Page 1

STM8S105xx

Access line, 16 MHz STM8S 8-bit MCU, up to 32 Kbytes Flash,

Datasheet - production data

integrated EEPROM,10-bit ADC, timers, UART, SPI, I²C

Features

Core

• 16 MHz advanced STM8 core with Harvar d

architecture and 3-stage pipeline

• Extended instruction set

Memories

• Medium-density Flash/EEPROM :

− Program memory up to 32 Kbytes; data

retention 20 years at 55°C after 10 kcycles

− Data memory up to 1 Kbytes true data

EEPROM; endurance 300 kcycles

• RAM: Up to 2 Kbytes

Timers

• 2x 16-bit general purpose timers, with 2+3

CAPCOM channels (IC, OC or PWM)

• Advanced control timer: 16-bit, 4 CAPCOM

channels, 3 complementary output s , dead-time

insertion and flexible synchronization

• 8-bit basic timer with 8-bit prescaler

• Auto wake-up timer

• Window and independent watchdog t i mers

Communications interfaces

• UART with clock output for synchronous

operation, Smartcard, IrDA, L IN

• SPI interface up to 8 Mbit/s

• I2C interface up to 400 Kbit/s

Analog-to-digital converter (ADC)

• 10-bit, ±1 LSB ADC with up to 10 multiplexed

channels, scan mode and analog watchdog

I/Os

• Up to 38 I/Os on a 48-pin package including 16

high sink outputs

• Highly robust I/O design, immune against current

injection

Clock, reset and supply management

• 2.95 V to 5.5 V operating voltage

• Flexible clock control, 4 master clock sources:

− Low power crystal resonator oscill ator

− External clock input

− Internal, user-trimmable 16 MHz RC

− Internal low power 128 kHz RC

• Clock security system with clock monitor

• Power management:

− Low power modes (wait, active-halt, halt)

− Switch-off peripheral clocks individually

• Permanently active, low consumption power-on

and power-down reset

Development support

• Embedded single wire interface module (SWIM)

for fast on-chip programming and non-intrusive

debugging

Unique ID

• 96-bit unique key for each device

Table 1: Device summary

Interrupt management

• Nested interrupt controller with 32 interrupts

• Up to 37 external interrupts on 6 vectors

Reference

STM8S105xx

STM8S105K4, STM8S105K6, STM8S105S4,

Part number

STM8S105S6, STM8S105C4, STM8S105C6

February 2014 DocID14771 Rev 13 1/99

This is information on a product in full production

www.st.com

Page 2

Contents

STM8S105xx

Contents

1 Introduction ....................................................................................... 8

2 Description ........................................................................................ 9

3 Block diagram ................................................................................. 10

4 Product overview ............................................................................ 11

4.1 Single wire interf ac e module (SWIM) and debug module (DM) ....... 11

4.2 Interrupt controller ........................................................................... 12

4.3 Flash program and data EEPROM memory .................................... 12

4.4 Clock controller ............................................................................... 13

4.5 Power management ........................................................................ 14

4.6 Watchdog timers ............................................................................. 14

4.7 Auto wakeup counter ...................................................................... 15

4.8 Beeper ............................................................................................ 15

4.9 TIM1 - 16-bit advanced control timer ............................................... 15

4.10 TIM2, TIM3 - 16-bit general purpose timers .................................... 15

4.11 TIM4 - 8-bit basic timer ................................................................... 16

4.12 Analog-to-digital converter (ADC1) ................................................. 16

4.13 Communication interfaces ............................................................... 17

4.13.1 UART2 .............................................................................................. 17

4.13.2 SPI .................................................................................................... 17

4.13.3 I²C ..................................................................................................... 18

5 Pinout and pin description ............................................................ 19

5.1 STM8S105 pinouts and pin description ........................................... 19

5.1.1 Alternate function remapping ........................................................... 24

6 Memory and register map .............................................................. 25

6.1 Memory map ................................................................................... 25

6.2 Register map ................................................................................... 26

6.2.1 I/O port hardware register map ........................................................ 26

6.2.2 General hardware register map ........................................................ 27

6.2.3 CPU/SWIM/debug module/interrupt controlle r registers .................. 34

7 Interrupt vector mapping ............................................................... 36

8 Option bytes .................................................................................... 37

9 Unique ID ......................................................................................... 41

2/99 DocID14771 Rev 13

Page 3

STM8S105xx

Contents

10 Electrical characteristics ............................................................... 42

10.1 Parameter conditions ...................................................................... 42

10.1.1 Minimum and maximum values ........................................................ 42

10.1.2 Typical values ................................................................................... 42

10.1.3 Typical curves ................................................................................... 42

10.1.4 Typical current consumption ............................................................ 42

10.1.5 Loading capacitor ............................................................................. 43

10.1.6 Pin input voltage ............................................................................... 43

10.2 Absolute maximum ratings .............................................................. 43

10.3 Operating conditions ....................................................................... 45

10.3.1 VCAP external capacitor .................................................................. 46

10.3.2 Supply current characteristics .......................................................... 47

10.3.3 External clock sources and timing characteristics ............................ 56

10.3.4 Internal clock sources and timing characteristics ............................. 58

10.3.5 Memory characteristics ..................................................................... 60

10.3.6 I/O port pin characteristics ................................................................ 61

10.3.7 Typical output level curves ............................................................... 64

10.3.8 Reset pin characteristics .................................................................. 68

10.3.9 SPI serial peripheral interface .......................................................... 70

10.3.10 I2C interface characteristics ............................................................. 73

10.3.11 10-bit ADC characteristics ................................................................ 74

10.3.12 EMC characteristics .......................................................................... 77

11 Package information ...................................................................... 80

11.1 48-pin LQFP package mechanical data .......................................... 80

11.2 44-pin LQFP package mechanical data .......................................... 81

11.3 32-pin LQFP package mechanical data .......................................... 82

11.4 32-lead UFQFPN package mechanical data ................................... 84

11.5 SDIP32 package mechanical data .................................................. 85

12 Thermal characteristics ................................................................. 87

12.1 Reference document ....................................................................... 87

12.2 Selecting the product temperature range ........................................ 87

13 Ordering information ...................................................................... 89

14 STM8S105 FASTROM microcontro ller option list ....................... 90

15 STM8 development tools ............................................................... 94

15.1 Emulation and in-circuit debugging tools ......................................... 94

DocID14771 Rev 13 3/99

Page 4

Contents

STM8S105xx

15.2 Software tools ................................................................................. 94

15.2.1 STM8 toolset .................................................................................... 94

15.2.2 C and assembly toolchains .............................................................. 95

15.3 Programming tools .......................................................................... 95

16 Revision history .............................................................................. 96

17 Disclaimer ....................................................................................... 99

4/99 DocID14771 Rev 13

Page 5

STM8S105xx

List of tables

List of tables

Table 1: Device summary ........................................................................................................................... 1

Table 2: STM8S105xx access line features ............................................................................................... 9

Table 3: Peripheral clock gating bit assignments in C LK_PCKENR1/2 registers .................................... 14

Table 4: TIM timer features ....................................................................................................................... 16

Table 5: Legend/abbreviations for pinout t ables ....................................................................................... 19

Table 6: Pin description for STM8S105 microcontrollers ......................................................................... 22

Table 7: Flash, Data EEPROM and RAM boundary addresses ............................................................... 26

Table 8: I/O port hardware register map ................................................................................................... 26

Table 9: General hardware register map .................................................................................................. 27

Table 10: CPU/SWIM/debug module/interrupt cont roller registers .......................................................... 34

Table 11: Interrupt mapping ...................................................................................................................... 36

Table 12: Option bytes .............................................................................................................................. 37

Table 13: Option byte description ............................................................................................................. 38

Table 14: Description of alternate function remapping bits [7:0] of OPT2 ................................................ 39

Table 15: Unique ID registers (96 bits) ..................................................................................................... 41

Table 16: Voltage characteristics .............................................................................................................. 43

Table 17: Current characteristics .............................................................................................................. 44

Table 18: Thermal characteristics ............................................................................................................. 45

Table 19: General operating conditions .................................................................................................... 45

Table 20: Operating conditions at power-up/power-down ........................................................................ 46

Table 21: Total current consumption with code execut ion in run mode at VDD = 5 V ............................. 47

Table 22: Total current consumption with code execut ion in run mode at VDD = 3.3 V .......................... 48

Table 23: Total current consumption in wait mode at VDD = 5 V ............................................................. 49

Table 24: Total current consumption in wait mode at V DD = 3.3 V .......................................................... 49

Table 25: Total current consumption in active halt m ode at VDD = 5 V ................................................... 50

Table 26: Total current consumption in active halt mode at VDD = 3.3 V ................................................ 51

Table 27: Total current consumption in halt mode at V DD = 5 V ............................................................. 51

Table 28: Total current consumption in halt mode at V DD = 3.3 V .......................................................... 52

Table 29: Wakeup times ........................................................................................................................... 52

Table 30: Total current consumption and timing in f orc ed reset state ...................................................... 53

Table 31: Peripheral current consumption ................................................................................................ 53

Table 32: HSE user external clock characteristic s ................................................................................... 56

Table 33: HSE oscillator characteristics ................................................................................................... 56

Table 34: HSI oscillator characteristics ..................................................................................................... 58

Table 35: LSI oscillator characteristics ..................................................................................................... 59

Table 36: RAM and hardware registers .................................................................................................... 60

