Stoelting M202B W/C Installation Manual

Model M202 IntelliTec™

OPERATORS MANUAL

Manual No. 513666 Rev.1

This manual provides basic information about the machine. Instructions and suggestions are

given covering its operation and care.

The illustrations and specifi cations are not binding in detail. We reserve the right to make

changes to the machine without notice, and without incurring any obligation to modify or provide new parts for machines built prior to date of change.

DO NOT ATTEMPT to operate the machine until instructions and safety precautions in this

manual are read completely and are thoroughly understood. If problems develop or questions

arise in connection with installation, operation, or servicing of the machine, contact Stoelting.

stoeltingfoodservice.com

Stoelting Foodservice Equipment

502 Highway 67

Kiel, WI 53042-1600

U.S.A.

Main Tel: 800.558.5807

Fax: 920.894.7029

Customer Service: 888.429.5920

Fax: 800.545.0662

Email: foodservice@stoelting.com

© 2014 PW Stoelting, LLC

A Few Words About Safety

Safety Information

Read and understand the entire manual before

operating or maintaining Stoelting equipment.

This manual provides the operator with information

for the safe operation and maintenance of Stoelting

equipment. As with any machine, there are hazards

associated with their operation. For this reason safety

is emphasized throughout the manual. To highlight

specifi c safety information, the following safety defi ni-

tions are provided to assist the reader.

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and

their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

If you need to replace a part, use genuine Stoelting

parts with the correct part number or an equivalent

part. We strongly recommend that you do not use

replacement parts of inferior quality.

Safety Alert Symbol:

This symbol Indicates danger, warning or caution.

Attention is required in order to avoid serious personal injury. The message that follows the symbol

contains important information about safety.

Signal Word:

Signal words are distinctive words used throughout

this manual that alert the reader to the existence and

relative degree of a hazard.

WARNING

The signal word “WARNING” indicates a potentially

hazardous situation, which, if not avoided, may result

in death or serious injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” indicates a potentially

hazardous situation, which, if not avoided, may result

in minor or moderate injury and equipment/property

damage.

CAUTION

The signal word “CAUTION” not preceded by the

safety alert symbol indicates a potentially hazardous

situation, which, if not avoided, may result in equipment/property damage.

NOTE (or NOTICE)

The signal word “NOTICE” indicates information or

procedures that relate directly or indirectly to the

safety of personnel or equipment/property.

