StorageWorks™Solutions

HSD05ArrayController

User’sGuide

Order Number: EK–HSD05–UG. B01

This manual is part of the StorageWorks family documentation set.

It describes the HSD05 Array Controller and contains installation

and configuration information. For day-to-day operation, this manual

includes a description of the user interface commands and procedures to

perform routine tasks.

Revision/Update Information: February 21, 1994

Digital Equipment Corporation

Maynard, Massachusetts

January, 1994

While Digital believes the information included in this publication is correct as of the date of

publication, it is subject to change without notice.

Digital Equipment Corporation makes no representations that the interconnection of its products

in the manner described in this document will not infringe existing or future patent rights, nor

do the descriptions contained in this document imply the granting of licenses to make, use, or sell

equipment or software in accordance with the description.

Any changes or modifications made to this equipment may void the user’s authority to operate the

equipment.

NOTE: This equipment generates, uses, and may emit radio frequency energy. The equipment has

been type tested and found to comply with the limits for a Class A digital device pursuant to Part

15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation.

Operation of this equipment in a residential area may cause interference in which case the user,

at his own expense, will be required to take whatever measures may be required to correct the

interference.

WARNING

This is a Class A product. In a domestic environment, this product may cause radio interference in

which case the user may be required to take adequate measures.

© Digital Equipment Corporation 1992, 1993, 1994.

Printed in the United States of America.

All rights reserved.

AXP, CI, DECchip, DEC 7000, DEC 10000, Digital, DSA, DSDF, HSD05, MSCP, OpenVMS, RF,

RA82, RF72, StorageWorks, TF, TMSCP, VAX, VAXcluster, VAX 4000, VAX 6000, and the DIGITAL

logo are trademarks of Digital Equipment Corporation.

Exabyte is a registered trademark of Exabyte Corporation.

All other trademarks and registered trademarks are the property of their respective holders.

The postpaid Reader’s Comments forms at the end of this document request your critical evaluation

to help prepare future documentation.

This document was prepared using VAX DOCUMENT Version 2.1.

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

1 Introduction

1.1 HSD05 Array Controller Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1.1.1 HSD05 Array Controller Features and Capabilities . . . . . . . . . . . . . . . 1–1

1.1.2 Overview of HSD05 Operating Requirements/Limitations . . . . . . . . . . 1–3

1.1.3 Connections to DSSI and SCSI Buses . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.1.4 Compatibility with StorageWorks Components . . . . . . . . . . . . . . . . . . 1–4

1.2 SBB Shelf Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.2.1 SBB Shelf Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.2.2 SBB Shelf SCSI Bus Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1.2.3 SBB Shelf SCSI Bus Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1.2.4 SBB Shelf Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1.3 HSD05 Array Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

2 Preparing to Use the HSD05 Array Controller

2.1 Site Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2.2 Unpacking the HSD05 Array Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2.3 HSD05 Array Controller Switches and Jumpers . . . . . . . . . . . . . . . . . . . . 2–2

2.4 Setting the Device Configuration on the HSD05 Array Controller . . . . . . . 2–4

2.4.1 DSSI ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–4

2.4.2 SCSI ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2.4.3 Selecting Bus Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

2.5 Installing the HSD05 Array Controller in an SBB Shelf . . . . . . . . . . . . . . 2–8

2.6 Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–9

2.7 Setting Parameters for the HSD05 Array Controller . . . . . . . . . . . . . . . . . 2–10

2.7.1 Starting PARAMS from the Console Prompt on OpenVMS VAX

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–10

2.7.2 Starting PARAMS from the Console Prompt on OpenVMS AXP

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–11

2.7.3 PARAMS Configuration Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

2.7.4 Display Device Parameters Using the PARAMS Config Utility . . . . . . 2–16

2.7.5 Set Device Parameters Using the PARAMS Configuration Utility . . . . 2–17

3 Operating the HSD05 Array Controller

3.1 HSD05 Device Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3.1.1 Starting UTILIT from the Console Prompt on OpenVMS VAX

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3.1.2 Starting UTILIT from the Console Prompt on OpenVMS AXP

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

iii

3.1.3 Starting the UTILIT Configuration Utility from the OpenVMS

Prompt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

3.1.4 UTILIT Device Utility Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

3.1.4.1 The HELP Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–4

3.1.4.2 The SHOW Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

3.1.4.3 The SELECT Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3.1.4.4 The DESELECT Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3.1.4.5 The ABORT Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

3.1.4.6 FORMAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

3.1.4.7 The QUALIFY Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

3.1.4.8 The DISKTEST Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–10

3.1.4.9 The TAPETEST Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–11

3.2 Device Utility Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–12

3.2.1 Formatting and Qualifying a SCSI Drive . . . . . . . . . . . . . . . . . . . . . . . 3–12

3.2.2 Exercising a Disk Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–13

3.2.3 Exercising a TAPE Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–15

3.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–16

3.4 HSD05 Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–18

3.4.1 Type 1 Error Logs for a Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–19

3.4.2 Type 1 Error Logs for a Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–20

3.4.3 Type 2 Error Logs for a Disk Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–21

3.4.4 Type 2 Error Logs for a Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–22

3.5 Removing and Replacing the HSD05 Array Controller . . . . . . . . . . . . . . . 3–23

A HSD05 Configuration Information

A.1 DSSI Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

A.2 HSD05 Cabling Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

Index

Examples

3–1 HELP Commands and Syntax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

3–2 SHOW Command Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–5

3–3 SELECT Operation Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–6

3–4 DESELECT Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

3–5 ABORT Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–7

3–6 FORMAT Operation Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–8

3–7 Write-Read Qualification Run Using the QUALIFY Command . . . . . . 3–9

3–8 Write-Read Qualification Run Using the DISKTEST Command . . . . . 3–10

3–9 TAPETEST Run Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–11

3–10 Format/Qualify Task Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–13

3–11 DISKTEST Task Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–15

3–12 TAPETEST Task Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–16

iv

Figures

1–1 HSD05 Array Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

1–2 HSD05 Array Controller Typical Installation . . . . . . . . . . . . . . . . . . . . 1–3

1–3 Typical SBB Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

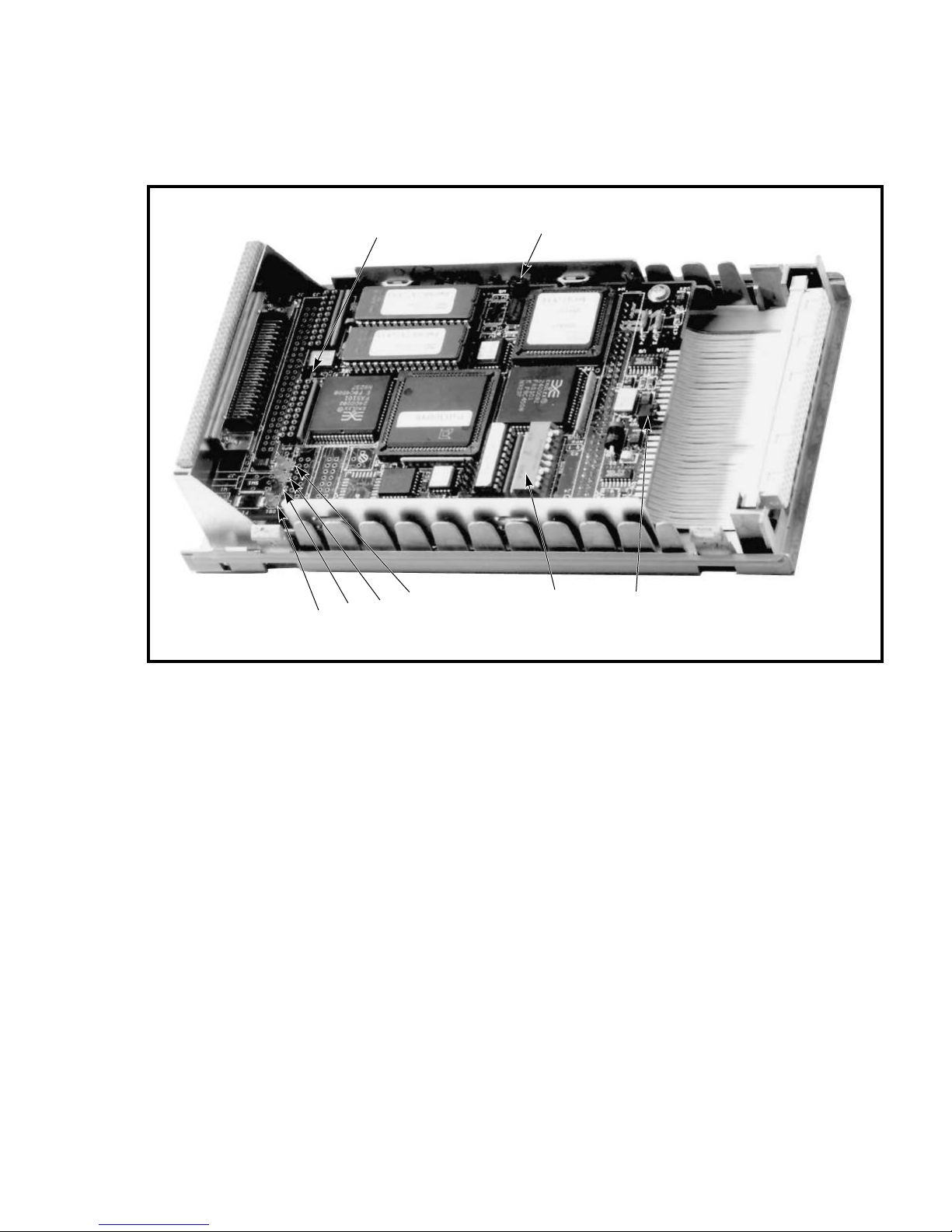

2–1 HSD05 Array Controller Module Board Layout . . . . . . . . . . . . . . . . . . 2–3