Table 37: Flash program memory/data EEPROM memory ...................................................................... 60

Table 38: I/O static characteristics ............................................................................................................ 61

Table 39: Output driving current (standard ports) ..................................................................................... 63

Table 40: Output driving current (true open drain ports) .......................................................................... 63

Table 41: Output driving current (high sink ports) .................................................................................... 63

Table 42: NRST pin characteristics .......................................................................................................... 68

Table 43: SPI characteristics .................................................................................................................... 71

Table 44: I2C characteristics .................................................................................................................... 73

Table 45: ADC characteristics .................................................................................................................. 74

Table 46: ADC accuracy with RAIN < 10 kΩ , VDDA= 5 V ...................................................................... 75

Table 47: ADC accuracy with RAIN < 10 kΩ RAIN, VDDA = 3.3 V .......................................................... 76

Table 48: EMS data .................................................................................................................................. 78

Table 49: EMI data .................................................................................................................................... 78

Table 50: ESD absolute maximum ratings ............................................................................................... 79

Table 51: Electrical sensitivities ................................................................................................................ 79

Table 52: 48-pin low profile quad flat package mechanical data .............................................................. 80

Table 53: 44-pin low profile quad flat package mechanical data .............................................................. 81

DocID14771 Rev 13 5/99

Page 6

List of tables

STM8S105xx

Table 54: 32-pin low profile quad flat package mechanical data .............................................................. 82

Table 55: 32-lead ultra thin fine pitch quad flat no-lead pac kage me chani cal dat a ................................. 84

Table 56: 32-lead shrink plastic DIP (400 ml) package mechanical data ................................................. 86

Table 57: Thermal characteristics (1) ....................................................................................................... 87

Table 58: Document revision history ........................................................................................................ 96

6/99 DocID14771 Rev 13

Page 7

STM8S105xx

List of figures

List of figures

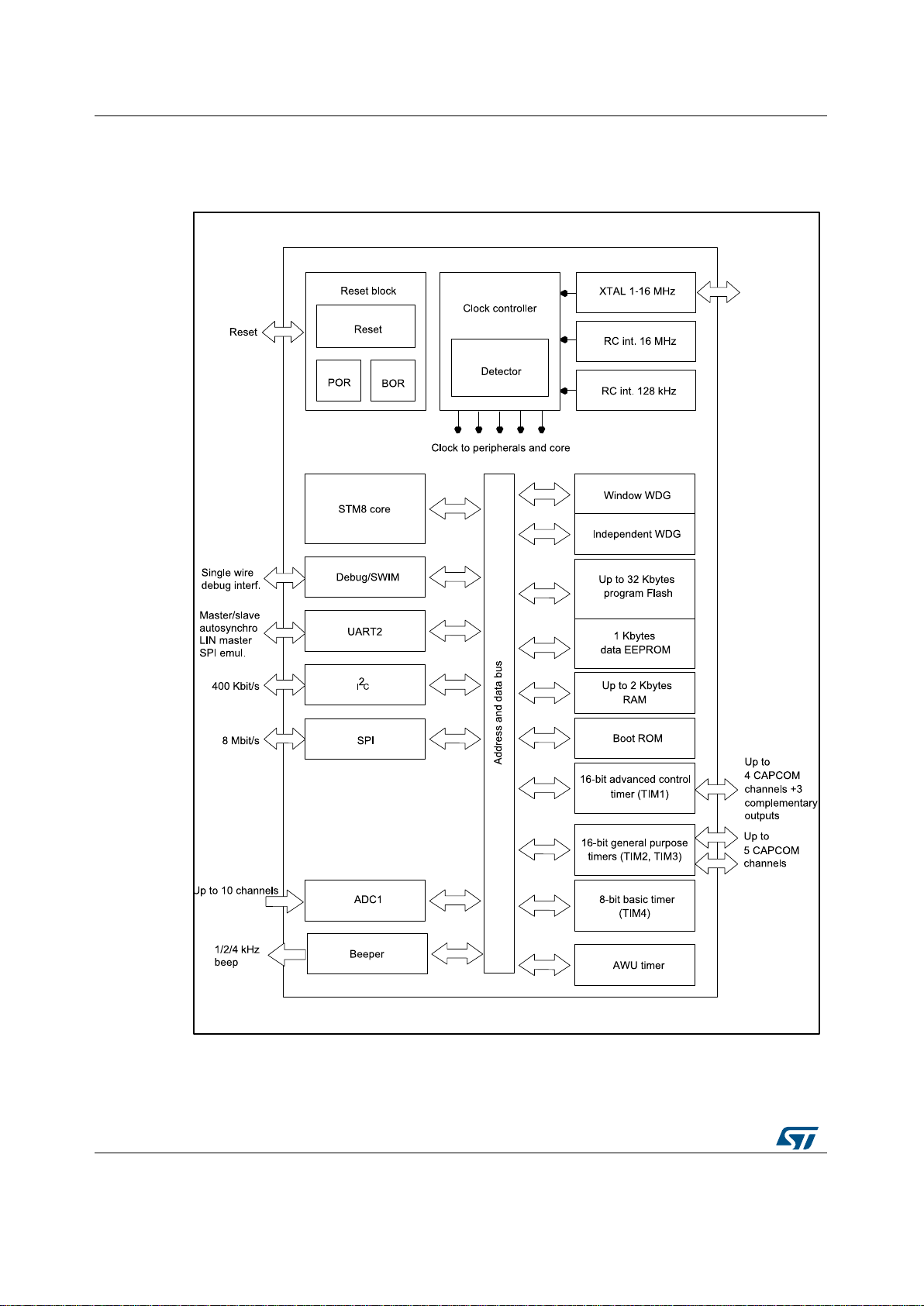

Figure 1: STM8S105xx access line block diagram ................................................................................... 10

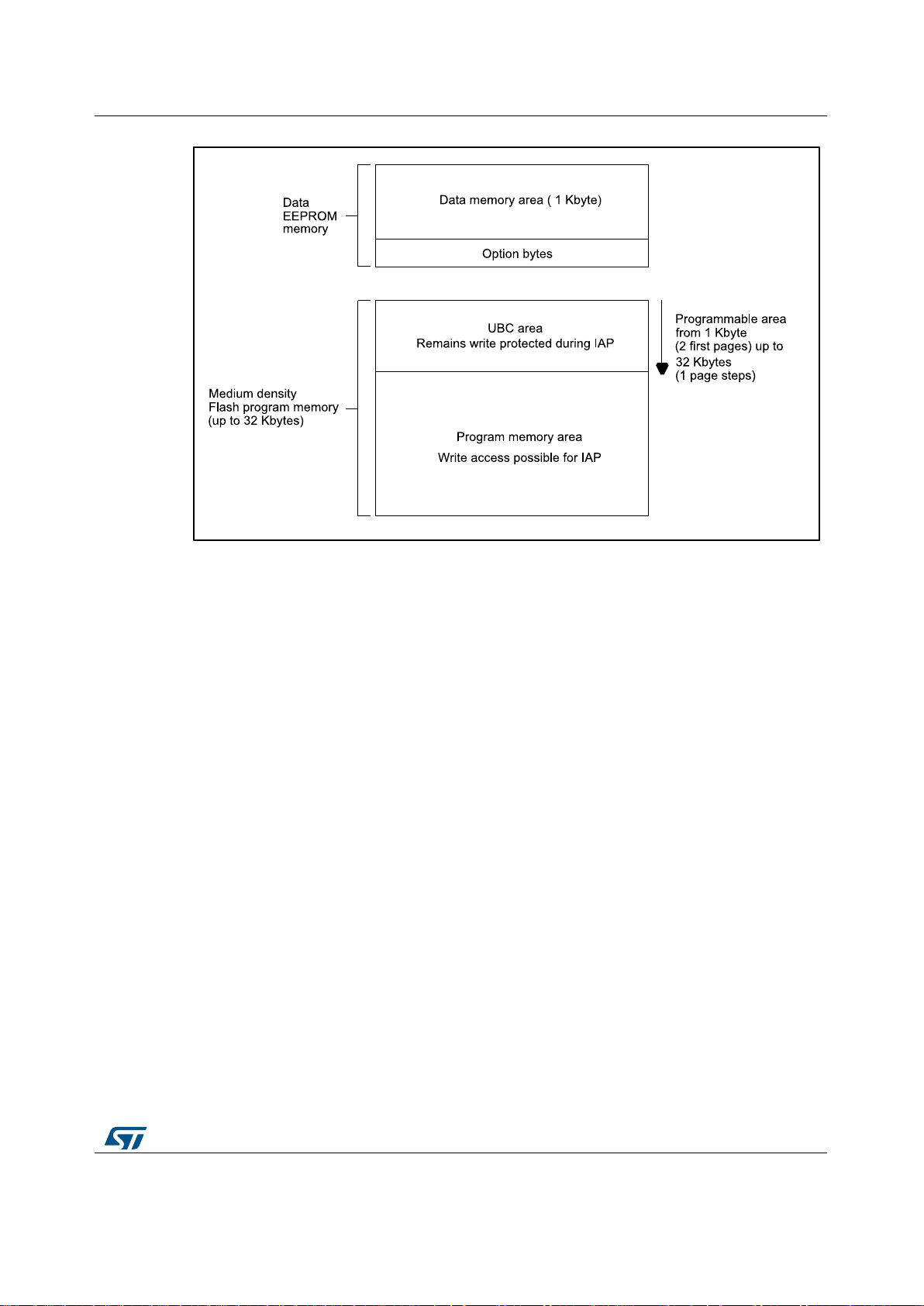

Figure 2: Flash memory organization ....................................................................................................... 13

