Page 1

UM2847

User manual

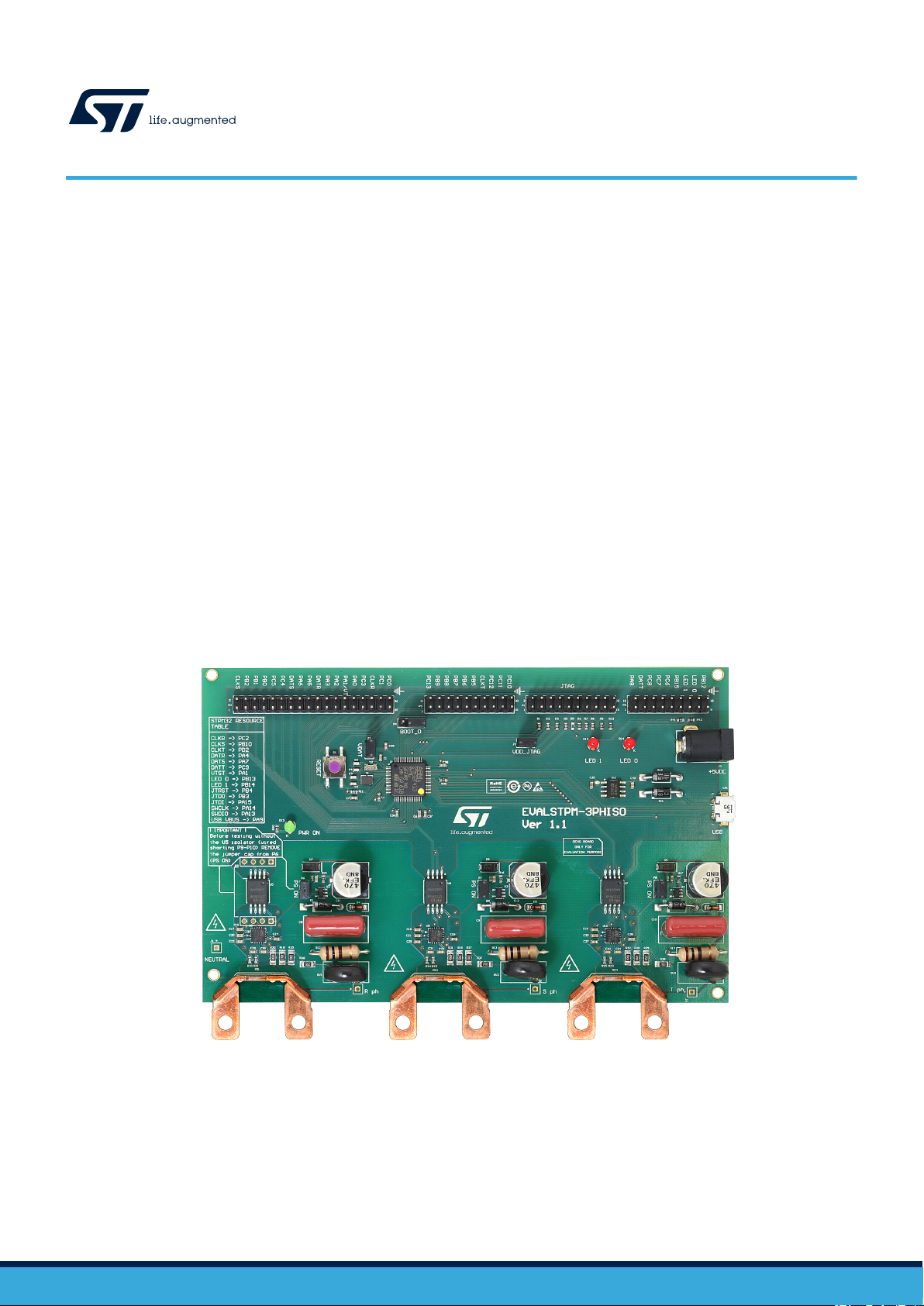

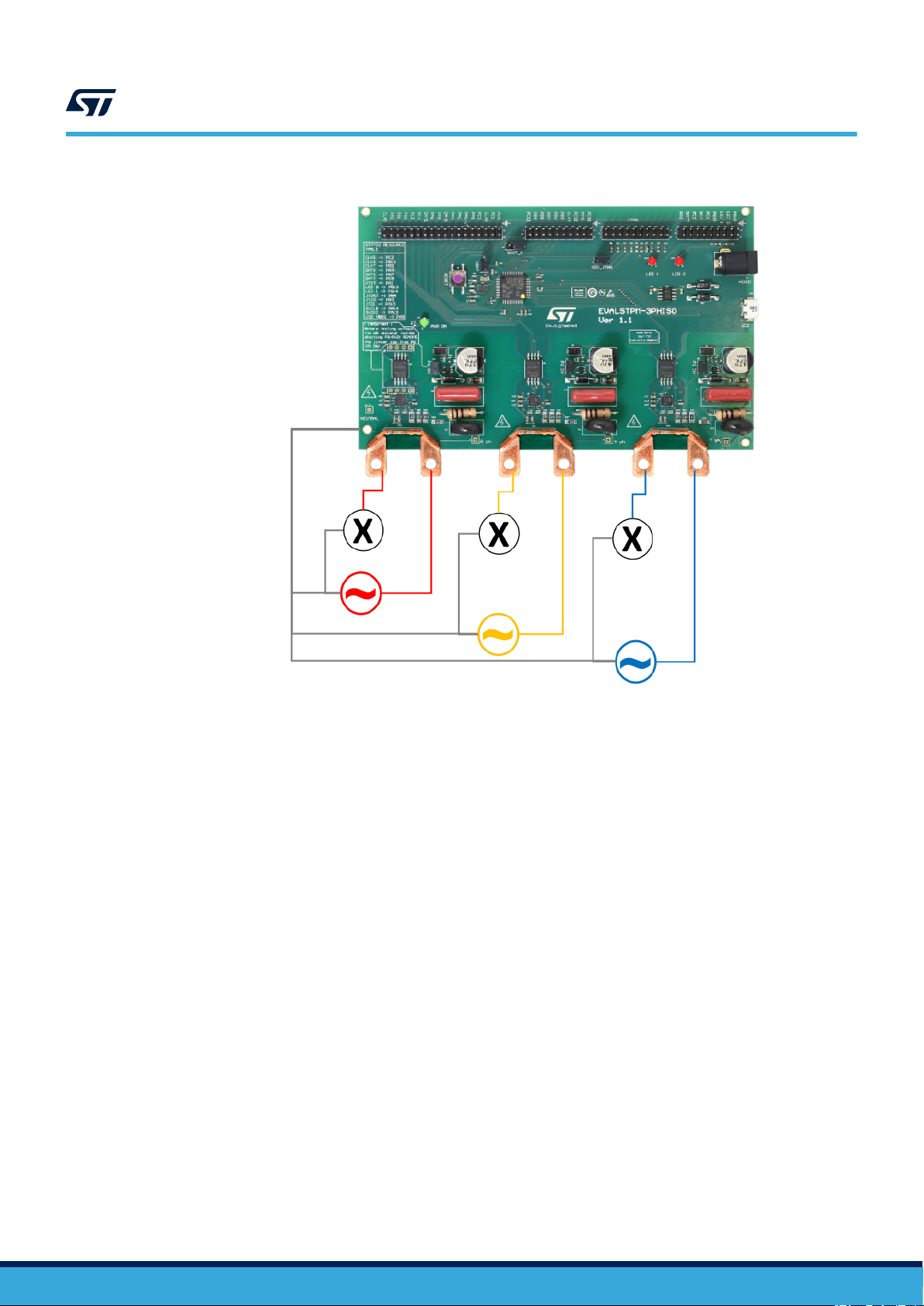

EVALSTPM-3PHISO: Getting started with the STPMS2 3-ph full shunt evaluation

board

Introduction

The EVALSTPM-3PHISO evaluation board implements a 3-phase AC Watt meter that meets accuracy class 0.5 according to

IEC 62053-22 standard using low-cost, electromagnetic-immune shunt sensors and advanced galvanic-isolation technology.

The evaluation board combines the high-accuracy STPMS2 metering front-end IC and the STISO621 digital isolator with

customizable firmware running on an STM32 microcontroller to compute metrology and power-quality data.

The STPMS2, a two-channel 24-bit second-order, sigma-delta modulator, measures voltage and current for each phase through

an on-board voltage divider and a shunt current sensor. It oversamples the signal using a synchronized 4 MHz clock distributed

by the microcontroller and multiplexes voltage and current sigma-delta bitstreams on a single output pin. Three STPMS2 are

used in the 3-phase system to collect voltage and current data from each phase.

The STISO621, a dual-channel digital isolator based on a 6 kV thick-oxide, galvanic-isolation technology, transfers data

between isolated domains and guarantees 6 kV VIOTM and 1.2 kV VIORM between the phases.

The FW implemented on the STPM32F413 uses digital filters for sigma-delta modulator (DFSDM) peripheral to demultiplex the

six bitstreams, convert them into 24-bit voltage and current values, and computes all metrology data in real-time every 200 µs.

The firmware also implements a Virtual COM port that provides access to internal parameters for reading metrology data,

modifying the internal configuration, and calibrating the board.

Figure 1. EVALSTPM-3PHISO image

UM2847 - Rev 1 - March 2021

For further information contact your local STMicroelectronics sales office.

www.st.com

Page 2

1 Safety and operating instructions

1.1 General terms

Warning:

During assembly, testing, and operation, the evaluation board poses inherent hazards due to high

voltage.

Danger:

There is danger of serious personal injury, property damage or death due to electrical shock if the

kit or components are improperly used or installed incorrectly.

The kit is not electrically isolated from the high-voltage supply AC/DC input. The evaluation board is

directly linked to the mains voltage. No barrier is present between the accessible parts and the high

voltage. All measuring equipment must be isolated from the mains before powering the board. When

