Page 1

Operating instructions

Front loader ProfiLine

Type FS, FS-rapid emptying, FZ, FZ-L

Status: 06/2018

3468290 B58FZS 0000000078 EN 002

Page 2

Company details

Wilhelm STOLL Maschinenfabrik GmbH

PO box 1181, 38266 Lengede

Bahnhofstr. 21, 38268 Lengede

Phone: +49 (0) 53 44/20 -0

Fax: +49 (0) 53 44/20 -182

E-mail: info@stoll-germany.com

Web: www.stoll-germany.com

Spare Parts Order

Phone: +49 (0) 53 44/20 -144 and -266

Administration

Phone: +49 (0) 53 44/20 -145 and -146

Fax: +49 (0) 53 44/20 -183

E-mail: parts@stoll-germany.com

Copyright

© Wilhelm STOLL Maschinenfabrik GmbH

Reproduction of these instructions, both completely and in excerpts, is only allowed with approval from Wilhelm STOLL

Maschinenfabrik GmbH. Any infringement shall entail full compensation of damages and can be punishable by law.

The original instructions were written in the German language.

Instructions in other languages were translated from German.

Page 3

Contents

1 About this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Documentation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Use and purpose of the operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Validity of the operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Storage of the documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Other applicable documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.7 Design tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.8 Nomenclature of the footer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Explanation of safety and warning notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Representation and layout of warning notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Danger grading of warning notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 EC Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 Operational limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.7 Basic safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.8 Danger zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.9 Safety equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.10 Adhesive safety label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.11 Personnel requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.12 Behaviour in case of emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.12.1 Behaviour if the tractor tips or falls over . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.12.2 Behaviour in case of flashovers from electrical power lines . . . . . . . . . . . . . . . . . 24

3 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Structure of FS front loaders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Structure of FZ front loaders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Equipment variations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.4 Attaching it to the tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.5 Change frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.5.1 Euro change frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.5.2 SMS change frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.5.3 Euro-SMS Combi change frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.5.4 Euro-Alö3 Combi change frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5.5 Euro-FR Combi change frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5.6 Skid-steer change frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.5.7 Reinforced Euro change frame (FZ 100) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.6 Hydraulic lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.7 Hydraulic couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.7.1 Plug-in couplings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.7.2 Multiple coupling Hydro-Fix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

B58FZS 0000000078 EN 002 2

Page 4

4 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1 Implement locking mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1.1 Mechanical implement locking mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1.2 Hydraulic implement locking mechanism – Hydro-Lock . . . . . . . . . . . . . . . . . . . . 39

4.2 Basic functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3 Float position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.3.1 Lifting arm float position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.3.2 Implement float position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.4 Indicator for implement position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.5 Parallel motion (FZ, FZ-L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.6 Rapid traverse emptying (FS) and quick emptying (FZ-L). . . . . . . . . . . . . . . . . . . . . . . . 46

4.7 Return-To-Level (FZ-L) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.8 Anti-lowering guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.9 Additional functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.9.1 Additional control circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.9.2 Comfort Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.9.3 Lowering throttle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.9.4 Camera system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 53

5.1 Initial operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.2 Check before each start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.3 Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.1 Preparations on the tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3.2 Ballasting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.4 Adjusting the front loader locking mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.4.1 Adjusting the FS and FZ 8 to 50 front loader locking mechanism . . . . . . . . . . . . 57

5.4.2 Adjusting the "Double locking mechanism" FZ 50 to 100 front loader locking

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.5 Mounting the front loader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5.6 Aligning the front loader for mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.1 Operating elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.1.1 Basic controls with levers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.1.2 Tractor's own operating lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.1.3 STOLL Base Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.1.4 STOLL Pro Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.1.5 STOLL Trac Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.1.6 Switch/changeover switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.1.7 Comfort-Hydraulic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.2 Operating the parking supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.3 Operating the hydraulic couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.3.1 Operating the plug-in coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6.3.2 Operating Hydro-Fix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6.4 Operating the implement locking mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.4.1 Operating the mechanical implement locking mechanism on Euro, SMS and

Combi change frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

6.4.2 Operating the mechanical implement locking mechanism on skid-steer change

6.4.3 Operating the hydraulic implement locking mechanism . . . . . . . . . . . . . . . . . . . . 81

6.5 Picking up and putting down the implement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

3 B58FZS 0000000078 EN 002

frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Page 5

6.5.1 Picking up implements with mechanical implement locking mechanism on Euro,

SMS and Combi change frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

6.5.2 Picking up implements with mechanical implement locking mechanism on skid-

steer change frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6.5.3 Picking up implements with a hydraulic implement locking mechanism. . . . . . . . 87

6.5.4 Putting down the implement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

6.6 Levelling in reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

6.7 Driving on roads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

6.7.1 Activating and deactivating the road operation lock . . . . . . . . . . . . . . . . . . . . . . . 91

6.7.2 Passing through low clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

6.8 Parking the tractor with the front loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

8 Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.1 Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.1.1 Lubrication points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

8.1.2 Lubrication schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.2 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.2.1 Service schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.2.2 Service instructions for front loader mountings . . . . . . . . . . . . . . . . . . . . . . . . . . 101

8.2.3 Service instructions for front loader locking mechanism . . . . . . . . . . . . . . . . . . . 102

8.2.4 Service instructions for Comfort Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.2.5 Service instructions for the hydraulic lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.2.6 Service instructions for oil changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.3 Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.1 Temporary decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.2 Recommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9.3 Final decommissioning and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10 Spare parts and customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

10.1 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

10.2 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

11 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

11.1 Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

11.2 Noise emissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

11.3 Tightening torque for screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

11.4 Hydraulic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

11.4.1 Hydraulic diagram FS and FS-rapid emptying . . . . . . . . . . . . . . . . . . . . . . . . . . 111

11.4.2 Hydraulics diagram FZ and FZ-L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

11.5 Electric circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

11.6 Arrangement of the hydraulic valves for additional functions. . . . . . . . . . . . . . . . . . . . . 114

12 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

B58FZS 0000000078 EN 002 4

Page 6

1 About this manual

1.1 Documentation overview

There are various instructions and technical documentation for the front loader, mounting kit and

accessories. Most documents are available in multiple languages.

If a set of instructions is missing or required in a different language:

Order the instructions through a dealer.

Download instructions free of charge from the Internet at www.stoll-germany.com.

Installation instructions

The installation of the mounting kit as well as the hydraulic and electric equipment may only be

performed by an authorised specialised workshop.

The installation instructions describe how to install the front loader mounting kit and the hydraulic and

electrical equipment up to the initial start-up of the front loader. They are intended for the specialist

workshop.

The installation instructions have been specially compiled for this tractor model. They do not contain

any information that is already included in the operating instructions.

The installation instructions contain information on spare parts for the tractor-specific mounting parts

and equipment.

ABOUT THIS MANUAL

Operating instructions of the front loader

These operating instructions describe the safe use of the front loader from the initial operation to its

disposal. They are intended for the operator and the user of the front loader.

The operating instructions are compiled specifically for the front loader series, they can therefore only

take tractor-specific equipment into account to a limited extent.