Figure 3: LQFP 48-pin pinout ................................................................................................................... 19

Figure 4: LQFP 44-pin pinout ................................................................................................................... 20

Figure 5: LQFP/UFQFPN 32-pin pinout .................................................................................................... 21

Figure 6: SDIP 32-pin pinout .................................................................................................................... 21

Figure 7: Memory map .............................................................................................................................. 25

Figure 8: Supply current measurement conditions ................................................................................... 42

Figure 9: Pin loading conditions ................................................................................................................ 43

Figure 10: Pin input voltage ...................................................................................................................... 43

Figure 11: fCPUmax versus VDD ............................................................................................................. 46

Figure 12: External capacitor CEXT ......................................................................................................... 47

Figure 13: Typ. IDD(RUN) vs. VDD, HSE user external clock, fCPU = 16 MHz ...................................... 54

Figure 14: Typ. IDD(RUN) vs. fCPU, HSE user external clock, VDD= 5 V .............................................. 54

Figure 15: Typ. IDD(RUN) vs. VDD, HSI RC osc, fCPU = 16 MHz .......................................................... 54

Figure 16: Typ. IDD(WFI) vs. VDD, HSE user external clock, fCPU = 16 MHz ....................................... 55

Figure 17: Typ. IDD(WFI) vs. fCPU, HSE user external clock VDD = 5 V ............................................... 55

Figure 18: Typ. IDD(WFI) vs. VDD, HSI RC osc, fCPU = 16 MHz ........................................................... 55

Figure 19: HSE external clocksource ....................................................................................................... 56

Figure 20: HSE oscillator circuit diagram.................................................................................................. 57

Figure 21: Typical HSI accuracy at VDD = 5 V vs 5 temper at ures ........................................................... 58

Figure 22: Typical HSI accuracy vs VDD @ 4 temperat ures ................................................................... 59

Figure 23: Typical LSI accuracy vs VDD @ 4 temperatures .................................................................... 59

Figure 24: Typical VIL and VIH vs VDD @ 4 temperatures ..................................................................... 62

Figure 25: Typical pull-up resistance vs VDD @ 4 t em peratures ............................................................. 62

Figure 26: Typical pull-up current vs VDD @ 4 temperatures .................................................................. 63

Figure 27: Typ. VOL @ VDD = 5 V (standard ports) ................................................................................ 64

Figure 28: Typ. VOL @ VDD = 3.3 V (standard ports) ............................................................................. 65

Figure 29: Typ. VOL @ VDD = 5 V (true open drain ports) ...................................................................... 65

Figure 30: Typ. VOL @ VDD = 3.3 V (true open drain ports) ................................................................... 66

Figure 31: Typ. VOL @ VDD = 5 V (high sink ports) ................................................................................ 66

Figure 32: Typ. VOL @ VDD = 3.3 V (high sink ports) ............................................................................. 67

Figure 33: Typ. VDD - VOH @ VDD = 5 V (standard ports) ..................................................................... 67

Figure 34: Typ. VDD - VOH @ VDD = 3.3 V (standard ports) .................................................................. 67

Figure 35: Typ. VDD - VOH @ VDD = 5 V (high sink ports) .................................................................... 68

Figure 36: Typ. VDD - VOH @ VDD = 3.3 V (high sink ports) ................................................................. 68

Figure 37: Typical NRST VIL and VIH vs VDD @ 4 temperatures ........................................................... 69

Figure 38: Typical NRST pull-up resistance vs VDD @ 4 t em peratures .................................................. 69

Figure 39: Typical NRST pull-up current vs VDD @ 4 tem peratures ....................................................... 70

Figure 40: Recommended reset pin protection ........................................................................................ 70

Figure 41: SPI timing diagram - slave mode and CPH A = 0 .................................................................... 72

Figure 42: SPI timing diagram - slave mode and CPH A = 1(1) ................................................................ 72

Figure 43: SPI timing diagram - master mode(1) ..................................................................................... 73

Figure 44: Typical application with I2C bus and timing diagram (1) ......................................................... 74

Figure 45: ADC accuracy characteristics .................................................................................................. 76

Figure 46: Typical application with ADC ................................................................................................... 77

Figure 47: 48-pin low profile quad flat package (7 x 7) ............................................................................. 80

Figure 48: 44-pin low profile quad flat package ........................................................................................ 81

Figure 49: 32-pin low profile quad flat package (7 x 7) ............................................................................. 82

Figure 50: 32-lead, ultra thin, fine pitch quad flat no-lead package (5 x 5) .............................................. 84

Figure 51: 32-lead shrink plastic DIP (400 ml) package ........................................................................... 85

Figure 52: STM8S105xx access line ordering information scheme ......................................................... 89

DocID14771 Rev 13 7/99

Page 8

Introduction

STM8S105xx

1 Introduction

This datasheet contains the description of the device features, pinout, electrical

characteristics, mechanical data and ordering information.

• For complete information on the STM8S microcontroller memory, registers and

peripherals, please refer to the STM8S microcont roller family reference manual

(RM0016).

• For information on programming, erasing and protection of the internal Flash memory

please refer to the STM8S Flash programming manu al (P M 0051).

• For information on the debug and SWIM (single wire interface module) refer to the

STM8 SWIM communication protocol and debug mo dul e user manual (UM0470).

• For information on the STM8 core, please refer to the S T M 8 CP U programming

manual (PM0044).

8/99 DocID14771 Rev 13

Page 9

STM8S105xx

Description

2 Description

The STM8S105xx access line 8-bit microcontrollers offer from 16 to 32 Kbytes Flash

program memory, plus integrated true data EE PROM. They are referred to as mediumdensity devices in the STM8S microcontroller family reference manual (RM0016).

All devices of the STM8S105xx access line provide t he f ol l owing benefits: reduced system

cost, performance and robustness, short development cycles, and product longevity.

The system cost is reduced thanks to an integrated true data EEPROM for up to 300k

write/erase cycles and a high system integration level with internal clock oscillators,

watchdog, and brown-out reset.

Device performance is ensured by a 16 MHz CPU clock frequency and enhanced

characteristics which include robust I/O, indepe ndent watchdogs (with a separate clock

source), and a clock security system.

Short development cycles are guaranteed due to ap plication scalability across common

family product architecture with compatible pinout , memory map and modular peripherals.

Full documentation is offered with a wide choi ce of development tools.

Product longevity is ensured in the STM8S family t hanks to their advanced core which is

made in a state-of-the art technology for applications with 2.95 V to 5.5 V operating supply.

Table 2: STM8S105xx access line features

Device

Pin count

Maximum

number of GPIOs

Ext. Interrupt pins

Timer CAPCOM

channels

complementary

A/D Converter

channels

High sink I/Os

Medium density

Flash Program

memory (bytes)

Data EEPROM

RAM (bytes)

Peripheral set

Timer

outputs

(bytes)

STM8S105C6 STM8S105C4 STM8S105S6 STM8S105S4 STM8S105K6 STM8S105K4

48

38

35

9

3

10

16

32K

1024

2K

Advanced control t i me r (TI M1 ) , G en eral-purpose timers (TIM2 and TIM3), Basic timer (TIM4) SPI, I2C,

48

38

35

9

3

10

16

16K

1024

2K

UART, Window WDG, Independent WDG, ADC

44

34

31

8

3

9

15

32K

1024

2K

44

34

31

8

3

9

15

16K

1024

2K

32

25

23

8

3

7

12

32K

1024

2K

32

25

23

8

3

7

12

16K

1024

2K

DocID14771 Rev 13 9/99

Page 10

Block diagram

STM8S105xx

3 Block diagram

Figure 1: STM8S105xx access line block diagram

10/99 DocID14771 Rev 13

Page 11

STM8S105xx

Product overview

4 Product overview

The following section intends to give an overview of the basic features of the device

functional modules and peripherals.

For more detailed information please refer to t he corresponding family reference manual

(RM0016).

Central processing unit STM8

The 8-bit STM8 core is designed for code efficien cy and performance.

It contains 6 internal registers which are directly addressable in each execution context, 20

addressing modes including indexed indirect and relative addressing and 80 instructions.

Architecture and registers

• Harvard architecture

• 3-stage pipeline

• 32-bit wide program memory bus - single cycle fetching for most instructions

• X and Y 16-bit index registers - enabling indexed addres sing m odes with or without

offset and read-modify-write type data manipulations

• 8-bit accumulator

• 24-bit program counter - 16-Mbyte linear memory space

• 16-bit stack pointer - access to a 64 K-level stack

• 8-bit condition code register - 7 condition flags for the result of the last instruction

Addressing

• 20 addressing modes

• Indexed indirect addressing mode for look-up table s located anywhere in the address

space

• Stack pointer relative addressing mode for local variables and parameter passing

Instruction set

• 80 instructions with 2-byte average instruction siz e

• Standard data movement and logic/arithmetic functions

• 8-bit by 8-bit multiplication

• 16-bit by 8-bit and 16-bit by 16-bit division

• Bit manipulation

• Data transfer between stack and accumulator (push/pop) with direct stack access

• Data transfer using the X and Y registers or direct memory-to-memory transfers

4.1 Single wire interface module (SWIM) a nd debug module (DM)

The single wire interface module and debug module permi ts non-intrusive, real-time incircuit debugging and fast memory programming.