using an oscilloscope with the demo, it must be isolated from the AC line. This prevents shock from

occurring as a result of touching any single point in the circuit, but does NOT prevent shock when

touching two or more points in the circuit.

All operations involving transportation, installation and use, and maintenance must be performed by skilled

technical personnel able to understand and implement national accident prevention regulations. For the purposes

of these basic safety instructions, “skilled technical personnel” are suitably qualified people who are familiar with

the installation, use and maintenance of power electronic systems.

UM2847

Safety and operating instructions

1.2 Intended use of evaluation board

The evaluation board is designed for demonstration purposes only. Technical data and information concerning the

power supply conditions are detailed in the documentation and should be strictly observed.

1.3 Installing the evaluation board

The board contains electrostatically-sensitive components that are prone to damage if used incorrectly. Do not

mechanically damage or destroy the electrical components (potential health risks).

1.4 Operating the evaluation board

To operate properly the board, follow these safety rules.

1. Work area safety:

– The work area must be clean and tidy.

– Do not work alone when boards are energized.

– Protect against inadvertent access to the area where the board is energized using suitable barriers and

signs.

– A system architecture that supplies power to the evaluation board must be equipped with additional

control and protective devices in accordance with the applicable safety requirements (i.e., compliance

with technical equipment and accident prevention rules).

– Use non-conductive and stable work surface.

– Use adequately insulated clamps and wires to attach measurement probes and instruments.

UM2847 - Rev 1

page 2/20

Page 3

Operating the evaluation board

2. Electrical safety:

– Proceed with the arrangement of measurement set-up, wiring or configuration paying attention to high

voltage sections.

– Remove power supply from the board and electrical loads before performing any electrical

measurement on the high voltage sections of the board.

– Once the set-up is complete, energize the board.

Danger:

Do not touch the evaluation board when it is energized or immediately after it has been

disconnected from the voltage supply as several parts and power terminals containing potentially

energized capacitors need time to discharge.

