Page 1

INSTALLER / CONSUMER

SAFETY INFORMATION

Please read this manual

before installing and using

the heater.

WARNING:

this manual is not followed

exactly, a fire or explosion may

result causing property damage,

personal injury or loss of life.

• Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbour’s phone. Follow the

gas supplier's instructions.

• If you cannot reach your gas

supplier, call the fire department.

• Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

If the infor

Installer: Leave this manual

with the heater.

Consumer: Retain this

manual for futur

This is an unvented gas-fir

heater. It uses air (oxygen) from

the room in which it is installed.

Provisions for adequate

combustion and ventilation air

must be pr

ovided. Refer to the

Installation section on page 3.

e r

mation in

ence.

efer

ed

Unvented

Gas-Fired Room Heater

Blue Flame Heaters

Models: RMC-LC10NG, RMC-LC10LP - 10,000 Btu/hr.

RMC-LC20NG(F), RMC-LC20LP(F) - 20,000 Btu/hr

RMC-LC30NG(F), RMC-LC30LP(F) - 30,000 Btu/hr

RMC-LC10NG(T), RMC-LC10LP(T) - 10,000 Btu/hr.

RMC-LC20NG(T),(F), RMC-LC20LP(T),(F) - 20,000 Btu/hr

RMC-LC30NG(T),(F), RMC-LC30LP(T),(F) - 30,000 Btu/hr

(F)=Fan, (T)=Thermostat Gas Control

Infra-Red Heaters

Models:

RMC-LI10NG, RMC-LI10LP - 10,000 Btu/hr

RMC-LI18NG(F), RMC-LI18LP(F) - 18,000 Btu/hr

RMC-LI30NG(F),

RMC-LI06NG, RMC-LI06LP - 6,000 Btu/hr.

RMC-LI10NG

RMC-LI18NG

RMC-LI30NG

(T)

(T),(F)

(T),(F)

RMC-LI30LP(F)

, RMC-LI10LP

, RMC-LI18LP

, RMC-LI30LP

(T)

(T),(F)

(T),(F)

- 30,000 Btu/hr

- 10,000 Btu/hr

- 18,000 Btu/hr

- 30,000 Btu/hr

(F)=Fan, (T)=Thermostat Gas Control

User’s Operation and Installation Manual

07/05 Rev 3.

Page 2

General Information

Table of Contents

Installer / Consumer Safety Information . . . . 1

General information . . . . . . . . . . . . . . . . . . . 2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Instructions . . . . . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . 10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 11

Replacement Parts . . . . . . . . . . . . . . . . . . . 12

Accessories . . . . . . . . . . . . . . . . . . . . . . . . 14

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

SAFETY: Accidents are always tragic especially because so

many of them could have been prevented with a little care and

attention. These are some basic good practices we hope you

will follow for safe use of your gas fired room heater.

TANT: Read this user's manual carefully and

IMPOR

completely before trying to assemble, operate or service

this heater. Improper use of this heater can cause serious

injury or death from burns, fire, explosion, electrical shock

(fan models) or carbon monoxide poisoning.

Early signs of carbon monoxide poisoning resemble the flu

with headaches, dizziness or nausea. If you have these signs,

the heater may not be working properly. Get fresh air at once!

Have heater serviced. Some people are more affected by

carbon monoxide than others. These include pregnant

women, people with heart or lung disease or anemia, those

under the influence of alcohol or those at high altitude.

Begin by ensuring proper installation and servicing. Ensure

that your qualified technician who installs this heater follows

ve

wher

,

Ha

e not

the installa

the installer show you where the gas supply shut off valve is

loca

hea

tightened, you may have a leak and therefore a faint gas

smell.

Some leaks can only be found with the main burner gas on

and this must be done by a qualified technician.

This appliance may be installed in an aftermarket,

per

prohibited by local codes. This appliance is only for use with the

type of gas indicated on the rating plate. This appliance is not

convertible for use with other gases.

its controls can be dangerous.

tion instructions provided with this product.

ted so tha

ter

manently located,

t you kno

If the connections are not perfectly sealed or

.

inding a leak is NOT a do-it-yourself procedure.

F

w where to shut off the gas to the

manufactur

ed (mobile) home

hange to this heater or

Any c

PRECAUTIONS

• Never use natural gas in a unit designed for propane gas.

• Never use propane in a unit designed for natural gas.

void the

o a

• Check all joints and connections.

danger of fire, accident or explosion, never check a

potential gas leak with an open flame.

An unvented room hea

•

10,000 BTU per hour shall not be installed in a bedroom or

ter ha

T

ving an input rating of more than

bathroom and an unvented room heater having an input

rating of more than 6,000 BTU per hour shall not be installed

in a bathroom.

• Do not install RMC-LC30,

bedroom or a bathroom.

• Do not install RMC-LC10 or LI10 hea

are allowed in bedrooms.

• LI06 heaters are allowed in bathrooms or bedrooms.

• This appliance is intended for supplemental heating.

• Do not use a blower or other accessory not approved for use

with this heater.

• Due to high temperatures, the appliance should be located

out of traffic and away from furniture and draperies. Keep

flammable objects more than 36” from the front and top of

the heaters and more than 10” from the sides of the heater

for the L106 heater).

( 8”

• Provide adequa

servicing the heater.

• Maintain adequa

w for proper and safe operation of the heater.

allo

WARNING: Do not allow fans to blow directly into the heater.

•

Avoid any drafts that alter the burner flame patterns.

te clearances for accessibility for purposes of

te clearances around the air openings to

LI30, LC20 or LI18 heaters in a

ters in a bathroom, they

SAFE OPERATION OF YOUR LEGACY

VENT FREE HEATER

• This heater needs fresh, outside air for combustion to run

properly. This heater has an oxygen depletion sensor (ODS)

pilot light safety system. The ODS shuts down the heater if

not enough fresh air (oxygen content > 18%) is available.

• Never run heater in confined space. Refer to page 4.

• If heater shuts off, do not relight until you provide fresh,

outside air. If heater keeps shutting off, clean it and have it

serviced.

• Keep appliance area clear and free from combustible

materials, gasoline and other flammable vapors and liquids.

• Keep burner and control compartment clean. See

maintenance section of this manual.

• Do not place clothing or other flammable material on or near

the appliance.

• Children and adults should be alerted to the hazard of high

surface temperatures and should stay away to avoid burns

and clothing ignition.

• Young children should be carefully supervised when they are

in the same room with the appliance. Never allow them to sit,

stand or play on or around the heater.

• Make sure tha

vicing or lighting the a

ser

operating the heater.

Do not use the hea

•

Immedia

room heater and to replace any part of the control system and

y gas control which has been under wa

an

The ODS pilot light safety system is designed to prevent

•

asphyxiation due to a lack of oxygen in the air.

The hea

•

t if the safety screen or guard is removed for

ppliance,

ter if an

tely call a qualified ser

ter does not monitor the air for CO.

it is replaced prior to

y part has been under water.

vice technician to inspect the

ter

.