SWIM

Single wire interface module for direct access to the debug module and memory

programming. The interface can be activated in all device operation modes. The maximum

data transmission speed is 145 bytes/ms.

DocID14771 Rev 13 11/99

Page 12

Product overview

STM8S105xx

Debug module

The non-intrusive debugging module features a pe rf ormance close to a full-featured

emulator. Beside memory and peripherals, also CPU operat i on can be monitored in realtime by means of shadow registers.

• R/W to RAM and peripheral registers in real-time

• R/W access to all resources by stalling the CPU

• Breakpoints on all program-memory instructions (software breakpoi nts)

• Two advanced breakpoints, 23 predefined configurati ons

4.2 Interrupt controller

• Nested interrupts with three software priority l evels

• 32 interrupt vectors with hardware priority

• Up to 37 external interrupts on 6 vectors including TLI

• Trap and reset interrupts

4.3 Flash program and data EEPROM memory

• Up to 32 Kbytes of Flash program single voltage Flash m em ory

• Up to 1 Kbytes true data EEPROM

• Read while write: Writing in data memory possible whil e executing code in program

memory

• User option byte area

Write protection (WP)

Write protection of Flash program memory and data EEPROM is provided to avoid

unintentional overwriting of memory that could re sult from a user software malfunction.

There are two levels of write protection. The first level is known as MASS (memory access

security system). MASS is always enabled and prot ects the main Flash program memory,

data EEPROM and option bytes.

To perform in-application programming (IA P), this write protection can be removed by

writing a MASS key sequence in a control register. T his all ows the application to write to

data EEPROM, modify the contents of main progr am memory or the device option bytes.

A second level of write protection, can be enabl ed to further protect a specific area of

memory known as UBC (user boot code). Refer to t he figure below.

The size of the UBC is programmable through the UBC option byte, in increments of 1

page (512 bytes) by programming the UBC option byte in I CP mode.

This divides the program memory into two areas:

• Main program memory: Up to 32 Kbytes minus UBC

• User-specific boot code (UBC): Configurable up to 32 Kbytes

The UBC area remains write-protected during in-appl i cat i on programming. This means that

the MASS keys do not unlock the UBC area. It protects the m emory used to store the boot

program, specific code libraries, reset and int errupt vectors, the reset routine and usually

the IAP and communication routines.

12/99 DocID14771 Rev 13

Page 13

STM8S105xx

Product overview

Figure 2: Flash memory organization

Read-out protection (ROP)

The read-out protection blocks reading and writing t he Flash program memory and data

EEPROM memory in ICP mode (and debug mode). Onc e the read-out protection is

activated, any attempt to toggle its status triggers a global erase of the program and data

memory. Even if no protection can be considered as totally unbreakable, the feature

provides a very high level of protection for a general purpose microcontroller.

4.4 Clock controller

The clock controller distributes the system clock (f

to the core and the peripherals. It also manages clo ck gating for low power modes and

ensures clock robustness.

Features

• Clock prescaler: To get the best compromise between speed and current

consumption the clock frequency to the CPU and peripherals can be adjusted by a

programmable prescaler.

• Safe clock switching: Clock sources can be changed safely on the fly in run mode

through a configuration register. The clock sig nal is not switched until the new clock

source is ready. The design guarantees glitch-f ree switching.

• Clock management: To reduce power consumption, t he cloc k controller can stop the

clock to the core, individual peripherals or memory .

• Master clock sources: Four different clock sour ces can be used to drive the master

clock:

− 1-16 MHz high-speed external crystal (HSE)

− Up to 16 MHz high-speed user-external clock (HSE user-ext)

− 16 MHz high-speed internal RC oscillator (HSI)

− 128 kHz low-speed internal RC (LSI)

) coming from different oscillators

MASTER

DocID14771 Rev 13 13/99

Page 14

Product overview

STM8S105xx

• Startup clock: After reset, the microcontroller restarts by default with an internal 2

MHz clock (HSI/8). The prescaler ratio and clock so urce can be changed by the

application program as soon as the code execution st art s.

• Clock security system (CSS): This feature can be e nabled by software. If an HSE

clock failure occurs, the internal RC (16 MHz/8) is a ut om atically selected by the CSS

and an interrupt can optionally be generated.

• Configurable main clock output (CCO): This outputs an external clock for use by

the application.

Table 3: Peripheral clock gating bit assignments in CLK_PCKENR1/2 registers

Bit Peripheral

PCKEN17

PCKEN16

PCKEN15

PCKEN14

clock

TIM1 PCKEN13 UART2 PCKEN27 Reserved PCKEN23 ADC

TIM3 PCKEN12 Reserved PCKEN26 Reserved PCKEN22 AWU

TIM2 PCKEN11

TIM4 PCKEN10

Bit Peripheral

clock

4.5 Power management

For efficient power management, the application can be put in one of four different lowpower modes. You can configure each mode to obtain the best compromise between

lowest power consumption, fastest start-up time and available wakeup sources.

• Wait mode: In this mode, the CPU is stopped, but peripheral s are kept running. The

wakeup is performed by an internal or external interrupt or reset.

• Active halt mode with regulator on: In this mode, the CPU and peripheral clocks are

stopped. An internal wakeup is generated at program mabl e i ntervals by the auto wake

up unit (AWU). The main voltage regulator is kept powered on, so current

consumption is higher than in active halt mode with regulator off, but the wakeup time

is faster. Wakeup is triggered by the internal AW U interrupt, external interrupt or reset.

• Active halt mode with regulator off: This mode is the same as active halt with

regulator on, except that the main voltage regulator is powered off, so the wake up

time is slower.

• Halt mode :In this mode the microcontroller uses the least power. The CPU and

peripheral clocks are stopped, the main voltage regulator is powered off. Wakeup is

triggered by external event or reset.

Bit Peripheral

clock

SPI PCKEN25 Reserved PCKEN21 Reserved

I2C PCKEN24 Reserved PCKEN20 Reserved

Bit Peripheral

clock

4.6 Watchdog timers

14/99 DocID14771 Rev 13

The watchdog system is based on two independent timers providing maximum security to

the applications.

Activation of the watchdog timers is controlled by option bytes or by software. Once

activated, the watchdogs cannot be disabled by the user program without performing a

reset.

Window watchdog timer

The window watchdog is used to detect the occurrence of a software fault, usually

generated by external interferences or by unexpected logical conditions, which cause the

application program to abandon its normal sequence.

The window function can be used to trim the watchdo g behavior to match the application

perfectly.

Page 15

STM8S105xx

Product overview

The application software must refresh the counter b efore time-out and during a limited time

window.

A reset is generated in two situations:

1. Timeout: At 16 MHz CPU clock the time-out period can be adjusted between 75 µs up

to 64 ms.

2. Refresh out of window: The downcounter is refreshed bef ore i t s value is lower than

the one stored in the window register.

Independent watchdog timer

The independent watchdog peripheral can be us ed to resolve processor malfunctions due

to hardware or software failures.

It is clocked by the 128 kHz LSI internal RC clock source, an d thus stays active even in

case of a CPU clock failure

The IWDG time base spans from 60 µs to 1 s.

4.7 Auto wakeup counter

• Used for auto wakeup from active halt mode

• Clock source: Internal 128 kHz internal low frequency RC oscillator or external clock

• LSI clock can be internally connected to TIM3 input capture channel 1 for calibration

4.8 Beeper

The beeper function outputs a signal on the BEE P pin for so und generation. The signal is

in the range of 1, 2 or 4 kHz.

The beeper output port is only available through the alternate function remap option bit

AFR7.

4.9 TIM1 - 16-bit advanced control timer

This is a high-end timer designed for a wide range of cont rol applications. With its

complementary outputs, dead-time control and c enter-aligned PWM capability, the field of

applications is extended to motor control, lighting and half-bridge driver

• 16-bit up, down and up/down autoreload counter with 16-bit prescaler

• Four independent capture/compare channels (CAPCOM) configurable as input

capture, output compare, PWM generation (edge and center aligned mode) and single

pulse mode output

• Synchronization module to control the timer with external signals

• Break input to force the timer outputs into a defined state

• Three complementary outputs with adjustable dead ti m e

• Encoder mode

• Interrupt sources: 3 x input capture/output compare, 1 x overflow/update, 1 x break

4.10 TIM2, TIM3 - 16-bit general purpose timers

• 16-bit autoreload (AR) up-counter

• 15-bit prescaler adjustable to fixed power of 2 ratios 1… 32768

• Timers with 3 or 2 individually configurable capture/compare channels

• PWM mode

• Interrupt sources: 2 or 3 x input capture/output compare, 1 x overflow/update

DocID14771 Rev 13 15/99

Page 16

Product overview

STM8S105xx

Additional AIN12 analog input is not selectable in A DC scan mode or with analog

4.11 TIM4 - 8-bit basic timer

• 8-bit autoreload, adjustable prescaler ratio to any power of 2 from 1 to 128

• Clock source: CPU clock

• Interrupt source: 1 x overflow/update

Table 4: TIM timer features

Timer Counter

size

(bits)

TIM1 16 Any

TIM2 16 Any

TIM3 16 Any

TIM4 8 Any

Prescaler Counting

mode

Up/Down 4 3 Yes No

integer

from 1 to

65536

Up 3 0 No

power of 2

from 1 to

32768

Up 2 0 No

power of 2

from 1 to

32768

Up 0 0 No

power of 2

from 1 to

128

CAPCOM

channels

4.12 Analog-to-digital converter (ADC1)

The STM8S105xx products contain a 10-bit successive approximation A/D converter

(ADC1) with up to 10 multiplexed input channels and the following main features:

Complem.

outputs

Ext.

trigger

Timer

synchronization/

chaining

• Input voltage range: 0 to V

• Input voltage range: 0 to V

DD

DDA

• Conversion time: 14 clock cycles

• Single and continuous and buffered continuous conver sion m odes

• Buffer size (n x 10 bits) where n = number of input channels

• Scan mode for single and continuous conversion of a sequence of channels

• Analog watchdog capability with programmable uppe r and l ower thresholds

• Analog watchdog interrupt

• External trigger input

• Trigger from TIM1 TRGO

• End of conversion (EOC) interrupt

watchdog. Values converted from AIN12 are stored only into the

ADC_DRH/ADC_DRL registers.

