Page 1

Starting STM8 Microcontrollers

STM8 microcontrollers are 8-bit general purpose microcontrollers from STMicroelectronics (STM).

STM is famous mainly for its line of 32-bit ARM Cortex microcontrollers – the STM32s. STM8

microcontrollers are rarely discussed in that context. However, STM8 MCUs are robust and most

importantly they come packed with lots of hardware features. Except for the ARM core, 32-bit

architecture, performance and some minor differences, STM8s have many peripheral similarities to

STM32s. In my opinion, STM8s are equally or sometimes more matched than the popular PICs and

AVRs in all areas. Unlike PICs and AVRs however, I have seen STM8s mostly in various SMD packages.

Only a handful of STM8 chips are available in PDIP/through-hole packages. I think it is a big reason for

which most small industries and hobbyists don’t play with them as much as with other 8-bit families.

People like to setup their test projects in breadboards, trial PCBs or strip-boards first, prototype and

then develop for production. To cope with this issue, STM has provided several affordable STM8

Discovery (Disco) boards to get started with. Besides there are many cheap STM8 breakout-boards

from China.

I have experience playing with AVRs, PICs, 8051s, STM32s, MSP430s, TivaC and so on. To be honest, I

thought learning about STM8 micros is a pure waste of time and energy. The learning curve will be

steep. Things and tools would be different and thus difficult. However, gradually I found these MCUs

very useful and there’s literally no complexity at all. The main drive factor for learning STM8s is the

price factor. They are hell cheap. When it comes down to other things, I have not found any book on

STM8s written in English. There’s literally no 100% complete blog post on the internet that shows the

basics. Similarly, same story with tools. I have been using MikroC for AVRs, 8051s and ARMs and it is

my favourite but at the time of writing, there’s no MikroC compiler for STM8 family. I have also not

stumbled upon any Arduino-like IDE that supports STM8 micros. Arduino-based solutions are also not

my favourite as they don’t go deep and have several limitations. Maybe it is not my luck. After much

study and search, I found out that there are a few C compilers for STM8s. However, any new tool is

both different and difficult at first. It is not always easy to adapt to new environments. You may never

know what unanticipated challenges and harshness a new environment may throw at you even when

you reach certain levels of expertise. I also don’t want to use any pirated software and so a free

compiler was a major requirement. I found out ST Visual Develop and Cosmic COSC compiler are both

free tools. Cosmic used to be a paid tool but now it is absolutely free. The only easy thing till then was

buying the STM8S Value Line Discovery board for just a few dollars and downloading the stuffs.

Page 2

The STM8 Family

There are over a hundred STM8 microcontrollers available today. The STM8 family can be simplified

into three categorical groups as shown below.

There are subgroups within these groups but broadly speaking these three groups are what by which

we can define the entire family. STM8S micros are general purpose robust and reliable micros that

can be employed in almost all scopes. This is the most commonly used group and in fact we will be

exploring it in this article. They are also cheap and smart. The second group – the STM8A family is

intended mainly for automotive industries. This group is packed with additional hardware interfaces

like CAN and LIN that are musts according to present-day automotive industry doctrine. The STM8As

are also very robust and are designed to withstand the harsh extremes of an automobile. For instance,

STM8As can withstand high temperatures, in excess of 100°C. The last group consists of STM8L micros

which are crafted for low power or battery-backed applications. Virtually they consume no power in

idle mode. Thus, if you need high power savings or energy cuts in your projects, this group is the best

choice. There are also low power versions of automotive-standard STM8 micros that are labelled

STM8AL. Apart from all these there is also one version of STM8 micros that are specifically designed

for capacitive touch applications. These are called STM8Ts.

The features and benefits of STM8 micros are numerous and can’t simply be expressed in few words.

The more you explore, the more you will feel. STM8s can be powered with 3.3V or 5V DC power

supplies and have built-in brownout detection circuitry. The low power editions can operate at much

lower voltages than these values. Official STM8 Discovery boards come with voltage selection jumpers

to allow users to select operating voltage level as required. There is very minimum risk of program

corruption due to EMI or some other similar unprecedented factors. There is fail-safe security for the

clock system which ensures that a system based on a STM8 micro won’t stop working or stuck up

should its external clock source fail. All internal hardware possesses more features than any other

competitive 8-bit microcontroller families that are widely available in the market. The best part is the

price benefit. You pay less for the most. All these features are well-suited for extremely harsh

industrial environments. STM8s are designed with maximum possible combinations of features.

Beyond your wildest wet dream, there are many extraordinary stuffs waiting to be unboxed.

Page 3

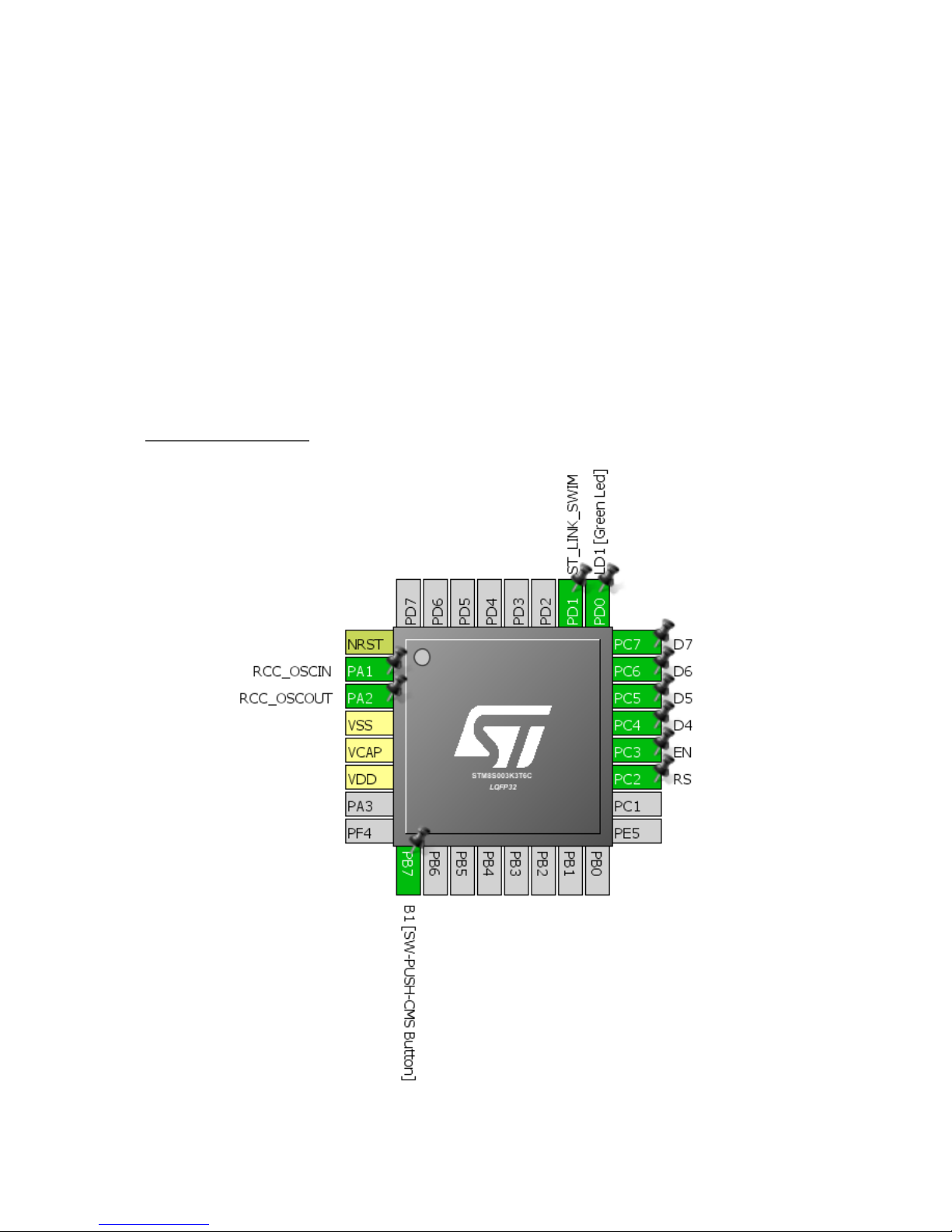

Overview of the Discovery Board

For getting started with STM8s, STM has provided several STM8 Disco boards. There are also other

third party boards too. However, I strongly recommend Disco boards for learning and experimental

purposes. There are several reasons for this recommendation. One main reason is the fact that all

Disco boards come with on-board detachable ST-Link programmers and they are extremely cheap.

Shown below is the top layout of a STM8S discovery board.

The board I used here in this article hosts a STM8S003K3T6 micro. It is an 32 pin entry-level micro with

8kB flash, 1kB RAM and 128 byte true data EEPROM. It comes with some additional hardware – a LED

connected to PD0 and a push button connected to PB7. Just as I said it also houses a detachable STLink programmer. However, I don’t recommend separating the programmer from the whole package.

The board also has a prototyping area should one needs to prototype something. The overall board

has a small form-factor and is a bit longer than a standard credit card. There are several other similar

and popular STM8 Discovery boards like the STM8S105 Discovery.

Page 4

There are also bulks of cheap Chinese minimum system STM8 dev boards hosting different STM8

chips. Overall the boards and the chips are so cheap that many simple cheap gadgets from China are

based on STM8 MCUs.

Some cheap STM8-based simple products are shown below:

The first one is a cheap DIY LC meter LC-100A. The other one is a simple DC panel meter. These are

just simple examples. There are many industrial and sophisticated products based on STM8 micros.

Page 5

Hardware Tools

The list of hardware tools needed is not very long. We will obviously need a STM8 board and I prefer

a Discovery board over other boards since it comes with a built-in ST-Link programmer/debugger

hardware. If you have some other board like the ones I already showed, you will need a ST-Link

programmer. I recommend an additional ST-Link programmer apart from the one available on board.

ST-Link programmers/debuggers communicate with target STM8 micros via SWIM interface. This

interface is the standard for all STM8 micros. Basically, it is a four-wire interface with two wire (VDD

and GND) being used for powering the target. The rest two are reset I/O and SWIM I/O. In the official

ST-Link V2 programmer unlike other ST-Link programmers, there is a dedicated port for SWIM

interface with STM8 inscribed near it. Cheap USB flash drive-sized ST-Links are also available in the

market and they are portable and as good as the official ones.

Apart from these we will also require some basic electronic lab stuffs like a USB-to-serial converter,

connecting/jumper wires, LEDs, buttons, various types of sensors, etc. that are typically found in a

common Arduino starter kit.