Spare parts list

The spare parts list of the front loader lists all the information required for ordering spare parts, the front

loader series and their options. Special adaptations for the tractor are not taken into account.

In addition, spare parts lists are available for front loader implements.

Operating instructions for front loader implements

The operating instructions describe the implements available for the front loader series.

Other documents

In addition to the above instruction manuals, there may be installation and operating instructions as well

as other Technical Information that deal with special additional equipment and extensions, which are

not included in the other documentation.

When you pass on the front loader or the tractor with a front loader attached, please also hand

over all the relevant documents. The next owner needs the information.

5 B58FZS 0000000078 EN 002

Page 7

ABOUT THIS MANUAL

11

66

55

44

33

77

22

Wilhelm Stoll Maschinenfabrik GmbH

Product Type XXXXXXXXXXXXXXXXXXXX

Serial-No. XXXXXXX

Month / Year XX XXXX

Weight XXXX kg

max. Hydraulic Pressure XXXX bar

Made in Germany Bahnhofstraße 21 · 38268 Lengede · Germany

11

66

55

44

33

77

22

Wilhelm Stoll Maschinenfabrik GmbH

Product Type XXXXXXXXXXXXXXXXXXXX

Serial-No. XXXXXXX

Month / Year XX XXXX

Weight XXXX kg

Max. Hydraulic Pressure XXXX bar

Made in Germany Bahnhofstraße 21 · 38268 Lengede · Germany

11

55

33

44

22

B029B029

1.2 Use and purpose of the operating instructions

The present operating instructions contain important information on the safe operation and for faultless,

proper and economical operation of front loaders from Wilhelm STOLL Maschinenfabrik GmbH. It is

intended for the operator and user of the front loader and should help to prevent risks, damage and

downtimes as well as ensure and increase the service life of the front loader.

Before start-up of the front loader, the operating instructions must be read and understood.

For better readability, Wilhelm STOLL Maschinenfabrik GmbH will be called "STOLL" in the following.

The operating instructions are compiled specifically for the front loader series, they can therefore only

take tractor-specific equipment into account to a limited extent.

1.3 Rating plate

The front loader is identified with a that is located on the inside of the left bar at the rear or on the cross

tube of the front loader.

Fig. 1 Rating plate on the front loader

Legend

1 Type of front loader (e.g. ProfiLine front loader FZ 20, Solid 38-20)

2 Serial number

3 Year of manufacture

4 Weight

5 Permissible hydraulic pressure

1.4 Validity of the operating Instructions

The operating instructions are valid only for the STOLL front loader ProfiLine, called "front loader" in the

following or "FS" or "FZ" as the special versions. The front loader type can be found on the rating plate.

The operating instructions covers all of the components and functions of the model.

1.5 Storage of the documents

The operating instructions are a part of the machine. The entire documentation, consisting of these

operating instructions as well as all other additional instructions supplied, must always be kept

accessible, safe and dry on or in the vehicle. When lending or selling the front loader, the entire

documentation must also be handed over.

B58FZS 0000000078 EN 002 6

Page 8

1.6 Other applicable documents

In conjunction with these operating instructions, the following additional documents also apply:

Operating instructions of the tractor

Operating instructions for the respective implements

Installation instructions for the respective mounting kit and front loader additional equipment

When handling the front loader and for all service work, please also observe:

The recognised technical regulations for safe and professional work,

The legal regulations for accident prevention,

The legal regulations for health and environmental protection,

The national regulations that apply in the country of the operator / user of the front loader,

The specifications that are relevant for the status of the technology,

The road traffic regulations.

1.7 Design tools

The operating instructions contain the following different symbols and markings in the text:

ABOUT THIS MANUAL

Warning symbol that is used for warning notices and is graduated based on the danger

(see 2 Safety)

Additional information and tips

List points

Requirement for a sequence of actions

Required tools

(1) Numbered action step

Result of an action or sequence of actions

Unnumbered action step

7 B58FZS 0000000078 EN 002

Page 9

ABOUT THIS MANUAL

11 22

Moreover, stylised drawings are used. For better understanding, some of the figures are exemplary,

simplified or with dismounted parts for better representation and explanation.

Please observe the following:

Dismounting is not always absolutely required for the respective description.

No different equipment variations are shown in the figures, unless otherwise specified.

The associated descriptive text always applies to the figures.

The following representation rules and elements apply:

Representation Meaning

Elements represented in yellow highlight the

components for the respective operating situation.

Item numbers designate assemblies or

components. In each figure, there is always an

explanatory legend for the item numbers.

Magnifying glasses serve to focus on individual

parts and details.

Arrows indicate a direction of movement or action

to be performed.

1.8 Nomenclature of the footer

The footer consists of the following parameters:

1234567 A12XYZ 0000001234 DE 123

Fig. 2 Nomenclature of the footer

Legend

1 Document number (order number)

2 Type of instructions

3 Internal system number

4 Language identifier

5Version

2211 33 44 55

B58FZS 0000000078 EN 002 8

Page 10

2 Safety

2.1 Explanation of safety and warning notices

The basic safety information comprises instructions that always apply for safe operation or to maintain

the safe condition of the front loader.

The action-related warning notices warn against residual dangers and are placed in front of dangerous

action sequences.

2.2 Representation and layout of warning notices

Warning notices are action-related and are designed according to the following principle:

⚠ DANGER

Type and source of danger!

Explanation of the type and source of danger.

Measures to prevent the danger.

SAFETY

2.3 Danger grading of warning notices

Warning notices are graded according to their level of danger and are represented as follows with the

corresponding signal words and warning symbols:

⚠ DANGER

Immediate lethal danger or serious injuries.

⚠ WARNING

Possible lethal danger or serious injuries.

⚠ CAUTION

Possible slight injuries.

NOTICE

Damage to the implement or the surroundings.

2.4 EC Conformity

STOLL front loaders comply with Machine Directive 2006/42/EC.

9 B58FZS 0000000078 EN 002

Page 11

SAFETY

2.5 Proper use

The ProfiLine front loader is a mounted implement for agricultural and forestry tractors and is designed

and intended solely for:

Mounting on tractors with the front loader mounting kit approved by STOLL (see 1.1 Documentation

overview),

Use with work implements specified by STOLL, which are suitable for the respective loading work

(see 6.5 Picking up and putting down the implement and operating instructions for the implement),

Use and operation within the defined limits (see 11 Technical specifications),

Control from the driver's seat.

The front loader may only be operated when it is in perfect condition. If faults impair safety, these must

be promptly repaired by an authorised specialist workshop.

The front loader must not be used in work processes and with implements that require the presence of

people close to the load when the front loader is in the raised position! This kind of work is only permitted

if the front loader is equipped with an anti-lowering guard (4.8 Anti-lowering guard).

The front loader and its implements must not be operated simultaneously with other hydraulic

equipment on the tractor.

Proper use also includes reading and observing the operating instructions, the associated additional

instructions, the other applicable documents as well as the safety information. To ensure operational

safety, prescribed maintenance work as well as intervals and conditions for care and service must also

be observed. Any use other or beyond those described in the manual is considered as improper use.