2

Page 3

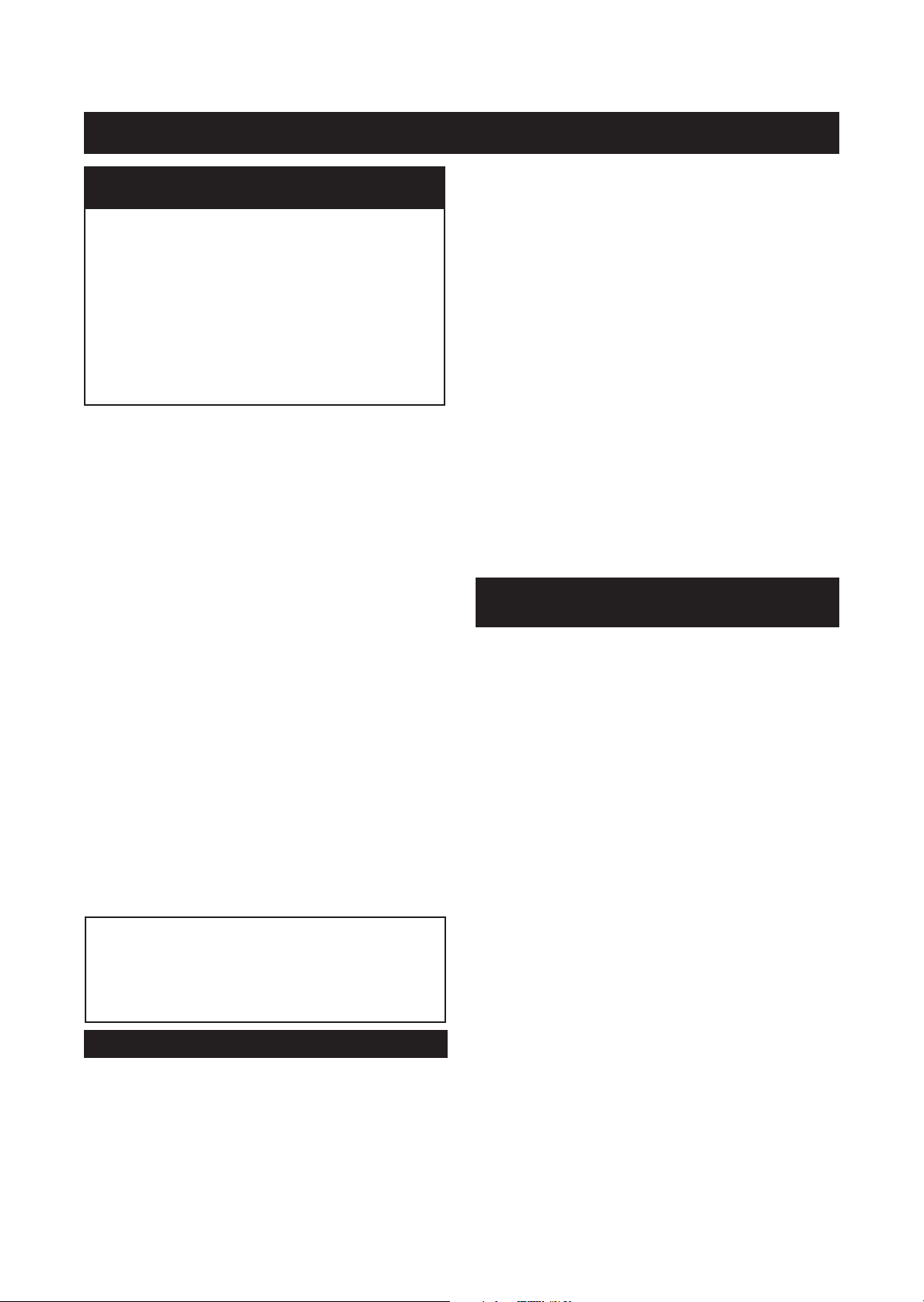

RMC-LCNG, RMC-LCLP, RMC-LING, RMC-LILP Specifications

Models

(Manual &

Thermostat)

RMC-LC30NG

RMC-LC20NG

RMC-LC10NG

RMC-LC30LP

RMC-LC20LP

RMC-LC10LP

RMC-LI30NG

RMC-LI18NG

RMC-LI10NG

RMC-LI06NG

RMC-LI30LP

RMC-LI18LP

RMC-LI10LP

RMC-LI06LP

Gas Type

Natural

LP

Natural

LP

Input Rating

(Btu/Hr) Variable

Min. Max Min. Max

Regulator

Pressure

Setting

15,000 30,000

10,000 20,000

4.0” w.c. 5.0” w.c. 11” w.c.

5,000 10,000

15,000 30,000

10,000 20,000

10” w.c. 11.0” w.c. 14.0” w.c.

5,000 10,000

6,400 30,000

6,400 18,000

5,500 10,000

- 6,000

6,400 30,000

6,400 18,00

5,500 10,000

10” w.c. 11.0” w.c. 14.0” w.c.

- 6,000

Inlet Gas Supply

Pressure

of Heater

27”x24”x8

3/8

19

”x22

1/2

x20

15

”

x24”x8

27”

3/8

19

”x22

1/2

15

”x20

27”x24”x8

3/8

19

”x22

1/2

15

”x20

1/2

15

”x20

27”x24”x8

3/8

19

”x22

1/2

15

”x20

1/2

15

”x20

Size

NOTE: For altitude above 2,000 feet, reduce the input ratings (Btu/Hr) 4% for each 1,000 feet above sea level.

DO NOT USE THIS HEATER AT AN ELEVATION ABOVE 4,500 FEET

1/2

” 30 lbs.

7/8

1/2

”x8

7/8

7/8

x7

”

1/2

”

7/8

1/2

”x8

7/8

7/8

”x7

1/2

”

7/8

1/2

”x8

7/8

7/8

”x7

7/8

7/8

”x7

1/2

”

7/

1/2

8

”x8

7/8

7/8

”x7

7/8

7/8

”x7

Weight

22 lbs.

”

17 lbs.

”

30 lbs.

22 lbs.

”

17 lbs.

”

30 lbs.

22 lbs.

”

17 lbs.

”

17 lbs.

”

30 lbs.

22 lbs.

”

17 lbs.

”

17 lbs.

”