Page 6

It is yet better if you have either a logic analyser or oscilloscope. A good multimeter and a wellregulated DC power supply/source are must haves. You can also use a cell phone charging power bank

as a power source since Disco boards have USB ports.

Page 7

Software Tools

Just like any other software developer, my choice of language for software development is C language.

I don’t want to spend time coding complex stuffs in assembly language. Apart from that I chose C

language for the fact that STMicroelectronics has provided a Standard Peripheral Library (SPL) that is

very easy to use. With SPL, it becomes totally unnecessary to program each register with meaningless

numbers and maintain coding sequence. We will never need to access registers for any reasons as

everything is done under the hood of SPL. All sequences are deal inside the SPL. All that we will ever

need is the clear concept of each hardware block, their working principles, their capabilities and

limitations.

We will need an Integrated Development Environment (IDE) and a C-language toolchain. The best

stuffs you can get your hands on at zero costs are ST Visual Develop (STVD) IDE and Cosmic C compiler.

Both are free but a rather difficult to use at first. STVD also comes with a programmer software tool

called ST Visual Programmer (STVP). We’ll need STVP to upload codes to target STM8 micros.

Cosmic used to be a paid tool just like your PC’s antivirus software but at the time of writing this article,

the Cosmic team has made it absolutely free for STM8 family. However, to use it you will need to

register and acquire a license key via email. Usually this procedure of acquiring license and registration

is maintained automatically by the software company’s server but with Cosmic it is different story.

You will need to wait for some guy at Cosmic end to respond to your license request. It may take a

few minutes or even a day but still the best part is getting a full version compiler for nothing.

You can get

STVD from here: http://www.st.com/en/development-tools/stvd-stm8.html and

Cosmic C compiler from here: http://www.cosmic-software.com/download.php.

Page 8

You need to register in order to download both software. For Cosmic you will also need to acquire a

free license for it work. So just fill in some basic info about you.

Firstly, we will need to install STVD. Installation procedure is simple and same as typical software

installation. Just click next, next and next. After that we will need to install Cosmic C compiler. Again,

just next, next and next until the screen as shown below.

Page 9

After installation, you’ll prompted for licence. You must register your license unless you have already

registered. If you have already registered, then you’ll be asked if to overwrite registration. You should

skip reregistering.

For the first run, you’ll get the following screen looking for a valid license.

You must fill all the starred (*) points to complete the process of registration. Select “Write to File”

option and save the file as a text (.txt) file. The file name should be “CM8_license.txt”. Send this file

to stm8_Free@cosmic.fr with subject “STM8FSE, STM32 32K License Request”. Now you’ll need to

wait for the Cosmic team to respond to you. They’ll send you an email back with an electronic key license.

The file will have a name like “license.lic” and the email will have some instructions.

Page 10

This was my emailed license.

Once you get the license, you’ll need to show the software its location and complete the licensing

process as shown below. Save the license file in a secured location.

At the end of this process, we can enjoy the compiler without any limitations.

I also recommend that you download Sublime Text (https://www.sublimetext.com/) or Notepad++

(https://notepad-plus-plus.org/) for viewing your code with ease. These are very cool software. This

is not mandatory though.

Page 11

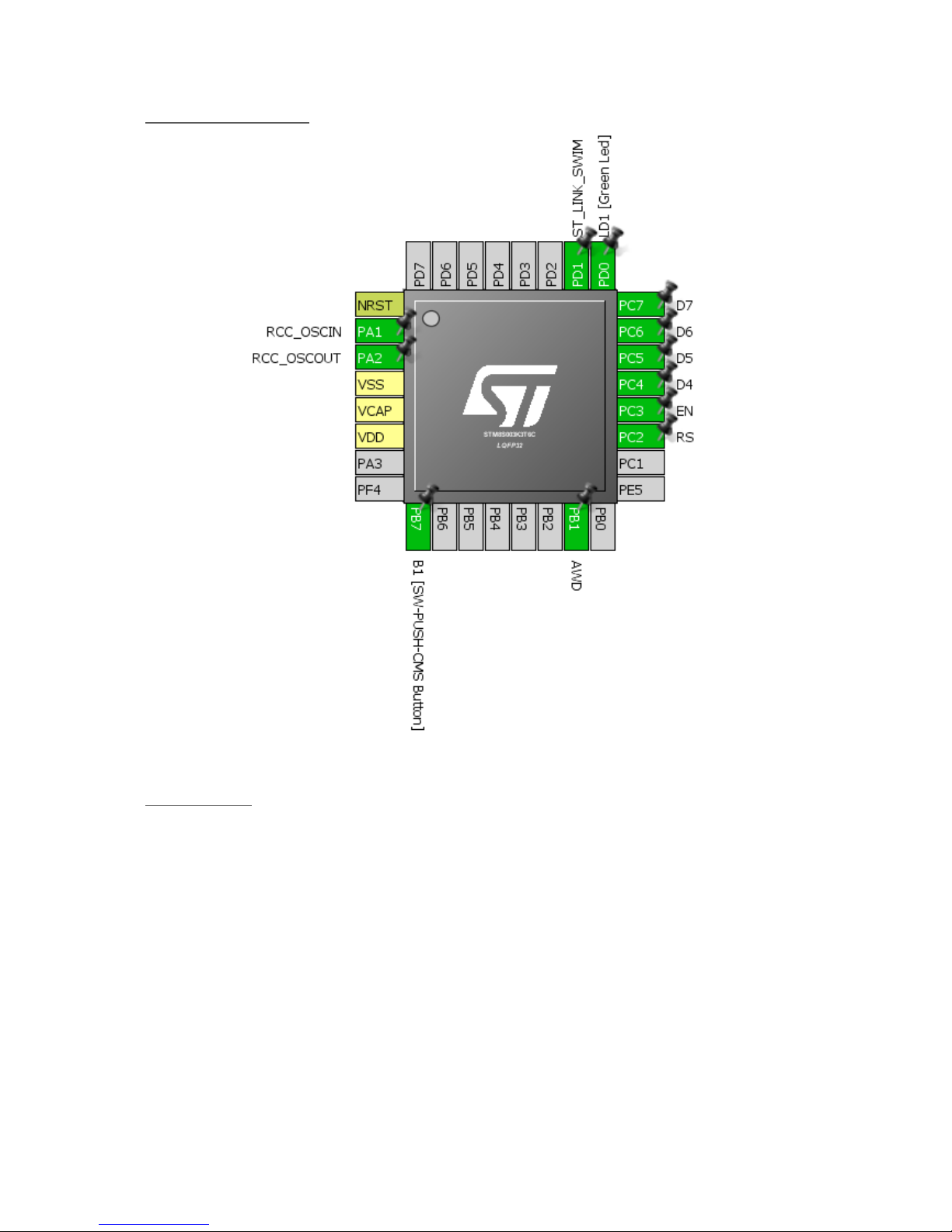

STM8CubeMX

Should I or should I not feel fortunate was my question at the time of writing this article and that’s

because STM8CubeMX was released in late February 2017. Yes, that’s the time when I was compiling

all these STM8 stuffs together. Prior to that I was wondering about a software similar to

STM32CubeMX but for STM8s. Back then, I could not find one and raw documentations were only

helpers. Although it is still in its early stages of development and still not as robust as its STM32 cousin

in terms of code generation capabilities and other areas, we can expect great innovations in the near

future. It reminds me of the early days of STM32CubeMX. Not everyone expected it to overcome all

the challenges in a very short period of time. At present, we can use STM8CubeMX for common info

on STM8 chips like pin assignments/mapping, basic technical specs like memory capacities, possible

clock configurations, etc. I can just wonder the potential future integrations and bug fixes. Power

consumption calculator is one such tool hopefully to be integrated. STM, most likely, has some serious

big plans for it. Nevertheless, we must thank STM for this cool software.

Visit http://www.st.com/en/development-tools/stm8cubemx.html to download STM8CubeMX.

I recommend using it only as reference. Don’t make yourself dependent on it. There are still many

bugs fixes that are yet to be addressed. One example is as in the above screenshot. Notice Timer 3

(TIM3) is missing although STM8S003 has this timer. I’m pretty sure the software developers are

working hard on such silly issues. For now, it is more like a promise of good tidings to come. This is

why I haven’t included it in the “must-have” software list and wanted it to be discussed separately.

Page 12

Preparing the Software Tools

Firstly, we need three major documents before starting to program STM8 micros. These are as follows:

1. STM8 Reference Manual.

http://www.st.com/content/ccc/resource/technical/document/reference_manual/9a/1b/85

/07/ca/eb/4f/dd/CD00190271.pdf/files/CD00190271.pdf/jcr:content/translations/en.CD001

90271.pdf

2. Datasheet of the MCU (STM8S003) that we’ll be using.

http://www.st.com/content/ccc/resource/technical/document/datasheet/42/5a/27/87/ac/

5a/44/88/DM00024550.pdf/files/DM00024550.pdf/jcr:content/translations/en.DM0002455

0.pdf

3. STM8SVLDiscovery Board User Manual.

http://www.st.com/content/ccc/resource/technical/document/user_manual/c8/37/11/ba/b

5/e7/4c/ee/DM00040810.pdf/files/DM00040810.pdf/jcr:content/translations/en.DM00040

810.pdf

These docs will be needed everywhere during learning session. The reference manual states the use

and purpose of all the hardware blocks in details. It includes register descriptions, naming conventions,

modes of operation of all hardware, etc. However, it does not specify the specifications of a given

STM8 micro and that’s because it is a generalized literature for all STM8S and STM8AF micros. As we

know even within a family of micros, one MCU differs from another in many aspects. Most commonly

this variation comes in the form of memory capacities and I/O pin counts. Sometimes electrical specs

also vary and so to know the limits and general specs of our target MCUs we need to checkout their

respective datasheets. Lastly the Discovery board user manual is most useful for the hardware

schematics, pin assignments and layouts. If you are using some other board then I suggest that you

acquire at least its schematic.

Now with Cosmic, STVD and STVP installed our software tool setup is almost ready. There are two

approaches to STM8 programming. The first uses the traditional concepts of register-access-based

coding, meaning you’ll have to set up every register on your own. The second way utilizes a specialized

method of coding by using standard libraries developed by STM that are both universal and platform

independent, meaning your C code will be same for any compiler using these libraries. These libraries

are called Standard Peripheral Libraries (SPL). With these libraries, no one will ever need to get down

to register-level access. The libraries are so coded that a coder will only have to know his/her chips’

hardware specs and some basics of these hardware. On the coding part, he/she will only have to set

properties and desired values. The SPL manages the rest. For instance, when setting up a UART, we

will only need to set interrupts, IOs and UART properties like baud rate, parity, etc. All of these setups

are done with meaningful numbers and texts.