2–2 Device Configuration Switchpack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–5

2–3 DSSI Trilink Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–8

3–1 HSD05 Array Controller Module Board Layout . . . . . . . . . . . . . . . . . . 3–17

3–2 Device Configuration Switchpack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–24

A–1 HSD05 DSSI Trilink Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–3

A–2 Interconnected SBB Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–4

A–3 DSSI Bus Terminated At The HSD05 Array Controller . . . . . . . . . . . . A–4

A–4 HSD05 At Mid-Point of DSSI Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–5

Tables

1 StorageWorks Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . vii

1–1 HSD05 Array Controller and SBB Shelf Dimensions . . . . . . . . . . . . . . 1–5

1–2 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

2–1 Thermal Stabilization Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

2–2 HSD05 Array Controller Module Board Jumpers . . . . . . . . . . . . . . . . . 2–4

2–3 Device Configuration Switchpack (SW2) Sections . . . . . . . . . . . . . . . . 2–4

2–4 DSSI ID Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

2–5 SCSI ID Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–7

2–6 PARAMS Configuration Utility HSD05 Array Controller

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–12

3–1 HSD05 LED Indicator Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–18

3–2 Port Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–18

3–3 SCSI Bus Phases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–19

3–4 Type 1 Disk Drive Error Log Bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–20

3–5 Type 2 Disk Drive Error Log Bytes . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–21

A–1 Host System to StorageWorks DSSI Cables . . . . . . . . . . . . . . . . . . . . A–1

A–2 HSD05 Interconnecting DSSI Cables . . . . . . . . . . . . . . . . . . . . . . . . . A–2

v

This manual describes the procedures for configuring, installing, operating, and

replacing the StorageWorks™ HSD05™ array controller.

Intended Audience

This manual is intended for use by customers and Digital™ employees responsible

for systems using the HSD05 array controller.

Structure

This manual is organized as follows:

Preface

Chapter 1 Describes the HSD05 array controller and related StorageWorks

Chapter 2 Contains procedures to install and configure the HSD05 array

Chapter 3 Contains procedures for using the HSD05 onboard utilities, along with

Appendix A Contains configuration information for the HSD05 and associated SBB

Related Documents

Table 1 lists the StorageWorks-related user documents. These documents are the

primary reference between the HSD05 array controller and the documentation

for related components in the StorageWorks building block (SBB) family. The

documents listed in Table 1 are provided with every StorageWorks system.

Table 1 StorageWorks Related Documentation

Document Title Order Number

StorageWorks Solutions Configuration Guide EK–BA350–CG

StorageWorks Family User’s Guide

StorageWorks Family StorageWorks Building Block User’s Guide EK–SBB35–UG

components.

controller.

representative tasks that can be performed by the onboard utilities.

This chapter also contains information on using the OpenVMS™ error

log to troubleshoot the HSD05 array controller, and a remove and

replace procedure.

shelves, including a listing of cables. This information supplements the

SBB shelf information contained in the StorageWorks documents listed

in Related Documents.

1

EK–BA350–UG

1

Includes BA350–SA SBB shelf user’s guide

vii

Documentation Conventions

The following conventions are used in this manual:

boldface type Boldface type indicates the first instance of terms being defined in text.

italic type Italic type indicates emphasis and complete manual titles.

OpenVMS VAX A shortened term indicating the OpenVMS operating system for VAX™

In code examples, user input is shown in boldface type.

hardware.

viii

The HSD05 array controller is the entry-level product of the StorageWorks HSD

family of bus controllers. Installed in a 3½-inch StorageWorks building block

(SBB), the HSD05 array controller is used to connect a Digital host DIGITAL

storage subsystem interconnect (DSSI) bus to up to seven Small Computer

System Interconnect (SCSI) drives.

This chapter presents a basic description of the HSD05 array controller’s

features, performance, and operating environment. The HSD05 array controller

is shown in Figure 1–1; Figure 1–2 presents a typical HSD05 installation,

showing the relationship among basic system components.

1.1 HSD05 Array Controller Description

Connecting to a single port on a host DSSI bus, the HSD05 array controller

provides connectivity for up to seven SCSI or SCSI–2 disk, tape, and solid-state

disk devices. Enclosed in a 3½-inch SBB, it is mounted in a BA350-type shelf

containing up to six drives. Two shelves may be connected together to support

the maximum seven SCSI devices.

A DSSI bus connects to the HSD05 through a connector on the front panel; SCSI

bus connection is made through the shelf backplane connector. The HSD05 is a

TMSCP™/MSCP™-compliant device that performs the translations required to

support devices conforming to SCSI or SCSI–2 protocols.

1

Introduction

The HSD05 array controller is shipped with a DSSI trilink connector and a

DSSI terminator that fits on the trilink connector. The trilink connector allows

the HSD05 array controller to be connected as either an endpoint or a middle

(daisy-chain) node on the DSSI bus. Configured as a bus endpoint, the DSSI

terminator is used to properly terminate bus signals.

One or more HSD05 array controllers may be connected on the DSSI bus

containing RF™xx/TF™xx drives, host nodes, or other DSSI-compliant nodes (up

to eight nodes maximum).

1.1.1 HSD05 Array Controller Features and Capabilities

The HSD05 array controller provides the following features:

• Warm-swapping of attached drives (with a quiesced SCSI bus)

• Support for both OpenVMS VAX and OpenVMS AXP™ systems

• Multihost support for up to three host DSSI nodes in a cluster environment

• User-selectable SCSI and DSSI node IDs

Introduction 1–1

Figure 1–1 HSD05 Array Controller

1–2 Introduction

CXO-4052A-PH

• DUP support for modifying operating parameters, such as DSSI nodename

and device allocation classes

• Host-based striping

• Host-based volume shadowing (with some restrictions)

The HSD05 array controller also exhibits the following performance metrics:

• 500+ requests/second (aggregate)

• 1.7 MB/second sustained throughput (aggregate)

Each device served by the HSD05 array controller is independently addressable.

Attached disk, tape, and solid-state drives appear to the host as standard

DIGITAL storage architecture (DSA™) devices. Disk allocation class is userdefinable, with all attached disks sharing the class value. Tape allocation class is

independently user-definable in the same manner.

The HSD05 array controller identifies itself on the CI™ bus as a device of type

RF72; its software revision is RFX B1. This identification is in device name only,

and does not reflect actual device geometries.

Figure 1–2 HSD05 Array Controller Typical Installation

SCSI

DEVICE

HOST

SYSTEM

DSSI BUS SCSI BUS

HSD05

ARRAY

CONTROLLER

UP TO 7 SCSI DEVICES

1.1.2 Overview of HSD05 Operating Requirements/Limitations

The HSD05 array controller is designed for installation in shelf slot 0. This

preserves the integrity of the backplane SCSI bus, as the HSD05 array controller

normally serves as a terminating end of the SCSI bus. Its factory-default SCSI

node address, or SCSI ID, is 7.

While attached drives may be removed when the SCSI bus is quiesced (warmswapped), they should not be removed with the SCSI bus active (hot-swapped)

to avoid the possibility of data corruption errors. The HSD05 array controller

itself should only be removed when the power is off to all nodes on the DSSI bus

that is attached to the HSD05 array controller, and shelf power is disconnected

(cold-swap).

SCSI

DEVICE

SCSI

DEVICE

CXO-4005B-MC

Depending upon the complexity of the configuration, total DSSI bus length should

be limited to between 30 to 60 feet with an HSD05 array controller attached to

guarantee DSSI bus integrity.

Though it comprises the low end of the HSD family of array controllers, the

HSD05 array controller does not support DIGITAL Standard Disk Format

(DSDF™) protocol. Drives written by the HSD05 array controller can only be

read by other StorageWorks array controllers using Transportable mode format;

refer to the documentation supplied by other units on the use of this mode.

The HSD05 array controller supports host-based volume shadowing, but does not

support controller-based shadowing assists. No HSD05 array controller-based

Redundant Array of Independent Disks (RAID) functionality is supported.

The HSD05 array controller identifies attached disk devices as RF72 or RA82

disk drives, and attached tape devices as TU81 tape drives. This does not affect

the actual accessible device storage space. However, the following restrictions

apply to creating shadow sets:

Introduction 1–3

• Due to device geometry differences, a disk drive served by the HSD05 array

controller cannot be part of a shadow set with true RF72 (or any other DSSI

device) disk drives.