TABLE OF

CONTENTS

Section Description Page

1 Description and Specifi cations

1.1 Description ..................................................................................................1

1.2 Specifi cations .............................................................................................2

2 Installation Instructions

2.1 Safety Precautions .....................................................................................3

2.2 Receiving the Custard Machine ..................................................................3

2.3 Machine Installation ....................................................................................3

A. Running Line Sets ................................................................................................3

B. Running Electrical Connections ...........................................................................4

C. Plumbing Connections .........................................................................................4

D. Receiving and Installing Remote Condensing Units ............................................5

E. Setting in Place and Making Machine Connections .............................................5

F. Running Product and Setting Pressures ..............................................................6

3 Initial Set-Up and Operation

3.1 Operator’s Safety Precautions ....................................................................9

3.2 Operating Controls and Indicators ..............................................................9

3.3 Sanitizing ....................................................................................................10

3.4 Freeze Down and Operation ......................................................................11

3.5 Mix Information ...........................................................................................12

3.6 Removing Mix from Machine ......................................................................12

3.7 Cleaning the Machine .................................................................................12

3.8 Disassembly of Machine Parts ...................................................................13

3.9 Cleaning the Machine Parts .......................................................................13

3.10 Assembly of Machine .................................................................................13

3.11 Routine Cleaning ........................................................................................14

3.12 Preventative Maintenance ..........................................................................14

3.13 Extended Storage .......................................................................................15

4 Troubleshooting

4.1 Error Codes ................................................................................................17

4.2 Troubleshooting Error Codes ......................................................................17

4.3 Troubleshooting Tables ...............................................................................19

5 Replacement Parts

5.1 Decals and Lubrication ...............................................................................21

5.2 Auger Shaft and Faceplate Parts ...............................................................22

5.3 Hopper Parts ..............................................................................................23

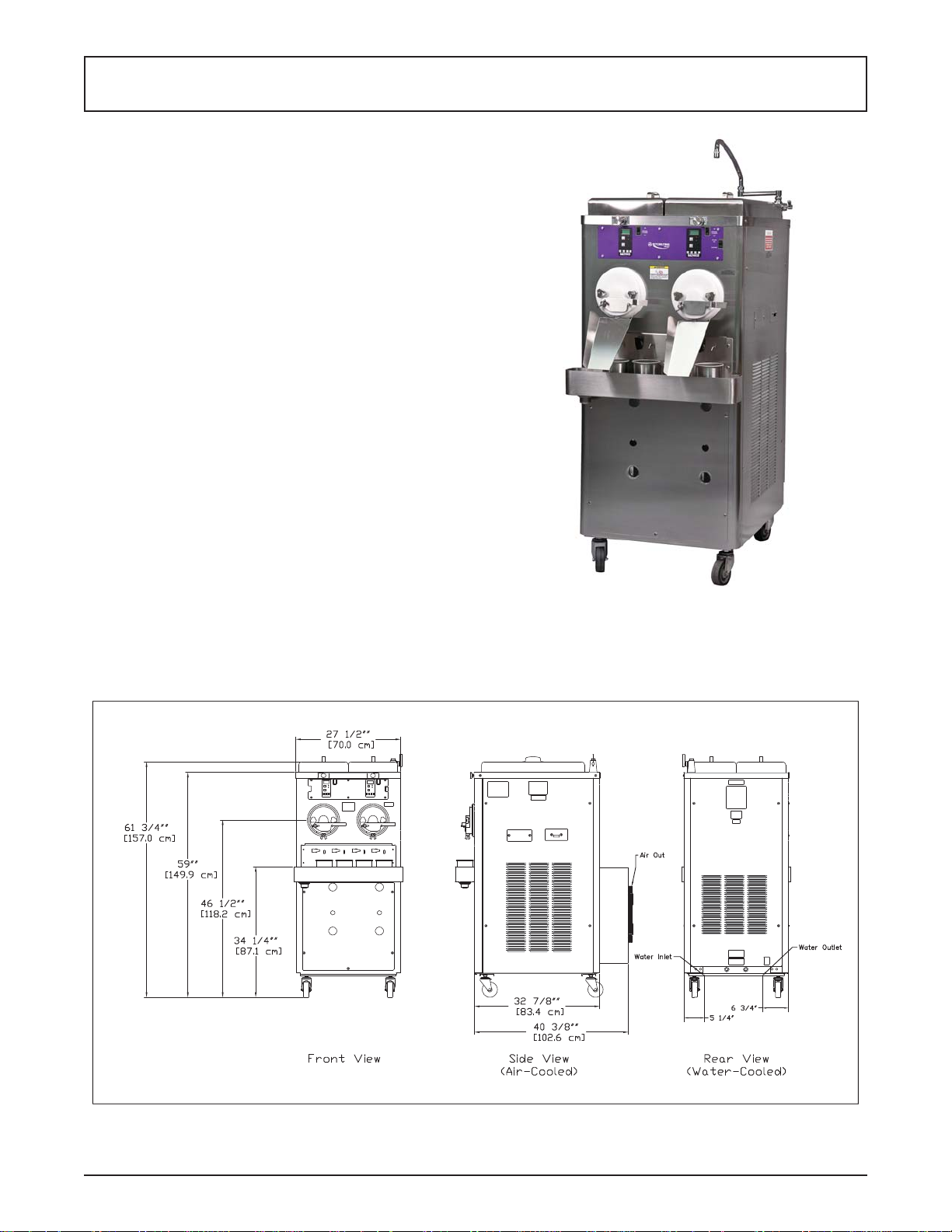

SECTION 1

DESCRIPTION AND SPECIFICATIONS

1.1 DESCRIPTION

The M202 is continuous fl ow custard machine. It is

equipped with fully automatic controls to provide a uniform product and feature Quick-Freeze technology . This

manual is designed to assist qualifi ed service personnel

and operators in the installation, operation and maintenance of the M202 frozen custard machine.

NOTE

Product breakdown could happen quicker if product

is stored in the freezing cylinders for more than one

hour. After a batch is made, close the fl ow control

and empty the contents of the freezing cylinder.