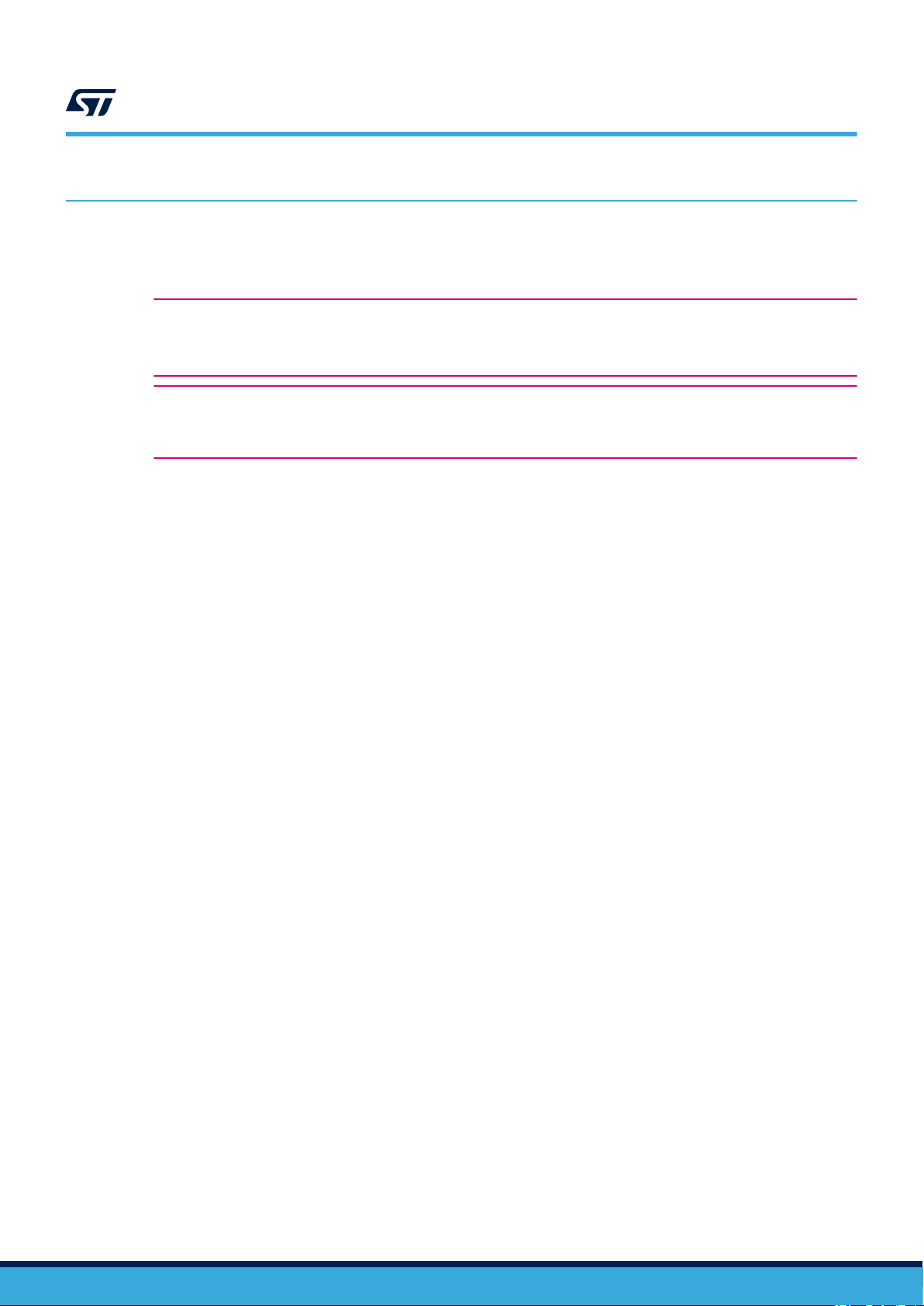

Parts of the kit are not electrically isolated from the AC/DC input. The USB interface, the JTAG

connector and the strip line connector are in the low voltage side of the board, so they can be used to

connect a host computer. Please refer to Figure 2.

3. Personal safety :

– Always wear suitable personal protective equipment such as insulating gloves and safety glasses.

– Take adequate precautions and install the board in such a way to prevent accidental touch. Use

protective shields such as an insulating box with interlocks if necessary.

Figure 2. High and low voltage sides

UM2847

UM2847 - Rev 1

page 3/20

Page 4

2 Getting started

2.1 Hardware and software requirements

Using the EVALSTPM-3PHISO evaluation board requires the following software and hardware:

• A Windows PC (XP, Vista, Win 7, Win 8, Win 10) to eventually install the software package available on

www.st.com (optional) or to communicate through the mini-shell

• A 'USB type A to Micro-B' cable, used to power on the board (through USB connector CN1) from host PC

and to allow communication with terminal or software GUI

• JTAG arm debugging probe (optional)

• 3-Ph AC power supply and 3-Ph load

• Reference meter (optional)

The system could be run and evaluated in the following ways:

• Installing the software GUI STSW-STPM005 from www.st.com . In this case please refer to the related

documentation.

• Connecting to a shell terminal on the host PC

• Using a JTAG arm debugging probe which can be connected to JTAG connector for debugging and

programming. For this purpose, it is necessary to install the IDE “IAR embedded workbench for ARM”

version 8.5.

UM2847

Getting started

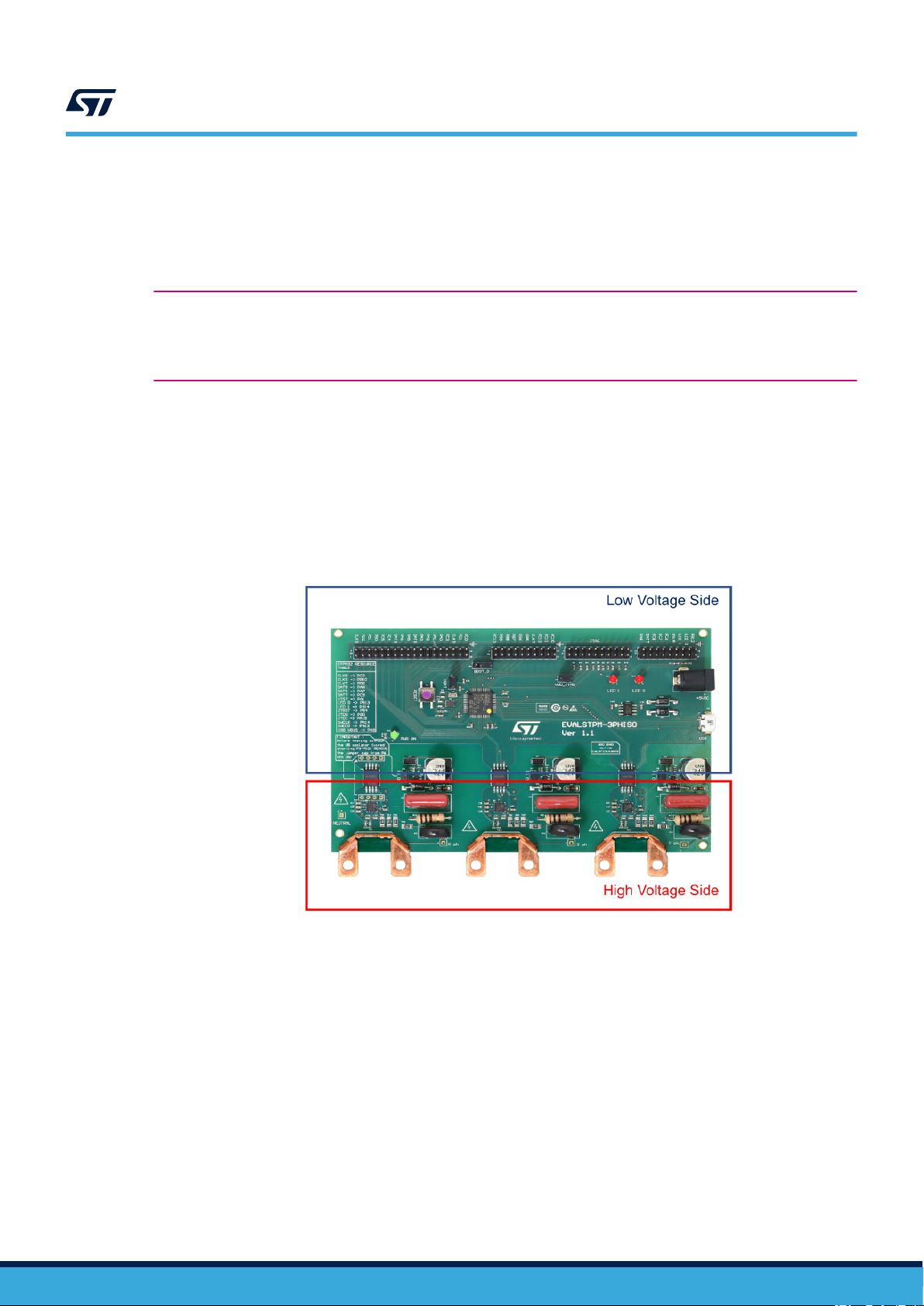

2.2 Hardware description

Figure 3. EVALSTPM-3PHISO board function description

2.2.1 Power supply

The board can be supplied alternatively by:

• connecting a USB cable to the PC

• providing 5 VDC by the coaxial jack

UM2847 - Rev 1

page 4/20

Page 5

Each phase STPMS2 is supplied by an independent capacitive power supply, providing the necessary 3.3 V to

the device. The jumpers P4, P7 and P8 must remain fit to use the power supply, otherwise it is bypassed.

2.2.2 Voltage and current sensing section

The STPMS2 devices onboard are configured as follows:

Table 1. STPMS2 HW configuration

PIN Connection Description

MS0 VCC HPR, amplifier GAIN selection g3 = 16

MS1 GND TC = 50 ppm/°C

MS2 GND Voltage channel ON, DATn = ~ [DAT =(CLK) ? bsV : bsC)]

MS3 GND Hard mode, BIST mode OFF

Note: For further information on STPMS2 configuration please refer to device datasheet.

The metrology section analog front-end component values are as follows:

UM2847

Running the built-in demonstration

Table 2. AFE components

Component Value Description

Shunt 0.3 mOhm Current sensor

R1 810 kOhm Voltage divider resistor (actually 3 x 270 kOhm)

R2 470 Ohm Voltage divider resistor

2.2.3 Board ratings

The ratings of the board, given by the parameters specified above, are as follows:

• Power stage supply voltage between 80 V RMS and 350 V RMS

• Maximum load current 86 A RMS

2.3 Running the built-in demonstration

The board comes with the demonstration firmware preloaded in the Flash memory. Please make sure to

download and use the latest release of STSW-STPM004 firmware from www.st.com.

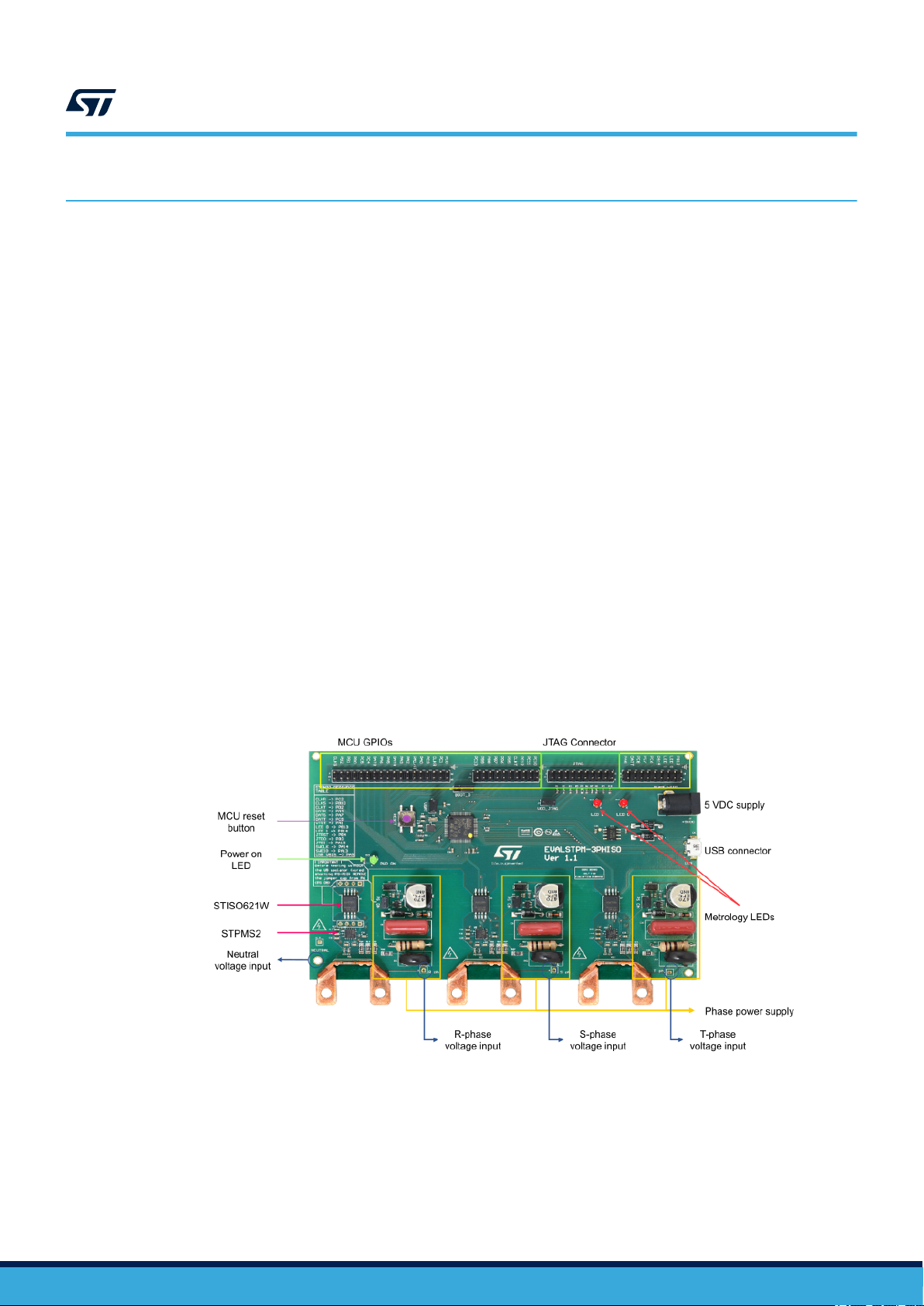

Before running the application, the user should establish the connection with the 3-phase full shunt board.

Follow the steps below to run it:

• Connect the board to a PC with a 'USB type A to Micro-B' cable through USB connector CN1 to power the

board. Green LED (PWR ON) then lights up.