Foreseeable misuse

Avoid the following:

Exceeding of the permissible axle load and the permissible total weight of the tractor

Use outside of the conditions and prerequisites that are specified in the technical manuals and

documents

Transport of persons

Transport of loads that are not intended for use with front loaders

Transport of loads in road traffic

Transport of unsecured loads (e.g. stone pallets)

2.6 Operational limits

The following operating conditions and requirements on the operational environment must be

observed:

If applicable, temperature range for proper operation of the tractor (see operating instructions of the

tractor)

Sufficient load capacity of the tires and the front axle of the tractor

B58FZS 0000000078 EN 002 10

Page 12

2.7 Basic safety information

The basic safety information comprises all safety measures grouped by theme and is applicable at all

times. In addition, the information is presented as warning notices at the correspoding positions in these

operating instructions.

Basic dangers

Mortal danger exists when persons are lifted or carried with the front loader. The front

loader is not equipped with the necessary safety equipment to be used as a work cage.

It is forbidden to lift or transport people with the front loader.

Mechanical dangers

There is a risk of crushing and impact of the upper and lower limbs due to projecting or

protruding frame parts and moving components of the machine.

Personnel must be instructed in the proper use of the machine and in the location

and types of danger.

Instruct persons to exit the danger and movement areas of the machine.

SAFETY

Wear suitable protective gear, if necessary, when performing service tasks.

There is a lethal risk of crushing and injury due to accidental movements of the tractor,

the front loader, and the implements.

Instruct unauthorised persons to exit the danger and action area of the machine.

Assistance from a second person for loading activities should only be allowed when

the front loader is lowered, provided that an anti-lowering guard is not installed.

For loading work as well as when mounting and dismounting the front loader,

ensure that the tractor is standing on level and solid ground.

The front loader may only be operated from the driver's seat of the tractor.

Operating elements outside of the tractor must not affect the front loader! In

particular, the operating elements of the front linkage must not affect the front

loader!

The front loader must only be operated by one person.

There is a lethal risk of injury due to exceeding of the maximum permissible load or with

improper use of the front loader resulting in breaking of the front loader or its

components.

Observe the load limits specified in the technical data.

When levelling or pushing snow, do not drive faster than 10 km/h.

Work only with mounted and locked implement.

Observe the load capacity of the tyres and the front axle of the tractor.

11 B58FZS 0000000078 EN 002

Page 13

SAFETY

0 Bar

Hydraulic dangers

There is a risk of injury due to escaping hydraulic fluids under high pressure.

Observe the safety stickers on the machine.

Check the hydraulic couplings and lines for leaks before uncoupling.

On tractors without a closed driver’s cab, mount tubes with splash guards.

There is a risk of crushing when machine parts move uncontrollably due to entrapped air

in the hydraulic system.

Before performing any work on the hydraulic system, depressurize the system.

Clean the hydraulic couplings and lines before coupling.

Change the hydraulic fluid regularly according to the service schedule.

Electrical dangers

There is lethal danger due to power surges when touching live machine parts, e.g. due

to short circuits in the on-board network of the tractor.

Installation and service tasks on the electrical system should only be performed by

Observe the operating instructions of the tractor.

There is lethal danger due to collision of the raised front loader with high-voltage lines.

Do not raise the front loader higher than 4 m when driving on roads.

Keep a safe distance away from electrical lines.

If you do not know the rated voltage, stay at least 4 m away from electrical lines.

There is lethal danger during excavation work due to collision with cables buried in the

ground.

Before performing excavation work, ensure that there are no cables in the ground.

an electrician.

Danger due to emissions

With long-lasting normal operation of the machine, hearing damage can be caused by

the noise level of the tractor and the hydraulic system.

Always wear personal hearing protection.

Observe special regulations for road operation and for operating machines in open

spaces.

B58FZS 0000000078 EN 002 12

Page 14

Dangers during packaging and transport

There is a risk of injury due to crushing, impacts or pinching if the front loader tips over or

falls from the lifting gear.

During all preparatory work, always ensure a secure stand of the machine.

Assisting persons must be instructed to exit the immediate danger area under the

front loader.

There is a risk of accidents during transport of the front loader if it is not correctly loaded

and secured.

The front loader must be correctly secured and transported.

SAFETY

Dangers during assembly for initial operation

There is a risk of injury when lifting and handling heavy machine parts as well as bulky

components of the front loader.

Heavy and bulky machine parts may only be lifted with the assistance of a second

person.

Avoid back injuries by lifting correctly.

Dangers when mounting and dismounting the front loader

There is a risk of injury when the front loader tips over during mounting or dismounting or

when the parked front loader tips over due to a lack of stability.

Ensure the stability of the front loader and the tractor.

Observe the instructions and sequence in these operating instructions for proper

mounting and dismounting of the front loader.

Check the proper locking of the front loader.

There is a risk of crushing of limbs when operating the parking supports to park the front

loader, especially on uneven ground.

Observe the instructions and sequence in these operating instructions for proper

operation of the parking supports.

13 B58FZS 0000000078 EN 002

Page 15

SAFETY

Dangers when picking up and putting down implements

There is a risk of serious injury and lethal danger due to implements falling down or

uncontrolled lowering of the front loader when unsuitable implements are used or if the

used implements are overloaded.

Check that the implements are suitable before use.

Check that the implement is locked correctly by repeatedly putting the implement

down on the ground.

Perform a visual check on the locking device.

Only perform the hydraulic locking of the implement up to a height of 1.5 m.

Check the proper functioning of the implements one time without load before

beginning work.

Dangers during loading work

There is a risk of serious injury and mortal danger when loading and transporting loads,

if the front loader is operated from one side, the load is raised too far over the driver's

seat or if unsuitable implements are used.

If not equipped, check for retrofitting a cab and/or a FOPS (falling objects protection

structure) / ROPS (roll-over protection structure) within the framework of work

safety regulations.

If there is no cab or safety equipment, never lift loads over the driver's seat.

Only use suitable implements, which prevent e.g. rolling back and falling on the

driver's seat.

B58FZS 0000000078 EN 002 14

Page 16

Dangers when operating the front loader

There is a risk of serious injury or lethal danger due to tipping of the tractor when working

on slopes, when going around bends, when the load on the rear axle is too low, and when

driving into the bulk to be lifted at a skewed angle.

The risk increases when the front loaders are raised up high because of the higher centre

of gravity.

Drive carefully when working on slopes. Never travel with a raised load across a

≥ 20%

10 km/h

slope.

Ensure that the ground is level enough.

When driving in curves, reduce the speed and lower the load.

Never start driving abruptly with the front loader raised high and fully loaded.

Observe and comply with the maximum load of the tractor.

Always use sufficient counterweights at the rear of the tractor.

In case of instability or tipping, lower the front loader and remain in the driver's cab.

Drive towards the load in a straight line and do not steer while driving into the load.

Use the safety belts.

SAFETY

Connect the brake pedals.

Switch off the front axle suspension.

On tractors with adjustable track width: set the maximum possible track width.

When driving on roads, there is a risk of serious injury and lethal danger for the operator

as well as for other road users if the tractor and the front loader a re no t correctly p repared

and operated for road traffic.

Only drive on roads without a load.

Before driving on roads, switch off the hydraulic system and lock it.

Raise the front loader.