Figure 1-1 Model M202

Figure 1-2 Model M202 Dimensions

Owner’s Manual #513666 Rev.1 1 M202B Model Machines

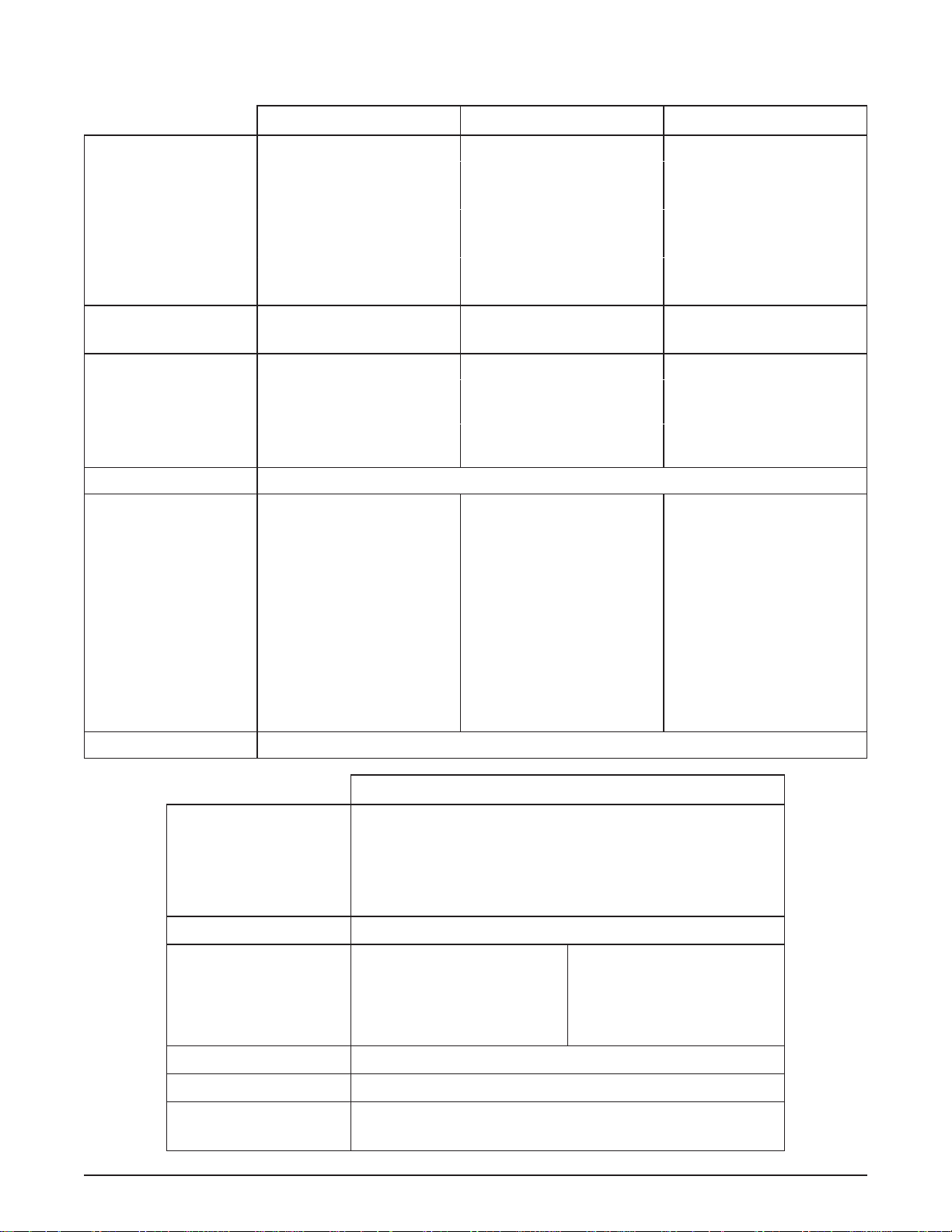

1.2 SPECIFICATIONS

Dimensions

M202B A/C M202B A/C Remote M202B W/C

Machine with crate Machine with crate Machine with crate

width

height

depth

Weight

Electrical

circuit ampacity

(per barrel)

overcurrent protection

device (per barrel)

27-1/2’’

(69,9 cm)

59’’

(149,9 cm)

40-3/8’’

(102,6 cm)

845 lbs

(383,2 kg)

1 PH 3 PH 1 PH 3 PH 1 PH 3 PH

20A 15A 15A 15A 20A 15A

25A 15A 15A 15A 25A 15A

48’’

(121,9 cm)

69-1/4’’

(175,9 cm)

60’’

(152,4 cm)

1100 lbs

(498,9 kg)

27-1/2’’

(69,9 cm)

57-1/2’’

(146,1 cm)

32’’

(81,3 cm)

645 lbs

(292,5 kg)

Drive Motor Two - 2 hp

Air cooled units require one

remote condensing unit

(with compressor) per barrel.

