surfing evolution

®

INDUSTRIAL & PROFESSIONAL

STM PRODUCTS s.r.l.

Via Schiaparelli, 15 | 37135 VERONA | ITALY |

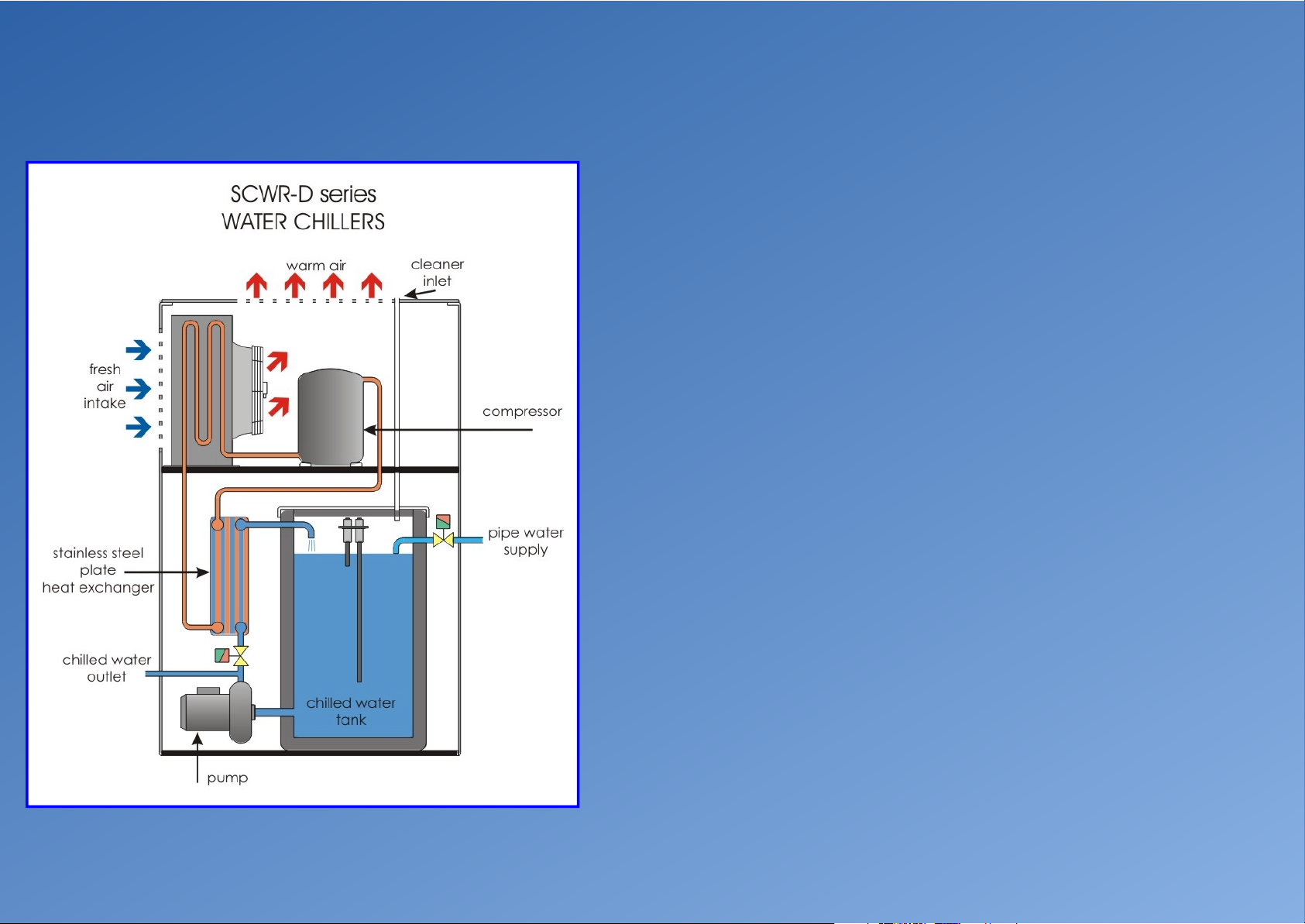

WATER CHILLERS

Tel. +39 045 585700 | Fax +39 045 585730 |

info@stm-products.com | www.stm-products.com

TRADITIONAL WATER CHILLERS

DIRECT CHILLERS WITH COIL INSIDE THE TANK

They cannot reach 2°C

The cooling process is very slow

The tank is difficult to clean

There is a sanitation risk being the tank normally over-dimensioned

The output flow for a water delivery is slow being the pump installed

normally under-dimensioned

Normally they are controlled by a simple thermostat

INDIRECT CHILLERS WITH DOUBLE COIL INSIDE THE TANK

They can deliver water at 2°C only at the beginning, but soon after the

temperature increases considerably

The output flow for a water delivery is very slow

STM WATER CHILLERS

THE HIGH TECHNOLOGY ADVANTAGES

The temperature is constantly kept at 2°C inside the tank

The temperature remains constant during the whole water delivery

After the end of each water delivery, the new incoming water is cooled

again in few minutes therefore cool water will be available for the next batch

The evaporation process takes place inside a stainless steel plate heat

exchanger. The high efficiency of this device speeds up the water cooling

with the advantage of using not over-dimensioned tanks

The pump used for the water circulation through the heat exchanger is the

same that is used to feed the doser-mixer with the result of a high rate flow

The STM chillers are controlled with an STM microprocessor control board

with an LCD user interface

MACHINE CONCEPT

THERMODYNAMIC CIRCUIT

In the evaporator the refrigerant absorbes heat from the

water to be cooled

The vapour coming out from the evaporator is

compressed by the compressor increasing its

temperature

The overheated vapour enters into the condenser where

it transfers to the external ambient the heat absorbed

from the evaporator and compressor

The liquid coming out from the condenser is laminated

to low temperature by the thermostatic valve and returns

to the evaporator

WATER CIRCUIT

Cooling phase: the pump circulates the tank water

through the evaporator while the compressor is working

Delivery phase: the pump sends the water to the doser

Charging phase: at the end of a delivery, the charging