The STMicroelectronics Standard Peripheral Libraries (SPL) for STM8 microcontrollers can be found

here: http://www.st.com/en/embedded-software/stsw-stm8069.html.

Page 13

I wrote this article using SPL since it will be ridiculous to code STM8s using the old-fashioned way of

configuring registers one-by-one manually. Thus, it is a mandatory download item. You should

preserve and retain the downloaded SPL zip file fully intact. You may need it when things get messy.

Now make two folders and name them “inc” and “src”. The “inc” folder will be filled with all the header

files (“.h” extension files) from the extracted zip file. Similarly, the “src” folder will be holding the

source files (“.c” extension files). For ease of work, it is better to keep these folders secured just like

the SPL zip file because every time when we will be making new projects the files in these folders will

be needed. You can copy these files to your project folder or you can keep it centrally somewhere. I

prefer the former method as doing so will not have any conflicting issue with other projects needing

modifications. However, it will cost hard-drive space. This method is however less confusing and

trouble-free for beginners. Extract all the files as shown below:

Note that there are more header files than source files. This is because there are two extra header

files – stm8s.h and stm8s_conf.h that define processor type and processor properties. To make things

work, we will have to comment one line of the stm8s_conf.h. You will find a line at the bottom of this

file written as:

#define USE_FULL_ASSERT (1).

You need to comment or disable this line, otherwise the compiler will throw tons of error messages.

Always check this at the start of a project. Surely, we don’t want to assert our code.

Page 14

Creating a New Code Project

Assuming that STVD, STVP and Cosmic are properly installed, we will see how to create a new project.

1. Firstly, run STVD.

2. Select File >> New Workspace.

3. Select Create workspace and project.

Page 15

4. Select workspace folder and workspace name.

5. Set project name and select toolchain STM8 Cosmic. You may need to set the path of your

Cosmic compiler’s installation location. In my case, it is:

C:\Program Files (x86)\COSMIC\FSE_Compilers\CXSTM8

Page 16

6. Type and select target chip part number. Last two or three digits and letters are enough for

finding the correct micro.

7. Now add the source and header files from the previously mentioned SPL folder.

Page 17

8. After file inclusions, the workspace tab changes as shown below.

9. Locate and open main.c file from the source tab, and then type #include "stm8s.h" at the top

as shown below:

Page 18

10. You’ll have to edit the STM8S.h header file and uncomment the chip number you are going to

use as shown below:

11. Compile the code once using the key combination CTRL+F7 or by pressing the compile button.

If everything is okay, there should be no error or warning message. The reason for this blank

compilation is to use the compiler’s powerful code assistant feature. With this feature, we can

predict or complete a piece of code line by only writing the first few letters and then pressing

CTRL + SPACE keys simultaneously.

Page 19

During compilation, you may get tons of errors for hardware files that are not available in your target

STM8S micro. For instance, CAN hardware is not available in STM8S003K3 and so if you have added

CAN source and header files you will get an error for that. Once identified by the error messages, the

corresponding header and source files for that particular hardware must be removed.

Similarly, one more caution must be observed. Unless your code is using any interrupt, interrupt

source and header files (stm8s_it.h and stm8s_it.c) must be excluded. Sometimes it is better to add

only those files that you will need to complete a project. For example, if your project is just using

GPIOs, it is better to add GPIO files only along with stm8s.h and stm8s_conf.h. However, I recommend

this technique only after you have mastered STM8 coding well because in most cases you will need

multiple hardware which have dependencies on each other. As an example, when using SPI, you’ll

need both GPIO and SPI modules. If you understand these dependencies, it is okay to select files as

per need. You can, then, comment out unnecessary hardware module files specified in the stm8s.h

header file and get a faster compilation and build process. After compilation, you should always

build/rebuild your project by hitting the Build or Rebuild button. This will generate the final s19 output

file in either Debug or Release folder according to the generation mode selected. If things are in order,

there should be no error or warning message.

Lastly, I have not found any useful simulation software like Proteus VSM or Electronic Workbench that

support STM8 family. Thus, we have to debug our code in real-life with real hardware. It may sound

difficult but actually it is not so. We can, however, use such software to make models of STM8 micros

and make our PCBs. I don’t like simulations as they are not always accurate and real-world type.

One more advice I would like to give to the readers. Please read the SPL help file. It is located in the

SPL zip file under the name stm8s-a_stdperiph_lib_um.chm. It explains each function, definition, data

structure, all internal hardware modules and how to use them properly. This is a very important

document and your best friend in coding STM8 micros. Apart from this document the reference

manual is equally important as it details the capabilities of all internal hardware. I won’t be detailing

the internal hardware much as these docs will be doing so.

Page 20

Uploading Code

Codes generated by Cosmic C compiler have s19 file extensions. It is similar to typical hex file format,

containing user code as hex values. Well since we don’t need to modify finally generated output files,

it doesn’t really matter in which format it is. All we will need is to upload them to our target MCUs.

We can do it in two ways – either by using STVP or STVD.

Firstly, let’s check the method with STVP. Run STVP software. For the first time the following window

will appear. From here we have to select ST-Link programmer, SWIM interface and our target chip.

STVP interface looks like any other programmer interface as shown below:

Page 21

Notice the mid tabs at the bottom of the hex values. From here we can see the hex values for program

memory, data/EEPROM memory and configuration settings. The configuration setting bits are

intended for setting some special hardware configurations or extending features of the target as well

as setting memory readout protection.

Try not to mess with security or protection bit at first or during tests as it will lock your chip up,

rendering it useless. You won’t simply be able to write it again until you unlock it. Unless needed, we

won’t be changing any default configuration bit. One thing to note is the fact that upon new

compilation and build, the newly generated output file is automatically reloaded. The rest of the stuffs

like loading or saving a s19 file, reading, writing and others are as simple as like with other

programmers. I won’t be explaining these steps as I assume that readers of this article already know

how to do all these from their previous experiences with other MCUs.

Now we will explore how we can upload a code to our target using STVD. After compiling and building

a project successfully without any error, the compiler will generate a s19 output file either in Debug

or Release folder depending on which mode of compilation selected. By default, Debug mode is

selected unless the coder changed it and so our desired s19 file will be in this folder. First, we need to

open the programmer interface. We can do that either by clicking the icon as shown below:

or we can go to Tools >> Programmer.

Page 22

We will get a new window as shown below:

As the name of the new window suggests, it is a light-weight programmer interface but good enough

for our purpose. Notice that there are many options and four tabs. Here again we need to select

programmer, programming interface (SWIM) and erase/blank check options. Then we go to the next

tab to select files for EEPROM (if any) and Program (also Flash/Code) memory as shown below. You

can add/remove files just as usually.

Page 23

Next, we set configuration bits if needed from the tab as shown below:

Finally, we are ready to upload code. Just hit the start button and wait for the process to finish.

Every time a code is programmed, it is verified automatically.

Page 24

General Purpose Input Output (GPIO)

The very first “Hello World” project that we do with every new embedded device is a simple LED

blinking program. Here we do the same. We will be basically testing both input and output function

by making a variable flash rate blinking LED. Check the schematic of the Disco board. Check the pins

with which the on-board LED and the push button are connected.

You can also use the STM8CubeMX in board selector mode for this too.

Page 25

Shown below is the internal block diagram of GPIO pins:

Because each I/O is independently configurable and have many options associated with it, its block

looks complex at first sight. Check the various options every I/O possess:

Page 26

Shown below are the SPL functions associated with the GPIO module.

Observe the code below. This is the power of the ST’s SPL. The code is written with no traditional

register access. Everything here has a meaningful nomenclature, just like regular naming/words of the

reference manual/comments. There shouldn’t be any issue understanding the code. The code is

almost Arduino-like. Here we are polling an input pin’s state to alter the blink rate of a LED.

Page 27

Hardware Connection

Co de Example

#include "STM8S.h"

void main (void)

{

bool i = 0;

GPIO_DeInit(GPIOB);

GPIO_DeInit(GPIOD);

GPIO_Init(GPIOB, GPIO_PIN_7, GPIO_MODE_IN_FL_NO_IT);

GPIO_Init(GPIOD, GPIO_PIN_0, GPIO_MODE_OUT_PP_LOW_FAST);

for(;;)

{

if(GPIO_ReadInputPin(GPIOB, GPIO_PIN_7) == FALSE)

{

while(GPIO_ReadInputPin(GPIOB, GPIO_PIN_7) == FALSE);

Page 28

i ^= 1;

}

switch(i)

{

case 0:

{

delay_ms(1000);

break;

}

case 1:

{

delay_ms(200);

break;

}

}

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

}

}

Explanation

The following lines deinitialize the GPIOs we used. Every time you reconfigure or setup a hardware

peripheral for the first time you must deinitialize it before using it. Though it is not mandatory, it will

remove any chance of wrong/conflicting configurations.

GPIO_DeInit(GPIOB);

GPIO_DeInit(GPIOD);

After deinitialization, we are good to go for initializing or setting up the GPIOs. Inputs can be with or

without internal pull-up resistors. Outputs can be either push-pull totem-pole or open drain types.

Each pin can be individually configured and does not have any dependency on another. The following

codes set GPIO PB7 as a floating input with no interrupt capability and GPIO PD0 as a fast push-pull

output. PB7 is set up as a floating input rather than an internally pulled-up input because the button

on the Disco board is already pulled up externally.

GPIO_Init(GPIOB, GPIO_PIN_7, GPIO_MODE_IN_FL_NO_IT);

GPIO_Init(GPIOD, GPIO_PIN_0, GPIO_MODE_OUT_PP_LOW_FAST);

The remaining part of the code in the main loop is just polling the button’s state and altering the delay

time for toggling the LED if the button is pressed.

for(;;)

{

if(GPIO_ReadInputPin(GPIOB, GPIO_PIN_7) == FALSE)

{

while(GPIO_ReadInputPin(GPIOB, GPIO_PIN_7) == FALSE);

i ^= 1;

}

switch(i)

{

case 0:

{

delay_ms(1000);

break;

}

Page 29

case 1:

{

delay_ms(200);

break;

}

}

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

}

Demo

Video link: https://www.youtube.com/watch?v=Rr1vpfoze4w

Page 30

Clock System (CLK)

The internal network of STM8 clock system allows us to tune up operating speeds of peripherals and

CPU according to our needs. Software delays and power consumption depend on how the clock

system is set.

In STM8 micros, there are three main clock sources – High Speed Internal Clock (HSI), High Speed

External Clock (HSE) and Low Speed Internal Clock (LSI). The HSI has an oscillating frequency of 16MHz

and is an internal RC oscillator with good precision – about 1% tolerant over a wide temperature range.

