4 Alarm Control Switch............................................................................................ 3–4

iv EK–SMCPP–UG. A01

4 Error Analysis and Fault Isolation

4.1 Storage Subsystem Error Reporting........................................................................... 4–1

4.2 EMU Error and Fault Status Reporting...................................................................... 4–4

4.3 EMU Subsystem Status LEDs.................................................................................... 4–5

4.3.1 EMU System Fault Code Displays......................................................................... 4–8

4.3.2 Controlled Power Shut Down............................................................................... 4–13

4.3.3 Automatic Shut Down ......................................................................................... 4–13

4.3.4 User-Initiated Master Enclosure Shut Down........................................................ 4–14

4.3.5 User-Initiated Expansion Enclosure Shut Down................................................... 4–15

4.4 Controller Error Conditions..................................................................................... 4–16

4.5 Storage Device Fault Notification............................................................................ 4–16

4.6 Power Supply Fault Notification.............................................................................. 4–18

4.7 I/O Module Error Reporting .................................................................................... 4–19

4.7.1 Incompatible I/O Modules................................................................................... 4–19

4.7.2 No I/O Module Installed...................................................................................... 4–19

4.7.3 TERMPOWER Errors.......................................................................................... 4–19

5 Replacing Components

5.1 Replacing a Controller or Cache Module................................................................... 5–1

5.1.1 Tools Required...................................................................................................... 5–1

5.1.2 Precautions............................................................................................................5–1

5.2 Preparing Your Host System...................................................................................... 5–2

5.2.1 Backup the System................................................................................................ 5–2

5.2.2 Shut Down the System........................................................................................... 5–2

5.3 Controller Module Removal...................................................................................... 5–2

5.4 Cache Module Removal............................................................................................. 5–5

5.5 Replacing an SBB Storage Device............................................................................. 5–6

5.5.1 Replacement Method.............................................................................................5–7

5.5.2 Before You Replace a Storage SBB....................................................................... 5–7

5.5.3 SBB Replacement.................................................................................................. 5–7

5.6 Replacing Storage Subsystem Blowers...................................................................... 5–9

5.7 Replacing a Power Supply SBB............................................................................... 5–11

5.8 Replacing a Power Entry Controller......................................................................... 5–12

5.9 Replacing an EMU.................................................................................................. 5–13

5.10 Replacing a PVA................................................................................................... 5–14

5.11 FRU Parts List....................................................................................................... 5–15

Contents

Reader Comment Form

EK–SMCPP–UG. A01 v

...................................................................Inside Back Cover

RA7000 nd ESA10000 Storage Subsystems

Figures

Figure 1–1 BA370 Rack Mountable Enclosure............................................................... 1–1

Figure 1–2 RAID 7000 Enclosure................................................................................... 1–2

Figure 1–3A ESA10000 Storage Cabinet (Shown with two BA370 Rack Mountable

Enclosures in one cabinet)...................................................................................... 1–2

Figure 1–3B ESA10000 Storage Cabinet (Shown with three BA370 Rack Mountable

Enclosures in two cabinets).................................................................................... 1–3

Figure 1–4 Configured BA370 Rack Mountable Unit Major Components....................... 1–4

Figure 1–5 HSZ70 Controller and Cache Modules.......................................................... 1–5

Figure 1–6 SCSI Buses................................................................................................... 1–6

Figure 1–7 Single-Ended I/O Module Location .............................................................. 1–7

Figure 1–8 Single-Ended I/O Module.............................................................................1–8

Figure 1–9 Environmental Monitor Unit (EMU)........................................................... 1–13

Figure 1–10 Power Verification and Addressing (PVA) Module................................... 1–15

Figure 1–11 Disk Drive SBB........................................................................................ 1–19

Figure 1–12 AC Power Entry Controller....................................................................... 1–21

Figure 1–13 Typical Shelf Power Supply SBB.............................................................. 1–22

Figure 1–14 Standard Power Configuration (4 + 1)....................................................... 1–24

Figure 1–15 Redundant Power Configuration (4 + 4).................................................... 1–25

Figure 1–16 External Cache Battery (ECB) SBB.......................................................... 1–26

Figure 1–17 Cache-to ECB-Connection........................................................................ 1–28

Figure 1–18 Dual Speed Blower Locations................................................................... 1–29

Figure 1–19 Enclosure SCSI Address Switch................................................................ 1–30

Figure 1–20 Enclosure SCSI Bus Addresses for all SBB Device IDs............................ 1–31

Figure 2–1 RA7000 Minimum Installation Clearance Measurements.............................. 2–1

Figure 2–2 Unpacking the RA7000 Storage Enclosure.................................................... 2–3

Figure 2–3 Installation of Ramp on Shipping Pallet........................................................ 2–4

Figure 2–4 Minimum Installation Clearance Measurements ........................................... 2–6

Figure 2–5 Shipping Container Contents ........................................................................ 2–7

Figure 2–6 Shipping Pallet Ramp Installation............................................................... 2–10

Figure 2–7 Shipping Bolts and Brackets....................................................................... 2–11

Figure 2–8 Removing the Cabinet from the Pallet ....................................................... 2–12

Figure 2–9 Leveler Foot Adjustment............................................................................ 2–16

Figure 2–10 Mounting Rail Orientation........................................................................ 2–18

Figure 2–11 Rail Installation into Cabinet.................................................................... 2–19

vi EK–SMCPP–UG. A01

Figures (continued)

Figure 2–12 ECB Position............................................................................................ 2–20

Figure 2–13 Installing ECB Y-Cables........................................................................... 2–20

Figure 2–14 Attaching Mounting Brackets to the BA370.............................................. 2–21

Figure 2–15 SE I/O Port Identification......................................................................... 2–24

Figure 2–16 SE I/O Port Wiring (One Expansion Unit) ................................................ 2–25

Figure 2–17 SE I/O Connections for Two Expansion Units........................................... 2–26

Figure 2–18 EMU Front Panel...................................................................................... 2–27

Figure 2–19 Multiple EMUs Connected Together......................................................... 2–27

Figure 2–20 PVA Module Front Panel.......................................................................... 2–28

Figure 2–21 Expansion Enclosure SCSI Bus Addresses................................................ 2–29

Figure 2–22 SCSI Bus Cabling for the ESA10000........................................................ 2–31

Figure 2-23 Installing Power Supply SBB (4+4 Shown) ............................................... 2–34

Figure 2–24 Installing the External Cache Batteries ..................................................... 2–36

Figure 4–1 Storage Subsystem Status LEDs ................................................................... 4–2

Figure 4–2 EMU Front Panel Layout.............................................................................. 4–4

Figure 4–3 Typical Controller OCP Display................................................................. 4–16

Figure 4–4 Storage SBB LEDs..................................................................................... 4–17

Figure 4–5 Power Supply SBB Status LEDs................................................................. 4–18

Figure 4–6 I/O Module LEDs....................................................................................... 4–20

Figure 5–1 HSZ70 Controllers and Cache Modules........................................................ 5–3

Figure 5–2 Trilink Connector......................................................................................... 5–4

Figure 5–3 Cache Module Replacement ......................................................................... 5–5

Figure 5–4 SBB Identification Label.............................................................................. 5–6

Figure 5–5 SBB Replacement......................................................................................... 5–9

Figure 5–6 Blower Replacement................................................................................... 5–10

Figure 5–7 Power Supply SBB Replacement................................................................ 5–11

Figure 5–8 Power Entry Controller Replacement......................................................... 5–12

Figure 5–9 EMU Module Replacement......................................................................... 5–13

Figure 5–10 PVA Module Replacement....................................................................... 5–14

Figure 5–11 Storage Cabinet Field Replaceable Parts (RA7000 Shown)....................... 5–16

Contents

EK–SMCPP–UG. A01 vii

RA7000 nd ESA10000 Storage Subsystems

Tables

Table 1–2 EMU Front Panel Component Descriptions.................................................. 1–14