• Shadow sets using HSD05 array controller-served disk drives must be of the

same SCSI device type, for example RZ26, RZ26L, or RZ28 disk drives.

Supported tape drives such as the TLZ06 and TLZ6L offer multiple tape density

settings, supported by the HSD05. Tape drives not offering his capability, such as

the TZ86, operate in single-density/noncompacted mode only.

The HSD05 array controller does not support dual pathing or failover operation

for attached devices.

The HSD05 array controller does not sequence disk drives when spinning up. To

minimize surge current to the disk drives, spin up one or two drives at a time.

1.1.3 Connections to DSSI and SCSI Buses

The DSSI bus 68-pin connector (J1) is located on the front panel of the SBB.

Connections to the backplane SCSI bus in the SBB shelf are made through a

connector (J2) at the rear of the SBB. The module board contains the switches to

select the DSSI ID, the SCSI ID, and bus termination. Indicators on the module

board are visible through the louvers in the front panel of the unit.

1.1.4 Compatibility with StorageWorks Components

The HSD05 array controller is fully compatible with the power and environmental

requirements of StorageWorks family devices. In a typical application, the HSD05

array controller can be installed in an SBB shelf without modification to the

shelf, the shelf backplane, or other SBB devices. See Section 1.3 for listings of the

physical and environmental specifications for the HSD05 array controller and the

SBB shelf unit.

1.2 SBB Shelf Overview

This section provides a brief overview of the SBB shelf and its components.

Refer to the StorageWorks documentation listed in Table 1 for further information

on SBB shelves and the StorageWorks family of products.

1.2.1 SBB Shelf Capacity

A typical SBB shelf can contain up to eight 3½-inch SBBs, as shown in

Figure 1–3. The SBB slots are numbered 0 through 7 from right to left, starting

with the slot adjacent to the SCSI connectors. Slot 7 is reserved for the power

supply SBB. Slot 6 can be used for either a storage SBB, a redundant power

supply, or a battery backup unit (BBU).

Cooling for the SBB shelf is supplied by two redundant blowers mounted on the

rear of the shelf.

1.2.2 SBB Shelf SCSI Bus Connections

There are two 50-pin, high-density, female SCSI connectors on the backplane

adjacent to slot 0. These connectors are accessible through the front of the SBB

shelf. These connectors are not normally used in an HSD05 array controller

installation, except when two SBB shelves are used (see Appendix A).

1–4 Introduction

Figure 1–3 Typical SBB Shelf

(7)

POWER

6 5 4 3 2 01

1.2.3 SBB Shelf SCSI Bus Addresses

There are seven SCSI bus device addresses (SCSI IDs) that are numbered 0

through 6. These addresses can be assigned to either 3½-inch or 5¼-inch SBBs.

The slot numbers and the SCSI device addresses are the same for slots 0 through

6. Slot 7 is reserved for the shelf power supply SBB and does not have a device

address.

1.2.4 SBB Shelf Power Supply

The StorageWorks cabinet ac or dc cable distribution unit (CDU) determines the

type of power supply to be installed in the shelf.

1.3 HSD05 Array Controller Specifications

This section contains listings of the physical and environmental specifications for

the HSD05 array controller and the SBB shelf unit.

Table 1–1 lists the dimensions of the HSD05 array controller and the SBB shelf.

Table 1–1 HSD05 Array Controller and SBB Shelf Dimensions

Description

Height

mm (in)

Width

mm (in)

SCSI

CONNECTORS

CXO-3617B-PH

Depth

mm (in)

HSD05 SBB 121 (4.8) 51 (2.0) 216 (8.5)

BA350 SBB shelf 150 (5.9) 445 (17.5) 350 (13.8)

The HSD05 array controller is fully compatible with the environmental

specifications for the StorageWorks family of products. These specifications

are given in Table 1–2.

Introduction 1–5

Table 1–2 Environmental Specifications

Condition Specification

Optimum Operating Environment

Temperature

Rate of change

Step change

Relative humidity 40% to 60% (noncondensing) with a step change of 10% or less

Altitude From sea level to 2400 meters (8000 feet)

Air quality Maximum particle count .5 micron or larger, not to exceed 500,000

Inlet air volume .026 cubic meters per second (50 cubic feet per minute)

Temperature +10° to +40°C (+50° to +104°F)

Relative humidity 10% to 90% (noncondensing)

Maximum Nonoperating or Storage Environment (Range)

Temperature

Nonoperating

Storage

Relative humidity

Nonoperating

Storage

Altitude From –300 meters (–1000 feet) to +3600 meters (+12,000 feet)

+18° to +24°C (+65° to +75°F)

3°C (5.4°F)

3°C (5.4°F)

(noncondensing)

particles per cubic feet of air

Maximum Operating Environment (Range)

Derate 1.8°C for each 1000 merters (1.0°F for each 1000 feet) of

altitude

Maximum temperature gradient 11°C/hr (20°F/hr) ±2°C/hr (4°F/hr)

Maximum wet bulb temperature: 28°C (82°F)

Minimum dew point: 2°C (36°F)

+18° to +29°C (+65° to +85°F)

–40° to +66°C (–40° to +151°F)

10% to 90% (noncondensing)

8% to 95% in original shipping container (noncondensing);

otherwise, 50% (noncondensing)

MSL

1–6 Introduction

Preparing to Use the HSD05 Array Controller

This chapter contains information and procedures for unpacking, configuring, and

installing the HSD05 array controller.

2.1 Site Preparation

The HSD05 array controller is fully compatible with all physical, electrical,

and environmental specifications for SBB shelves and components. Refer to

Section 1.3 for a listing of applicable factors to be considered when installing or

storing the HSD05 array controller.

Environmental Stabilization

To ensure proper operation of Digital storage devices, the SBB shelf temperature

must be within 18–29°C (65–85°F). Table 2–1 specifies the time required to

thermally stabilize the HSD05 array controller and other SBBs based on the

ambient shipping temperature.

CAUTION

Be sure to thermally stabilize the HSD05 array controller in the operating

environment prior to installation or operation. Otherwise, the associated

electronics may be damaged when power is applied to the unit.

2

If condensation is visible on the outside of the HSD05 array controller:

Stabilize the HSD05 array controller in the operating environment for 6

hours or until the condensation is no longer visible, whichever is longer. Do

not insert the HSD05 array controller into the shelf until it is fully stabilized.

If condensation is not visible on the outside of the HSD05 array

controller:

Thermally stabilize the HSD05 array controller for the amount of time

specified in Table 2–1.

Preparing to Use the HSD05 Array Controller 2–1

Table 2–1 Thermal Stabilization Specifications

Ambient

Temperature

Range °C

60 to 66 140 to 151 3 hours

50 to 59 122 to 139 2 hours

40 to 49 104 to 121 1 hour

30 to 39 86 to 103 30 minutes

18 to 29 65 to 85 None

10 to 17 50 to 64 30 minutes

0 to 9 32 to 49 1 hour

–10 to –1 14 to 31 2 hours

–20 to –11 –4 to 13 3 hours

–30 to –21 –22 to –5 4 hours

–40 to –31 –40 to –21 5 hours

Ambient

Temperature

Range °F

2.2 Unpacking the HSD05 Array Controller

Use the following procedure to remove the HSD05 array controller from its

shipping carton :

1. Before unpacking the HSD05 array controller, inspect the shipping carton

for signs of external damage. Report any damage to the local carrier, and to

Digital Multivendor Services or your local Digital sales office.

Minimum

Stabilization

Time

2. Be sure to thermally stabilize the HSD05 array controller as given in

Environmental Stabilization and Table 2–1.

3. After removing the HSD05 array controller from its shipping container,

inspect the array controller for signs of external damage. Report any damage

to the local carrier, and to Digital Multivendor Services or your local Digital

sales office.

4. To prevent damage from electrostatic discharge (ESD), do not touch the

HSD05 DSSI or SCSI connectors.

2.3 HSD05 Array Controller Switches and Jumpers

The HSD05 array controller module board contains switches and jumpers, as

shown in Figure 2–1. All jumpers are installed at the factory and do not need

to be set during normal installation of the HSD05 array controller. The switch

sections on the device configuration switchpack need to be set to configure the

DSSI ID and the SCSI ID.

2–2 Preparing to Use the HSD05 Array Controller

Figure 2–1 HSD05 Array Controller Module Board Layout

DS1

DS2

W8

DS3

DS4

W3

SW2

W9

CXO-4053A-PH

The functions of the switches and jumpers on the module board are given in the

following tables:

• Table 2–2 lists the jumper settings for the HSD05 array controller. These

settings need not be changed during a normal installation.

• Table 2–3 lists the switch sections in the device configuration switchpack

(SW2). You will need to set these switches according to the procedures given

in Section 2.4.