LOCAL CODES

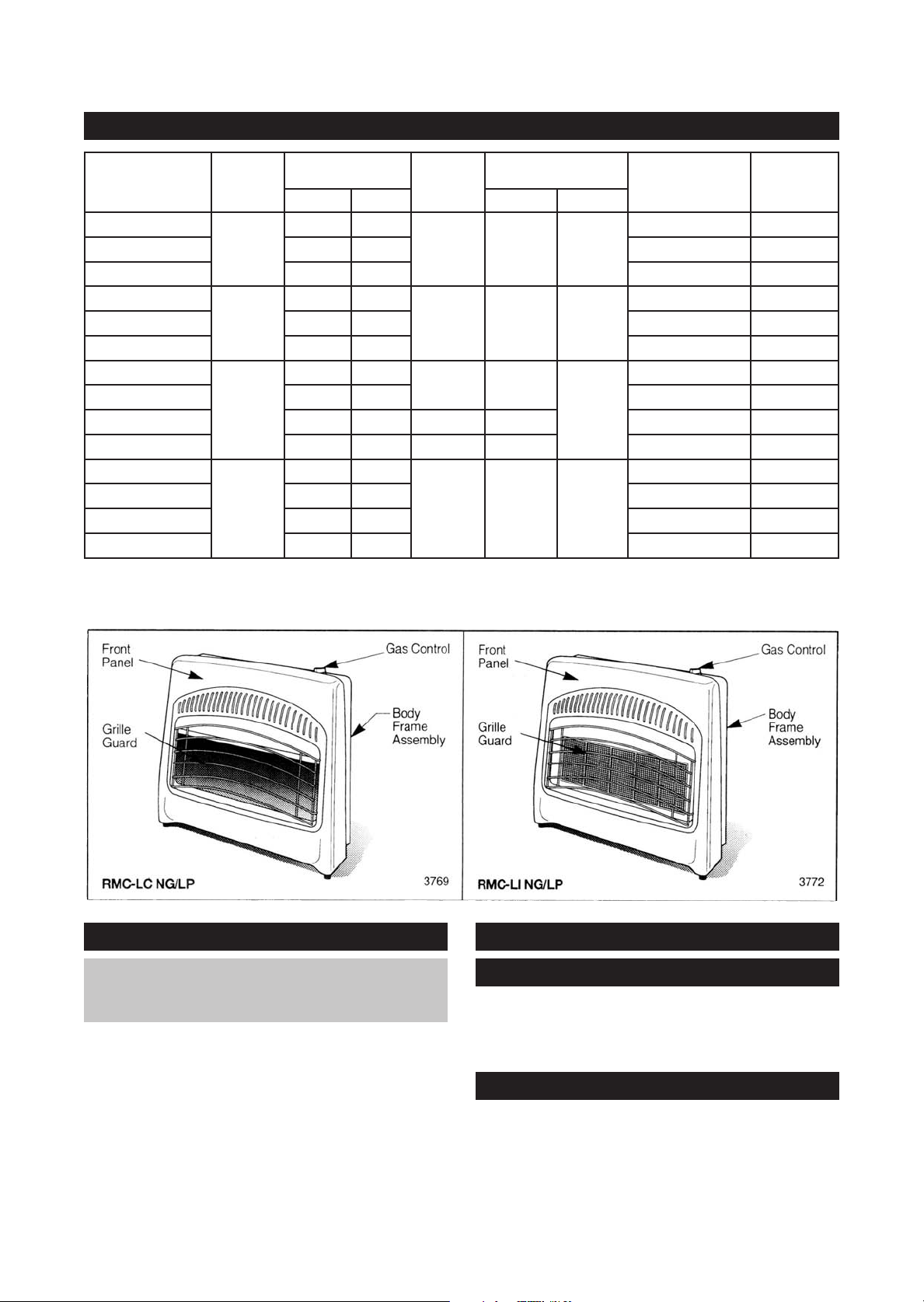

RMC-LC30 / RMC-LC20 / RMC-LC10

RMC-LI30 / RMC-LI18 / RMC-LI10 / RMC-LI06

Certified to ANSI Z21.11.2b-2004 Unvented Heaters

Install and use heater with care. Follow all local codes. In the

absence of local codes,

Fuel Gas Code

ANSI Z223.2,

Available from:

American Na

Standards Institute,

tional

Inc.

1430 Broadway

NY 10018

ork,

Y

New

use the la

test edition of the National

tional F

Na

Associa

A54.

tion,

also kno

wn as NFP

Batterymarch Park

y, MA 02269

Quinc

ire Protection

Inc.

PRODUCT FEATURES

SAFETY DEVICE

This heater has a pilot with an Oxygen Depletion Sensor Shutoff system (ODS).

ters.

free hea

The ODS pilot is a required fea

The ODS pilot shuts off the hea

oxygen content is reduced belo

w 18%.

ture for vent-

ter if the normal air

PIEZO IGNITION SYSTEM

This system requires no ma

This hea

es,

ter has a piezo ignitor

tteries or other electrical sources to light the heater.

ba

.

tch

-

3

Page 4

Installation

PROVIDE ADEQUATE COMBUSTION

AND VENTILATION AIR

• This heater shall not be installed in a confined space or

unusually tight construction unless provisions are provided

for adequate combustion and ventilation air.

This heater must have fresh air for proper operation. If not,

•

poor fuel combustion could result. Read the following

instructions to insure proper fresh air for this and other fuel

burning appliances in your home.

Modern construction standards have resulted in homes that

are highly energy efficient and that allow little heat loss.

However, your home needs to breathe and all fuel burning

appliances need fresh air to function properly and safely.

Exhaust fans, clothes dryer, fireplaces and other fuel burning

appliances all use the air inside the building. If the available

fresh air supply is insufficient to meet the demands of these

appliances, problems can result.

Confined Space:

The National fuel Gas Code, ANSI Z223.1 / NFPA 54 defines a

confined space as a space whose volume is less than 50

cubic feet per 1000 BTU per hour (4.8 m3 per kw) of the

aggregate input rating of all appliances installed in that space.

Unconfined Space:

An unconfined space is defined in the same standards as a

space whose volume is not less than 50 cubic feet per 1000

BTU per hour (4.8 m3 per kw) of the aggregate input rating of

all appliances installed in that space. Rooms communicating

directly with the space in which the appliances are installed,

through openings not furnished with doors, are considered a

part of the unconfined space.

Example:

10,000 BTU Legacy heater should only be installed in a room

whose volume is more than 500 cubic feet. A room that is 8'

x 8' x 8' (512 cubic feet) would be acceptable for a Legacy

10,000 BTU/hour heater.

If an additional fuel fired appliance is installed in the same

ppliance should be added to

the input ra

room,

t of the Legac

tha

room that should be serviced by both appliances.

Unusually tight construction is defined as construction

where:

a) Walls and ceilings exposed to the outside atmosphere have a

continuous wa

10-11 kg per pa-sec-m2) or less with openings gasketed or

sealed;

Weather stripping has been added on openable windows and

b)

doors; and

c) Caulking or sealants are applied to areas such as joints

around windo

between wall-ceiling joints,

floors,

penetrations for plumbing, electrical and gas lines and at

other openings.

ting of tha

y hea

ter va

w and door frames, between sole plates and

t a

ter to determine the minimum sized

pour retarder with a rating of 1 perm (6 x

t

between wall panels,

a

WARNING: If the area in which the heater may be operated is

smaller that that defined as an unconfined space or if the

building is of unusually tight construction, provide adequate

combustion and ventila

described in the National fuel Gas code, ANSI Z223.1 / NFPA

Section 5.3 or applicable local codes.

54,

tion air by one of the methods

GAS TYPE

Verify the type of gas supply to be used, either natural gas or

LP (Propane), and make sure the marking on the appliance

rating plate agrees with that of the supply gas. The rating plate

is located on the side of the heater, which indicates the type of

gas the heater is manufactured for.

WARNING: This appliance is only for use with the type of gas

indicated on the rating plate.

This appliance is not convertible for use with other gases.

ITEMS NEEDED FOR

HEATER INSTALLATION

Before installing the heater, make sure you have these items:

• Gas piping (check local codes)

• Test gauge connection

• Sealant (resistant to LP gases) - approved thread

compound

• Manual shut-off valve*

• Sediment trap - where required

• Ground joint union

• Tee joint and pipe wrench

*An installer supplied design-certified manual shut-off valve

with 1/8 NPT tap connection.

4

Page 5

LOCATING THE HEATER

• Due to high tempera

tures, the appliance should be located out

of traffic and away from furniture and draperies. Keep flammable objects more than 36” from the front and top of the

heaters and more than 10” from the sides of the heater.

• Provide adequate clearances for accessibility for purposes of

vicing the heater.

ser

• Maintain adequate clearances around the air openings to

allow for proper and safe operation of the heater.

• WARNING: Do not allow fans to blow directly into the heater.