HSE can be an external clock circuitry, temperature-compensated crystal oscillator (TCXO) or ordinary

crystal resonator. It accepts all frequencies from 1MHz to 24MHz. Lastly, LSI clock is also an

independent internal RC oscillator-based clock source that is mainly intended for idle or low power

operating modes and the independent watchdog timer (IWDG). It has a fixed factory calibrated

operating frequency of 128kHz and is not as accurate as HSI or HSE. There are also clock

dividers/prescalers at various points to scale clocks as per requirement. Mainly two prescalers are

what we need – the HSI prescaler and the CPU divider. Peripherals are directly feed by the main clock

source. Additionally, there is a clock output pin (CCO) that outputs a given clock frequency. It can be

used to clock another micro, generate clock for other devices like logic ICs. It can also be used as a free

oscillator or perform clock performance tests. There’s fail-safe clock security that makes HSI backup

of HSE. Should HSE fail, HSI takes over automatically. Check the internal block diagram below:

Page 31

Hardware Connection

Page 32

Co de Example

The code example below demonstrates how to run the CPU at 2MHz clock using HSI and extract

500kHz clock output from CCO pin using CCO output selection. HSE is divided by 8, i.e. 16MHz divided

by 8 equals 2MHz. This 2MHz is the master clock source and further divided four times to get 500kHz.

Note CCO pin is only available in some pins. For example, in STM8S003K3 this pin is either PD0 pin or

PC4. We will need to override the default function of PD0 pin to favour for CCO output. To do so, we

will need to change Alternate Function (AFR5) configuration bit during code upload.

#include "STM8S.h"

#define LED_pin GPIO_PIN_0

#define LED_port GPIOD

void setup(void);

void clock_setup(void);

void GPIO_setup(void);

void main(void)

{

setup();

GPIO_WriteLow(LED_port, LED_pin);

while(TRUE)

{

};

}

void setup(void)

{

clock_setup();

GPIO_setup();

}

void clock_setup(void)

{

CLK_DeInit();

CLK_HSECmd(DISABLE);

CLK_LSICmd(DISABLE);

CLK_HSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_HSIRDY) == FALSE);

CLK_ClockSwitchCmd(ENABLE);

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV8);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV4);

CLK_ClockSwitchConfig(CLK_SWITCHMODE_AUTO, CLK_SOURCE_HSI,

DISABLE, CLK_CURRENTCLOCKSTATE_ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_I2C, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_SPI, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_UART1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_ADC, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER2, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER4, DISABLE);

Page 33

CLK_CCOConfig(CLK_OUTPUT_CPU);

CLK_CCOCmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_CCORDY) == FALSE);

}

void GPIO_setup(void)

{

GPIO_DeInit(LED_port);

GPIO_Init(LED_port, LED_pin, GPIO_MODE_OUT_OD_HIZ_FAST);

}

Explanation

The full explanation of this code is given in the last segment of this article. The only thing I’ll describe

here is this part:

CLK_CCOConfig(CLK_OUTPUT_CPU);

CLK_CCOCmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_CCORDY) == FALSE);

These lines select the clock source that the CCO pin will output, enable the CCO module and wait for

it to stabilize. Here I selected the CCO to output CPU clock.

Demo

Video link: https://www.youtube.com/watch?v=IeLUc_s3jBE

Page 34

External Interrupt (EXTI)

External interrupt is an additional feature of GPIOs in input mode. It makes a micro to respond

instantly to changes done on it GPIO input pin(s) by an external events/triggers, skipping other tasks.

External interrupts are useful in many scenarios. For instance, an emergency button. Consider the case

of a treadmill. You are running at a speed and suddenly you get an ache in one of your ankles. You’ll

surely want to stop running immediately. Rather decreasing speed in small steps, you can hit the

emergency button to quickly stop the treadmill. The emergency button will interrupt all other

processes and immediately instruct the treadmill’s CPU to decrease speed faster than otherwise

possible. Thus, it has high priority over other processes.

In most 8-bit micros, there are few external interrupt pins and very limited options are available for

them but that’s not the case with STM’s micros. In STM8s, almost all GPIO pins have independent

external interrupt capability with input Schmitt triggers. Additionally, there’s interrupt controller to

set interrupt priority.

Page 35

Hardware Connection

Co de Example

We will do the same variable flash rate LED blinking example as in the GPIO example but this time with

the DISCO board’s button in external interrupt mode. The code here needs special attention as now

we will see how interrupts are configured and coded. This code is way different than anything I saw

before. I’m saying so because you’ll need to follow certain steps unlike other compilers. In other

compilers, all we do is create the interrupt function and tell the compiler the interrupt vector address.

Same here too but too many steps involved.

Page 36

Now check the interrupt vector table of STM8S003 below:

You’ll find this table not in the reference manual but in the device’s datasheet. This table varies with

devices and so be sure of correct datasheet. The DISCO board’s button is connected to PB7 and so

clearly, we will need IRQ4, i.e. EXTI1 or PORTB external interrupts. All external interrupts on GPIOB

pin are masked in this vector address.

Please note that codes that use peripheral interrupts need stm8s_it.h and stm8s_it.c files. Therefore,

add them if you are to use interrupts.

Page 37

main.c

#include "stm8s.h"

bool state = FALSE;

void GPIO_setup(void);

void EXTI_setup(void);

void clock_setup(void);

void main(void)

{

GPIO_setup();

EXTI_setup();

clock_setup();

do

{

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

if(state == TRUE)

{

delay_ms(100);

}

else

{

delay_ms(1000);

}

}while (TRUE);

}

void GPIO_setup(void)

{

GPIO_DeInit(GPIOB);

GPIO_Init(GPIOB, GPIO_PIN_7, GPIO_MODE_IN_PU_IT);

GPIO_DeInit(GPIOD);

GPIO_Init(GPIOD, GPIO_PIN_0, GPIO_MODE_OUT_PP_LOW_FAST);

}

void EXTI_setup(void)

{

ITC_DeInit();

ITC_SetSoftwarePriority(ITC_IRQ_PORTB, ITC_PRIORITYLEVEL_0);

EXTI_DeInit();

EXTI_SetExtIntSensitivity(EXTI_PORT_GPIOB, EXTI_SENSITIVITY_FALL_ONLY);

EXTI_SetTLISensitivity(EXTI_TLISENSITIVITY_FALL_ONLY);

enableInterrupts();

}

void clock_setup(void)

{

CLK_DeInit();

CLK_HSECmd(DISABLE);

CLK_LSICmd(DISABLE);

CLK_HSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_HSIRDY) == FALSE);

Page 38

CLK_ClockSwitchCmd(ENABLE);

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV1);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV1);

CLK_ClockSwitchConfig(CLK_SWITCHMODE_AUTO, CLK_SOURCE_HSI,

DISABLE, CLK_CURRENTCLOCKSTATE_ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_SPI, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_I2C, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_ADC, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_UART1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER2, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER4, DISABLE);

}

stm8_interrupt_vector.c

/* BASIC INTERRUPT VECTOR TABLE FOR STM8 devices

* Copyright (c) 2007 STMicroelectronics

*/

#include "stm8s_it.h"

typedef void @far (*interrupt_handler_t)(void);

struct interrupt_vector {

unsigned char interrupt_instruction;

interrupt_handler_t interrupt_handler;

};

//@far @interrupt void NonHandledInterrupt (void)

//{

/* in order to detect unexpected events during development,

it is recommended to set a breakpoint on the following instruction

*/

// return;

//}

extern void _stext(); /* startup routine */

struct interrupt_vector const _vectab[] = {

{0x82, (interrupt_handler_t)_stext}, /* reset */

{0x82, NonHandledInterrupt}, /* trap */

{0x82, NonHandledInterrupt}, /* irq0 */

{0x82, NonHandledInterrupt}, /* irq1 */

{0x82, NonHandledInterrupt}, /* irq2 */

{0x82, NonHandledInterrupt}, /* irq3 */

{0x82, (interrupt_handler_t)EXTI1_IRQHandler}, /* irq4 */

{0x82, NonHandledInterrupt}, /* irq5 */

{0x82, NonHandledInterrupt}, /* irq6 */

{0x82, NonHandledInterrupt}, /* irq7 */

{0x82, NonHandledInterrupt}, /* irq8 */

{0x82, NonHandledInterrupt}, /* irq9 */

{0x82, NonHandledInterrupt}, /* irq10 */

{0x82, NonHandledInterrupt}, /* irq11 */

{0x82, NonHandledInterrupt}, /* irq12 */

{0x82, NonHandledInterrupt}, /* irq13 */

{0x82, NonHandledInterrupt}, /* irq14 */

{0x82, NonHandledInterrupt}, /* irq15 */

{0x82, NonHandledInterrupt}, /* irq16 */

{0x82, NonHandledInterrupt}, /* irq17 */

Page 39

{0x82, NonHandledInterrupt}, /* irq18 */

{0x82, NonHandledInterrupt}, /* irq19 */

{0x82, NonHandledInterrupt}, /* irq20 */

{0x82, NonHandledInterrupt}, /* irq21 */

{0x82, NonHandledInterrupt}, /* irq22 */

{0x82, NonHandledInterrupt}, /* irq23 */

{0x82, NonHandledInterrupt}, /* irq24 */

{0x82, NonHandledInterrupt}, /* irq25 */

{0x82, NonHandledInterrupt}, /* irq26 */

{0x82, NonHandledInterrupt}, /* irq27 */

{0x82, NonHandledInterrupt}, /* irq28 */

{0x82, NonHandledInterrupt}, /* irq29 */

};

Now check the top parts of the stm8s_it.h and stm8s_it.c files respectively.

stm8s_it.h

stm8s_it.c

These must be coded.