Preparing to Use the HSD05 Array Controller 2–3

Table 2–2 HSD05 Array Controller Module Board Jumpers

Jumper Definition

W1 Reserved

W2 Reserved

W3 EPROM size

W4 Wait state

W5 Reserved

W6 Reserved

W7 Reserved

W8 DSSI terminator power supplied by module

W9 SCSI terminator power supplied by module

Table 2–3 Device Configuration Switchpack (SW2) Sections

Section Definition Default

SW2–1 MSB of DSSI ID Open (DSSI ID = 0)

SW2–2 NSB of DSSI ID Open

SW2–3 LSB of DSSI ID Open

SW2–4 MSB of SCSI ID Closed (SCSI ID = 7)

SW2–5 NSB of SCSI ID Closed

SW2–6 LSB of SCSI ID Closed

SW2–7 Spare Open

SW2–8 Spare Open

SW2–9 Spare Open

SW2–10 Active SCSI termination Closed (terminators installed)

2.4 Setting the Device Configuration on the HSD05 Array Controller

This section contains the procedure to set the switches on the HSD05 array

controller module board prior to installation in the SBB shelf. To access the

switches, look through the slot in the back cover of the HSD05 array controller

and locate the configuration switchpack, as shown in Figure 2–2.

The device configuration switchpack contains 10 switch elements, divided into

DSSI ID and SCSI ID sections as shown in Figure 2–2. Refer to The NAME_

ALGRM Parameter for detailed information on the makeup of the MSCP/TMSCP

unit numbers.

2.4.1 DSSI ID

The DSSI port (J1) on the front panel connects the HSD05 array controller to a

standard DSSI bus device, such as a VAX 4000™ host computer.

2–4 Preparing to Use the HSD05 Array Controller

Figure 2–2 Device Configuration Switchpack

DSSI

NODE ID

SCSI

ID

NOT

USED

SCSI

TERMINATION

(OPEN)

(CLOSED)

CXO-4020A-MC

Selecting the DSSI ID

Each device on the DSSI bus requires a unique device address in the range of 0

through 7. DSSI ID 7 has the highest priority on the bus and DSSI ID 0 has the

lowest priority. The DSSI ID is factory set to 0; you may need to change this ID

to one that is currently not being used on your system.

Setting the DSSI ID

Table 2–4 lists the sections of SW2 and the corresponding settings for each DSSI

ID. On the switchpack, the closed position is with the switch in the down position,

and the open position is with the switch in the up position.

Preparing to Use the HSD05 Array Controller 2–5

Table 2–4 DSSI ID Switch Settings

DSSI

ID SW2–1 SW2–2 SW2–3

0 Open Open Open

1 Open Open Closed

2 Open Closed Open

3 Open Closed Closed

4 Closed Open Open

5 Closed Open Closed

6 Closed Closed Open

7 Closed Closed Closed

Use the following procedure to set the DSSI ID:

1. At the system console prompt, enter the console command SHOW DEVICE on

OpenVMS VAX systems, or SHOW CONFIG on OpenVMS AXP systems, to

determine the DSSI ID numbers currently active on the DSSI bus.

2. Select an unused DSSI ID number for the HSD05 array controller.

3. Refer to Figure 2–2 and Table 2–3 to locate the DSSI ID switches on the

device configuration switchpack.

4. Using a small blade screwdriver or similar tool, reach through the slot in the

rear panel of the HSD05 array controller, and set the switchpack to the DSSI

ID number selected in Step 2.

2.4.2 SCSI ID

The SCSI port (J2) plugs into the SBB shelf backplane when the HSD05 array

controller is installed in the shelf. This port must have a unique SCSI ID for that

SBB shelf.

Selecting the SCSI ID

The HSD05 array controller is factory set to SCSI ID = 7 to give it the highest

priority on the SCSI bus. The other devices in the configuration must have SCSI

ID numbers between 0 and 6. For normal operation, you should not need to reset

the SCSI ID.

Setting the SCSI ID

Table 2–5 lists the sections of SW2 and the corresponding sections used to set the

SCSI ID. On the switchpack, the closed position is with the switch in the down

position, and the open position is with the switch in the up position.

2–6 Preparing to Use the HSD05 Array Controller

Table 2–5 SCSI ID Switch Settings

SCSI

ID SW2–4 SW2–5 SW2–6

0 Open Open Open

1 Open Open Closed

2 Open Closed Open

3 Open Closed Closed

4 Closed Open Open

5 Closed Open Closed

6 Closed Closed Open

7 Closed Closed Closed

Use the following procedure to set the SCSI ID, if required:

1. Select an unused SCSI ID for the HSD05 array controller.

2. Refer to Figure 2–2 and Table 2–3 to locate the SCSI ID switches on the node

configuration switchpack.

3. Using a small blade screwdriver or similar tool, reach through the slot in the

rear panel of the HSD05 array controller and set the switchpack to the SCSI

ID number selected in Step 2.

2.4.3 Selecting Bus Termination

DSSI and SCSI bus rules require that these buses be terminated at both physical

ends.

The DSSI bus can be terminated externally by using a terminator on the

DSSI trilink connector (shown in Figure 2–3), supplied with the HSD05 array

controller. Because the HSD05 array controller typically occupies one end of the

DSSI bus, this terminator is normally installed. Make sure that the other end of

the DSSI bus is properly terminated.

The DSSI bus uses two types of connectors: either a microribbon

connector or a tab-and-socket connector. If you are connecting to a

KFMSA/KFMSB host adapter, the cable will have microribbon connectors

at both ends. All other host adapters use a tab-and-socket connector. The

trilink has two microribbon connectors.

Selecting a terminator on the SCSI bus is dependent on the exact configuration

of the SBB shelf in the chain of SCSI devices. The HSD05 array controller is

shipped with active SCSI bus termination enabled. When installed in SBB shelf

slot 0, it provides termination at the HSD05 array controller end of the SCSI bus.

Make sure that the other end of the SCSI bus is also terminated properly.

Refer to the StorageWorks documentation for the rules used to select terminations

on the SCSI bus. Appendix A contains diagrams of some typical installations of

the HSD05 array controller.

Note

Preparing to Use the HSD05 Array Controller 2–7

2.5 Installing the HSD05 Array Controller in an SBB Shelf

Before starting this procedure, verify that the SBB shelf receiving the HSD05

array controller is the correct one, and that it is permissible to change any SCSI

cables connected to JA1 and JB1 of the shelf to suit the planned configuration.

Figure 2–3 DSSI Trilink Connector

REAR VIEW

FRONT VIEW

CXO-3851A-MC

The HSD05 array controller should be installed in shelf slot 0. SCSI bus integrity

can be compromised if the HSD05 array controller is installed in any other slot

of a standard SBB shelf. Refer to the StorageWorks documentation for further

information on selecting an SBB slot and on cable configuration rules for the SBB

shelf.

Installation Procedure

Use the following procedure to install the HSD05 array controller in the SBB

shelf:

1. Remove power from the shelf by removing the input power cable(s) to the

power supply SBB(s) in the shelf. If there is only one power supply SBB in

the shelf, it will be in slot 7.

2. Remove all SCSI devices from the SBB shelf.

3. For single-shelf HSD05 array controller configurations, disconnect any cables

at JA1 and JB1 of the shelf.

4. For dual-shelf HSD05 array controller configurations, see Figure A–2 for a

diagram showing interconnected shelves.

5. Insert the HSD05 array controller into shelf slot 0.

6. Take all DSSI nodes off line to remove power from the DSSI bus that will be

connected to the HSD05 array controller.

2–8 Preparing to Use the HSD05 Array Controller

Make sure that the trilink connector pins are not bent or damaged before

installing it on the HSD05 array controller.

7. Install a DSSI trilink connector (part number 12–39921–02), shown in

Figure 2–3, at J1 on the front panel of the HSD05 array controller.

8. Connect the DSSI cables to the trilink connector as directed in either of the

the following:

• If the HSD05 array controller occupies one end of the DSSI bus, connect

the DSSI cable to one of the connectors on the trilink. Install a DSSI bus

terminator (part number 12–31281–01) on the other trilink connector.

• If the HSD05 array controller occupies a mid-point of the DSSI bus,

connect the DSSI bus cables from adjacent nodes to the trilink connectors.

The DSSI bus terminator is not used on the trilink in this configuration.

Appendix A shows several typical HSD05 array controller cable

configurations.

9. Restore power to the DSSI bus nodes, but do not boot the host systems at this

time.

2.6 Applying Power

CAUTION

Apply power to the SBB shelf and the HSD05 array controller as follows:

1. Connect the input power cable(s) to the power supply SBB(s) in the shelf.

2. Verify that the Shelf Status indicator on the power supply SBB is lit. If this

indicator is not lit, refer to the StorageWorks documentation to troubleshoot

the cause of the fault.