Avoid any drafts that alter the burner flame patterns.

This heater is designed to be mounted on a wall or on the floor.

WARNING: Never install the heater;

• in a bathroom*

• in a recreational vehicle

• where curtains, furniture, clothing or other flammable are

less than 36” from the front, top or sides of the heater

• as a fireplace insert

• in high traffic areas

• in windy or drafty areas

*Models RMC-L106NG or LP Permitted for bathroom installation.

WARNING: Vent-free heaters add moisture to the air. Although

this is beneficial, installing heater in rooms without enough

ventilation may cause mildew formation from too much

moisture content. See National Fuel Code for Fresh Air for

Combustion and Ventilation.

This appliance may be installed in an aftermarket, permanently

located manufactured (mobile) home, were not prohibited by

state or local codes.

Caution: If you install the heater in a home garage:

• Heater must be at least 18” above floor

• Locate heater where moving vehicle will not hit it.

• Install to

ANSI Z223.2 / NFPA 54 using fixed gas supply piping.

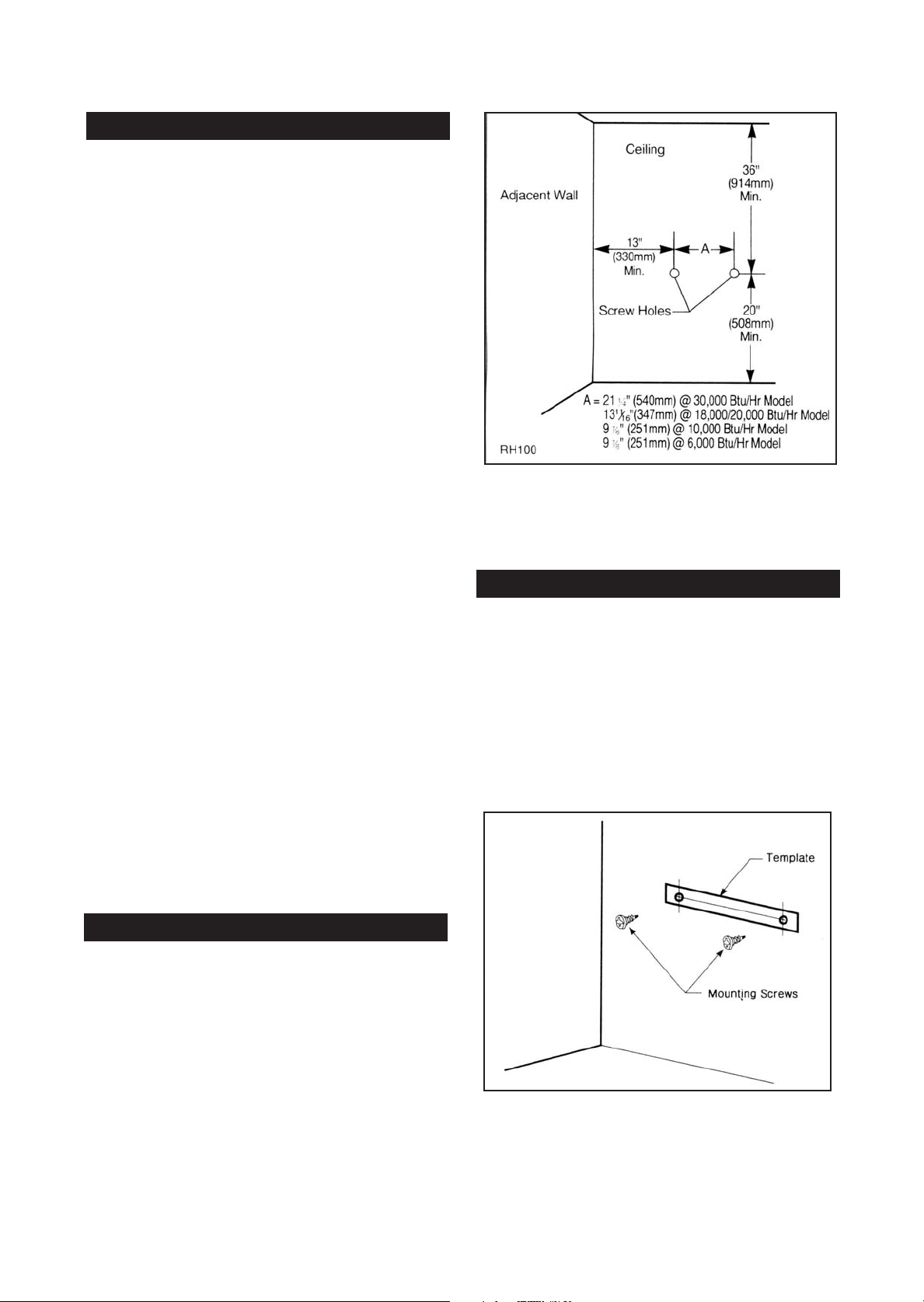

Fig. 2 Minimum clearances from mounting holes to top surface of flooring,

adjacent walls and ceiling

ATTACH MOUNTING SCREWS TO WALL

NOTE: Wall anchors and mounting screws are in hardware

package provided with heater.

1. Install mounting screws on wall as shown in Figure 3. Use

enclosed paper template for proper location of holes. Be

sure template is level. It may be necessary to use plastic or

lead anchors for plaster walls.

2. Drill holes at marked location using 9/64” drill bit.

Insert mounting screws.

3. Leave screw head out from wall far enough to attach

heater.

PREPARING FOR INSTALLATION

1. Remove heater from carton

Remove all protective packa

2.

for shipment.

3. Check heater for any shipping damage. If heater is

promptly inform dealer/distributor.

ged,

dama

Select a loca

4.

tion for the hea

exposure of the radiant surface to the room, but will not be

subjected to accidental contact.

learance must be a

te c

Adequa

5.

ing. Refer to Figure 2 for clearances that must be maintained to the side walls,

.

rounding the hea

ter

ging applied to heater

t will provide maximum

ter tha

vailable around the air open

floor and horizontal surface sur-

-

3

Fig.

Be sure templa

Use pa

per templa

te is level.

te supplied to mark loca

tion of mounting holes.

5

Page 6

WALL ANCHOR METHOD

FLOOR INSTALLATION

When mounting hea

ter to hollow walls (wall areas between

studs) or solid walls (concrete or masonry) it may be neces-

y to use wall anchors.

sar

1. Place paper template on wall maintaining minimum clearance. Be sure template is level.

2. Drill holes at marked locations using 5/16”drill bit.

For solid walls, concrete or masonry, drill holes at least

1”deep.

3. Insert plastic anchor. Tap anchor flush to wall. (Fig. 4)

4. Insert screw into wall anchor leaving screw head out far

enough to attach heater. (Fig. 4)

5. Hang heater on mounting screws in holes provided at the

rear of the heater.

1. Heater may only be installed on a noncombustible flat

surface. Where the flooring is carpeting, tile or of other

combustible material other than wood flooring, maintain the

minimum clearances to the floor as shown in figure 2 or

else use a metal or wood panel (not supplied) extending the

full width and depth of the appliance.

2. Measure heater mounting screw location “X” as desired

above floor. (Fig. 5)

3. Use enclosed “paper template” for proper distance between

holes. Be sure template is level. It maybe necessary to use

plastic or lead anchors for plaster walls.