16/99 DocID14771 Rev 13

Page 17

STM8S105xx

Product overview

4.13 Communication interfaces

The following communication interfaces are implem ented:

• UART2: Full feature UART, synchronous mode, SPI master mode, Smartcard mode,

IrDA mode, LIN2.1 master/slave capability

• SPI : Full and half-duplex, 8 Mbit/s

• I²C: Up to 400 Kbit/s

4.13.1 UART2

Main features

• One Mbit/s full duplex SCI

• SPI emulation

• High precision baud rate generator

• Smartcard emulation

• IrDA SIR encoder decoder

• LIN master mode

• LIN slave mode

Asynchronous communication (UART mode)

• Full duplex communication - NRZ standard format (mark/space)

• Programmable transmit and receive baud rates up to 1 M bi t/s (f

following any standard baud rate regardless of t he i nput frequency

• Separate enable bits for transmitter and receiver

• Two receiver wakeup modes:

− Address bit (MSB)

− Idle line (interrupt)

• Transmission error detection with interrupt generation

• Parity control

/16) and capable of

CPU

Synchronous communication

• Full duplex synchronous transfers

• SPI master operation

• 8-bit data communication

• Maximum speed: 1 Mbit/s at 16 MHz (f

LIN master mode

• Emission: Generates 13-bit synch break frame

• Reception: Detects 11-bit break frame

LIN slave mode

• Autonomous header handling - one single interrupt per valid message header

• Automatic baud rate synchronization - maximum toler ated initial clock deviation ±15 %

• Synch delimiter checking

• 11-bit LIN synch break detection - break detection always active

• Parity check on the LIN identifier field

• LIN error management

• Hot plugging support

4.13.2 SPI

• Maximum speed: 8 Mbit/s (f

• Full duplex synchronous transfers

/16)

CPU

/2) both for master and slave

MASTER

DocID14771 Rev 13 17/99

Page 18

Product overview

STM8S105xx

• Simplex synchronous transfers on two lines with a possibl e bi directional data line

• Master or slave operation - selectable by hardware or software

• CRC calculation

• 1 byte Tx and Rx buffer

• Slave/master selection input pin

4.13.3 I²C

• I²C master features:

• I²C slave features:

• Generation and detection of 7-bit/10-bit addressing and general call

• Supports different communication speeds:

− Clock generation

− Start and stop generation

− Programmable I2C address detection

− Stop bit detection

− Standard speed (up to 100 kHz)

− Fast speed (up to 400 kHz)

18/99 DocID14771 Rev 13

Page 19

STM8S105xx

Pinout and pin description

5 Pinout and pin description

Table 5: Legend/abbreviations for pinout tables

Type I= Input, O = Output, S = Power supply

Level

Output speed

Port and control

configuration

Reset state Bold X (pin state after internal res et release).

5.1 STM8S105 pinouts and pin descripti on

Input CM = CMOS

Output HS = High sink

O1 = Slow (up to 2 MHz)

O2 = Fast (up to 10 MHz)

O3 = Fast/slow programmabilit y with slow as default state after reset

O4 = Fast/slow programmabilit y with fast as default state after reset

Input float = floating, wpu = weak pull-up

Output T = True open drain, OD = Open drain, PP = Push pull

Unless otherwise specified, the pin state is the same during the reset

phase and after the internal reset r elease.

Figure 3: LQFP 48-pin pinout

1. (HS) high sink capability.

2. (T) True open drain (P-buffer and protection diode to V

not implemented).

DD

3. [ ] alternate function remapping option (If the same al ternate function is shown twice, it

indicates an exclusive choice not a duplication of t he function).

DocID14771 Rev 13 19/99

Page 20

Pinout and pin description

STM8S105xx

Figure 4: LQFP 44-pin pinout

1. (HS) high sink capability.

2. (T) True open drain (P-buffer and protection diode to V

not implemented).

DD

3. [ ] alternate function remapping option (If the same al ternate function is shown twice, it

indicates an exclusive choice not a duplication of t he function).

20/99 DocID14771 Rev 13

Page 21

STM8S105xx

Pinout and pin description

Figure 5: LQFP/UFQFPN 32-pin pinout

1. (HS) high sink capability.

2. [ ] alternate function remapping option (If the same al ternate function is shown twice, it

indicates an exclusive choice not a duplication of t he function).

Figure 6: SDIP 32-pin pinout

1. (HS) high sink capability.

2. (T) True open drain (P-buffer and protection diode to V

not implemented).

DD

3. [ ] alternate function remapping option (If the same al ternate function is shown twice, it

indicates an exclusive choice not a duplication of t he function).

DocID14771 Rev 13 21/99

Page 22

Pinout and pin description

STM8S105xx

LQFP32/

UFQFPN32

PP

Table 6: Pin description for STM8S105 microcontrollers

Pin number

LQFP48 LQFP44

1 1 1 6

2 2 2 7 PA1/ OSC IN I/O

3 3 3 8 PA2/ OSC OUT I/O

4 4 - 5 5 4 9

6 6 5 10

7 7 6 11

8 8 7 12

9 - - - PA3/ TIM2 _CH3

10 9 - 11 10 - 12 11 - -

- - 8 13 PF4/ AIN1 2

13 12 9 14

14 13 10 15

15 14 - - PB7/ AIN7 I/O

16 15 - - PB6/ AIN6 I/O

17 16 11 16 PB5/ AIN5

18 17 12 17 PB4/ AIN4

19 18 13 18 PB3/ AIN3

20 19 14 19 PB2/ AIN2

21 20 15 20 PB1/ AIN1

22 21 16 21 PB0/ AIN0

23 - - - PE7/ AIN8 I/O

24 22 - - PE6/ AIN9 I/O

25 23 17 22 PE5/SPI_NSS I/O

26 24 18 23 PC1/ TIM1_CH1

SDIP32

Pin name

NRST

V

SSIO_1

VSS

VCAP

VDD

V

DDIO_1

[TIM3 _CH1]

PA4

PA5

PA6

(1)

V

DDA

V

SSA

2

[I

C_ SDA]

2

[I

C_ SCL]

[TIM1_ ETR]

[TIM1_CH3N]

[TIM1_CH2N]

[TIM1_CH1N]

UART2_CK

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Type

S

S

S

S

S

S

S

Input

floating

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

wpu

Ext. interrupt

X

X

X X

X X

X X HS O3 X X

X X HS O3 X X

X X HS O3 X X

X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X HS O3 X X

Output

High sink

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

O1 X X

Speed

OD

Main

function

(after

reset)

Port A1

Port A2

I/O ground

Digital ground

1.8 V regulator capacitor

Digital power supply

I/O power supply

Port A3

Port A4

Port A5

Port A6

Port F4

Analog power supply

Analog ground

Port B7

Port B6

Port B5

Port B4

Port B3

Port B2

Port B1

Port B0

Port E7

Port E6

Port E5

SPI master/slave select

Port C1

Alternate function

Default alternate

function

Reset

Resonator crystal in

Resonator crystal out

Timer 2 - channel 3 TIM3_CH1 [AFR1]

clock

(2)

(3)

Analog input 12

Analog input 7

Analog input 6

Analog input 5

Analog input 4

Analog input 3

Analog input 2

Analog input 1

Analog input 0

Analog input 8

Analog input 9

Timer 1 – channel 1/

UART2 synchronous

after remap

[option bit]

I2C_SDA [AFR6]

I2C_SCL [AFR6]

TIM1_ETR [AFR5]

TIM1_CH3N [AFR5]

TIM1_ CH2N [AFR5]

TIM1_CH1N [AFR5]

22/99 DocID14771 Rev 13

Page 23

STM8S105xx

Pinout and pin description

LQFP32/

UFQFPN32

PP

Pin number

LQFP48 LQFP44

27 25 19 24 PC2/ TIM1_CH2 I/O

28 26 20 25 PC3/ TIM1_CH3 I/O

29 - 21 26 PC4/ TIM1_CH4 I/O

30 27 22 27 PC5/ SPI_SCK I/O

31 28 - 32 29 - 33 30 23 28 PC6/ SPI_MOSI I/O

34 31 24 29 PC7/ SPI_MISO I/O

35 32 - 36 33 - 37 - - - PE3/ TIM1_BKIN I/O

38 34 - - PE2/ I2C_SDA I/O

39 35 - - PE1/ I2C_ SCL I/O

40 36 - - PE0/ CLK_ CCO I/O

41 37 25 30 PD0/ TIM3_CH2

SDIP32

Pin name

Type

V

S

S

SSIO_2

V

DDIO_2

PG0

I/O

PG1

I/O

I/O

Input

floating

X

X

X

X

X

X

X

X

X

X

X

X

X

wpu

Ext. interrupt

X X HS O3 X X

X X HS O3 X X

X X HS O3 X

X X HS O3 X X

X X HS O3 X X

X X HS O3 X X

X

X

X X

X

X

X X HS O3 X X

X X HS O3 X X

Output

High sink

O1 X X

O1 X X

O1 X X

O1 T

O1 T

Speed

OD

(4)