Page 40

Explanation

Most part of the code is same as previous codes and so I won’t be going through them again. However,

there’s something new:

void EXTI_setup(void)

{

ITC_DeInit();

ITC_SetSoftwarePriority(ITC_IRQ_PORTB, ITC_PRIORITYLEVEL_0);

EXTI_DeInit();

EXTI_SetExtIntSensitivity(EXTI_PORT_GPIOB, EXTI_SENSITIVITY_FALL_ONLY);

EXTI_SetTLISensitivity(EXTI_TLISENSITIVITY_FALL_ONLY);

enableInterrupts();

}

This function is where we are setting up the external interrupt. The first two lines deinitiate the

interrupt controller and set priority while initiating it. It is not mandatory unless you want to set

interrupt priority. Then we configure the external interrupt on PORTB pins. We also set the edge that

will invoke an interrupt. Finally, we enable global interrupt. There goes the main.c file

Now it’s time to explain the stm8_interrupt_vector.c file. The top part of this file must include this

line #include "stm8s_it.h". It must also have the following section commented out:

//@far @interrupt void NonHandledInterrupt (void)

//{

/* in order to detect unexpected events during development,

it is recommended to set a breakpoint on the following instruction

*/

// return;

//}

We need to let our compiler know the name of the function that it should call when a particular

interrupt is triggered. There are two parts for that. Firstly, the interrupt vector address and secondly

the name of the function. This is reason for this line:

{0x82, (interrupt_handler_t)EXTI1_IRQHandler}, /* irq4 */

Lastly, the stm8s_it.h and stm8s_it.c files contain the prototype and the function that will execute the

interrupt service routine (ISR). In our case, the ISR will change the logic state of the Boolean variable

state. This will alter that flashing rate in the main loop.

Demo

Video link: https://www.youtube.com/watch?v=P6qdmWgH-Ls

Page 41

Beeper (BEEP)

The beeper hardware is a sound generation unit. This is a hardware not found in other micros and is

useful in scenarios where we need an audible output. An alarm is a good example. The beeper unit

uses LSI to generate 1kHz, 2kHz and 4kHz square wave outputs that can be directly feed to a small

piezo tweeter (not buzzer). In most STM8 micros, the beeper module’s I/O pin (PD4) is not accessible

unless alternate function configuration bit is altered during code upload. However, there are few

exceptional chips like the STM8S003 in which we don’t need to change any configuration bit at all. The

beeper module has dependencies with the Auto-Wake-Up (AWU) module.

Hardware Connection

Page 42

Co de Example

#include "STM8S.h"

void clock_setup(void);

void GPIO_setup(void);

void beeper_setup(void);

void main(void)

{

clock_setup();

GPIO_setup();

beeper_setup();

while(TRUE)

{

GPIO_WriteLow(GPIOD, GPIO_PIN_0);

BEEP_Cmd(ENABLE);

delay_ms(200);

GPIO_WriteHigh(GPIOD, GPIO_PIN_0);

BEEP_Cmd(DISABLE);

delay_ms(200);

};

}

void clock_setup(void)

{

CLK_DeInit();

CLK_HSECmd(DISABLE);

CLK_LSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_LSIRDY) == FALSE);

CLK_HSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_HSIRDY) == FALSE);

CLK_ClockSwitchCmd(ENABLE);

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV1);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV1);

CLK_ClockSwitchConfig(CLK_SWITCHMODE_AUTO, CLK_SOURCE_HSI,

DISABLE, CLK_CURRENTCLOCKSTATE_ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_SPI, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_I2C, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_ADC, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_UART1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER2, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER4, DISABLE);

}

void GPIO_setup(void)

{

GPIO_DeInit(GPIOD);

GPIO_Init(GPIOD, GPIO_PIN_0, GPIO_MODE_OUT_OD_LOW_FAST);

GPIO_Init(GPIOD, GPIO_PIN_4, GPIO_MODE_OUT_PP_HIGH_FAST);

}

void beeper_setup(void)

Page 43

{

BEEP_DeInit();

BEEP_LSICalibrationConfig(128000);

BEEP_Init(BEEP_FREQUENCY_2KHZ);

}

Explanation

As stated earlier beeper module is dependent on the AWU module and so we need to enable this

module’s peripheral clock:

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, ENABLE);

We need to set the beeper port pin as an output pin:

GPIO_Init(GPIOD, GPIO_PIN_4, GPIO_MODE_OUT_PP_HIGH_FAST);

Configuring the beeper is straight. Just like other peripherals, we deinitialize it first and set both LSI

and beep frequency. Optionally we can calibrate the LSI.

void beeper_setup(void)

{

BEEP_DeInit();

BEEP_LSICalibrationConfig(128000);

BEEP_Init(BEEP_FREQUENCY_2KHZ);

}

To activate/deactivate the beeper we need to use the following instructions:

BEEP_Cmd(ENABLE);

BEEP_Cmd(DISABLE);

Demo

Video link: https://www.youtube.com/watch?v=LDPtULsJao8

Page 44

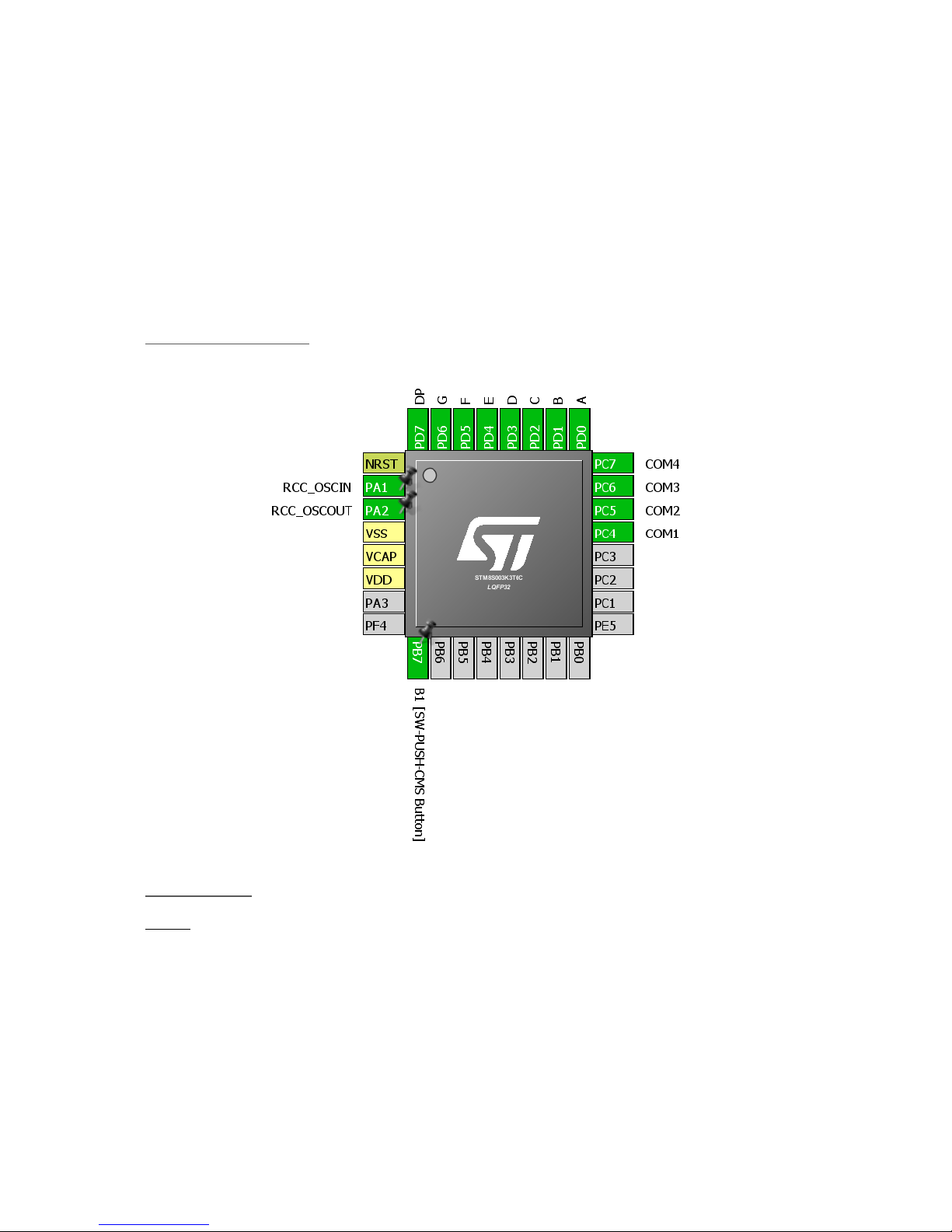

Alphanumerical LCD

Alphanumerical displays are the most common and basic form of displays after seven segments and

LED displays. They are useful for projecting multiple data quickly in ways that are otherwise difficult

with other kinds of displays.

To interface a LCD with a STM8 micro, we need LCD library. The STM8 SPL does not have a library for

such displays and we need to code it on our own. Interfacing a LCDs are not difficult tasks as no special

hardware is required to drive LCDs other than GPIOs. However, there are some tasks needed in the

software end. We need to include the library files. The process of library inclusion is discussed in the

later part of this article as it needs some special attentions. The example I’m sharing here uses 6 GPIO

pins from GPIOC. The read-write (R/W) pin of the LCD is connected to ground. The layout is as shown

below.

Hardware Connection

Page 45

Co de Example

lcd.h

#include "stm8s.h"

#define LCD_PORT GPIOD

#define LCD_RS GPIO_PIN_2

#define LCD_EN GPIO_PIN_3

#define LCD_DB4 GPIO_PIN_4

#define LCD_DB5 GPIO_PIN_5

#define LCD_DB6 GPIO_PIN_6

#define LCD_DB7 GPIO_PIN_7

#define clear_display 0x01

#define goto_home 0x02

#define cursor_direction_inc (0x04 | 0x02)

#define cursor_direction_dec (0x04 | 0x00)

#define display_shift (0x04 | 0x01)

#define display_no_shift (0x04 | 0x00)

#define display_on (0x08 | 0x04)

#define display_off (0x08 | 0x02)

#define cursor_on (0x08 | 0x02)

#define cursor_off (0x08 | 0x00)

#define blink_on (0x08 | 0x01)

#define blink_off (0x08 | 0x00)

#define _8_pin_interface (0x20 | 0x10)

#define _4_pin_interface (0x20 | 0x00)

#define _2_row_display (0x20 | 0x08)

#define _1_row_display (0x20 | 0x00)

#define _5x10_dots (0x20 | 0x40)

#define _5x7_dots (0x20 | 0x00)

#define DAT 1

#define CMD 0

void LCD_GPIO_init(void);

void LCD_init(void);

void LCD_send(unsigned char value, unsigned char mode);

void LCD_4bit_send(unsigned char lcd_data);

void LCD_putstr(char *lcd_string);

void LCD_putchar(char char_data);

void LCD_clear_home(void);

void LCD_goto(unsigned char x_pos, unsigned char y_pos);

void toggle_EN_pin(void);

void toggle_io(unsigned char lcd_data, unsigned char bit_pos, unsigned char pin_num);

Page 46

lcd.c

#include "lcd.h"

void LCD_GPIO_init(void)

{

GPIO_Init(LCD_PORT, LCD_RS, GPIO_MODE_OUT_PP_HIGH_FAST);