Table 1–2 Storage Subsystem Major Power Components ............................................. 1–20

Table 1–3 ECB Status Indications ................................................................................ 1–27

Table 1–4 Expansion Enclosure Address Combinations............................................... 1–32

Table 2–2 Installing Rails for the Upper BA370........................................................... 2–18

Table 2–3 Installing Rails for the Lower BA370........................................................... 2–18

Table 2–5 Expansion Enclosure Address Combinations............................................... 2–28

Table 3–1 EMU Set Point Temperatures......................................................................... 3–3

Table 4–1 Subsystem Status LEDs .................................................................................. 4–3

Table 4–2 EMU Subsystem Status LEDs........................................................................4–5

Table 4–3 EMU LED Displays.......................................................................................4–6

Table 4–4 EMU Fault Code LED Displays..................................................................... 4–9

Table 4–5 Storage SBB Status LED Displays................................................................. 4–7

Table 4–6 Power Supply SBB Status LED Displays ..................................................... 4–18

Table 5–1 RAID Controller Response to an SBB Replacement....................................... 5–8

Table 5–2 Subsystem Field Replaceable Units.............................................................. 5–15

viii EK–SMCPP–UG. A01

Revision Record

This Revision Record provides a concise publication history of this guide. It lists the

manual revision levels, release dates, and summary of changes.

The following revision history lists all revisions of this publication and their effective

dates. The publication part number is included in the Revision Level column, with the

last entry denoting the latest revision.

Revision Level Date Summary of Changes

EK–SMCPP–UG. A01 July 1997 Initial release

EK–SMCPP–UG. A01 ix

About This Guide

This section identifies the users of this guide and describes the contents and st r ucture. In

addition, it includes a list of conventions used in this guide and related documentation.

RA7000 and ESA10000 Storage Subsystems User's Guide

This guide provides a product description, set up, configuration, and maintenance

information for the RAID Array 7000 (RA7000) and the Enterprise Storage

Array 10000 (ESA10000) Storage Subsystems.

Visit Our Web Site for the Latest Information

Check our web for the latest drivers , technical tips, and documentation. We can

be found in the technical area of our web page,

Intended Audience

This guide is intended for users who are responsible for installing, configuring,

and repairing the RA7000 and ESA10000 Storage Subsystems.

Document Structure

This guide contains the following chapters:

http://www.storage.digital.com/

Chapter 1: Product Description

Product Description

ESA10000 Storage Subsystems. It also describes their components, features, and

operating functions.

provides a product overview of the RA7000 and

Chapter 2: Unpacking and Installation

Unpacking and Installation

Chapter 3: Configuring the Storage cabinet

Configuring the Storage Cabinet

communications bus and setting monitoring controls.

EK–SMCPP–UG. A01 xi

describes how to unpack and install the subsystem.

describes how to connect the EMU

RA7000 and ESA10000 Storage Subsystems

Chapter 4: Error Analysis and Fault Isolation

Error Analysis and Fault Isolation

events that may occur during the enclosure's initialization and operation.

describes the errors, faults, and significant

Chapter 5: Replacing Components

Replacing Components

Replaceable Units (FRUs) in the subsystem.

describes the procedures to remove and install the Field

Conventions

This guide uses the following conventions:

Style Meaning

boldface type For emphasis and user input.

italic type

plain monospace type

For emphasis, manual titles, utilities, menus,

screens, and filenames

Screen text.

Related Documentation

For additional information on the RAID controller, refer to the following

StorageWorks documents:

Document Title Document Part Number

CLI Reference Manual EK-CLI70-RM

Configuration Manual EK-HSZ70-CG

Service Manual EK-HSZ70-SV

xii EK–SMCPP–UG. A01

1

Product Description

This chapter describes the RA7000 and ESA10000 Storage Subsystems including the

Ultra Small Computer System Interface (SCSI-3) connections (ports) for StorageWorks

building block (SBB) shelves.

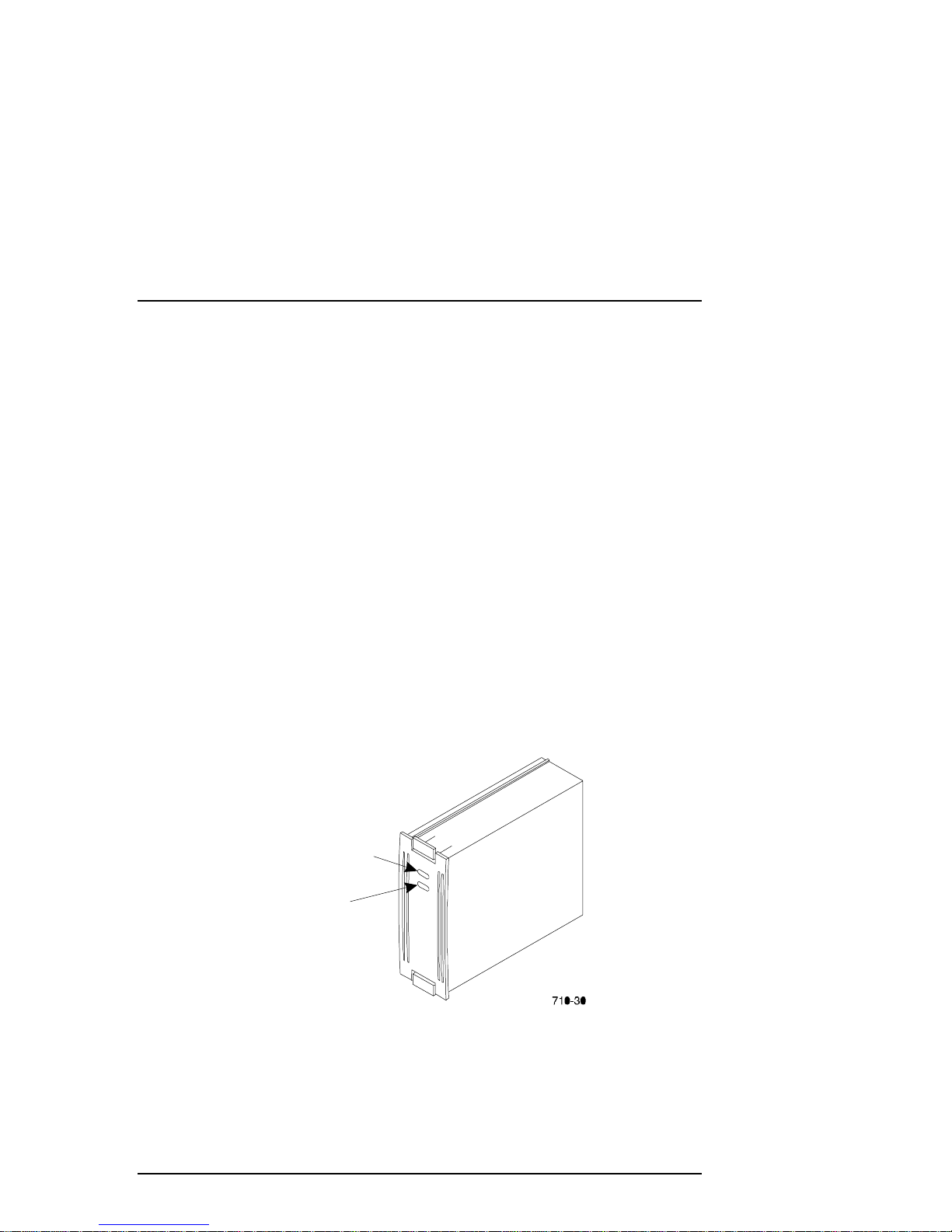

1.1 Subsystem Overview

The RA7000 and ESA10000 Storage Subsystems are members of DIGITAL’s

StorageWorks family of modular enclosures. They share a common major

component, the BA370 Rack Mountable Enclosure (Figure 1-1), that includes an

Environmental Monitor Unit (EMU) and a Power Verification and Addressing

(PVA) module. StorageWorks storage devices, power supplies, controller(s),

cache module(s), External Cache Battery (ECB),and power entry controllers may

also be included. Figures 1-2, 1-3A, and 1-3B show three possible BA370

configurations.