15 B58FZS 0000000078 EN 002

Page 17

SAFETY

Dangers due to falling loads

There is mortal danger due to raised loads falling down on the driver's seat. There is a

particularly high risk when lifting pallets or bales above the driver's cab and when working

on slopes. Even the standard protection systems (roll-over protection structure ROPS,

falling objects protective structures FOPS) do not provide fully adequate protection.

When working on slopes, reduce the implement filling and lower the load.

Check the inclination of the implement. Do not scoop too far with the implement.

Use implements that are designed such that they prevent loads from falling onto the

driver's seat.

Only use the appropriate implements when loading piece goods (e.g. bale grabber

for bales or pallet fork for pallets).

Lift pallets or bales one at a time. Never stack several loads on top of each other,

since the top load could fall down on the driver's seat.

Compensate for the increased angle on front loaders without parallel motion when

lifting by “dumping” with the implement.

Do not operate the front loader without parallel motion while driving in reverse.

On tractors without a cab or 4-post roll-over protection structure, do not lift large

load items, in particular bales, any higher than the pivot point of the lifting arm.

Watch the load as you are lifting. Do not lift the load when reversing.

Dangers during maintenance

Maintenance work carried out incorrectly (care and cleaning, service, repairs) impair the

safety of the front loader.

Check the front loader regularly for defects.

Check mounting parts (brackets) regularly for damage (cracks).

Care and cleaning work must be carried out correctly.

Only have repair work performed by authorised qualified personnel.

B58FZS 0000000078 EN 002 16

Page 18

2.8 Danger zones

B081

11

22

33

On and around the front loader, there are the following areas with increased risk to safety of the operator

or safety of other persons:

Fig. 3 Top view (from above)

Legend

1 Work area (yellow)

2 Outer danger zones (hatched in orange)

3 Inner danger zones (red)

SAFETY

Danger zone Description Danger

Work area Overall possible movement area of the tractor incl.

Outer danger zone Overall field of action of the tractor and front loader

Inner danger zone Area on and around the tractor and front loader,

Observe the danger zones and instruct unauthorised persons out of these areas.

2.9 Safety equipment

Depending on the equipment, the front loader has the following protective and safety equipment:

the front loader during loading work.

as well as the area in which the tractor or front

loader could tip over in case of accident:

On the sides (left and right): height of the

tractor with the front loader raised as far as it

goes (incl. implement)

Front and rear: half the height of the tractor

with the front loader raised as far as it goes

(incl. implement)

especially between the wheels of the tractor,

directly in front of and behind the tractor as well as

on and under the front loader.

Standing in the working area represents a risk.

When the tractor tips over or when loads fall

down, people can be seriously injured.

Persons can be pinched in between the

wheels of the tractor.

Persons can be overseen by the tractor driver

and run over.

Moving machine parts can move

uncontrollably and thereby crush and injure

people.

Protective/safety equipment Function

Safety stickers Safety stickers warns against hazards at danger points (see 2.10 Adhesive safety

label).

Anti-lowering guard The anti-lowering guard protects against accidental lowering of the front loader during

work that requires another person in the working or danger zone of the front loader

(see 4.8 Anti-lowering guard).

17 B58FZS 0000000078 EN 002

Page 19

SAFETY

1010

22

1

133

3

3

4

4

5

5

6

6

7

7

8

8

8

8

12

12

9

9

11

11

B06S

1313

1414 1414

2.10 Adhesive safety label

Safety stickers warn of hazards at danger points and are an important part of the safety equipment of

the front loader.

Clean safety stickers if they are soiled.

Replace damaged or illegible safety stickers (see 10.1 Spare parts).

If necessary, equip new spare parts with the corresponding safety stickers.

Position of the safety sticker on the front loader

Fig. 4 Front loader FZ (exemplary figure)

Legend

1 Safety instructions on the left pillar

2 Safety instructions in the tractor driver's cab

3 Safety instructions on the left and right lifting arm

4 Safety instructions on the right parking support

5 Safety instructions on the left parking support

6 Mounting and dismounting instructions for the front loader on the right pillar

7 Information on the operation of Comfort-Drive on the cross tube

8 Information for crane transport above, below or next to the hole for the hook

(on the deviation triangle on FZ front loaders, on the frame on FS front loaders)

9 Sticker for safe manual implement locking, on the locking plug

10 Safety instructions for hydraulic implement locking, in the driver's cab (optional)

11 Safety instructions for hydraulic implement locking, on the cover plate (optional)

12 Safety instructions for pressure oil under the casing on the cross tube (optional)

13 Safety instruction for pressure accumulator on the accumulator on the cross tube (optional)

14 Safety instructions for working zone of the front loader lifting arm on the left and right of the change frame

B58FZS 0000000078 EN 002 18

Page 20

Description of the safety sticker

5h

1

2

3

4

5

3441830b

3462690a-3-re

3462690a-4-li

3449070c

B07A

1a1a

1b

1b

1e

1e

1f

1f

1g

1g

1c

1c

1d

1d

2a

2a

2h

2h

2g2g

2b

2b

2c

2c

2e

2e

2f

2f

2i

2i

2j

2j

2d

2d

3a

3a 3b3b

4a

4a

5b

5b

4b

4b

5a5a

The numbering corresponds to the positions on the front loader (see Position of the safety

sticker on the front loader).

SAFETY

Fig. 5 Safety sticker position 1-5

19 B58FZS 0000000078 EN 002

Page 21

SAFETY

Position Description

1a Re-tighten all the fixing screws on the mounting kit after the first 5 hours of operation.

1b Keep a safe distance away from electrical lines.

1c Do not stack several loads on top of each other.

1d Only use suitable implement to prevent the load from falling down.

1e Increased risk of tilting when the front loader is raised.

1f Do not stand under the raised front loader.

1g Do not lift or transport persons with the front loader.

2a Observe the operating instructions.

2b Only use suitable implement to prevent the load from falling down.

2c Do not stack several loads on top of each other. Check the inclination of the implement.

2d Do not lift or transport persons with the front loader.

2e Do not stand in the working area of the front loader.

2f Keep a safe distance away from electrical lines.

2g Keep a distance of at least 4 m from electrical high-voltage lines.

2h Do not stand under the raised front loader.

2i Increased risk of tilting when the front loader is raised.

2j Be careful of hydraulic oil under high pressure.

3a Observe the operating instructions.

3b Do not stand in the working area of the front loader. Possible danger due to loads falling down.

4a Only park the front loader with attached implement with a minimum weight of 70 kg.

4b Procedure for unfolding the parking supports.

5a Only park the front loader with attached implement with a minimum weight of 70 kg.

5b Procedure for unfolding the parking supports.

B58FZS 0000000078 EN 002 20

Page 22

3441840

1 2

3 4

5

67

8

1 2

3

4

5

6

B07B

3343590a

3377220a

99

1111

6a

6a

6b

6b

7a7a

7b7b

7c7c

8

8

1212

1313

1010

1414

SAFETY

Fig. 6 Safety sticker position 6-13

21 B58FZS 0000000078 EN 002

Page 23

SAFETY

Position Description

6a Instructions for mounting of the front loader.

6b Instructions for dismounting of the front loader.

7a The front loader is lowered when the Comfort Drive is switched on.