(4)

[TIM1_BKIN]

[CLK_CCO]

42 38 26 31 PD1/ SWIM

(5)

43 39 27 32 PD2/ TIM3_CH1

[TIM2_CH3]

44 40 28 1

PD3/

I/O

I/O

I/O

X

X X HS O4 X X

X

X X HS O3 X X

X

X X HS O3 X X

TIM2_CH2

[ADC_ETR]

X

45 41 29 2

PD4/

I/O

X X HS O3 X X

TIM2_CH1

[BEEP]

X

46 42 30 3

47 43 31 4

48 44 32 5

PD5/

UART2_TX

PD6/

UART2_RX

PD7/ TLI

I/O

I/O

I/O

X

X

X X

X X

X X

O1 X X

O1 X X

O1 X X

[TIM1_CH4]

Notes:

(1)

A pull-up is applied to PF4 during the reset phase. This pin is input floating after reset release.

(2)

AIN12 is not selectable in ADC scan mode or with analog watchdog.

(3)

In 44-pin package, AIN9 cannot be used by ADC scan mode.

(4)

In the open-drain out put column, ‘T’ defines a true op en -drain I/O (P-buffer, weak pull-up and protection diode to VDD are not implemented).

(5)

The PD1 pin is in input pull-up during the reset phase and after internal reset release.

Main

function

(after

reset)

Port C2

Port C3

Port C4

Port C5

Port C6

Port C7

Port G0

Port G1

Port E3

Port E2

Port E1

Port E0

Port D0

Port D1

Port D2

Port D3

Port D4

Port D5

Port D6

Port D7

Alternate function

Default alternate

function

SPI clock

Timer 1- channel 2

Timer 1 - channel 3

Timer 1 - channel 4

I/O ground

I/O power supply

SPI master out/slave in

SPI master in/ slave out

Timer 1 - break input

I2C data

I2C clock

Configurable clock

output

Timer 3 - channel 2 TIM1_BKIN [AFR3]/

SWIM data interface

Timer 3 - channel 1 TIM2_CH3 [AFR1]

Timer 2 - channel 2 ADC_ETR [AFR0]

Timer 2 - channel 1 BEEP output [AFR7]

UART2 data transmit

UART2 data receive

Top level interrupt TIM1_CH4 [AFR4]

after remap

[option bit]

CLK_CCO [AFR2]

DocID14771 Rev 13 23/99

Page 24

Pinout and pin description

STM8S105xx

5.1.1 Alternate function remapping

As shown in the rightmost column of the pin descripti on table, some alternate functions can

be remapped at different I/O ports by programming one of eight AFR (alternate function

remap) option bits. When the remapping option is act i ve, the default alternate function is no

longer available.

To use an alternate function, the corresponding peri pheral must be enabled in the

peripheral registers.

Alternate function remapping does not aff ect GPIO capabilities of the I/O ports (see the

GPIO section of the family reference manual, RM0 016).

24/99 DocID14771 Rev 13

Page 25

STM8S105xx

Memory and register map

6 Memory and register map

6.1 Memory map

Figure 7: Memory map

The following table lists the boundary addresses for each memory size. The top of the

stack is at the RAM end address in each case.

DocID14771 Rev 13 25/99

Page 26

Memory and register map

STM8S105xx

Table 7: Flash, Data EEPROM and RAM boundary addresses

Memory area Size (bytes) Start address End address

Flash program memory 32K 0x00 8000 0x00 FFFF

RAM 2K 0x00 0000 0x00 07FF

Data EEPROM 1024 0x00 4000 0x00 43FF

6.2 Register map

6.2.1 I/O port hardware register map

Table 8: I/O port hardware register map

Address Block Register label Register name Reset status

0x00 5000 Port A PA_ODR Port A data output latch register 0x00

0x00 5001 PA_IDR P ort A input pin value register 0xXX

0x00 5002 PA_DDR Port A data direction register 0x00

0x00 5003 PA_CR1 Port A control register 1 0x00

0x00 5004 PA_CR2 Port A control register 2 0x00

0x00 5005 Port B PB_ODR Port B data output latch register 0x00

0x00 5006 PB_IDR P ort B input pin value register 0xXX

0x00 5007 PB_DDR Port B data direction register 0x00

0x00 5008 PB_CR1 Port B control register 1 0x00

0x00 5009 PB_CR2 Port B control register 2 0x00

0x00 500A Port C PC_ODR Port C data output latch register 0x00

0x00 500B PC_IDR Port C input pin value register 0xXX

0x00 500C PC_DDR Port C data direction register 0x00

0x00 500D PC_CR1 Port C control register 1 0x00

0x00 500E PC_CR2 Port C control register 2 0x00

0x00 500F Port D PD_ODR Port D data output latch register 0x00

0x00 5010 PD_IDR Port D input pin value register 0xXX

0x00 5011 PD_DDR Port D data direction re gister 0x00

0x00 5012 PD_CR1 Port D control register 1 0x02

0x00 5013 PD_CR2 Port D control register 2 0x00

0x00 5014 Port E PE_ODR Port E data output latch register 0x00

0x00 5015 PE_IDR P ort E input pin value register 0xXX

0x00 5016 PE_DDR Port E data direction register 0x00

0x00 5017 PE_CR1 Port E control register 1 0x00

0x00 5018 PE_CR2 Port E control register 2 0x00

0x00 5019 Port F PF_ODR Port F data output latch register 0x00

16K 0x00 8000 0x00 BFFF

26/99 DocID14771 Rev 13

Page 27

STM8S105xx

Memory and register map

Address Block Register label Register name Reset status

0x00 501A PF_IDR Port F input pin value register 0xXX

0x00 501B PF_DDR Port F data direction re gister 0x00

0x00 501C PF_CR1 Port F control register 1 0x00

0x00 501D PF_CR2 Port F control register 2 0x00

0x00 501E Port G PG_ODR Port G data output latch register 0x00

0x00 501F PG_IDR Port G input pin value register 0xXX

0x00 5020 PG_DDR Port G data direction register 0x00

0x00 5021 PG_CR1 Port G control register 1 0x00

0x00 5022 PG_CR2 Port G control register 2 0x00

0x00 5023 Port H PH_ODR Port H data output latch regis ter 0x00

0x00 5024 PH_IDR Port H input pin value register 0xXX

0x00 5025 PH_DDR Port H data direction re gister 0x00

0x00 5026 PH_CR1 Port H control register 1 0x00

0x00 5027 PH_CR2 Port H control register 2 0x00

0x00 5028 Port I PI_ODR Port I data output latch register 0x00

0x00 5029 PI_IDR Port I input pin value register 0xXX

0x00 502A PI_DDR Port I data direction register 0x00

0x00 502B PI_CR1 Port I control register 1 0x00

0x00 502C PI_CR2 Port I control register 2 0x00

6.2.2 General hardware register map

Table 9: General hardware register m ap

Address Block Register label Register name Reset

0x00 5050 to

0x00 5059

0x00 505A Flash FLASH_CR1 Flash control r egister 1 0x00

0x00 505B FLASH_CR2 Flash control register 2 0x00

0x00 505C FLASH_NCR2 Flash complementary control

0x00 505D FLASH _FPR Flash protection register 0x00

0x00 505E FLASH _NFPR Flash complementary protection

0x00 505F FLASH _IAPSR Flash in-application programming

0x00 5060 to

0x00 5061

0x00 5062 Flash FLASH _PUKR Flash program memory

status

Reserved area (10 bytes)

0xFF

register 2

0xFF

register

0x00

status register

Reserved area (2 bytes)

0x00

unprotection register

DocID14771 Rev 13 27/99

Page 28

Memory and register map

STM8S105xx

(2)

Address Block Register label Register name Reset

0x00 5063 Reserved area (1 byte)

0x00 5064 Flash FLASH _DUKR Data EEPROM unprotection

register

0x00 5065 to

Reserved area (59 bytes)

0x00 509F

0x00 50A0 ITC EXTI_CR1 External interru pt control register 1 0x00

0x00 50A1 EXTI_CR2 External interrupt control register 2 0x00

0x00 50A2 to

Reserved area (17 bytes)

0x00 50B2

0x00 50B3 RST RST_SR Reset status register 0xXX

0x00 50B4 to

Reserved area (12 bytes)

0x00 50BF

0x00 50C0 CLK CLK_ICKR Internal clock control register 0x01

0x00 50C1 CLK_ECKR External clock control register 0x00

0x00 50C2 Reserved area (1 byte)