4. Leave screw head out from wall far enough to attach heater.

3/4

x = 17

45 CM 30,000 BTU/hr units

"

1/2

42 CM 18 & 20,000 BTU/hr units

16

"

1/4

14

" 36 CM 6 & 10,000 BTU/hr units

Fig. 4 Wall anchor.

Fig. 5 Optional wall mounting screws for floor installation.

6

Page 7

CONNECT TO GAS SUPPLY

Installation should be done by a qualified service person.

Before connecting the appliance, turn off all gas appliances.

Close the main gas valve a

certain there is good ventilation where the installation will be

Installation should comply with all applicable building

made.

codes and ANSI Z223.1, latest edition. Use PLP gas resistant

pipe compound to seal threaded joints.

An installer supplied,

regulator must be installed to bring the gas supply pressure

down to 14" w.c. for LP gas or 11" for natural gas.

WARNING: Never connect an unregulated gas line to the

heater.

IMPORTANT: Check gas line pressure before connecting heater

to gas line. Gas line pressure must not be higher higher than

14" w.c. for LP gas or 11" for natural gas.

NOTE: The gas line connection can be made with 3/8”black or

steel pipe. Internally tinned copper tubing may be used in certain areas. Check your local codes. Use pipe of large enough

diameter to allow proper gas volume to heater. If pipe is too

small, undue pressure loss will occur.

CAUTION: Use pipe joint sealant that is resistant to liquefied

petroleum gases. Install sediment trap in supply as shown in

Figure 6.

Locate sediment trap where it is within reach for cleaning.

Locate sediment trap where matter is not likely to freeze. A

sediment trap prevents moisture and contaminant's from going

into the heater controls. If the sediment trap is not installed or is

installed wrong, the heater may not operate properly.

Test for gas leaks with a mild soap and water solution. Apply

water/soap solution with brush only - do not over apply.

NEVER test with an open flame.

t the gas meter or LP tank. Make

design certified gas pressure

PRESSURE TEST GAS SUPPLY

PIPING SYSTEM

ppliance and its individual shut off (control) valve must

The a

be disconnected from the gas supply piping system during any

pressure testing of the system at test pressure in excess of

1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping

system by closing the individual manual shut-off valve (fig. 7)

during any pressure testing of the gas supply system at test

pressure equal to or less than 1/2 psi (3.5 kPa).

Fig. 7 Manual shut-off valve location.

Fig. 6 Gas line connection

LEAK TESTING HEATER

GAS CONNECTION

1. Make sure control knob of heater is in the OFF position.

2. Open manual shut-off valve.

3. Open main gas valve located near gas meter.

4. check all joints from manual gas valve up to control valve

and including the manifold assembly. Apply the soap solution

around the connections, valve and tubing. Soap bubbles will

appear where a leak is present.

5. If a leak is present, immediately turn off gas supply, tighten

any leaky fittings, turn gas on and recheck.

6. To check burner and safety valve, the burner must be lit. (See

Operating Instructions) Check the rest of the connections for

leaks.

7. Turn off the heater prior to making any gas connection

repairs.

7

Page 8

Operation Instructions

FOR YOUR SAFETY - READ THIS

SECTION BEFORE LIGHTING

ARNING: IF YOU DO NOT FOLLOW THESE INSTRUCTIONS

W

EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE

A. BEFORE LIGHTING smell all around the appliance area for

gas. Be sure to smell next to floor because some gas is

heavier than air and will settle on the floor.

IF YOU SMELL GAS:

1. Do not try to light appliance.

2. Do not touch electrical switches; do not use any phone in

your building.

3. Immediately call your gas supplier from a neighbour’s phone.

Follow your gas suppliers instructions.

4. If you cannot reach you gas supplier’s, call the fire department.

B. Use only your hand to push in or turn the gas valve control

knob. Never use tools. If the knob will not push in or turn by

hand, do not try to repair it, call a qualified service technician.

Force or attempted repair may result in a fire or explosion.

C. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of this control system and

any gas control which has been under water.

ATTENTION:

Keep burner and control compartment clean.

See installation and operating instructions accompanying the

heater.

See the safety information on the sides of the heater.

WARNINGS:

Do not touch.

Hot while in opera

Keep children, clothing and furniture away.

Do not light or opera

flammable va

8

Fig.

Control knobs

tion.

te where gasoline and other liquids ha

pors are present.

RMC-LC10, RMC-LI10 & LI06 Only

ving

LIGHTING INSTRUCTIONS

MANUAL GAS CONTROL

Stop! Read and Heed the Warnings and Cautions on the side

1.

of the heater.

2. Check that gas supply to the heater is on.

3. Push in gas control knob slightly and turn clockwise

to “OFF” position.

NOTE: knob cannot be turned from "PILOT" to "OFF" unless

knob is pushed in slightly. Do not force.

4. Wait five (5) minutes to clean out any air. Then smell for gas,

including near the floor. If you smell gas, STOP! Follow "B" in

the safety information on the side of the heater. If you do not

smell gas, go to the next step.

5. Push in gas control knob slightly and turn counterclockwise

to "PILOT/IGN” and depress for five (5) seconds.

NOTE: The first time that the heater is operated after connecting

the gas supply, the control knob should be depressed for

about thirty (30) seconds. This will allow air to bleed from

the gas system.

6. Release control knob and turn clockwise to "OFF".

7. Depress control knob while "OFF", then turn back to

to "PILOT/IGN”. This should cause the spark from the piezo

ignitor to light the pilot gas. Keep control knob depressed for

ten (10) seconds before releasing. If pilot does not light,

repeat steps 5, 6 and 7 or use a match.

8. When pilot is lit, turn the ignition knob to "ON".

9. To select the heating level desired, use the knob LOW to HIGH.

THERMOSTAT GAS CONTROL

1. Stop! Read and Heed the Warnings and Cautions on the side

of the hea

2. Check that gas supply to the heater is on.

3. Push in gas control knob slightly and turn clockwise

to “OFF” position.

4. Wait five (5) minutes to clean out any air. Then smell for gas,

including near the floor. If you smell gas, STOP! Follow "B" in

the safety information on the side of the heater. If you do not

smell gas, go to the next step.

5. Turn control knob counterclockwise to “PILOT”

position. Press in control knob for five (5) seconds.

NOTE: The first time that the heater is operatedafter connecting

6. With control knob pressed in, push down and release ignitor

button. This will light pilot. If needed, keep pressing ignitor

button until pilot lights.

7. Keep control knob pressed in for 30 seconds after lighting

pilot. After 30 seconds, release control knob.

8. If pilot goes out, repeat steps 5 through 7 or use a match.

9. When pilot is lit, turn control knob to on.Turn control knob

counterclockwise to desired heating level between

5 and 1.

ter.

the gas supply, the control knob should be depressed for

about thirty (30) seconds. This will allow air to bleed from

the gas system.

8

Page 9

TO TURN OFF GAS TO APPLIANCE

MANUAL GAS CONTROL

Turning Heater Off

Push in gas control knob slightly and turn c

to "OFF" position. Do not force.

Turning Burner Only Off (Pilot stays lit).

urn control knob clockwise to the PILOT position.

T

CAUTION: Do not try to adjust heating levels by using the

manual shut-off valve.

NOTE: The thermostat sensing bulb measures the temperature

of air near the heater cabinet. This may not always agree with

room temperature (depending on housing construction, installation location, room size, ect.). Frequent use of your heater will let

you determine your own comfort levels.

lockwise

THERMOSTAT GAS CONTROL

Turning Heater Off

Turn control knob clockwise to “OFF” position.