Condensing units #285090

and #285091 ship from the

factory with 20 lbs of R-404A

for up to a 50’ line set. Add

1 lb of refrigerant for every

10’ increase to the line set.

Line set max 100’. (Remote

condensers CU-0050 and CU-

0060 do not ship charged and

require 20 lbs of R-404A)

Cooling

Self contained air cooled units

require 6” (15,2 cm) air space

on sides and 24” (60,9 cm) at

the back. They are charged

with R-404A.

42-1/2’’

(108,0 cm)

67’’

(170,2 cm)

48’’

(121,9 cm)

945 lbs

(428,6 kg)

27-1/2’’

(69,9 cm)

57-1/2’’

(146,1 cm)

32’’

(81,3 cm)

845 lbs

(383,2 kg)

Water cooled units are self

contained and require a

Standard Hose Adapter water

fi tting and a 1/2” OD drain

fi tting for each barrel. They are

charged with R-404A.

42-1/2’’

(108,0 cm)

67’’

(170,2 cm)

48’’

(121,9 cm)

1100 lbs

(498,9 kg)

Hopper Volume Two - 5.4 gallon (20,57 liters)

Remote Condensing Unit (1 per barrel)

Dimensions Condenser

width 37-3/4’’ (95,9 cm)

height 17-1/4’’ (43,7 cm)

depth 28-1/4’’ (71,7 cm)

Weight 222 lbs (100,7 kg)

Electrical

circuit ampacity

overcurrent protection

device

Refrigerant R-404A

Charge 20 lbs. (Charged at Factory)

Refrigerated Line

Sizes

Owner’s Manual #513666 Rev.1 2 M202B Model Machines

1 Phase, 208-230 VAC, 60Hz 3 Phase, 208-230 VAC, 60Hz

20A minimum 15A minimum

25A maximum 20A maximum

Liquid Line - 3/8”

Suction Line - 5/8”

SECTION 2

INSTALLATION INSTRUCTIONS

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the machine until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the machine. The labels have been put there to help maintain a safe working

environment. The labels have been designed to withstand

washing and cleaning. All labels must remain legible for

the life of the machine. Labels should be checked periodically to be sure they can be recognized as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and quantity

required along with your address and mail to:

STOELTING

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

2.2 RECEIVING THE CUSTARD MACHINE

A. Upon arrival, check the entire machine for any

damage that may have occurred during transit.

With the method of packaging used, the machine

should arrive in excellent condition. The carrier

is responsible for all damage in transit, whether

visible or concealed. Do not pay the freight bill

until the machine has been checked for damage.

Have the carrier note any visible damage on the

freight bill. If concealed damage or a shortage is

found later, advise the carrier within 10 days and

request inspection. The customer must place a

claim for damages and/or shortages in shipment

with the carrier. Stoelting cannot make any claims

against the carrier.

B. Remove the top of the crate using a hammer or

pry bar.

C. Remove the eight lag bolts from the machine

using a 1/2” ratchet. Remove the front and rear

crate walls.

D. Remove the four lag bolts located inside the left

and right crate walls using 1/2” ratchet. Remove

the left and right crate walls.

E. Remove the plastic wrapping on the machine.

Remove the lower front and back panel on the

machine.

F . Remove the four lag bolts located inside machine

on the frame with a 9/16” ratchet. Remove the

two lag bolts that hold the skid together with a

9/16” socket.

G. If the machine has the shipping casters or if it is

water-cooled, the casters will be in a box located

in the hopper pan. A set of casters includes two

casters with locks and two casters without locks.

Screw the casters into the threaded holes and

tighten them using a pair of channel locks. After

installing the casters, knock out bottom 4” x 4” of

the machine skid.

NOTE

If the machine does not come with casters, install

the stainless steel legs. The legs are located in the

hopper pan on top of the machine. After installing

the legs, use a pallet jack to move machine into

place.

H. Put front and back panels on the machine.

2.3 MACHINE INSTALLATION

The following instructions are intended for a qualifi ed

electrician/refrigeration specialist. Do not attempt these

procedures unless you are qualifi ed.

CAUTION

Installation MUST be completed by a qualifi ed

electrician/refrigeration specialist

Incorrect installation may cause personal injury,

severe damage to the machine and will void factory warranty.