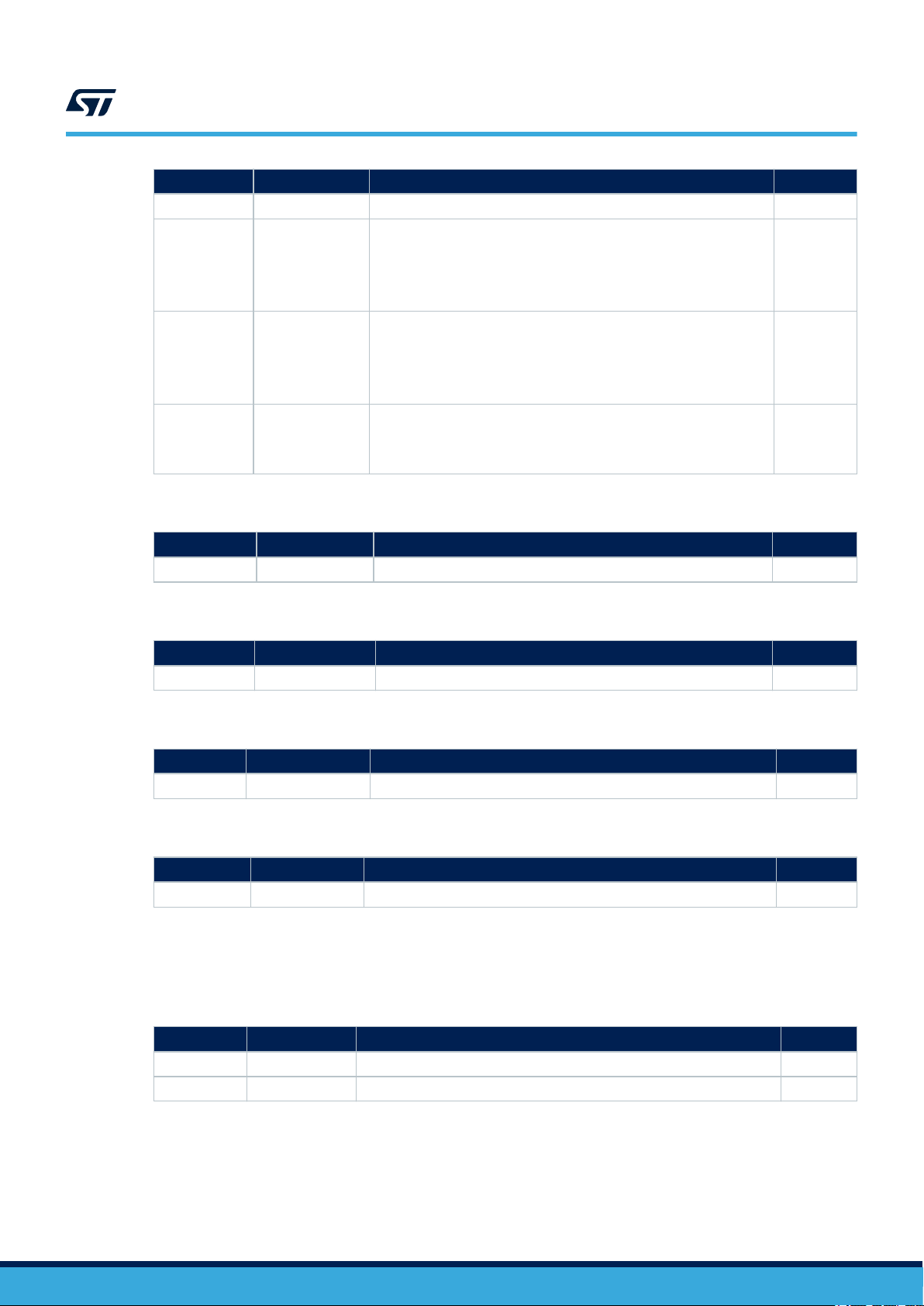

• First connect the board to a 3-phase generator and load as shown in the figure below, then power on the

generator:

UM2847 - Rev 1

page 5/20

Page 6

Figure 4. Electric connections

UM2847

Running the built-in demonstration

• When the load is connected, LED0 and LED1 blink with a frequency proportional to respectively active and

reactive power consumption.

• Connect a shell terminal to the board Virtual COM port as specified in Section 4.3 below.

• Alternatively, use the software GUI STSW-STPM005 to read/calibrate the metrology data. For more details

on the Metrology GUI please refer to its user manual.

• For application development and debug, connect the JTAG probe and open “IAR Embedded Workbench for

ARM” IDE. For STSW-STPM004 FW details please refer to related user manual.

UM2847 - Rev 1

page 6/20

Page 7

3 Metrology application

3.1 Metrology calculations

The metrology features implemented by EVALSTPM-3PHISO FW are the following:

• 6 channels V-I decimated samples available every 200 us

• Line period and phase shift measurement for each phase

• Phase to phase voltage delays

• RMS and THD calculation (optional) of each V-I signal

• 1-ph Active wideband, active fundamental and reactive power/energy calculation

• 1-ph Apparent RMS power/energy calculation

• 3-ph Active wideband, active fundamental and reactive power/energy calculation

• 3-ph Apparent RMS power/energy calculation

• Data latch in STPM3x like registers

• Full calibration (amplitude, power offset and samples offset for DC measurement)

• DC measurement optional excluding high-pass filter on ADC data

• Status bits for power sign, frequency error and signal stuck

• Two configurable LEDs for pulsed outputs

• Interface to Metrology GUI through USB

UM2847

Metrology application

3.2

Power is a signed value, that can be expressed as a normalized value as:

p n

P

norm

Energy register is an up/down counter, always positive, that increases or decreases according to the power sign.

All metrology calculations are performed in real-time every 200 us, which is the signal sampling period.

Time registers, like period, V-C phase shift and phase to phase voltage delay have an LSB equal to 8 us.

For more information on the signal processing and register LSBs please refer to FW user manual.