3. Verify that the following HSD05 array controller indicators (shown in

Figure 2–1), visible from top to bottom through the front panel louvers, are as

follows:

Indicator Color Status

DS4 Green On to show that termination power, supplied by either the

DS3 Green On to show that termination power, supplied by either the

DS2 Red Blinks for 15 seconds during module boot. If this indicator

DS1 Green Blinks during normal operation while the subsystem is

HSD05 array controller or the SBB shelf, is applied to the

SCSI bus

HSD05 array controller or the host bus, is applied to the

DSSI bus.

blinks for longer than 15 seconds, there is a device fault.

booted.

CAUTION

Device unit numbers as seen by the hosts must be unique through

the system or cluster containing the HSD05 array controller. If a unit

number is added that overlaps the unit number of another device on

another controller of a system or cluster, all the devices on the other

Preparing to Use the HSD05 Array Controller 2–9

controller can disappear. In this event, the unit number conflict should be

resolved, and controller power should then be cycled off/on to make the

devices available to the host system or cluster.

4. At the system console prompt, enter the console command SHOW DEVICE on

OpenVMS VAX systems, or SHOW CONFIG on OpenVMS AXP systems, to

verify that the HSD05 DSSI node address is on line to the host systems.

2.7 Setting Parameters for the HSD05 Array Controller

The OpenVMS diagnostic and utility protocol (DUP) utility provides a gateway

to modifying HSD05 array controller parameters. You can run this utility from

either the system console or from the OpenVMS system prompt.

Once a DUP connection to the HSD05 array controller is established, the onboard

PARAMS configuration utility is used to set and show HSD05 parameters.

Chapter 3 contains procedures for using the HSD05 onboard device and diagnostic

utility (UTILIT) during normal operation of the subsystem.

In the following sections, user input is shown in boldface type in the examples.

2.7.1 Starting PARAMS from the Console Prompt on OpenVMS VAX Systems

Use the following procedure to start PARAMS from the console prompt on

OpenVMS VAX systems:

1. At the console prompt, enter the SHOW DEVICE command as shown in the

following example:

>>> SHOW DEVICE

DSSI Node ID 0 (DSSI nodename)

DSSI NODE ID 5 (*)

UQSSP Disk Controller 0 (772150)

-DUA0 (RA82)

Ethernet Adapter

-ESA0 (08-00-2B-13-80-85)

This is the HSD05 array controller. The DSSI nodename is initially a

six-digit number. Do not confuse this number with the DSSI ID value.

2. Depending upon your installation, enter one of the following two command

lines to use the DUP utility to establish a connection to the HSD05 array

controller:

>>> SET HOST/DUP/DSSI a

Starting DUP server...

Copyright (C) 1994 Digital

HSD05 Serial No: 8

Firmware Rev. B1 (X36 )

DIRECT V1.0 D Dec 21 1993 16:59:31

PARAMS V1.0 D Dec 21 1993 16:59:31

UTILIT V1.0 D Dec 21 1993 16:59:31

End of directory

Task Name?

where a is the DSSI ID of the HSD05 array controller.

2–10 Preparing to Use the HSD05 Array Controller

You may have to explicitly specify the DSSI bus (0 or 1) to properly establish

a connection to the HSD05 array controller. In such cases use the following

command line:

>>> SET HOST/DUP/DSSI/BUS:n a

Starting DUP server...

Copyright (C) 1994 Digital

HSD05 Serial No: 8

Firmware Rev. B1 (X36 )

DIRECT V1.0 D Dec 21 1993 16:59:31

PARAMS V1.0 D Dec 21 1993 16:59:31

UTILIT V1.0 D Dec 21 1993 16:59:31

End of directory

Task Name?

where:

n is the DSSI bus ID number (0 or 1).

a is the DSSI ID for the HSD05 array controller.

3. At the ‘‘Task Name?’’ prompt, enter PARAMS. If you do not see the ‘‘Task

Name?’’ prompt, DUP has not established a connection to the HSD05 array

controller. In this event, see your system manager.

4. At the PARAMS prompt, see Section 2.7.3 to configure HSD05 parameters.

2.7.2 Starting PARAMS from the Console Prompt on OpenVMS AXP Systems

Use the following procedure to start PARAMS from the console prompt on

OpenVMS AXP systems:

1. At the console prompt, enter the SHOW CONFIG command as shown in the

following example:

>>>SHOW CONFIGURATION

Console V2.8-9900 VMS PALcode X5.37F, OSF PALcode X1.28F

CPU 0 P B2001-BA DECchip (tm) 21064-3

CPU1 Memory 0 Memory 1 Memory 2 Memory 3 P B2002-DA 128 MB

Ethernet 0 P 08-00-2B-32-E6-AB

Ethernet 1 P 08-00-2B-32-E6-AA

ID 0 ID 1 ID2 ID 3 ID 4 ID 5 ID 6 ID 7

A SCSI P RZ73 Host

B SCSI P RZ73 Host

C DSSI P RF73 RF72

Host

D DSSI P RF73 Host

E SCSI P TZ85 RRD42 Host

Futurebus+ P FBD0 Host

System Status Pass Type b to boot duc1.1.0.2.0

This display is a map of the attached devices and their SCSI/DSSI bus

addresses. The HSD05 array controller is displayed as device RF72. In

this example, the ID 4 column shows that the DSSI ID = 4, and row C

shows that the DSSI bus designation where the HSD05 resides is C.

Preparing to Use the HSD05 Array Controller 2–11

2. Enter the following command to use the DUP utility to establish a connection

to the HSD05 array controller:

>>> SET HOST -DUP d

where d is the appropriate port address identifier for the HSD05 array

controller.

The following command line shows an example of this entry:

>>> SET HOST -DUP PUC0.4.0.2.0

Starting DUP server...

Copyright (C) 1994 Digital

HSD05 Serial No: 8

Firmware Rev. B1 (X36 )

DIRECT V1.0 D Dec 21 1993 16:59:31

PARAMS V1.0 D Dec 21 1993 16:59:31

UTILIT V1.0 D Dec 21 1993 16:59:31

End of directory

Task?

3. At the ‘‘Task?’’ prompt, enter PARAMS. If you do not see the ‘‘Task?’’ prompt,

DUP has not established a connection to the HSD05 array controller. In this

event, see your system manager.

4. At the PARAMS prompt, see Section 2.7.3 to configure HSD05 parameters.

2.7.3 PARAMS Configuration Utility

The PARAMS configuration utility display shows the settings for HSD05 array

controller parameters. At the PARAMS prompt, enter SHOW /ALL to display the

current HSD05 parameters. When entering this command, a space is required

between the SHOW and /ALL qualifier. The meaning of each parameter is given

in Table 2–6.

HSD05 array controller operating parameters are initialized by manufacturing.

Depending upon the specific configuration of your system or cluster, suggested

parameters that may need to be set include:

• NODENAME

• DISK_ALCS

• TAPE_ALCS

• UNIT_OFFSET

Table 2–6 PARAMS Configuration Utility HSD05 Array Controller Parameters

Parameter

Name Definition

NODENAME HSD05 node name. This value must be unique among all systems

in the VAXcluster™ system. The string cannot include the dollar

sign ($), or underscore (_) characters and should be no longer than

eight characters. The factory default for the node name is a unique

six-digit number.

(continued on next page)

2–12 Preparing to Use the HSD05 Array Controller

Table 2–6 (Cont.) PARAMS Configuration Utility HSD05 Array Controller

Parameters

Parameter

Name Definition

SYSTEMID Specifies the lower order 32 bits of the 48-bit system identification

DISK_ALCS Determines the device allocation class for all disk devices connected

TAPE_ALCS Determines the device allocation class for all tape devices connected

INTERVAL Controls the rate at which SCSI device scanning is done. This value

NUMPOLL Controls the number of SCSI devices to look for during each

UNIT_OFFSET Helps to differentiate devices when a system has two DSSI buses.

SYNC_RATE The rate in MHz that data is transferred during the data

MAX_HOSTS Determines the maximum number of hosts with which the HSD05

FASTSCAN Reduces the SCSI SELECT timeout to a much smaller value, with

SCANNING Enables/disables the HSD05 array controller’s ability to scan for

DISCONNECT Enables/disables the ability to disconnect all SCSI devices connected

number. The factory default for this identifier is the same as

specified by the NODENAME parameter.

to HSD05 array controller. If disks are to be served to other nodes

within the VAXcluster, this parameter must be non-zero and match

the ALLOCLASS SYSGEN parameter on connected systems. The

factory default for this parameter is zero.

to the HSD05 array controller. If tapes are to be served to other

nodes within the VAXcluster, this parameter must be non-zero and

match the ALLOCLASS SYSGEN parameter on connected systems.

The factory default for this parameter is zero.

is only used if SCANNING is enabled. The factory default for this

parameter is 60 seconds.

INTERVAL. This parameter is currently not implemented but

may be activated in a future revision of the firmware. The factory

default for this parameter is 7, which scans for all available units at

each interval.