Figure 1–1 BA370 Rack Mountable Enclosure

EK–SMCPP–UG. A01 1–1

CXO5797A

RA7000 and ESA10000 Storage Subsystems

Figure 1–2 RAID 7000 Enclosure

Figure 1–3A ESA10000 Storage Cabinet (Shown with two BA370 Rack

Mountable Enclosures in a sngle cabinet)

1–2 EK–SMCPP–UG. A01

1

0

0

1

0

CXO5828A

Chapter 1. Product Description

Figure 1–3B ESA10000 Storage Cabinet (Shown with three BA370 Rack

Mountable Enclosures in two cabinets)

1

0

0

1

0

0

1

0

CXO5845A

The major features of the BA370 rack mountable enclosure are as follows:

•

StorageWorks compatible

•

Holds up to twenty-four 3½-inch disk drive SBBs per BA370

•

Redundant power distribution to eliminate single points of failure

•

Contains six, single-ended, Ultra Wide SBB backplane SCSI buses

•

No internal SCSI bus cables

•

A StorageWorks HSZ70 RAID array controller that is compatible with the

approved host computer SCSI bus adapters

•

Redundant ac power entry controllers

•

All major components, except the single ended I/O modules and PVA

module, can be replaced using the hot-swap method described in Chapter 5.

•

Fault monitoring and reporting capability for incorrect voltages, shelf

blower failure, power supply failure, and excessive operating temperature.

•

The BA370 may be used as a master or an expansion unit

The master unit contains the controller(s) and

cache module(s). Expansion units contain

additional storage devices on the same SCSI

buses.

•

The 24-SBB RAID Array 7000 storage subsystem and the ESA10000

storage subsystem are Class A FCC certified.

EK–SMCPP–UG. A01 1–3

NOTE

RA7000 and ESA10000 Storage Subsystems

1.2 Major Components

A fully configured redundant subsystem (Figure 1-4) consists of the following

major components:

1) A BA370 Rack mountable enclosure (1)

2) Dual-Speed Blowers (8)

3) Single-Ended I/O Modules (6)

4) Power Verification and Addressing (PVA) Module (1)

5) AC Input Power Controllers (2)

6) Cache Modules (2)

7) HSZ70 SCSI RAID Array Controllers (2)

8) Environmental Monitor Unit (EMU) (1)

9) SBB Power Supplies (8)

10) External Cache Batteries (2)

also:

11) Power Distribution Unit (2)

Figure 1–4 Configured BA370 Rack Mountable Unit Major Components

Not shown, mounted in ESA10000 cabinet only

10

1

9

2

8

7

5

6

4

3

CXO5803A

1–4 EK–SMCPP–UG. A01

Chapter 1. Product Description

1.2.1 HSZ70 RAID Array Controllers

The controller connects a host system to the subsystem and appears as another

SCSI device connected to one of its I/O buses. The controller then processes the

I/O requests to the storage devices of the subsystem. The HSZ70 RAID array

controller(s) mount in the lower front of the cabinet (see Figure 1-5). Installing

two HSZ70 controllers with cache modules provides complete controller

redundancy as described in the

Figure 1–5 HSZ70 Controller and Cache Modules

HSZ70 Service Manual

.

Controllers and Cache modules removed from

control ler card cage for c larit y. Modul es are not a

single unit.

The controller documentation describes procedures for:

Configuring the controller

•

Setting initial controller parameters using a maintenance terminal

•

Determining the proper method for replacing SBBs (hot-swap)

•

The controller software revision level determines the devices supported by the

controller.

EK–SMCPP–UG. A01 1–5

NOTE

RA7000 and ESA10000 Storage Subsystems

1.2.2 SCSI Buses

There are six Ultra Wide SCSI buses associated with the controller. The ports

and device addresses for the master unit are shown in Figure 1-6.

Figure 1–6 SCSI Buses

1–6 EK–SMCPP–UG. A01

Chapter 1. Product Description

The subsystem enclosure supports single-ended, Ultra Wide storage devices. The

configuration rules for the SCSI buses are as follows:

All devices and ports in the same column are on the same SCSI bus or port

•

All devices in the same row (device shelf) have the same device address

•

You may only install controller-compatible Ultra Wide storage SBBs

•

Device addresses 4 and 5 are only used when the SBB has a device address

•

switch

Device addresses are determined by the backplane connector into which the

•

device is inserted unless the SBB has a device address switch

1.2.3 Single-Ended I/O Module (SE I/O)

Figure 1–7 Single-Ended I/O Module Location

EK–SMCPP–UG. A01 1–7

RA7000 and ESA10000 Storage Subsystems

Each SCSI enclosure, whether it is a master or an expansion enclosure, has six

I/O modules mounted at the bottom rear of the enclosure as shown in Figure 1-7.

In all enclosures these modules are the interconnection point between the

controller in the master enclosure and the devices in the expansion enclosures. In

an UltraSCSI RAID subsystem, the I/O modules, the internal SCSI buses, and the

controller ports all have the same number. For example, controller port 2, SCSI

bus 2, and I/O module 2 are different elements of the same bus. The major

features of the single-ended I/O module are described in the following sections.

1.2.3.1 Expanding the UltraSCSI Bus

Each I/O module has an UltraSCSI single-ended bus expansion integrated circuit.

This device isolates the internal and external SCSI bus and extends the length of

the SCSI bus.

Figure 1–8 Single-Ended I/O Module

External

TERM POWER

disable LED

The two VHDCI female connectors are the connection points for expanding the

SCSI buses between enclosures (see Figure 1-8). These connectors are wired in

parallel and act as a tri-link connector. In an expansion configuration, DIGITAL

recommends that maximum cable length not exceed 1.5 m (4.6 ft.) between

enclosures. DIGITAL supplies a cable kit, DS-BNK37-IE, containing the

necessary cables to connect an expansion unit.

1–8 EK–SMCPP–UG. A01

Internal

TERM POWER

disable LED

CXO5947A

Chapter 1. Product Description

1.2.3.2 Controlling the Internal SCSI Bus

The I/O module controls the internal SCSI bus in the following manner:

Isolates the internal SCSI bus from the external SCSI bus.

•

Provides single-ended SCSI bus termination.

•

Disconnects the internal SCSI bus from the external SCSI bus when the

•

EMU so directs.

Distributes TERMPOWER (+5 V dc) to the internal SCSI bus.

•

Turns ON the green internal TERMPOWER LED (see Figure 1-8) when the

•

internal TERMPOWER is present.

Turns OFF the green internal TERMPOWER LED (see Figure 1-8) when

•

there is an internal TERMPOWER overcurrent condition.

1.2.3.3 Controlling the External SCSI Bus

The I/O module controls the external SCSI bus in the following manner:

Provides single-ended SCSI bus termination.

•

Distributes TERMPOWER (+5 V dc) to the external SCSI bus.

•

Turns ON the green external TERMPOWER LED (see Figure 1-8) when the

•

external TERMPOWER is present.

Turns OFF the green external TERMPOWER LED(see Figure 1-8) when

•

there is an external TERMPOWER overcurrent condition.

Automatically disables the external bus termination when a cable is

•

connected to the right hand VHDCI connector.

1.2.3.4 Controlling the Fault Bus

The I/O module controls the fault bus operation in the following manner:

Provides a fault bus driver for improved signal transmission.

•

Distributes the FAULT_CLK and FAULT_DATA signals from the master

•

enclosure to the expansion enclosures.