valve opens till the tank is full. At the same time the

cooling phase starts too. Thermostating phase: an hysteresis parameter controls the start of the

compressor to keep constant the tank temperature

TECHNICAL CHARACTERISTICS

OF THE MACHINE

Whole structure in AISI 304 stainless steel

AISI 316 stainless steel plate heat exchanger

Hermetic compressor for R404A gas in case of standard ambient

conditions or R134a gas in case of high ambient temperatures

AISI 316 stainless steel pump for water recycling and delivering

Safety devices: double pressure switch and relief valve

High precision temperature probe

Overflow drain

CHARACTERISTICS OF THE

MICROPROCESSOR ELECTRONICS

Alphanumeric LCD back-lighted display

Control of the machine’s normal function

Weekly program for automatic daily self switch-on, helping to save energy

Self-diagnosis

Automatic self-cleaning system, awarded with the Innovation Trophy at the

Europain fair of Paris. During this process a detergent solution is circulated

by the pump through the tank and the evaporator

Remote pump control from a water doser: the STM doser-mixer is the ideal

coupling for the SCWR-D PRO water chiller

THE ELECTRONICS FUNCTIONS

To change the language

To choose between Metric or Imperial units

To set the water temperature

To program the weekly automatic self switch-on

To set the day, time and length of the self-cleaning processes

To manage the alarms and the cleaning process

To check the inputs and outputs

USER INTERFACE

LEDS

Power supply

Compressor

Condenser fan

Process water pump

Process water tank full

Delivery in progress

Washing in progress

KEYBOARD

To switch-on and switch-off manually the chiller

To set the tank water temperature

To increase and to decrease the values

To program the weekly automatic switch-on of the machine

To set the clock and to cancel the alarms

To start a washing

SCWR-D PRO SERIES

W D H

100/50 70 50 20 ÷ 50 2200 7,2 / 10,6 / 26,0 208V - 1 - 60 Hz 150

180/50 130 50 20 ÷ 50 3800 10,5 / 16,1 / 51,0 208V - 1 - 60 Hz 165

265/70 190 70 30 ÷ 80 5500 9,7 / 14,8 / 45,0 208V - 3 - 60 Hz 205

365/70 260 70 30 ÷ 80 7700 13,1 / 18,3 / 55,0 208V - 3 - 60 Hz 240

530/70 380 70 30 ÷ 120 11100 19,2 / 31,8 / 106,0 208V - 3 - 60 Hz 250

WEIGHT

[kg]

DIM ENSIONS [ m m ]

MODEL

PRODUC T IO N

[L/h]

TANK

[L]

FLOW

[L/m in]

COOL ING

POWER [W]

ABS ORBED CURRENT

RLA/MAX/LRA [A]