7b Lever position to switch on the Comfort Drive.

7c Lever position to switch off the Comfort Drive.

8 Mounting points for crane transport of the front loader.

9 Identification of the locked position of the mechanical implement locking mechanism.

10 Be careful with using the hydraulic implement locking mechanism when persons are standing around the front

loader.

11 Pin position for the hydraulic implement locking mechanism.

12 The hydraulic system is under oil pressure. Parts can only be removed or repaired after the pressure has been

relieved according to the instructions in the installation instructions or in the tractor operating instructions.

13 The pressure accumulator is under pressure from the gas and oil. Parts should only be removed and repaired

according to the instructions in the installation instructions.

14 Do not stand in the working area of the front loader. Possible danger due to loads falling down.

B58FZS 0000000078 EN 002 22

Page 24

2.11 Personnel requirements

In the operating instructions, a distinction is made between the following persons:

Operators

Qualified personnel

Specialised tradesmen

All person groups must have read and understood the operating instructions. The table lists the other

respective qualifications and responsibilities.

Personnel Qualification/responsibility

Operators

are responsible for the proper operation of the front loader

instruct qualified personnel on how to handle the front loader

ensure regular inspection and service of the front loader in a specialised workshop

Qualified personnel

are responsible for the proper operation of the front loader

are physically able to control the front loader and the tractor

ensure regular service of the front loader

know the relevant road traffic regulations

are in possession of the prescribed driving license

are familiar with driving tractors safely

Specialised

tradesmen

perform maintenance work (service and repairs)

have a recognised training certificate or specialised knowledge that is required to observe the

existing specifications, regulations, and directives

SAFETY

Work on electrical components of the machine may only be performed by an electrician

according to the electro-technical regulations.

Welding work may only be performed in an authorised workshop.

23 B58FZS 0000000078 EN 002

Page 25

SAFETY

2.12 Behaviour in case of emergency

Initiate the following measures to avoid further damage in cases of emergency:

(1) Secure the accident site correctly.

(2) Provide first aid (if necessary).

(3) Call rescue workers, describe the situation briefly and concisely. Wait for feedback.

(4) Inform the employer or operator.

2.12.1 Behaviour if the tractor tips or falls over

If the tractor tips or falls over with the front loader, observe the following instructions:

(1) Lower the load.

(2) Stay in the driver's cab until professional help arrives.

2.12.2 Behaviour in case of flashovers from electrical power lines

In the vicinity of electrical power lines, flashovers can happen quickly that cause high electrical voltage

on the outside of the tractor. This results in large voltage differences on the ground around the machine.

In the case of a flashover:

Do not exit the driver's cab.

Do not touch any metal parts.

There must be no connection to the earth.

Warn any persons standing around against coming closer.

Have the power switched off.

Wait for professional rescue workers.

If it is still necessary to exit the driver's cab, e.g. due to the threat of fire:

Jump away from the tractor and be sure not to touch it.

Take small steps to move away from the tractor.

B58FZS 0000000078 EN 002 24

Page 26

3Structure

11

11

2

2

3

3

4

4

5

5

6

6

8

8

9

9

11

11

12

12

13

13

14

14

15

15

1616

17

17

18

18

19

19

10

10

3

3

22

5

5

6

6

8

8

B065

77

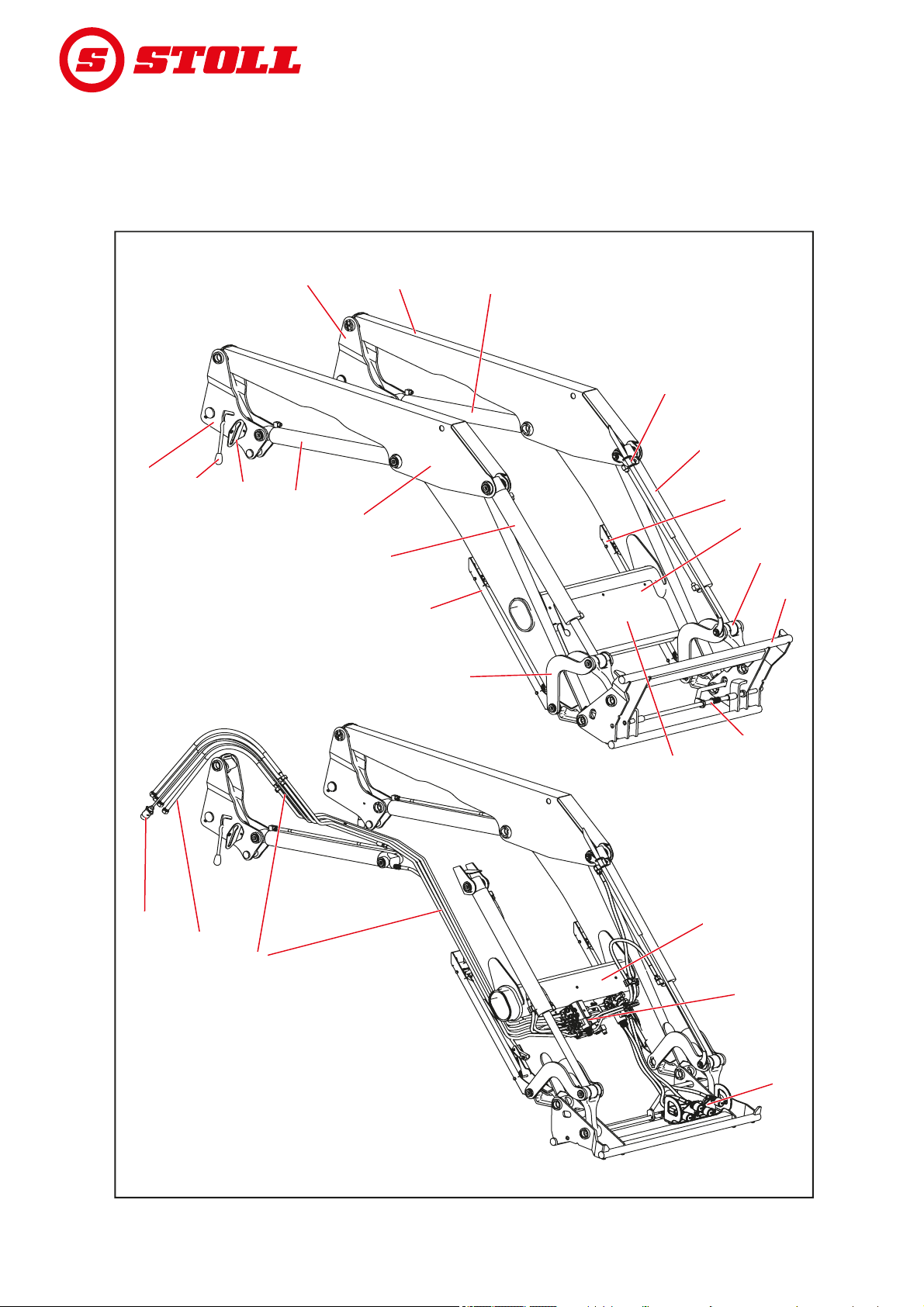

3.1 Structure of FS front loaders

FS front loaders are composed of the following main components:

STRUCTURE

Fig. 7 FS front loader

25 B58FZS 0000000078 EN 002

Page 27

STRUCTURE

Legend

1 Pillars (drive-in system)

2 Lifting arm (base frame)

3 Lifting cylinder: hydraulic cylinder for lifting and lowering

4 Upper support for the implement position indicator

5 Implement cylinders: hydraulic cylinders for dumping and scooping (differential cylinders)

6 Parking supports

7 Rating plate

8 Lever mechanism dumping/scooping

9 Euro change frame (implement support)

10 Implement locking mechanism

11 Cap for hydraulic and electrical distribution and additional equipment

12 Front loader locking mechanism

13 Coupling holder

14 Hydraulic couplings for the 3rd and 4th control circuit (optional)

15 Hydraulic and electrical distribution valves for additional equipment

16 Cross tube

17 Hydraulic tubes

18 Hydraulic hoses to the tractor (interface on the mounting part)

19 Connection cable (optional, multiple versions possible)

Sizes, see 11 Technical specifications.