Turning Burner Only Off (Pilot stays lit).

Turn control knob clockwise to the PILOT position.

CAUTION: Do not try to adjust heating levels by using the

manual shut-off valve.

NOTE: The thermostat sensing bulb measures the temperature

of air near the heater cabinet. This may not always agree with

room temperature (depending on housing construction, installation location, room size, ect.). Frequent use of your heater will let

you determine your own comfort levels.

MANUAL LIGHTING INSTRUCTION

Fig. 9 Proper pilot flame

Fig. 10 Correct burner flame pattern for the RMC-LC blue flame burner.

1. Use a long match or a BBQ lighter. If not available, remove

guard assembly by flexing it.

2. Follow steps 1 through 4 as stated under Lighting

Instructions.

3.

Press and turn control knob counterc

PILOT/IGN position

4. With control knob pressed in, strike match, hold match to pilot

until pilot lights.

5. Keep control knob pressed in for 30 seconds after lighting

pilot. After 30 seconds, release control knob.

Replace guard assembly if it was removed in step 1.

6.

lockwise to the

PILOT AND BURNING INSPECTION

Each time you light your heater check that the pilot flame and

igures 9, 10 and 11. If

burner flame pa

flame pa

dealer or qualified gas technician for assistance. Do not operate

ter until the pilot flame is correct.

the hea

ARNING:

W

increased levels of carbon monoxide. If burning flame pattern

shows yellow tipping, follow instruction in the Troubleshooting

section on pa

NOTE: Do not mistake orange flames with yellow tipping. Dirt or

other partic

orange flame

tterns are as sho

tterns are incorrect,

w tipping occurs,

If yello

ge 10.

les may enter the hea

.

wn in F

Contact your

turn the hea

ter and cause transient pa

ter off.

your heater could produce

tches of

11

Fig.

Correct burner flame pa

ttern for the RMC-LC plaque hea

.

ter

9

Page 10

Troubleshooting

Problem Possible Cause What To Do

When control knob is pressed in

and turned counterc

ignition, there is no spark at

ODS pilot.

When control knob is pressed in

and turned counterc

ignition/pilot position there is

spark but no ignition

ODS pilot lights but flame

goes out when control knob

is released.

lockwise to

lockwise to

1. Ignitor electrode positioned wrong.

Ignitor electrode broken.

2.

3. Ignitor cable pinched or broken.

4. Ignitor cable not connected to ignitor

electrode.

1. Gas supply turned off.

Control knob not in pilot position.

2.

3. Control knob not pressed in while in pilot

position.

4. ODS pilot is clogged.

5. Air in gas lines.

1.Control knob not pressed long enough.

2. Safety interlock is triggered.

3. Pilot flame not touching the thermocouple.

Problem could be result of one or both of

the following:

• Partially clogged ODS pilot orifice.

• Low gas pressure.

4. Thermocouple damaged.

5. Thermocouple connection loose at gas

control valve.

6. Gas control valve damaged.

1. Reposition ignitor electrode.

Replace electrode.

2.

3. Free ignitor cable, if damaged, replace.

4. Connect cable to electrode

1. Turn gas supply on.

Turn control knob to pilot position.

2.

3. Press in control while in pilot position.

Call a qualified service technician.

4.

5. Purge gas lines and repeat ignition operation.

1. After ODS pilot lights, keep control knob

pressed in approximately 30 seconds.

2. Wait one minute, repeat ignition operation.

3. Contact your gas company, gas supplier or

qualified service technician.

4. Replace thermocouple.

5. Hand tight until snug then tighten 1/4 turn with

a wrench.

6. Replace gas control.

Burner does not light after ODS

pilot is lit.

Delayed ignition. 1. Main burner carry over ports clogged.

Burner backfiring during

operation.

w flames during burner

ello

Y

operation. (RMC-LC)

Burner plaque(s) does not glow.

(RMC-LI)

Slight smoke and odor during

initial operation.

ter produces a whistling

Hea

noise when burner is lit.

1. Burner orifice clogged.

2. Gas supply pressure is very low.

2.

Gas supply pressure is very low.

1. Burner orifice is clogged.

2. Burner ports damaged.

Not enough air

1.

1. Plaque(s) is damaged.

2. Inlet gas pressure too low.

3. Control knob set between locked positions.

1. Residues from manufacturing processes. 1. Will stop after a few hours of operation.

Air passa

1.

Air in gas line.

2.

geways blocked.

1. Clean burner orifice.

2. Contact gas supplier.

1. Clean main burner ports.

2.

Contact gas supplier.

1. Clean burner orifice.

2. Replace burner.

Check air passa

1.

debris (Refer to Maintenance section)

1. Replace burner.

2. Contact local gas supplier.

3. Turn control knob until it locks at desired

setting.

Check minimum installa

1.

passageways for debris.

te burner until the air is completely

Opera

2.

purged.

geways and burner for dirt and

learances and air

tion c

10

Page 11

Troubleshooting continued

Problem Possible Cause What To Do

ter produces a clicking

Hea

noise just after burner is lit or

turned off.

Gas odor even when control

knob is in OFF position.

Gas odor during combustion. 1. Foreign matter in gas or on burner ports.

Heater shuts off on ODS. 1. Not enough fresh air is available.

Metal expanding and contracting.

1.

1. Gas leaks. Refer to front of page Warnings.

2. Gas control defective.

2. Heater burning vapors form paint,

impurities in air.

3. Gas leaks, refer to front page Warnings.

2. Low gas pressure.

3. ODS pilot partially clogged.

Maintenance

Repair should be done by a qualified service person.

The appliance should be inspected before use and at least

annually by a professional service person. More frequent

cleaning may be required due to excessive lint from carpeting,

bedding material, etc. It is imperative that control

compartments, burners and circulating air passageways of the

heater be kept clean. Dust, lint, cobwebs or debris may affect

heater performance. The heater draws air into it during normal

operation and in the process dust, lint or debris may be drawn

in also. It is important to keep the burner, gas control and

combustion and circulating air passageways clean. Inspect or

have these areas inspected annually at the beginning of the

heating season by a qualified service person. Depending on

the surroundings, the room heater may require frequent cleaning due to excessive lint or debris.

Before cleaning ensure the gas supply is off and the gas control knob is in the OFF position.

WARNING: Danger of bodily injury. If fan assembly accessory is used, turn off power supply at disconnect switch or

service panel before removing any access panels from

heater.

Make sure the hea

ter is cool.

BURNER AND ODS PILOT CLEANING

Clean the exterior with soft bristle brush, vacuum cleaner or

pressurized air. Never use a wooden toothpick as it may break

off and clog the ODS pilot or main burner port.

Use a flashlight to inspect the main burner inlet to ensure it is

not blocked. If obstruction can be seen, use a metal wire coat

hanger that has been straightened out. Use a vacuum cleaner

to clean the primary air openings to the main burner(s).

WARNING: Failure to keep the primary air openings to the

burner(s) clean may result in sooting and property damage.

In order to clean ODS pilot orifice, use pressurized air to blow

dust out.

will get rid of the accumulated dirt. If that does not work blow

out any dust through primary air openings of pilot assemblies

(This unit has two openings; one benea

the second one opposite from bimetal strip. Use the one wide

open, do not try to lift the bimetal strip.)