ELECTRIC SUPPLY

720 640 1250

760 790 1550

the professional water chillers - R404A gas standard version

The hourly production is referred to the following project and testing conditions:

ambient temperature = 25°C

inlet water temperature = 25°C

full tank emptying batch

cooling down to 2°C

Working limits:

max ambient temperature = 38°C

max inlet water temperature = 35°C

max ambient+inlet temperature sum = 60°C

SCWR-TR-D PRO SERIES

W D H

100/50 70 50 20 ÷ 50 2200 8,7 / 12,4 / 47,0 208V - 1 - 60 Hz 150

170/50 120 50 20 ÷ 50 3500 11,5 / 18,7 / 50,0 208V - 1 - 60 Hz 175

225/70 160 70 30 ÷ 80 4700 10,4 / 26,8 / 99,0 208V - 3 - 60 Hz 220

350/70 250 70 30 ÷ 80 7400 15,0 / 28,0 / 99,0 208V - 3 - 60 Hz 250

460/70 330 70 30 ÷ 120 9700 20,2 / 33,9 / 128,0 208V - 3 - 60 Hz 260

WEIGHT

[kg]

DIM ENSIONS [ m m ]

MODEL

PRODUC T IO N

[L/h]

TANK

[L]

FLOW

[L/m in]

COOL ING

POWER [W]

ABS ORBED CURRENT

RLA/MAX/LRA [A]

ELECTRIC SUPPLY

720 640 1250

760 790 1550

tropical version with R134a gas for high ambient temperatures

The hourly production is referred to the following project and testing conditions:

ambient temperature = 35°C

inlet water temperature = 25°C

full tank emptying batch

cooling down to 2°C

Working limits:

max ambient temperature = 50°C

max inlet water temperature = 45°C

max ambient+inlet temperature sum = 85°C

SCWR-D & SCWR-TR-D SERIES

W D H

600/140 430 140 30 ÷ 120 12400 13,2 / 31,8 / 106,0 208V - 3 - 60 Hz 380

800/140 570 140 60 ÷ 220 16700 28,2 / 44,4 / 137,0 208V - 3 - 60 Hz 390

980/140 700 140 60 ÷ 220 20600 35,3 / 48,4 / 155,0 208V - 3 - 60 Hz 395

1050/280 760 280 80 ÷ 310 22200 35,3 / 45,0 / 155,0 208V - 3 - 60 Hz 430

1600/280 1140 280 80 ÷ 310 32300 42,8 / 61,0 / 210,0 208V - 3 - 60 Hz 475

2550/280 1820 280 80 ÷ 310 50500 60,7 / 93,0 / 314,0 208V - 3 - 60 Hz 615

WEIGHT

[kg]

DIM ENSIONS [ m m ]

MODEL

PRODUC T IO N

[L/h]

TANK

[L]

FLOW

[L/m in]

COOL ING

POWER [W]

ABS ORBED CURRENT

RLA/MAX/LRA [A]

ELECTRIC SUPPLY

1430 890 1710

+ remot e condens er

1430 890 1710

360/140 260 140

60 ÷ 210 8800 11,5 / 20,3 / 80,0 400V - 3 - 50 Hz 380

490/140 350 140 60 ÷ 210 11200 14,7 / 26,8 / 90,0 400V - 3 - 50 Hz 390

760/140 540 140 60 ÷ 210 16300 17,9 / 34,8 / 115,0 400V - 3 - 50 Hz 395

810/280 580 280 100 ÷ 360 17400 18,1 / 35,0 / 115,0 400V - 3 - 50 Hz 430

1250/280 910 280 100 ÷ 360 26200 25,2 / 55,0 / 210,0 400V - 3 - 50 Hz 475

1850/280 1320 280 100 ÷ 360 37200 32,6 / 77,0 / 260,0 400V - 3 - 50 Hz 495

+ remote condenser

1430 890 1710

1430 890 1710

Industrial water chillers – standard R404A gas and tropical R134a gas versions

8770047 rev 3 - oct 2012

What makes the STM water chiller better than others?

It supplies water at the desired temperature during all the working day, thanks to

the high efficiency of its plate heat exchanger

It allows to have the water at 2°C constantly

The tank has just the capacity for each delivery

It saves energy, thanks to the automatic switch-on weekly program

STM electronics controls every phase of the process

CONCLUSIONS

The automatic self-cleaning system

It is produced in order to satisfy the customer requirements

There is a model for each installation

It is not more expensive, especially if the compressor power is compared to other

machines

It is perfectly bound together with the STM water doser-mixer, the most reliable on

the market

Loading...

Loading...