Unit offset is specified as the value to be used in the thousands

position of the MSCP unit ID, such as x for DIAx210. This offset is

automatically created by the system. The unit offset values must

be unique for each DSSI bus on the system. The factory default for

this parameter is 0.

transmission phase between target and host. The factory default for

this parameter is 7 MHz.

array controller will communicate. This parameter is primarily

used for disk and tape credit allotment. For best performance, set

this parameter to the maximum number of hosts to be used. Digital

supports up to three hosts (the factory default) in a multihost

HSD05 array controller configuration.

the default timeout set at 250 milliseconds. This parameter is

currently not implemented. The factory default for this parameter

is 0 (disabled).

newly connected devices. If scanning is disabled, the HSD05 array

controller only does one scan for devices at power up, and will not

look for new devices every INTERVAL seconds. The factory default

for this parameter is 1.

to the HSD05 array controller. When only one device is connected

to the HSD05 array controller, this parameter should be disabled

for better performance. The factory default for this parameter is 1.

(continued on next page)

Preparing to Use the HSD05 Array Controller 2–13

Table 2–6 (Cont.) PARAMS Configuration Utility HSD05 Array Controller

Parameters

Parameter

Name Definition

POWERONRST Enables/disables issuing a SCSI BUS RESET command when the

TRYSYNC Enables/disables synchronous negotiation when a SCSI device is

SPIN_DOWN Enables/disables the ability of the HSD05 array controller to

TAGGED_CMD Enables/disables simple tag queuing. The factory default for this

TRUNCATE This parameter truncates the number of blocks to be divisible

DEVICE_TYPE This parameter applies to disk drives only. When disabled (set

IMMEDIATE When enabled, this parameter causes the IMMEDIATE bit in the

CMD_P3 Determines the type of transmission used on the DSSI bus for

TMARKSEARCH Enables fast tape mark searching. Because some tape drives

SHORT_TMARK Enables/disables writing short filemarks on Exabyte® devices.

system is turned on. The factory default for this parameter is 1

(enabled).

initialized. For very short cables, synchronous negotiation can be

disabled for better performance in ASYNC mode rather than SYNC

mode. The factory default for this parameter is 1 (enabled).

spin down drives or eject media when the operating system

issues a spin down command, such as the OpenVMS command

DISMOUNT/UNLOAD. The factory default for this parameter is 1

(enabled).

parameter is 1 (enabled).

by 126. The factory default for this parameter is 1. This default

supports faster OpenVMS volume shadowing catch-up time. A value

of 0 selects no truncation for compatibility with other third-party

units.

to 0), the device type reported by the HSD05 array controller to

the OpenVMS operating system is an RA82™ disk drive. When

enabled, the HSD05 array controller reports the RF72™ device

type. The device type reported to the host does not affect the

accessible disk space. The factory default for this parameter is 1

(enabled).

SCSI START and STOP commands to be set. Note that when

IMMEDIATE is set to 0, the OpenVMS prompt does not return

until the drive’s media is ejected or the drive has spun down. The

factory default for this parameter is 1 (enabled).

single host configurations only: 0 for standard and 1 for fast mode.

This is a hidden parameter that is not displayed by the PARAMS

SHOW /ALL, SHOW /SCSI, or SHOW /SCS commands. To display

this parameter value, use the SHOW CMD_P3 command in the

PARAMS utility. The factory default for this parameter is 1 (fast

mode).

perform slowly while looking for tape marks during operations

on large space records, a skip tapemark is done instead. Because

the device does not report the number of records skipped between

tapemarks, the position (object) count is not correct when this

parameter is enabled. The factory default for this parameter is 0

(disabled).

When disabled, all filemarks are written as large filemarks. The

factory default for this parameter is 1 (enabled).

(continued on next page)

2–14 Preparing to Use the HSD05 Array Controller

Table 2–6 (Cont.) PARAMS Configuration Utility HSD05 Array Controller

Parameters

Parameter

Name Definition

WT_PROTECTED Enables/disables write protection for each SCSI ID. When disabled

ONLINE Controls whether devices are on line or off line to the host. This

NAME_ALGRM This parameter is fully described in The NAME_ALGRM Parameter.

SCSI_ID_X Used in conjunction with the NAME_ALGRM parameter to set

(set to 0), it allows read-write access to a SCSI ID, and when

enabled, it restricts access to read only. This parameter is in the

form of a boolean matrix, with the leftmost position representing a

SCSI ID of 7, and the rightmost position representing a SCSI ID

of 0. For example, a WT_PROTECTED setting of 00000001 allows

read-write access to SCSI IDs 1 through 7 and read only access to

SCSI ID 0. The factory default for this parameter is 00000000 (no

devices write protected).

parameter is in the form of a boolean matrix, with the leftmost

position representing SCSI ID=7, and the rightmost position

representing SCSI ID=0. For example, a WT_PROTECTED setting

of 10000000 sets SCSI IDs 0 through 6 off line and SCSI ID 7 on

line. The factory default for this parameter is 11111111 (all devices

on line).

alternative device names for each SCSI ID.

The NAME_ALGRM Parameter

The NAME_ALGRM parameter toggles between the HSD05 array controller’s

standard device naming convention and an alternative convention based upon the

TMSCP/MSCP unit number. When NAME_ALGRM is set to the default of 0, the

HSD05 array controller uses its standard naming algorithm, which assigns a unit

number composed of the DSSI ID of the HSD05 array controller according to the

following parameters:

• Unit offset—A unique number (0 - 9) for each host DSSI bus. This

parameter can be used to modify bus numbering conflicts in multiple DSSI

bus configurations.

• DSSI ID—The DSSI device address for the HSD05 array controller.

• SCSI ID—The SCSI device address for the storage device. This is set by

either the device’s shelf slot position or by ID switches on the device.

• SCSI logical unit number—The device address of a subdevice attached to a

SCSI device identified by SCSI ID x.

Setting NAME_ALGRM to 1 activates the alternative naming algorithm, which

assigns a unit number in conjunction with the SCSI_ID_X parameter. These two

conventions are summarized as follows:

Preparing to Use the HSD05 Array Controller 2–15

NAME_ALGRM

Setting

0 wxyz 1234 where: w = 1, x = 2, y = 3, z = 4

1 scsi_id_x + ((w + 1) * z) Assuming w = 1, z = 1, and the scsi_id_x parameter

Formula for MSCP/TMSCP

Unit Number

1

Example

values are as follows:

1

where:

w = UNIT_OFFSET parameter

x = DSSI ID

y = SCSI ID

z = SCSI logical unit number

SCSI ID

0 0 2

1 10 12

2 20 22

3 30 32

4 40 42

5 50 52

6 60 62

7 70 72

SCSI_ID_X MSCP/TMSCP Unit Number

2.7.4 Display Device Parameters Using the PARAMS Config Utility

To display the device parameters, enter SHOW /ALL at the PARAMS prompt; a

space is required between the SHOW and /ALL qualifier. The default settings are

as follows:

PARAMS> SHOW /ALL

Parameter Name Active Min. Max. Units

---------------- ------- ----- ------- ------NODENAME "xxxxxx" 1 8 Ascii

SYSTEMID xxxxxx 1 268435456 DecimalNum

DISK_ALCS 0 0 255 DecimalNum

TAPE_ALCS 0 0 255 DecimalNum

INTERVAL 60 0 32768 Seconds

NUMPOLL 7 0 7 DecimalNum

UNIT_OFFSET 0 0 9 DecimalNum

SYNC_RATE 7 1 10 DecimalNum

MAX_HOSTS 4 1 7 DecimalNum

FASTSCAN 0 0 1 Boolean

SCANNING 1 0 1 Boolean

POWERONRST 1 0 1 Boolean

TRYSYNC 1 0 1 Boolean

SPIN_DOWN 1 0 1 Boolean

TAGGED_CMD 1 0 1 Boolean

TRUNCATE 1 0 1 Boolean

DEVICE_TYPE 1 0 1 Boolean

IMMEDIATE 1 0 1 Boolean

TMARKSEARCH 0 0 1 Boolean

SHORT_TMARK 1 0 1 Boolean

WT_PROTECTED 00000000 0 1 BooleanM

2–16 Preparing to Use the HSD05 Array Controller

ONLINE 11111111 0 1 BooleanM

NAME_ALGRM 0 0 255 DecimalNum

SCSI_ID_0 0 0 9999 DecimalNum

SCSI_ID_1 10 0 9999 DecimalNum

SCSI_ID_2 20 0 9999 DecimalNum

SCSI_ID_3 30 0 9999 DecimalNum

SCSI_ID_4 40 0 9999 DecimalNum

SCSI_ID_5 50 0 9999 DecimalNum

SCSI_ID_6 60 0 9999 DecimalNum

SCSI_ID_7 70 0 9999 DecimalNum

2.7.5 Set Device Parameters Using the PARAMS Configuration Utility

Use the following procedure to set new device parameters:

1. At the PARAMS prompt, enter the parameters you wish to change, as shown

in the following example:

PARAMS> SET NODENAME HSD1

PARAMS> SET DISK_ALCS 10

In this example, the NODENAME has been changed to HSD1 and the DISK_

ALCS parameter set to 10.