−1 ∙ 228∙ p n 28 + p n 27: 0

=

28

2

Metrology registers

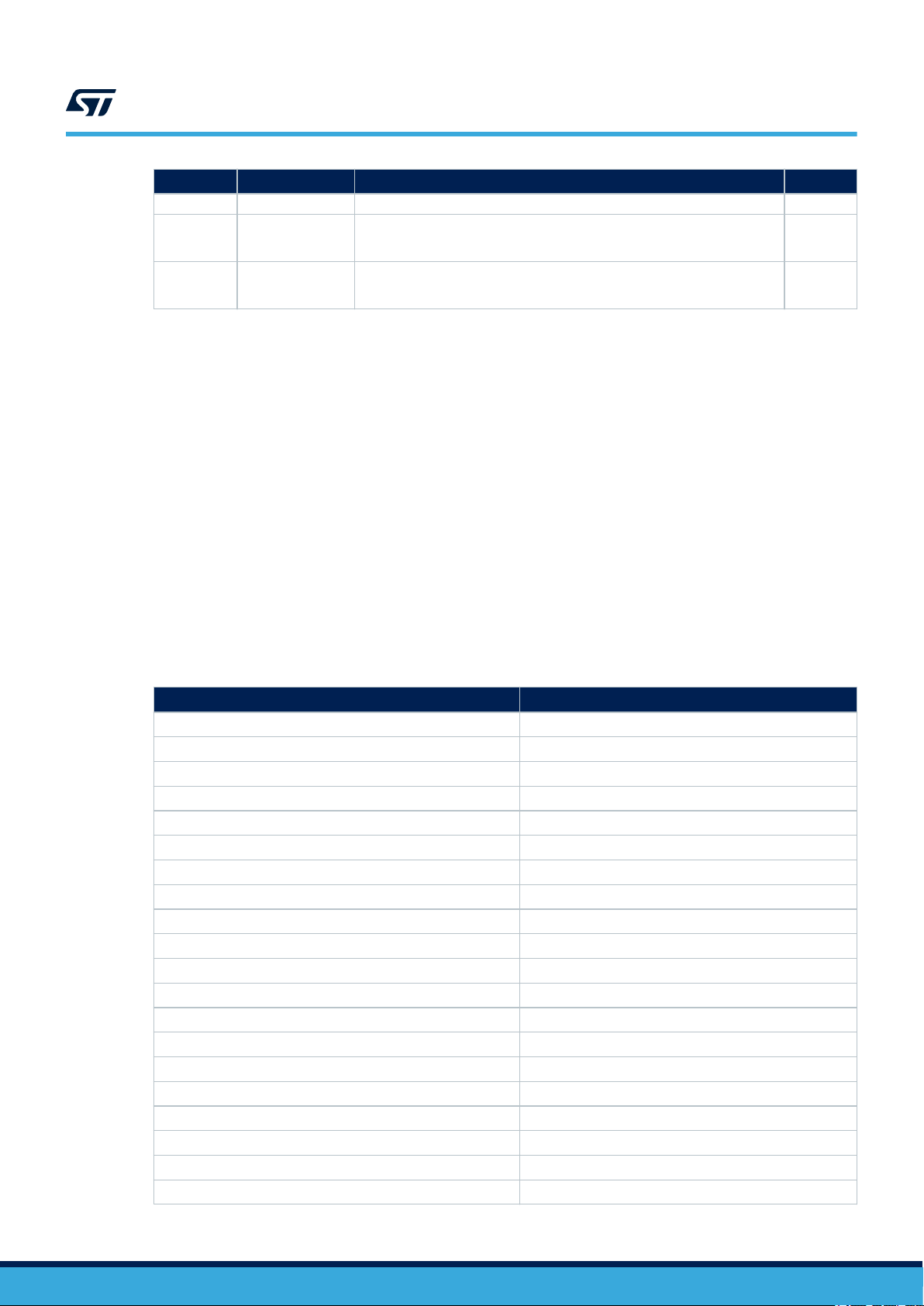

The data can be accessed in STPM32-like registers; data mapping in the registers is shown in Figure 5. Not all

the STPM32 registers are filled; only the used registers are shown.

UM2847 - Rev 1

page 7/20

Page 8

Figure 5. Registers map

ST Confidential

Address

(R)ead

(W)rite

(L)atch

Name

Default

Value

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

4 08 RW DSPCTRL5 00000800

5 0A RW DSPCTRL6 00000800

6 0C RW DSPCTRL7 00000000

7 0E RW DSPCTRL8 00000000

8 10 RW DSPCTRL9 00000000

9 12 RW DSPCTRL10 00000000

14 1C RW

V Freq ERR

V Signal

Stuck

C Signal

Stuck

RE_S

AF_S

AWB_S

DSPIRQ1 00000000

16 20 RWL

V Freq ERR

V Signal

Stuck

C Signal

Stuck

RE_S

AF_S

AWB_S

DSPSR1 00000000

21 2A R L

V Freq ERR

V Signal

Stuck

C Signal

Stuck

RE_S

AF_S

AWB_S

DSPEVENT1 00000000

23 2E RL DSP_REG1 00000000

24 30 RL DSP_REG2 00000000

25 32 RL DSP_REG3 00000000

28 38 RL DSP_REG6 00000000

29 3A R L DSP_REG7 00000000

32 40 RL DSP_REG10 00000000

33 42 RL DSP_REG11 00000000

36 48 RL DSP_REG14 00000000

37 4A R L DSP_REG15 00000000

38 4C RL DSP_REG16 00000000

39 4E RL DSP_REG17 00000000

42 54 RL CH1_REG1 00000000

43 56 RL CH1_REG2 00000000

44 58 RL CH1_REG3 00000000

45 5A R L CH1_REG4 00000000

46 5C RL CH1_REG5 00000000

47 5E RL CH1_REG6 00000000

48 60 RL CH1_REG7 00000000

49 62 RL CH1_REG8 00000000

51 66 RL CH1_REG10 00000000

52 68 RL CH1_REG11 00000000

66 84 RL TOT_REG1 00000000

67 86 RL TOT_REG2 00000000

68 88 RL TOT_REG3 00000000

69 8A R L TOT_REG4 00000000

DSPCTRL1

04000000

LPW1

[3:0]

31:28

27:24

23:20

19:16

15:12

11:8

7:4

3:0

LPS1

[1:0]

BHPFC1

BHPFV1

000RW

DSP Control Register #1

LCS1

[1:0]

204RW

DSP Control Register #3

DSPCTRL3

00000000

DSPCTRL2

24000000

LPW2

[3:0]

LCS2

[1:0]

102RW

DSP Control Register #2

LPS2

[1:0]

CHV [11:0]

CHC [11:0]

Padding

Padding

OFFV [23:0]

OFFC [23:0]

LATCH

REF_FREQ

LED2OFF

LED1OFF

Auto LATCH

OFAF [9:0]

OFA [9:0]

OFS [9:0]

OFR [9:0]

V Period [11:0]

Padding

V Sample [23:0]

Padding

C Sample [23:0]

THD V

THD C

Padding

V Fund Sample [23:0]

Padding

C Fund Sample [23:0]

1-PH Active Power[28:0]

V-C Angle [11:0]

C RMS Data [16:0]

C Fund RMS Data [16:0]

V RMS Data [14:0]

V Fund RMS Data [14:0]

V_V Delay[15:0]

3-PH Active Energy

3-PH Fundamental Energy

3-PH Reactive Energy

3-PH Apparent Energy

Padding

1-PH Momentary Active Power[28:0]

Padding

1-PH Momentary Fundamental Power[28:0]

Padding

1-PH Fundamental Power[28:0]

Padding

1-PH Reactive Power[28:0]

Padding

1-PH Apparent RMS Power[28:0]

1-PH Active Energy

1-PH Fundamental Energy

1-PH Reactive Energy

1-PH Apparent Energy

Padding

UM2847

Metrology registers

In the registers map, registers are divided in:

1. Configuration and calibration registers:

– Red field registers configure application LEDs and reference frequency. Since these configurations

refer to the whole application and are common to all the phases, they must be set only in the first

phase configuration registers.