B58FZS 0000000078 EN 002 26

Page 28

3.2 Structure of FZ front loaders

B064

11

11

2

2

3

3

4

4

5

5

6

6

7

7

9

9

10

10

12

12

13

13

14

14

15

15

16

16

17

17

1818

19

19

20

20

21

21

11

11

3

3

4

4

6

6

7

7

9

9

4

4

88

FZ front loaders are additionally equipped with parallel motion and are composed of the following main

components:

STRUCTURE

Fig. 8 FZ front loader

27 B58FZS 0000000078 EN 002

Page 29

STRUCTURE

Legend

1 Pillars (drive-in system)

2 Lifting arm (base frame)

3 Lifting cylinder: hydraulic cylinder for lifting and lowering

4 Deviation triangle of the parallel motion

5 Indicator for implement position

6 Implement cylinder: hydraulic cylinder for dumping and scooping (synchronised cylinder)

7 Parking supports

8 Rating plate

9 Lever mechanism dumping/scooping

10 Euro change frame (implement support)

11 Implement locking mechanism

12 Cap for hydraulic and electrical distribution and additional equipment

13 Front loader locking mechanism

14 Coupling holder

15 Control rod of the parallel motion

16 Hydraulic couplings for the 3rd and 4th control circuit (optional)

17 Hydraulic and electrical distribution valves for additional equipment

18 Cross tube

19 Hydraulic tubes

20 Hydraulic hoses to the tractor (interface on the mounting part)

21 Connection cable (optional, multiple versions possible)

Sizes, see 11 Technical specifications.

B58FZS 0000000078 EN 002 28

Page 30

3.3 Equipment variations

The table shows the different equipment variations for FS and FZ front loaders:

Equipment Front loader

Basic equipment

Parallel motion (mechanical) ─ ─ ● ●

Change frame

Euro ●●●●

SMS ○ ○ ○ ○

Skid-Steer ○○○○

Euro-MX combi-frame ○ ○ ○ ○

Euro-SMS combi-frame ○ ○ ○ ○

Euro-Alö Type 3 combi-frame ○ ○ ○ ○

Implement locking mechanism

mechanical ● ● ● ●

hydraulic ○ ○ ○ ○

Hydraulic and electrical couplings

4 Plug-in couplings ● ● ● ●

7-pin electrical plug connection ○ ● ○ ●

Hydro-Fix multiple hydraulic coupling ○ ○ ○ ○

Hydro-Fix multiple coupling

for hydraulic and electric

Tractor-specific multi-coupler (○) (○) (○) (○)

Additional functions

Comfort Drive (mechanical operation) ○ ○ ○ ○

Comfort Drive (electrical operation) ○ ○ ○ ○

2

3rd control circuit

4th control circuit

Rapid emptying ─ ● ─ ─

Quick emptying ─ ─ ─ ●

Return-to-Level ─ ─ ─ ●

Camera system ○ ○ ○ ○

○○○○

2

STRUCTURE

FS FS-rapid

emptying

○○○○

○○○○

FZ FZ-L

1

1

1

1

● = Series, ○ = Optional, ─ = not available, () = not for all tractors

1

Standard equipment on FZ 100

2

Alternatively with screw couplings, plug-in couplings or multiple couplings

29 B58FZS 0000000078 EN 002

Page 31

STRUCTURE

B06E

11 22

33

2211

3.4 Attaching it to the tractor

The front loader is attached to the tractor using the mounting kit for tractors. The mounting kit consists

of the following components:

Fig. 9 Mounting kit for tractors

Legend

1 Front guard left and right

2 Mounting parts left and right

3 Mountings/catch hooks

The components remain permanently mounted on the tractor. They can look different depending on the

tractor model.

Observe the installation instructions for the mounting kit.

Observe the regulations for the registration of the changed empty weight in the vehicle documents

for the tractor.

The front loader can only be mounted on the tractor if the associated mounting kit is already

installed. Only an authorized specialist workshop is allowed to install the mounting kit on the

tractor.

B58FZS 0000000078 EN 002 30

Page 32

3.5 Change frame

The change frame is a fixed component of the front loader. The different types are designed and

adapted for the mounting of standardised implements of this type.

As a matter of principle, the following change frames are available for FS and FZ 8 to 80.1 front loaders:

Euro change frame

SMS change frame

Euro-SMS Combi change frame

Euro-Alö

3

Combi change frame

Euro-FR Combi change frame

Skid-steer change frame

The basic equipment of the change frames includes a mechanical implement locking mechanism,

however, a hydraulic implement locking mechanism can be installed as an option (see 4.1 Implement

locking mechanism).

For FZ 100 front loaders, there is a reinforced Euro change frame, which is always equipped with

hydraulic implement locking.

The change frames will be presented without implements in the following.

STRUCTURE

3.5.1 Euro change frame

These change frames are installed on FS and

FZ 8 to 80.1 front loaders.

They are intended for mounting implements

complying with the Euro standard.

The implement cylinder serves to swivel the

change frame around its pivot point.

On the support, the couplings for a 3rd and

4th control circuit can be installed as an option

(see 4.9.1 Additional control circuits).

11

22

33

44

55667788

B06T

Fig. 10 Euro change frame

Legend

1 Implement cylinder

2 Upper cross bar

3 Support with hydraulic couplings for the

3rd/4th control circuit

4 Mounting on the left

5Spring

6 Lower cross bar

7 Mounting on the right

8 Pivot point

31 B58FZS 0000000078 EN 002

Page 33

STRUCTURE

B06J

11

22

11

2

2

B06K

3.5.2 SMS change frame

These change frames are installed on FS and

FZ 8 to 80.1 front loaders.

The implement is hinged on the top cross bar and

is secured with the locking mechanism.

Its function is similar to that of the Euro change

frame.

Fig. 11 SMS change frame

Legend

1 Upper cross bar

2 Locking mechanism

3.5.3 Euro-SMS Combi change frame

These change frames are installed on FS and

FZ 8 to 80.1 front loaders.

They are intended for mounting implements

complying with the Euro standard as well as the

SMS standard.

Euro implements are hinged onto the outer pins.

SMS implements are hinged onto the cross bar.

The function is the same as for Euro and

SMS change frames.

