Page 1

Lewis Large Series

Ultrasonic Cleaners

• RobustConstruction

• LargeCapacity

• DependableUltrasonics

• TroubleFreeOperation

• EnvironmentallyFriendly

CONTROLS

NEMA-12 oor mount enclosure contains

Allen-Bradley ange mount fused

disconnect. NEMA type 4/13 rated

lights, switches, and push-buttons.

Digital cycle timer. Indicator lights for heat,

pump, generators, and low liquid level.

Cleanable air intake lter grill, air cooled

cabinet, and rack mounted generators.

TRANSDUCERS

Lewis magneostrictive transducers, the heart of the system,

are zero spaced, nickel laminated and silver brazed to the

1/4" 316L stainless steel tank bottom. Virtually unaffected

by shock or high temperature, they are designed for heavyduty continuous operation and will not degrade or change.

Since 1965, Lewis has been building ultrasonic cleaning

systems. Not one transducer has ever failed. We offer an

unconditional 10-year warranty on the transducer assembly.

GENERATORS

Model L-5036 with 10,000 watts

of ultrasonic power. Other models available from

80 gallons. Custom and automated systems

are also available.

The Lewis L-series offers high performance and reliability to industries with large capacity cleaning

requirements. These rugged cleaners incorporate high-powered ultrasonics and precision-fabricated

stainless steel tanks to deliver consistent, dependable performance. The L-series cleaner can be used

with the matching rinse and drying units to give a complete Ultrasonic Wash, Rinse and Dry operation.

All solid-state providing high efciency and low maintenance.

Transducers operate at 20kHz. Synchronous operation, provides 2000 watts continuous power in each module. Typical

systems use multiples of our standard 2000 watt generators.

However, for unusual applications, we can build system with

very high densities of more than 12 watts per square inch

of radiating surface. Lewis generators are forced air cooled

which means they will deliver years of reliable service.