0x00 50C3 CLK CLK_CMSR Clock master status register 0xE1

0x00 50C4 CLK_SWR Clock master switch register 0xE1

0x00 50C5 CLK_SWCR Clock switch control register 0xXX

0x00 50C6 CLK_CKDIVR Clock divider regist er 0x18

0x00 50C7 CLK_PCKENR1 Peripher al clock gating register 1 0xFF

0x00 50C8 CLK_CSSR Clock security system register 0x00

0x00 50C9 CLK_CCOR Configurable clock control register 0x00

0x00 50CA CLK_PCKENR2 Peripheral clock gating registe r 2 0xFF

0x00 50CB CLK_CANCCR CAN clock control register 0x00

0x00 50CC CLK_HSITRIMR HSI clock calibration trimming

register

0x00 50CD CLK_SWIMCCR

0x00 50CE to

SWIM clock control register 0bXXXX

Reserved area (3 bytes)

0x00 50D0

0x00 50D1 WWDG WWDG_CR WWDG control regist er 0x7F

0x00 50D2 WWDG_WR WWDR window register 0x7F

0x00 50D3 to

Reserved area (13 bytes)

0x00 50DF

0x00 50E0 IWDG IWDG_KR IWDG key register 0xXX

0x00 50E1 IWDG_PR IWDG prescaler register 0x00

0x00 50E2 IWDG_RLR IWDG reload register 0xFF

0x00 50E3 to

Reserved area (13 bytes)

0x00 50EF

0x00 50F0 AWU AWU_CSR1 AWU control/ status register 1 0x00

status

0x00

(1)

0x00

XXX0

28/99 DocID14771 Rev 13

Page 29

STM8S105xx

Memory and register map

Address Block Register label Register name Reset

0x00 50F1 AWU_APR AWU asynchronous prescaler

buffer register

0x00 50F2 AWU_TBR AWU timebase selection register 0x00

0x00 50F3 BEEP BEEP_CSR BEEP control/ status register 0x1F

0x00 50F4 to

Reserved area (12 bytes)

0x00 50FF

0x00 5200 SPI SPI_CR1 SPI control register 1 0x00

0x00 5201 SPI_CR2 SPI control register 2 0x00

0x00 5202 SPI_ICR SPI interrupt control register 0x00

0x00 5203 SPI_SR SPI status register 0x02

0x00 5204 SPI_DR SPI data register 0x00

0x00 5205 SPI_CRCPR SPI CRC polynomial register 0x07

0x00 5206 SPI_RXCRCR SPI Rx CRC register 0xFF

0x00 5207 SPI_TXCRCR SPI Tx CRC register 0xFF

0x00 5208 to

Reserved area (8 bytes)

0x00 520F

0x00 5210 I2C I2C_CR1 I2C control register 1 0x00

0x00 5211 I2C_CR2 I2C control register 2 0x00

0x00 5212 I2C_FREQR I2C frequency register 0x00

0x00 5213 I2C_OARL I2C Own address register low 0x00

0x00 5214 I2C_OARH I2C own address register high 0x00

0x00 5215 Reserved

0x00 5216 I2C_DR I2C data register 0x00

0x00 5217 I2C_SR1 I2C status register 1 0x00

0x00 5218 I2C_SR2 I2C status register 2 0x00

0x00 5219 I2C_SR3 I2C status register 3 0x00

0x00 521A I2C_ITR I2C interrupt control register 0x00

0x00 521B I2C_CCRL I2C clock control register low 0x00

0x00 521C I2C_CCRH I2C clock control register high 0x00

0x00 521D I2C_TRISER I2C TRISE register 0x02

0x00 521E I2C_PECR I2C packet error checking register 0x00

0x00 521F to

Reserved area (17 bytes)

0x00 522F

0x00 5230 to

Reserved area (6 bytes)

0x00 523F

0x00 5240 UART2 UART2_SR UART2 status register 0xC0

0x00 5241 UART2_DR UART2 data register 0xXX

0x00 5242 UART2_BRR1 UART2 baud rate regist er 1 0x00

status

0x3F

DocID14771 Rev 13 29/99

Page 30

Memory and register map

STM8S105xx

Address Block Register label Register name Reset

0x00 5243 UART2_BRR2 UART2 baud rate regist er 2 0x00

0x00 5244 UART2_CR1 UART2 control register 1 0x00

0x00 5245 UART2_CR2 UART2 control register 2 0x00

0x00 5246 UART2_CR3 UART2 control register 3 0x00

0x00 5247 UART2_CR4 UART2 control register 4 0x00

0x00 5248 UART2_CR5 UART2 control register 5 0x00

0x00 5249 UART2_CR6 UART2 control register 6 0x00

0x00 524A UART2_GTR UART2 guard ti me register 0x00

0x00 524B UART2_PSCR UART2 prescaler register 0x00

0x00 524C to

Reserved area (4 bytes)

0x00 524F

0x00 5250 TIM1

0x00 5251 TIM1_CR2 TIM1 control register 2 0x00

TIM1_CR1 TIM1 control register 1 0x00

0x00 5252 TIM1_SMCR TIM1 slave mode control register 0x00

0x00 5253 TIM1_ETR TIM1 external trigger register 0x00

0x00 5254 TIM1_IER TIM1 interrupt enable register 0x00

0x00 5255 TIM1_SR1 TIM1 status register 1 0x00

0x00 5256 TIM1_SR2 TIM1 status register 2 0x00

0x00 5257 TIM1_EGR TIM1 event generation register 0x00

0x00 5258 TIM1_CCMR1 TIM1 capture/ compare mode

register 1

0x00 5259 TIM1_CCMR2 TIM1 capture/compare mode

register 2

0x00 525A TIM1_CCMR3 TIM1 capture/ compare mode

register 3

0x00 525B TIM1_CCMR4 TIM1 capture/compare mode

register 4

0x00 525C TIM1_CCER1 TIM1 capture/ compare enable

register 1

0x00 525D TIM1_CCER2 TIM1 capture/compare enable

register 2

0x00 525E TIM1_CNTRH TIM1 counter high 0x00

0x00 525F TIM1_CNTRL TIM1 counter low 0x00

0x00 5260 TIM1_PSCRH TIM1 prescaler register high 0x00

0x00 5261 TIM1_PSCRL TIM1 prescaler register low 0x00

0x00 5262 TIM1_ARRH TIM1 auto-reload register high 0xFF

0x00 5263 TIM1_ARRL TIM1 auto-reload register low 0xFF

0x00 5264 TIM1_RCR TIM1 repetition counter register 0x00

status

0x00

0x00

0x00

0x00

0x00

0x00

30/99 DocID14771 Rev 13

Page 31

STM8S105xx

Memory and register map

Address Block Register label Register name Reset

0x00 5265 TIM1_CCR1H TIM1 capture/ compare register 1

high

0x00 5266 TIM1_CCR1L TIM1 capture/ compare register 1

low

0x00 5267 TIM1_CCR2H TIM1 capture/ compare register 2

high

0x00 5268 TIM1_CCR2L TIM1 capture/ compare register 2

low

0x00 5269 TIM1_CCR3H TIM1 capture/ compare register 3

high

0x00 526A TIM1_CCR3L TIM1 capture/ compare register 3

low

0x00 526B TIM1_CCR4H TIM1 capture/ compare register 4

high

0x00 526C TIM1_CCR4L TIM1 capture/ compare register 4

low

0x00 526D TIM1_BKR TIM1 break r egister 0x00

0x00 526E TIM1_DTR TIM1 dead-time register 0x00

0x00 526F TIM1_OISR TIM1 output idle state register 0x00

0x00 5270 to

Reserved area (147 bytes)

0x00 52FF

0x00 5300 TIM2

0x00 5301 TIM2_IER T IM2 interrupt enable register 0x00

TIM2_CR1 TIM2 control register 1 0x00

0x00 5302 TIM2_SR1 TIM2 status register 1 0x00

0x00 5303 TIM2_SR2 TIM2 status register 2 0x00

0x00 5304 TIM2_EGR TIM2 event generation register 0x00

0x00 5305 TIM2_CCMR1 TIM2 capture/ compare mode

register 1

0x00 5306 TIM2_CCMR2 TIM2 capture/ compare mode

register 2

0x00 5307 TIM2_CCMR3 TIM2 capture/ compare mode

register 3

0x00 5308 TIM2_CCER1 TIM2 capture/ compare enable

register 1

0x00 5309 TIM2_CCER2 TIM2 capture/ compare enable

register 2

0x00 530A TIM2_CNTRH TIM2 counter high 0x00

0x00 530B TIM2_CNTRL TIM2 counter low 0x00

0x00 530C TIM2_PSCR TIM2 prescaler register 0x00

0x00 530D TIM2_ARRH T IM2 auto-reload register high 0xFF

0x00 530E TIM2_ARRL TIM2 auto-reload register low 0xFF

status

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

DocID14771 Rev 13 31/99

Page 32

Memory and register map

STM8S105xx

Address Block Register label Register name Reset

0x00 530F TIM2_CCR1H TIM2 capture/ compare regis ter 1

high

0x00 5310 TIM2_CCR1L TIM2 capture/ compare register 1

low

0x00 5311 TIM2_CCR2H TIM2 capture/ compare reg. 2 high 0x00

0x00 5312 TIM2_CCR2L TIM2 capture/ compare register 2

low

0x00 5313 TIM2_CCR3H TIM2 capture/ compare register 3

high

0x00 5314 TIM2_CCR3L TIM2 capture/ compare register 3

low

0x00 5315 to

Reserved area (11 bytes)