2. Enter the SHOW /ALL command to display your changed parameters:

PARAMS> SHOW /ALL

Parameter Name Active Min. Max. Units

---------------- ------- ----- ------- ------NODENAME "HSD1 " 1 8 Ascii

SYSTEMID 131072 1 268435456 DecimalNum

DISK_ALCS 10 0 255 DecimalNum

TAPE_ALCS 0 0 255 DecimalNum

INTERVAL 60 0 32768 Seconds

.

.

.

SCSI_ID_4 40 0 9999 DecimalNum

SCSI_ID_5 50 0 9999 DecimalNum

SCSI_ID_6 60 0 9999 DecimalNum

SCSI_ID_7 70 0 9999 DecimalNum

3. Save the changes to nonvolatile memory with the following command:

PARAMS> WRITE

4. Reboot the HSD05 array controller to use the new parameters:

PARAMS> RESTART

5. Install the SCSI devices in the SBB shelf, making sure that the SCSI IDs

are unique for each HSD05, and that they do not overlap each other or the

SCSI address of the HSD05 array controller (default = 7). You do not need to

remove power from the SBB shelf for this step.

6. Check that the Device Fault indicators on the front panels of the storage

unit SBBs are not lit. If any indicator is lit, refer to the StorageWorks

documentation to troubleshoot the cause of the fault.

Preparing to Use the HSD05 Array Controller 2–17

7. At the system console prompt, enter the console command SHOW DEVICE

on OpenVMS VAX systems or OpenVMS AXP systems to verify that the SCSI

devices are available to the host systems.

CAUTION

The HSD05 array controller returns a limited set of device type

identification names to the host. All attached tape drives are identified

as TU81 (MUAxxx). All attached disk drives are normally identified as

RF72 (DIAxxx); this can be changed to identification as RA82 (DUAxxx)

by setting the HSD05 parameter DEVICE_TYPE to 0. These device types

as reported to the host do not affect actual accessible device storage space.

Due to device geometry differences, a disk drive served by the HSD05

array controller cannot be part of a shadow set with true RF72, or any

other DSSI disk drives. Shadow sets using HSD05 array controller-served

disk drives must be of the same SCSI device type; for example, RZ26,

RZ26L, or RZ28 disk drives.

8. Reboot the host systems to update the host device tables to the new settings

for the HSD05 array controller and attached devices. Verify that any

parameter changes are shown at both the console and within the OpenVMS

operating system.

2–18 Preparing to Use the HSD05 Array Controller

Operating the HSD05 Array Controller

This chapter contains procedures used in the everyday operation of the HSD05

array controller, including how to run the onboard utilities, troubleshooting

procedures, and a remove and replace procedure for the HSD05 array controller.

Whenever a host on a DSSI bus containing an HSD05 array controller

is rebooted, Digital recommends that the HSD05 array controller is also

reset to ensure consistent reporting of HSD05-served devices to the host.

This can be accomplished by issuing a ‘‘restart’’ command in the PARAMS

configuration utility, or simply by removing and restoring power to the

HSD05-served shelf.

3.1 HSD05 Device Utilities

The HSD05 onboard utilities (UTILIT) allow you to monitor, format, qualify, and

exercise SCSI devices from the OpenVMS operating system. The onboard utilities

are accessed through the diagnostic and utility protocol (DUP) server, either

through the system console or from the OpenVMS prompt.

3

CAUTION

In this chapter, user input is shown in boldface type in the examples.

CAUTION

The HSD05 array controller returns a limited set of device type

identification names to the host. All attached tape drives are identified

as TU81 (MUAxxx). All attached disk drives are normally identified as

RF72 (DIAxxx); this can be changed to identification as RA82 (DUAxxx)

by setting the HSD05 parameter DEVICE_TYPE to 0. These device types

as reported to the host do not affect actual accessible device storage space.

Due to device geometry differences, a disk drive served by the HSD05

array controller cannot be part of a shadow set with true RF72, or any

other DSSI disk drives. Shadow sets using HSD05 array controller-served

disk drives must be of the same SCSI device type; for example, RZ26,

RZ26L, or RZ28 disk drives.

Operating the HSD05 Array Controller 3–1

3.1.1 Starting UTILIT from the Console Prompt on OpenVMS VAX Systems

Use the following procedure to start UTILIT from the console prompt on

OpenVMS VAX systems:

1. At the console prompt, enter the SHOW DEVICE command as shown in the

following example:

>>> SHOW DEVICE

DSSI Node ID 0 (DSSI nodename)

-DIA200 (RF72)

-DIA210 (RF72)

-DIA250 (RF72)

DSSI NODE ID 5 (*)

UQSSP Disk Controller 0 (772150)

-DUA0 (RA82)

Ethernet Adapter

-ESA0 (08-00-2B-13-80-85)

This is the HSD05 array controller. The DSSI nodename is initially a

six-digit number. Do not confuse this number with the DSSI ID value.

2. Depending upon your installation, enter one of the following two command

lines to use the DUP utility to establish a connection to the HSD05 array

controller:

>>> SET HOST/DUP/DSSI a

Starting DUP server...

Copyright (C) 1994 Digital

HSD05 Serial No: 8

Firmware Rev. B1 (X36 )

DIRECT V1.0 D Dec 21 1993 16:59:31

PARAMS V1.0 D Dec 21 1993 16:59:31

UTILIT V1.0 D Dec 21 1993 16:59:31

End of directory

Task Name?

where a is the DSSI ID of the HSD05 array controller.

You may have to explicitly specify the DSSI bus (0 or 1) to properly establish

a connection to the HSD05 array controller. In such cases, use the following

command line:

>>> SET HOST/DUP/DSSI/BUS:n a

Starting DUP server...

Copyright (C) 1994 Digital

HSD05 Serial No: 8

Firmware Rev. B1 (X36 )

DIRECT V1.0 D Dec 21 1993 16:59:31

PARAMS V1.0 D Dec 21 1993 16:59:31

UTILIT V1.0 D Dec 21 1993 16:59:31

End of directory

Task Name?

where:

n is the DSSI bus ID number (0 or 1).

a is the DSSI ID for the HSD05 array controller.

3–2 Operating the HSD05 Array Controller

3. At the ‘‘Task Name?’’ prompt, enter UTILIT. If you do not see the ‘‘Task

Name?’’ prompt, DUP has not established a connection to the HSD05 array

controller. In this event, see your system manager.

4. At the UTILIT prompt, refer to Section 3.1.4 to configure HSD05 parameters.

3.1.2 Starting UTILIT from the Console Prompt on OpenVMS AXP Systems

Use the following procedure to start UTILIT from the console prompt on

OpenVMS AXP systems:

1. At the console prompt, enter the SHOW CONFIG command as shown in the

following example:

>>>SHOW CONFIGURATION

Console V2.8-9900 VMS PALcode X5.37F, OSF PALcode X1.28F

CPU 0 P B2001-BA DECchip (tm) 21064-3

CPU1 Memory 0 Memory 1 Memory 2 Memory 3 P B2002-DA 128 MB

Ethernet 0 P 08-00-2B-32-E6-AB

Ethernet 1 P 08-00-2B-32-E6-AA

A SCSI P RZ73 Host

B SCSI P RZ73 Host

C DSSI P RF73 RF72

D DSSI P RF73 Host

E SCSI P TZ85 RRD42 Host

Futurebus+ P FBD0 Host

System Status Pass Type b to boot duc1.1.0.2.0

This display is a map of the attached devices and their SCSI/DSSI bus

addresses. The HSD05 array controller is displayed as device RF72. In

this example, the ID 4 column shows that the DSSI ID = 4, and row C

shows that the DSSI bus designation is C.

ID 0 ID 1 ID2 ID 3 ID 4 ID 5 ID 6 ID 7

Host

2. Enter the following command to use the DUP utility to establish a connection

to the HSD05 array controller.

>>> SET HOST -DUP d

where d is the appropriate port address identifier for the HSD05 array

controller.

The following command line shows an example of this entry:

>>> SET HOST -DUP PUC0.4.0.2.0

Starting DUP server...

Copyright (C) 1994 Digital

HSD05 Serial No: 8

Firmware Rev. B1 (X36 )

DIRECT V1.0 D Dec 21 1993 16:59:31

PARAMS V1.0 D Dec 21 1993 16:59:31

UTILIT V1.0 D Dec 21 1993 16:59:31

End of directory

Task?

Operating the HSD05 Array Controller 3–3

3. At the ‘‘Task?’’ prompt, enter UTILIT. If you do not see the ‘‘Task?’’ prompt,

DUP has not established a connection to the HSD05 array controller. In this

event, see your system manager.

4. At the UTILIT prompt, refer to Section 3.1.4 to configure HSD05 parameters.

3.1.3 Starting the UTILIT Configuration Utility from the OpenVMS Prompt

You can start the UTILIT configuration utility from the OpenVMS prompt if both

of the following are true:

• You have the appropriate system manager privileges on the host system.

• The DUP utility on your system has been started.