GPIO_Init(LCD_PORT, LCD_EN, GPIO_MODE_OUT_PP_HIGH_FAST);

GPIO_Init(LCD_PORT, LCD_DB4, GPIO_MODE_OUT_PP_HIGH_FAST);

GPIO_Init(LCD_PORT, LCD_DB5, GPIO_MODE_OUT_PP_HIGH_FAST);

GPIO_Init(LCD_PORT, LCD_DB6, GPIO_MODE_OUT_PP_HIGH_FAST);

GPIO_Init(LCD_PORT, LCD_DB7, GPIO_MODE_OUT_PP_HIGH_FAST);

delay_ms(10);

}

void LCD_init(void)

{

LCD_GPIO_init();

toggle_EN_pin();

GPIO_WriteLow(LCD_PORT, LCD_RS);

GPIO_WriteLow(LCD_PORT, LCD_DB7);

GPIO_WriteLow(LCD_PORT, LCD_DB6);

GPIO_WriteHigh(LCD_PORT, LCD_DB5);

GPIO_WriteHigh(LCD_PORT, LCD_DB4);

toggle_EN_pin();

GPIO_WriteLow(LCD_PORT, LCD_DB7);

GPIO_WriteLow(LCD_PORT, LCD_DB6);

GPIO_WriteHigh(LCD_PORT, LCD_DB5);

GPIO_WriteHigh(LCD_PORT, LCD_DB4);

toggle_EN_pin();

GPIO_WriteLow(LCD_PORT, LCD_DB7);

GPIO_WriteLow(LCD_PORT, LCD_DB6);

GPIO_WriteHigh(LCD_PORT, LCD_DB5);

GPIO_WriteHigh(LCD_PORT, LCD_DB4);

toggle_EN_pin();

GPIO_WriteLow(LCD_PORT, LCD_DB7);

GPIO_WriteLow(LCD_PORT, LCD_DB6);

GPIO_WriteHigh(LCD_PORT, LCD_DB5);

GPIO_WriteLow(LCD_PORT, LCD_DB4);

toggle_EN_pin();

LCD_send((_4_pin_interface | _2_row_display | _5x7_dots), CMD);

LCD_send((display_on | cursor_off | blink_off), CMD);

LCD_send(clear_display, CMD);

LCD_send((cursor_direction_inc | display_no_shift), CMD);

}

void LCD_send(unsigned char value, unsigned char mode)

{

switch(mode)

{

case DAT:

{

GPIO_WriteHigh(LCD_PORT, LCD_RS);

break;

}

case CMD:

{

GPIO_WriteLow(LCD_PORT, LCD_RS);

Page 47

break;

}

}

LCD_4bit_send(value);

}

void LCD_4bit_send(unsigned char lcd_data)

{

toggle_io(lcd_data, 7, LCD_DB7);

toggle_io(lcd_data, 6, LCD_DB6);

toggle_io(lcd_data, 5, LCD_DB5);

toggle_io(lcd_data, 4, LCD_DB4);

toggle_EN_pin();

toggle_io(lcd_data, 3, LCD_DB7);

toggle_io(lcd_data, 2, LCD_DB6);

toggle_io(lcd_data, 1, LCD_DB5);

toggle_io(lcd_data, 0, LCD_DB4);

toggle_EN_pin();

}

void LCD_putstr(char *lcd_string)

{

do

{

LCD_send(*lcd_string++, DAT);

}while(*lcd_string != '\0');

}

void LCD_putchar(char char_data)

{

LCD_send(char_data, DAT);

}

void LCD_clear_home(void)

{

LCD_send(clear_display, CMD);

LCD_send(goto_home, CMD);

}

void LCD_goto(unsigned char x_pos, unsigned char y_pos)

{

if(y_pos == 0)

{

LCD_send((0x80 | x_pos), CMD);

}

else

{

LCD_send((0x80 | 0x40 | x_pos), CMD);

}

}

void toggle_EN_pin(void)

{

GPIO_WriteHigh(LCD_PORT, LCD_EN);

delay_ms(2);

GPIO_WriteLow(LCD_PORT,LCD_EN);

}

void toggle_io(unsigned char lcd_data, unsigned char bit_pos, unsigned char pin_num)

Page 48

{

bool temp = FALSE;

temp = (0x01 & (lcd_data >> bit_pos));

switch(temp)

{

case TRUE:

{

GPIO_WriteHigh(LCD_PORT, pin_num);

break;

}

default:

{

GPIO_WriteLow(LCD_PORT, pin_num);

break;

}

}

}

main.c

#include "STM8S.h"

#include "lcd.h"

void clock_setup(void);

void GPIO_setup(void);

void main(void)

{

const char txt1[] = {"MICROARENA"};

const char txt2[] = {"SShahryiar"};

const char txt3[] = {"STM8S003K"};

const char txt4[] = {"Discovery"};

unsigned char s = 0x00;

clock_setup();

GPIO_setup();

LCD_init();

LCD_clear_home();

LCD_goto(3, 0);

LCD_putstr(txt1);

LCD_goto(3, 1);

LCD_putstr(txt2);

delay_ms(4000);

LCD_clear_home();

for(s = 0; s < 9; s++)

{

LCD_goto((3 + s), 0);

LCD_putchar(txt3[s]);

delay_ms(90);

}

for(s = 0; s < 9; s++)

{

LCD_goto((3 + s), 1);

LCD_putchar(txt4[s]);

Page 49

delay_ms(90);

}

while (TRUE);

}

void clock_setup(void)

{

CLK_DeInit();

CLK_HSECmd(DISABLE);

CLK_LSICmd(DISABLE);

CLK_HSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_HSIRDY) == FALSE);

CLK_ClockSwitchCmd(ENABLE);

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV8);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV1);

CLK_ClockSwitchConfig(CLK_SWITCHMODE_AUTO, CLK_SOURCE_HSI,

DISABLE, CLK_CURRENTCLOCKSTATE_ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_SPI, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_I2C, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_ADC, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_UART1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER2, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER4, DISABLE);

}

void GPIO_setup(void)

{

GPIO_DeInit(LCD_PORT);

}

Explanation

There’s little to explain this code as it involves GPIOs only. The codes for the LCD are coded using all

available info on its datasheet, just initialization and working principle. One thing to note, however, is

the CPU clock speed. If the CPU clock is too fast, LCDs may not work. This is because most LCDs have

a maximum working frequency of 250kHz. It is best to keep this frequency below 200kHz.

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV8);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV1);

Page 50

Demo

Video link: https://www.youtube.com/watch?v=TJg2Tuu4QaQ

Page 51

Analog-to-Digital Converter (ADC)

ADC is a very important peripheral in any modern-day microcontroller. It is used to read analogue

outputs from sensors, sense voltage levels and so on. For example, we can use an ADC to read a LM35

temperature sensor. The voltage output from the sensor is proportional to temperature and so we

can use the voltage info to back-calculate temperature. STM8S003K3 has four ADC channels

associated with one ADC block. Other STM8 micros have more ADC channels and ADC blocks. The ADC

of STM8 micros is just as same as the ADCs of other micros. There are a few additional features. Shown

below is the block diagram of the STM8’s ADC peripheral:

A few things must be noted before using the ADC. These enhance performance significantly:

• Input impedance should be less than 10kΩ.

• It is better to keep ADC clock within or less than 4MHz.

• Schmitt triggers must be disabled.

• Opamp-based input buffer and filter circuits are preferred if possible.

• If the ADC has reference source pins, they should be connected to a precision reference source

like LM336. It is recommended to use a good LDO regulator chip otherwise.

• Unused ADC pins should not be configured or disabled. This will reduce power consumption.

• Rather taking single samples, ADC readings should be sampled at fixed regular intervals and

averaged to get rid of minute fluctuations in readings.

• Right-justified data alignment should be used as it is most convenient to use.

• PCB/wire tracks leading to ADC channels must be short to reduce interference effects.

Page 52

Hardware Connection

Co de Example

#include "STM8S.h"

void clock_setup(void);

void GPIO_setup(void);

void ADC1_setup(void);

void lcd_print(unsigned char x_pos, unsigned char y_pos, unsigned int value);

void main()

{

unsigned int A0 = 0x0000;

clock_setup();

GPIO_setup();

ADC1_setup();

Page 53

LCD_init();

LCD_clear_home();

LCD_goto(0, 0);

LCD_putstr("STM8 ADC");

LCD_goto(0, 1);

LCD_putstr("A0");

while(TRUE)

{

ADC1_StartConversion();

while(ADC1_GetFlagStatus(ADC1_FLAG_EOC) == FALSE);

A0 = ADC1_GetConversionValue();

ADC1_ClearFlag(ADC1_FLAG_EOC);

lcd_print(4, 1, A0);

delay_ms(90);

};

}

void clock_setup(void)

{

CLK_DeInit();

CLK_HSECmd(DISABLE);

CLK_LSICmd(DISABLE);

CLK_HSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_HSIRDY) == FALSE);

CLK_ClockSwitchCmd(ENABLE);

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV2);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV4);

CLK_ClockSwitchConfig(CLK_SWITCHMODE_AUTO, CLK_SOURCE_HSI,

DISABLE, CLK_CURRENTCLOCKSTATE_ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_SPI, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_I2C, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_ADC, ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_UART1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER2, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER4, DISABLE);

}

void GPIO_setup(void)

{

GPIO_DeInit(GPIOB);

GPIO_Init(GPIOB, GPIO_PIN_0, GPIO_MODE_IN_FL_NO_IT);

GPIO_DeInit(GPIOC);

GPIO_DeInit(GPIOD);

GPIO_Init(GPIOD, GPIO_PIN_3, GPIO_MODE_IN_PU_NO_IT);

}

void ADC1_setup(void)

{

ADC1_DeInit();

ADC1_Init(ADC1_CONVERSIONMODE_CONTINUOUS,

ADC1_CHANNEL_0,

Page 54

ADC1_PRESSEL_FCPU_D18,

ADC1_EXTTRIG_GPIO,

DISABLE,

ADC1_ALIGN_RIGHT,

ADC1_SCHMITTTRIG_CHANNEL0,

DISABLE);

ADC1_Cmd(ENABLE);

}

void lcd_print(unsigned char x_pos, unsigned char y_pos, unsigned int value)

{

char chr = 0x00;

chr = ((value / 1000) + 0x30);

LCD_goto(x_pos, y_pos);

LCD_putchar(chr);

chr = (((value / 100) % 10) + 0x30);

LCD_goto((x_pos + 1), y_pos);

LCD_putchar(chr);

chr = (((value / 10) % 10) + 0x30);

LCD_goto((x_pos + 2), y_pos);

LCD_putchar(chr);

chr = ((value % 10) + 0x30);

LCD_goto((x_pos + 3), y_pos);

LCD_putchar(chr);

}

Explanation

First, we need to enable the peripheral clock of the ADC module:

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, DISABLE);

Secondly, we have to set out ADC pin as a floating GPIO with no interrupt capability:

GPIO_Init(GPIOB, GPIO_PIN_0, GPIO_MODE_IN_FL_NO_IT);

ADC setup needs a few info regarding the desired ADC channel:

void ADC1_setup(void)

{

ADC1_DeInit();

ADC1_Init(ADC1_CONVERSIONMODE_CONTINUOUS,

ADC1_CHANNEL_0,

ADC1_PRESSEL_FCPU_D18,

ADC1_EXTTRIG_GPIO,

DISABLE,

ADC1_ALIGN_RIGHT,

ADC1_SCHMITTTRIG_CHANNEL0,

DISABLE);

ADC1_Cmd(ENABLE);

}

Page 55

The second line of the above function states that we are going to use ADC channel 0 (PB0) with no

Schmitt trigger. We are also not going to use external triggers from timer/GPIO modules. Since the

master clock is running at 8MHz, the ADC prescaler divides the master/peripheral clock to get a

sampling frequency of 444kHz. We are also going to use continuous conversion mode because we

want to continually read the ADC input and don’t want to measure it in certain intervals. Lastly rightjustified data alignment is used as it is easy to read from such.