CLEANING AIR PASSAGEWAYS AND

Use a vacuum c

tion and circulating air passageways and dampened cloth to

clean the cabinet/casing.

This is common with heaters. If noise is

1.

excessive, contact a qualified service

technician.

1. Locate and correct leaks immediately.

2. Replace gas control.

1. Check gas passage way and burner.

2. Ventilate room, stop storing and using odor

causing products near heater.

3. Locate and correct leaks immediately.

1. Open window.

2. Contact gas supplier.

3. Clean the pilot.

Sometimes blowing air backwards through the pilot

th the bimetal strip and

UNIT CASINGS

leaner or pressurized air to c

lean the combus

-

11

Page 12

RMC-LI NG/LP Unvented Room Heater

Item/Model Number RMC-LI06NG/LP RMC-LI10NG(T)/LP(T) RMC-LI18NG(T)/LP(T) RMC-LI30NG(T)/LP(T)

1. Lower Heat Cover LI10LP-01-01-02 LI10LP-01-01-02 LI18LPT-01-01-03 LI30NG-01-01-02

2. Guard Assembly LC10NG-01-04 LC10NG-01-04 LI18LPT-01-04 LC30NGTF-01-04

3. Reflector LI10LP-01-01-01 LI10LP-01-01-01 LI18LPT-01-01-01 LI30NG-01-01-01

4. Upper Heat Cover LC10NG-01-01-02 LC10NG-01-01-02 LI18LPT-01-01-02 LC30NGTF-01-01-02

5. Leg Front LC10NG-05 LC10NG-05 LC10NG-05 LC10NG-05

6. Front Panel LC10NG-01-03 LC10NG-01-03 LI18LPT-01-03 LC30NGTF-01-03

7. Burner Assembly Body LI6LP-03-00 LI10LP-03-00 LI18LPT-03-00 LI30LPTF-03-00

8. Ceramic Plate LI18LPT-03-09 LI10LP-03-03 LI18LPT-03-09 LI18LPT-03-09

9. Body Frame Assembly LC10NG-02-00 LC10NG-02-00 LC20NG-02-00 LC30LP-02-00

10. Knob – Valve LC10NG-12-00 LC10NG-12-00 LC10NG-12-00 LC10NG-12-00

11. Leg – Rear LC10NG-04 LC10NG-04 LC10NG-04 LC10NG-04

12. Valve Link LI6LP-02 LI6LP-02 LI18LPF-02 LI30NG-02

13. Fix Pin – Link LI6LP-03 LI6LP-03 LI6LP-03 LI6LP-03

14a. Gas Control CK-890SL-A1/00(B) CK-890SL-A1/00(D) CK-890SL-A1/00(E) CK-890SL-A1/00(E)

14b. Thermostat Gas Control LI18LPT-04-00 LI18LPT-04-00 LI18LPT-04-00

15. Tubing Inlet Assembly LI6LP-07-00 LI10LP-07-00 LI18LPF-07-01 LI30NG-07-01

16a. Outlet Tubing Assembly LI10NGT-08-00 LI18LPT-08-00 LI30LPTF-08-00

16b. Tubing Outlet – A Assembly LI6LP-08-00 LI10LP-08-00 LI18LPF-08-00 LI30NG-08-00

17. Tubing Outlet – B Assembly LI10LP-10-00 LI18LPF-10-00 LI30NG-10-01-00

18. Tubing Outlet – BL Assembly LI30NG-10-02-00

19. Tubing Outlet – BR Assembly LI30NG-10-03-00

20. Tubing Outlet – C Assembly LI18LPF-11-00 LI30NG-11-01-00

21. Tubing Outlet – CL Assembly LI30NG-11-02-00

22. Tubing Outlet – CR Assembly LI30NG-11-03-00

23a. Manifold – “C” LI30NG-10-02

23b. Manifold Assembly - LI10NGT-03-02-00 LI18LPT-03-02-00 LI30LPTF-03-02-00

24. ODS Tubing Assembly LI6LP-09-00 LI10LP-09-00 LI18LPF-09-00 LI30NG-09-00

tor – LP

t Shield

tural

144NG 4-7" NG 8224 NG 8224 NG 8224

TZ-11/20B4

R

LC10NG-01 LC10NG-01 - LC30NGTF-01

TZ-11/20B2

R

TZ-11/20B4

R

TZ-11/20B4

R

25a. ODS Pilot

25b. ODS Pilot Assembly – LP 158LP 8-11" LPG 8420 LPG 8420 LPG 8420

26a. Main Nozzle – Natural LI6NG-08-05 LI10NG-08-05 LI6NG-08-05 LI6NG-08-05

26b. Main Nozzle – LP LI6LP-08-05 LI10LP-08-05 LI06LP-08-05 LI06LP-08-05

27. Connector – “B” LC10NG-05-02 LC10NG-05-02 LC10NG-05-02 LC10NG-05-02

28a. Pressure Regulator – Natural RTZ-11/20B3 RTZ-11/20B1 RTZ-11/20B3 RTZ-11/20B3

28b. Pressure Regula

29. Rear Radiant Hea

30. Shield - - LI18LPT-01 -

31. Optional Fan-Natural/LP - - RMA-FT RMA-FT

Assembly – Na

12

Page 13

CFM Home Products reserves the right to make changes in design, materials, specifications, prices and discontinue colors and

products at any time, without notice.

WARNING: Failure to position the parts in accordance with this diagram or failure to use only parts specifically approved with this

heater may result in property damage or personal injury.

13

Page 14

RMC-LC NG/LP Unvented Room Heater

Item/Model Number RMC-LC10NG/LP RMC-LC20NG/LP RMC-LC30NG/LP

1. Guard

2. Glass Panel LC10NG-01-02-01 LC20NGT-01-02-01 LC30NGTF-01-02-01

3. Glass Holder LC10NG-01-02-02 LC10NG-01-02-02 LC10NG-01-02-02

4. Reflector LC10NG-01-01-01 LC20NGT-01-01-01 LC30NGTF-01-01-01

5. Heat Cover – Upper LC10NG-01-01-02 LI18LPT-01-01-02 LC30NGTF-01-01-02

6a. Pressure Regula

6b. Pressure Regulator – LP RTZ-11/20B2 RTZ-11/20B2 RTZ-11/20B2

7. Nozzle Holder LC10NG-03-13 LC10NG-03-13 LC10NG-03-13

8a. ODS Pilot Assembly – Natural NG 8224 NG 8224 NG 8224

8b. ODS Pilot Assembly – LP LPG 8420 LPG 8420 LPG 8420

9. Fix Nut – Nozzle Holder LC10NG-03-11 LC10NG-03-11 LC10NG-03-11

10a. Main Nozzle – Na

10b. Main Nozzle – LP LC10LP-03-12 LC20LP-03-12 LC30LP-03-12

11a. Valve Bracket-Manual Gas Control LC10NG-04-02 LC10NG-04-02 LC10NG-04-02

11b. Valve Bracket-Thermostat Gas Control LI18LPT-04-02 LI18LPT-04-02 LI18LPT-04-02

12a. Manual Gas Control-Na

12b. Manual Gas Control-LP CK-890SL-A1/00(C) CK-890SL-A1/00(F) CK-890SL-A1/00(F)