Enviro

Smart

Page 2

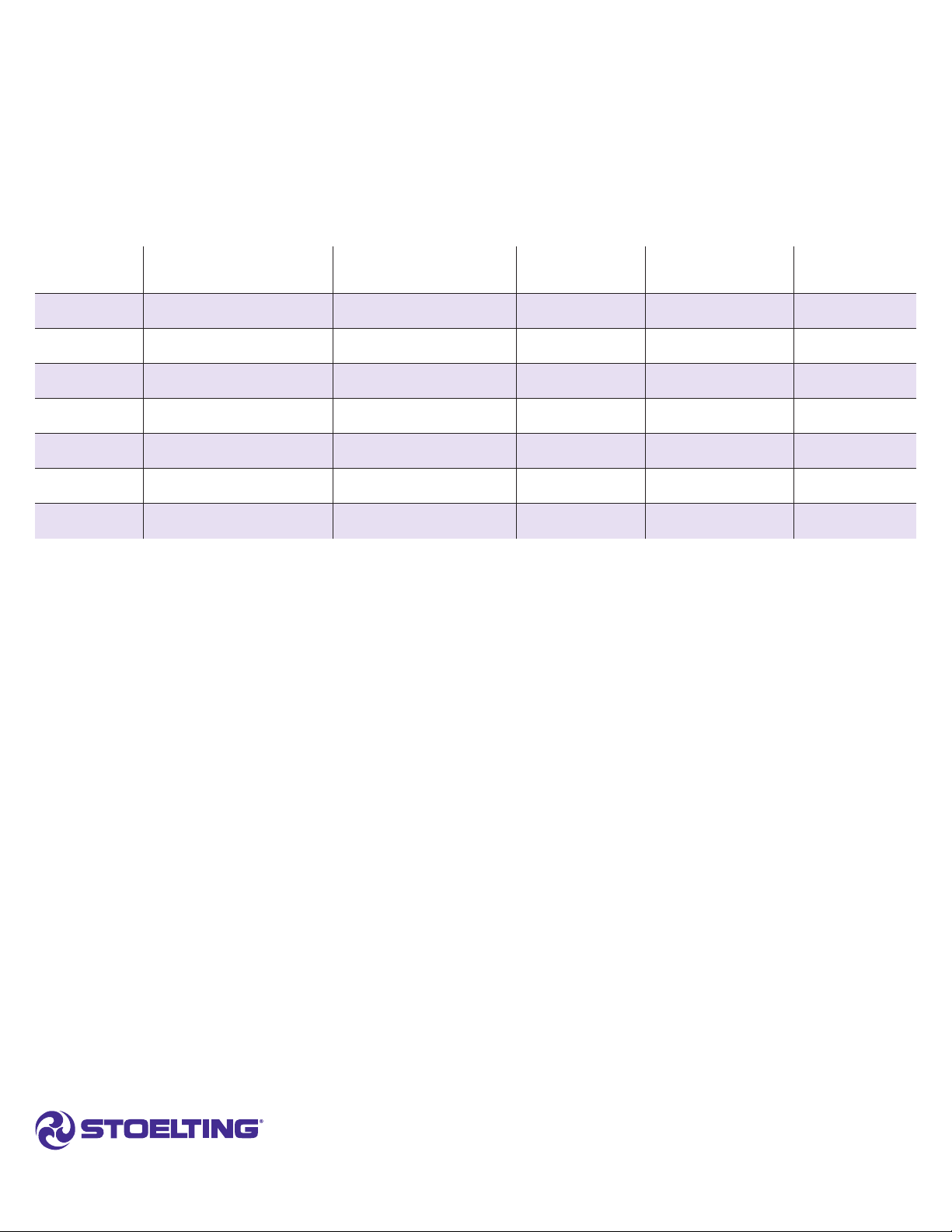

TypicalL-SeriesSpecicationandAccessories

All Lewis L-Series cleaners include NEMA-12 generator cabinet, 20 feet of exible conduit or wiring harness for

customer installation, heat system, cycle timer, low liquid level protection, and single point ll and drain connections.

Tank cabinets and frame are stainless steel construction with hinged insulated spring assist lids, drip-proof counter

tops with both thermal and sound insulation. All systems are less than 85 dBA and are available in any customerspecied voltage. Pneumatic cylinder opens and closed tank lid on Model L-5036H and larger.

MODEL

L-3625H

L-5018H

L-5425H

L-7225H

L-5036H

L-7536H

L-5450H

*All specications subject to change without notice.

TANK DIMENSIONS

(L x W x D)

36" x 25" x 24"

50" x 18" x 24"

54" x 25" x 35"

72" x 25" x 35"

50" x 36" x 35"

75" x 36" x 35"

54" x 50" x 35"

LIQUID LEVEL

20"

20"

30"

30"

30"

30"

30"

AlsoAvailable

• Custom Sizes

• Simple or Cabinetized Immersion Rinser

• Built-in or External Pump and Filter Systems (10 or 20 GPM)

• Alcove Immersion Heaters for Rinse Tanks with Thermostat

• Air Conditioned or Water Cooled

• Generator Enclosures

• Customer Specied Components

• Digital Temperature Indicators

• Cabinetized Hot Air Dryer

• Oil Coalescing Systems

• Automatic Liquid Level Controls

• Pneumatic Lift/Lower Work Platforms

GALLONS

80

80

175

230

230

350

350

ULTRASONIC

POWER

6,000

6,000

8,000

10,000

10,000

12,000

12,000

HEATER POWER

12 kW

12 kW

24 kW

24 kW

24 kW

36 kW

36 kW

A Vollrath Company

stoeltingcleaning.com

800-545-0661 | (920) 894-2293 | Fax: (920) 894-7029 | E-mail: cleaning@stoelting.com

|

502 Highway 67 | Kiel, WI 53042-1600

ISO 9001:2008 Registered | STMC-205 08/12

Loading...

Loading...