In the main loop, we need to start ADC conversion and wait for the conversion to complete. We are

not using interrupt methods and so we need to poll if ADC conversion has completed. At the end of

conversion, we can read the ADC and clear ADC End of Conversion (EOC) flag.

ADC1_StartConversion();

while(ADC1_GetFlagStatus(ADC1_FLAG_EOC) == FALSE);

A0 = ADC1_GetConversionValue();

ADC1_ClearFlag(ADC1_FLAG_EOC);

The rest of the code is about printing the ADC data on a LCD.

Demo

Video link: https://www.youtube.com/watch?v=rx68zPDEZUU

Page 56

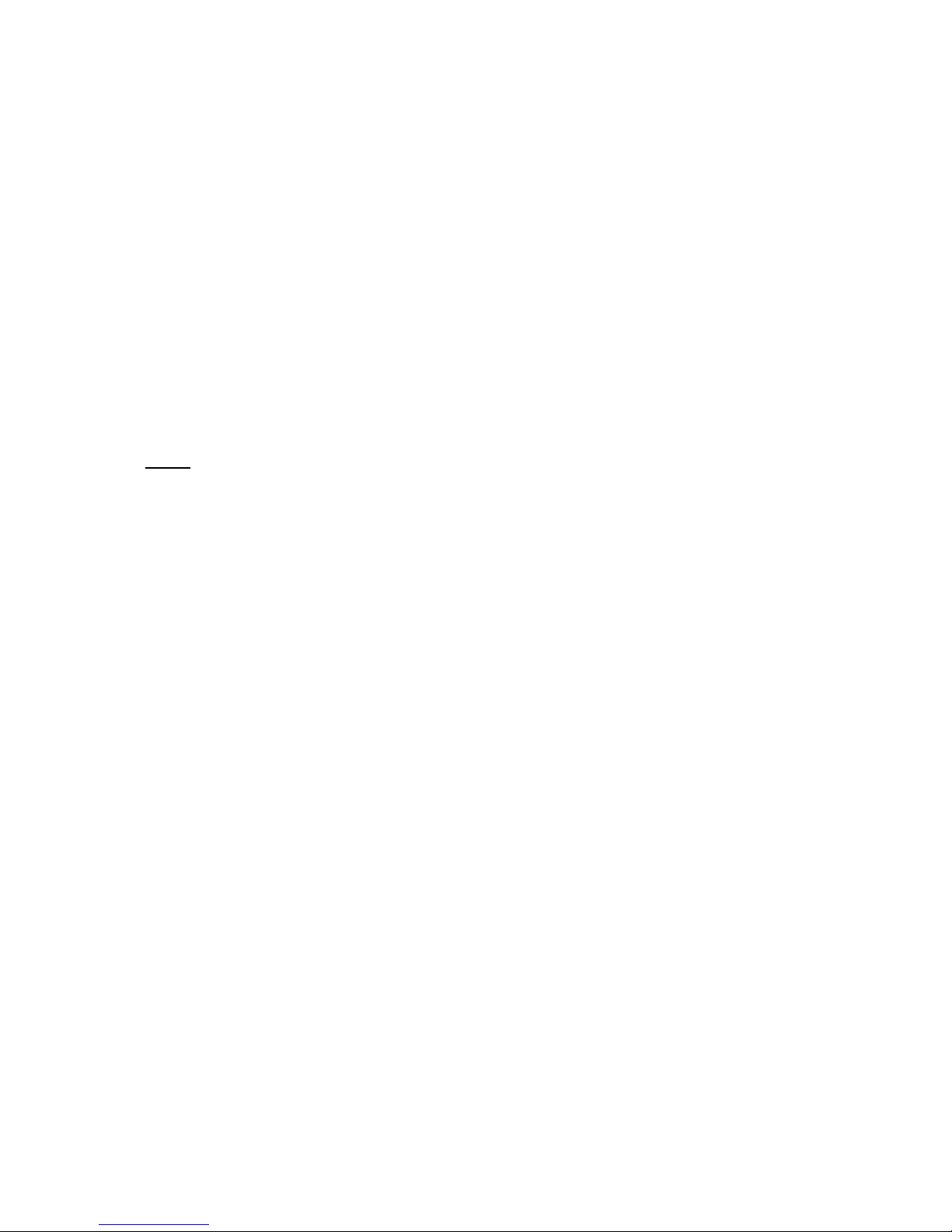

Analog Watchdog (AWD)

The AWD is one additional feature that most microcontrollers in the market do not have. AWD is more

like a comparator but with the exception that we can set both the upper and lower limits of this

comparator as per our requirement unlike fixed levels in other micros. The region between the upper

and lower limits is called guarded zone. Beyond the boundaries of the guarded zone, the AWD unit

kicks off.

The AWD unit is very useful in situations where we need to monitor the output of a sensor for example

and take quick actions. For instance, consider a temperature controller. We would want the controller

to turn on a heater should temperature fall below some level and turn it off when temperature rises

to some high value without complex calculations and constant monitoring in our application firmware.

In other microcontrollers, we would have accomplished this simple task using conditional IF-ELSE

statements.

Page 57

Hardware Connection

Co de Example

#include "STM8S.h"

void clock_setup(void);

void GPIO_setup(void);

void ADC1_setup(void);

void lcd_print(unsigned char x_pos, unsigned char y_pos, unsigned int value);

void main()

{

unsigned int a1 = 0x0000;

clock_setup();

GPIO_setup();

ADC1_setup();

LCD_init();

LCD_clear_home();

Page 58

LCD_goto(0, 0);

LCD_putstr("STM8 AWD");

LCD_goto(0, 1);

LCD_putstr("A1");

while (TRUE)

{

ADC1_ClearFlag(ADC1_FLAG_EOC);

ADC1_StartConversion();

while(ADC1_GetFlagStatus(ADC1_FLAG_EOC) == 0);

a1 = ADC1_GetConversionValue();

lcd_print(4, 1, a1);

if(ADC1_GetFlagStatus(ADC1_FLAG_AWD))

{

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

ADC1_ClearFlag(ADC1_FLAG_AWD);

}

else

{

GPIO_WriteHigh(GPIOD, GPIO_PIN_0);

}

delay_ms(90);

};

}

void clock_setup(void)

{

CLK_DeInit();

CLK_HSECmd(DISABLE);

CLK_LSICmd(DISABLE);

CLK_HSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_HSIRDY) == FALSE);

CLK_ClockSwitchCmd(ENABLE);

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV2);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV4);

CLK_ClockSwitchConfig(CLK_SWITCHMODE_AUTO, CLK_SOURCE_HSI,

DISABLE, CLK_CURRENTCLOCKSTATE_ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_SPI, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_I2C, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_ADC, ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_UART1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER2, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER4, DISABLE);

}

void GPIO_setup(void)

{

GPIO_DeInit(GPIOB);

GPIO_Init(GPIOB, GPIO_PIN_1, GPIO_MODE_IN_FL_NO_IT);

GPIO_DeInit(GPIOD);

GPIO_Init(GPIOD, GPIO_PIN_0, GPIO_MODE_OUT_PP_HIGH_FAST);

GPIO_Init(GPIOD, GPIO_PIN_3, GPIO_MODE_IN_PU_NO_IT);

}

Page 59

void ADC1_setup(void)

{

ADC1_DeInit();

ADC1_Init(ADC1_CONVERSIONMODE_SINGLE,

ADC1_CHANNEL_1,

ADC1_PRESSEL_FCPU_D10,

ADC1_EXTTRIG_GPIO,

DISABLE,

ADC1_ALIGN_RIGHT,

ADC1_SCHMITTTRIG_CHANNEL1,

DISABLE);

ADC1_AWDChannelConfig(ADC1_CHANNEL_1, ENABLE);

ADC1_SetHighThreshold(600);

ADC1_SetLowThreshold(200);

ADC1_Cmd(ENABLE);

}

void lcd_print(unsigned char x_pos, unsigned char y_pos, unsigned int value)

{

char chr = 0x00;

chr = ((value / 1000) + 0x30);

LCD_goto(x_pos, y_pos);

LCD_putchar(chr);

chr = (((value / 100) % 10) + 0x30);

LCD_goto((x_pos + 1), y_pos);

LCD_putchar(chr);

chr = (((value / 10) % 10) + 0x30);

LCD_goto((x_pos + 2), y_pos);

LCD_putchar(chr);

chr = ((value % 10) + 0x30);

LCD_goto((x_pos + 3), y_pos);

LCD_putchar(chr);

}

Explanation

The code for the AWD example is just as the one demonstrated in the ADC example. However, this

time the ADC channel is channel 1 (PB1). Setting up the AWD is simple. We just need to set the limits,

specify which channel to be monitored and enable the AWD unit.

ADC1_AWDChannelConfig(ADC1_CHANNEL_1, ENABLE);

ADC1_SetHighThreshold(600);

ADC1_SetLowThreshold(200);

Here we have set 600 and 200 ADC counts as upper and lower limits respectively.