– Yellow fields contain calibration and configuration data specific for each phase, so they must be set in

2. Data registers, indicated in blue, contain calculated data; they are all computed by the processing kernel on

UM2847 - Rev 1

each phase configuration register.

All the configuration registers, both application and phase ones, are written by the application and not

modified by the processing kernel. They can be configured in one of the following ways:

– either by setting them in the metroDefaultNvm in the handler_metrology.c file (please refer to FW user

– or at runtime by sending a write command (please refer to Section 3.3 below).

a 200 us basis, but updated in the registers upon request by setting the Latch bit in DSPCTRL3. Setting the

AutoLatch bit instead, these data are automatically updated every 200 us.

manual for details)

page 8/20

Page 9

3.2.1 Registers description

Bit Config. Description Default

19 BHPFV

20 BHPFC

24-27 LPW1

28-29 LPS1

30-31 LCS1

Table 3. DSP control register 1 (DSPCTRL1)

Bypass Hi-Pass Filter for voltage channel:

BHPFV = 0: HPF enabled

BHPFV = 1: HPF bypassed

Bypass Hi-Pass Filter for current channel:

BHPFC = 0: HPF enabled

BHPFC = 1: HPF bypassed

LED1 Speed Dividing Factor: 0x0 = 2-4, 0xF = 2

Default 0x4 = 1

LED1 pulse-out power selection:

LPS1 = 00: Active

LPS1 = 01: Active fundamental

LPS1 = 10: Reactive

LPS1 = 11: Apparent

LED1 pulse-out channel selection:

LCS1 = 00: Phase 1

LCS1 = 01: Phase 2

LCS1 = 10: Phase 3

LCS1 = 11: Three-phase

11

UM2847

Metrology registers

0x0

0x0

0x4

0x0

0x3

Bit

24-27 LPW2

28-29 LPS2

30-31 LCS2

Bit

21 Latch

Config. Description Default

Config. Description Default

Table 4. DSP control register 2 (DSPCTRL2)

LED2 Speed Dividing Factor: 0x0 = 2-4, 0xF = 2

Default 0x4 = 1

LED2 pulse-out power selection:

LPS2 = 00: Active

LPS2 = 01: Active fundamental

LPS2 = 10: Reactive

LPS2 = 11: Apparent

LED2 pulse-out channel selection:

LCS2 = 00: Phase 1

LCS2= 01: Phase 2

LCS2 = 10: Phase 3

LCS2 = 11: Three-phase

11

Table 5. DSP control register 3 (DSPCTRL3)

Updates measurement registers

This bit is automatically set to zero after action

0x4

0x2

0x3

0x0

UM2847 - Rev 1

page 9/20

Page 10

UM2847

Metrology registers

Bit Config. Description Default

23 Auto Latch Updates measurement registers at 5 kHz 0x0

LED1 pin output disable

24 LED1OFF

25 LED2OFF

27 REF_FREQ

Bit Config. Description Default

0-11 CHV Calibration register of voltage channel 0x800

‘0’: LED1 output on

‘1’: LED1 output disabled

When the LED output is disabled the pin is set at low state

LED2 pin output disable

‘0’: LED2 output on

‘1’: LED2 output disabled

When the LED output is disabled the pin is set at low state

Reference line frequency:

‘0’: 50Hz,

‘1’: 60Hz

Table 6. DSP control register 5 (DSPCTRL5)

0x0

0x0

0x0

Table 7. DSP control register 6 (DSPCTRL6)

Bit

0-11 CHC Calibration register of current channel 0x800

Config. Description Default

Table 8. DSP control register 7 (DSPCTRL7)

Bit

0-23 OFV Offset compensation of voltage channel 0x800

Config. Description Default

Table 9. DSP control register 8 (DSPCTRL8)

Bit

0-23 OFC Offset compensation of current channel 0x800

Config. Description Default

Offset on voltage and current is added to ADC sample in case of DC measurement, then if the bit BHPF for the

respective signal is set. Offset register LSB is equal to voltage or current sample register LSB.

Table 10. DSP control register 9 (DSPCTRL9)

Bit

12-21 OFA Offset compensation of active wideband power 0x0

22-31 OFAF Offset compensation of active fundamental power 0x0

Config. Description Default

UM2847 - Rev 1

page 10/20

Page 11

UM2847

Metrology registers

Table 11. DSP control register 10 (DSPCTRL10)

Bit Config. Description Default

12-21 OFR Offset compensation of reactive power 0x0

22-31 OFS Offset compensation of apparent power 0x0

Power offset is added to its respective power value to compensate error at low current. This register LSB is equal

to four times power register LSB:

LSB

Table 12. DSP interrupt register (DSPIRQ1)

Bit Config. Description Default

12 AWB_S If set, upon event occurrence an interrupt variable is set 0x0

13 AF_S If set, upon event occurrence an interrupt variable is set 0x0

14 RE_S If set, upon event occurrence an interrupt variable is set 0x0

20 C Signal Stuck If set, upon event occurrence an interrupt variable is set 0x0

24 V Signal Stuck If set, upon event occurrence an interrupt variable is set 0x0

25 V Freq Err If set, upon event occurrence an interrupt variable is set 0x0

POFF

= 4*LSB

P

Table 13. DSP status register (DSPSR1)

Bit

12 AWB_S

13 AF_S

14 RE_S

20 C Signal Stuck

24 V Signal Stuck

25 V Freq Err

Config. Description Default

If set, active wideband power sign is negative

Set by the processing kernel, must be cleared by the application

If set, active fundamental power sign is negative

Set by the processing kernel, must be cleared by the application

If set, reactive power sign is negative

Set by the processing kernel, must be cleared by the application

If set, current signal bitstream is stuck to 1 or 0

Set by the processing kernel, must be cleared by the application

If set, current signal bitstream is stuck to 1 or 0

Set by the processing kernel, must be cleared by the application

If set, voltage frequency is out of the range [33 Hz, 83 Hz]

Set by the processing kernel, must be cleared by the application

0x0

0x0

0x0

0x0

0x0

0x0

Table 14. DSP live events register (DSPEV1)

Bit

12 AWB_S

13 AF_S

14 RE_S

20 C Signal Stuck If set, current signal bitstream is stuck to 1 or 0 0x0

Config. Description Default

If set, active wideband power sign is negative

Set and cleared by the processing kernel

If set, active fundamental power sign is negative

Set and cleared by the processing kernel

If set, reactive power sign is negative

Set and cleared by the processing kernel

0x0

0x0

0x0

UM2847 - Rev 1

page 11/20

Page 12

Bit Config. Description Default

Set and cleared by the processing kernel

24 V Signal Stuck

25 V Freq Err

If set, current signal bitstream is stuck to 1 or 0

Set and cleared by the processing kernel

If set, voltage frequency is out of the range [33 Hz, 83 Hz]

Set and cleared by the processing kernel

3.3 Register access through mini-shell

It is possible to access all the metrology data by connecting to the virtual serial COM port associated to the board

with the following settings:

• Baud rate: 115200

• Handshake: request to send

• Parity: none

• Data bits: 8

• Stop bits: 1

To communicate with the board use the command set in Table 15, where:

• <phase> could be 1, 2 or 3;

• <address> is the address or the register to read, as in the second column of the registers map in Figure 5 ;

• <n> is the number of registers to read, maximum is 70. Please consider that some of the registers are

unused, they are not listed in Figure 5 but are actually present in the memory structure. It is necessary to

take them into account when requesting a read or write access on several registers.