A. RUNNING LINE SETS

NOTE

If the machine is water-cooled, proceed to “B. Running Electrical Connections”.

Line sets are not supplied with the machine.

The lines sets can be installed prior to receiving the

custard machine.

1 An air-cooled machine requires a remote

condensing unit and line set for each freezing

cylinder. The line sets must be 3/8” for the liquid

line and 5/8” for the suction line. When running

the line sets, each 10’ of vertical rise, install a

p-trap in the suction line. For every horizontal

line set run, pitch the suction line towards the

compressor to assist with oil returning back to

the compressor.

2 After the line set is installed, perform a thorough

leak test. Malfunctions of the equipment due

to leaks in the line set are not covered by the

Stoelting/Ross warranty.

Owner’s Manual #513666 Rev.1 3 M202B Model Machines

3 Insulate the suction line with a minimum of 3/8” wall

thickness or the wall thickness required by local

code. In humid areas, use thicker insulation. In

areas that are exposed to extreme temperatures,

insulate the liquid line to prevent excessive

sub cooling or heating of the liquid refrigerant.

Fasten all lines securely along ceilings, walls

and roofs. Avoid creating any type of kink in the

lines. The Stoelting/Ross warranty does not cover

malfunctions or capacity issues with equipment

caused by kinks in the line sets.

4 Use good piping practices when installing line sets.

Seal the ends of the line sets during installation to

prevent exposure to the atmosphere and foreign

objects. Blow the lines out with dry nitrogen to

remove any debris that might be in the line sets.

When running line sets through a wall or roof,

mark the lines to eliminate confusion as to which

line set is running to which cylinder.

Example: Mark the liquid and suction lines with

the respective cylinder number. Facing the front

of the machine, cylinders are numbered left to

right.

5 When brazing the joints, purge dry nitrogen

through the lines to minimize oxidation of copper

inside of the lines. The Stoelting/Ross warranty

does not cover problems with the refrigeration

system that are caused by oxidized material in

the lines.

B. RUNNING ELECTRICAL CONNECTIONS

1 The machine requires a separate electrical

connection for each freezing cylinder. Refer to the

nameplate on the machine for proper electrical

supply. Each freezing cylinder has its own

electrical system and condenser so if one cylinder

fails, the other cylinder will still be operational.

NOTE

An air-cooled machine needs two circuits for each

freezing cylinder, one for the remote condensing

unit and one for the freezing cylinder.

4 Do not turn on the power to the machine or

the condensing unit until the refrigeration lines

have been connected and the system has been

charged with refrigerant. Label the circuit breakers

with information regarding which cylinder and

condensing unit the breaker is designated for to

prevent confusion if power ever needs to be shut

off.

5 When connecting power to the machine, run the

line under the machine and through the bottom

of the electrical box. Remove the electrical box

cover by loosening the four screws. The screws

do not have to be removed. Connect the power

to the terminal strip. The terminal strip is labeled

L1, L2, L3, and GND. After connections are made,

place the cover on the electrical box, but do not

tighten the cover (for single-phase machines the

cover can be tightened). The electrical box may

need to be accessed when checking for proper

rotation of the motor.

C. PLUMBING CONNECTIONS

1 On water-cooled machines, the water inlet is a

standard garden hose connection and the water

outlet is 5/8” OD copper tubing. The connections

are located at the back of the machine. Remove

the rear panel to access the connections. Run

the plumbing under the machine frame. Watercooled machines use approximately 3 gallons of

75°F water per minute when the compressor is

operating. The machine does not use any water

when not in use.

2 The machine is equipped with a dipping trough

that requires a water inlet line and a drain line.

The water inlet has 1/2” NPT close nipple fi tting.

Install a shutoff valve in the water inlet line. The

drain connection is 1-1/2”. Run a drain line from

the trough to a drain on the fl oor. Leave enough

slack in the drain line so that the lower front panel

can be easily removed for service.

A water-cooled machine needs one circuit for each

freezing cylinder.

2 The electrical boxes are located behind the lower

front panel. Labels indicate which cylinder each

electrical box powers. No pigtails are supplied

with the machine or condensing unit.

3 If the condensing unit is on the roof or ground,

a quick disconnect box needs to be installed to

provide power.

Owner’s Manual #513666 Rev.1 4 M202B Model Machines

Loading...

Loading...