Distributes the SHELF_OK and SWAP_L signals from the expansion

•

enclosures to the master enclosure.

1.2.3.5 “Warm Swapping” I/O Modules and Cables

You can replace either the I/O module or a cable when the associated SCSI bus is

quiesced (no data transfers occurring) – a warm swap. This enables you to

correct problems affecting only one bus without disrupting data transfers on the

other five buses.

EK–SMCPP–UG. A01 1–9

RA7000 and ESA10000 Storage Subsystems

The maximum bus length, including external cables (distance from the I/O

module terminator to the last terminator on the bus) is a function of the bus speed

and the number of devices. If the external bus is configured point to point (from

SE I/O module-to-SE I/O module with no devices installed in between), the

cables may be extended to 20 meters due to the isolation and re-timing circuitry

of the SE I/O module.

1.3 Error Detection and Reporting

The subsystem error detection and reporting function has two major elements –

the fault bus and the EMU (environmental monitor unit). For a detailed

discussion of error detection, fault reporting, and correction, refer to Chapter 4,

Error Analysis and Fault Isolation.

1.3.1 Fault Bus

The subsystem fault bus monitors subsystem operation and reports fault

conditions to the HSZ70 RAID array controller and the EMU. The controller and

EMU then report the error condition to the user. The fault bus monitors the

following conditions:

Blower failure (SHELF_OK)

•

Power supply failure (SHELF_OK)

•

Storage device removal (SWAP_L)

•

Storage device installation (SWAP_L)

•

SBB failure (FAULT_CLK, FAULT_DATA)

•

The fault bus consists of three subsystem backplane signals routed to the

controller port connectors as follows:

•

Shelf Status Signal

subsystem power (ac and dc) and blower operation

•

SBB Swap Signal

removed from or inserted in the subsystem

•

SBB Fault Signals

address or indicates a device fault. This device fault LED is controlled by

the fault clock (FAULT_CLK) and the fault data (FAULT_DATA) control

signals.

– The SHELF_OK status signal indicates the state of

– The SWAP_L signal is asserted whenever an SBB is

– The SBB amber LED displays either the storage

1–10 EK–SMCPP–UG. A01

Chapter 1. Product Description

1.3.2 Environmental Monitor Unit (EMU)

The primary function of the EMU (see Figure 1-9) is to monitor, process, report,

and display enclosure and controller environmental status information for the

power supplies, temperature, blowers, configuration, SCSI addressing, I/O

modules, communications, and the EMU microcode type. The EMU and

controller can exchange and process this information.

CAUTION

Proper operation of an UltraSCSI subsystem

requires an operational EMU and PVA in each

BA370 rack m ountable enclosur e. You mus t also

establish communications links between the

EMUs to ensur e proper subsystem operation and

error reporting.

The primary EMU function is monitoring and reporting UltraSCSI enclosure

environmental status. In conjunction with the PVA and the controller, the EMU

identifies controller faults and alerts the user of existing or impending failures

using one or more of the following error reporting systems:

EMU LEDs

•

The EMU audible alarm

•

Error messages on the host interface

•

Enclosure system OK LED

•

Enclosure system fault LED

•

In some instances, such as blower failures or high ambient or internal enclosure

temperatures, the EMU automatically initiates corrective actions (for example,

operating the blowers at high speed).

When there is the possibility of component damage due to overheating, the EMU

can initiate an automatic controlled power shut down.

1.3.2.1 Controller Status

The master EMU also monitors the state of both controllers. Should the EMU

detect a controller fault it can:

Sound the audible alarm

•

Cause the EMU system fault status LED to flash

•

Display a controller fault code on the blower LEDs when you momentarily

•

press the Alarm Control switch

EK–SMCPP–UG. A01 1–11

RA7000 and ESA10000 Storage Subsystems

When an error is detected on the EMU controller communications path, it causes

a controller fault.

1.3.2.2 I/O Module Status

The EMU also ensures that all six I/O modules are present, are properly installed,

and that each has TERMPOWER. If any of these conditions are not met, the

EMU reports an error condition. The EMU also reports each I/O module type to

the controller. Should the controller determine that the I/O module configuration

is incorrect, it displays this information on the console.

An integrated circuit on each I/O module functions as an UltraSCSI bus

extender. The EMU and the controller can enable or disable individual I/O

module circuits, thereby controlling individual external SCSI buses.

1.3.2.3 Enclosure Configuration Information

The EMU maintains the following configuration information:

Enclosure number

•

EMU microcode version

•

EMU message protocol version

•

PVA SCSI ID setting

•

Temperature sensor set points

•

The number of installed power supplies by location

•

The number of installed SBBs by location

•

The number of installed blowers by location

•

1–12 EK–SMCPP–UG. A01

Chapter 1. Product Description

1.3.2.4 EMU Front Panel

The EMU front panel contains all of the user interface controls, connectors, and

displays (see Figure 1-9 and Table 1-2).

Figure 1–9

Environmental Monitor Unit (EMU)

EMU

COMMUNICATIONS

CONNECTOR

SYSTEM FAULT LED

AND ALARM CONTROL

SWITCH

EMU

MAINTENANCE

CONNECTOR

TEMPERATURE

FAULT LED

EMU

COMMUNICATIONS

CONNECTOR

POWER

STATUS LED

BLOWER

FAULT LED(S)

EK–SMCPP–UG. A01 1–13

RA7000 and ESA10000 Storage Subsystems

Table 1–2 EMU Front Panel Component Descriptions

Component Function

EMU Com. Connector

(LEFT )

System Fault LED

(amber) and Alarm

Control Switch

Provides inter-EMU communications to another

EMU.

The System Fault LED in the Alarm Control Switch is

ON whenever there is an error condition.

This LED is FLASHING whenever the EMU has one

or more fault codes to display.

When there is a fault code, momentarily pressing this

switch turns OFF the audible alarm and starts the

fault code LED display.

Pressing the Alarm Control switch for at least 5

seconds clears all the active fault codes.

After a controlled power shut down, momentarily

pressing this switch will restore power to the

enclosure.

Temperature Fault LED

(amber)

Whenever either the ambient temperature or the

enclosure backplane temperature exceeds the user-

defined temperature set point, this LED is ON until

the condition is corrected.

Power Status LED

(green)

This LED is ON whenever there are:

At least four operational +5 V dc power supplies

At least four operational +12 V dc power supplies

TERMPOWER is present on all six I/O modules

This LED is OFF whenever there are:

Fewer than four operational +5 V dc power supplies

Fewer than four operational +12 V dc power supplies

One or more I/O modules are missing

TERMPOWER

EMU Maintenance

Connector

You can connect a maintenance terminal or PC to

this connector to display EMU:

Error messages

Information messages

A PC can also load EMU microcode through this

connector.

Blower Fault LEDs

(amber)

One or more of these eight blower fault LEDs are

ON whenever one or more blowers are:

Not operating

Not operating at the correct speed.

Removed

There is a fault code display

EMU Com. Connector

(RIGHT)

Provides inter-EMU communications to another

EMU.

1–14 EK–SMCPP–UG. A01

Chapter 1. Product Description

1.3.3 Power Verification and Addressing (PVA) Module

Proper operation of the subsystem, whether it be a master or an expansion

enclosure, requires both a PVA module and an EMU module. The PVA (Figure

1-10) and its associated EMU ensures that all major UltraSCSI components are

functioning properly. When an error condition occurs, these modules notify the

user that a problem exists. The controller identifies the specific problem. The

PVA and EMU LED displays identify possible causes of the problem.

The PVA mounts in the lower right section of the enclosure, directly above the

controller. The PVA and EMU have the same physical dimensions, use the same

type connectors, and are mounted next to each other – the EMU on the left and

the PVA on the right (see Figure 1-6). They are not interchangeable.