Fig. 12 Euro-SMS Combi change frame

Legend

1 Outer pin

2 Cross bar

B58FZS 0000000078 EN 002 32

Page 34

3.5.4 Euro-Alö3 Combi change frame

These change frames are installed on FS and

FZ 8 to 80.1 front loaders.

They are intended for mounting implements

complying with the Euro standard as well as the

Alö3 standard.

Euro implements are hinged onto the outer pins.

Alö3 implements are hinged onto the inner pin.

The function is the same as for Euro change

frames.

STRUCTURE

2

2

11

Fig. 13 Euro-Alö3 Combi change frame

Legend

1 Outer pin

2 Inner pin

B06L

3.5.5 Euro-FR Combi change frame

These change frames are installed on FS and

FZ 8 to 80.1 front loaders.

They are intended for mounting implements

complying with the Euro standard as well as the

FR standard.

For the use of FR implements, both supports

must be mounted on the outside of the change

frame and locked with linch pins. The mountings

are attached to the support when using Euro

implements.

The function is the same as for Euro change

frames.

44

33

22

11

Fig. 14 Euro-FR Combi change frame

Legend

1Pin

2Linch pin

3 Mounting

4 Support for mounting

33

B08H

33 B58FZS 0000000078 EN 002

Page 35

STRUCTURE

B076

11

22

11

5

5

4

4

3

3

2

2

B06I

3.5.6 Skid-steer change frame

These change frames are installed on FS and

FZ 8 to 20 front loaders.

They are intended for mounting implements

complying with the skid-steer standard.

The implement is attached to the locking hooks

using the lever.

Fig. 15 Skid-steer change frame

Legend

1 Lever

2 Locking hooks

3.5.7 Reinforced Euro change frame (FZ 100)

The structure of this change frame is similar to

the FS and FZ 8 to 80.1 Euro change frame.

However, they are designed for higher loads and

are always equipped with a hydraulic implement

locking mechanism (see 4.1.2 Hydraulic

implement locking mechanism – Hydro-Lock).

Fig. 16 Reinforced Euro change frame (FZ 100)

Legend

1 Upper cross bar

2 Support with hydraulic couplings for the

3rd/4th control circuit

3 Locking pins (left)

4 Hydraulic cylinder for the implement locking

mechanism

5 Locking pins (right)

B58FZS 0000000078 EN 002 34

Page 36

3.6 Hydraulic lines

⚠ CAUTION

There is a risk of injury due to escaping hydraulic fluids!

If the hydraulic lines are not depressurized before the coupling procedures, oil can spray out and injure

the skin or other body parts (e.g. eyes).

Always depressurize the hydraulic system before any coupling procedures.

Clean the couplings on a regular basis.

The tractor and front loader are connected with

4 hydraulic lines, which can be found in the right

pillar of the front loader.

A2A2 A1

B2B2 A2A2 A1A1 B1B1

A1 B1B1B2B2

STRUCTURE

Hydraulic line Colour of the

protective cap

A1 yellow Lifting function

A2 blue Scooping function

B1 green Lowering function

B2 red Dumping function

3.7 Hydraulic couplings

3.7.1 Plug-in couplings

The plugs of the plug-in couplings are located on

the hydraulic lines of the front loader.

The couplings can be found on the right-side

mounting part for the tractor. They are connected

to the hydraulic valve either directly or with hose

lines.

Plugs and couplings are equipped with coloured

caps to facilitate assignment.

Description

B061

Fig. 17 Hydraulic lines

A2A2A1A1B1B1 B2B2

Promptly replace damaged or missing

labels (e.g. caps).

B062

Fig. 18 Plug-in couplings connected

35 B58FZS 0000000078 EN 002

Page 37

STRUCTURE

B08L

11

11

B084

22

3.7.2 Multiple coupling Hydro-Fix

As an option, the front loader can be equipped

with the Hydro-Fix coupling. This enables

simultaneous connection of all hydraulic lines

with the couplings.

The Hydro-Fix upper part is located on the

hydraulic lines of the front loader. The Hydro-Fix

lower part is located on the right-side mounting

part for the tractor.

Fig. 19 Hydro-Fix: Position on the front loader

Legend

1 Hydro-Fix lower part

Fig. 20 Hydro-Fix

Legend

1 Hydro-Fix upper part

B58FZS 0000000078 EN 002 36

2 Hydro-Fix lower part

Page 38

4Functions

4.1 Implement locking mechanism

4.1.1 Mechanical implement locking mechanism

Euro, SMS and Combi change frames

⚠ WARNING

Risk of injury due to implements falling down!

The implement may fall down if the implement locking mechanism is open or not locked correctly. This

can cause serious injury to persons standing in the surrounding area.

Only actuate the implement locking mechanism when the implement is set down on the ground or

on a secure rack.

Always check that the implement is correctly locked.

⚠ CAUTION

FUNCTIONS

Risk of crushing due to spring tension!

There is spring tension on the handle of the implement locking mechanism, which closes the locking

mechanism when the handle is lifted. Improper use can lead to injury to hands and fingers.

Always operate the handle with one hand and grab it in the middle.

37 B58FZS 0000000078 EN 002

Page 39

FUNCTIONS

B06O

11

3

322

6

6

2

2

4

4 77 88

4

4

6

6

7

7

5

5

The mechanical implement locking mechanism

on Euro, SMS and Combi change frames is

actuated manually.

The implement is hinged with its hooks on the top

cross bar on the change frame.

Below, the implement rests on the bottom cross

bar. Both eyelets of the implement project into the

mountings of the change frame.

The locking mechanism is held open by the stop.

When lifting the handle, the locking mechanism is

closed by the spring, as the front loader pin is

pushed through the eyelets of the implement.

When scooping, the handle is lifted by a guide

piece on the lifting arm, and the locking

mechanism closes automatically.

Doe not raise the front load higher than

1.5 m until proper locking of the implement

locking mechanism has been checked!

Fig. 21 Open (top) and closed (bottom) locking

mechanism

Legend

1 Implement

2 Hook

3 Upper cross bar

4 Handle

5Stop

6Eyelet

7Spring

8 Lower cross bar

B58FZS 0000000078 EN 002 38

Page 40

FUNCTIONS

Skid-steer change frame

⚠ WARNING

Risk of injury due to implements falling down!

The implement may fall down if the implement locking mechanism is open or not locked correctly. This

can cause serious injury to persons standing in the surrounding area.

Only actuate the implement locking mechanism when the implement is set down on the ground or

on a secure rack.

Always check that the implement is correctly locked.

⚠ CAUTION

Risk of crushing due to spring tension!

There is spring tension on the handle of the implement locking mechanism, which closes the locking

mechanism when the handle is lifted. Improper use can lead to injury to hands and fingers.

Always operate the handle with one hand and grab it in the middle.

The mechanical implement locking mechanism

on skid-steer change frames is actuated

manually.

To attach implements, the edge of the mounting

surfaces is pushed into the mounting on the

implement. As soon as the implement is resting

on the change frame, the locking mechanism is

closed with the lever. The locking hooks then

engage with the lug on the implement.

1

1

2

2

Fig. 22 Mechanical implement locking mechanism on

Legend

1Lever

2 Mounting surface

3 Locking hooks

4.1.2 Hydraulic implement locking mechanism – Hydro-Lock

⚠ WARNING

Risk of injury due to implements falling down!