Page 60

In the main function, we are simply polling AWD flag. If an AWD (beyond boundary zone) event on

PB1 pin occurs the LED on PD0 starts flashing. If PB1 senses voltage between 200 and 600 ADC counts,

the LED is turned off, indicating guarded zone.

if(ADC1_GetFlagStatus(ADC1_FLAG_AWD))

{

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

ADC1_ClearFlag(ADC1_FLAG_AWD);

}

else

{

GPIO_WriteHigh(GPIOD, GPIO_PIN_0);

}

Page 61

Demo

Video link: https://www.youtube.com/watch?v=bvVNuVpeFPk

Page 62

Independent Watchdog (IWDG)

The IWDG is just the ordinary watchdog timer we usually find in any modern micro. The purpose of

this timer is to recover a micro from an unanticipated event that may result in unresponsive or erratic

behaviour. As the name suggests, this timer does not share anything with any other internal hardware

peripheral and is clocked by LSI (128kHz) only. Thus, it is invulnerable to main clock (HSE or HSI) failure.

The IWDG works by decrementing a counter, counting time in the process. When the counter hits

zero, a reset is issued. Usually we would want that this reset never occurs and so the counter is

periodically updated in the application firmware. If for some reason, the counter is not refreshed, a

reset will occur, recovering the MCU from a disastrous situation.

Configuring the IWDG is very easy with SPL. There are certain steps to follow but SPL manages them

well internally. All we’ll need is to configure the IWDG and reload it periodically before time runs out.

The formula required to calculate timeout is given below:

Page 63

Typical values of timeout are as shown below:

Hardware Connection

Page 64

Co de Example

#include "STM8S.h"

void clock_setup(void);

void GPIO_setup(void);

void IWDG_setup(void);

void main(void)

{

unsigned int t = 0;

clock_setup();

GPIO_setup();

GPIO_WriteLow(GPIOD, GPIO_PIN_0);

for(t = 0; t < 60000; t++);

IWDG_setup();

while(TRUE)

{

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

for(t = 0; t < 1000; t++)

{

if(GPIO_ReadInputPin(GPIOB, GPIO_PIN_7) == FALSE)

{

IWDG_WriteAccessCmd(IWDG_WriteAccess_Enable);

IWDG_ReloadCounter();

IWDG_WriteAccessCmd(IWDG_WriteAccess_Disable);

}

}

};

}

void clock_setup(void)

{

CLK_DeInit();

CLK_HSECmd(DISABLE);

CLK_LSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_LSIRDY) == FALSE);

CLK_HSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_HSIRDY) == FALSE);

CLK_ClockSwitchCmd(ENABLE);

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV8);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV4);

CLK_ClockSwitchConfig(CLK_SWITCHMODE_AUTO, CLK_SOURCE_HSI,

DISABLE, CLK_CURRENTCLOCKSTATE_ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_SPI, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_I2C, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_ADC, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_UART1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER2, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER4, DISABLE);

}

Page 65

void GPIO_setup(void)

{

GPIO_DeInit(GPIOB);

GPIO_DeInit(GPIOD);

GPIO_Init(GPIOB, GPIO_PIN_7, GPIO_MODE_IN_PU_NO_IT);

GPIO_Init(GPIOD, GPIO_PIN_0, GPIO_MODE_OUT_PP_LOW_FAST);

}

void IWDG_setup(void)

{

IWDG_Enable();

IWDG_WriteAccessCmd(IWDG_WriteAccess_Enable);

IWDG_SetPrescaler(IWDG_Prescaler_128);

IWDG_SetReload(0x99);

IWDG_WriteAccessCmd(IWDG_WriteAccess_Disable);

}

Explanation

In this example, we need not to look at peripheral and CPU clock as IWDG is not dependent on them.

Still we can see that the CPU is running at 500kHz speed while the peripherals at 2MHz speed.

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV8);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV4);

To setup the IWDG, we need to enable it first and then apply Write Access Protection key (0x55). We

just need to set the prescaler and the counter value. The down counter will start from this value and

count down to zero unless refreshed. In this example, the prescaler is set to 128 and reload value is

set to 153 (0x99). Thus, with these we get a timeout of approximately 300ms. After entering these

values we must prevent accidental changes in the firmware and so to do so the write access must be

disabled.

void IWDG_setup(void)

{

IWDG_Enable();

IWDG_WriteAccessCmd(IWDG_WriteAccess_Enable);

IWDG_SetPrescaler(IWDG_Prescaler_128);

IWDG_SetReload(0x99);

IWDG_WriteAccessCmd(IWDG_WriteAccess_Disable);

}

Disco board’s user button and LED are used for the demo. At the very beginning, the LED is lit for some

time before the IWDG is configured, indicating the start of the firmware. In the main loop, the LED is

toggled with some delay arranged by a for loop. Inside the loop, the button’s state is polled. If the

button is kept pressed it will always be in logic low state, reloading the IWDG counter. If its state

changes to logic high and 300ms passes out, a reset is triggered.

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

for(t = 0; t < 1000; t++)

{

if(GPIO_ReadInputPin(GPIOB, GPIO_PIN_7) == FALSE)

{

IWDG_WriteAccessCmd(IWDG_WriteAccess_Enable);

IWDG_ReloadCounter();

IWDG_WriteAccessCmd(IWDG_WriteAccess_Disable);

}

}

Page 66

Note it is possible to calibrate LSI. It is however rarely needed.

Demo

Video link: https://www.youtube.com/watch?v=05XKoy0ieHo

Page 67

Window Watchdog (WWDG)

The WWDG is a bit more advanced watchdog timer. Unlike the IWDG, it will trigger a reset condition

if its counter is reloaded earlier or later than a predefined time window. This kind of timer is usually

found in high-end microcontrollers like ARMs, ATXMegas and recently released micros. Cool features

like this and others make me feel that indeed STM8s are high-end affordable 8-bit alternatives when

compared to traditional 8-bit MCUs.

The WWDG works by comparing a down counter against a window register. The counter can only be

refreshed when its value is greater than 0x3F and less than window register value. If the counter is

refreshed before the value set on window register or when the counter is less than or equal to 0x3F.

If the counter hits the value 0x3F, reset automatically triggers. It is programmer’s responsibility to

refresh the counter at proper time. Note unlike IWDG, WWDG is not independent of main clock.

Page 68

Hardware Connection

Co de Example

The code example here demonstrates WWDG action. Simply Disco board’s user LED and button are

used. When the code starts executing, the LED starts blinking slowly, indicating the start of the code.

When the code executes the main loop, the LED blinks rapidly to indicate main loop execution. If the

button is pressed randomly the micro is reset because the counter is refreshed before the allowed

time. Sometimes the micro may not reset because the counter may be in the allowed window – hence

the name Window Watchdog.

#include "STM8S.h"

void clock_setup(void);

void GPIO_setup(void);

void WWDG_setup(void);

void main(void)

{

unsigned char i = 0x00;

clock_setup();

GPIO_setup();

for(i = 0x00; i < 0x04; i++)

{

Page 69

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

delay_ms(40);

}

WWDG_setup();

while(TRUE)

{

if((GPIO_ReadInputPin(GPIOB, GPIO_PIN_7) == FALSE) || ((WWDG_GetCounter() > 0x60) &&

(WWDG_GetCounter() < 0x7F)))

{

WWDG_SetCounter(0x7F);

}

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

delay_ms(20);

};

}

void clock_setup(void)

{

CLK_DeInit();

CLK_HSECmd(DISABLE);

CLK_LSICmd(DISABLE);

CLK_HSICmd(ENABLE);

while(CLK_GetFlagStatus(CLK_FLAG_HSIRDY) == FALSE);

CLK_ClockSwitchCmd(ENABLE);

CLK_HSIPrescalerConfig(CLK_PRESCALER_HSIDIV8);

CLK_SYSCLKConfig(CLK_PRESCALER_CPUDIV64);

CLK_ClockSwitchConfig(CLK_SWITCHMODE_AUTO, CLK_SOURCE_HSI,

DISABLE, CLK_CURRENTCLOCKSTATE_ENABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_I2C, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_SPI, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_ADC, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_AWU, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_UART1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER1, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER2, DISABLE);

CLK_PeripheralClockConfig(CLK_PERIPHERAL_TIMER4, DISABLE);

}

void GPIO_setup(void)

{

GPIO_DeInit(GPIOB);

GPIO_Init(GPIOB, GPIO_PIN_7, GPIO_MODE_IN_PU_NO_IT);

GPIO_DeInit(GPIOD);

GPIO_Init(GPIOD, GPIO_PIN_0, GPIO_MODE_OUT_OD_HIZ_FAST);

}

void WWDG_setup(void)

{

WWDG_Init(0x7F, 0x60);

}

Page 70

Explanation

There’s no way to enable watchdogs manually in software as they are always enabled. However, there

are configuration bits to select if the IWDG and the WWDG are enabled in software or hardware. They

only come in effect when configured. This is cool.

For WWDG, we just need to set the value of the down counter and the window register value only.

void WWDG_setup(void)

{

WWDG_Init(0x7F, 0x60);

}

We need to monitor the WWDG in order to reload it when it is the right time window.

while(TRUE)

{

if((GPIO_ReadInputPin(GPIOB, GPIO_PIN_7) == FALSE) || ((WWDG_GetCounter() > 0x60) && (WWDG_GetCounter() <

0x7F)))

{

WWDG_SetCounter(0x7F);

}

GPIO_WriteReverse(GPIOD, GPIO_PIN_0);

delay_ms(20);

};

Remember too early of too late will reset the micro.

Demo

Video link: https://www.youtube.com/watch?v=a_JWHJCh_-o

Page 71

Timer Overview

Timers are perhaps the most versatile piece of hardware in any micro. As their name tells, timers are

useful for measurement of timed events like frequency, time, phase sequence, etc. and generate

time-based events like PWM, waveform, etc.

Timers are also needed for touch sensing applications.

In any STM8 micro, there are three categories of timers. These are:

• Advanced Control Timer (TIM1)

• General Purpose Timers (TIM2, TIM3 & TIM5)

• Basic Timers (TIM4 & TIM6)

The basic working principle of all timers are same with some minor differences. Advanced timers are

mainly intended for applications requiring specialized motor control, SMPSs, inverters, waveform

generation, pulse width measurements, etc. Then there are general purpose timers that share almost

all the features of advanced timer without the advanced features like brake, dead-time control, etc.

Basic timers are all same as general purpose timers but lack PWM output/capture input pins and are

intended mainly for time base generations. Here’s the summary of all timers of STM8 micros:

Unlike the timers of other micros, STM8 timers have the more functionality that are otherwise only

available in some special micros only. Timer cover a significant part of the reference manual. They are

so elaborate that it is not possible to describe all of them in just one post. Therefore, here we’ll be

exploring the basics for now.

Page 72

Time Base Generation (TIM2)