Figure 1–10 Power Verification and Addressing (PVA) Module

As shown in Figure 1-10, the major user-accessible components of the PVA

include the following:

The dc power shutoff switch includes a green power status LED

•

The UPS connector (RJ-45) for future expansion

•

The enclosure SCSI address switch that establishes the enclosure address

•

and thereby the SCSI bus Ids for each storage device

EK–SMCPP–UG. A01 1–15

RA7000 and ESA10000 Storage Subsystems

The PVA has two status indicators:

The green power status LED in the power Shut down switch. This LED is

•

ON whenever there at least four operational power supplies. When an error

condition occurs, the LED is OFF and the PVA reports the error to the

EMU. The EMU also monitors the power supplies for this condition

An audible alarm that beeps at a slow rate when the PVA detects removal of

•

or improper installation of the EMU. This ensures you are aware the EMU

must be replaced within 8 minutes to prevent a system shut down

The primary functions of the PVA include the following:

1) Ensures that there is a minimum of four operational power supplies in the

enclosure. If the PVA senses less than four power supplies, it notifies the

EMU.

2) Allows the user to select the DIGITAL-supported device SCSI bus

addresses for the master and each expansion enclosure.

3) Monitors the EMU status and:

Notifies the user of removal of the EMU

•

Notifies the user when there is no master EMU

•

Notifies the user when there are multiple master EMUs

•

Provides the user a switch to disconnect dc power from the enclosure

•

power buses

Monitors the optional UPS for proper operation and reporting the UPS

•

status

1.3.3.1 Monitoring Power Supply Operation

For accurate, reliable transfer of data without data corruption or loss, the

enclosure requires a minimum of four operational power supplies to furnish both

+5 and +12 Vdc for operation of the following:

Storage Devices (SBBs)

•

Controllers and cache memories

•

EMU

•

PVA

•

1–16 EK–SMCPP–UG. A01

Chapter 1. Product Description

Therefore, both the EMU and PVA monitor all of the power supplies (a

maximum of eight) to ensure that at least four are operational. An error condition

is indicated by one of the following conditions:

The +5 Vdc voltage drops to +4.7 Vdc

•

The +12 Vdc voltage drops to 11.4 Vdc

•

Another voltage essential for proper operation is the +5 Vdc termination power

(TERMPOWER) required for the SCSI bus on each of the six I/O modules. If

this voltage drops to +4.5 Vdc, an error condition exists.

As long as there are four operational supplies and TERMPOWER is correct, the

EMU and PVA generate the POK (power OK) signal. As long as POK is present

the controller can continue to transfer data providing there are no other error

conditions.

The loss of the POK signal for any reason causes the controller to reset and halt

all data transfers. All six buses remain quiesced (no data transfers occurring)

until the controller determines that power is correct. The controller does this by

checking the status of the POK signal. Until the POK reports that there are at

least four operational power supplies and that TERMPOWER is correct, the

controller, the cache memories, and all the devices remain passive. The EMU

and the PVA continue to monitor the system and report the error condition.

1.3.3.2 Master Enclosure Controlled Power Shutdown

The EMU can shut down the dc power in the master enclosure or the subsystem

when one of the following conditions occur:

The EMU determines an extreme over-temperature condition that requires

•

removing power from the subsystem

The user presses and holds down the PVA dc power switch until the EMU

•

initiates a controlled power shut down

NOTE

This is only true if both controllers have been

shut_down

When you initiate a controlled power shut down from the master enclosure PVA

the sequence of events is as follows:

1) The EMU changes its status to indicate that the dc power switch was pressed

2) The master EMU notifies the controller of the change in status.

3) When the controller is ready, it sends a controlled power shutdown

command to the master EMU.

4) A controlled power shut down is completed on all the subsystem cabinets.

EK–SMCPP–UG. A01 1–17

RA7000 and ESA10000 Storage Subsystems

NOTE

If the master EM U is not communi cating with t he

controller or the controller does not support a

control led s hut down, t he m ast er EM U c ommands

all enclosures to perform an immediate power

shut down.

1.3.3.3 Expansion Enclosure Initiated Power Shutdown

NOTE

This procedure will only work when the

controller(s) have been shut_down.

When you press the PVA dc power switch on the enclosure and the expansion

EMU

communicate with the master EMU, one of the following power

can

shutdown operations occurs:

NOTE

When the expansion EMU

with the master EMU, pressing the dc power

switch causes an immediate controlled power

shutdown of only the expansion enclosure.

cannot

communicate

1. The slave EMU changes its status to indicate that the dc power switch was

pressed.

2. The master EMU notes the change in status.

3. The master EMU notifies the controller of the change in status.

4. When the controller is ready, it sends a controlled power shut down

command to the master EMU.

5. A controlled power shut down is completed on all the subsystem cabinets.

NOTE

If the master EM U is not communi cating with t he

controller or the controller does not support a

control led s hut down, t he m ast er EM U c ommands

all enclosures to perform an immediate power

shut down.

1–18 EK–SMCPP–UG. A01

Chapter 1. Product Description

1.3.3.4 PVA UPS (Uninterruptable Power Supply) Options

DIGITAL does not supply any options for this product. When you install an

optional UPS power source, you can use the PVA to monitor its status. Connect

the UPS to the UPS Connector on the front of the PVA using a 9-pin RS-232-to8-pin RJ-45 adapter cable. The PVA monitors the following UPS signals and

reports the status to the EMU:

UPS installed

•

UPS has only two minutes of battery power left

•

UPS has lost ac input

•

1.4 Storage Device SBBs

The subsystem can accommodate up to twenty four 3½-inch storage device SBBs

(Figure 1-11). Each occupies one slot (six SBBs per shelf). The SCSI device

addresses of the SBBs can be assigned in the following ways:

By the backplane connector

•

With the SCSI device address switch mounted on the rear of the SBB

•

The HSZ70 RAID array controller software product descriptions and release

notes list the subsystem compatible SBBs.

Figure 1–11 Disk Drive SBB

DEVICE

ACTIVITY

(GREEN)

DEVICE

FAULT

(AMBER)

EK–SMCPP–UG. A01 1–19

RA7000 and ESA10000 Storage Subsystems

1.5

Power Configuration

There are two primary storage subsystem power configurations:

•

Standard

five power supply SBBs on power bus

•

Redundant

– 4 + 1 power configuration includes one ac power controller and

A

– 4 + 4 power configuration includes one ac power controller

and four power supply SBBs on power bus A and four power supply SBBs

on power bus

B

When there are less than four operational power supplies, the subsystem will

cease operating to preserve and protect the data. Table 1-2 lists the storage

subsystem power components and configurations.

CAUTION

A minimum of four operational SBB power

supplies are required for operation of the

subsystem. The fifth SBB power supply prov ides

redundancy.

Table 1–2 Storage Subsystem Major Power Components

Component Order No. Power Configurations

Standard Redundant

ac Power Entry

Controller

Shelf Power Supply

SBB

DS-BA35X-HE 1 2

DS-BA35X-HH 5 8

1.5.1 AC Power Entry Controllers

The ac input power is routed from the wall outlet to one of the power entry

controllers (Figure 1-12) that may have either of the following input voltages:

100 – 120 V ac, 60 Hz, single-phase, 12A

•

220 – 240 V ac, 50 Hz, single-phase, 6A

•

Each power entry controller has a system ON/OFF switch and distributes ac

power to all power supply SBBs on either power bus A or power bus B.

1–20 EK–SMCPP–UG. A01

Figure 1–12 AC Power Entry Controller

Chapter 1. Product Description

EK–SMCPP–UG. A01 1–21

RA7000 and ESA10000 Storage Subsystems

1.6 Power Supply SBBs

CAUTION

The subsystem requires power s uppl y SBBs r ated

for at least 180 W such as the DS-BA35X-HH.