UM2847

Register access through mini-shell

0x0

0x0

Table 15. Minishell commands

Command Data received

met metro 0 1 <phase> Voltage Period

met metro 6 1 <phase> 1 1 Current RMS

met metro 6 1 <phase> 2 1 Voltage RMS

met metro 17 1 <phase> 1 1 Fund Current RMS

met metro 17 1 <phase> 2 1 Fund Voltage RMS

met metro 18 1 <phase> 1 Current THD

met metro 18 1 <phase> 2 Voltage THD

met metro 7 1 <phase> Phase shift

met metro 19 1 <phase> V - V delay

met metro 1 1 <phase> 1 1-ph Active WB power

met metro 1 1 <phase> 2 1-ph Active Fund power

met metro 1 1 <phase> 3 1-ph Reactive power

met metro 1 1 <phase> 4 1-ph Apparent power

met metro 2 1 <phase> 1 1-ph Active WB energy

met metro 2 1 <phase> 2 1-ph Active Fund energy

met metro 2 1 <phase> 3 1-ph Reactive energy

met metro 2 1 <phase> 4 1-ph Apparent energy

met metro 20 1 1 3-ph Active WB energy

met metro 20 1 2 3-ph Active Fund energy

met metro 20 1 3 3-ph Reactive energy

UM2847 - Rev 1

page 12/20

Page 13

Register access through mini-shell

Command Data received

met metro 20 1 4 3-ph Apparent energy

met metro 21 1 <phase> All data

met rd <phase> <address> <Nb> Read < Nb > registers starting from <address>

met wr <phase> <address> <Nb> <data1> <data2> … <dataNb>

Write < Nb > registers starting from <address> ; <datax> is

the 32-bit register value to write

UM2847

UM2847 - Rev 1

page 13/20

Page 14

4 Accuracy results

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

0.001 0.01 0.1 1 10 100

3-ph AWB

phi = 0° phi = 60° phi =-60°

IEC Class 0.5 PF 0.5 Limits IEC Class 0.5 PF 1 Limits

The board needs to be calibrated to get target accuracy. For this purpose, it is possible to use the procedure

indicated in application note AN4470, “The STPM3x and the STCOMET application calibration”.

All the design and calibration formulas apply to the STPMS2 application as well, using the AFE parameters

reported in Table 2 and the application constants in Table 16.

An excel file with all the related formulas is available on request.

Parameter Value Unit Description

Vref 1.2 V Voltage reference value

Ai 16 Current channel gain

Au 2 Voltage channel gain

Cal_i 0.875 Calibrator mid value

Cal_v 0.875 Calibrator mid value

Dclk 5000 Hz Decimation frequency

UM2847

Accuracy results

Table 16. Application constants

Some of the accuracy test results after calibration are reported below:

Figure 6. Active wideband energy error over full scale current input range

UM2847 - Rev 1

page 14/20

Page 15

Figure 7. Current RMS error over full scale input range

-2.00%

-1.50%

-1.00%

-0.50%

0.00%

0.50%

1.00%

1.50%

2.00%

0.1 1 10 100

RMS Current

I1

I2

I3

UM2847

Accuracy results

UM2847 - Rev 1

page 15/20

Page 16

Revision history

UM2847

Table 17. Document revision history

Date Version Changes

10-Mar-2021 1 Initial release.

UM2847 - Rev 1

page 16/20

Page 17

UM2847

Contents

Contents

1 Safety and operating instructions ..................................................2

1.1 General terms .................................................................2

1.2 Intended use of evaluation board .................................................2

1.3 Installing the evaluation board....................................................2

1.4 Operating the evaluation board ...................................................2

2 Getting started ....................................................................4

2.1 Hardware and software requirements..............................................4

2.2 Hardware description ...........................................................4

2.2.1 Power supply ...........................................................4

2.2.2 Voltage and current sensing section ..........................................5

2.2.3 Board ratings............................................................5

2.3 Running the built-in demonstration ................................................5

3 Metrology application..............................................................7

3.1 Metrology calculations ..........................................................7

3.2 Metrology registers .............................................................7

3.2.1 Registers description......................................................9

3.3 Register access through mini-shell ...............................................12

4 Accuracy results .................................................................14

Revision history .......................................................................16

Contents ..............................................................................17

List of tables ..........................................................................18

List of figures..........................................................................19

UM2847 - Rev 1

page 17/20

Page 18

UM2847

List of tables

List of tables

Table 1. STPMS2 HW configuration ............................................................. 5

Table 2. AFE components ....................................................................5

Table 3. DSP control register 1 (DSPCTRL1).......................................................9

Table 4. DSP control register 2 (DSPCTRL2).......................................................9

Table 5. DSP control register 3 (DSPCTRL3).......................................................9

Table 6. DSP control register 5 (DSPCTRL5)...................................................... 10

Table 7. DSP control register 6 (DSPCTRL6)...................................................... 10

Table 8. DSP control register 7 (DSPCTRL7)...................................................... 10

Table 9. DSP control register 8 (DSPCTRL8) ...................................................... 10

Table 10. DSP control register 9 (DSPCTRL9) ...................................................... 10

Table 11. DSP control register 10 (DSPCTRL10) .................................................... 11

Table 12. DSP interrupt register (DSPIRQ1) ....................................................... 11

Table 13. DSP status register (DSPSR1) ......................................................... 11

Table 14. DSP live events register (DSPEV1) ...................................................... 11

Table 15. Minishell commands .................................................................12

Table 16. Application constants ................................................................ 14

Table 17. Document revision history .............................................................16

UM2847 - Rev 1

page 18/20

Page 19

UM2847

List of figures

List of figures

Figure 1. EVALSTPM-3PHISO image ...........................................................1

Figure 2. High and low voltage sides ............................................................3

Figure 3. EVALSTPM-3PHISO board function description .............................................4

Figure 4. Electric connections ................................................................6

Figure 5. Registers map ....................................................................8

Figure 6. Active wideband energy error over full scale current input range ................................. 14

Figure 7. Current RMS error over full scale input range .............................................. 15

UM2847 - Rev 1

page 19/20

Page 20

UM2847

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. For additional information about ST trademarks, please refer to www.st.com/trademarks. All other product or service

names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2021 STMicroelectronics – All rights reserved

UM2847 - Rev 1

page 20/20

Loading...

Loading...