12c. Thermostat Gas Control-Natural LC10NGT-04-00 LC20NGT-04-00 LC30NGTF-04-00

12d. Thermostat Gas Control-LP LC10NGT-04-00 LC20NGT-04-00 LC30NGTF-04-00

13. Outlet Tubing Assembly LC10NG-08-00 LC20NG-08-00 LC30LP-08-00

14. ODS Tubing Assembly LC10NG-09-00 LC20NG-09-00 LC30LP-09-00

15. Inlet Tubing Assembly LC10NG-07-00 LC20NG-07-00 LC30LP-07-00

16. Leg – Front LC10NG-05 LC10NG-05 LC10NG-05

17. Front Panel LC10NG-01-03 LI18LPT-01-03 LC30NGTF-01-03

18. Burner Assembly LC10NG-03-00 LC20NGT-03-00 LC30NGTF-03-00

19a. Burner Support – Left LC10NG-03-08 LC10NG-03-08 LC10NG-03-08

19b. Burner Support – Right LC10NG-03-09 LC10NG-03-09 LC10NG-03-09

20. Bod

21. Leg – Rear LC10NG-04 LC10NG-04 LC10NG-04

22. Knob – Valve LC10NG-12-00 LC10NG-12-00 LC10NG-12-00

23. Shield - LI18LPT

24. Rear Radiant Shield LC10NG-01 LC30NGTF-01

25. Optional Fan-Natural/LP - RMA-FT RMA-FT

Assembly

rame

y F

tor – Natural

tural

Assembly

tural

LC10NG-01-04 LI18LPT

TZ-11/20B5

R

LC10NG-03-12 LC20NG-03-12 LC30NGTF-03-12

CK-890SL-A1/00(C) CK-890SL-A1/00(F) CK-890SL-A1/00(F)

LC10NG-02-00 LC20NG-02-00 LC30LP-02-00

-01-04

TZ-11/20B1

R

-01

LC30NGTF-01-04

TZ-11/20B1

R

-

The following accessories are available from your local distributors/dealer. Each accessory comes with a separate installation

instruction. Be sure to read each instruction thoroughly before installation.

Accessories

OPERATION & MAINTENANCE INSTRUCTIONS

FMA-(F,FT) MANUALLY & THERMOSTATICALLY CONTROLLED

BLOWERS

:

IMPOR

The blo

ANT

T

prong grounding plug for your safety and protection against

electric shock.

outlet source.

Do not modify the plug provided if it will not fit the

ve the proper source outlet installed near the

Ha

heater location to avoid damage to the power cord. Source outlet

and grounding plug are illustra

14

wer cord is equipped with a three

wer po

12.

ted in the F

ig.

Description Model Number

Manual Fan Kit

Thermostat Fan Kit

FMA-F

FMA-FT

Fig. 12

Page 15

CFM Home Products reserves the right to make changes in design, materials, specifications, prices and discontinue colors and

products at any time, without notice.

WARNING: Failure to position the parts in accordance with this diagram or failure to use only parts specifically approved with this

heater may result in property damage or personal injury.

Accessories continued

CAUTION: Damaged power cord can cause a fire or electric

shock.

Prior to installing the blower, check for blower for any shipping

wer is damaged, promptly inform dealer where

If blo

ge.

dama

.

you bought the blo

INSTALLATION: Plug the blower power cord into a 110-120V

properly grounded type outlet (three prong receptacle) protected

by a 15 amp time delay or Circuit Sa

WARNING: Do not let your fingers touch the prongs of plug

when installing or removing the plug from the power outlet.

OPERATION:

Manually Oper

witch the blo

s

Manually & Thermostatically Controlled: Use the

MAN/OFF/AUTO rocker switch to MAN for manual ON or AUTO

wer

ver fuse for circuit breaker

ated:

Use the ON/OFF rocker s

wer ON or OFF as desired.

witch to manually

for thermosta

turns the blo

area reaches 105F and turns it OFF when the temperature at the

aforementioned location goes down to 86F.

MAINTENANCE:

WARNING: For your safety, turn switch “OFF” and remove plug

from po

.

blower. If power cord is worn, cut, or damaged in any way,

have it replaced immediately.

CARE OF BLOWER

In normal use, blower may accumulate excessive lint or dust,

so the blower should be vacuumed or brushed and checked

for proper operation at least once each year by a qualified

service personnel. Excessive accumulation of lint and dust can

cause the blower motor to overheat frequently and burn out.

tically controlled operation as desired. Thermostat

wer ON when the tempera

wer source outlet before c

ture near the discharge

leaning and maintaining

15

Page 16

WARRANTY

Service and Limited Warranty

CFM Home Products warrants this product to be free from

defects in materials and components for three (3) years from

te of first purchase, provided that the product has been

the da

properly installed, operated and maintained in accordance

with all a

warranty the Bill of Sale or cancelled check must be presented. This warranty is extended only to the original retail purchaser. This warranty covers the cost of part(s) required to

restore this heater to proper operating condition and labor

when provided by a CFM Home Products Authorized Service

Center.

Warranty part(s) MUST be obtained through authorized dealers

of this product and/or CFM Home Products who will provide

original factory replacement parts. Failure to use original factory replacement parts voids this warranty. The heater MUST

be installed by a qualified installer in accordance with all local

codes and instructions furnished with the unit.

This warranty does not apply to parts that are not in original

condition because of normal wear and tear, or parts that fail or

become damaged as a result of misuse, accidents, lack of

proper maintenance or defects caused by improper installation. Travel, diagnostic cost, labor, transportation and any and

all such other costs related to repairing defective heater will

be the responsibility of the owner.

pplicable instructions. To make a claim under this

THE FULL EXTENT ALLOWED BY THE LAW OF THE JURIS-

TO

DICTION THAT GOVERNS THE SALE OF THE PRODUCT; THIS

EXPRESS WARRANTY EXCLUDES ANY AND ALL OTHER

EXPRESSED WARRANTIES AND LIMITS THE DURATION OF ANY

AND ALL IMPLIED WARRANTIES, INCLUDING WARRANTIES OF

MERCHANT

POSE TO THREE (3) YEARS FROM THE DATE OF FIRST PURCHASE; AND CFM HOME PRODUCTS' LIABILITY IS HEREBY

LIMITED TO THE PURCHASE PRICE OF THE PRODUCT AND CFM

HOME PRODUCTS SHALL NOT BE LIABLE FOR ANY OTHER

DAMAGES WHATSOEVER INCLUDING INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

Some sta

warranty lasts or an exclusion or limitation of incidental or

consequential damages, so the above limitation on implied

warranties, or exclusion or limitation on damages may not

apply to you.

This warranty gives you specific legal rights,

have other rights that vary from state to state. Always specify

model and serial number when communicating with the

factory.

ABILITY AND FITNESS FOR A PARTICULAR PUR-

tes do not allow a limitation on how long an implied

and you may also

Contact CFM Home Products with questions concerning prices

and policies covering replacement parts. Parts may be ordered

through CFM Home Products distributor or dealer

need the follo

parts:

• The appliance model number.

• The serial number.

• A description of the part.

wing informa

tion when ordering replacement

. You will

Should you need additional information beyond

what your dealer can furnish, contact:

DISTRIBUTOR:

CFM Home Products

2695 Meadowv

Mississauga, Ontario, L5N 8A3

A

ANAD

C

Telephone: 1-800-668-5323

ale Boulevard

Model and serial numbers are listed on the rating plate

(located on right side of heater).

Record your model and serial number here for future

reference.

Model #

Serial #

Loading...

Loading...