Activate the DUP server and use the following procedure to start the UTILIT

utility:

1. On OpenVMS VAX systems, connect to the DUP server as follows:

$ MC SYSGEN CONNECT DUP_server/NOADAPTER

where DUP_server is the system DUP server and is typically ‘‘FYA0:’’.

On OpenVMS AXP systems, connect to the DUP server as follows:

$ MC SYSMAN IO CONNECT DUP_server/NOADAPTER/DRIVER=SYS$FDRIVER

where DUP_server is the system DUP server and is typically ‘‘FYA0:’’.

2. Enter the following to start the UTILIT configuration utility:

$ SET HOST/DUP/TASK=UTILIT/SERVER=MSCP$DUP n

Copyright (C) 1994 Digital

DIRECT V1.0 D Dec 21 1993 16:59:31

PARAMS V1.0 D Dec 21 1993 16:59:31

UTILIT V1.0 D Dec 21 1993 16:59:31

End of directory

where n is the DSSI nodename. See your system manager if you have

difficulty after entering this command line.

3. At the UTILIT prompt, refer to Section 3.1.4 to configure the HSD05

parameters.

HSD05 Serial No: 8

Firmware Rev. B1 (X36 )

UTILIT>

3.1.4 UTILIT Device Utility Commands

This section lists the UTILIT device commands and describes the action

performed by each command.

3.1.4.1 The HELP Command

The HELP command lists the onboard utilities command and the proper syntax

for each command, as shown in Example 3–1.

3–4 Operating the HSD05 Array Controller

Example 3–1 HELP Commands and Syntax

UTILIT> HELP

HELP

SHOW [device_name] | [/ALL]

SELECT device_name

DESELECT device_name

ABORT device_name

- Disk Commands FORMAT device_name

QUALIFY device_name [/WRITE]

DISKTEST device_name [/WRITE]

- Tape Commands TAPETEST device_name

UTILIT>

The symbol device_name refers to a valid MSCP/TMSCP™ device label for either

a direct access or sequential access device. Direct access devices, such as disk

drives, are specified with the ‘‘DIA’’ or ‘‘DUA’’ prefix to the device label, for

example, ‘‘DIA100’’. Sequential access devices, such as tape drives, are specified

with the ‘‘MUA’’ prefix, for example, ‘‘MUA120’’.

3.1.4.2 The SHOW Command

The SHOW command displays device information for either the device specified

by the device_name or for all devices by specifying the /ALL qualifier, as shown in

Example 3–2

Example 3–2 SHOW Command Display

UTILIT> SHOW DIA220

DeviceSIDVendorModelRevDev StatMaint OperMaint Status

------------------------------------------------------------------------DIA220 2-0 DEC RZ28 435E MAINT DISKTEST IN PROGRESS

UTILIT> SHOW /ALL

Device SID Vendor Model Rev Dev Stat Maint Oper Maint Status

------------------------------------------------------------------------MUA210 1-0 DEC TLZ06 0491 MAINT IDLE READY

DIA220 2-0 DEC RZ28 435E MAINT IDLE READY

MUA240 4-0 DEC TLZ6 0491 AVAILABLE

DIA260 6-0 DEC RZ26 329A AVAILABLE

UTILIT>

Device is the MSCP or TMSCP device name.

SID is the SCSI ID in the form target-logical unit number (LUN).

Vendor is the first seven characters of the manufacturer’s name.

Model is the first seven characters of the manufacturer’s model name.

Rev is the manufacturer’s firmware revision code.

Dev Stat is the current device status.

Maint Oper is the UTILIT maintenance operation.

Maint Status is the UTILIT maintenance operation status.

Operating the HSD05 Array Controller 3–5

3.1.4.3 The SELECT Command

The SELECT command is used to specify a device for maintenance before you

perform a format, qualify, or exercise operation.

Use the SHOW command to determine if the device is AVAILABLE to the HSD05

array controller. Devices that are listed as being OFFLINE or ONLINE to the

HSD05 array controller cannot be selected.

When a device is selected, its operational status becomes MAINT and the device

is not available to the OpenVMS operating system.

Command Syntax

The following is the syntax of the SELECT command:

SELECT device_name

The symbol device_name refers to a valid MSCP/TMSCP device label for either

a direct access or sequential access device. Direct access devices, such as disk

drives, are specified with the ‘‘DIA’’ or ‘‘DUA’’ prefix to the device label, for

example, ‘‘DIA100’’. Sequential access devices, such as tape drives, are specified

with the ‘‘MUA’’ prefix, for example, ‘‘MUA120’’.

Example 3–3 is an example of the SELECT operation display.

Example 3–3 SELECT Operation Display

UTILIT> SELECT DIA100

DeviceSIDVendorModelRevDev StatMaint OperMaint Status

------------------------------------------------------------------------DIA220 2-0 DEC RZ28 435E MAINT IDLE READY

UTILIT>

Device is the MSCP device name.

SID is the SCSI ID (target/lun).

Vendor is the first seven characters of the manufacturer’s name.

Model is the first seven characters of the manufacturer’s model name.

Rev is the manufacturer’s firmware revision code.

Dev Stat is the current device status.

Maint Oper is the UTILIT maintenance operation.

Maint Status is the UTILIT maintenance operation status.

3.1.4.4 The DESELECT Command

The DESELECT command deselects the devices that were selected for

maintenance by the UTILIT command SELECT. The deselected devices are

then returned to the AVAILABLE state.

3–6 Operating the HSD05 Array Controller

Command Syntax

The following is the syntax of the DESELECT command:

DESELECT device_name

The symbol device_name refers to a valid MSCP/TMSCP device label for either

a direct access or sequential access device. Direct access devices, such as disk

drives, are specified with the ‘‘DIA’’ prefix to the device label, for example,

‘‘DIA100’’. Sequential access devices, such as tape drives, are specified with

the ‘‘MUA’’ prefix, for example, ‘‘MUA120’’.

Example 3–4 is an example of the DESELECT command.

Example 3–4 DESELECT Command

UTILIT> DESELECT DIA100

UTILIT>

3.1.4.5 The ABORT Command

Use the ABORT command to terminate the QUALIFY, DISKTEST, and

TAPETEST operations. These operations normally run until stopped with the

ABORT command or by powering off the HSD05 array controller.

Command Syntax

The following is the syntax of the ABORT command:

The symbol device_name refers to a valid MSCP/TMSCP device label for either

a direct access or sequential access device. Direct access devices, such as disk

drives, are specified with the ‘‘DIA’’ prefix to the device label, for example,

‘‘DIA100’’. Sequential access devices, such as tape drives, are specified with

the ‘‘MUA’’ prefix, for example, ‘‘MUA120’’.

Example 3–5 is an example of the ABORT command.

Example 3–5 ABORT Command

3.1.4.6 FORMAT

After a device is selected with the SELECT command, you can use the FORMAT

command to perform a format operation.

ABORT device_name

UTILIT> ABORT DIA100

UTILIT>

Operating the HSD05 Array Controller 3–7

Command Syntax

The following is the syntax of the FORMAT command:

FORMAT device_name

The symbol device_name refers to a valid MSCP device label for a direct access

device. Direct access devices, such as disk drives, are specified with the ‘‘DIA’’

prefix to the device label, for example, ‘‘DIA100’’.

Command Description

You are prompted to confirm the format operation on the selected drive.

Answering ‘‘N’’ or ‘‘NO’’ aborts the operation with no change to the data on

the device. Answering ‘‘Y’’ or ‘‘YES’’ to this prompt starts the format operation on

the device.

The FORMAT command does not display a completion message. You can

monitor the format operation by periodically entering the SHOW command or

by observing the device’s activity indicator. After formatting the device, you

should run one or more qualification passes with the QUALIFY command.

Once started, you cannot abort the FORMAT operation. Example 3–6 shows of a

FORMAT operation display:

Example 3–6 FORMAT Operation Display

UTILIT> FORMAT DIA100

DeviceSIDVendorModelRevDev StatMaint OperMaint Status

------------------------------------------------------------------------DIA220 2-0 DEC RZ28 435E MAINT IDLE READY

FORMAT will destroy all data on this device. Are you sure (Y/N)? YES

UTILIT>

Device is the MSCP device name.

SID is the SCSI ID (target/lun).

Vendor is the first seven characters of the manufacturer’s name.

Model is the first seven characters of the manufacturer’s model name.

Rev is the manufacturer’s firmware revision code.

Dev Stat is the current device status.

Maint Oper is the UTILIT maintenance operation.

Maint Status is the UTILIT maintenance operation status.

3.1.4.7 The QUALIFY Command

You should run one or more qualification passes with the QUALIFY command

after a drive is formatted. The device to be qualified must first be selected with

the SELECT command.

3–8 Operating the HSD05 Array Controller

Command Syntax

The following is the syntax of the QUALIFY command:

QUALIFY device_name [/write]

The symbol device_name refers to a valid MSCP device label for a direct access

device. Direct access devices, such as disk drives, are specified with the ‘‘DIA’’