0x00 531F

0x00 5320 TIM3 TIM3_CR1 TIM3 control register 1 0x00

0x00 5321 TIM3_IER TIM3 interrupt enable register 0x00

0x00 5322 TIM3_SR1 TIM3 status register 1 0x00

0x00 5323 TIM3_SR2 TIM3 status register 2 0x00

0x00 5324 TIM3_EGR TIM3 event generation register 0x00

0x00 5325 TIM3_CCMR1 TIM3 capture/ compare mode

register 1

0x00 5326 TIM3_CCMR2 TIM3 capture/ compare mode

register 2

0x00 5327 TIM3_CCER1 TIM3 capture/ compare enable

register 1

0x00 5328 TIM3_CNTRH TIM3 counter high 0x00

0x00 5329 TIM3_CNTRL TIM3 counter low 0x00

0x00 532A TIM3_PSCR TIM3 prescaler register 0x00

0x00 532B TIM3_ARRH TIM3 auto-reload register high 0xFF

0x00 532C TIM3_ARRL TIM3 auto-reload register lo w 0xFF

0x00 532D TIM3_CCR1H TIM3 c apture/ compare register 1

high

0x00 532E TIM3_CCR1L TIM3 capture/ compare register 1

low

0x00 532F TIM3_CCR2H TIM3 capture/ compare regis ter 2

high

0x00 5330 TIM3_CCR2L T IM3 capture/ compare register 2

low

0x00 5331 to

Reserved area (15 bytes)

0x00 533F

0x00 5340 TIM4 TIM4_CR1 TIM4 control register 1 0x00

0x00 5341 TIM4_IER TIM4 interrupt enable register 0x00

status

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

32/99 DocID14771 Rev 13

Page 33

STM8S105xx

Memory and register map

Address Block Register label Register name Reset

0x00 5342 TIM4_SR TIM4 status register 0x00

0x00 5343 TIM4_EGR TIM4 event generation register 0x00

0x00 5344 TIM4_CNTR TIM4 counter 0x00

0x00 5345 TIM4_PSCR TIM 4 prescaler register 0x00

0x00 5346 TIM4_ARR TIM4 auto-reload register 0xFF

0x00 5347 to

Reserved area (153 bytes)

0x00 53DF

0x00 53E0 to

ADC1 ADC _DBxR ADC data buffer registers 0x00

0x00 53F3

0x00 53F4 to

Reserved area (12 bytes)

0x00 53FF

0x00 5400 ADC1 ADC _CSR ADC control/ status register 0x00

0x00 5401 ADC_CR1 ADC configuration register 1 0x00

0x00 5402 ADC_CR2 ADC configurat i on r egister 2 0x00

0x00 5403 ADC_CR3 ADC configurat i on r egister 3 0x00

0x00 5404 ADC_DRH ADC data register high 0xXX

0x00 5405 ADC_DRL ADC data register low 0xXX

0x00 5406 ADC_TDRH ADC Schmitt trigger disable

register high

0x00 5407 ADC_TDRL ADC Schmitt trigger disable

register low

0x00 5408 ADC_HTRH ADC high threshold register high 0x03

0x00 5409 ADC_HTRL ADC high threshold register low 0xFF

0x00 540A ADC_LTRH ADC low threshold r egister high 0x00

0x00 540B ADC_LTRL ADC low threshold register low 0x00

0x00 540C ADC_AWSRH ADC analog watchdog status

register high

0x00 540D ADC_AWSRL ADC analog watchdog status

register low

0x00 540E ADC _AWCRH ADC analog watchdog control

register high

0x00 540F ADC_AWCRL ADC analog watchdog control

register low

0x00 5410 to

Reserved area (1008 bytes)

0x00 57FF

Notes:

(1)

Depends on the previous reset source.

(2)

Write only register.

status

0x00

0x00

0x00

0x00

0x00

0x00

DocID14771 Rev 13 33/99

Page 34

Memory and register map

STM8S105xx

6.2.3 CPU/SWIM/debug module/interrupt controller registers

Table 10: CPU/SWIM/debug module/interrupt controller registers

Address Block Register

Register name Reset

label

0x00 7F00 CPU

0x00 7F01 PCE Program counter extended 0x00

(1)

A Accumulator 0x00

0x00 7F02 PCH Program counter high 0x00

0x00 7F03 PCL Program counter low 0x00

0x00 7F04 XH X index register high 0x00

0x00 7F05 XL X index register low 0x00

0x00 7F06 YH Y index register high 0x00

0x00 7F07 YL Y index register low 0x00

0x00 7F08 SPH Stack pointer high 0x07

0x00 7F09 SPL Stack pointer low 0xFF

0x00 7F0A CCR Condition code register 0x28

0x00 7F0B to 0x00

Reserved area (85 bytes)

7F5F

0x00 7F60 CPU CFG_GCR Global configurat ion register 0x00

0x00 7F70 ITC ITC_SPR1 Interrupt software priority register 1 0xFF

0x00 7F71 ITC_SPR2 Interrupt software priority register 2 0xFF

0x00 7F72 ITC_SPR3 Interrupt software priority register 3 0xFF

0x00 7F73 ITC_SPR4 Interrupt software priority register 4 0xFF

0x00 7F74 ITC_SPR5 Interrupt software priority regist er 5 0xFF

0x00 7F75 ITC_SPR6 Interrupt software priority register 6 0xFF

0x00 7F76 ITC_SPR7 Interrupt software priority register 7 0xFF

0x00 7F77 ITC_SPR8 Interrupt software priority register 8 0xFF

0x00 7F78 to 0x00

Reserved area (2 bytes)

7F79

0x00 7F80 SWIM SWIM_CSR SWIM control status register 0x00

0x00 7F81 to 0x00

Reserved area (15 bytes)

7F8F

0x00 7F90 DM DM_BK1RE DM breakpoint 1 register extended

byte

0x00 7F91 DM_BK1RH DM breakpoint 1 regis ter high byte 0xFF

0x00 7F92 DM_BK1RL DM breakpoint 1 register low byte 0xFF

0x00 7F93 DM_BK2RE DM breakpoi nt 2 register extended

byte

0x00 7F94 DM_BK2RH DM breakpoint 2 regis ter high byte 0xFF

0x00 7F95 DM_BK2RL DM breakpoint 2 register low byte 0xFF

0x00 7F96 DM_CR1 DM debug module control 0x00

status

0xFF

0xFF

34/99 DocID14771 Rev 13

Page 35

STM8S105xx

Memory and register map

register 1

Address Block Register

label

Register name Reset

status

0x00 7F97 DM_CR2 DM debug module control

register 2

0x00 7F98 DM_CSR1 DM debug module control/status

register 1

0x00 7F99 DM_CSR2 DM debug module control/status

register 2

0x00 7F9A DM_ENFCTR DM enable function register 0xFF

0x00 7F9B to 0x00

Reserved area (5 bytes)

7F9F

Notes:

(1)

Accessible by debug module only

0x00

0x10

0x00

DocID14771 Rev 13 35/99

Page 36

Interrupt vector mapping

STM8S105xx

7 Interrupt vector mapping

Table 11: Interrupt mapping

IRQ

no.

Source

block

Description Wakeup from

halt mode

Wakeup from

active-halt

Vector

address

mode

RESET Reset Yes Yes 0x00 8000

TRAP Software interrupt - - 0x00 8004

0 TLI Exter nal top level interrupt

- - 0x00 8008

1 AWU Auto wake up from halt - Yes 0x00 800C

2 CLK Clock controller - - 0x00 8010

3 EXTI0 Port A external interrupts Yes

(1)

Yes

(1)

0x00 8014

4 EXTI1 Port B external interrupts Yes Yes 0x00 8018

5 EXTI2 Port C external interrupts Yes Yes 0x00 801C

6 EXTI3 Port D external interrupts Yes Yes 0x00 8020

7 EXTI4 Port E external interrupts Yes Yes 0x00 8024

8

9

Reserved - - 0x00 802C

0x00 8028

10 SPI End of transfer Yes Yes 0x00 8030

11 TIM1 TIM1 update/ overflow/

- - 0x00 8034

underflow/ trigger/ break

12 TIM1 TIM1 capture/ compare - - 0x 00 8038

13 TIM2 TIM update/ overflow - - 0x00 803C

14 TIM2 TIM capture/ compare - - 0x00 8040

15 TIM3 Update/ overflow - - 0x00 8044

16 TIM3 Capture/ comp ar e - - 0x00 8048

17

18

Reserved - - 0x00 804C

Reserved - - 0x00 8050

19 I2C I2C interrupt Yes Yes 0x00 8054

20 UART2 Tx complete - - 0x00 8058

21 UART2 Receive register DATA

- - 0x00 805 C

FULL

22 ADC1 ADC1 end of conversion/

- - 0x00 8060

analog watchdog interrupt

23 TIM4 TIM update/ overflow - - 0x00 8064

24 Flash EOP/ WR_PG_DIS - - 0x00 8068

Reserved

0x00 806C to

0x00807C

Notes:

(1)

Except PA1

36/99 DocID14771 Rev 13

Page 37

STM8S105xx

Option bytes

8 Option bytes

Option bytes contain configurations for device hardware features as well as the memory

protection of the device. They are stored in a dedicated block of the memory. Except for the

ROP (read-out protection) byte, each option byt e has to be stored twice, in a regular form

(OPTx) and a complemented one (NOPTx) for redundancy.

Option bytes can be modified in ICP mode (via SWIM) by accessing the EEPROM address

shown in the table below.

Option bytes can also be modified ‘on the fly’ by the application in IAP mode, except the

ROP option that can only be modified in ICP mode (v ia S WIM).

Refer to the STM8S Flash programming manual (PM0051) and STM8 SWIM