You cannot use l ower rat ed s upplies , s uch as the

131 W (DS-BA35X-HA), the 145 W (DS-BA35XHD), or the 150 W (DS-BA35X-HF).

The 180 W shelf power supply SBB (Figure 1-13) converts the ac voltage from

the power controller to +5 V dc and +12 V dc for distribution throughout the

storage subsystem. The maximum capacity of the storage subsystem is eight

power supplies.

Figure 1–13 Typical Shelf Power Supply SBB

POWER

STATUS LED

(GREEN)

POWER SUPPLY

STATUS LED

(GREEN)

The 4 + 1 standard configuration provides five power supplies connected to

power bus A (the black power cords). As long as any four of these supplies are

operational, the subsystem is operational. The failure of a second supply places

the subsystem controller in a reset state. This precludes further data processing

and prevents the corruption or loss of the stored data.

With the 4 + 4 full redundant power option, the subsystem can survive multiple

power supply faults. To fully realize the benefits of the 4 + 4 configuration,

connect the power controllers to different ac distribution circuits on the same site

distribution panel.

1–22 EK–SMCPP–UG. A01

Chapter 1. Product Description

The four subsystem power supply SBBs on the left end of the shelf are connected

to power controller A. The four on the right end of the shelf are connected to

power controller B.

1.7 Standard (4 + 1) Power Configuration

NOTE

The black power c ord at the upper right c orner of

the subsystem is used only for the standard (4 +

1) configur ati on. It is not us ed for the r edundant (4

+ 4) configuration.

This standard power configuration (Figure 1-14) is the minimum configuration

DIGITAL recommends. If a power supply SBB fails you might be able to replace

it before a second fails. The standard power configuration has the following

components:

5 – power supply SBBs

•

1 – power entry controller

•

Any one of the following errors will cause the subsystem to cease operation:

Failure of two power supply SBBs

•

Failure of the power entry controller

•

Failure of the ac power source

•

Failure of the PDU (ESA10000 only)

•

EK–SMCPP–UG. A01 1–23

RA7000 and ESA10000 Storage Subsystems

Figure 1–14 Standard Power Configuration (4 + 1)

1–24 EK–SMCPP–UG. A01

Chapter 1. Product Description

1.8 Redundant (4 + 4) Power Configuration

A full redundant power configuration requires two separate power sources, two

ac power controllers, and eight shelf power supplies (Figure 1-15). DIGITAL

recommends this configuration to provide complete power system redundancy

thereby ensuring complete data protection. Any one of the following error

conditions will cause the subsystem to cease operation:

Failure of five power supply SBBs

•

Failure of both power entry controllers

•

Failure of the ac power source

•

Failure of both PDUs (ESA10000 only)

•

The primary ac source provides power to controller A, which distributes the ac

power through the four black power cords to the four power supply SBBs on the

left end of each shelf.

The second, or redundant, ac source provides power to controller B. The four

power supply SBBs on the right end of each shelf are connected to power bus B

with the four gray power cords.

Figure 1–15 Redundant Power Configuration (4 + 4)

EK–SMCPP–UG. A01 1–25

RA7000 and ESA10000 Storage Subsystems

1.9 ECB SBBs

The external cache battery (ECB) SBB provides power to the RAID array

controller cache module if system power fails. The cache module in turn

provides power to the ECB during normal operation. Two ECBs mounted in each

SBB module provide support for two cache modules. Each has a power

connector, status LED, and battery disable switch (see Figure 1-15).

To check the ECB status, look at the ECB status LED (one for each cache

module) for the appropriate indication (see Figure 1-16 and Table 1-3).

Figure 1–16 External Cache Battery (ECB) SBB

1–26 EK–SMCPP–UG. A01

Table 1–3 ECB Status Indications

LED Status Battery Status

System power is on and the ECB is fully charged.

System power is on and the ECB is charging.

System power is off and the ECB is supplying power to the cache.

System power is off and the ECB is not supplying power to the cache.

LEGEND

Chapter 1. Product Description

=Off = On = Blink

fast

= Blink

slow

The ECB SBB is mounted at the top of the SW370 cabinet. A Y-cable connects

the ECB to the array controller cache module. The cache is mounted under the

controller and is identified by the single plug in the middle of the module (Figure

1-17). Cache module to ECB cables are factory installed.

CAUTION

The ECB cable is configured in a “Y” for

convenient r outi ng wit hin t he c abinet . The c abl e i s

only to be us ed to connect ONE batt ery to ON E

cache module. Do not connect both ends of the

ECB “Y” cable at the same time during normal

operation. See chapter 5 of this manual for ECB

replacement.

EK–SMCPP–UG. A01 1–27

RA7000 and ESA10000 Storage Subsystems

Figure 1–17 Cache-to ECB-Connection

1.10 Subsystem Cooling

As shown in Figure 1-18, the subsystem is equipped with eight dual-speed

blowers. These blowers pull air in from the front of the cabinet, through the

SBBs, controllers and EMUs, and exhaust it out the rear. Backplane connectors

provide +12 V dc to operate the blowers and route the blower status signals to

the shelf backplane and the EMU.

The EMU may be set to automatically increase fan speed or set to a constant

fanspeed of high. Refer to the

commands.

If set for automatic, the EMU switches all operational blowers from low-speed to

high-speed when one or more of the following conditions occur:

When a blower is removed

•

When a blower malfunctions

•

When a blower is not rotating at the right speed

•

When the EMU detects an over-temperature condition

•

When the fault condition is corrected, the EMU returns the blowers to low speed.

1–28 EK–SMCPP–UG. A01

CLI Reference Manual

for the

set_emu

Figure 1–18 Dual Speed Blower Locations

Chapter 1. Product Description

EK–SMCPP–UG. A01 1–29

RA7000 and ESA10000 Storage Subsystems

1.11 Setting the PVA SCSI Address

The SCSI bus address switch on the front of the PVA module (see Figure 1-19)

controls the SCSI address (device ID) of each storage device in the enclosure.

The following configuration rules (restrictions) apply in establishing the PVA

SCSI bus address:

1. The master PVA address is always 0.

2. There is only one master PVA in any subsystem installation.

3. In an expansion subsystem, no two enclosures can have the same address.

4. DIGITAL does not support any PVA address that assigns SCSI bus device

addresses 6 or 7 to any storage device.

5. DIGITAL does not support any combination of PVA addresses that assign the

same SCSI bus device address to more than one device on any SCSI bus.

Figure 1–19 PVA SCSI Address Switch

DECREASE

SWITCH

To decrease the configuration number:

Press the upper switch to step the address down one address at a time

(decrement) until the preferred configuration number is displayed.

To increase the configuration number:

Press the lower switch to step the address up one address at a time (increment)

until the preferred configuration number is displayed.

1–30 EK–SMCPP–UG. A01

INCREASE

SWITCH

Chapter 1. Product Description

1.11.1 DIGITAL Supported Master PVA Address

DIGITAL supports PVA address “0” only for the master enclosure. Figure 1-20

defines the SBB device IDs for a master enclosure, one expansion, and two

expansion units. The device addresses are denoted to the right of Figure 1-20.

Figure 1–20 Enclosure SCSI Bus Addresses for all SBB Device IDs

SCSI

Bus 2

SCSI

Bus 1

ID3

ID2

ID1

Typical Backplane Connection

ID0

SCSI

Bus 3

SCSI

Bus 4

SCSI

Bus 6

SCSI

Bus 5

Device

Address 3/11/15

Device

Address 2/10/14

Device

Address 1/9/13

Device

Address 0/8/12

ID7

ID6

Cache module Cache module

EK–SMCPP–UG. A01 1–31

EMU

PVA

PVA

Address 0/2/3

Device

Address 7

Device

Address 6

CXO5889A

RA7000 and ESA10000 Storage Subsystems

1.11.2 DIGITAL Supported Expansion PVA Addresses

DIGITAL only supports PVA addresses 2 and 3 for expansion enclosures. Figure

1-20 defines the SBB device IDs for these two settings of the PVA SCSI bus

address switch, respectively. The use of these addresses in combination depends

on the number of enclosures and possible addressing conflicts.