If not installed or operated correctly, the implement can fall down. This can cause serious injury to

persons standing in the surrounding area.

The hydraulic implement locking mechanism must only be installed by a specialist workshop.

Only use switches that are approved by STOLL.

Set the implement on the ground or on a safe support before using the implement locking function.

As an option, the front loader can be equipped with a hydraulic implement locking mechanism.

It attaches the implement to the change frame via 2 pins activated by a hydraulic cylinder.

33

B06M

skid-steer change frames

39 B58FZS 0000000078 EN 002

Page 41

FUNCTIONS

B01J

11

33

2

2

4.2 Basic functions

⚠ DANGER

Lethal danger due to loads falling down from front loaders without parallel motion!

On front loaders without parallel motion, the implement tilts to the rear when lifting. As a result, the load

can fall on the driver and cause lethal injuries.

Watch the load as you are lifting. Do not lift the load when reversing.

Compensate for the increased angle on front loaders without parallel motion when lifting by

“dumping” with the implement.

⚠ WARNING

Risk of injury and material damage caused by falling loads or lowering front loader!

With dumping implements that are long or protrude far to the front, the centre of gravity can shift and

cause the pressure relief valve of the front loader to open by itself. As a result, the front loader dumps

or lowers uncontrollably and can lead to serious injuries and damage.

Observe the maximum load of the front loader (see 11 Technical specifications).

Always use sufficient counterweights at the rear of the tractor (see 5.3.2 Ballasting).

During loading work, instruct persons to exit the working area (see 2.8 Danger zones).

The front loader has 4 basic functions that are required to move the lifting arms and the implement.

Lifting

The 2 lifting cylinders are extended and thus

raise the lifting arm and the implement.

Without parallel motion, the angle between the

lifting arm and the implement remains constant

so that the implement changes its orientation.

With parallel motion, the angle between the lifting

arm and the implement changes so that the

implement maintains its original orientation.

To move the implement, see 4.5 Parallel

motion (FZ, FZ-L).

Fig. 23 Lifting function

Legend

1 Lifting cylinders on the left and right

2 Lifting arm

3 Implement

B58FZS 0000000078 EN 002 40

Page 42

Lowering

B01K

11

2

2

3

3

The 2 lifting cylinders are retracted and thus

lower the lifting arm and the implement.

Without parallel motion, the angle between the

lifting arm and the implement remains constant

so that the implement changes its orientation.

With parallel motion, the angle between the lifting

arm and the implement changes so that the

implement maintains its original orientation.

To move the implement, see 4.5 Parallel

motion (FZ, FZ-L).

FUNCTIONS

Fig. 24 Lowering function

Legend

1 Lifting cylinders on the left and right

2Lifting arm

3Implement

Scooping

The 2 implement cylinders are retracted and thus

swivel the implement upwards. The implement

scoops.

1

1

22

Fig. 25 Scooping function

Legend

1 Implement cylinders on the left and right

2Implement

B01L

41 B58FZS 0000000078 EN 002

Page 43

FUNCTIONS

B01M

22

1

1

Dumping

The 2 implement cylinders are extended and thus

swivel the implement downwards. The load is

dumped out.

Fig. 26 Dumping function

Legend

1 Implement cylinders on the left and right

2 Implement

B58FZS 0000000078 EN 002 42

Page 44

4.3 Float position

⚠ WARNING

Possible risk of injury due to unexpected movement!

If the front loader is not completely lowered, a vacuum may form in the hydraulic cylinders during the

float position. This causes uncontrolled lowering of the front loader at a later time. This can cause

persons to be injured or crushed.

Only use the float position when the front loader is completely lowered.

Do not use the float position with implements that require the presence of other persons!

Only use the float position if nobody is in the danger zone.

Do not scoop while in float position.

⚠ WARNING

Possible risk of injury due to unexpected movement!

On FZ-RTL front loaders, the front loader may "sag" during quick emptying if it had previously scooped

when the float position was switched on. This can cause persons to be injured or crushed.

Do not use the float position with implements that require the presence of other persons!

Only use the float position if nobody is in the danger zone.

Do not scoop while in float position.

FUNCTIONS

⚠ WARNING

Possible risk of injury due to the implement tipping over!

On FS front loaders, the float position for the implement may not be activated for the scooping and

dumping functions. This could cause the implement to tip over unintentionally to the rear. This may

result in serious accidents.

The activation of the float position must be ruled out through the assembly on FS front loaders. If

this is not the case, work with the front loader must be stopped immediately and the specialist

workshop must be contacted, to have the float position deactivated for the scooping and dumping

functions. The front loader may only be used again when the float position has been deactivated for

the scooping and dumping functions.

The float position is used to improve ground adaptation, since the implement can then follow the ground

contours and "floats" on it.

43 B58FZS 0000000078 EN 002

Page 45

FUNCTIONS

B008

11

22

3

3

4.3.1 Lifting arm float position

For the float position of the lifting arms, the

hydraulic cylinders are depressurized, i.e., they

are open towards the tank. The front loader lies

on the ground through the pressure of its own

weight.

Activating the lifting arm float position:

(1) Fully lower the front loader.

(2) Move the operating lever all the way to the

front until it engages (see 6.1 Operating

elements).

The float position is activated.

Fig. 27 Front loader in float position

Legend

1 Hydraulic cylinder

2 Implement

3Ground

4.3.2 Implement float position

For the implement float position, the front loader must be equipped with Hydac valves as well as parallel

motion and must have a STOLL Pro Control operating element.

The float position for the implement must be explicitly activated in STOLL Pro Control during the

installation.

Activating the implement float position:

(1) Lower the front loader close to the ground.

(2) Move the operating lever to the right and press button T2 (green) (see 6.1.4 STOLL Pro Control).

The float position is activated.

B58FZS 0000000078 EN 002 44

Page 46

4.4 Indicator for implement position

The indicator for the implement position is

located on the left implement cylinder. It allows

the horizontal position of the implement to be

read from the driver's seat.

The rod is attached on the lower bearing pin and

runs through the tube, which is attached to the

upper bearing pin with the support. When

dumping or scooping, the rod moves in the tube.

When the implement is in horizontal position, the

rod and the tube are flush.

Setting of the indicator:

(1) Position the implement horizontally.

(2) Lower the front loader to the ground.

(3) Switch off the tractor.

Apply the parking brake.

Stop the engine.

FUNCTIONS

11

2

2

3

3

4

4

(4) Loosen the clamping screw.

(5) Push the tube into the support until the top

end of the tube is flush with the rod.

(6) Tighten the clamping screw.

The indicator is set.

4.5 Parallel motion (FZ, FZ-L)

With the parallel motion, the guide linkage

ensures constant orientation/inclination of the

implement.

The function is particularly suitable for loading

pallets and stacking bales.

The function can only be executed when

the implement is horizontal or in scooping

position.

B01E

Fig. 28 Indicator for implement position

Legend

1 Clamping screw

2 Holder

3Tube

4Rod

B06G

Fig. 29 Parallel motion

45 B58FZS 0000000078 EN 002

Page 47

FUNCTIONS

B06H