CAUTION

DIGITAL does not support any PVA address

combination not listed in Table 1-4.

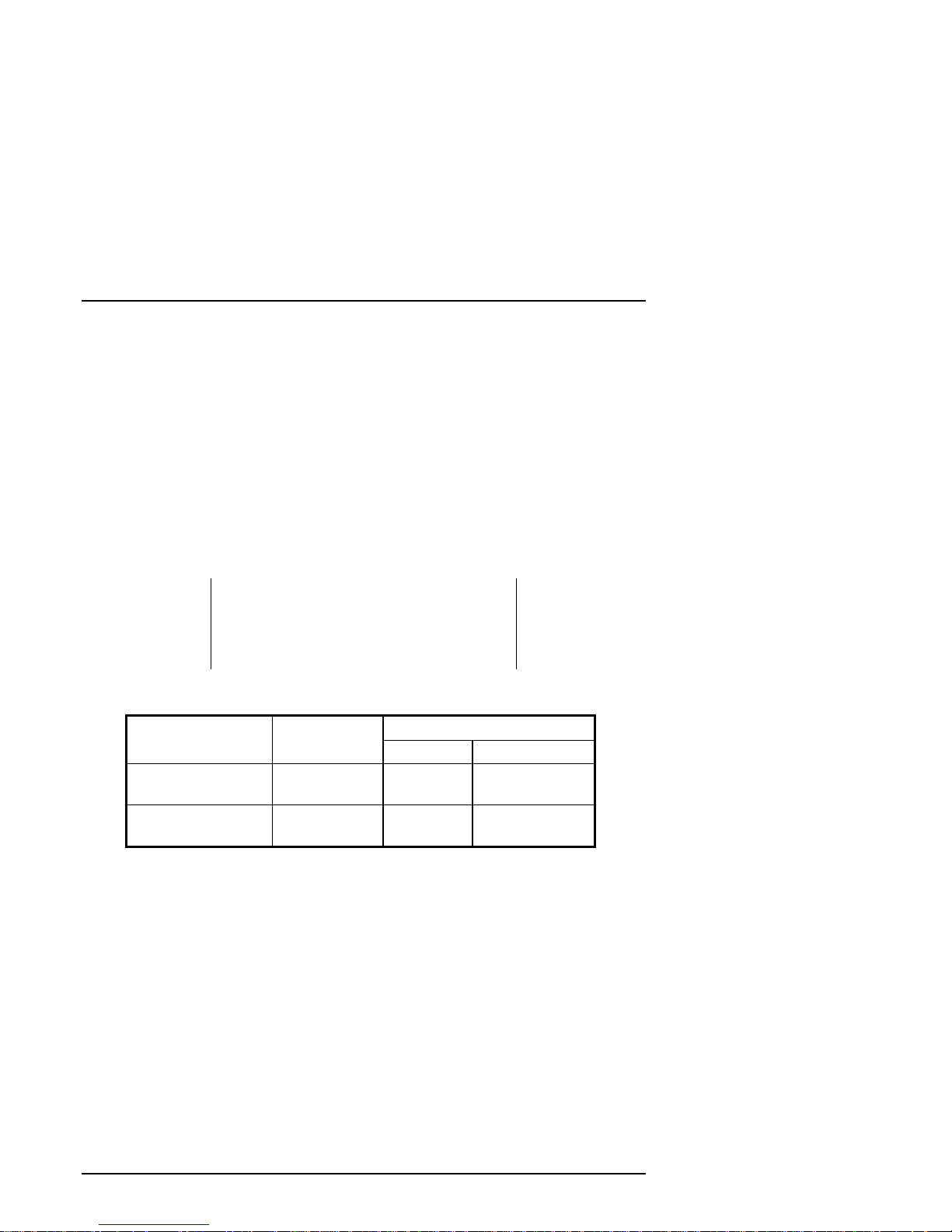

Table 1–4 Expansion Enclosure Address Combinations

Enclosure PVA Address Switch

Setting for Two BA370

Rack Mountable units

Master

First

Expansion Unit

Second

Expansion Unit

00

22

N/A 3

PVA Address Switch

Setting for Three BA370

Rack Mountable units

1.11.3 Non-Supported PVA SCSI Bus Addresses

DIGITAL

Address 1

•

Address 4

•

Address 5

•

Address 7

•

does not

This PVA address assigns controller SCSI bus device addresses 6 and

7 to storage devices.

This PVA address assigns addresses already assigned to the master

enclosure.

This PVA address assigns controller SCSI bus device addresses 6 and

7 to storage devices.

This PVA address assigns addresses already assigned to the master

enclosure.

support the following PVA SCSI bus addresses:

1–32 EK–SMCPP–UG. A01

2

Unpacking and Installation

for the RA7000 and ESA10000

Storage Subsystems

This chapter describes the site preparation, unpacking, and installation procedures for

the RA7000 and ESA10000 Storage Subsystems.

2.1 Installing the RA7000

2.1.1 RA7000 Site Preparation

The RA7000 storage cabinet is designed for installation in a Federal

Communications Commission (FCC) Class A environment. Before installing the

storage cabinet, make sure that adequate space is available in front of the cabinet

for opening the front door (19 inches clearance) and around the cabinet for

adequate airflow. See Figure 2-1 for specific space requirements.

Figure 2–1 RA7000 Minimum Installation Clearance Measurements

482.60 mm

(19.00 in)

FRONT

DOOR

EK–SMCPP–UG. A01 2–1

DS-SWXRA-H

539.75 mm

x

(21.25 in)

482.60 mm

(19.00 in)

RA7000 and ESA10000 Storage Subsystems

2.1.2 Unpacking the RA7000 Subsystem Enclosure

The storage cabinet is packed in a corrugated carton attached to a wooden

shipping pallet, as shown in Figure 2-2A. Unpack the cabinet as follows:

NOTE

Before unpacking the equipment, inspect the

shipping carton for signs of external damage.

Report any dam age to the local carrier and to your

sales representative.

1. Remove the shipping straps (Figure 2-2A).

2. Remove the top cover (Figure 2-2B).

3. Remove the ramp from the top of the shipping carton (Figure 2-2B) and set

it aside for subsequent use in moving the cabinet off the pallet.

4. Remove the two foam cushions from the top of the cabinet container (Figure

2-2B).

5. Remove the cardboard carton surrounding the expansion cabinet

(Figure 2-2B).

6. Remove the plastic barrier bag (Figure 2-2C).

7. Once the cabinet is exposed (Figure 2-2D), examine the equipment for any

apparent damage. Report any problems immediately to your sales

representative.

2–2 EK–SMCPP–UG. A01

Chapter 2. Unpacking and Installation

Figure 2–2 Unpacking the RA7000 Storage Enclosure

2.1.3 Removing the RA7000 from the Pallet

Use the following procedure to remove the storage cabinet from the shipping

pallet:

Serious personnel injury may result if correct

safety precautions are not taken during the

removal procedure.

EK–SMCPP–UG. A01 2–3

WARNING

RA7000 and ESA10000 Storage Subsystems

1. Attach the ramp to the shipping pallet by fitting the lip of the ramp into the

groove on the pallet, as shown in Figure 2-3.

Figure 2–3 Installation of Ramp on Shipping Pallet

2. Lift the lock lever on each front caster to its up position so that the storage

cabinet can be moved.

WARNING

We recomm end that three people be as signed to

the task of unloadi ng the c abinet fr om it s shi pping

pallet. Failure to use sufficient personnel may

result in personnel injury and equipment damage.

CAUTION

Do not drop the storage cabinet from a height of

more than two inches as serious structural

damage can result.

2–4 EK–SMCPP–UG. A01

Chapter 2. Unpacking and Installation

3. Grasping the sheet metal base assembly, carefully lift the rear of the storage

cabinet over the “hump” in the center of the pallet and then roll the cabinet off

the pallet and down the ramp to the floor. If any further lifting of the cabinet is

required, grasp the sheet metal base assembly on the side and lift it carefully.

4. Retain the shipping container and all packing materials.

2.1.4 Placing the RA7000 Storage Enclosure

Use the following procedure to move the storage cabinet to its designated site:

WARNING

To prevent damage to the cabinet and injury to

personnel, make sur e to provide a cl ear path for

the casters.

1. Roll the expansion cabinet to the desired location.

2. If required, engage the lock on each front caster to prevent the cabinet from

moving.

2.1.5 Connecting the Enclosure to the Host

Refer to the

Getting Started Installation Guide

describing how to connect the RAID Array 7000 subsystem to the host.

for specific instructions

EK–SMCPP–UG. A01 2–5

RA7000 and ESA10000 Storage Subsystems

2.2 Installing the ESA10000

2.2.1 Site Preparation

Before installing the ESA10000, ensure that adequate space is available in front

of the enclosure for opening the front door and around the enclosure for adequate

airflow. See Figure 2-4 for specific space requirements.

Figure 2–4 Minimum Installation Clearance Measurements

600 mm

(23.6 in)

Rear door

Front door

SW600-series

cabinet

(Top view)

600 mm

(23.6 in)

900 mm

(35.4 in)

600 mm

(23.6 in)

2100 mm

(82.7 in)

CXO5825A

2–6 EK–SMCPP–UG. A01

Chapter 2. Unpacking and Installation

2.2.2 Unpacking the ESA10000 Subsystem

The ESA10000 comes wrapped in shrink wrap and attached to a wooden

shipping pallet. European shipments are also packaged with an outer corrugated

cardboard piece, which must be removed first. On the outside of both types of

packages, there resides an international de-skidding label, showing how to deskid the cabinet. Under the first layer of shrink wrap is the international

unpacking labels, showing how to unpack the ESA10000 and further instructions

on how to de-skid the ESA10000 cabinet. Unpack the unit as instructed by the

international unpacking label. See Figure 2-5.

NOTE

Before unpacking the equipment, inspect the

shipping carton for signs of external damage.

Report any dam age to the local carrier and to your

sales representative.

Figure 2–5 Shipping Container Contents

EK–SMCPP–UG. A01 2–7

RA7000 and ESA10000 Storage Subsystems

After using the international unpacking label information to unpack your

ESA10000, follow the de-skidding instructions on the international unpacking

label and the information on the international de-skidding label to push the

ESA10000 off the shipping pallet, keeping in mind the following warnings and

cautions.

WARNING

Serious personnel injury can result if correct

safety precautions are not taken during the

removal procedure.

We recomm end that three people perform the task

of unloading the ESA10000 SW600 cabinet from

its shipping pallet. Failure to use sufficient

personnel can result in personnel injury and

equipment damage.

The following procedure, along with the international unpacking label and Figure

2-5, will help you to remove the ESA10000 from the shipping pallet:

1. Remove the cover, the fasteners, and the corrugated board from the pallet.

2. Remove the cartons containing the ramp set and skirt kit and set them aside.

3. Cut the shipping straps. Some cabinets are packaged in a plastic or barrier

bag. If the cabinet arrives in a plastic bag, leave the bag in place until the

cabinet has adjusted to the local temperature and humidity.

4. Once the cabinet is unpacked, examine the front and rear doors, right and

left side panels, top panel, and undercarriage for any apparent damage.

Report such problems immediately.

5. Retain the shipping container and all packing materials.

2–8 EK–SMCPP–UG. A01

Chapter 2. Unpacking and Installation

2.2.3 Removing the ESA10000 from the Pallet

Use the following procedure to remove the cabinet from the shipping pallet:

1. Remove any packing material remaining on the pallet.

2. Remove the two unloading ramps from the carton and inspect them.

WARNING

Serious personal injury may resul t if correct safety

precautions are not observed during the

unpacking procedure. All personnel should wear

safety glasses. The ramps, ramp side rails, and

metal hardware should be inspected for the

following defects:

• Cracks more than 25 percent of the ramp

depth, either across or lengthwise on the

ramp.

• Knots or knotholes going through the

thickness of the ramp and greater than 50

percent of the ramp width.

• Loose, missing, or broken ramp side rails.

• Loose, missing, or bent metal hardware.

If any of thes e def ect s ex is t, do not us e the r amp.

Investigate alternate means of removing the

cabinet or order a new ramp. (The part number for

the ramp set is 99-08897-05.)

3. Attach the ramps by fitting the metal prongs into the holes on the pallet, as

shown in Figure 2-6. Make sure that the arrows on the ramps match up with

the arrows on the pallet.

EK–SMCPP–UG. A01 2–9

RA7000 and ESA10000 Storage Subsystems

Figure 2–6 Shipping Pallet Ramp Installation

4. Extend the ramps to their full length.

5. See Figure 2-7 for the location of the shipping bolts. Remove the bolts.

6. Remove the shipping brackets, shown in Figure 2-7, from the cabinet

levelers and set them aside.

2–10 EK–SMCPP–UG. A01

Figure 2–7 Shipping Bolts and Brackets

WARNING

Chapter 2. Unpacking and Installation

The levelers mus t be r ai sed f ull y for t he cabi net t o

roll easily down the unloading ramps. Failure to do

so may res ult in per s onnel i njur y as a res ult of the

cabinet tipping off the pallet or ramp

.

7. Loosen the leveler locking nuts and screw the four cabinet levelers all the

way up into the cabinet.

EK–SMCPP–UG. A01 2–11

RA7000 and ESA10000 Storage Subsystems

WARNING

Three people are required to unload the cabinet

from the shippi ng cabinet. Fai lure t o use s uffi cient

personnel may result in injury and equipment

damage.

8. Carefully roll the cabinet off the pallet and down the ramps to the floor as

shown in Figure 2-8.

Figure 2–8 Removing the Cabinet from the Pallet

2–12 EK–SMCPP–UG. A01

Chapter 2. Unpacking and Installation

2.2.4 Moving the ESA10000 to It’s Designated Site

WARNING

Using extreme caution when rolling the cabinet

across the floor. Failure to raise all leveler feet

and to provide a clear path for the cabinet's

caster s may res ult in t he c abinet tippi ng over and

injury to personnel.

Once the cabinet rack space is configured as desired, the cabinet may be rolled to

its final installation position. Secure loose cabinet cables up and out of the way

when rolling the cabinet.

2.2.5 Joining Adjacent ESA10000s

NOTE

Skip to Sec tion 2. 2.7 “Lev eling t he Cabinet” if y ou

do not have to join adjacent ESA10000 cabinets.

A cabinet joiner kit comes secured within the ESA10000 packaging. Use the

joiner kit to join two ESA10000 cabinets. In the joiner kit are instructions to

position the cabinets, to remove the side panels, to install the necessary joiner kit

hardware, to use the supplied Allen wrench, and how to complete the procedure

by installing trim pieces onto the cabinets. The following text will also help you

to start and complete the joining procedure, as you are referring to the

instructions contained in the joiner kit.

When joining two ESA10000’s, the recommended configuration is to have the

cabinet that resides on the left (viewed from the front) to have two BA370’s

installed with no controllers and for the cabinet that resides on the right to have

one BA370 in the bottom position with controllers installed in that BA370.

EK–SMCPP–UG. A01 2–13

RA7000 and ESA10000 Storage Subsystems

You must first remove one of the side panels from each cabinet before the joiner

kit can be installed. Refer to the joiner kit instructions and follow this procedure.

1. Open the back door of the cabinet to gain access to the screw attaching the

side panel to the cabinet.

2. Use a standard 5/16” nut driver or wrench to remove the single screw